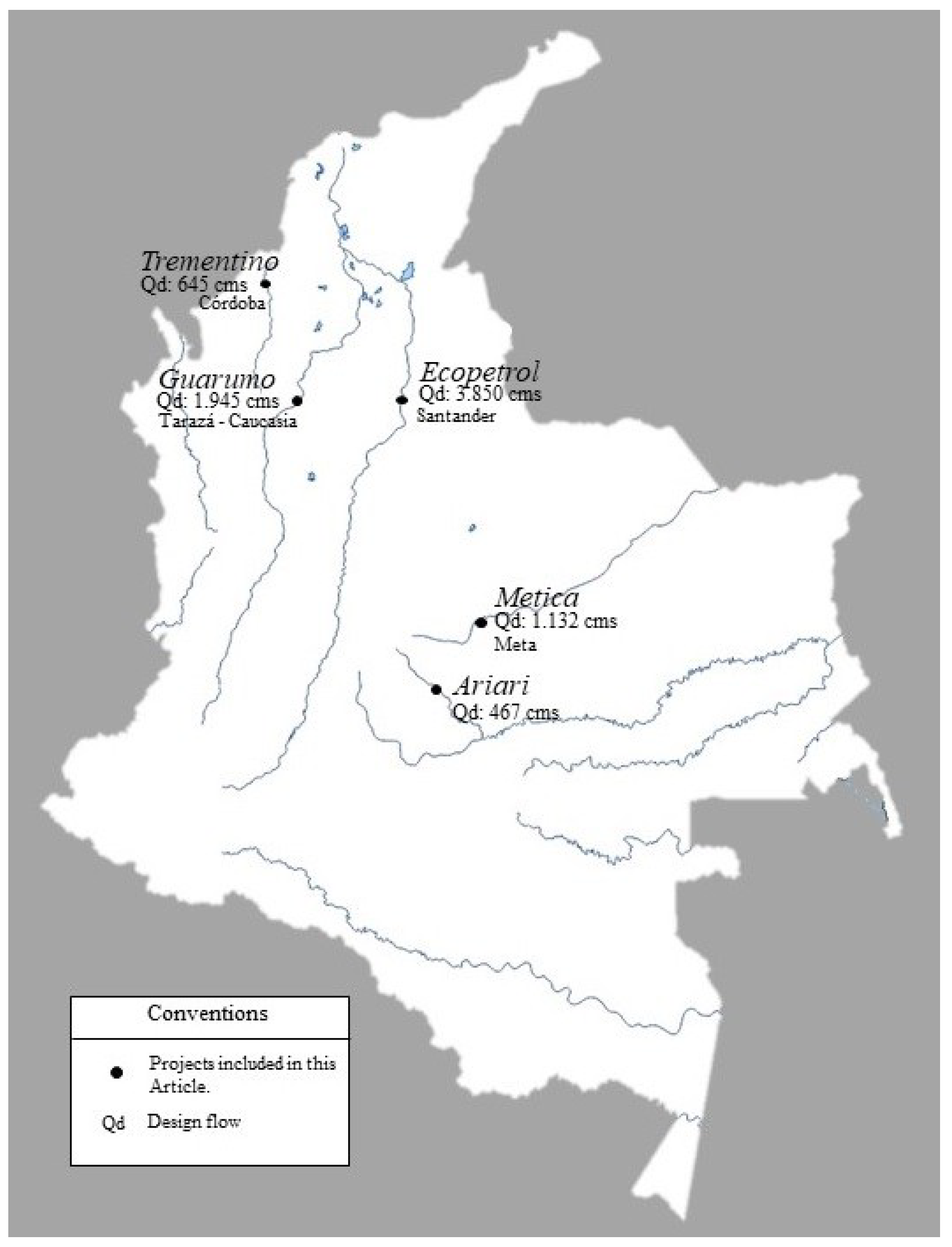

Submerged Vane Technology in Colombia: Five Representative Projects

Abstract

:1. Introduction

2. Technical Basis for the Use of Submerged Vanes

3. Applications of Submerged Vane Technology in Colombia

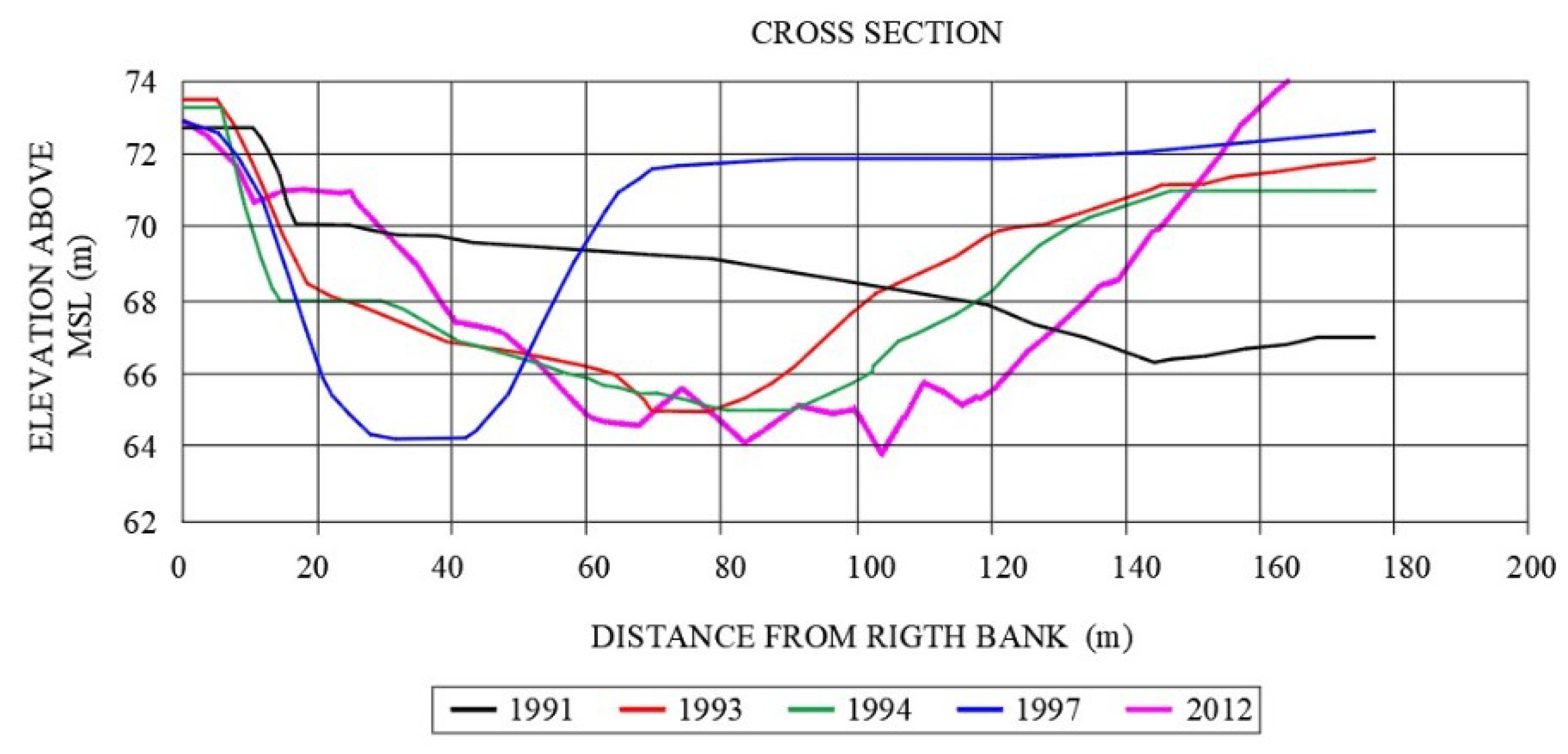

3.1. Magdalena River: ECOPETROL Aromatics Pier in Barrancabermeja (1991)

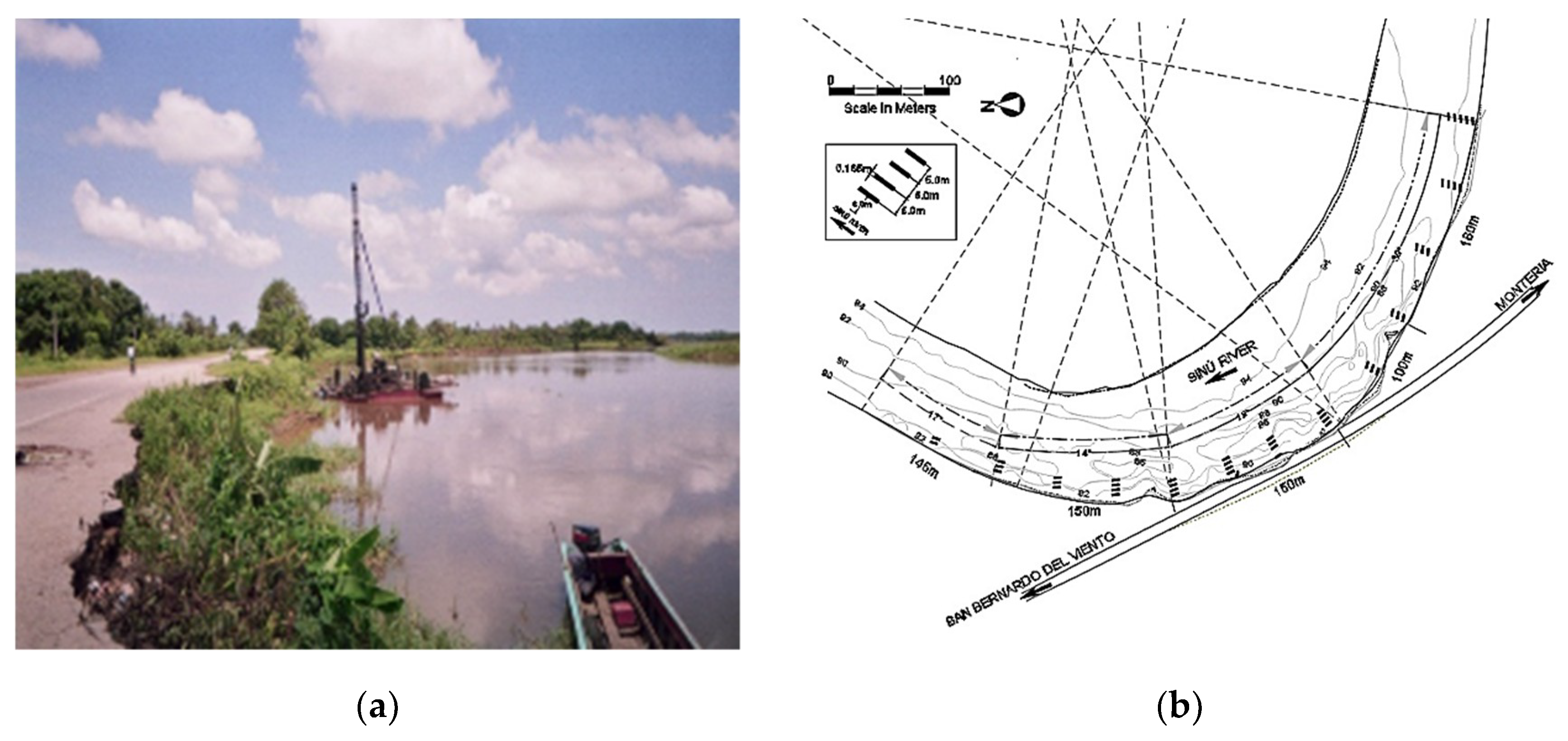

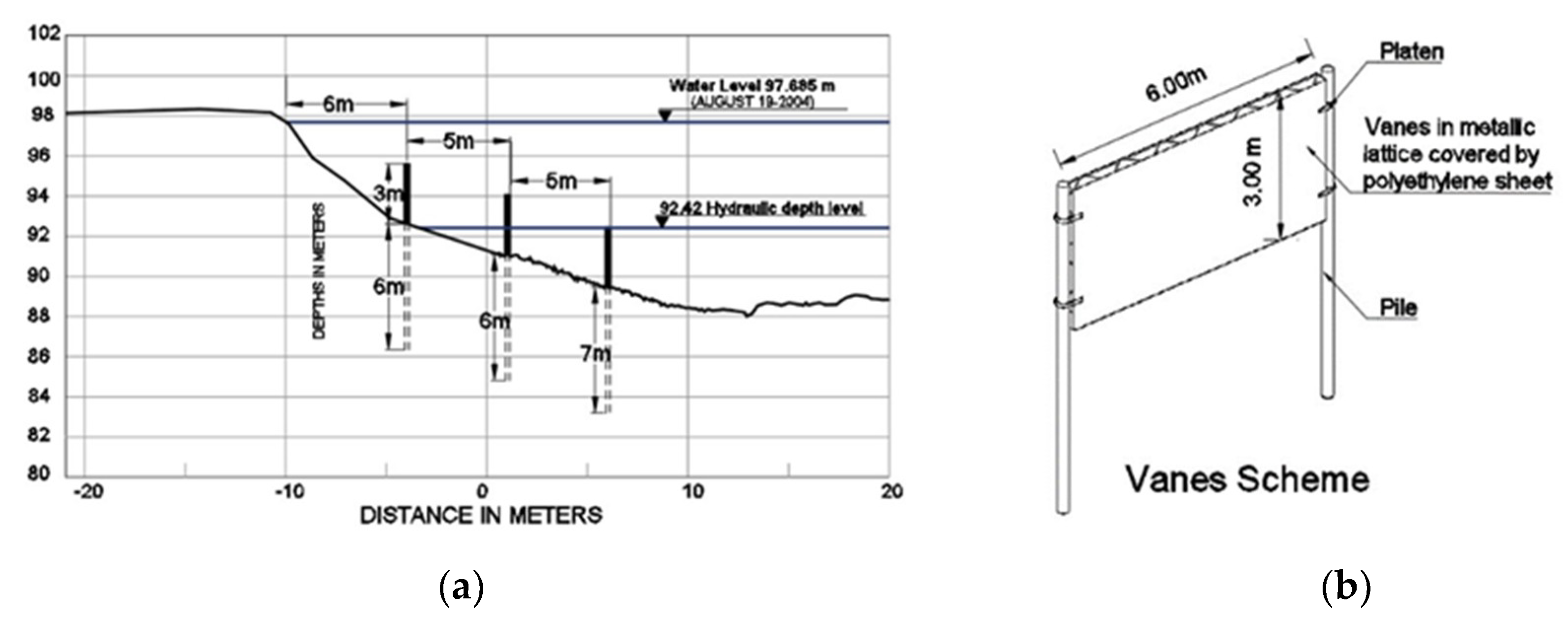

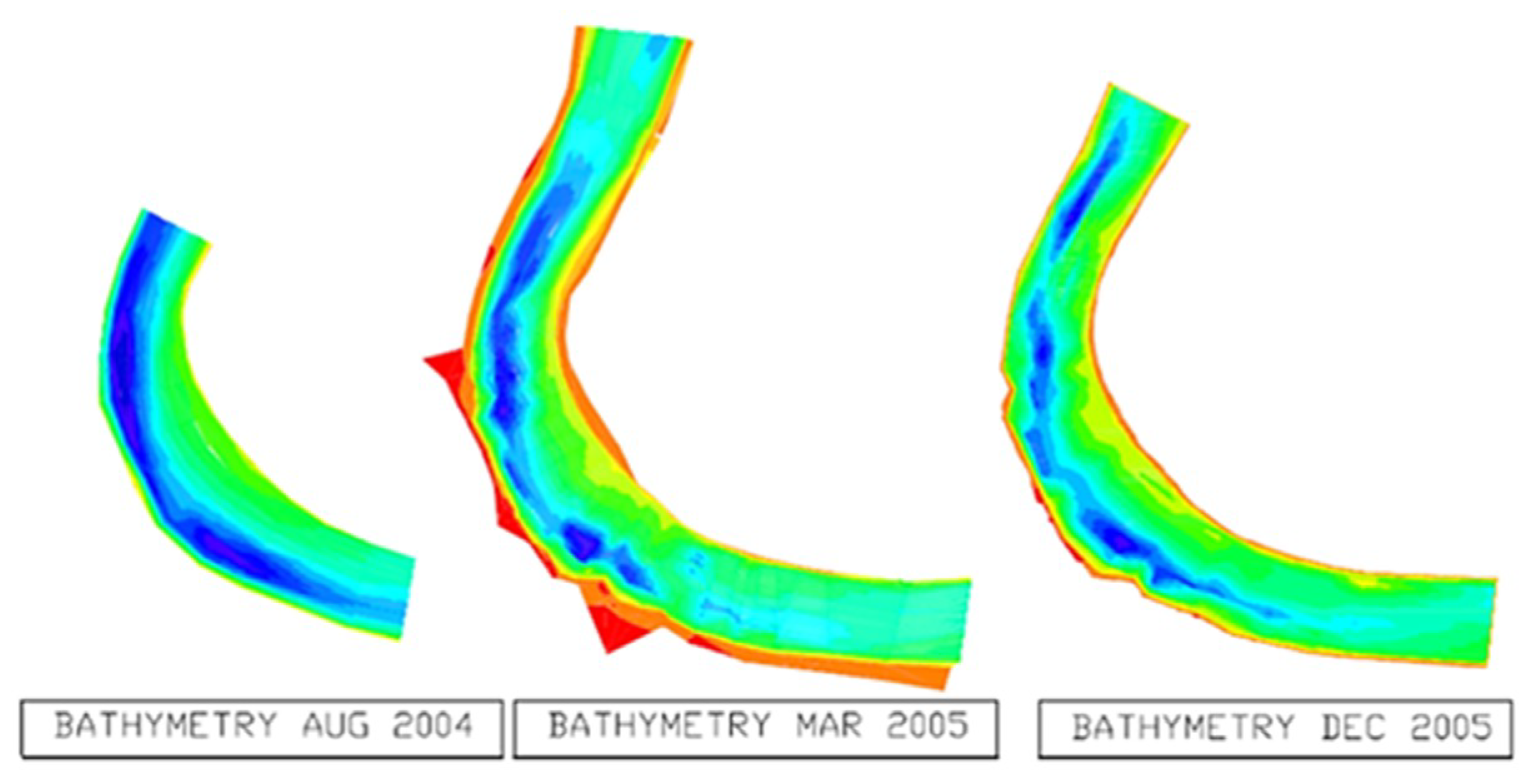

3.2. Sinú River, in Trementino (2004)

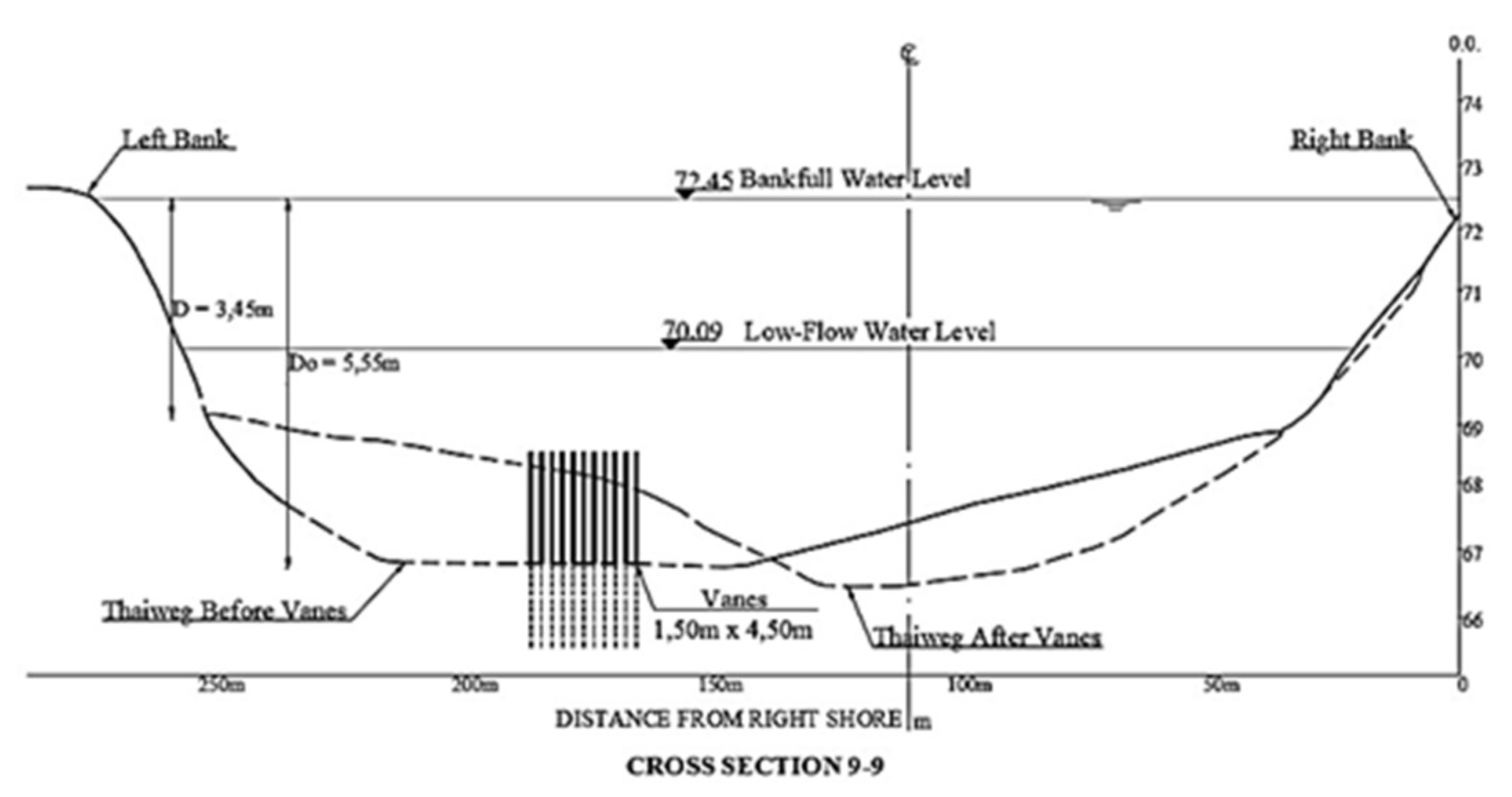

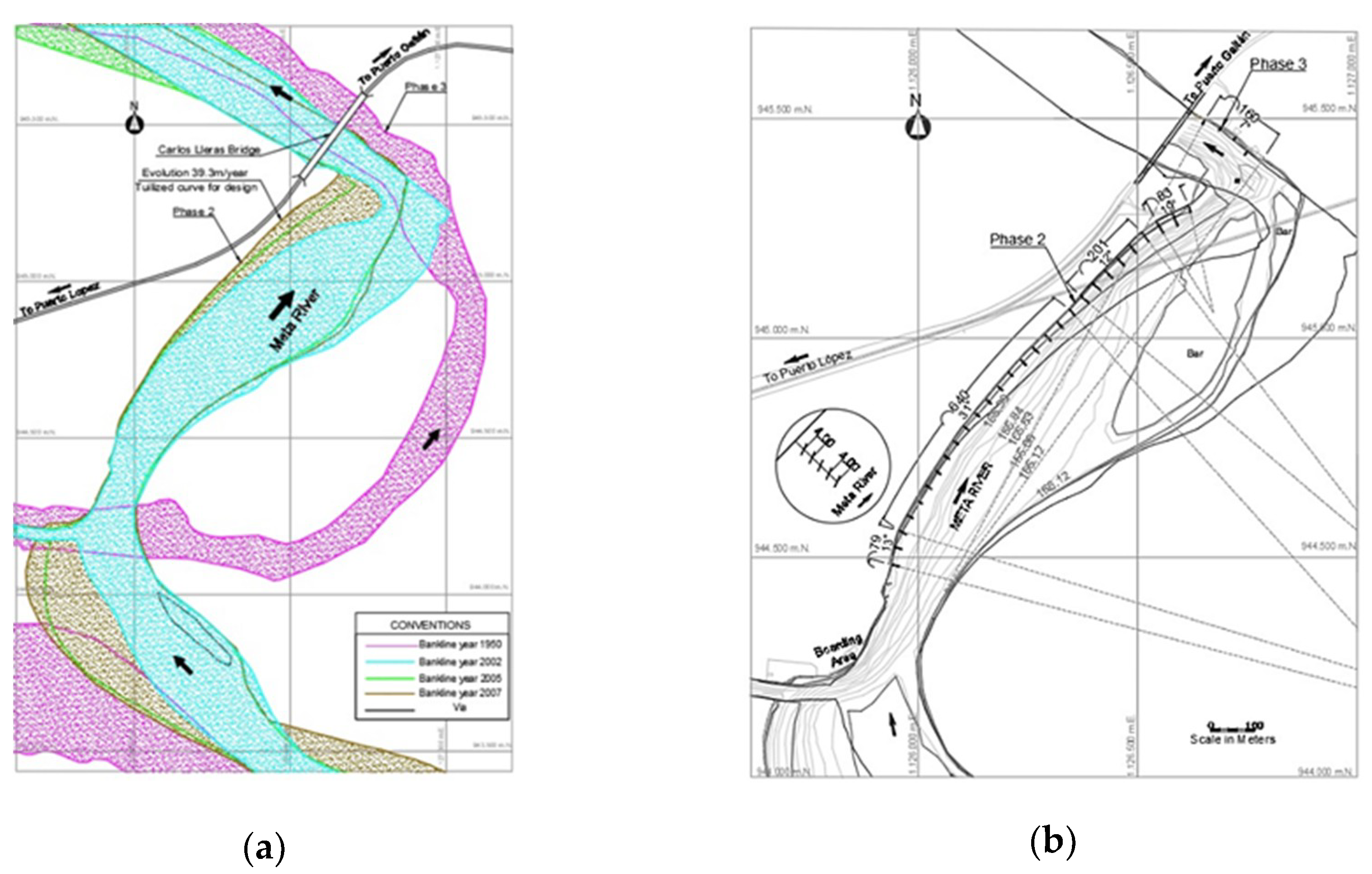

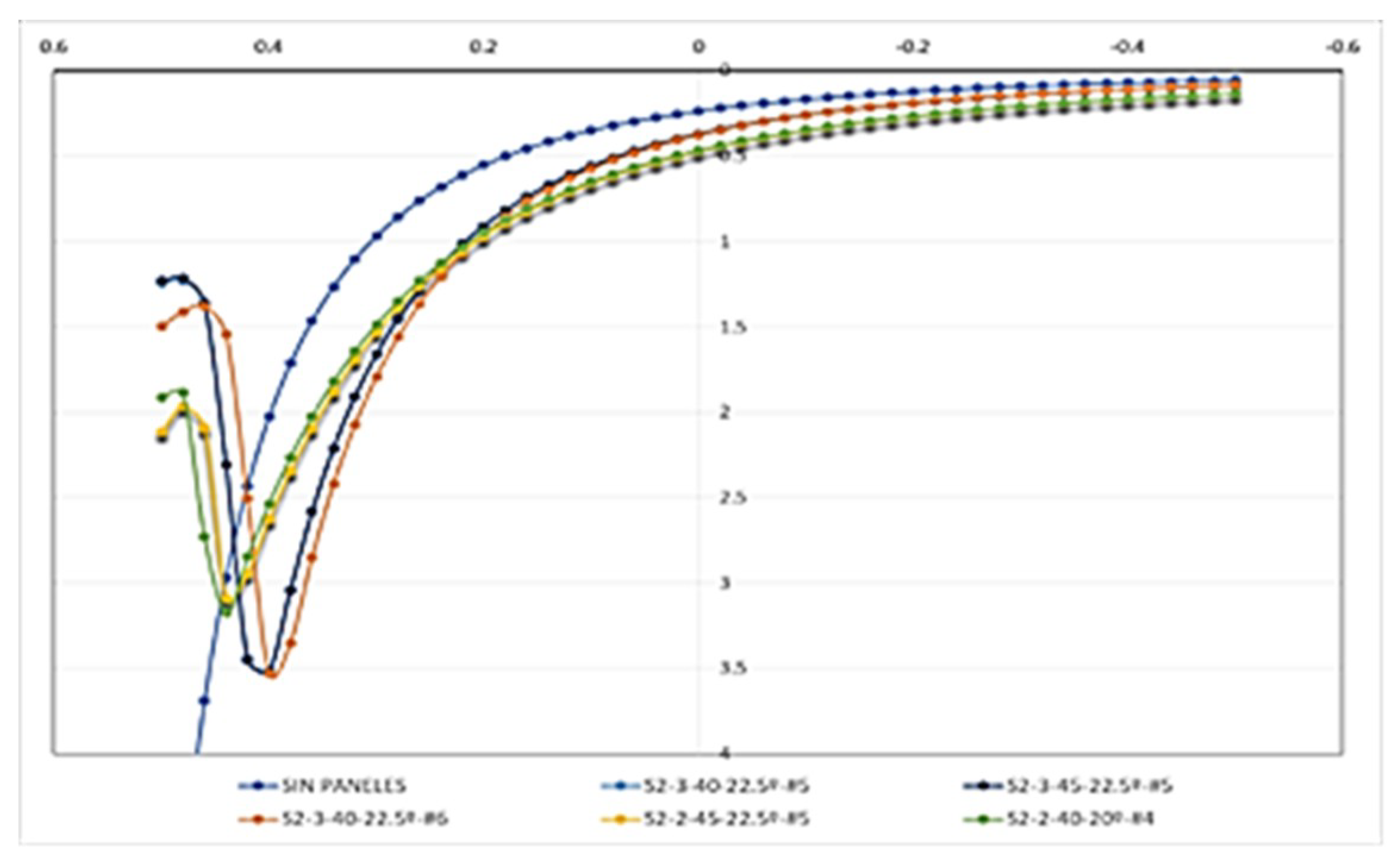

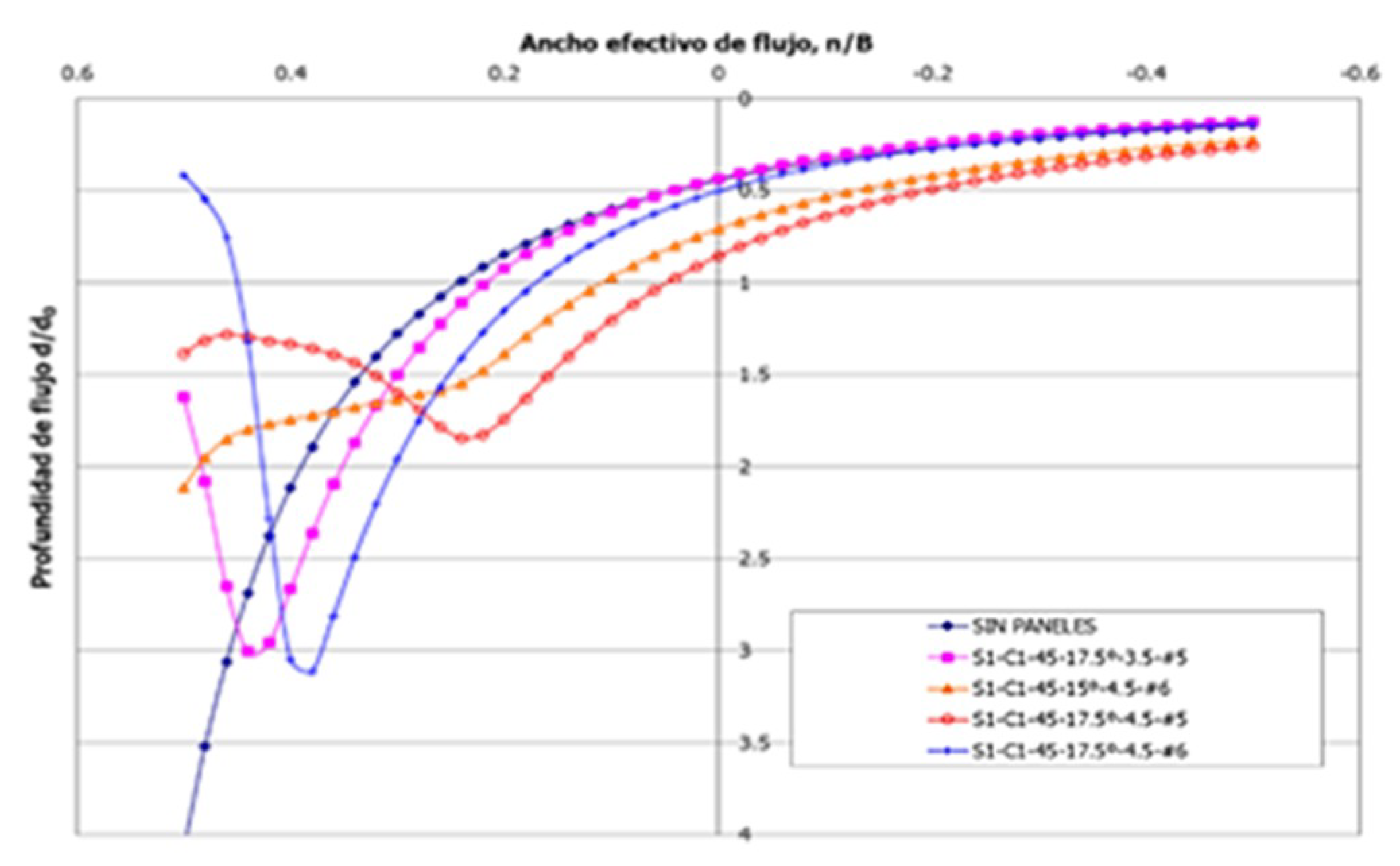

3.3. Rio Metica, in Puerto López, Sector 2 (2007)

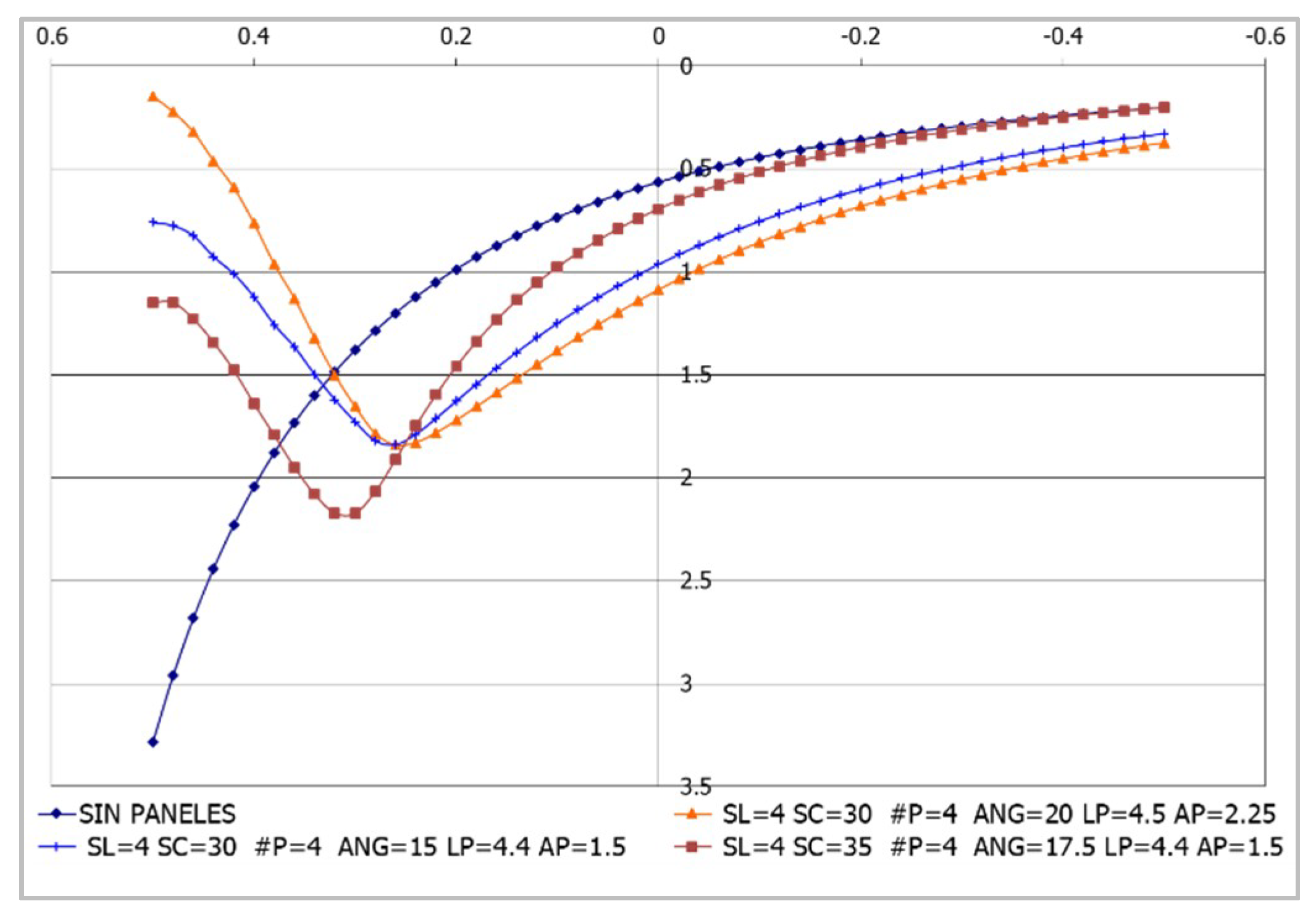

| Water temperature, (T °C) | : 20 °C |

| Average particle size, D50, mm | : 0.08 |

| Flow to full bench, m3/s | : 1.132 |

| Water level slope, S0 (m/m) | : 1.74 × 4.40 |

| Incidence angle | : 10°, 15°, 18° or 20° |

| Number of panels per set | : 4, 5, 6 or 7 |

| Maximum separation between sets, m | : 45 |

| Separation between panels, m | : 3 and 4, 5 |

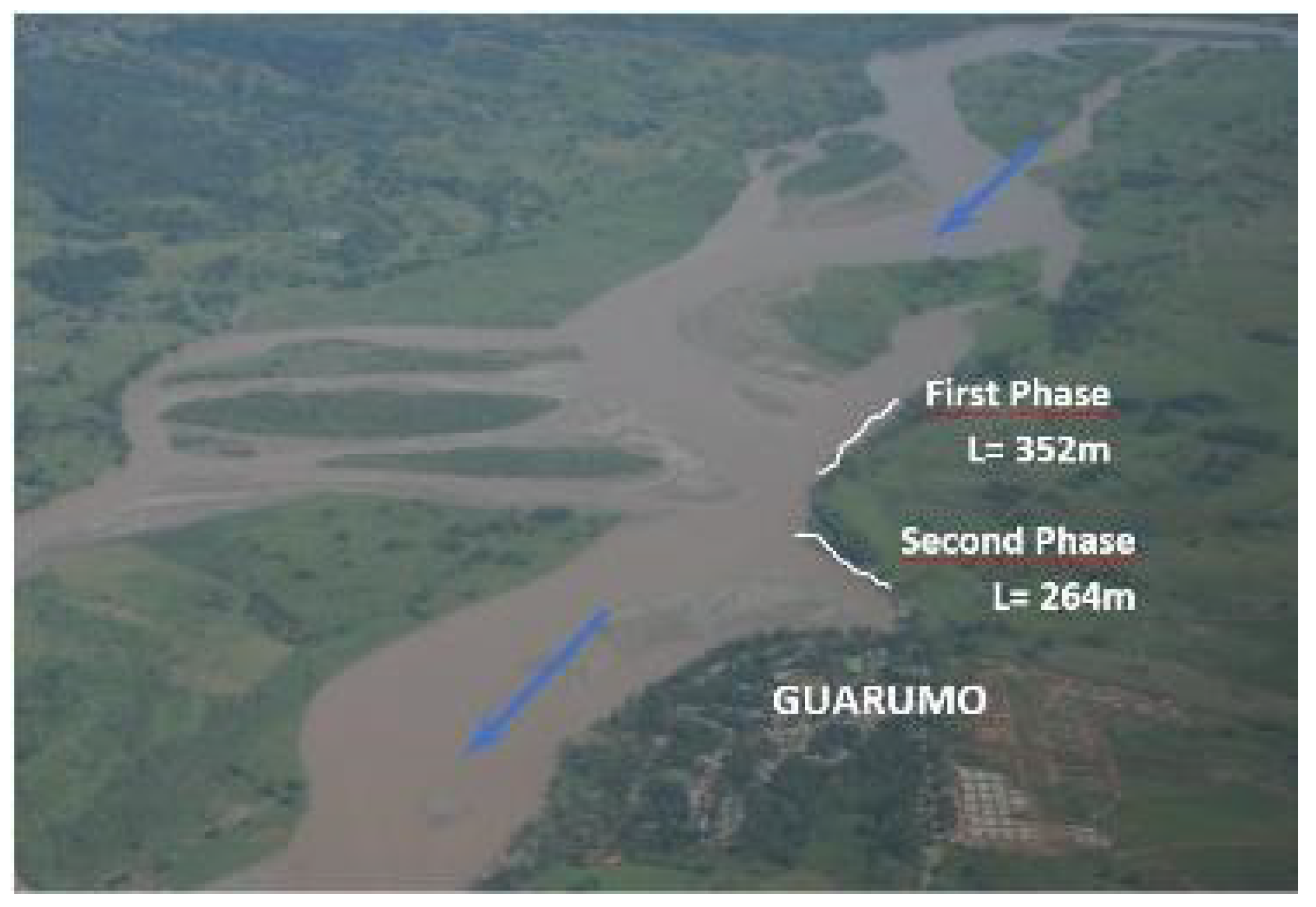

3.4. Cauca River, Guarumo Site (2009)

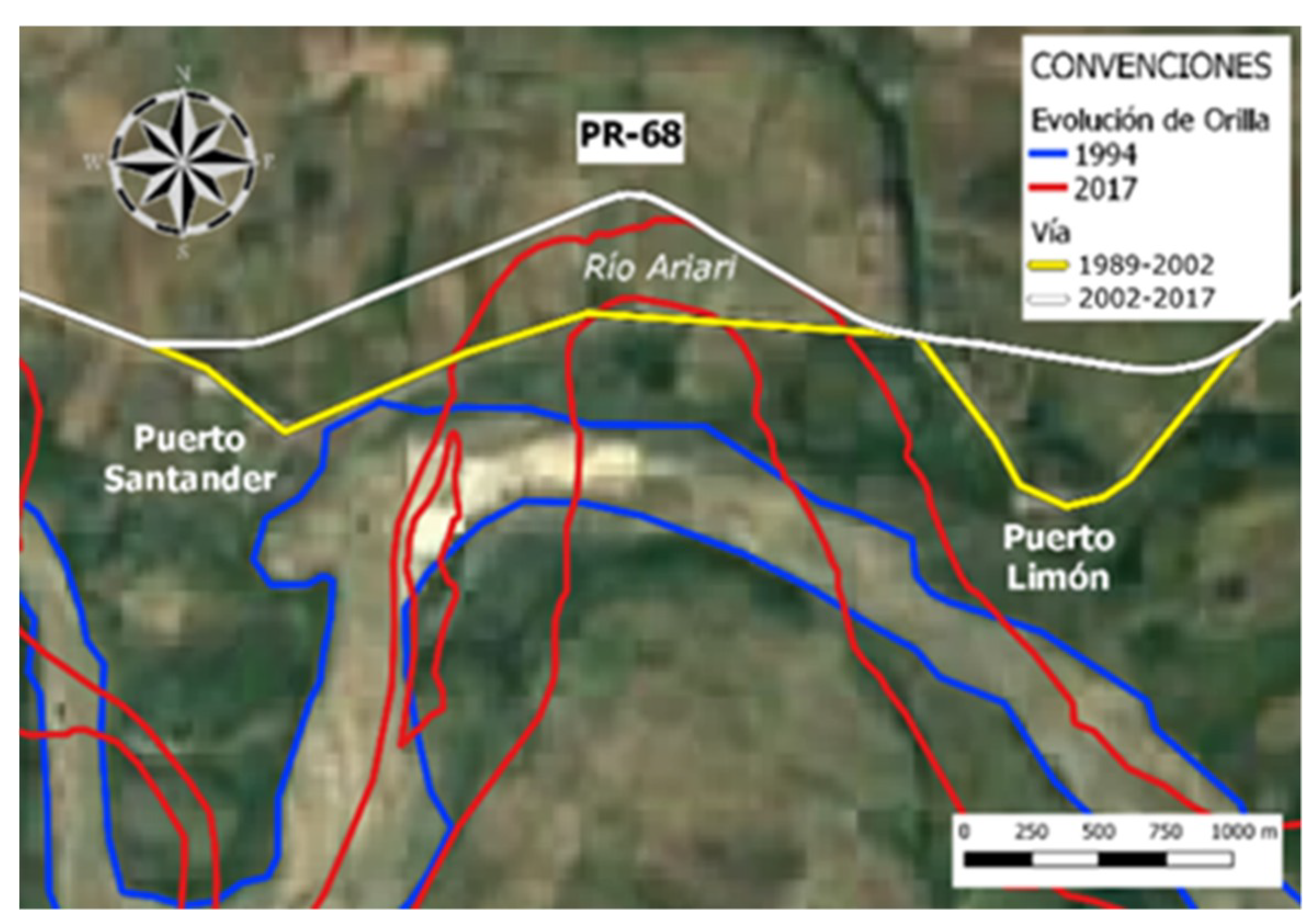

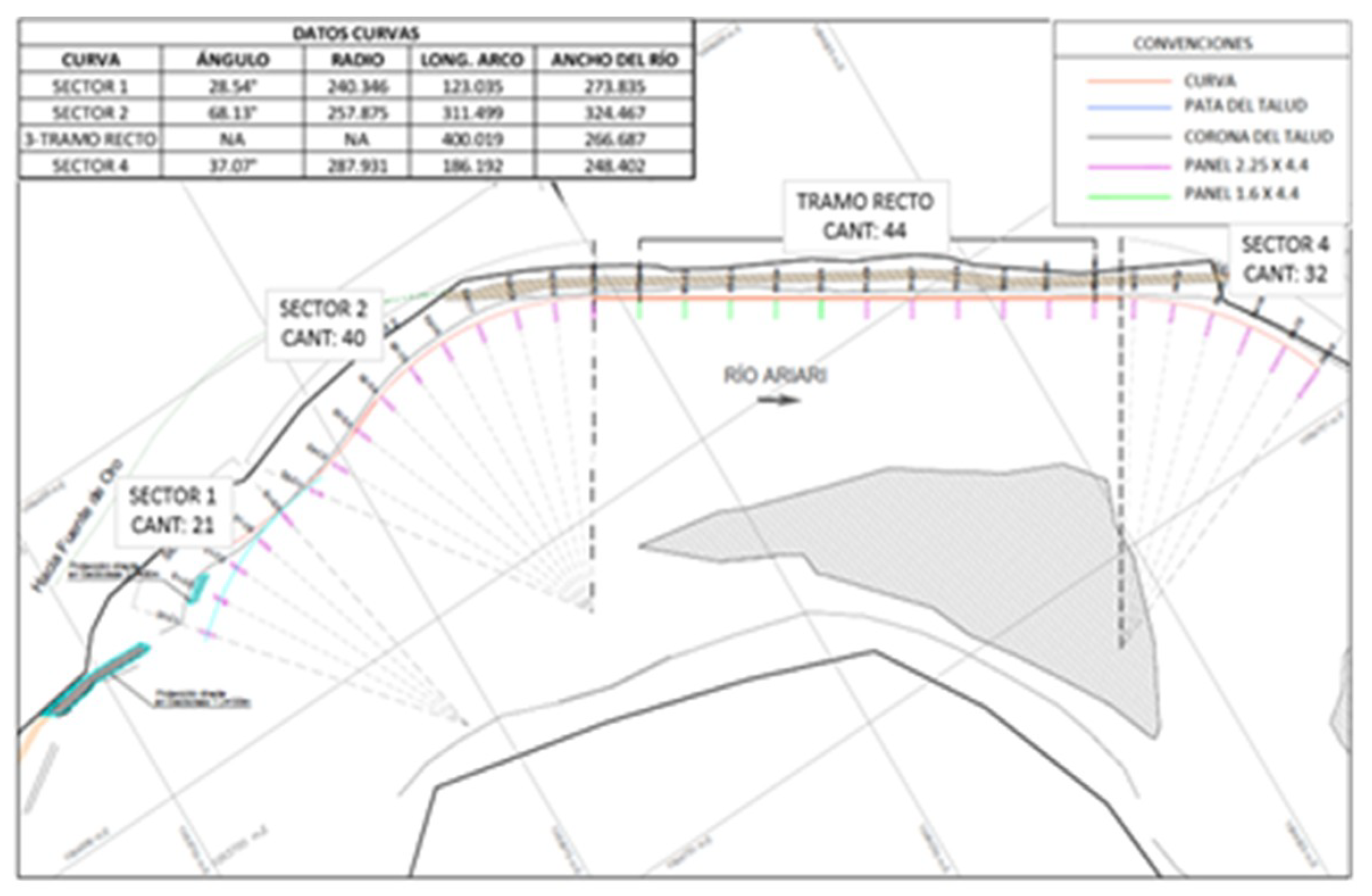

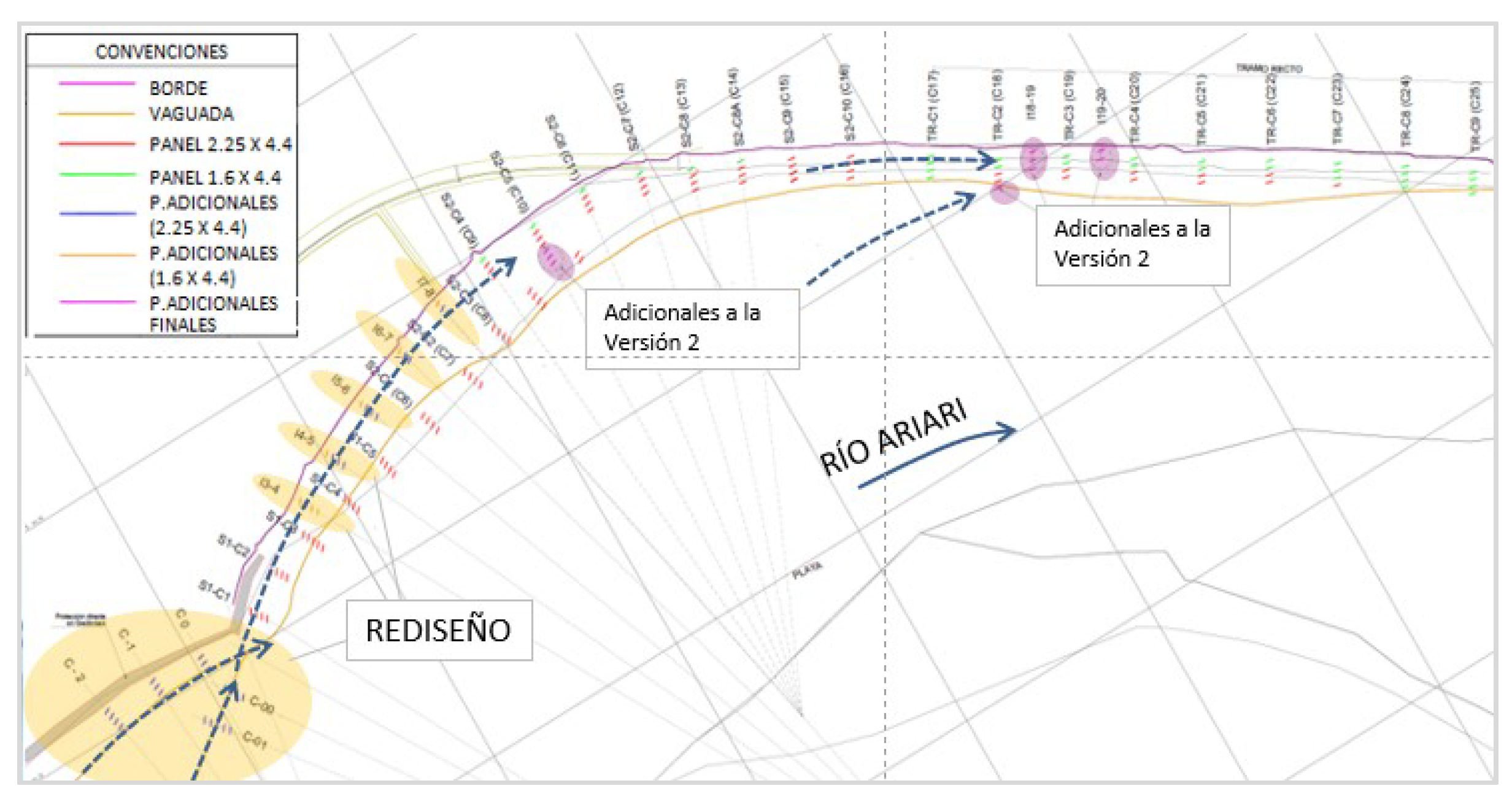

3.5. Ariari River, PR68 Puerto Lleras-Ye de Granada Road, Meta (2018)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Odgaard, A.J.; Kennedy, J.F. River-bend bank protection by submerged vanes. J. Hydraul. Eng. ASCE 1983, 109, 1161–1173. [Google Scholar] [CrossRef]

- Odgaard, A.J.; Spoljaric, A. Sediment control by submerged vanes. J. Hydraul. Eng. ASCE 1983, 112, 1164–1181. [Google Scholar] [CrossRef]

- Odgaard, A.J.; Wang, Y. Sediment management with submerged vanes. I: Theory. J. Hydraul. Eng. ASCE 1991, 117, 267–283. [Google Scholar] [CrossRef]

- Odgaard, A.J.; Mosconi, C.E. Streambank protection by submerged vanes. J. Hydraul. Eng. ASCE 1987, 113, 520–536. [Google Scholar] [CrossRef]

- Odgaard, A.J.; Wang, Y. Sediment management with submerged vanes. II: Applications. J. Hydraul. Eng. ASCE 1991, 117, 284–302. [Google Scholar] [CrossRef]

- Odgaard, A.J. River Training and Sediment Management with Submerged Vanes; ASCE Press: Reston, VA, USA, 2009. [Google Scholar]

- Wang, Y.; Odgaard, A.J.; Melville, B. Sediment control at water intakes. J. Hydraul. Eng. ASCE 1996, 117, 284–302. [Google Scholar] [CrossRef]

- Hidroconsulta Ltda. Diseño de Paneles Rígidos Sumergidos Para el Control de sedimentación, Muelle de Aromáticos, CIB-Ecopetrol; Informe Técnico; Complejo Industrial Barrancabermeja, CIB, Empresa Colombiana de Petróleos, Ecopetrol: Bogotá, Colombia, 1991. [Google Scholar]

- Hidroconsulta Ltda. Ajuste Estudios y Diseños Utilizando Estructuras Sumergidas, Entre el PR3+700 y el PR4+0100, sitio Trementino de la Carretera Puerto Rey-Moñitos-Lorica, Sector San Bernardo del Viento-Lorica, Ruta 90, Tramo 9003); Informe Final; Oficina de Prevención y Atención de Emergencias, Instituto Nacional de Vías: Bogotá, Colombia, 2004. [Google Scholar]

- Odgaard, A.J. BVANE: A computer model for the design of submerged vanes for sediment control. Restricted Distrib. 1996.

- ESRI. World Imagery of ESRI. 2018. Available online: https://services.arcgisonline.com/ArcGIS/rest/services/World_Imagery/MapServer (accessed on 2 September 2019).

- Hidroconsulta Ltda. Atención de Obras de Emergencia Mediante la Construcción de Paneles Sumergidos Para el Reencauzamiento del río Metica en el Bajo Menegua, Tendiente a Recuperar y Proteger la Estructura de la Banca Entre el PR 3+0000 y el PR 7+0000, de la Carretera Puerto López-Puerto Gaitán; “Informe de actualización del diseño”, Contrato 2716/2006, Consorcio Río Meta; Oficina de Prevención y Atención de Emergencias, Instituto Nacional de Vías, INVIAS: Bogotá, Colombia, 2007. [Google Scholar]

- Hidroconsulta Ltda. Ajuste a los Estudios y Diseños Utilizando Paneles Sumergidos, Para la Protección de la Carretera Puerto López–Puerto Gaitán (4008), Entre el PR3+0000 y el PR7+0000″; Informe Final (versión 1.0), Contrato 314/2005; Oficina de Prevención y Atención de Emergencias, Instituto Nacional de Vías, INVIAS: Bogotá, Colombia, 2005. [Google Scholar]

- USACE. HEC-RAS: River Analysis System; User´s Manual, Version 3.0; Hydrologic Engineering Center, (HEC), US Army Corps of Engineers: Davis, CA, USA, April 2003.

- Hidroconsulta Ltda. Diseño y Construcción de las Etapas I y II de la Protección con Paneles Sumergidos de la Carretera Tarazá—Caucasia (2512) Contra la Erosión Causada por el río Cauca, sitio Guarumo, Cáceres; Resumen Ejecutivo. Contratos 3138 de 2007 y 0493 de 2008. Premios Sociedad Colombiana de Ingenieros, Convocatoria 2010; Instituto Nacional de Vías, INVIAS: Bogotá, Colombia, 2010. [Google Scholar]

- Hidroconsulta, S.A.S. Elaboración de los Estudios y Diseños Detallados de Obras Hidráulicas Para el control de Evolución del río Ariari y Mejoramiento de la vía: Cruce Puerto Rico-Ye de Granada, Mediante una Variante Entre los PR67+000 y PR70+000 y los PR38+000 y el PR41+000 de La Ruta 65, Tramo 6508, en el Departamento del Meta; Informe de diseño de obras (versión 1.1); Consorcio Meta Ye Jad. Instituto Nacional de Vías, INVIAS: Bogotá, Colombia, December 2017. [Google Scholar]

- LANDSAT. Landsat 5 Image from 30 December 1994, resolution of 30 m per pixel. Available online: https://www.usgs.gov/land-resources/nli/landsat/landsat-data-access?qt-science_support_page_related_con=0#qt-science_support_page_related_con (accessed on 2 September 2019).

- LANDSAT. Landsat 7 Image from 25 July 2001, resolution 30 m por pixel. Available online: https://www.usgs.gov/land-resources/nli/landsat/landsat-data-access?qt-science_support_page_related_con=0#qt-science_support_page_related_con (accessed on 2 September 2019).

- LANDSAT. Landsat 7 Image from 30 September 2002, resolution 30 m per pixel. Available online: https://www.usgs.gov/land-resources/nli/landsat/landsat-data-access?qt-science_support_page_related_con=0#qt-science_support_page_related_con (accessed on 2 September 2019).

- Hidroconsulta, S.A.S. Informe Final de Obra: Construcción de Paneles Sumergidos en la Orilla del río Ariari Para la Protección de la Carretera Granada-San José del Guaviare, en el PR39-PR40 y PR68, Para el Control de Evolución del río Ariari y Mejoramiento de la vía: Cruce Puerto Rico-Ye de Granada, Mediante una variante Entre los PR67+000 y PR70+000 y los PR38+000 y el PR41+000 de La Ruta 65, Tramo 6508, en el departamento del Meta; Consorcio Meta Ye Jad. Instituto Nacional de Vías, INVIAS: Bogotá, Colombia, November 2018. [Google Scholar]

- USACE. HEC-RAS: River Analysis System; User´s Manual, Version 5.0.1; Hydrologic Engineering Center, (HEC), US Army Corps of Engineers: Davis, CA, USA, April 2016.

| Sector | Dimensions H (m) × L (m) × e(m) | Panels/Set (Number) | Separation Panels (m)/Array (m) | Protected Length (m) | Arrays (No.) | Total Vanes |

|---|---|---|---|---|---|---|

| 1A | 3.0 × 6.0 × 0.165 | 3 | 5.0/60.0 | 180.0 | 4 | 15 |

| 1B | 3.0 × 6.0 × 0.165 | 3 | 5.0/50.0 | 100.0 | 1 | 3 |

| 2 | 3.0 × 6.0 × 0.165 | 4 | 4.0/50.0 | 150.0 | 4 | 16 |

| 3 | 3.0 × 6.0 × 0.165 | 4 | 4.0/50.0 | 200.0 | 3 | 12 |

| TOTAL | 630.0 | 12 | 46 |

| Sector | Curve | Number of Vanes per Array | Separation (m) | Protected Bank Length (m) | Number of Arrays | Total Number of Vanes | |

|---|---|---|---|---|---|---|---|

| Between Vanes | Between Arrays | ||||||

| 3 | 0 | 5 | 4.0 | 40.0 | 79.2 | 2 | 10 |

| 3 | 1 | 4 o 5 | 4.0 | 40.0 | 653.7 | 17 | 74 |

| 3 | 2 | 6 | 4.5 | 45.0 | 249.6 | 6 | 36 |

| 3 | 3 | 7 | 4.5 | 45.0 | 65.3 | 2 | 14 |

| TOTAL | 1047.8 | 27 | 134 | ||||

| Sector | Units per Array | Separation (m) | Protection Length (m) | Number of Arrays | Total Vanes | |

|---|---|---|---|---|---|---|

| Between Vanes | Between Arrays | |||||

| 1 | 4 o 5 | 3.5 | 30 | 150 | 5 | 21 |

| 2 | 5 | 4 | 35 | 350 | 9 | 40 |

| 3A* | 4 | 4 | 40 | 170 | 5 | 20 |

| 3B | 4 | 4 | 40 | 265 | 6 | 24 |

| 4 | 4, 5, 6 and 7 | 4 | 35 | 175 | 6 | 32 |

| TOTAL | 1.110 | 31 | 137 | |||

| Project (Year) | Aromáticos (1993) | Trementino (2005) | Puerto López, Sector 2 (2007) | Guarumo: of the Steps (2009) | PR68 (2018) |

|---|---|---|---|---|---|

| RIVER | Magdalena | Sinú | Metica | Cauca | Ariari |

| QDESIGN, m3/s | 3850.0 | 645.0 | 1132.0 | 1945.0 | 467.0 |

| Total, arrays | 9 | 13 | 27 | 17 (9 + 8) | 39 |

| Total, Vanes | 71* | 45** | 134*** | 98 (41 + 57) | 186 |

| Protected length, m | N/A | 630.0 | 1050.0 | 616.0 | 1110.0 |

| Starting date | 01/06/93 | 13/09/04 | 01/29/2007 | 26/12/07 08/09/08 | 04/05/18 |

| Ending date | 23/08/93 | 20/12/04 | 28/07/2007 | 31/03/08 25/11/08 | 10/08/18 |

| Savings obtained | USD 1.15 million/year for more than ten years. | USD 1.6 million | USD 1.9 million | USD 1.07 million plus the unquantified cost of dredging | USD 5 to 10 million (1) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Amaya, C.; Durán-Ariza, A.; Duarte-Méndez, S. Submerged Vane Technology in Colombia: Five Representative Projects. Water 2020, 12, 984. https://doi.org/10.3390/w12040984

Rodríguez-Amaya C, Durán-Ariza A, Duarte-Méndez S. Submerged Vane Technology in Colombia: Five Representative Projects. Water. 2020; 12(4):984. https://doi.org/10.3390/w12040984

Chicago/Turabian StyleRodríguez-Amaya, Carlos, Argelino Durán-Ariza, and Santiago Duarte-Méndez. 2020. "Submerged Vane Technology in Colombia: Five Representative Projects" Water 12, no. 4: 984. https://doi.org/10.3390/w12040984

APA StyleRodríguez-Amaya, C., Durán-Ariza, A., & Duarte-Méndez, S. (2020). Submerged Vane Technology in Colombia: Five Representative Projects. Water, 12(4), 984. https://doi.org/10.3390/w12040984