1. Introduction

Because the impeller of a vortex pump is arranged on one side of the pump cavity, its working principle is different from that of general centrifugal pumps and it mainly relies on the interaction of the tinternal circulation flow and through flow to achieve the purpose of conveying media. Due to the semi-open impeller structure and the existence of a bladed area, the anti-clogging performance of vortex pumps is better than that of general pumps. However, the efficiency of vortex pumps is usually less than 50%, which is lower than that of traditional centrifugal pumps [

1,

2,

3]. This is because the current state research on the movement of solid particles in pumps is still immature, especially for two-phase flow pumps such as vortex pumps which still use the hydraulic design method based on the clean water pump. The characteristics of the two-phase flow in the pump under different working conditions are not clear, which leads to a slightly lower efficiency when conveying complex media, and the overflow components are not optimized for particle movement, resulting in typical wear and blockage problems [

4,

5].

According to the Lagrange and Euler methods, two fluid model (TFM) and discrete particle method (DPM) are two widely used solid-liquid two-phase methods. In TFM, the mixture model is used to calculate the two-phase flow in the pump. In TFM, the mixture model is used to calculate the two-phase flow in the pump. Peng et al. [

6] used the particle model to study the wear of a slurry pump under the condition of biased design. The results showed that under the condition of small flow, the interface between the sheath and the rotor near the tongue had serious local wear. Zhou et al. [

7] analyzed the performances of pumps. The results show that the existence of end clearance reduces the flow rate, which leads to the aggravation of flow separation in the diffuser channel and further reduces the performance of electric submersible pumps. Zhao et al. [

8] simulated the double channel pump by using the mixture multiphase flow model and compared it with the single-phase flow test of clean water. The results show that the method can be used to predict the external characteristics of the double channel pump. Meanwhile, Zhang et al. [

9] studied the sediment wear characteristics of a centrifugal pump by an Eulerian algorithm and analyzed the effects of turbulence intensity and particle dynamic scale on the distribution of the solid phase. The results show that considering the turbulence effect is more in line with the actual wear situation of centrifugal pump. Huang and Zhao et al. [

10,

11] used the DPM model and semi empirical wear model to calculate the wear phenomenon in centrifugal pump. The DPM model was applied by Shen et al. [

12] to simulate a spiral centrifugal pump. The results showed that the motion track of low-density fine particles is longer, the number of collisions with the flow passage parts is more and the energy loss is more.

Due to the difficulty and high cost of two-phase flow tests in actual pumps, numerical simulation is widely used at this stage. TFM assumes that the particles occupy the space of a pseudo fluid and a real fluid, which penetrate each other and generate an interphase force. Although the calculation speed is fast and the particle size cannot be limited, the key information of pseudo fluid particles is lost and it is difficult to approach the real physical phenomenon [

13]. The DPM model assumes that particles are particles moving in the fluid, and the particles do not occupy the volume, so it does not consider the collisions between particles, so it is only suitable to simulate dilute phase flow, and it is difficult to accurately reflect the particle movement in the pump. Through the coupling of DEM and CFD, using the discrete element solver to calculate the particles, we can track the force and movement track of each discrete particle in the system, fully consider the various forces and the collision between particles, between particles and the wall, which can more intuitively analyze the flow law of particles in the pump, closer to the real physical phenomenon [

14,

15]. Blais et al. [

16,

17,

18] carried out theoretical research and practical engineering analysis on DEM-CFD coupling, and made some achievements in the application of agitators, analyzed the influence of particle properties on mixing dynamics, and proved the reliability of this method in the simulation of rotating machinery through experiments. Li et al. [

19] calculated the solid-liquid two-phase flow in the deep-sea mining pump by DEM-CFD coupling. The results show that when the rotating speed increases, the solid movement in the pump is more regular and the collision is reduced, which helps to reduce the blockage between the impeller and the guide vane.

In this paper, the flow of spherical particles in the internal flow field of the vortex pump is studied based on the DEM-CFD simulation method. In order to obtain the flow track characteristics of particles in the pump, and the influence of particle sizes and concentration on the pump performance, different particle sizes and volume fractions were selected to simulate the flow characteristics in the pump, and the vortex structure and flow separation of the flow field in the pump were analyzed.

4. Results and Discussion

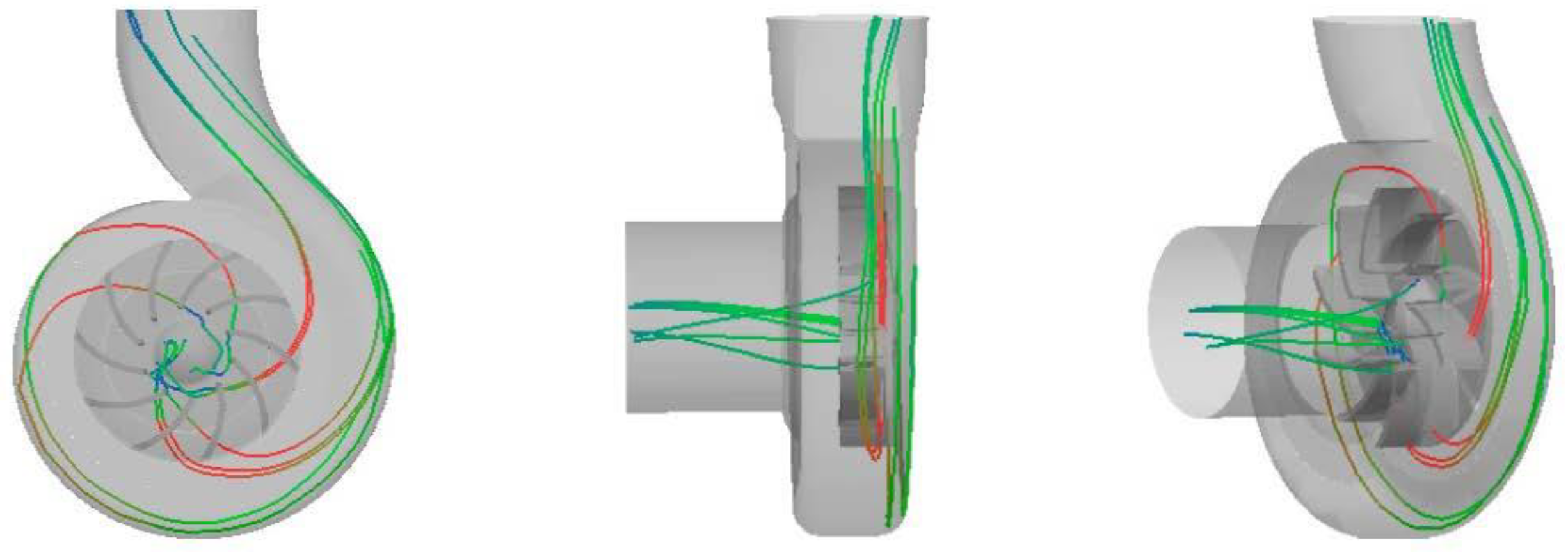

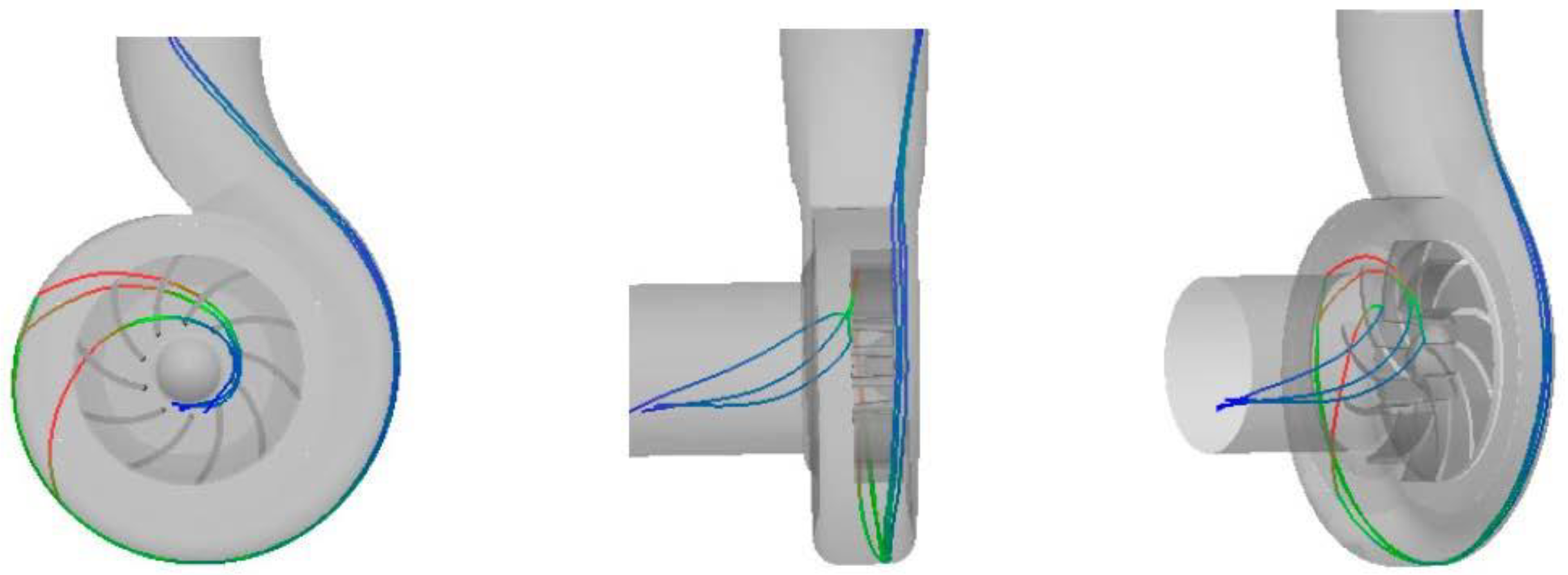

4.1. Particle Track

Particles with diameters of 1, 2 and 3 mm and concentrations of 1% and 5% were tracked. In the particle movement, it can be clearly observed that there are three typical movement tracks of solid particles in the vortex pump, as shown in

Figure 5,

Figure 6 and

Figure 7. In the figures, the three particle movement tracks are shown for the condition of 2 mm particle size and 5% concentration.

Track A is the movement process of particles pumped out of the vortex pump by the action of through flow. The particle flow characteristics are that the particles enter the lateral cavity from the center of the inlet, which is less affected by the internal circulation flow of the pump chamber and the particle movements are dominated by axial velocity. Therefore, the particles pass through the lateral cavity directly into the impeller and particles enter the volute through the rotation of the impeller and the particles movements near the back of the volute.

The motion of track B is mainly affected by the circulating flow of the cavity. The characteristic of the track movements are that the particles are greatly affected by the rotating reflow in the inlet. The particles have both of circumferential velocity and axial velocity, but the particle movements are dominated by the circumferential velocity. Therefore, the particles do not enter the impeller directly, but rather enter the volute with the vortex flow caused by the impeller.

Track C is affected by both of the circulation flow and the through flow. The characteristics of the particle track are that particles pass through lateral cavity, then enter the impeller from the impeller front cover inlet area, because there is a lateral cavity in the vortex pump, the particles do not enter the volute directly through the impeller, but re-enter the lateral cavity under the influence of the circulation flow.

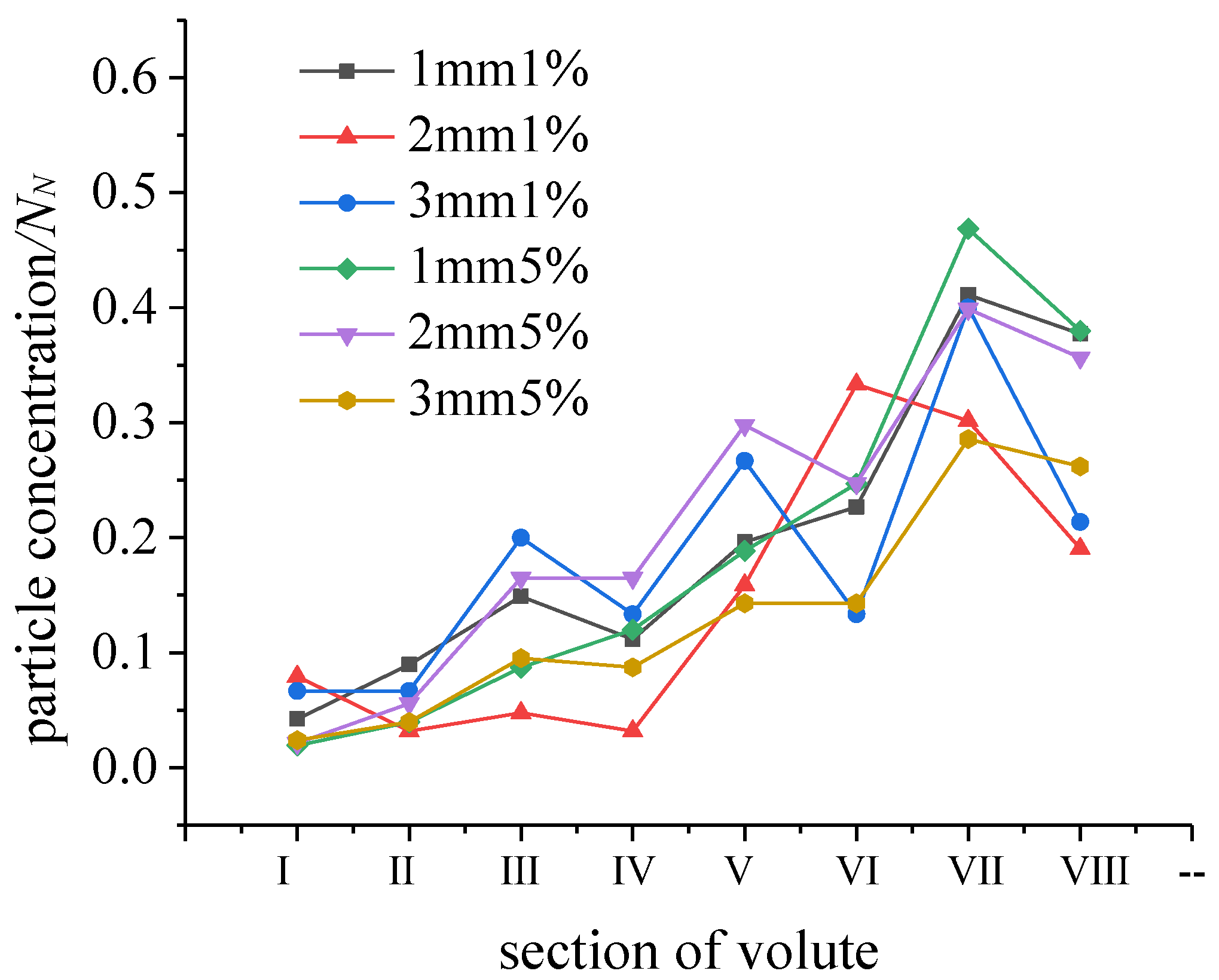

4.2. Particle Distribution in Volute with Different Particle Size and Concentration

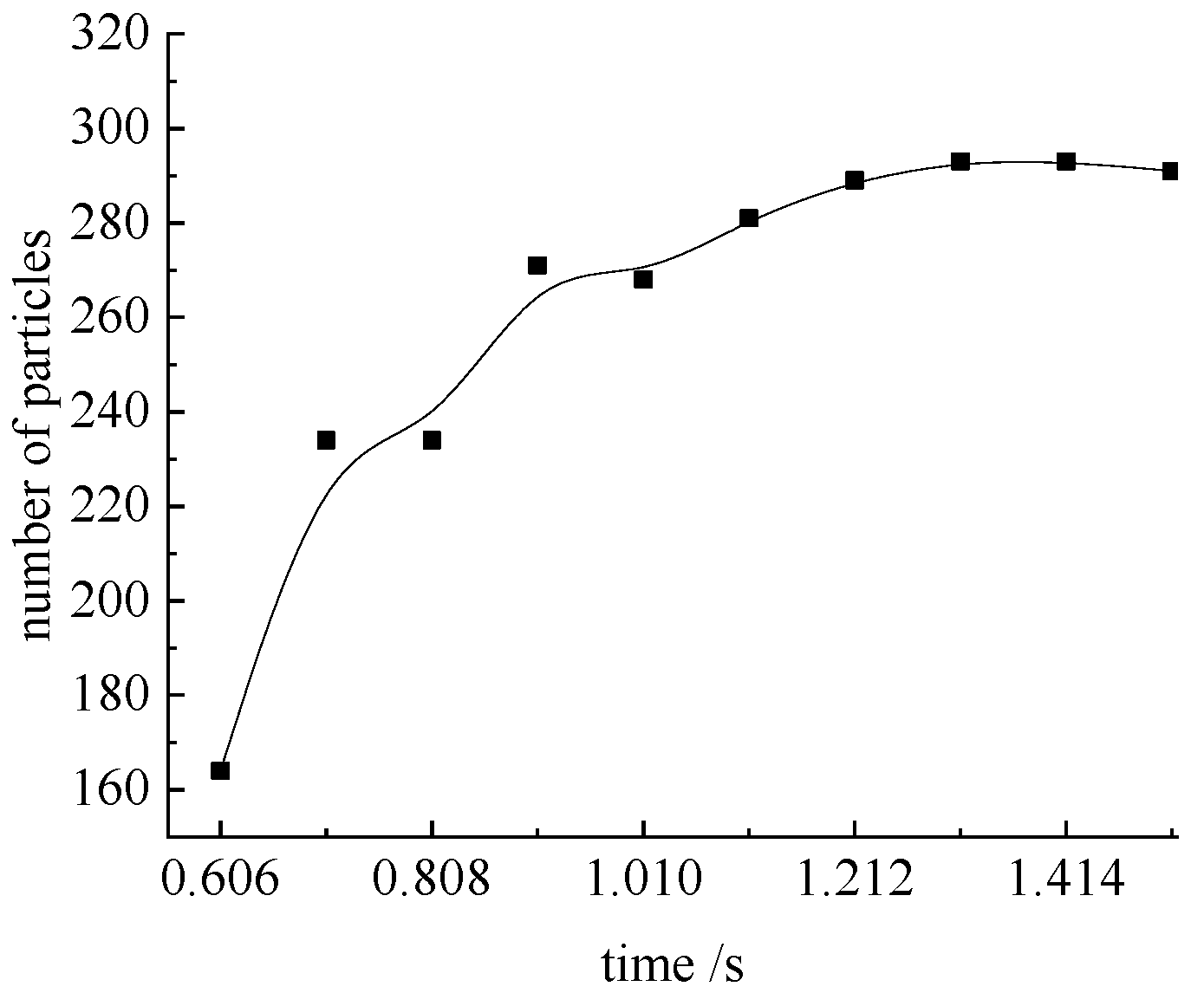

For different particle size and concentration conditions, the number of particles in the section was extracted, and the dimensionless number of absolute particle concentrations

NN is defined to represent the particle concentration in this region:

Among them,

Nx is the number of particles in the area to be tested, and

N1 is the number of particles in Section 1. The specific results are shown in

Figure 8, which are the distribution of absolute concentration of particles in 1, 2 and 3 mm under six working conditions of 1% and 5%, and all are the rated flow.

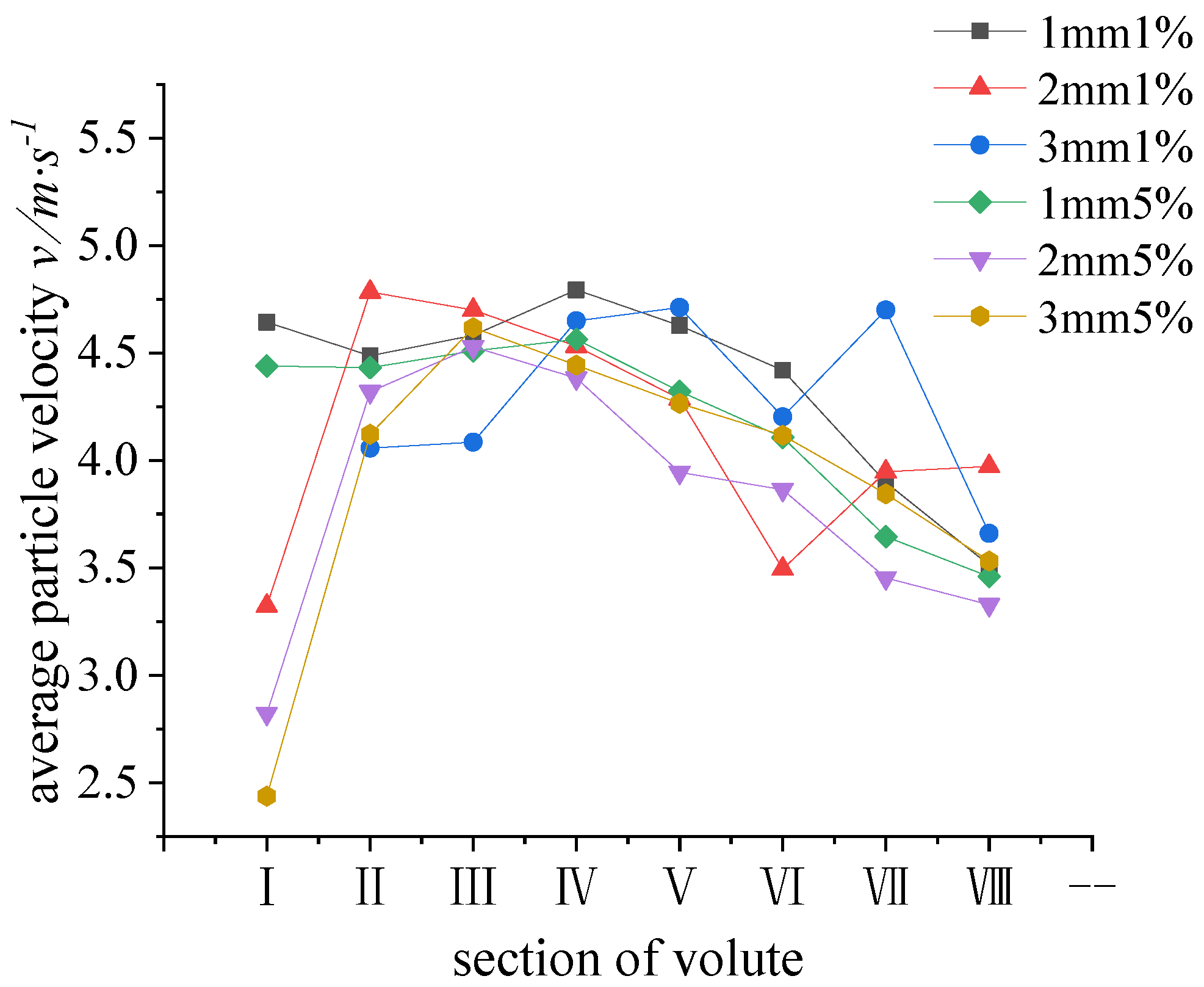

Figure 9 shows the average velocity distribution of particles in each volute section region. In the

Figure 8 and

Figure 9, “1 mm.1%” means the condition of particle size of 1 mm and concentration of 1%, and so on.

From

Figure 8, it can be seen that with the increase of section area of volute I to VIII, the trend of particle number in each section area is basically the same, and the particle distribution fluctuates most violently under the condition of 3 mm particle size, which indicates that with the increase of particle size, particles in the volute no longer move along the volute chamber, becoming more disordered.

The number of particles in Section V increases sharply, and the number of particles in Section VI also fluctuates. This phenomena are caused by track B mentioned above, which basically enters the volute at Section V, which directly leads to an increase of the particle number. The particles pumped through the lateral cavity, i.e., track B, have a large kinetic energy. There is a phenomenon that the particles are far away from the area after collision at Section V at the same time, the influence of the weight of the particles and the increase of the number of particles cause a slow- down of the flow velocity of the particles in the area. It can be seen from

Figure 9 that the particle velocity at Sections V and VI of the volute obviously declines compared with the previous section area. The results show that the increase of the number of particles in Section V results in the movement of more particles along track B, while the increase of the number of particles is no longer obvious under the condition of 3 mm particle size, indicating that the large particles are less affected by the swirl in the inlet. In the area of Section VI, the particle concentration decreases more under the condition of 2 mm, which is caused by the effect of gravity and the increase of particles number. As the particle number of 3 mm is less, the impact of accumulation is not significant, while the particle number of 1 mm is less at the Section VI due to its small weight and good follow-up.

Section VII is close to the outlet of volute and has the largest section area, so the number of particles in this area is the largest under all working conditions. However, the number of particles in Section VIII is reduced to some extent, which results from some particles entering into the volute chamber in the middle section area or losing part of their energy due to collisions and they do not have enough kinetic energy to enter the outlet section, so they are blocked by the tongue and enter the cochlear chamber circulation. It can be clearly seen that the particle number decreases most obviously under the condition of 3 mm, which indicates that 3 mm particles are more easily blocked by the tongue and re-enter the volute, but this does not mean that 3 mm particles have poor traffic ability in the volute. On the contrary, after the volute is recycled, 3 mm particles can achieve greater speed.

4.3. Analysis on the Transportability of Vortex Pumps with Different Particle Size and Concentration

According to the same method of Section 2 in the previous section, it can be seen that the retention amount of particles in the volute of the vortex pump under different working conditions can provide a reference for the evaluation of the whole pump delivery performance. The details are shown in

Table 6.

It can be seen from the

Table 5 that when the vortex pump works under the condition of 3 mm particle size and 1% concentration, it can send solid particles out of the volute very well, while under the condition of 2 mm.1%, some particles stay in the volute, which is mainly because the number of particles increases under this condition and the particle size is greater than 1 mm under the influence of gravity, and most particles lose kinetic energy through mutual extrusion and collision, resulting in insufficient velocity, the particles re-entry into the chamber by volute tongue obstructs, which results in the low concentration of Section 2 particles, and the phenomenon improves when the concentration increases. In general, the above table shows that solid particles have a good pumping performance and can be pumped out of the volute in time with pumping small particles. This is mainly due to the good follow-up of small particles, which is mainly affected by the force of the flow field. When the concentration increases, the collision probability between particles increases, and the particles in the pump become more disorderly which will reduce the delivery performance of the pump. It can be seen that the particles with a diameter of 3 mm have been great impacted.

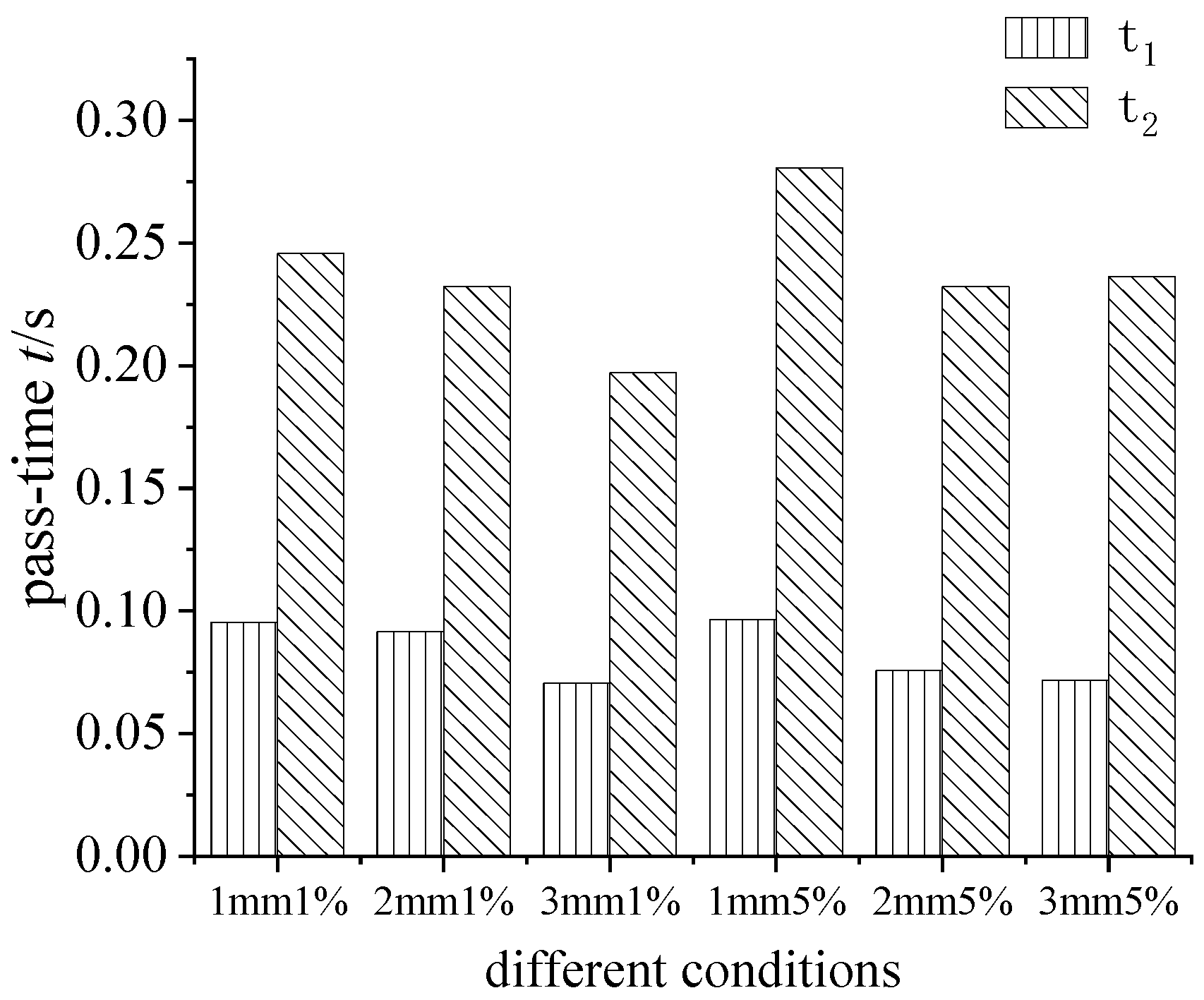

4.4. Analysis of Particle Passing Time under Different Particle Size and Concentration

Under all working conditions, we take the particles in Section 1 as an example and count the time taken for particles to move to Section II, that is, the time taken for particles to pass through the volute, where T1 represents the time for the first particles to reach Section II, and T2 represents the time for all selected samples to pass Section II, as shown in

Figure 10.

It can be seen from the

Figure 10 that under various working conditions, the time for the first particle to pass through the volute is not much different, and the time for large particles is relatively less; however, the total passing time is more related to the number of particles, for example, the time for 1 mm.5% working condition is the longest, and the time for 3 mm.1% working condition is the shortest, and the relationship with particle size is not significant.

4.5. Analysis of Flow Pattern in Volute

In this paper, three kinds of different particle sizes and two kinds of particle volume fractions are involved in six simulation examples. A typical case of large particles, i.e., the case of 2 mm particle size 5% concentration, is selected to analyze the velocity distribution on the volute section at 1.2121 s. The vortex core is determined by the regularize helicity [

24,

25]. According to the angle between the velocity vector and the vorticity, this method captures the position of the vortex core, which is defined as the modeling of the point product of the velocity and the vorticity. It is used to determine the rotation direction of the vortex core, and its value is between [–1, 1], as follows [

26]:

where

w is relative velocity,

Ω is absolute vorticity.

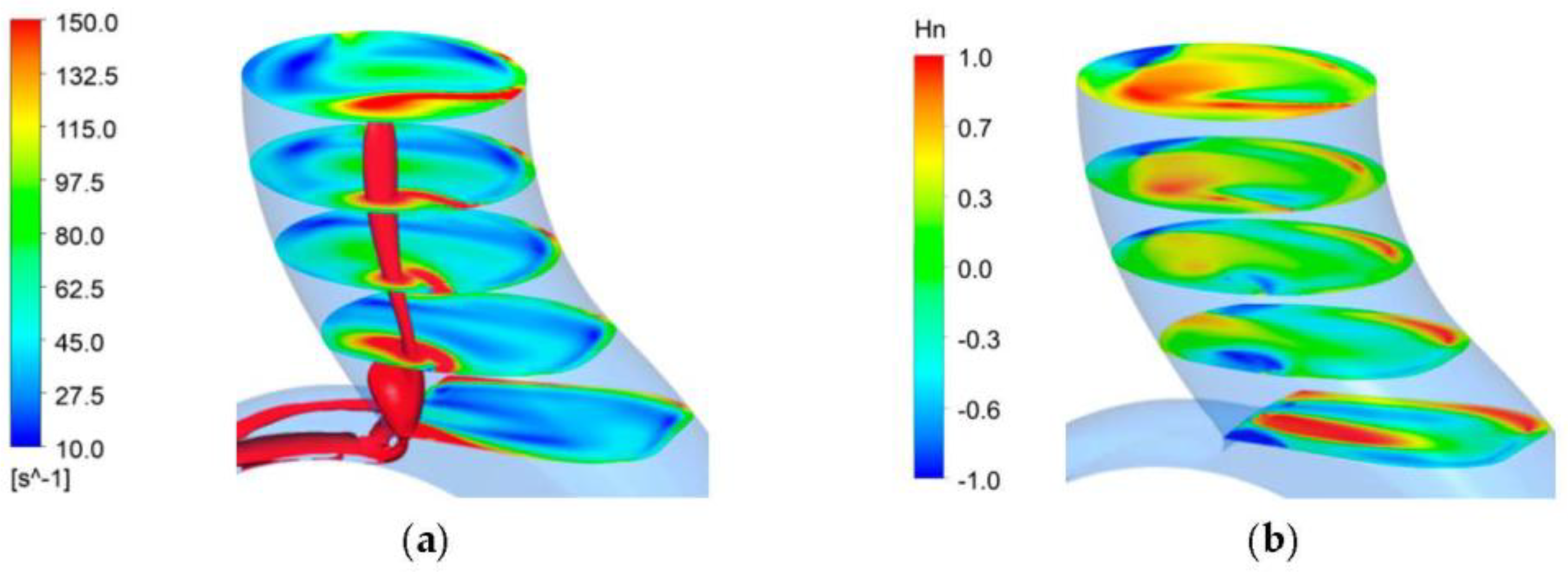

Figure 11 shows the normalized helicity distribution of the impeller section, with the flow direction as the positive direction.

Hn is negative value, and the vortex is rotating clockwise.

Hn is positive, the vortex rotates counterclockwise, From

Figure 12, it can be seen that there are a pair of whirlpools with opposite rotation direction near the outlet of the impeller passage, among which the whirlpool direction near the suction surface of the blade is consistent with the flow direction, and there are whirlpools with opposite flow direction in the middle of the passage. It can be seen from Figure 14b that the vortex structure opposite to the rotation direction of the impeller will be formed at the junction of the volute due to the weakening of the direct effect of the impeller in the bladed cavity.

Figure 13 shows the regularized helicity and streamline distribution of four sections of the volute. It can be seen from the streamline that the velocity distribution is obviously asymmetric. There are two opposite vortices on the four selected sections, among which the vortices near the front side of the volute exist in the lateral cavity and do not belong to the volute section, and the vortices near the back side of the volute are large and located in the volute chamber, which is different from the ordinary centrifugal pump, mainly due to the arrangement of the offset side of the impeller of the vortex pump. The vortices at the front side are mainly caused by cyclic flow. With the increase of the area of the volute section, the vortices in the cochlear chamber gradually move to the center of the cochlear chamber and occupy the main position.

Vortexes can be judged by the Q criterion, that is, the rotation of the fluid in the vortex area of the pump plays a decisive role, rather than the strain rate of the fluid.

Figure 13a,b show the evolution of vortex structure in the pump cavity. When Q = 54,288 s

−2, the vortex structure appears at the outlet of impeller and the tongue, and the complete vortex appears at the place without blade cavity near the inlet, which is a symmetrical distribution. When the value of Q increases to 5301 s

−2, there is a long vortex in the volute, because the fluid near the front side of the volute lacks the restriction of the impeller, which is only driven by the circulation flow. The fluid in the volute is easily blocked by the reverse pressure gradient at the tongue to separate the flow. The vortex formed is different from the rotation direction of the impeller. The reverse flow in the volute section at the front side of the volute goes through the tongue to mix with the incoming flow into the diffusion section, which shows that there are particles near the first and second sections of the volute which enter the diffusion section of the volute at the tongue, and the particles in the diffusion section will rise and flow out of the volute in a more obvious spiral shape.

Figure 14a shows the vortex structure of the diffusion segment of the volute with Q = 5301 s s

−2, and the section is made with an interval of 22 mm. Through the analysis of the vorticity dynamics, it is found that there is an area with larger vorticity intensity in the diffusion section of the volute, which is located near the front side of the volute. The model value of the vorticity in the whole diffusion section is stable without large fluctuation, and the position of the vortex center does not have large transfer, and it can be seen that the main vortex is a bunch of return vortices generated from the volute section. There is obvious tensile tearing deformation at the septum tongue. The distribution of vortex core extracted by regularization helicity (b) is rather disordered. It can be seen that there are two pairs of vortex with opposite direction on the cross section near the septum tongue, while there is only one forward rotating vortex and one reverse vortex core accumulation area on the exit section of volute. The reverse vortex core is at the edge of the cross section and there is no dominant medium flow in the diffusion section. It can be inferred that it is the return vortex and the main-stream. The interaction and the disturbance to the main flow also show that the vortex structure in the criterion has obvious deformation.

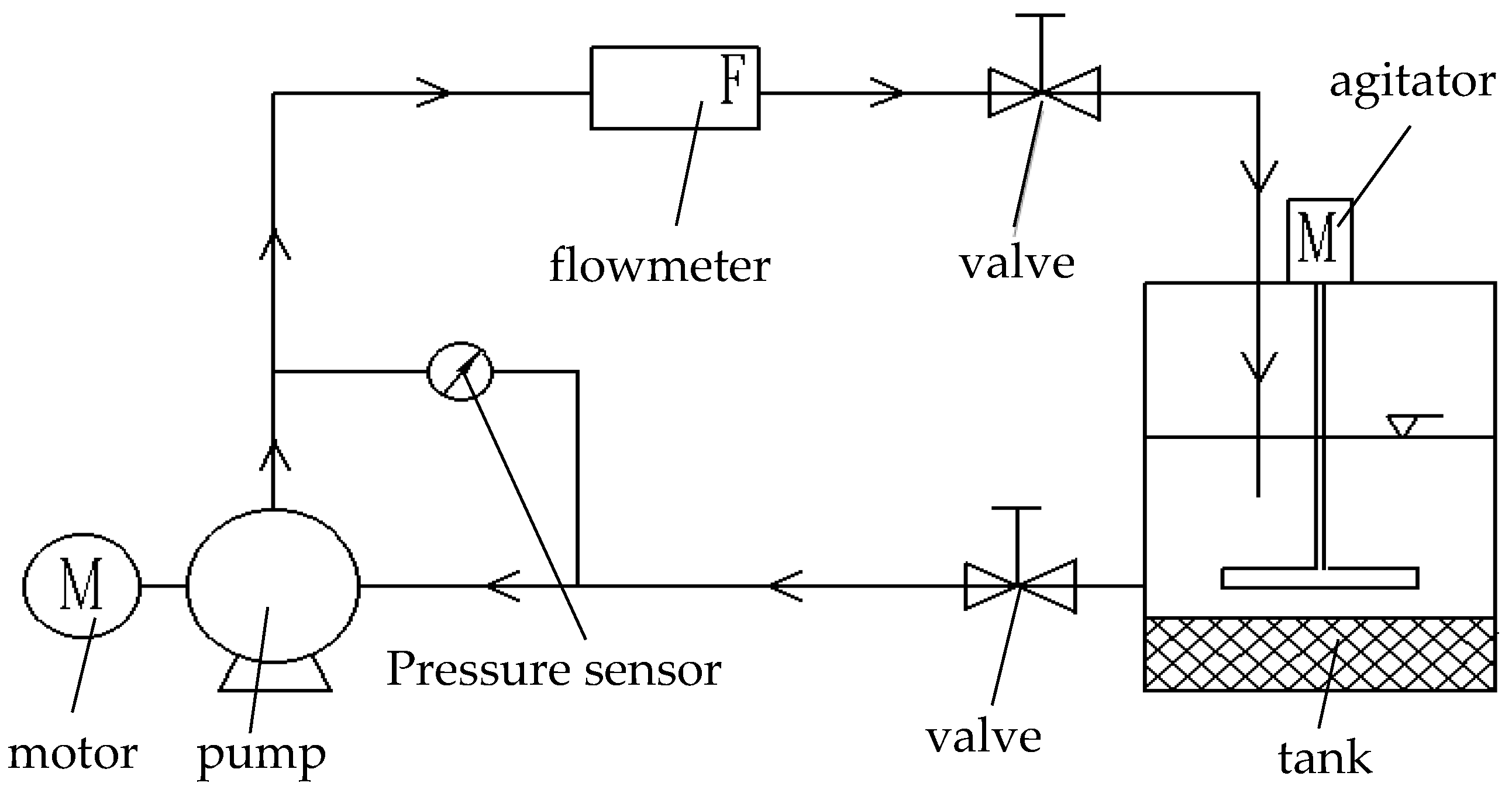

5. Test Verification

In order to verify the accuracy of the numerical calculation, a performance test of the model pump was carried out, where the particle flow characteristics of the pump inlet were captured by high-speed photography. The impeller, volute and inlet section were manufactured from polymethyl methacrylate, which has good light transmission and is convenient for high frequency camera shooting, as presented in

Figure 15. The design of the open test-bed, shown in

Figure 16, included a flow control device, data acquisition device, and data processing device, An agitator is installed in the tank to stir the particles so that they are evenly mixed in the water.

The pump outlet flow is measured by a LDBE-80S-M2X100-80 electromagnetic flowmeter (Wuxi Dihua Automation Equipment Co. Ltd., Wuxi, Jiangsu, China); the motor power is measured by 8962c1 three-phase electrical parameter measuring instrument; the range of inlet pressure transmitter is −100~100 kpa; the range of outlet pressure transmitter is 0~100 kpa; the sampling frequency of the I-SPEED 3 high-speed camera (iX Cameras Ltd., Locks Hill Rochford Essex, UK) is 1000 Hz. In the test, rapeseed was used for solid particles. The diameter is about 2 mm and a particle concentration of 5% was selected. During the experiments, the agitator starts at a constant speed, the flow rate and the pressure were measured by the electromagnetic flowmeter and the pressure sensor. Then, by adjusting the valve opening, the pressure at different flow rates was measured, and all signals were input to the computer software for calculation. In this process, the rotating reflux phenomenon of the inlet was also photographed by high-speed photographic instrument.

The experimental results are shown in

Figure 17. The numerical simulation was carried out at 4.7, 9.4, 14.1, 18.8, 23.5, 28.2, 32.9 and 37.6 m

3/h. It was obvious that the CFD results were in good agreement with the experimental results. The experimental results were relatively lower than the CFD results, but the error was less than 5% and they had the same change trend at different flow rates. Hence, the method of this study is credible. The reason for the decrease in test results was probably the neglect of mechanical losses in the calculations.

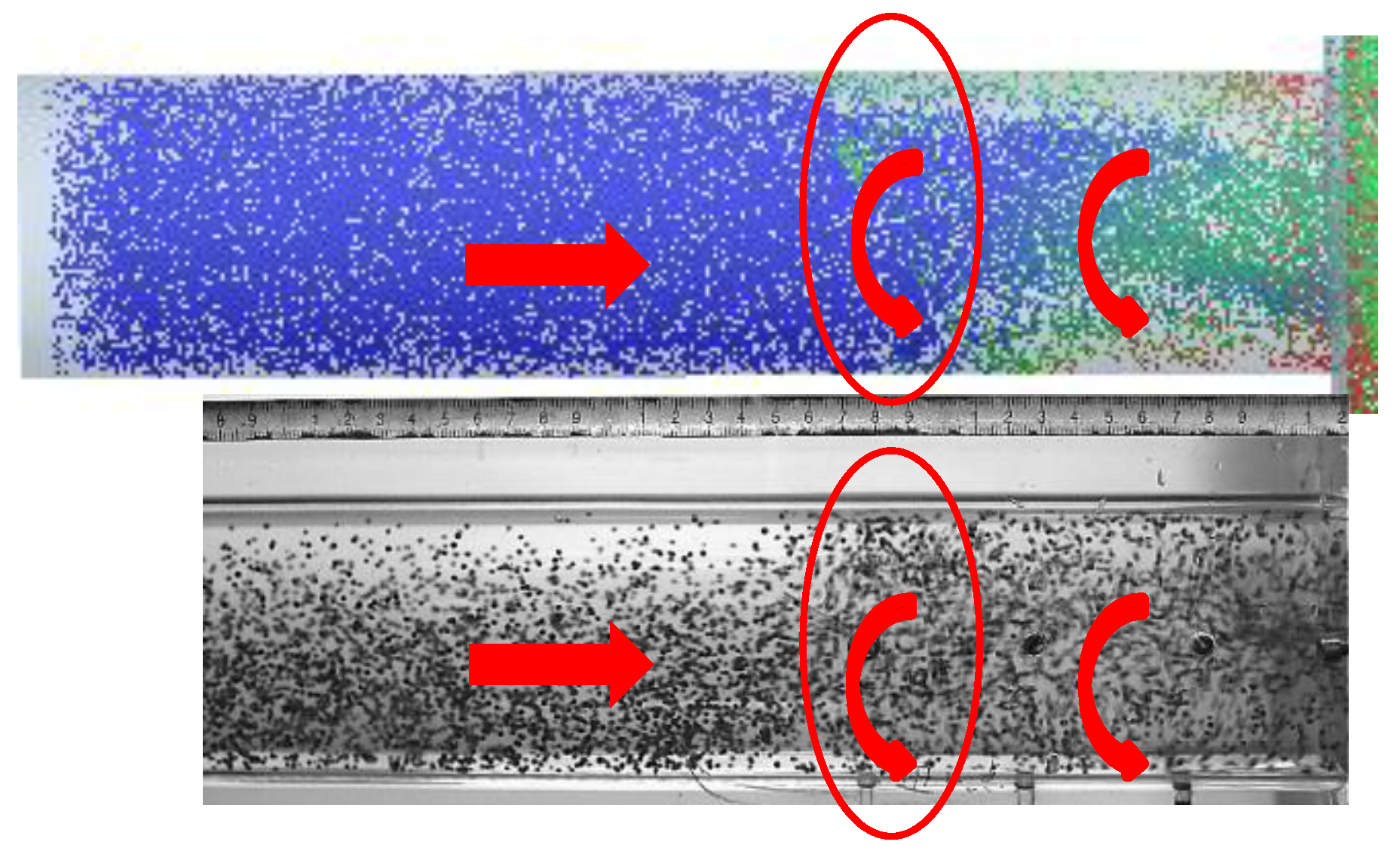

It can be seen from

Figure 18a that the high-speed photography instrument can catch that the two-phase flow rotating reflux from the lateral cavity into the inlet section, and the spiral reflux movement against the wall of the inlet, the direction of rotation is the same as that of the impeller. The rotating reflux is stopped by mixing with the inlet incoming flow at a certain point. The stop position of the rotating reflux depends on the flow rate, the stop position of the rotating reflux is close to the pump cavity at large flow condition, while away from the pump cavity at small flow condition.

Through the snapshot POD method, the swirl phenomenon in the inlet is decomposed. The rotating reflux phenomenon of pump inlet photographed by high-speed photography instrument is modal decomposed. The first-order spatial modal as shown in

Figure 18b, it can be intuitively seen that the energy of the first-order spatial modal is relatively high, and it presents a large scale reflux vortex structure. It can be seen from

Figure 19 that the numerical simulation results show that the stop position of the rotating reflux is consistent with the experimental results. Hence, the method of this study is credible.