Methodology to Increase the Efficiency of the Mineral Water Extraction Process

Abstract

1. Introduction

2. Problem Statement

- the use of mineral water has more than doubled, due to which the natural distribution of the vertical hydraulic gradient in the upper layers of the hydrolithosphere has greatly changed;

- due to the above, a deterioration in the quality composition of mineral waters has been noticed;

- due to changes in the vertical hydraulic gradient, a downward flow is activated, with which the aquifer is polluted by municipal and domestic wastewater.

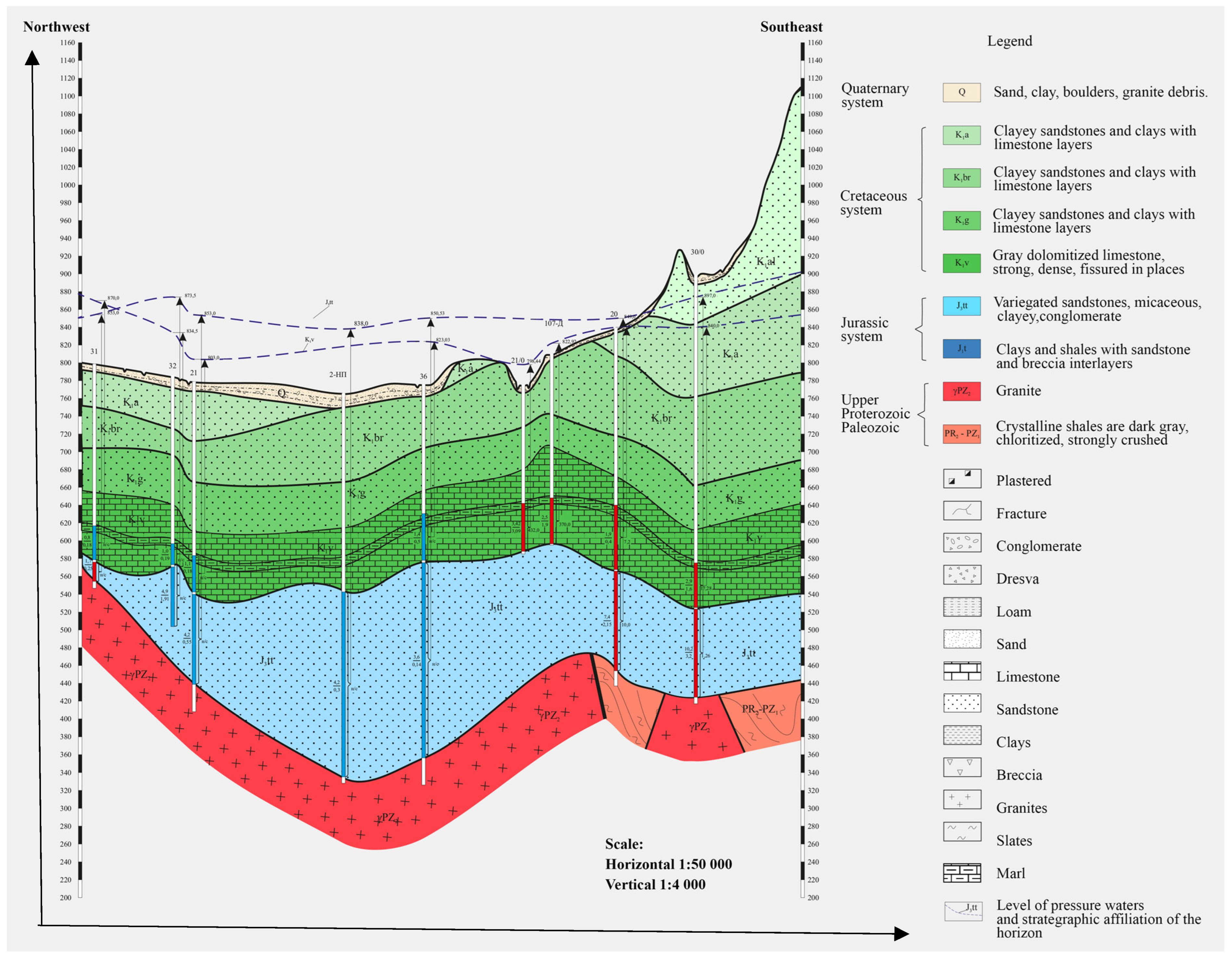

3. Research Background

3.1. Background of the Research

- I.

- Grozny source of oil pollution.

- II.

- Mozdok source of oil pollution.

- III.

- Neftekumsk source of oil and chemical pollution.

- IV.

- Zaterechny source of oil and chemical pollution.

- V.

- South Sukhukumsky center of oil and chemical pollution.

- VI.

- Ryzdvyansky center of oil product, phenolic and chemical pollution.

3.2. Characteristics of the Research Object

3.3. Technogenic Agricultural System

| Be | 2 Mg | Co | 40 Mg | Cr | 30 Mg |

| Mn | 750 Mg | Pb | 9 Mg | Sr | 500 Mg |

| Mo | 1,5 Mg | Cd | 8 Mg | Ba | 125 Mg |

| Cu | 25 Mg | Zr | 55 Mg | B | 80 Mg |

| Zn | 45 Mg | Ti | 900 Mg | F | 13000 Mg |

3.4. Technogenic Industrial System

4. Methodology

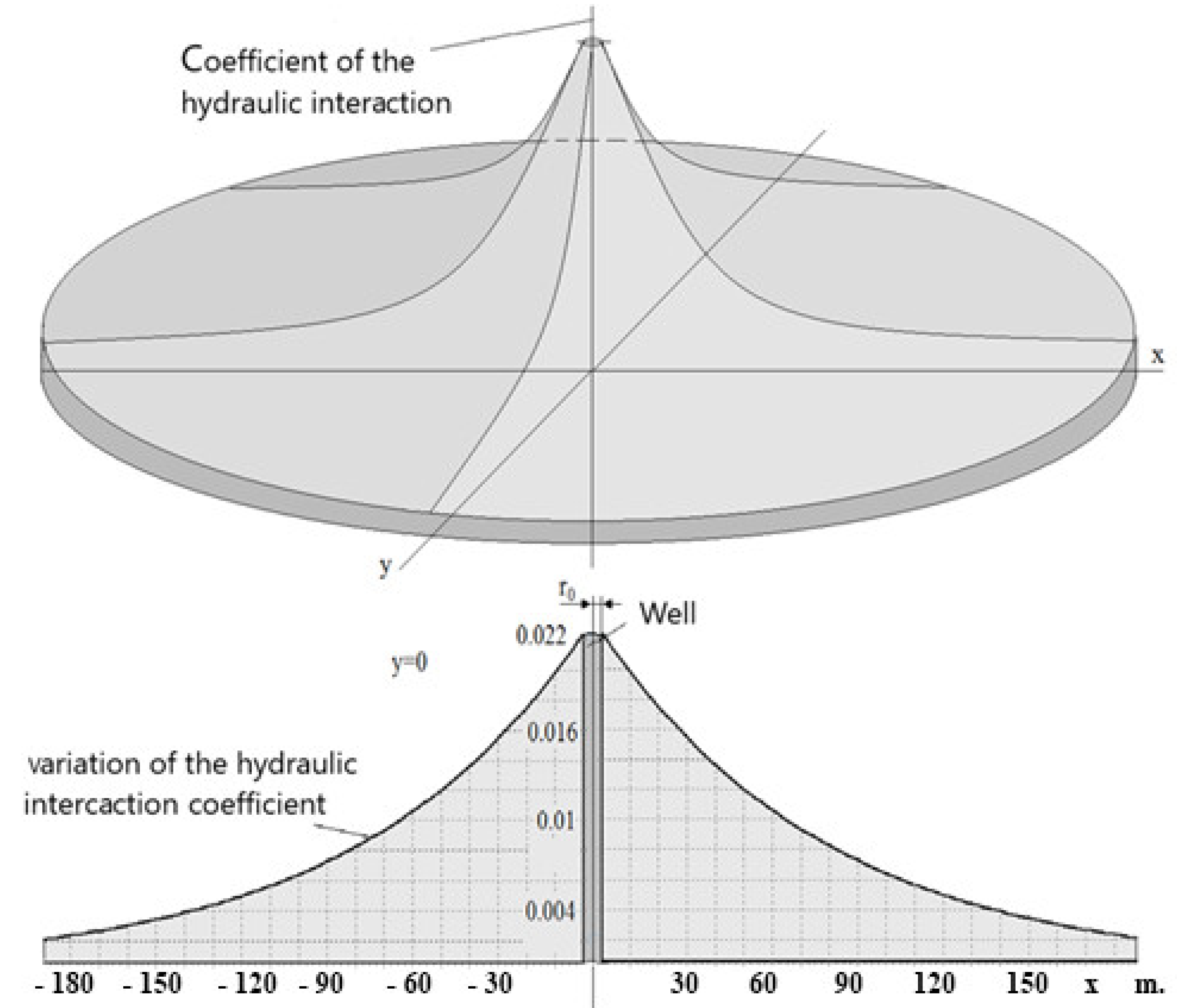

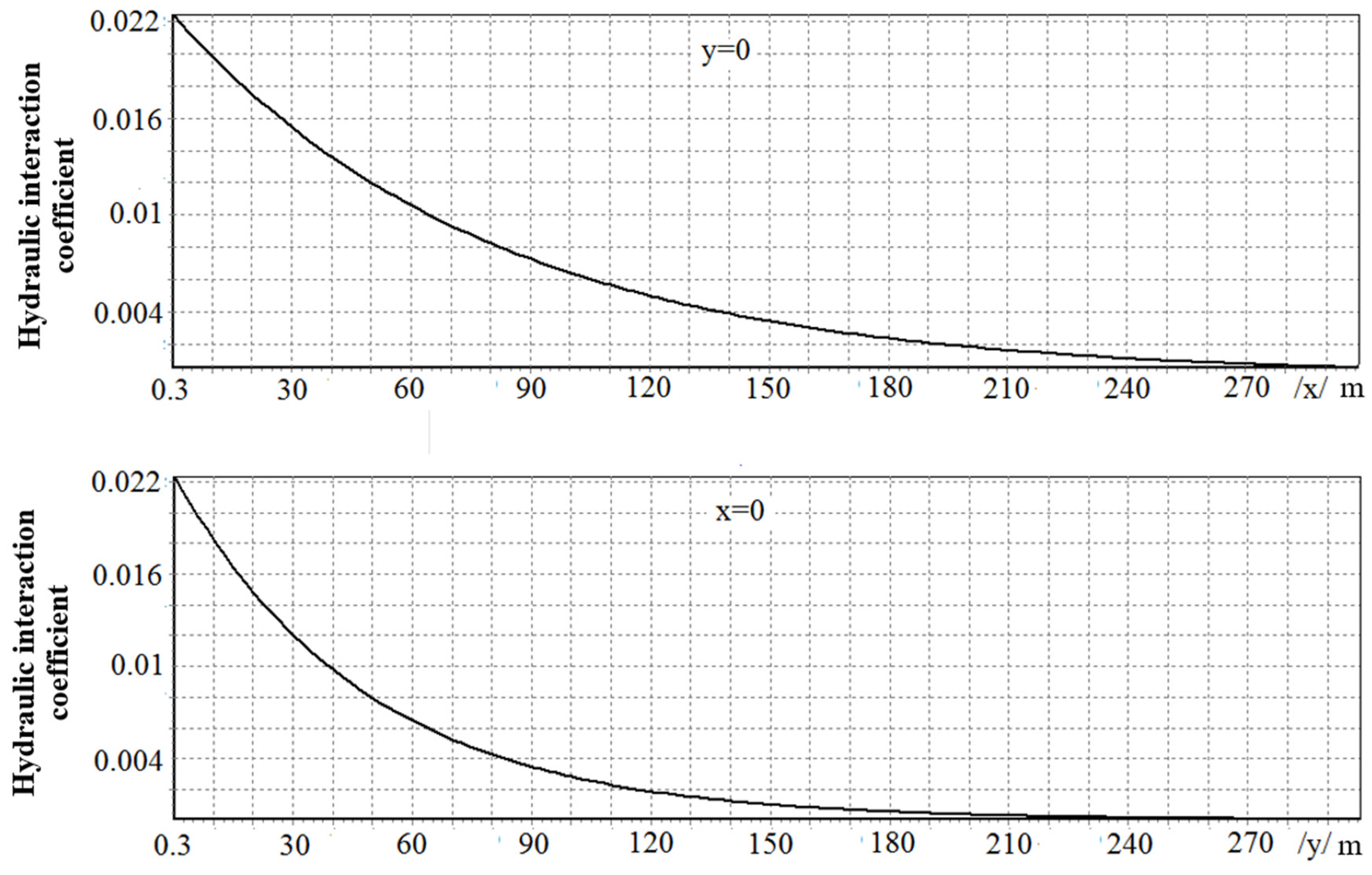

4.1. Approximation of Dynamic and Static Characteristics of Hydro-Lithospheric Processes

4.2. The Practical Aspects

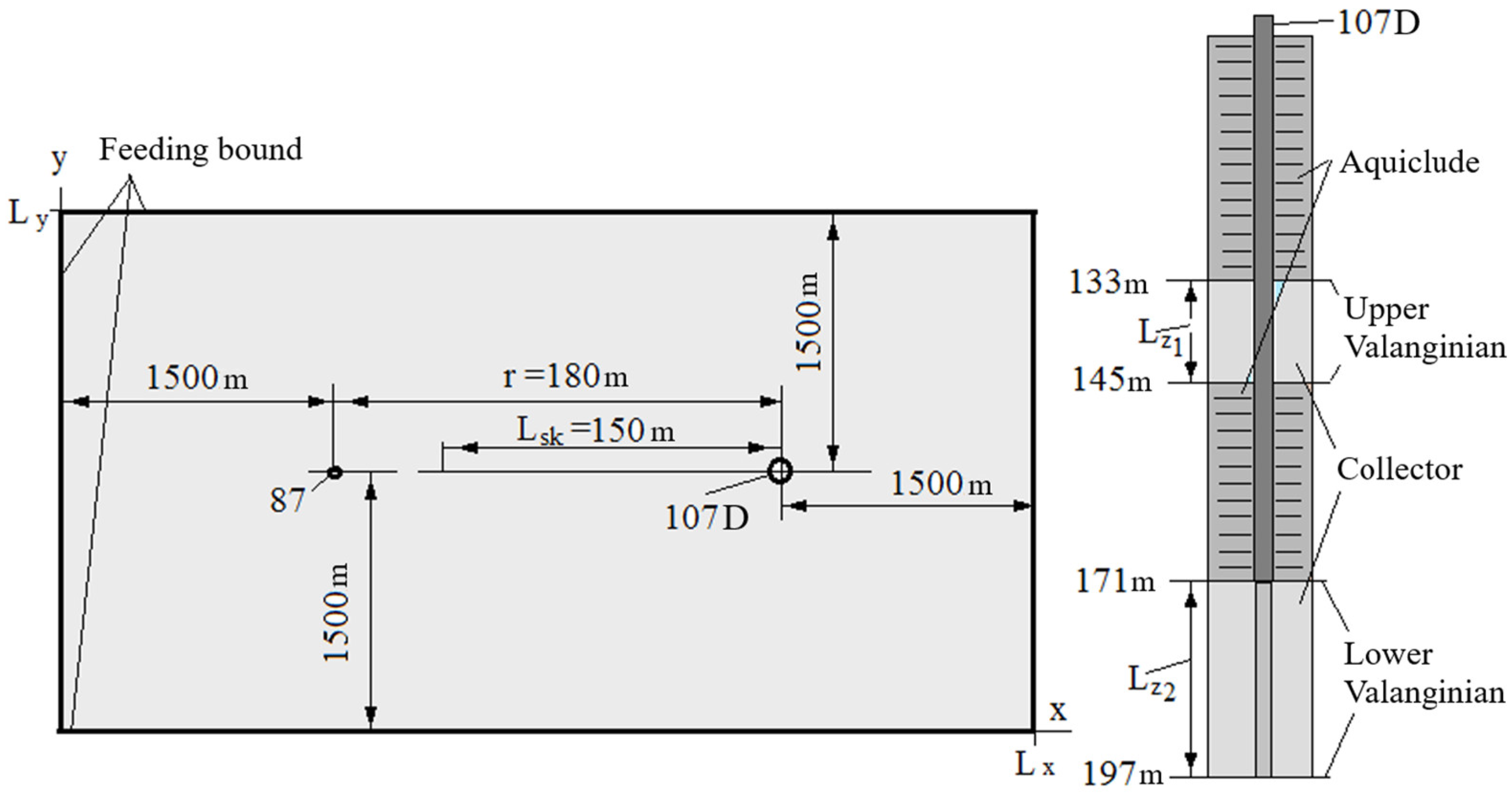

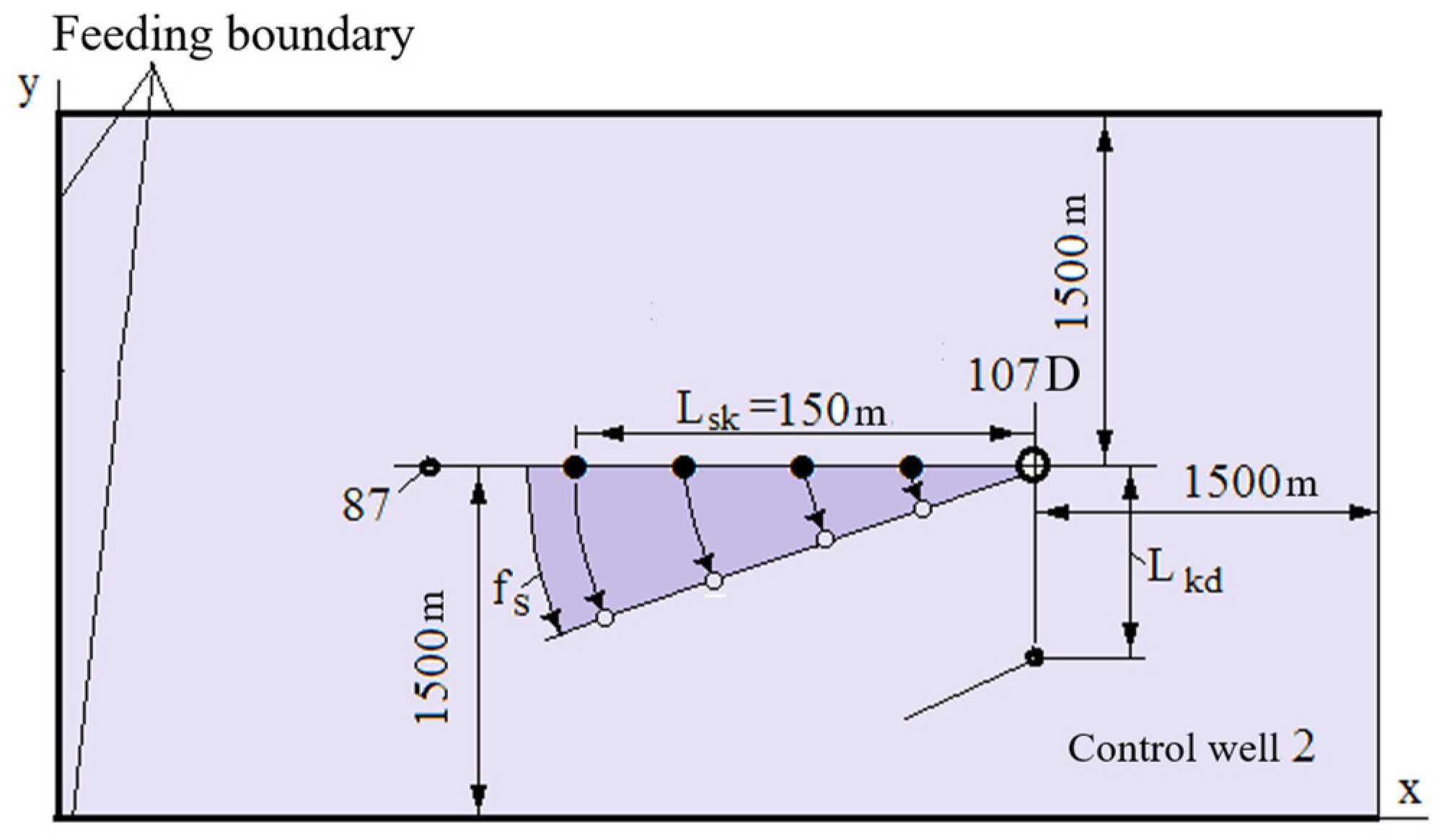

5. Influence of Well Location on Total Production

- (1)

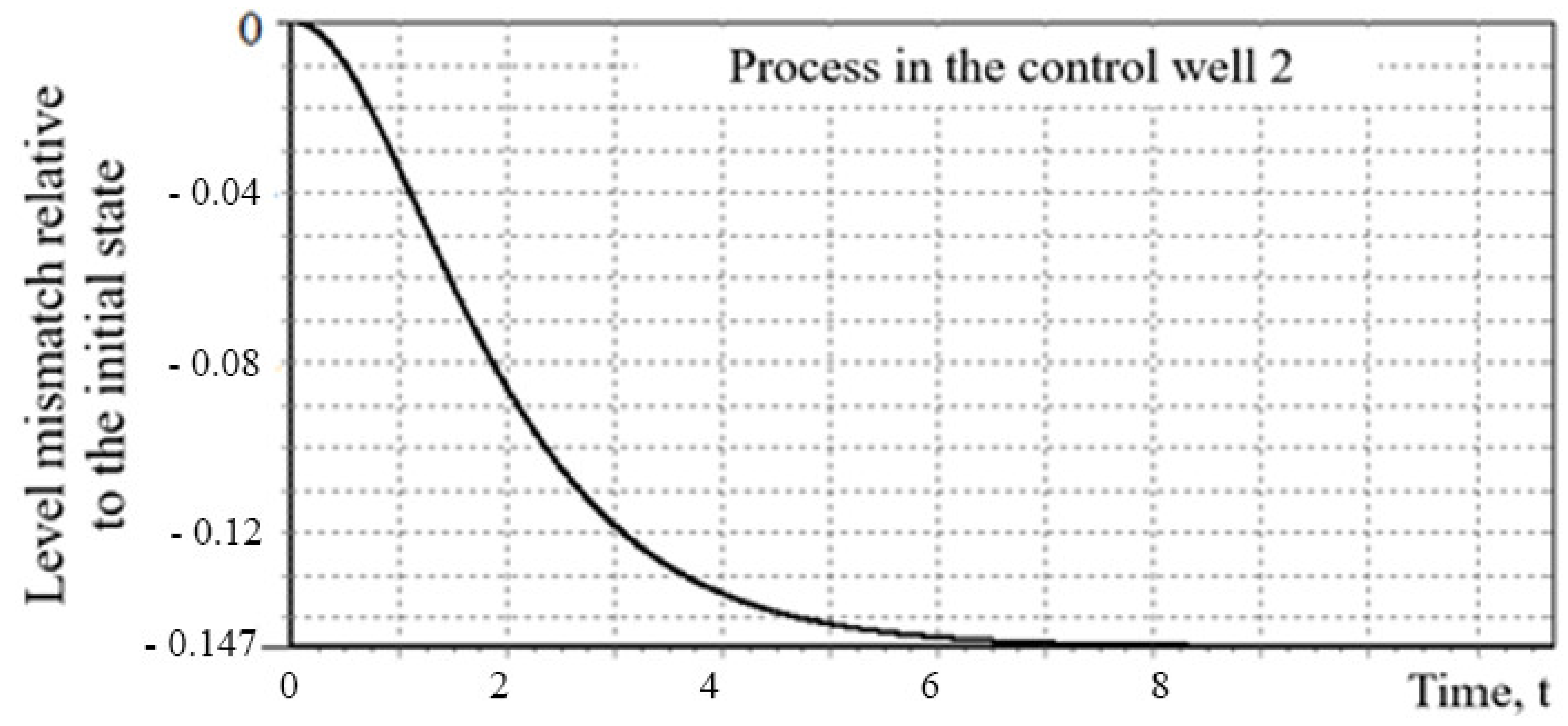

- lowering the level in the control well 2/average production:

- K3 = (−0.147)/(−508) = 0.00028937

- (2)

- Now, the parameters of the approximating link can be calculated.

- (3)

- The statement of the problem of optimizing the choice of the location of wells in the fs sector: for the field under consideration (having n production wells located in the segment Lsk), the value fst ≤ fs needs to be determined, which ensures maximum profit (PP) over ten years of field operation. In this case, we will assume the following:

- -

- extraction of hydromineral raw materials is carried out within 3650 days;

- -

- r0,i = 0.2 m;

- -

- N—the cost of 1 m3 of hydromineral raw materials is RUB 300/1,000,000 million;

- -

- Cp—the average costs for the development and maintenance of one well for 10 years amount to RUB 6 million;

- -

- tax on subsoil use of 7.5%;

- -

- expenses for the maintenance of buildings, equipment and personnel (P) for ten years of operation amount to RUB 87 million;

- -

- the location of production wells is shown in Figure 8 (Lsk = 150 m);

- -

- the specified level drop in the wells is 12 m; fs = 15°.

- (1)

- Let us write down the impact of the j-th working well on the level decrease in the μ-working well as follows:

- (2)

- The total flow rate (Q) is determined from the following ratio:

- (3)

- Let us calculate the profit for 10 years of production at the considered field:

6. Discussion

7. Conclusions

- The diagram of the monitoring system for the state of hydrodynamic processes in the region is shown.

- The results of experimental filtration studies carried out on well cluster No. 107D (disturbing) and two observation wells, namely No. 87, in the Valanginian aquifer are presented.

- The procedure for determining the parameters of a link that approximates the specific decrease in level at a given point is described, using the results of experimental filtration studies.

- The procedure for determining the optimal number of production wells for their various placement methods (on a given segment or in a given area) is shown.

- The verification of discrete mathematical models of hydrodynamic processes is considered using the results of the experimental filtration studies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rudneva, I.I.; Gaisky, P.V.; Shaida, V.G.; Shaida, O.V. Assessing Climate and Human Activity Effects on Hypersaline Lake Ecosystem: Case Study of Saki Lake, Crimea. Water 2023, 15, 456. [Google Scholar] [CrossRef]

- Gonçalves, V.; Albuquerque, A.; Almeida, P.G.; Cavaleiro, V. DRASTIC Index GIS-Based Vulnerability Map for the Entre-os-Rios Thermal Aquifer. Water 2022, 14, 2448. [Google Scholar] [CrossRef]

- Meerkhan, H.; Teixeira, J.; Espinha Marques, J.; Afonso, M.J.; Chaminé, H.I. Delineating Groundwater Vulnerability and Protection Zone Mapping in Fractured Rock Masses: Focus on the DISCO Index. Water 2016, 8, 462. [Google Scholar] [CrossRef]

- Saleh, A.; Gad, A.; Ahmed, A.; Arman, H.; Farhat, H.I. Groundwater Hydrochemical Characteristics and Water Quality in Egypt’s Central Eastern Desert. Water 2023, 15, 971. [Google Scholar] [CrossRef]

- Hou, X.; Yang, H.; Cao, J.; Feng, W.; Zhang, Y. A Review of Advances in Groundwater Evapotranspiration Research. Water 2023, 15, 969. [Google Scholar] [CrossRef]

- French, H.K.; Hansen, M.C.; Moe, K.G.; Stene, J. Modelling Plume Development with Annual Pulses of Contaminants Released from an Airport Runway to a Layered Aquifer, Evaluation of an In Situ Monitoring System. Water 2023, 15, 985. [Google Scholar] [CrossRef]

- Al Khoury, I.; Boithias, L.; Labat, D. A Review of the Application of the Soil and Water Assessment Tool (SWAT) in Karst Watersheds. Water 2023, 15, 954. [Google Scholar] [CrossRef]

- Guillemoto, Q.; Picot-Colbeaux, G.; Valdes, D.; Devau, N.; Thierion, C.; Idier, D.; Mathurin, F.A.; Pettenati, M.; Mouchel, J.-M.; Kloppmann, W. Multi-Annual Dynamics of a Coastal Groundwater System with Soil-Aquifer Treatment and Its Impact on the Fate of Trace Organic Compounds. Water 2023, 15, 934. [Google Scholar] [CrossRef]

- Baranovskaya, E.I.; Kharitonova, N.A.; Chelnokov, G.A.; Tarasenko, I.A.; Maslov, A.A. Chemical and Isotopic Features of a High pCO2 Natural Mineral Water from Essentuki Field (Caucasian Mineral Water Region, Russia). Water 2023, 15, 901. [Google Scholar] [CrossRef]

- Pershin, I.M.; Papush, E.G.; Malkov, A.V.; Kukharova, T.V.; Spivak, A.O. Operational Control of Underground Water Exploitation Regimes. In Proceedings of the III International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 30 October–1 November 2019; pp. 77–80. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Mir-Amal, A.M.; Chernyshev, A.B. Assessment of a Hydrogeological Object’s Distributed Control System Stability. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering, ElConRus 2022, St. Petersburg, Russia, 25–28 January 2022; pp. 768–771. [Google Scholar] [CrossRef]

- Liu, Q.; Xue, Y.; Ma, D.; Li, Q. Failure Characteristics of the Water-Resisting Coal Pillar under Stress-Seepage Coupling and Determination of Reasonable Coal Pillar Width. Water 2023, 15, 1002. [Google Scholar] [CrossRef]

- Kim, D.; Jang, C.; Choi, J.; Kwak, J. A Case Study: Groundwater Level Forecasting of the Gyorae Area in Actual Practice on Jeju Island Using Deep-Learning Technique. Water 2023, 15, 972. [Google Scholar] [CrossRef]

- Alharbi, T. Mapping of Groundwater, Flood, and Drought Potential Zones in Neom, Saudi Arabia, Using GIS and Remote Sensing Techniques. Water 2023, 15, 966. [Google Scholar] [CrossRef]

- Sechu, G.L.; Nilsson, B.; Iversen, B.V.; Greve, M.B.; Greve, M.H. Historical Loss of Groundwater-Dependent Terrestrial Ecosystems in Undrained and Artificially Drained Landscapes in Denmark. Water 2023, 15, 946. [Google Scholar] [CrossRef]

- Wang, W.; Li, W.; Xue, M.; Gu, X.; Ye, C.; Jiao, Y.; Liu, B.; Han, Y.; Tong, Y.; Zhang, X. Spatial-Temporal Characteristics and Influencing Factors of Lake Water and Groundwater Chemistry in Hulun Lake, Northeast China. Water 2023, 15, 937. [Google Scholar] [CrossRef]

- Espinoza Vigil, A.J.; Booker, J. Hydrological Vulnerability Assessment of Riverine Bridges: The Bajo Grau Bridge Case Study. Water 2023, 15, 846. [Google Scholar] [CrossRef]

- Knobloch, S.; Klonowski, A.M.; Tómasdóttir, S.; Kristjánsson, B.R.; Guðmundsson, S.; Marteinsson, V.P. Microbial intrusion and seasonal dynamics in the groundwater microbiome of a porous basaltic rock aquifer used as municipal water reservoir. FEMS Microbiol. Ecol. 2021, 97, fiab014. [Google Scholar] [CrossRef]

- Marinin, M.A.; Marinina, O.A.; Rakhmanov, R.A. Methodological approach to assessing influence of blasted rock fragmentation on mining costs. Gorn. Z. 2023, 2023, 28–34. [Google Scholar] [CrossRef]

- Kozyrev, B.A.; Sizyakov, V.M.; Arsentyev, V.A. Principles of rational processing of red mud with the use of carboxylic acids. Non-Ferr. Met. 2022, 53, 30–34. [Google Scholar] [CrossRef]

- Kellermann, C.; Selesi, D.; Lee, N.; Hügler, M.; Esperschütz, J.; Hartmann, A.; Griebler, C. Microbial CO2 fixation potential in a tar-oil-contaminated porous aquifer. FEMS Microbiol. Ecol. 2012, 81, 172–187. [Google Scholar] [CrossRef]

- Wildung, R.; Li, S.; Murray, C.; Krupka, K.; Xie, Y.; Hess, N.; Roden, E. Technetium reduction in sediments of a shallow aquifer exhibiting dissimilatory iron reduction potential. FEMS Microbiol. Ecol. 2004, 49, 151–162. [Google Scholar] [CrossRef]

- Asadulagi, M.-A.M.; Fedorov, M.S.; Trushnikov, V.E. Control Methods of Mineral Water Wells. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 26–28 September 2023; pp. 152–155. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Eremeeva, A.M.; Nelkenbaum, K.S.; Baulin, O.A.; Dubovikov, O.A. Development of environmentally friendly diesel fuel. Pet. Sci. Technol. 2019, 12, 1478–1484. [Google Scholar] [CrossRef]

- Wilhartitz, I.C.; Kirschner, A.K.; Stadler, H.; Herndl, G.J.; Dietzel, M.; Latal, C.; Mach, R.L.; Farnleitner, A.H. Heterotrophic prokaryotic production in ultraoligotrophic alpine karst aquifers and ecological implications. FEMS Microbiol. Ecol. 2009, 68, 287–299. [Google Scholar] [CrossRef]

- Gafur, S.; Andrey, S.; Liliya, S.; Vadim, F. Assessment of Damage of Metallic Elements in Oil and Gas Facilities using Small Punch Test. Int. J. Appl. Eng. Res. 2017, 12, 11583–11587. [Google Scholar]

- Fetisov, V.; Gonopolsky, A.M.; Davardoost, H.; Ghanbari, A.R.; Mohammadi, A.H. Regulation and impact of VOC and CO2 emissions on low-carbon energy systems resilient to climate change: A case study on an environmental issue in the oil and gas industry. Energy Sci. Eng. 2023, 11, 1516–1535. [Google Scholar] [CrossRef]

- Fillinger, L.; Hug, K.; Griebler, C. Selection imposed by local environmental conditions drives differences in microbial community composition across geographically distinct groundwater aquifers. FEMS Microbiol. Ecol. 2019, 95, fiz160. [Google Scholar] [CrossRef] [PubMed]

- Kukharova, T.V.; Pershin, I.M. Conditions of Application of Distributed Systems Synthesis Methods to Multidimensional Object. In Proceedings of the 2018 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 3–4 October 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Drovosekova, T.I.; Pershin, I.M. Peculiarities of modelling hydro-lithospheric processes in the region of Kavkazskiye Mineralnye Vody (caucasus mineral springs). In Proceedings of the 2016 XIX IEEE International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 25–27 May 2016; pp. 215–217. [Google Scholar] [CrossRef]

- Underwood, J.C.; Akob, D.M.; Lorah, M.M.; Imbrigiotta, E.T.; Harvey, R.W.; Tiedeman, C.R. Microbial community response to a bioaugmentation test to degrade trichloroethylene in a fractured rock aquifer, Trenton, N.J. FEMS Microbiol. Ecol. 2022, 98, fiac077. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Zhang, M.; Kawabe, Y.; Katayama, T. Effects of ferrous iron supplementation on reductive dechlorination of tetrachloroethene and on methanogenic microbial community. FEMS Microbiol. Ecol. 2021, 97, fiab069. [Google Scholar] [CrossRef]

- Kozyrev, B.A.; Sizyakov, V.M. Heap leaching of red mud by the formate method. Obogashchenie Rud 2021, 4, 40–45. Available online: https://rudmet.ru/journal/2040/article/34204/ (accessed on 20 November 2023).

- Bengtsson, G.; Bergwall, C. Heterotrophic denitrification potential as an adaptive response in groundwater bacteria. FEMS Microbiol. Ecol. 1995, 16, 307–318. [Google Scholar] [CrossRef]

- Brielmann, H.; Griebler, C.; Schmidt, S.I.; Michel, R.; Lueders, T. Effects of thermal energy discharge on shallow groundwater ecosystems. FEMS Microbiol. Ecol. 2009, 68, 273–286. [Google Scholar] [CrossRef]

- Smith, H.J.; Zelaya, A.J.; De León, K.B.; Chakraborty, R.; Elias, A.D.; Hazen, T.C.; Arkin, A.P.; Cunningham, A.B.; Fields, M.W. Impact of hydrologic boundaries on microbial planktonic and biofilm communities in shallow terrestrial subsurface environments. FEMS Microbiol. Ecol. 2018, 94, fiy191. [Google Scholar] [CrossRef] [PubMed]

- Longnecker, K.; Da Costa, A.; Bhatia, M.; Kujawinski, E.B. Effect of carbon addition and predation on acetate-assimilating bacterial cells in groundwater. FEMS Microbiol. Ecol. 2009, 70, 456–470. [Google Scholar] [CrossRef] [PubMed]

- Taylor, R.; Cronin, A.; Pedley, S.; Barker, J.; Atkinson, T. The implications of groundwater velocity variations on microbial transport and wellhead protection—Review of field evidence. FEMS Microbiol. Ecol. 2004, 49, 17–26. [Google Scholar] [CrossRef] [PubMed]

- Asadulagi, M.M.; Ioskov, G.V. Simulation of the control system for hydrodynamic process with random disturbances. Topical Issues of Rational Use of Natural Resources. In Proceedings of the International Forum-Contest of Young Researchers, 2018, St. Petersburg, Russia, 18–20 April 2018; pp. 399–405. [Google Scholar]

- Ignatenko, A.; Afanaseva, O. Application of system analysis methods for the research of mining enterprise activity. In Proceedings of the 2023 Sixth International Conference of Women in Data Science at Prince Sultan University (WiDS PSU), Riyadh, Saudi Arabia, 14–15 March 2023; pp. 180–184. [Google Scholar] [CrossRef]

- Afanaseva, O.; Neyrus, S.; Navatskaya, V.; Perezhogina, A. Risk Assessment of Investment Projects Using the Simulation Decomposition Method. In Fundamental and Applied Scientific Research in the Development of Agriculture in the Far East (AFE-2022); Zokirjonugli, K.S., Muratov, A., Ignateva, S., Eds.; AFE 2023; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 706, pp. 776–785. [Google Scholar] [CrossRef]

- Dagaev, A.; Pham, V.D.; Kirichek, R.; Afanaseva, O.; Yakovleva, E. Method of Analyzing the Availability Factor in a Mesh Network. In Distributed Computer and Communication Networks; Communications in Computer and Information Science; 1552 CCIS; Springer: Berlin/Heidelberg, Germany, 2022; pp. 346–358. [Google Scholar] [CrossRef]

- Pershin, I.M.; Papush, E.G.; Kukharova, T.V.; Utkin, V.A. Modeling of Distributed Control System for Network of Mineral Water Wells. Water 2023, 15, 2289. [Google Scholar] [CrossRef]

- Pershin, I.M.; Kukharova, T.V.; Tsapleva, V.V. Designing of distributed systems of hydrolithosphere processes parameters control for the efficient extraction of hydromineral raw materials. J. Phys. Conf. Ser. 2021, 1728, 012017. [Google Scholar] [CrossRef]

- Ibarra-Olivares, G.; Miranda-Avilés, R.; Ramos-Leal, J.A.; Morán-Ramirez, J.; Puy-Alquiza, M.J.; Li, Y.; Ángeles-Moreno, E.; Kshirsagar, P. Hydrogeochemical Characterization of Groundwater at the Boundaries of Three Aquifers in Central México. Water 2023, 15, 3948. [Google Scholar] [CrossRef]

- Akpan, A.E.; Ekwok, S.E.; Ben, U.C.; Ebong, E.D.; Thomas, J.E.; Ekanem, A.M.; George, N.J.; Abdelrahman, K.; Fnais, M.S.; Eldosouky, A.M.; et al. Direct Detection of Groundwater Accumulation Zones in Saprock Aquifers in Tectono-Thermal Environments. Water 2023, 15, 3946. [Google Scholar] [CrossRef]

- Asadulagi, M.M.; Ioskov, G.V.; Tronina, E.V. Synthesis of Lumped and Distributed Controllers for Control System of Hydrodynamic Process. In Proceedings of the 2019 International Multi-Conference on Industrial Engineering and Modern Technologies, FarEastCon 2019, Vladivostok, Russia, 1–4 October 2019; Institute of Electrical and Electronics Engineers Inc.: Vladivostok, Russia, 2019; p. 8933859. [Google Scholar] [CrossRef]

- Asadulagi, M.M.; Vasilkov, O.S. The Use of Distributed and Lumped Type Controllers for the Hydro-lithospheric Process Control System of the Kislovodskoye Field. In Proceedings of the 2019 3rd International Conference on Control in Technical Systems, CTS 2019, St. Petersburg, Russia, 30 October–1 November 2019; Institute of Electrical and Electronics Engineers Inc.: St. Petersburg, Russia, 2019; pp. 7–10. [Google Scholar] [CrossRef]

- Sidorenko, A.A.; Dmitriev, P.N.; Alekseev, V.Y.; Sidorenko, S.A. Improvement of techno-logical schemes ofmining of coal seams prone to spontaneous combustion and rockbumps. J. Min. Inst. 2023, 264, 949–961. Available online: https://cyberleninka.ru/article/n/improvement-of-technological-schemes-of-mining-of-coal-seams-prone-to-spontaneous-combustion-and-rock-bumps/viewer (accessed on 20 November 2023).

- Marinina, O.; Nechitailo, A.; Stroykov, G.; Tsvetkova, A.; Reshneva, E.; Turovskaya, L. Technical and Economic Assessment of Energy Efficiency of Electrification of Hydrocarbon Production Facilities in Underdeveloped Areas. Sustainability 2023, 15, 9614. [Google Scholar] [CrossRef]

- Nechitailo, A.R.; Marinina, O.A. Analysis of technological directions of electrification of hydrocarbon production facilities in poorly developed territories. Sever i rynok: Formirovanie ekonomicheskogo poryadka. North Mark. Form. Econ. Order 2022, 2, 45–57. [Google Scholar] [CrossRef]

- Proteau-Bedard, F.; Baudron, P.; Benoit, N.; Nastev, M.; Post, R.; Masse-Dufresne, J. Investigating Multilayer Aquifer Dynamics by Combining Geochemistry, Isotopes and Hydrogeological Context Analysis. Hydrology 2023, 10, 211. [Google Scholar] [CrossRef]

- Golovina, E.; Shchelkonogova, O. Possibilities of Using the Unitization Model in the Development of Transboundary Groundwater Deposits. Water 2023, 15, 298. [Google Scholar] [CrossRef]

- Gitter, A.C.; Boellstorff, D.E.; Gholson, D.M.; Pieper, K.J.; Mena, K.D.; Mendez, K.S.; Gentry, T.J. Texas Well User Stewardship Practices Three Years after Hurricane Harvey. Water 2023, 15, 3943. [Google Scholar] [CrossRef]

- Arias-Díaz, A.; Murcia, H.; Vallejo-Hincapié, F.; Németh, K. Understanding Geodiversity for Sustainable Development in the Chinchiná River Basin, Caldas, Colombia. Land 2023, 12, 2053. [Google Scholar] [CrossRef]

- Golovina, E.I.; Grebneva, A.V. Management of groundwater resources in transboundary territories (on the example of the Russian Federation and the Republic of Estonia). J. Min. Inst. 2021, 252, 788–800. [Google Scholar] [CrossRef]

- Andreichyk, A.; Tsvetkov, P. Study of the Relationship between Economic Growth and Greenhouse Gas Emissions of the Shanghai Cooperation Organization Countries on the Basis of the Environmental Kuznets Curve. Resources 2023, 12, 80. [Google Scholar] [CrossRef]

- Chang, Y.; Chen, X.; Liu, D.; Tian, C.; Xu, D.; Wang, L. Study on the Control of Saltwater Intrusion Using Subsurface Dams. Water 2023, 15, 3938. [Google Scholar] [CrossRef]

- Cheremisina, O.V.; Ponomareva, M.A.; Molotilova, A.Y.; Mashukova, Y.A.; Soloviev, M.A. Sorption purification of acid storage facility water from iron and titanium on organic polymeric materials. J. Min. Inst. 2023, 264, 971–980. [Google Scholar] [CrossRef]

- Khouz, A.; Jaffal, M.; Trindade, J.; Bougadir, B.; El Bchari, F.; Kchikach, A.; El Ghorfi, M.; Ibouh, H.; Jadoud, M.; Kadiri, O.; et al. Understanding the Deep Structure of the Essaouira Basin Using Gravity Data: Hydrogeological Inferences for a Semiarid Region in Central-Western Morocco. Geosciences 2023, 13, 345. [Google Scholar] [CrossRef]

- Buslaev, G.; Lavrik, A.; Lavrik, A.; Tcvetkov, P. Hybrid system of hydrogen generation by water electrolysis and methane partial oxidation. Int. J. Hydrogen Energy 2023, 48, 24166–24179. [Google Scholar] [CrossRef]

- Marinina, O.; Nevskaya, M.; Lijuan, Z.; Que, C.T. Analysis of the influence of macroeconomic factors on the sustainable development of the chinese coal industry. In Proceedings of the 21st International Multidisciplinary Scientific Geoconference: Ecology and Renewable Energy Sources. Nano, Bio and Green Technologies for a Sustainable Future, SGEM 2021, Albena, Bulgaria, 16 August 2021; Volume 21, pp. 487–494. [Google Scholar] [CrossRef]

- Pashkevich, M.A.; Korotaeva, A.E.; Matveeva, V.A. Experimental simulation of a system of swamp biogeocenoses to improve the efficiency of quarry water treatment. J. Min. Inst. 2023, 263, 785–794. Available online: https://pmi.spmi.ru/pmi/article/view/16180 (accessed on 20 November 2023).

- Rogachev, M.K.; Aleksandrov, A.N. Justification of a comprehensive technology for preventing the formation of asphalt-resin-paraffin deposits during the production of highlyparaffinic oil by electric submersible pumps from multiformation deposits. J. Min. Inst. 2021, 250, 596–605. [Google Scholar] [CrossRef]

- Stevenazzi, S.; Del Gaudio, E.; Ruggiero, D.; D’Aniso, C.; Patelli, A.M.; Ducci, D. Geochemical and Isotopic Evidence for Investigating the Impacts of Landfills on Groundwater: A Case Study in the Campania Region (Southern Italy). Sustainability 2023, 15, 15822. [Google Scholar] [CrossRef]

- Aleksandrov, A.N.; Kishchenko, M.A.; Nguyen, V.T. Simulating the formation of wax deposits in wells using electric submersible pumps. In Advances in Raw Material Industries for Sustainable Development Goals; CRC Press: London, UK, 2021; pp. 283–295. [Google Scholar] [CrossRef]

- Miky, Y.; Issa, U.H.; Mahmod, W.E. Developing Functional Recharge Systems to Control Saltwater Intrusion via Integrating Physical, Numerical, and Decision-Making Models for Coastal Aquifer Sustainability. J. Mar. Sci. Eng. 2023, 11, 2136. [Google Scholar] [CrossRef]

- Correa-González, A.; Hernández-Bedolla, J.; Martínez-Cinco, M.A.; Sánchez-Quispe, S.T.; Hernández-Hernández, M.A. Assessment of Nitrate in Groundwater from Diffuse Sources Considering Spatiotemporal Patterns of Hydrological Systems Using a Coupled SWAT/MODFLOW/MT3DMS Model. Hydrology 2023, 10, 209. [Google Scholar] [CrossRef]

- Marinina, O.; Tsvetkova, A.; Vasilev, Y.; Komendantova, N.; Parfenova, A. Evaluating the Downstream Development Strategy of Oil Companies: The Case of Rosneft. Resources 2022, 11, 4. [Google Scholar] [CrossRef]

- Plotnikov, A.V.; Trushnikov, V.E.; Pervukhin, D.A.; Shestopalov, M.Y. Mathematical Simulation of the Formation Pressure Monitoring System in the Water-Drive Gas Reservoir. In Proceedings of the 2023 26th International Conference on Soft Computing and Measurements, SCM 2023, St. Petersburg, Russia, 24–26 May 2023; pp. 77–81. [Google Scholar] [CrossRef]

- Afanasyev, M.; Pervukhin, D.; Kotov, D.; Davardoost, H.; Smolenchuk, A. System Modeling in Solving Mineral Complex Logistic Problems with the Anylogic Software Environment. Transp. Res. Procedia 2022, 68, 483–491. [Google Scholar] [CrossRef]

- Bochkov, A.; Pervukhin, D.; Grafov, A.; Nikitina, V. Construction of lorenz curves based on empirical distribution laws of economic indicators. Math. Stat. 2020, 8, 637–644. [Google Scholar] [CrossRef]

- Martirosyan, K.V.; Chenyshev, A.B.; Martirosyan, A.V. Application of Bayes Networks in the Design of the Information System “Mineral Water Deposit”. In Proceedings of the 2023 XXVI International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 24–26 May 2023; pp. 236–239. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Kukharov, T.V.; Fedorov, M.S. Research of the Hydrogeological Objects’ Connection Peculiarities. In Proceedings of the 2021 IV International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2021; pp. 34–38. [Google Scholar] [CrossRef]

- Kazanin, O.I.; Sidorenko, A.A.; Sidorenko, S.A.; Ivanov, V.V.; Mischo, H. High productive longwall mining of multiple gassy seams: Best practice and recommendations. Acta Montan. Slovaca 2022, 27, 152–162. [Google Scholar] [CrossRef]

- Makarova, A.A.; Kaliberda, I.V.; Kovalev, D.A.; Pershin, I.M. Modeling a Production Well Flow Control System Using the Example of the Verkhneberezovskaya Area. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Russia, 25–28 January 2022; pp. 760–764. [Google Scholar] [CrossRef]

- Katysheva, E. Analysis of the Interconnected Development Potential of the Oil, Gas and Transport Industries in the Russian Arctic. Energies 2023, 16, 3124. [Google Scholar] [CrossRef]

- Ilyushina, A.N.; Pershin, I.M.; Trushnikov, V.E.; Novozhilov, I.M.; Pervukhin, D.A.; Tukeyev, D.L. Design of Induction Equipment Complex using the Theory of Distributed Parameter Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 26–28 September 2023; pp. 79–82. [Google Scholar] [CrossRef]

- Sidorenko, A.A.; Ivanov, V.V.; Sidorenko, S.A. Computer modeling of rock massif stress condition for mining planning on overworked seam. J. Phys. Conf. Ser. 2020, 1661, 012082. [Google Scholar] [CrossRef]

- Katysheva, E.G. Application of BigData technology to improve the efficiency of Arctic shelf fields development. IOP Conf. Ser. Earth Environ. Sci. 2021, 937, 042080. [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Kondrasheva, N.K.; Khasanov, A.F.; Oleynik, I.L. Environmentally Friendly Diesel Fuel Obtained from Vegetable Raw Materials and Hydrocarbon Crude. Energies 2023, 16, 2121. [Google Scholar] [CrossRef]

- Zolotov, O.I.; Iliushina, A.N.; Novozhilov, I.M. Spatially Distributed System for Monitoring of Fields Technical Condition in Mineral Resources Sector. In Proceedings of the 2021 XXIV International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 26–28 May 2021; pp. 93–95. [Google Scholar] [CrossRef]

- Iliushina, A.N.; Novozhilov, I.M. Development of the Spatial-Distributed Mathematical Model of a Drilling Rig. In Proceedings of the 2019 III International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 30 October–1 November 2019; pp. 156–159. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Eremeeva, A.M. Production of biodiesel fuel from vegetable raw materials. J. Min. Inst. 2023, 260, 248–256. [Google Scholar] [CrossRef]

- Golovina, E.; Khloponina, V.; Tsiglianu, P.; Zhu, R. Organizational, Economic and Regulatory Aspects of Groundwater Resources Extraction by Individuals (Case of the Russian Federation). Resources 2023, 12, 89. [Google Scholar] [CrossRef]

- Tarabarinova, T.A.; Golovina, E.I. Capitalization of mineral resources as an innovation ecological strategy. Geol. Miner. Resour. Sib. 2021, 4, 86–96. [Google Scholar] [CrossRef]

- Ilyushina, A.N.; Pershin, I.M.; Trushnikov, V.E.; Novozhilov, I.M.; Pervukhin, D.A.; Tukeyev, D.L. Design of a Software Complex for Control of Induction Equipment of Metallurgical Manufacture using Systems Theory. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 26–28 September 2023; pp. 83–87. [Google Scholar] [CrossRef]

- Shapiro, S.L.; Kopkov, M.P.; Potseshkovskaya, I.V. Problems of the organization of surface and underground space (e.g. historical embankments of Saint Petersburg). E3S Web Conf. 2021, 266, 03016. [Google Scholar] [CrossRef]

- Potseshkovskaya, I.V.; Soroka, A.N. Revitalization of urban industrial areas based on sustainable development principles. E3S Web Conf. 2021, 266, 08012. [Google Scholar] [CrossRef]

- Kuo, W.; Li, X.; Zhang, Y.; Li, W.; Wang, Q.; Li, L. Prediction Model of Water Abundance of Weakly Cemented Sandstone Aquifer Based on Principal Component Analysis–Back Propagation Neural Network of Grey Correlation Analysis Decision Making. Water 2024, 16, 551. [Google Scholar] [CrossRef]

- Ke, H.; Zhang, F.; Sikai, Y.; Zhe, M.; Bin, X. Using Machine Learning Models to Forecast the Conversion Coefficient between Electricity Consumption and Water Pumped for Irrigation Wells in Baicheng City, China. Water 2024, 16, 523. [Google Scholar] [CrossRef]

- Zhou, L.; Yan, P.; Zhang, Y.; Lei, H.; Hao, S.; Ma, Y.; Sun, S. Using Particle Swarm Optimization with Backpropagation Neural Networks and Analytic Hierarchy Process to Optimize the Power Generation Performance of Enhanced Geothermal System (EGS). Water 2024, 16, 509. [Google Scholar] [CrossRef]

- Chatterjee, T.; Gogoi, U.R.; Samanta, A.; Chatterjee, A.; Singh, M.K.; Pasupuleti, S. Identifying the Most Discriminative Parameter for Water Quality Prediction Using Machine Learning Algorithms. Water 2024, 16, 481. [Google Scholar] [CrossRef]

- Zhang, B.; Ma, J.; Khan, M.A.; Repnikova, V.; Shidlovskaya, K.; Barykin, S.; Ahmad, M.S. The Effect of Economic Policy Uncertainty on Foreign Direct Investment in the Era of Global Value Chain: Evidence from the Asian Countries. Sustainability 2023, 15, 6131. [Google Scholar] [CrossRef]

- Golovina, E.; Karennik, K. Modern Trends in the Field of Solving Transboundary Problems in Groundwater Extraction. Resources 2021, 10, 107. [Google Scholar] [CrossRef]

- Gerasimova, I.G.; Oblova, I.S.; Golovina, E.I. The Demographic Factor Impact on the Economics of the Arctic Region. Resources 2021, 10, 117. [Google Scholar] [CrossRef]

- Demenkov, P.A.; Trushko, O.V.; Potseshkovskaya, I.V. Numerical experiments on the modeling of compensatory injection for the protection of buildings during tunneling. ARPN J. Eng. Appl. Sci. 2018, 13, 9161–9169. [Google Scholar]

- Shubin, A.A.; Tulin, P.K.; Potseshkovskaya, I.V. The mechanism of underground cavities formation and the methods of their elimination. Int. J. Civ. Eng. Technol. 2017, 8, 667–681. [Google Scholar]

- Katysheva, E. Creation of the integrated field model to increase the oil and gas assets management. In Proceedings of the 20th International Multidisciplinary Scientific GeoConference SGEM 2020, Albena, Bulgaria, 18–24 August 2020; Ecology, Economics, Education and Legislation, Issue 5.2. Environmental Economics. SGEM: Albena, Bulgaria, 2020; Volume 20, pp. 153–160. [Google Scholar] [CrossRef]

- Sidorenko, A.; Sirenko, Y.G.; Sidorenko, A.S. An assessment of multiple seam stress conditions using a 3-D numerical modelling approach. J. Phys. Conf. Ser. 2019, 1333, 032078. [Google Scholar] [CrossRef]

- Sidorenko, A.; Ivanov, V.V.; Sidorenko, A.S. Modelling of computational fluid dynamics of gas dynamic processes on longwall panel during underground mining of flat gassy coal multi-seam. J. Phys. Conf. Ser. 2019, 1333, 032079. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Chernyshev, A.B. Investigation of Popov’s Lines’ Limiting Position to Ensure the Process Control Systems’ Absolute Stability. In Proceedings of the 2023 XXVI International Conference on Soft Computing and Meas urements (SCM), St. Petersburg, Russia, 24–26 May 2023; pp. 69–72. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Grudyaeva, E.K.; Chernyshev, A.B. Calculation of the Temperature Maximum Value Access Time at the Observation Point. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), 26–28 January 2021; pp. 1014–1018. [Google Scholar] [CrossRef]

- Martirosyan, A.A.; Martirosyan, K.V. Quality improvement information technology for mineral water field’s control. In Proceedings of the 2016 IEEE Conference on Quality Management, Transport and Information Security, Information Technologies (IT&MQ&IS), Nalchik, Russia, 4–11 October 2016; pp. 147–151. [Google Scholar] [CrossRef]

- Asadulagi, M.M.; Pervukhin, D.A. Stochastic control system of hydrodynamic processes in aquifers/Innovation-Based Development of the Mineral Resources Sector: Challenges and Prospects. In Proceedings of the 11th Conference of the Russian-German Raw Materials, Potsdam, Germany, 7–8 November 2019; pp. 175–185. [Google Scholar]

- Asadulagi, M.-A.M.; Pershin, I.M.; Tsapleva, V.V. Research on Hydrolithospheric Processes Using the Results of Groundwater Inflow Testing. Water 2024, 16, 487. [Google Scholar] [CrossRef]

- Plotnikov, A.V.; Pervukhin, D.A.; Trushnikov, V.E.; Shestopalov, M.Y. Mathematical Modeling of the Automatic Control System of Formation Pressure in a Gas Reservoir. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2023; pp. 126–129. [Google Scholar] [CrossRef]

- Marinina, O.; Kirsanova, N.; Nevskaya, M. Circular Economy Models in Industry: Developing a Conceptual Framework. Energies 2022, 15, 9376. [Google Scholar] [CrossRef]

- Lebedev, A.; Cherepovitsyn, A. Waste Management during the Production Drilling Stage in the Oil and Gas Sector: A Feasibility Study. Resources 2024, 13, 26. [Google Scholar] [CrossRef]

- Cherepovitsyn, A.; Lebedev, A. Drill Cuttings Disposal Efficiency in Offshore Oil Drilling. J. Mar. Sci. Eng. 2023, 11, 317. [Google Scholar] [CrossRef]

- Pershin, I.M.; Nosova, V.A.; Tsapleva, V.V. Methodology for Designing Distributed Self-tuning Control Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 26–28 September 2023; pp. 110–114. [Google Scholar] [CrossRef]

- Nosova, V.A.; Pershin, I.M. Determining the Optimal Number of Wells during Field Development. In Proceedings of the 2021 IV International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2021; pp. 42–44. [Google Scholar] [CrossRef]

- Li, C.; Jiao, Y.; Kan, G.; Fu, X.; Chai, F.; Yu, H.; Liang, K. Comparisons of Different Machine Learning-Based Rainfall–Runoff Simulations under Changing Environments. Water 2024, 16, 302. [Google Scholar] [CrossRef]

- Sheikh, M.R.; Coulibaly, P. Review of Recent Developments in Hydrologic Forecast Merging Techniques. Water 2024, 16, 301. [Google Scholar] [CrossRef]

- Zhen, L.; Bărbulescu, A. Comparative Analysis of Convolutional Neural Network-Long Short-Term Memory, Sparrow Search Algorithm-Backpropagation Neural Network, and Particle Swarm Optimization-Extreme Learning Machine Models for the Water Discharge of the Buzău River, Romania. Water 2024, 16, 289. [Google Scholar] [CrossRef]

- Babyr, N.V. Topical Themes and New Trends in Mining Industry: Scientometric Analysis and Research Visualization. Int. J. Eng. Trans. A Basics 2024, 37, 439–451. [Google Scholar] [CrossRef]

- Marinina, O.; Parfenova, A.; Tsvetkova, A.; Komendantova, N. Assortment Strategy as A Driver of Fuel and Energy Complex Competitiveness. In Proceedings of the 21st International Multidisciplinary Scientific Geoconference: Ecology and Renewable Energy Sources. Nano, Bio and Green Technologies for a Sustainable Future, SGEM 2021, Albena, Bulgaria, 16–22 August 2021; Volume 21, pp. 503–510. [Google Scholar] [CrossRef]

- Nevskaya, M.; Marinina, O.; Kosovtseva, T.; Que, C.T. Coal Companies in Vietnam: Production Sustainability Analysis. In Proceedings of the 21st International Multidisciplinary Scientific Geoconference: Geology and Mining Technologies. Geoinformatics and Remote Sensing. Forest Ecosystems and Water Resources, SGEM 2021, Albena, Bulgaria, 16–22 August 2021; Volume 21, pp. 81–87. [Google Scholar] [CrossRef]

- Golovina, E.I.; Tselmeg, B. Cost estimate as a tool for managing fresh groundwater resources in the Russian Federation. Geol. Miner. Resour. Sib. 2023, 4, 81–91. [Google Scholar] [CrossRef]

- Shchirova, E.; Tsvetkova, A.; Komendantova, N. Analysis of the possibility of implementing carbon dioxide sequestration projects in Russia based on foreign experience. In Proceedings of the 21st International Multidisciplinary Scientific GeoConference SGEM 2021, Albena, Bulgaria, 16–22 August 2021; Volume 21, pp. 203–210. [Google Scholar] [CrossRef]

- Marinina, O.A.; Nevskaya, M.A. Specific nature of labour management in the oil and gas sector in the Russian Far North. Int. J. Appl. Bus. Econ. Res. 2017, 15, 177–185. [Google Scholar]

- Fedorova, E.; Pupysheva, E.; Morgunov, V. Modelling of Red-Mud Particle-Solid Distribution in the Feeder Cup of a Thickener Using the Combined CFD-DPM Approach. Symmetry 2022, 14, 2314. [Google Scholar] [CrossRef]

- Fedorova, E.R.; Pupysheva, E.A.; Morgunov, V.V. Settling Parameters Determined during Thickening and Washing of Red Muds. Tsvetnye Metally. 2023, 4, 77–85. [Google Scholar] [CrossRef]

- Semenova, T.; Martínez Santoyo, J.Y. Economic Strategy for Developing the Oil Industry in Mexico by Incorporating Environmental Factors. Sustainability 2024, 16, 36. [Google Scholar] [CrossRef]

- Semenova, T.; Al-Dirawi, A.; Al-Saadi, T. Environmental Challenges for Fragile Economies: Adaptation Opportunities on the Examples of the Arctic and Iraq. Agronomy 2022, 12, 2021. [Google Scholar] [CrossRef]

- Semenova, T. Value Improving Practices in Production of Hydrocarbon Resources in the Arctic Regions. J. Mar. Sci. Eng. 2022, 10, 187. [Google Scholar] [CrossRef]

- Afanaseva, O.; Bezyukov, O.; Pervukhin, D.; Tukeev, D. Experimental Study Results Processing Method for the Marine Diesel Engines Vibration Activity Caused by the Cylinder-Piston Group Operations. Inventions 2023, 8, 71. [Google Scholar] [CrossRef]

- Islamov, S.R.; Bondarenko, A.V.; Mardashov, D.V. Substantiation of a well killing technology for fractured carbonate reservoirs. In Youth Technical Sessions Proceedings: VI Youth Forum of the World Petroleum Council—Future Leaders Forum; Taylor & Francis: London, UK, 2019; pp. 256–264. [Google Scholar] [CrossRef]

- Kazanin, O.I.; Sidorenko, A.A.; Meshkov, A.A.; Sidorenko, S.A. Reproduction of the longwall panels: Modern requirements for the technology and organization of the development operations at coal mines. Eurasian Min. 2020, 2, 19–23. [Google Scholar] [CrossRef]

- Olt, J.; Maksarov, V.V.; Efimov, A.E. Improving the Surface Quality of Titanium-Alloy Components in Machining. Russ. Eng. Res. 2023, 43, 319–322. [Google Scholar] [CrossRef]

- Korshunov, G.I.; Eremeeva, A.M.; Seregin, A.S. Justification of reduction in air requirement in ventilation of coal roadways with running diesel engines. MIAB Min. Inf. Anal. Bull. 2022, 3, 47–59. (In Russian) [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Ilyashenko, I.S.; Korshunov, G.I. The possibility of application of bioadditives to diesel fuel at mining enterprises. Min. Informational Anal. Bull. 2022, 39–49. [Google Scholar] [CrossRef]

- Legkokonets, V.A.; Islamov, S.R.; Mardashov, D.V. Multifactor analysis of well killing operations on oil and gas condensate field with a fractured reservoir. In Proceedings of the International Forum-Contest of Young Researchers: Topical Issues of Rational Use of Natural Resources; Taylor & Francis: London, UK, 2019; pp. 111–118. [Google Scholar]

- Kondrasheva, N.K.; Eremeeva, A.M.; Nelkenbaum, K.S. Development of domestic technologies of produsing high quality clean diesel fuel. ChemChemTech [Izv. Vyssh. Uchebn. Zaved. Khim. Khim. Tekhnol.] 2018, 61, 76–82. (In Russian) [Google Scholar] [CrossRef]

- Schipachev, A.; Fetisov, V.; Nazyrov, A.; Donghee, L.; Khamrakulov, A. Study of the Pipeline in Emergency Operation and Assessing the Magnitude of the Gas Leak. Energies 2022, 15, 5294. [Google Scholar] [CrossRef]

- Nikolaev, A.K.; Romanov, A.V.; Zaripova, A.N.; Fetisov, V.G. Modeling of flow in field pipeline to confirm effectiveness of insertion of splitting couplings in control of rill-washing corrosion. IOP Conf. Ser. Earth Environ. Sci. 2018, 194, 082030. [Google Scholar] [CrossRef]

- Meshkov, A.A.; Korshunov, G.I.; Kondrasheva, N.K.; Eremeeva, A.M.; Seregin, A.S. Method of Reducing Air Pollution of the Coal Mines Working Areas with Diesel Locomotives Harmful Emissions. Bezop. Tr. V Promyshlennosti 2020, 1, 68–72. (In Russian) [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Kondrasheva, N.K.; Nelkenbaum, K.S. Studying the possibility of improving the properties of environmentally friendly diesel fuels. Sci. Pract. Stud. Raw Mater. Issues 2019, 2020, 108–114. [Google Scholar] [CrossRef]

- Maksarov, V.V.; Minin, A.O.; Zakharova, V.P. Ensuring surface quality in AlMn alloy items during high-frequency wave impact boring. Tsvetnye Met. 2023, 4, 90–95. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilyushin, Y.V.; Nosova, V.A. Methodology to Increase the Efficiency of the Mineral Water Extraction Process. Water 2024, 16, 1329. https://doi.org/10.3390/w16101329

Ilyushin YV, Nosova VA. Methodology to Increase the Efficiency of the Mineral Water Extraction Process. Water. 2024; 16(10):1329. https://doi.org/10.3390/w16101329

Chicago/Turabian StyleIlyushin, Yury Valeryevich, and Victoria Andreevna Nosova. 2024. "Methodology to Increase the Efficiency of the Mineral Water Extraction Process" Water 16, no. 10: 1329. https://doi.org/10.3390/w16101329

APA StyleIlyushin, Y. V., & Nosova, V. A. (2024). Methodology to Increase the Efficiency of the Mineral Water Extraction Process. Water, 16(10), 1329. https://doi.org/10.3390/w16101329