Cool Steam Method for Desalinating Seawater

Abstract

:1. Introduction

2. Cool Steam Technology

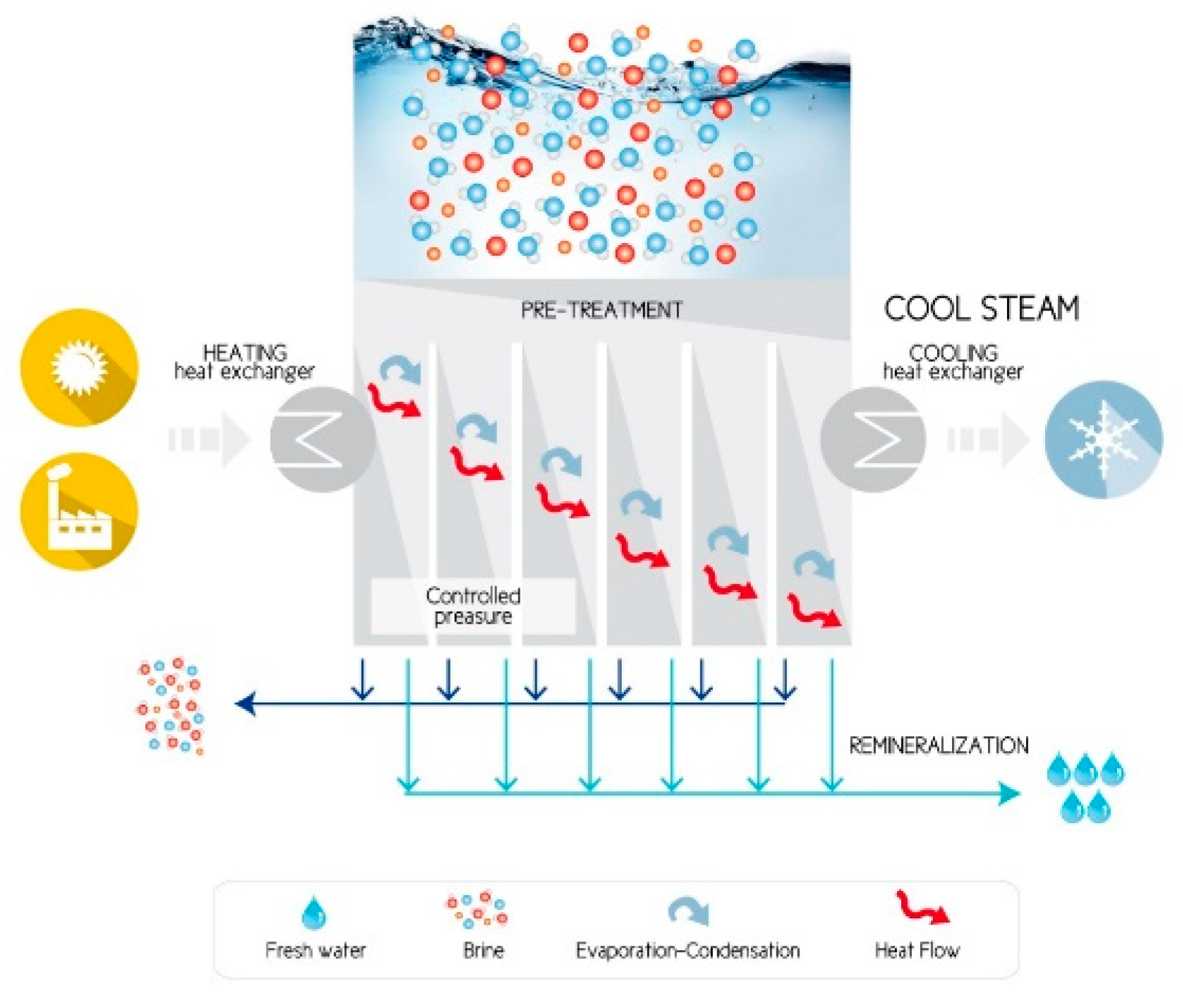

- Pretreatment, which is performed on all the water entering the system. It is reduced to basic primary treatment, much less strict than that required in reverse osmosis (SWRO) processes, given the delicacy of the membranes used in the latter. It will consist of roughing, flocculation, and decantation. The roughing process is the arrangement of grids and sieves for the retention of thick solids that can carry water, such as algae, crustaceans, waste, etc., thus avoiding deposits and obstructions in conduits, ensuring the proper functioning of the equipment, and improving the efficiency of the subsequent treatments. Flocculation is only necessary if seawater has a high content of colloidal matter, and in this case, the suspended organic matter and colloidal particles are eliminated, avoiding biological deposits and bacterial growth, and decreasing the biological oxygen demand (BOD) of the water. Decantation is the precipitation of solids in suspension (for example, sands or lands), as well as flocculated organic matter, which will occur in the raw water tank itself by the exclusive action of gravity. The estimated retention time is two hours, which in turn will help the water to increase its entrance temperature to the system by solar radiation.

- Water degassing tanks, at which all dissolved gases are removed from the saline water so as to not alter the vacuum generating step. This process is performed in two tanks that work alternatively. The desalination process under the CS method takes place in a tight and isolated system under vacuum. To guarantee the vacuum rate required for the process to remain self-operating, the incondensable gases dissolved in the feed water must be removed before entering the system to avoid them from hindering the water vapor transport. These incondensable gases correspond to the air dissolved in the water.

- Mechanical feeding system based on piston push and pull mechanism for controlled dispensing of feed water. Synchronized system of pistons that allow volumetric control. We have designed a system of volumetric control of liquids, with two pistons controlled by electromechanical linear actuators that would drain and fill and simultaneously, to induce calibrated flow streams under vacuum conditions. To ensure smooth operation at pressures near-vacuum, the whole system would be isolated in a chamber at the same pressure as the one at the liquid source chamber.

- Multi-stage vacuum distillation core, which is composed of several chambers separated through metallic heat transfer barrier. The multi-stage cool steam distillation core is a consecution of evaporation–condensation chambers placed in series but fed in parallel. Some stages can be implemented depending on the overall available temperature gradient. As a result, there is a net heat flux between the heat source and the sink. Water vapor acts as a heat carrier. There is no mass exchange between stages and latent heat transmits from one stage to the next one by conduction through thin metal walls. Within each stage, seawater is fed from the top and is evaporated in contact with the warmer surface. This water vapor travels to the cooler surface and condensates in contact with it. The latent heat of condensation is then conducted through the wall to the next stage. As a result, two different streams are obtained: Reject (non-evaporated feed water) and distilled water (condensed water vapor).

- Fresh water and brine discharge system, which are outlet means for final extraction from the vacuum system: Self-controlled gates for outgoing batches to drain reject and distillate from the vacuum chamber (avoiding water vapor losses) and two paired floodgates that work alternatively to ensure the steady-state performance of the distillation core and vacuum keeping within it.

3. Main Results of Cool Steam Technology: Methods and Equipment Description

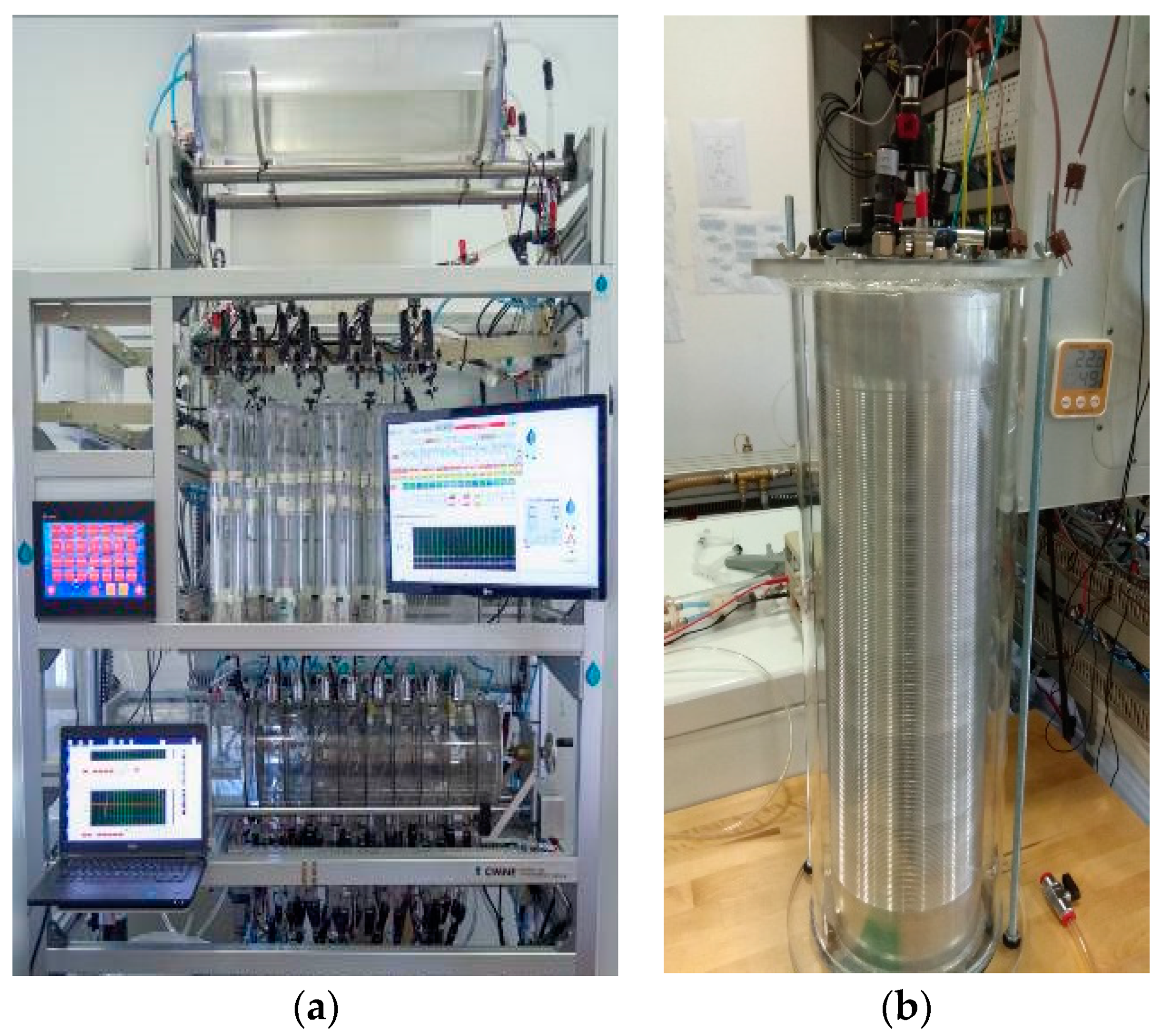

3.1. Equipment Description

3.2. Basic Comparisons

- MED between 70–40 °C;

- MSF below 120 °C;

- CS between 20–50 °C:

- Reduces scaling problems:

- CaSO4 precipitates at temperatures over 120 °C;

- CaCO3 and MgOH precipitate at alkaline pHs.

- MED and MSF need medium-grade heat (100–400 °C) provided in the form of compressed steam (generated in a boiler or from any waste heat source);

- CS uses low-grade heat (<100 °C) from both vapor and liquid streams to perform:

- A wider range of natural/waste heat sources (once it is in enough quantity and there is an available temperature gradient).

- MED and MSF have serial stages;

- CS has parallel stages;

- MED and MSF have separated evaporation/condensation chambers tubes exchangers:

- Need to pump water from one effect to the other;

- High friction losses and temperature drop;

- CS perform evaporation/condensation within each chamber:

- Reduces heat losses and pumping needs;

- More compact devices;

- CS precise high tightness level.

- MED 2.5–3 kWh/m3;

- MSF 4–6 kWh/m3;

- RO 2.5–4 kWh/m3;

- CS 1.2 kWh/m3.

- Cp: Heat capacity or specific heat at constant pressure. At a temperature of 25 °C, the heat required to raise the temperature of 1 kg of water by 1 °C is 4179.6 J; that is, the specific heat of water at this temperature is 4.1796 (kJ/Kg·K). At this temperature, the Cp of air is 1.0 (kJ/Kg·K).

- T: Temperature gradient suffered.

3.3. Energy

4. Discussion

5. Conclusions

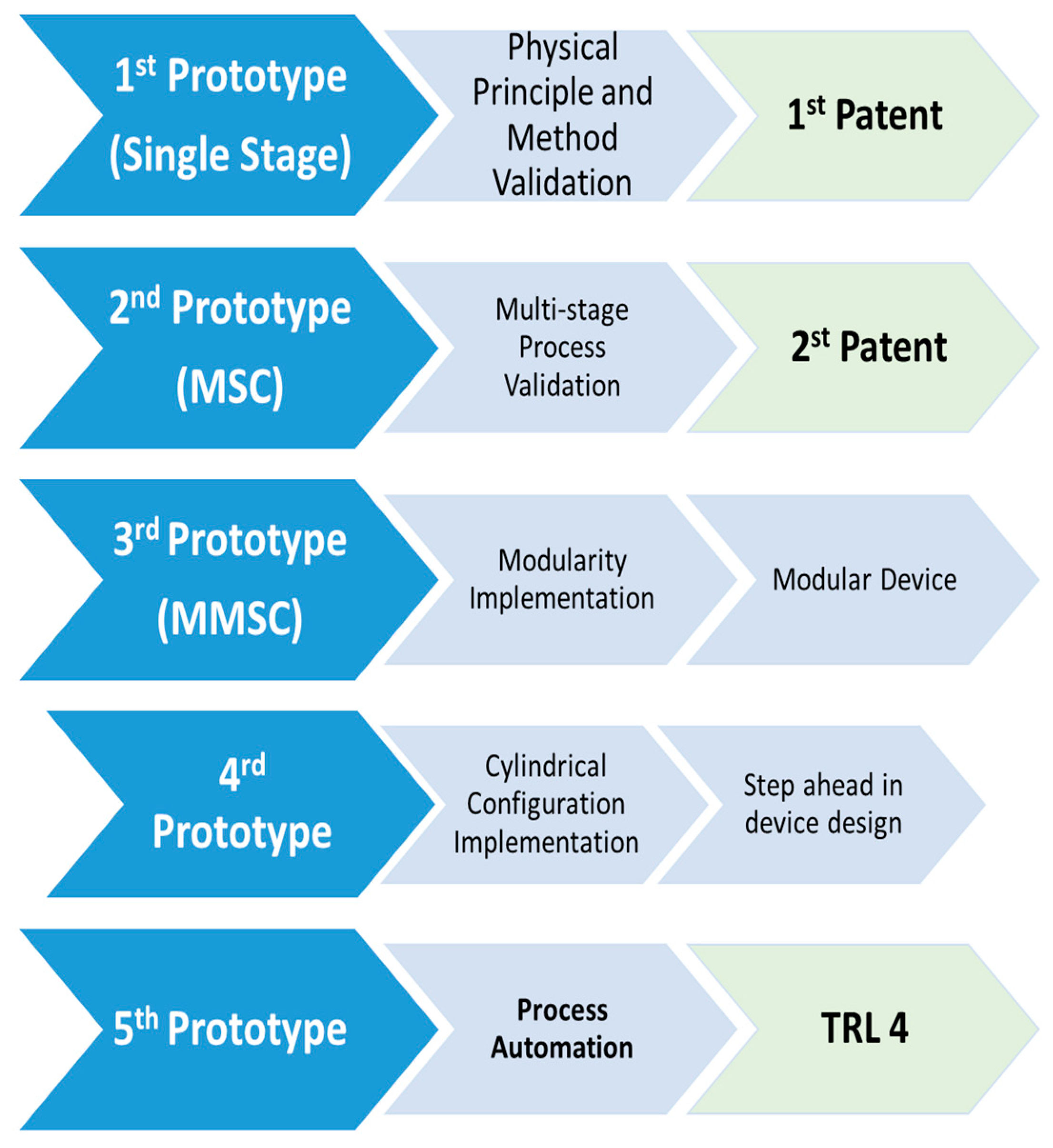

6. Patents

- Device, apparatus, and method for desalinating seawater, Arnau del Amo, Pedro Antonio, Oñate Ibáñez de Navarra, Eugenio, Hanganu, Dan Alexandru and Navarro Navarro, Naeria. European Patent Office. Espacenet. Application number: EP2013038219620130528. Publication date: 2014-12-4.

- System and method for desalinating seawater, Arnau del Amo, Pedro Antonio, Oñate Ibáñez de Navarra, Eugenio, Hanganu, Alex. European Patent Office. Espacenet, Application num: EP2011038219820110615. Publication date: 2012-12-19.

- System and method for desalinating seawater Arnau del Amo, Pedro Antonio, Oñate Ibáñez de Navarra, Eugenio, Hanganu, Dan Alexandru. Saudi Arabia/GCC, National Phase. Application number: 112 33 0608. Publication date: 2012-6-11.

- Device, apparatus and method for desalinating seawater, Arnau del Amo, Pedro Antonio, Oñate Ibáñez de Navarra, Eugenio, Hanganu, Dan Alexandru and Navarro Navarro, Naeria. US, National Phase. Application number: 10315932. Publication date: 2019-6-11.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ASD | Agenda for Sustainable Development |

| BOD | Biological Oxygen Demand |

| CS | Cool Steam |

| EEA | European Environment Agency |

| ED | Electrodialysis |

| LTTD | Low-temperature thermal distillation |

| MSF | Multi-Stage Flash |

| MED | Multi-Effect Distillation |

| OTEC | Ocean Thermal Energy Conversion |

| PV | Photovoltaic |

| RE | Renewable Energy |

| SEM | South-Eastern Mediterranean |

| SWRO | Seawater Reverse Osmosis |

| UN | United Nations |

| VC | Vapor Compression |

| WHO | World Health Organization |

References

- United Nations. Transforming our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- United Nations. International Decade for Action, Water for Sustainable Development, 2018–2028; United Nations: New York, NY, USA, 2016. [Google Scholar]

- Mangion, J.; Mundo, F.; Puig, A.; Antolin, M.; Zacharian, M.; Eliades, P.; Duchemin, J.; Nasser Al Abdel-Shafy, H.; Abu Awwad, A.; Mohammed, A.; et al. Mediterranean Wastewater Reuse Report. Mediterranean Wastewater Reuse Working Group, EC, 2007. Available online: https://ec.europa.eu/environment/water/blueprint/pdf/med_final_report.pdf (accessed on 13 November 2019).

- Kirhensteine, I.; Cherrier, V.; Jarritt, N.; Farmer, A.; de Paoli, G.; Delacamara, G.; Psomas, A. EU-Level Instruments on Water Reuse; Amec Foster Wheeler Environment & Infrastructure UK Ltd., IEEP, ACTeon, IMDEA and NTUA: Luxembourg, 2016; ISBN 978-92-79-62616-6. [Google Scholar]

- Hochstrat, R.; Joksimovic, D.; Wintgens, T.; Melin, D.; Savic, D. Economic considerations and decision support tool for wastewater reuse scheme planning. Water Sci. Technol. 2007, 56, 175–182. [Google Scholar] [CrossRef] [PubMed]

- Cramer, W.; Guiot, J.; Fader, M.; Garrabou, J.; Gattuso, J.-P.; Iglesias, A.; Lange, M.A.; Lionello, P.; Llasat, M.C.; Paz, S.; et al. Climate change and interconnected risks to sustainable development in the Mediterranean. Nat. Clim. Chang. 2018, 8, 972–980. [Google Scholar] [CrossRef]

- Plan, B. A Sustainable Future for the Mediterranean: The Blue Plan’s Environment and Development Outlook; Benoit, G., Comeau, A., Eds.; Chapter on “Coastal Areas”; Earthscan: London, UK, 2005; pp. 303–356. [Google Scholar]

- United Nations. Probabilistic Population Projections Based on the World Population Prospects: The 2015 Revision; Population Division; United Nations Department of Economic and Social Affairs (DESA): New York, NY, USA, 2015; Available online: http://esa.un.org/unpd/ppp/ (accessed on 13 November 2019).

- United Nations World Water Assessment Programme. The United Nations World Water Development Report 2014: Water and Energy; The United Nations Educational, Scientific and Cultural Organization (UNESCO): Paris, France, 2014; Available online: http://unesdoc.unesco.org/images/0022/002257/225741E.pdf (accessed on 13 November 2019).

- Mehzer, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar]

- Al-Kharaghouli, A.; Kazmerski, L.L. Energy consumption and water production cost of renewable energy powered desalination processes. Renew. Sustain. Energy Rev. 2013, 24, 343–356. [Google Scholar] [CrossRef]

- Alkaisia, A.; Mossadb, R.; Sharifian-Barforoush, A. A review of the water desalination systems integrated with renewable energy. Energy Procedia 2017, 110, 268–274. [Google Scholar] [CrossRef]

- Arnau del Amo, P.A.; Oñate Ibáñez de Navarra, E.; Hanganu, D.A. System and Method for Desalinating Seawater. European Patent Office, Espacenet Application No. EP2,011,038,219,820,110,615, 19 December 2012. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&II=1&ND=3&adjacent=true&locale=en_EP&FT=D&date=20160505&CC=US&NR=2016122205A1&KC=A1#?locale=en_EP&II=0&date=20170426&CC=CY&NR=1117333T1&ND=3&KC=T1&rnd=1546855789713&adjacent=true&FT=D&DB=EPODOC (accessed on 26 April 2017).

- Arnau del Amo, P.A.; Oñate Ibáñez de Navarra, E.; Hanganu, D.A. System and Method for Desalinating Seawater. Saudi Arabia/GCC, National Phase Application No. 112,330,608, 6 November 2012. [Google Scholar]

- Arnau del Amo, P.A.; Oñate Ibáñez de Navarra, E.; Hanganu, D.A.; Navarro Navarro, N. Device, Apparatus and Method for Desalinating Seawater. European Patent Office, Espacenet Application No. EP2,013,038,219,620,130,528, 4 December 2014. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?DB=EPODOC&II=1&ND=3&adjacent=true&locale=en_EP&FT=D&date=20160505&CC=US&NR=2016122205A1&KC=A1 (accessed on 5 May 2016).

- Arnau del Amo, P.A.; Oñate Ibáñez de Navarra, E.; Hanganu, D.A.; Navarro Navarro, N. Device, Apparatus and Method for Desalinating Seawater. U.S. Patent Application No. US10,315,932 B2, 11 June 2019. Available online: http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO1&Sect2=HITOFF&p=1&u=/netahtml/PTO/srchnum.html&r=1&f=G&l=50&d=PALL&s1=10315932.PN (accessed on 11 June 2019).

- Rognoni, M.; Kathiroli, S.; Jalihal, P. Low Temperature Thermal Desalination (LTTD): New sustainable desalination process. Int. J. Nucl. Desalin. 2008, 3, 69–78. [Google Scholar] [CrossRef]

- Akers, J.N. Multi-Stage Water Distilling Apparatus. U.S. Patent O 3,275,530, 27 September 1966. [Google Scholar]

- Petrek, J.P.; Cantrell, C.M. Multiple Effect Thin Film Distillation System and Process. U.S. Patent US4402793A, 6 September 1983. [Google Scholar]

- Inoue, K.; Abe, Y.; Murakami, M.; Mori, T. Feasibility study of desalination technology utilizing the temperature difference between seawater and inland atmosphere. Desalination 2006, 197, 137–153. [Google Scholar] [CrossRef]

- Gude, G.V.; Nirmalakhandan, N. Desalination at low temperatures and low pressures. Desalination 2009, 244, 239–247. [Google Scholar] [CrossRef]

- Ling-Chin, J.; Bao, H.; Ma, Z.; Taylor, W.; Roskilly, A.P. State-of-the-Art Technologies on Low-Grade Heat Recovery and Utilization in Industry. In Energy Convers—Current Technologies and Future Trends; Al-Bahadly, I.H., Ed.; IntechOpen: London, UK; Available online: https://www.intechopen.com/books/energy-conversion-current-technologies-and-future-trends/state-of-the-art-technologies-on-low-grade-heat-recovery-and-utilization-in-industry (accessed on 5 November 2018). [CrossRef]

- Kishore, R.A.; Priya, S. A Review on Low-Grade Thermal Energy Harvesting: Materials, Methods and Device. Materials 2018, 11, 1433. [Google Scholar] [CrossRef] [PubMed]

- Aghahosseini, A.; Bogdanov, D.; Ghorbani, N.; Breyer, C. The role of a 100% renewable energy system for the future of Iran: Integrating solar PV, wind energy, hydropower and storage. In Proceedings of the 11th International Renewable Energy Storage Conference, Düsseldorf, Germany, 14–16 March 2017. [Google Scholar]

- Barbosa, L.S.N.S.; Bogdanov, D.; Vainikka, P.; Breyer, C. Hydro, wind and solar power as a base for a 100%Renewable Energy supply for South and Central America. PLoS ONE 2017, 12, e173820. [Google Scholar] [CrossRef] [PubMed]

- Child, M.; Bogdanov, D.; Breyer, C. The role of storage technologies for the transition to a 100% renewable energy system in Europe. Energy Procedia 2018, 155, 44–60. [Google Scholar] [CrossRef]

- Caldera, U.; Bogdanov, D.; Breyer, C. Local cost of seawater RO desalination based on solar PV and wind energy: A global estimate. Desalination 2016, 385, 207–216. [Google Scholar] [CrossRef]

- Libes, S.M. An Introduction to Marine Biogeochemistry; John Wiley & Sons: Hoboken, NJ, USA, 1992. [Google Scholar]

- Reddy, K.V.; Ghaffour, N. Overview of the cost of desalinated water and costing methodologies. Desalination 2007, 205, 340–353. [Google Scholar] [CrossRef]

- Al-Zahrani, A.; Orfi, J.; Al-Suhaibani, Z.; Salim, B.; Al-Ansary, H. Thermodynamic analysis of a reverse osmosis desalination unit with energy recovery system. Procedia Eng. 2012, 33, 404–414. [Google Scholar] [CrossRef]

- Loutatidou, S.; Chalermthai, B.; Marpu, P.R.; Arafat, H. Capital cost estimation of RO plants: GCC countries versus southern Europe. Desalination 2014, 347, 103–111. [Google Scholar] [CrossRef]

- Kittner, N.; Lill, F.; Kammen, M.D. Energy storage deployment and innovation for the clean energy transition. Nat. Energy 2017, 2, 17125. [Google Scholar] [CrossRef]

- Schmidt, O.; Hawkes, A.; Gambhir, A.; Staffell, I. The future cost of electrical energy storage based on experience rates. Nat. Energy 2017, 2, 17110. [Google Scholar] [CrossRef]

| T (°C) | Pv, H2O (mbar) | N2 CN2 (mmol/m3) | O2 CO2 (mmol/m3) | CO2 CCO2 (mmol/m3) | Ar CAr (mmol/m3) |

|---|---|---|---|---|---|

| 0 | 6.09 | 636 | 356 | 23.4 | 17.0 |

| 5 | 8.70 | 566 | 313 | 19.3 | 15.0 |

| 10 | 12.26 | 508 | 279 | 16.1 | 13.3 |

| 15 | 17.04 | 461 | 250 | 13.6 | 12.0 |

| 20 | 23.37 | 420 | 226 | 11.6 | 10.8 |

| 25 | 31.67 | 386 | 205 | 10 | 9.81 |

| 30 | 42.43 | 355 | 187 | 8.66 | 8.93 |

| T (°C) | Pv,H2O (mbar) | 1 mbar E (kWh /m3) | 2 mbar E (kWh /m3) | 5 mbar E (kWh /m3) | 10 mbar E (kWh /m3) |

|---|---|---|---|---|---|

| 0 | 6.09 | 0.68 | 0.34 | 0.14 | 0.07 |

| 5 | 8.70 | 0.61 | 0.30 | 0.12 | 0.06 |

| 10 | 12.26 | 0.54 | 0.27 | 0.11 | 0.05 |

| 15 | 17.04 | 0.49 | 0.24 | 0.10 | 0.05 |

| 20 | 23.37 | 0.44 | 0.22 | 0.09 | 0.04 |

| 25 | 31.67 | 0.41 | 0.20 | 0.08 | 0.04 |

| 30 | 42.43 | 0.37 | 0.19 | 0.07 | 0.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arnau, P.A.; Navarro, N.; Soraluce, J.; Martínez-Iglesias, J.M.; Illas, J.; Oñate, E. Cool Steam Method for Desalinating Seawater. Water 2019, 11, 2385. https://doi.org/10.3390/w11112385

Arnau PA, Navarro N, Soraluce J, Martínez-Iglesias JM, Illas J, Oñate E. Cool Steam Method for Desalinating Seawater. Water. 2019; 11(11):2385. https://doi.org/10.3390/w11112385

Chicago/Turabian StyleArnau, Pedro Antonio, Naeria Navarro, Javier Soraluce, Jose María Martínez-Iglesias, Jorge Illas, and Eugenio Oñate. 2019. "Cool Steam Method for Desalinating Seawater" Water 11, no. 11: 2385. https://doi.org/10.3390/w11112385

APA StyleArnau, P. A., Navarro, N., Soraluce, J., Martínez-Iglesias, J. M., Illas, J., & Oñate, E. (2019). Cool Steam Method for Desalinating Seawater. Water, 11(11), 2385. https://doi.org/10.3390/w11112385