Research on the Mechanism and Evolution Law of Delayed Water Inrush Caused by Fault Activation with Mining

Abstract

:1. Introduction

2. Theoretical Mechanism of Delayed Water Inrush Caused by Fault Activation

2.1. Expand and Extend Mechanism of Microstructures in Fault Zone

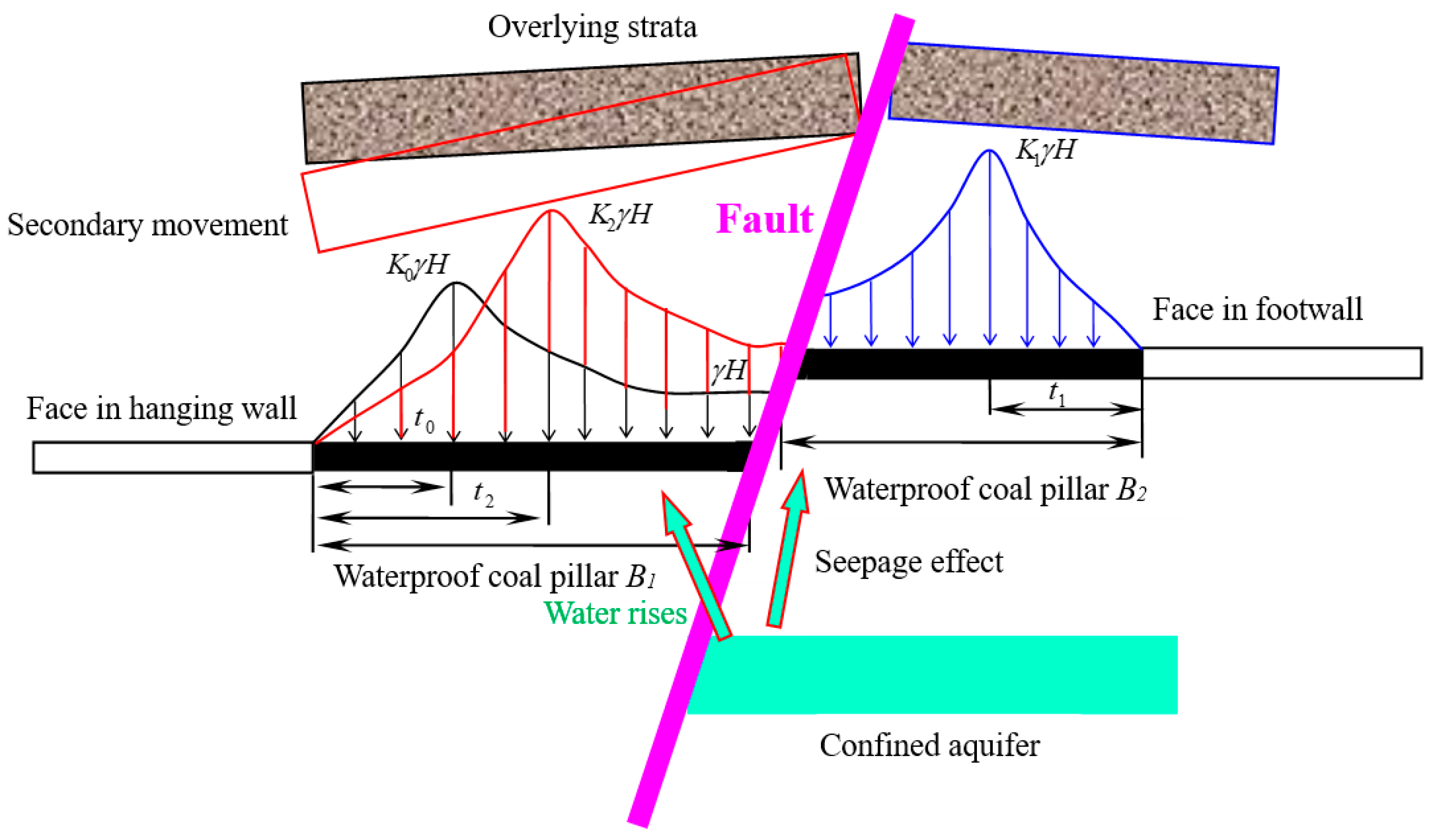

2.2. Delayed Water Inrush Caused by Fault Activation with Overlying Strata Movement

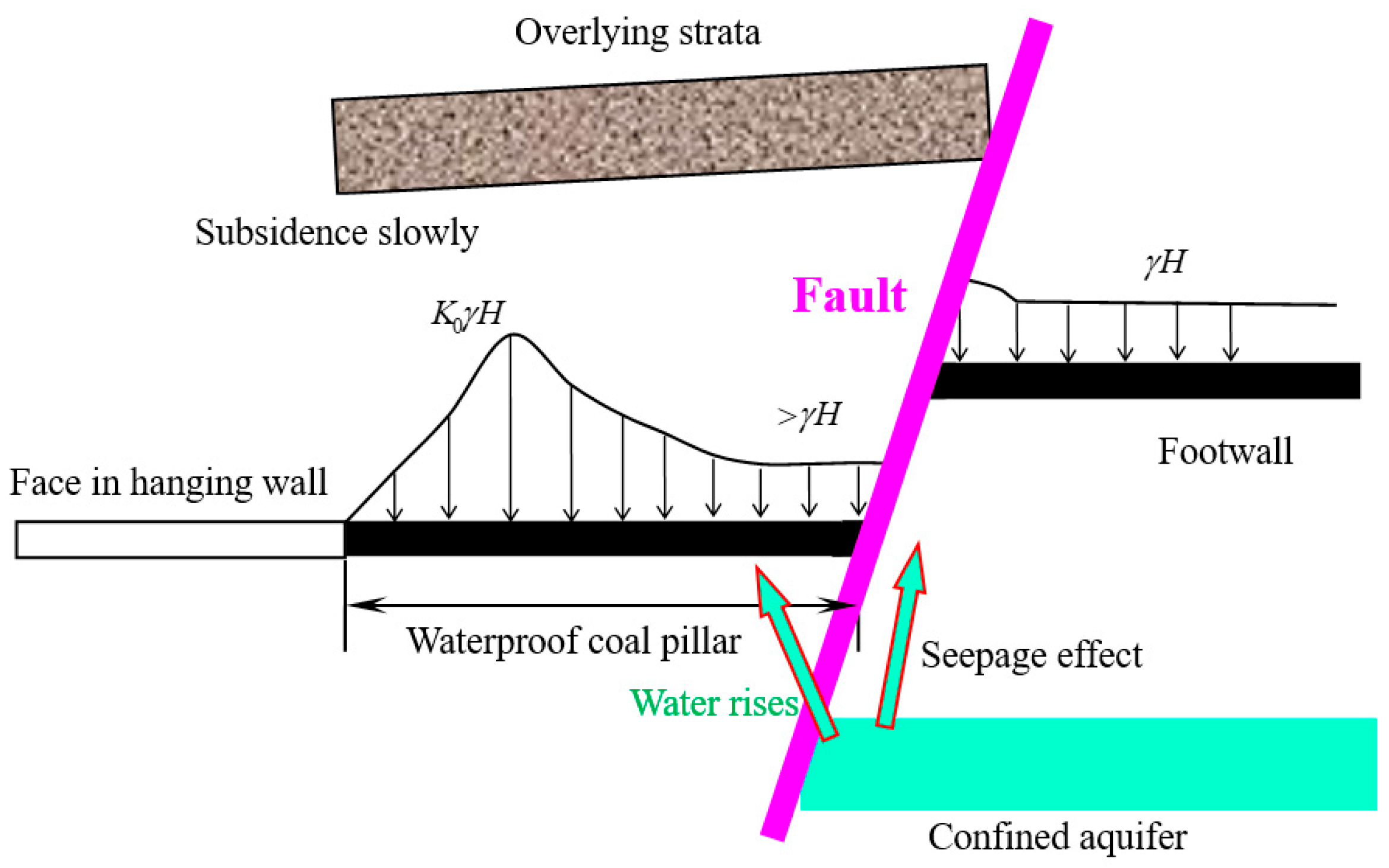

2.3. Delayed Water Inrush Caused by Fault Activation with Surrounding Rock Creep Failure

3. Similar Simulation Test of Delayed Water Inrush Caused by Fault Activation

3.1. Engineering Background

3.2. Solid–Liquid Coupling with Similar Simulation Materials

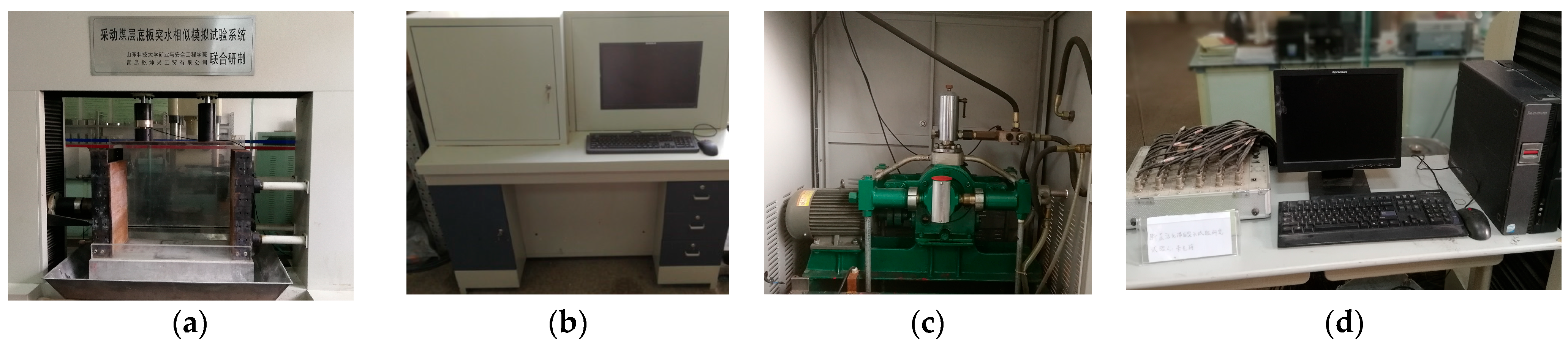

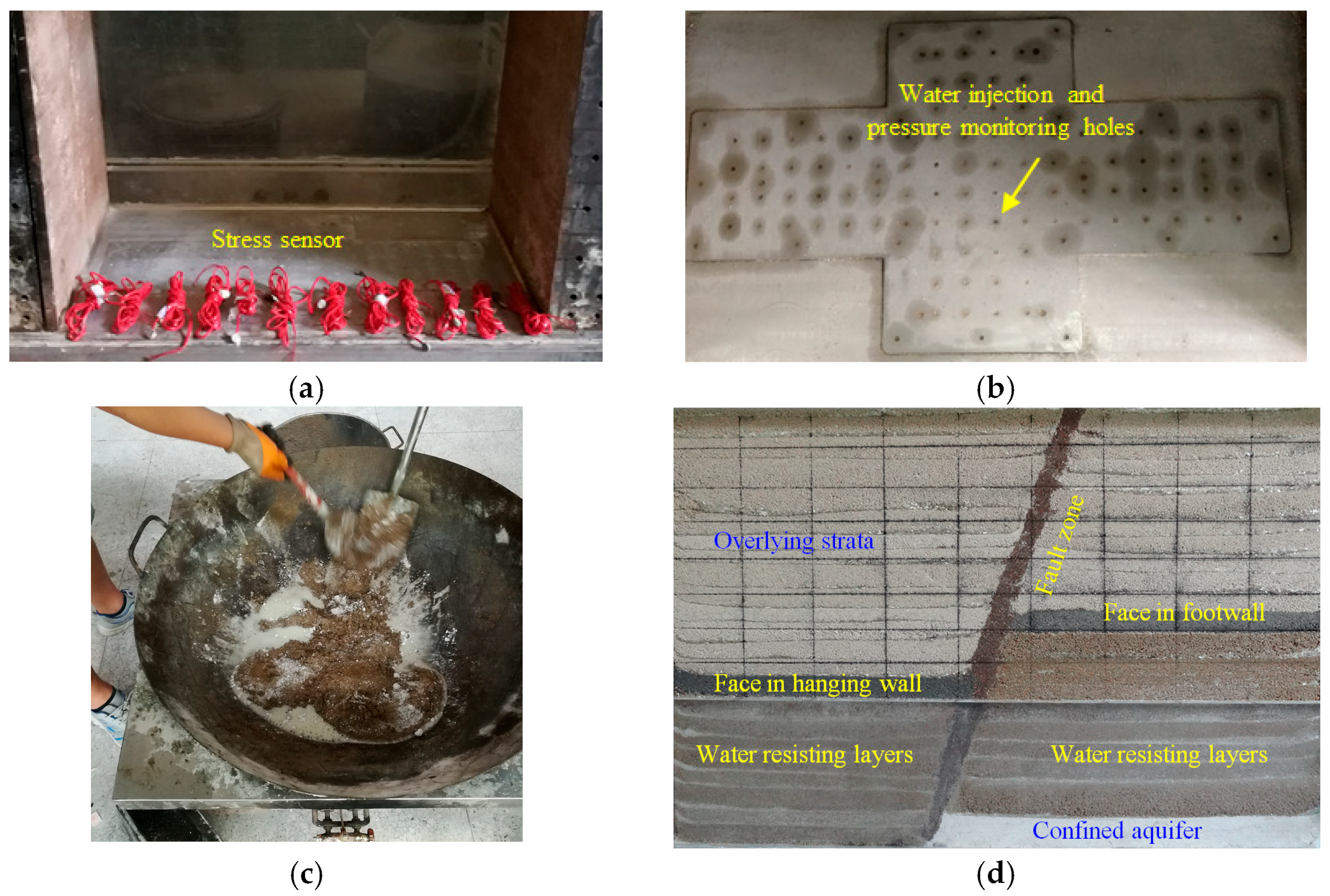

3.3. Test Equipment

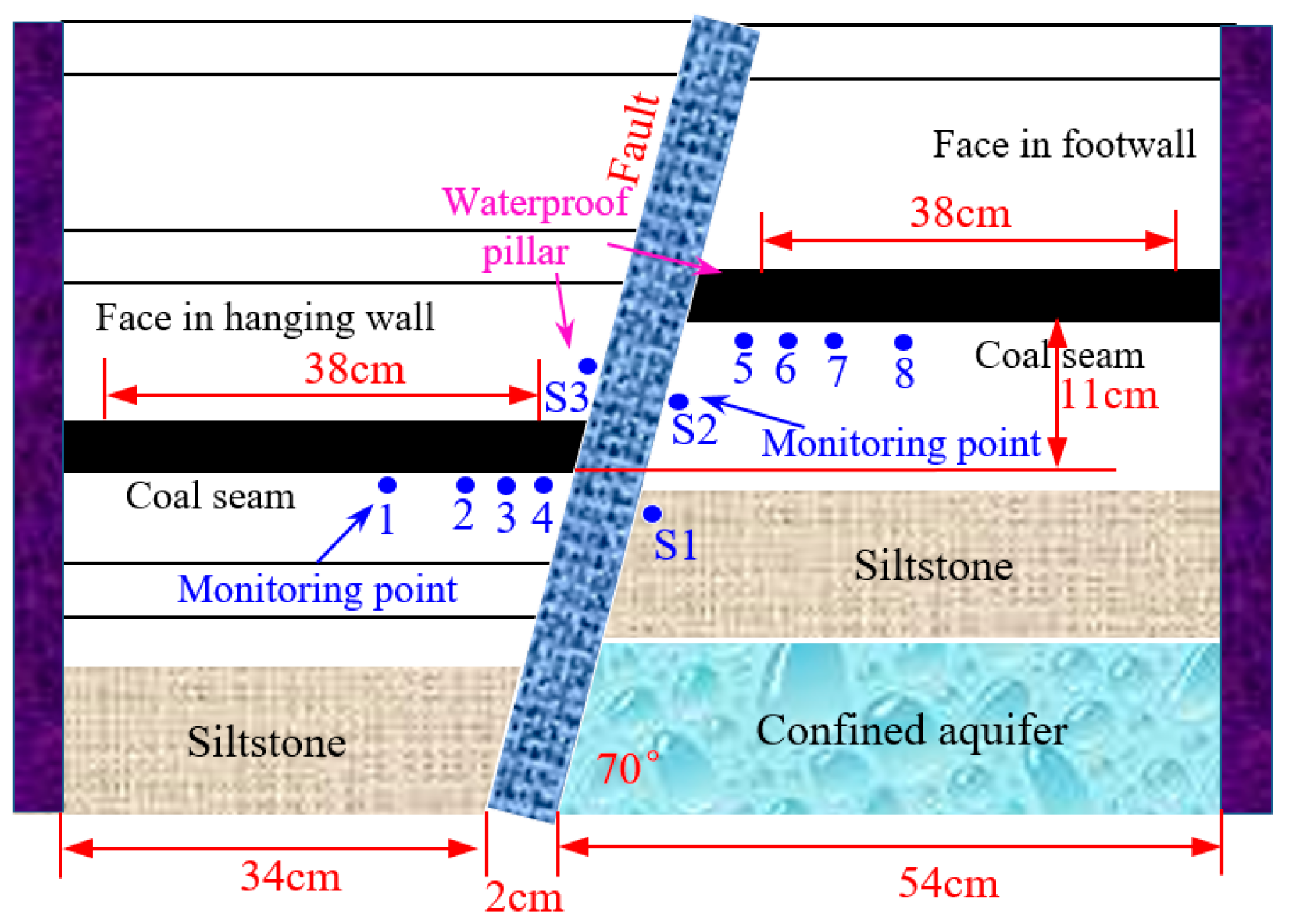

3.4. Test Scheme

3.5. Test Procedures

4. Evolution Law of Delayed Water Inrush Caused by Fault Activation

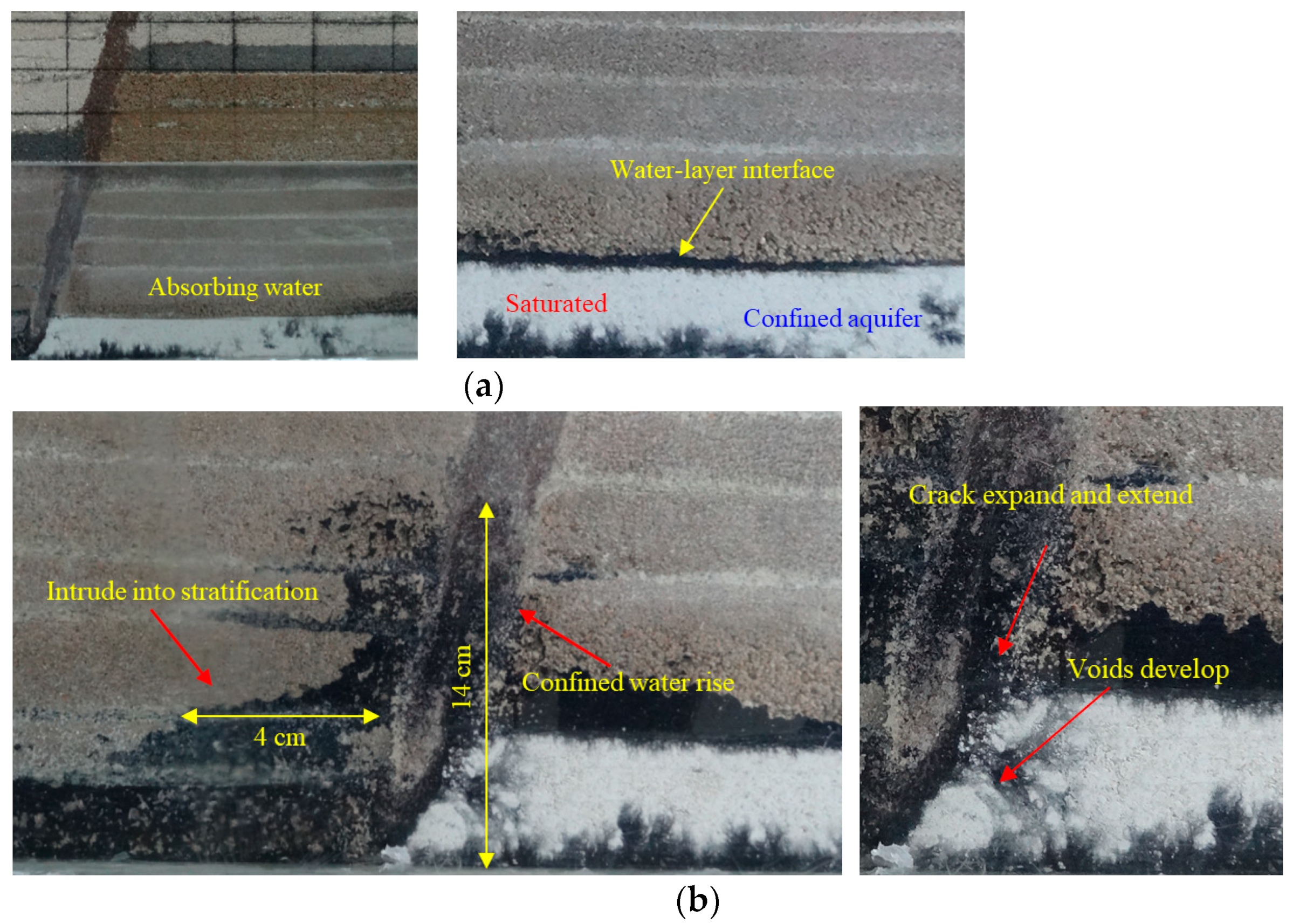

4.1. Micro-Activation Stage of Crack Development

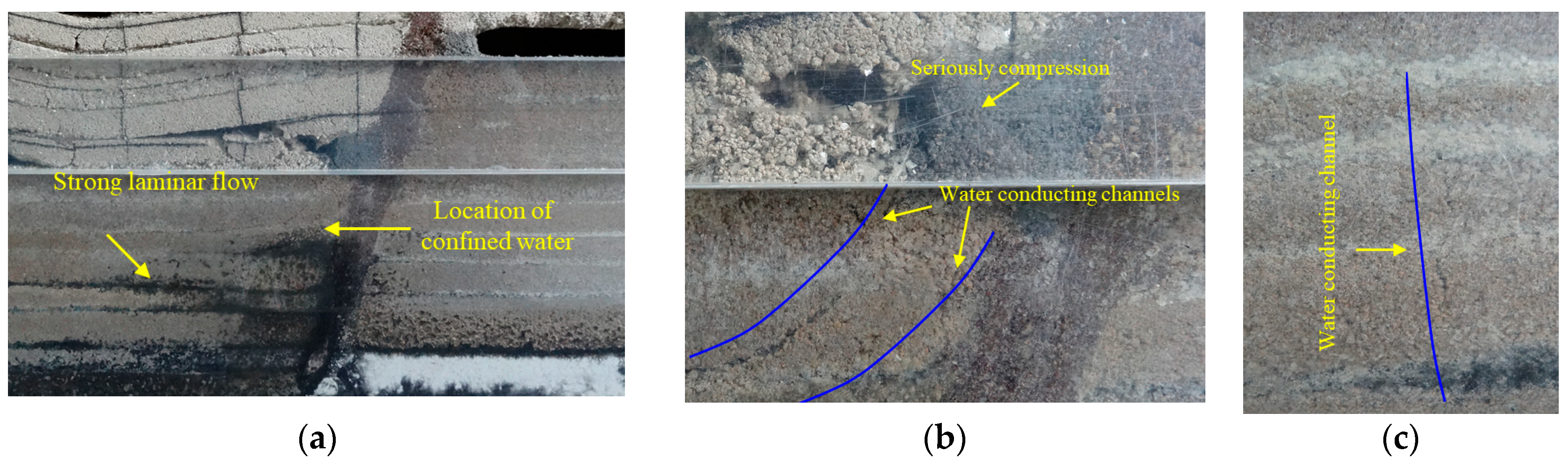

4.2. Macro-Activation Stage of Water-Conducting Channel Formation

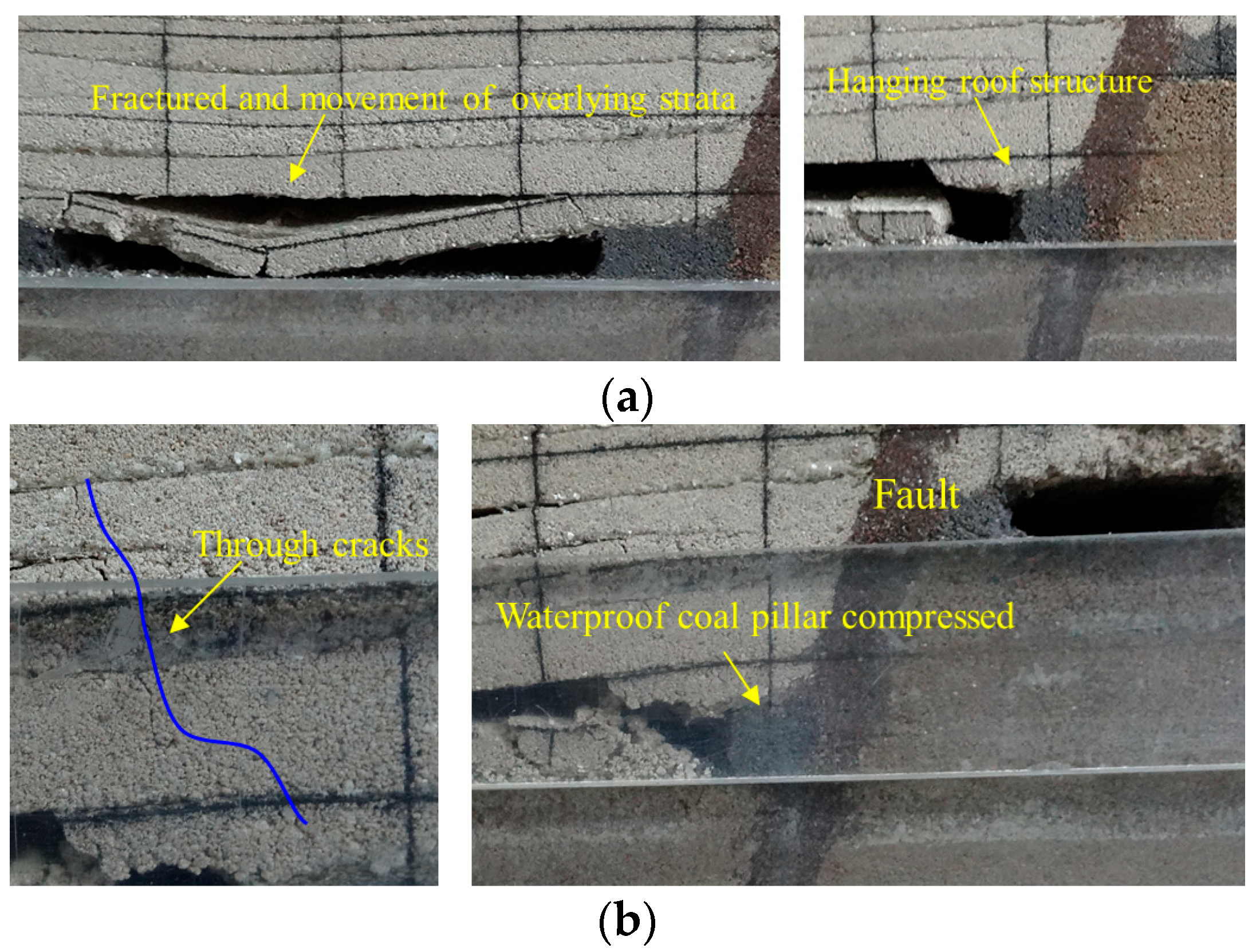

4.2.1. Evolution Law of Overlying Strata Fracture and Movement

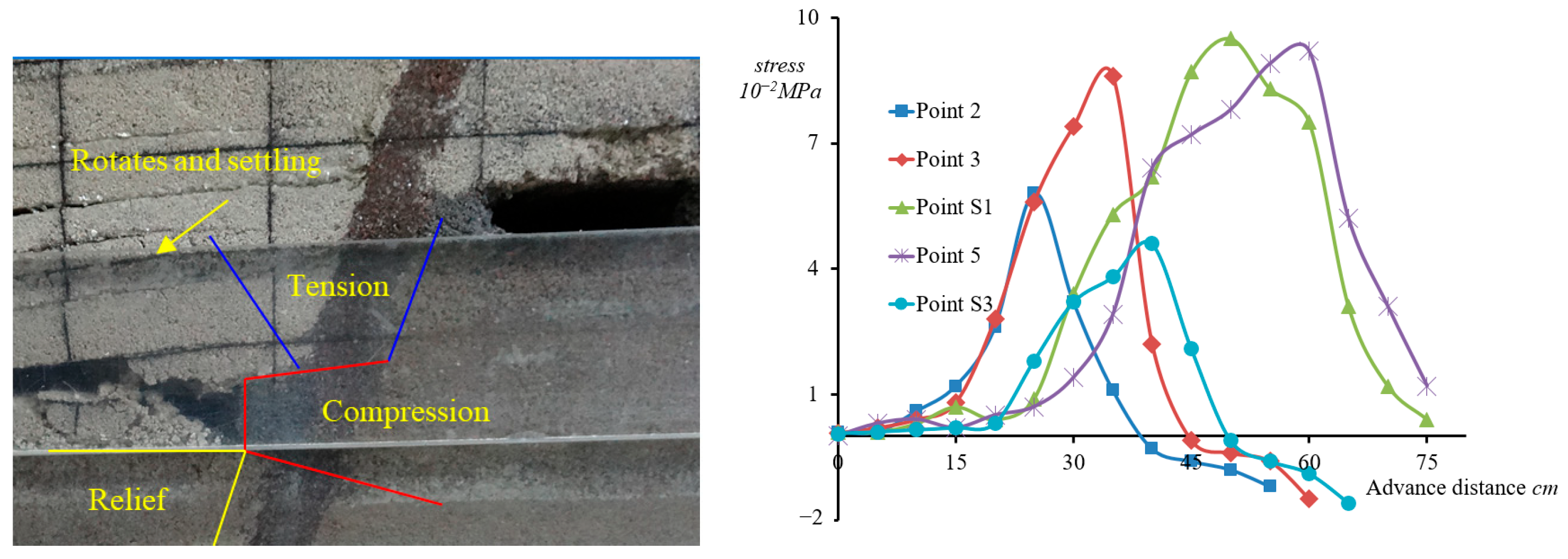

4.2.2. Stress Evolution Law of Waterproof Coal Pillar

4.2.3. Formation Process of Water-Conducting Channels

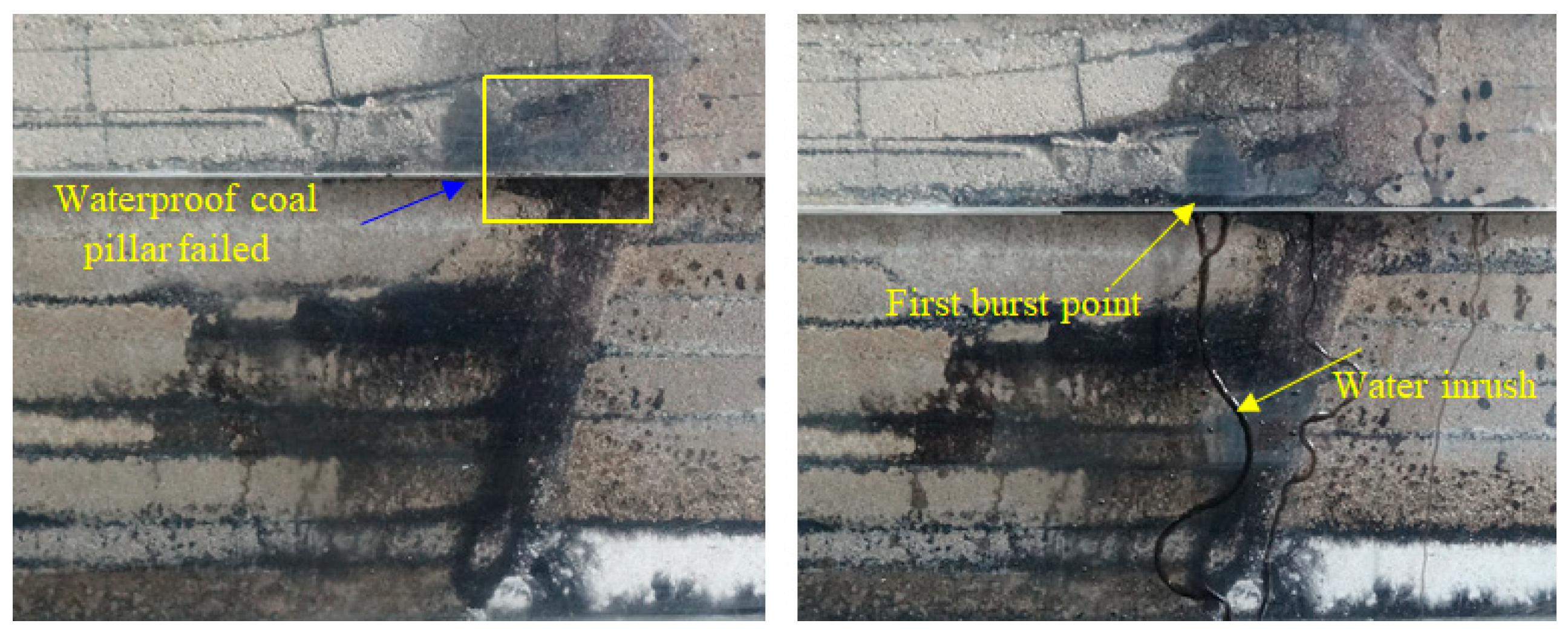

4.3. Confined Water Burst Stage of Coal Pillar and Floor Failure

5. Conclusions

- (1)

- The expansion and time effect of rock mass microstructures around the fault zone are the essential reasons for fault activation and delayed water inrush disaster, which includes two basic forms: overlying strata movement and long-term creep failure of surrounding rock. By comparison, fault activation and water inrush caused by the surrounding rock creep failure have a long time effect, which can reach several years or even decades.

- (2)

- The solid–liquid coupling with similar simulation materials developed for the water-resisting layer, water-bearing layer, and fault zone are proven to be reasonable and feasible via the similar simulation test of delayed water inrush caused by fault activation. They can be applied in the geotechnical and architectural engineering fields.

- (3)

- Delayed water inrush caused by fault activation can be divided into three stages. The micro-activation stage of crack development: with the effect of mining activities and confined water, microstructures develop, expand, and extend to form natural water inrush weakness points. The macro-activation stage of water-conducting channel formation: cracks expand and extend rapidly to form water-conducting channels because of stress state and the changing amount of the waterproof coal pillar and the fault zone with coal seam mining in the footwall. The confined water burst stage of coal pillar and floor failure: the waterproof coal pillar failure and cracks through the floor cause a water inrush disaster, and the first bursting point is located at the junction between the waterproof coal pillar and the gob floor.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, H. Research review of the state key research development program of China: Deep rock mechanics and mining theory. J. Chin. Coal Soc. 2019, 44, 1283–1305. [Google Scholar]

- Li, W.; Qiao, W.; Li, X.; Sun, R. Characteristics of water disaster, evaluation methods and exploration direction for controlling groundwater in deep mining. J. Chin. Coal Soc. 2019, 44, 2437–2448. [Google Scholar]

- Yuan, L. Research progress of mining response and disaster prevention and control in deep coal mines. J. Chin. Coal Soc. 2021, 46, 716–725. [Google Scholar]

- Lu, H.; Shen, D.; Yao, D.; Hu, Y. Analytical solution of critical water inrush pressure of mining floor affected by fault. J. Min. Saf. Eng. 2014, 31, 888–895. [Google Scholar]

- Lin, Y.; Tu, M.; Fu, B.; Li, C. Mechanical mechanisms of fault self-locking and activation and its stability control. J. Min. Saf. Eng. 2019, 36, 898–905. [Google Scholar]

- Zhang, P.; Zhu, X.; Sun, W.; Yang, H.; Yang, F. Study on mechanism of delayed water inrush caused by mining-induced filling fault activation. Coal Sci. Technol. 2022, 50, 136–143. [Google Scholar]

- Zhu, G.; Zhang, W.; Wang, S.; Zhang, P. Experimental research on characteristics of fault activation and confined water rising. Geotech. Geol. Eng. 2018, 36, 2625–2636. [Google Scholar] [CrossRef]

- Sun, W.; Yang, H.; Zhao, J.; Xue, Y.; Zhang, X.; Liu, Q. Basic experimental research on the delineation of the evolutionary process of fault water inrush. Coal Sci. Technol. 2023, 51, 118–128. [Google Scholar]

- Chen, J.; Guo, W.; Yin, L.; Lu, C.; Chang, X.; Zhang, S.; Zhang, C. Experimental study of floor cracking under deep mining. Chin. J. Rock Mech. Eng. 2016, 35, 2298–2306. [Google Scholar]

- Ma, D.; Duan, H.; Zhang, J.; Feng, X.; Huang, Y. Experimental investigation of creep-erosion coupling mechanical properties of water inrush hazards in fault fracture rock masses. Chin. J. Rock Mech. Eng. 2021, 40, 1751–1763. [Google Scholar]

- Liu, W.; Mu, D.; Yang, L.; Li, L.; Shi, C. Calculation method and main factor sensitivity analysis of inclined coal floor damage depth. J. Chin. Coal Soc. 2017, 42, 849–859. [Google Scholar]

- Lu, Y.; Wang, L. Numerical simulation of mining-induced fracture evolution and water flow in coal seam floor above a confined aquifer. Comput. Geotech. 2015, 67, 157–171. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Li, S.; Liu, R.; Zheng, Z.; Bai, J. The seepage-flowing conversion mechanism of the fault lagging water inrush and its numerical simulation. J. Min. Saf. Eng. 2017, 34, 323–329. [Google Scholar]

- Zhu, G.; Wang, S.; Zhang, W. Research on risk assessment of water inrush caused by fault activation based on unascertained mathematics theory. Geotech. Geol. Eng. 2019, 37, 4381–4389. [Google Scholar] [CrossRef]

- Yuan, F.; Ma, K.; Zhuang, D.; Wang, Z.; Sun, X. Preparation mechanism of water inrush channels in bottom floor of Dongjiahe Coal Mine based on microseismic monitoring. J. Chin. Coal Soc. 2019, 44, 1846–1856. [Google Scholar]

- Shi, L.; Zhang, R.; Xu, D.; Li, Y.; Qiu, M.; Gao, W. Prediction of water inrush from floor based on GWO-Elman neural network. J. Chin. Coal Soc. 2020, 45, 2455–2463. [Google Scholar]

- Song, Z.; Hao, J.; Tang, J.; Shi, Y. Study on water inrush from faults prevention and control theory. J. Chin. Coal Soc. 2013, 38, 1511–1515. [Google Scholar]

- Hua, Z.; Zhang, Y.; Meng, S.; Wang, L.; Wang, X.; Lv, Y.; Li, J.; Ren, S.; Bao, H.; Zhang, Z.; et al. Response Characteristics and Water Inflow Prediction of Complex Groundwater Systems under High-Intensity Coal Seam Mining Conditions. Water 2023, 15, 3376. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, Y.; Hu, R.; Yang, Z. Groundwater flow through fractured rocks and seepage control in geotechnical engineering: Theories and practices. J. Rock Mech. Geotech. 2023, 15, 1–36. [Google Scholar] [CrossRef]

- Li, X.; Dong, D.; Liu, K.; Zhao, Y.; Li, M. Identification of Mine Mixed Water Inrush Source Based on Genetic Algorithm and XGBoost Algorithm: A Case Study of Huangyuchuan Mine. Water 2022, 14, 2150. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, J.; Guo, S.; Cao, J. Research on the underground water inrush mechanism based on the influence of fault. Geotech. Geol. Eng. 2022, 40, 3531–3550. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, S.; Zhang, W. Fluid–solid coupling materials to similar simulation test on water inrush in geotechnical and mining engineering. Geotech. Geol. Eng. 2022, 40, 5755–5768. [Google Scholar] [CrossRef]

- Wang, M.; Cai, M. Modeling of time-dependent deformation of jointed rock mass. Rock Mech. Rock Eng. 2022, 55, 2049–2070. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, J.; Liu, W.; Wei, D. The evolution and prevention of water inrush due to fault activation at working face No. II 632 in the Hengyuan Coal Mine. Mine Water Environ. 2019, 38, 93–103. [Google Scholar] [CrossRef]

- Yin, H.; Xu, G.; Zhang, Y.; Zhai, P.; Li, X.; Guo, Q.; Wei, Z. Risk Assessment of Water Inrush of a Coal Seam Floor Based on the Combined Empowerment Method. Water 2022, 14, 1607. [Google Scholar] [CrossRef]

- Tounsi, H.; Pouya, A.; Rohmer, J. Coupled hydro-chemo-mechanical model for fault activation under reactive fluid injection. Eur. J. Environ. Civ. Eng. 2023, 27, 2836–2849. [Google Scholar] [CrossRef]

- Zhang, D.; Duan, Y.; Du, W.; Chai, J.; Feng, G. Experimental study on physical similar model of fault activation law based on distributed optical fiber monitoring. Shock Vib. 2021, 2021, 4846977. [Google Scholar] [CrossRef]

- Cheng, G.; Li, L.; Zhu, W.; Yang, T.; Tang, C.; Zheng, Y.; Wang, Y. Microseismic investigation of mining-induced brittle fault activation in a Chinese coal mine. Int. J. Rock Mech. Min. 2019, 123, 104096. [Google Scholar] [CrossRef]

- Rutqvist, J.; Graupner, B.; Guglielmi, Y.; Kim, T.; Maßmann, J.; Nguyen, T.S.; Park, J.-W.; Shiu, W.; Urpi, L.; Yoon, J.S.; et al. An international model comparison study of controlled fault activation experiments in argillaceous claystone at the Mont Terri Laboratory. Int. J. Rock Mech. Min. 2020, 136, 104505. [Google Scholar] [CrossRef]

- Yin, H.; Sang, S.; Xie, D.; Zhao, H.; Li, S.; Li, H.; Zhuang, X. A numerical simulation technique to study fault activation characteristics during mining between fault bundles. Environ. Earth Sci. 2019, 78, 1903. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, G.; Wang, S.; Zhang, W.; Li, B. Research on the Mechanism and Evolution Law of Delayed Water Inrush Caused by Fault Activation with Mining. Water 2023, 15, 4209. https://doi.org/10.3390/w15244209

Zhu G, Wang S, Zhang W, Li B. Research on the Mechanism and Evolution Law of Delayed Water Inrush Caused by Fault Activation with Mining. Water. 2023; 15(24):4209. https://doi.org/10.3390/w15244209

Chicago/Turabian StyleZhu, Guangli, Shuli Wang, Wenquan Zhang, and Baoyu Li. 2023. "Research on the Mechanism and Evolution Law of Delayed Water Inrush Caused by Fault Activation with Mining" Water 15, no. 24: 4209. https://doi.org/10.3390/w15244209

APA StyleZhu, G., Wang, S., Zhang, W., & Li, B. (2023). Research on the Mechanism and Evolution Law of Delayed Water Inrush Caused by Fault Activation with Mining. Water, 15(24), 4209. https://doi.org/10.3390/w15244209