Pyrolysis Process as a Sustainable Management Option of Poultry Manure: Characterization of the Derived Biochars and Assessment of their Nutrient Release Capacities

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Raw Poultry Manure

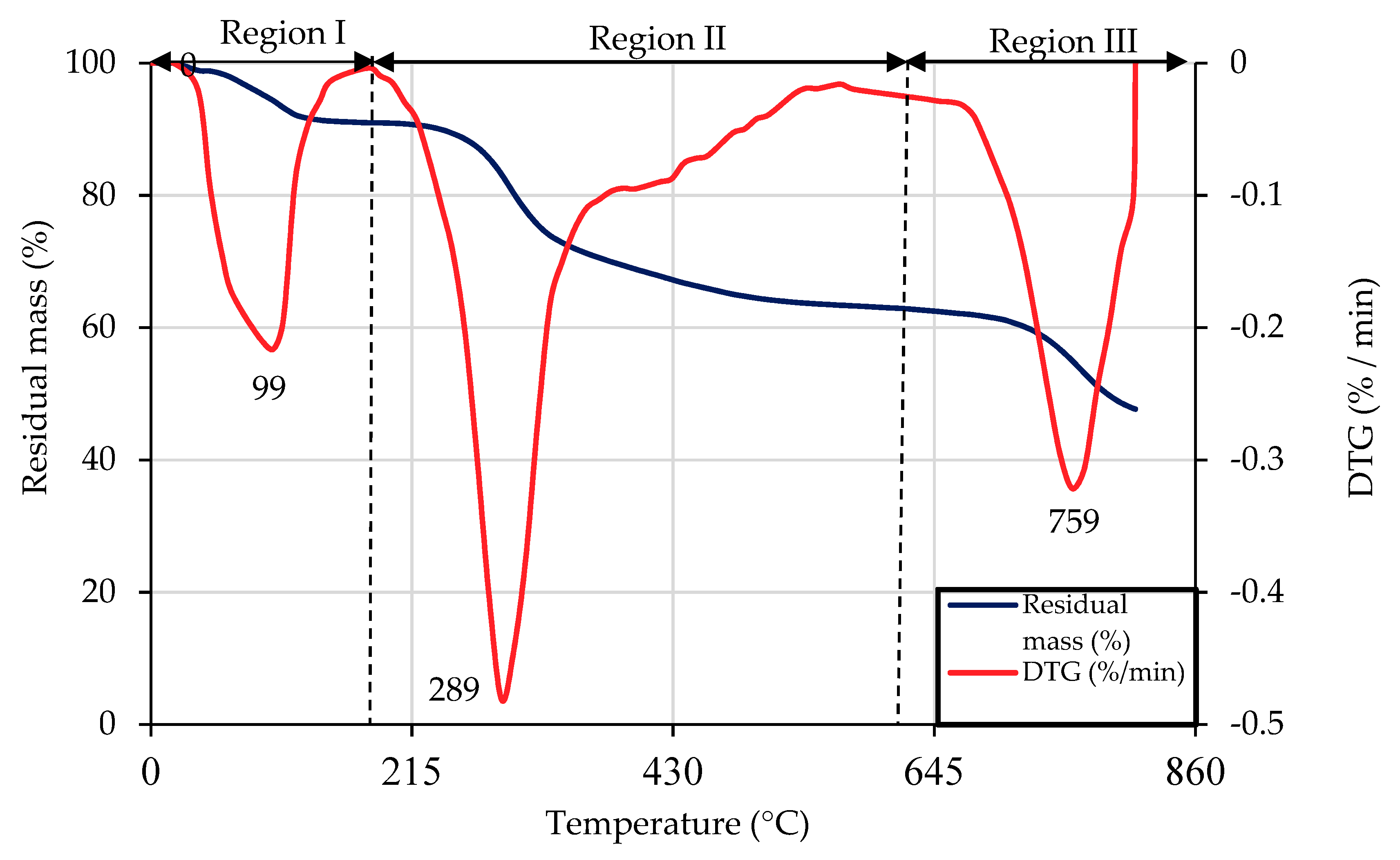

2.2. Thermogravimetric Analysis of RPM

2.3. Biochar Production and Characterization

2.4. Batch Nutrient Release Experiments

2.4.1. Effect of Contact Time

2.4.2. Effect of Initial Aqueous pH

2.4.3. Effect of RPM and RPM-Derived Biochars Doses

2.4.4. Successive Nutrient Release Experiments

2.5. Statistical Analysis

3. Results and Discussion

3.1. Thermogravimetric Analysis of Raw Poultry Manure

3.2. Characterization of Raw Poultry Manure and Biochars

3.3. Phosphorus and Potassium Release

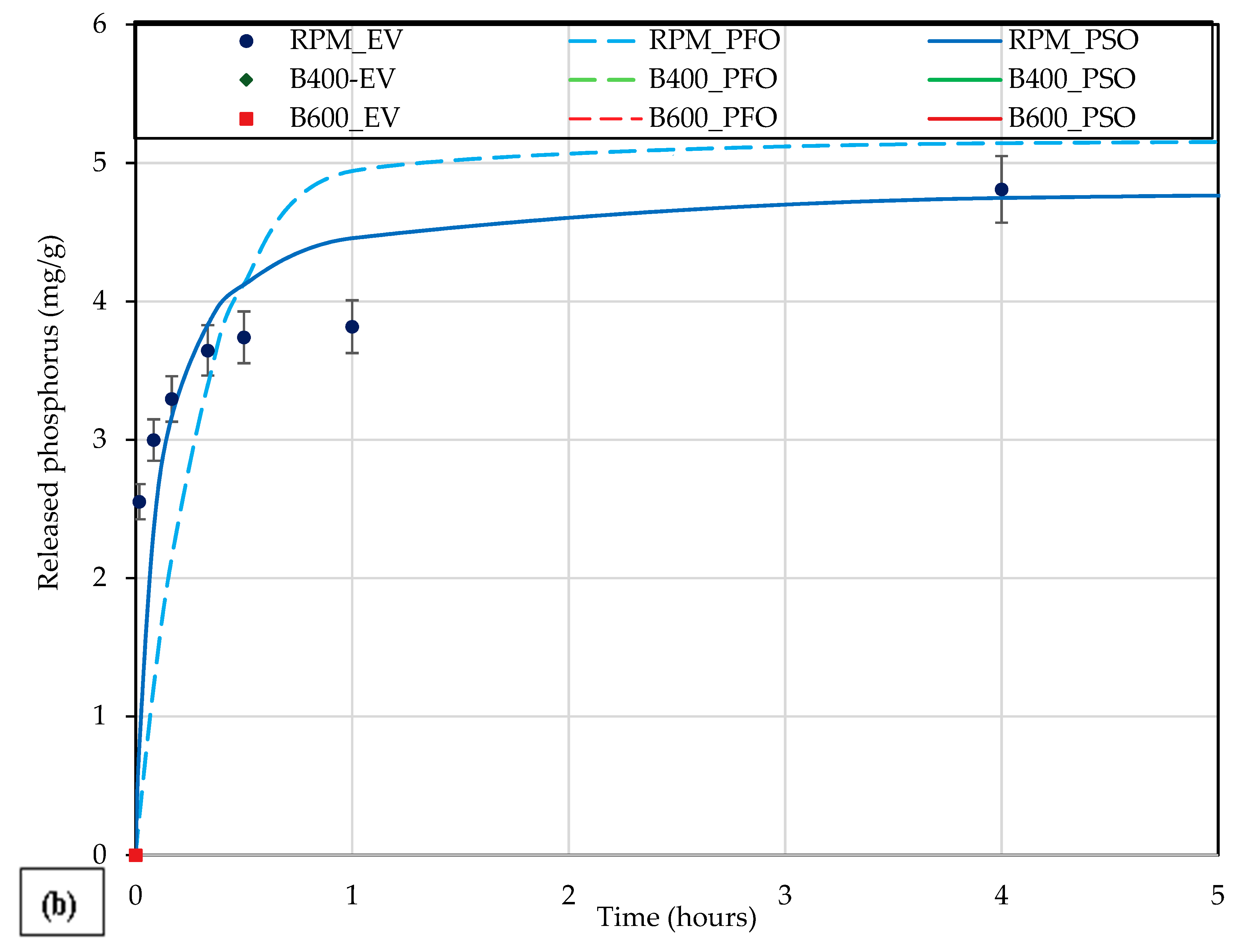

3.3.1. Effect of Contact Time—Kinetic Release Study

3.3.2. Effect of pH

3.3.3. Effect of Dose

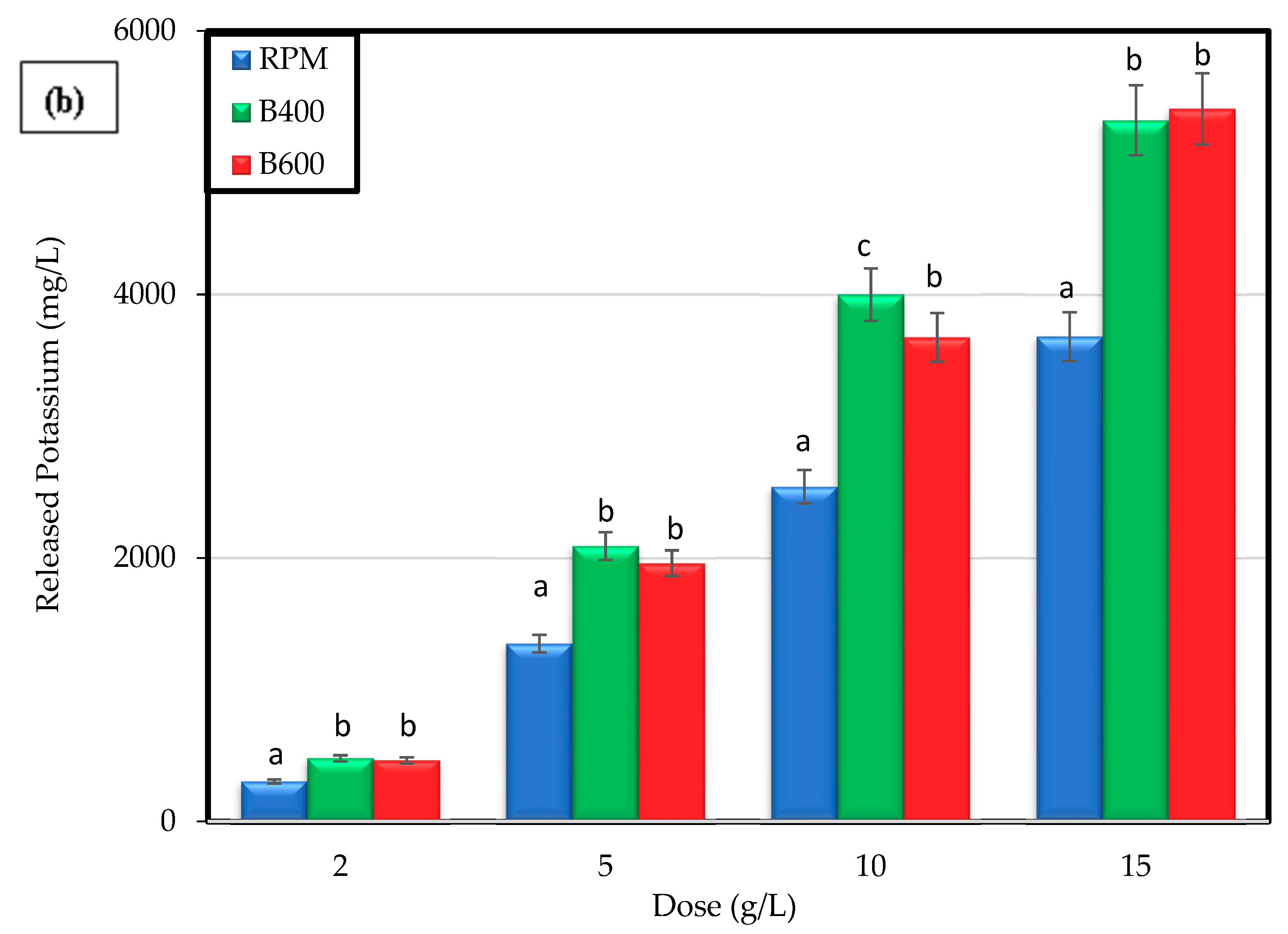

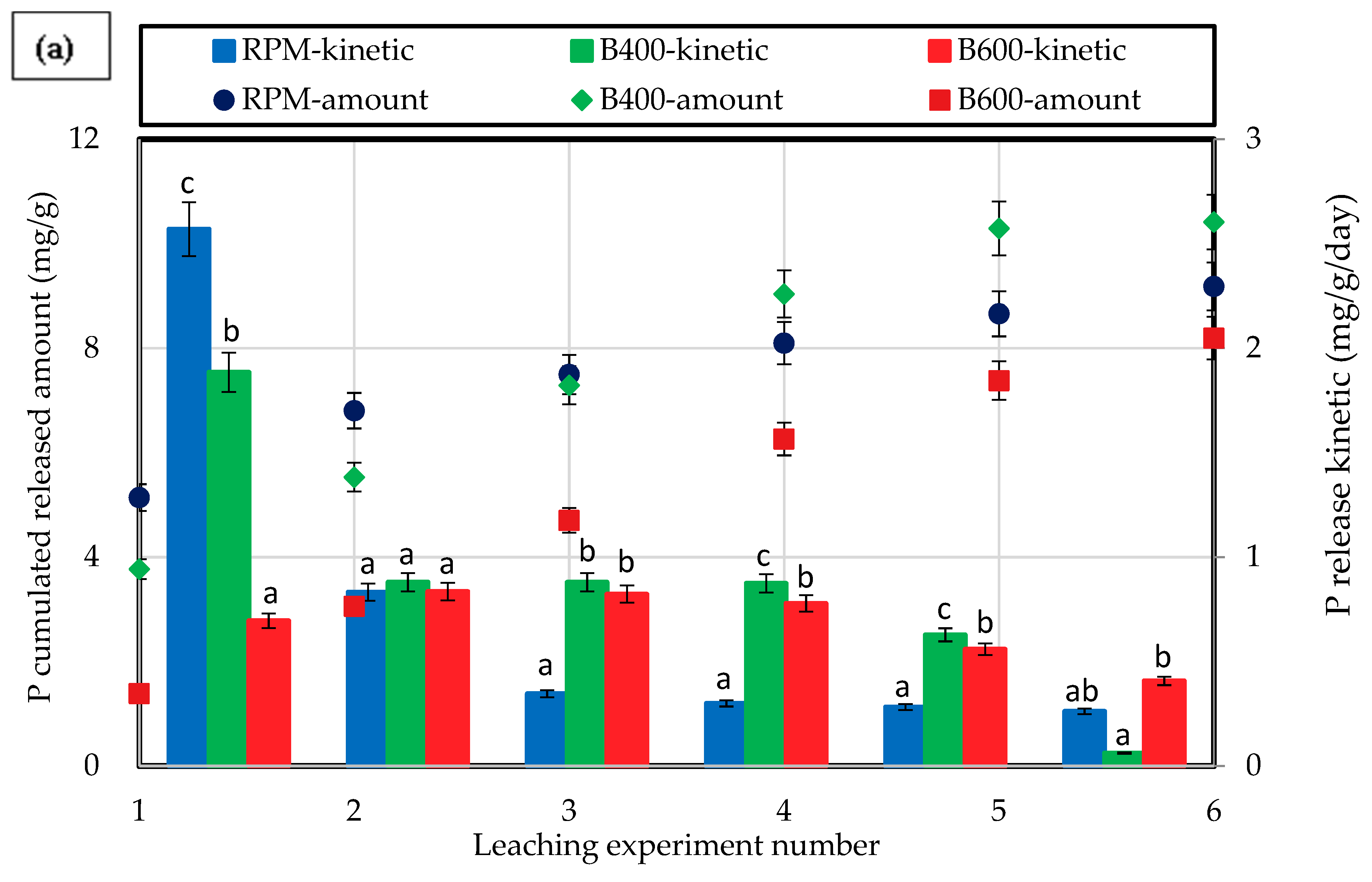

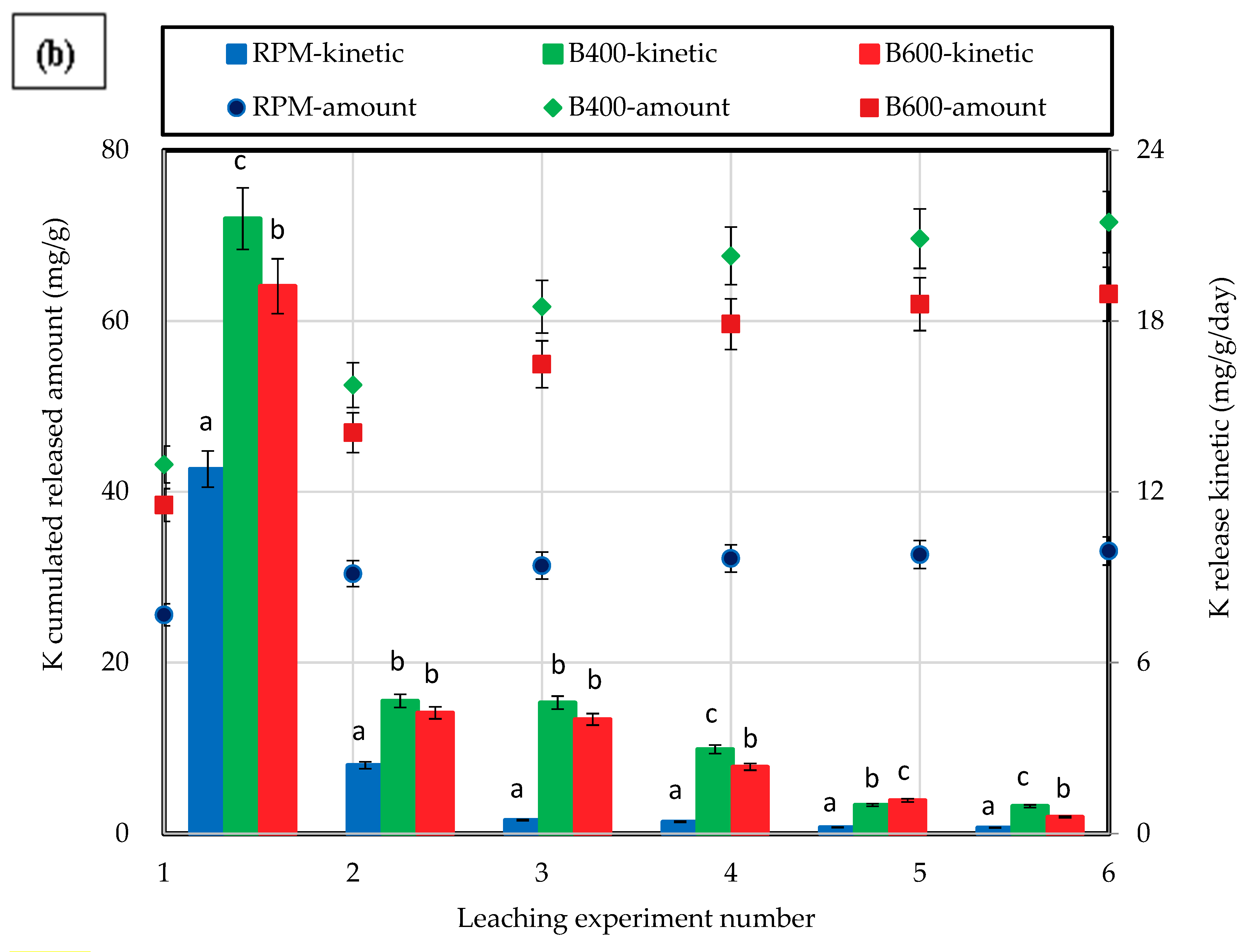

3.3.4. Successive Leaching Experiments—Nutrient Slow Release

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mante, O.D.; Agblevor, F.A. Influence of pine wood shavings on the pyrolysis of poultry litter. Waste Manag. 2010, 30, 2537–2547. [Google Scholar] [CrossRef] [PubMed]

- Akdeniz, N. A systematic review of biochar use in animal waste composting. Waste Manag. 2019, 88, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Sellami, F.; Jarboui, R.; Hachicha, S.; Medhioub, K.; Ammar, E. Co-composting of oil exhausted olive-cake, poultry manure and industrial residues of agro-food activity for soil amendment. Bioresour. Technol. 2008, 99, 1177–1188. [Google Scholar] [CrossRef] [PubMed]

- Turan, N.G. The effects of natural zeolite on salinity level of poultry litter compost. Bioresour. Technol. 2008, 99, 2097–2101. [Google Scholar] [CrossRef] [PubMed]

- Rodic, V.; Peric, L.; Djukic-Stojcic, M.; Vukelic, N. The environmental impact of poultry production. Biotechnol. Anim. Husb. 2011, 27, 1673–1679. [Google Scholar] [CrossRef]

- Lu, L.; Liao, X.D.; Luo, X.G. Nutritional strategies for reducing nitrogen, phosphorus and trace mineral excretions of livestock and poultry. J. Integr. Agric. 2017, 16, 2815–2833. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 2017, 107, 111–130. [Google Scholar] [CrossRef]

- Cely, P.; Gascó, G.; Paz-Ferreiro, J.; Méndez, A. Agronomic properties of biochars from different manure wastes. J. Anal. Appl. Pyrolysis 2015, 111, 173–182. [Google Scholar] [CrossRef]

- Lynch, D.; Henihan, A.M.; Kwapinski, W.; Zhang, L.; Leahy, J.J. Ash agglomeration and deposition during combustion of poultry litter in a bubbling fluidized-bed combustor. Energy Fuels 2013, 27, 4684–4694. [Google Scholar] [CrossRef]

- Taupe, N.C.; Lynch, D.; Wnetrzak, R.; Kwapinska, M.; Kwapinski, W.; Leahy, J.J. Updraft gasification of poultry litter at farm-scale—A case study. Waste Manag. 2016, 50, 324–333. [Google Scholar] [CrossRef]

- Kelleher, B.P.; O’Callaghan, M.N.; Leahy, M.J.; O’Dwyer, T.F.; Leahy, J.J. The use of fly ash from the combustion of poultry litter for the adsorption of chromium (III) from aqueous solution. J. Chem. Technol. Biotechnol. 2002, 77, 1212–1218. [Google Scholar] [CrossRef]

- Agyarko-Mintah, E.; Cowie, A.; Singh, B.P.; Joseph, S.; Van Zwieten, L.; Cowie, A.; Harden, S.; Smillie, R. Biochar increases nitrogen retention and lowers greenhouse gas emissions when added to composting poultry litter. Waste Manag. 2017, 61, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Wongrod, S.; Simon, S.; Guibaud, G.; Lens, P.N.L.; Pechaud, Y.; Huguenot, D.; van Hullebusch, E.D. Lead sorption by biochar produced from digestates: Consequences of chemical modification and washing. J. Environ. Manag. 2018, 219, 277–284. [Google Scholar] [CrossRef]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from biomass and waste. Waste Biomass Valoriz. 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Mau, V.; Gross, A. Energy conversion and gas emissions from production and combustion of poultry-litter-derived hydrochar and biochar. Appl. Energy 2018, 213, 510–519. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Biomass Pyrolysis: A Review of the Process Development and Challenges from Initial Researches up to the Commercialisation Stage. J. Energy Chem. 2019, 109–143. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, Y.; Liu, S.; Huang, X.; Li, Z.; Tan, X.; Zeng, G.; Zhou, L. Potential Benefits of Biochar in Agricultural Soils: A Review. Pedosphere 2017, 27, 645–661. [Google Scholar] [CrossRef]

- Shashvatt, U.; Benoit, J.; Aris, H.; Blaney, L. CO2-assisted phosphorus extraction from poultry litter and selective recovery of struvite and potassium struvite. Water Res. 2018, 143, 19–27. [Google Scholar] [CrossRef]

- Ghanim, B.M.; Pandey, D.S.; Kwapinski, W.; Leahy, J.J. Hydrothermal carbonisation of poultry litter: Effects of treatment temperature and residence time on yields and chemical properties of hydrochars. Bioresour. Technol. 2016, 216, 373–380. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jellali, S.; Akrout, H.; Assadi, A.A.; Bousselmi, L. Optimization of a cationic dye removal by a chemically modified agriculture by-product using response surface methodology: Biomasses characterization and adsorption properties. Environ. Sci. Pollut. Res. 2016, 24, 9831–9846. [Google Scholar] [CrossRef]

- Abdallah, M.M.; Ahmad, M.N.; Walker, G.; Leahy, J.J.; Kwapinski, W. Batch and Continuous Systems for Zn, Cu, and Pb Metal Ions Adsorption on Spent Mushroom Compost Biochar. Ind. Eng. Chem. Res. 2019, 58, 7296–7307. [Google Scholar] [CrossRef]

- Song, W.; Guo, M. Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2012, 94, 138–145. [Google Scholar] [CrossRef]

- Trazzi, P.A.; Leahy, J.J.; Hayes, M.H.B.; Kwapinski, W. Adsorption and desorption of phosphate on biochars. J. Environ. Chem. Eng. 2016, 4, 37–46. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Y.; Chiu, P.C.; Imhoff, P.T.; Guo, M. Phosphorus release behaviors of poultry litter biochar as a soil amendment. Sci. Total Environ. 2015, 512–513, 454–463. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Cao, X.; Zhao, L.; Xu, X.; Harris, W. Phosphorus Release from Dairy Manure, the Manure-Derived Biochar, and Their Amended Soil: Effects of Phosphorus Nature and Soil Property. J. Environ. Qual. 2014, 43, 1504–1509. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jellali, S.; Assadi, A.A.; Bousselmi, L. Chemical treatment of orange tree sawdust for a cationic dye enhancement removal from aqueous solutions: Kinetic, equilibrium and thermodynamic studies. Desalin. Water Treat. 2016, 57, 22107–22119. [Google Scholar] [CrossRef]

- Haddad, K.; Jellali, S.; Jeguirim, M.; Ben Hassen Trabelsi, A.; Limousy, L. Investigations on phosphorus recovery from aqueous solutions by biochars derived from magnesium-pretreated cypress sawdust. J. Environ. Manag. 2018, 216, 305–314. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, B. Investigation of thermodynamic parameters in the pyrolysis conversion of biomass and manure to biochars using thermogravimetric analysis. Bioresour. Technol. 2013, 146, 485–493. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, X.; Mašek, O.; Zimmerman, A. Heterogeneity of biochar properties as a function of feedstock sources and production temperatures. J. Hazard. Mater. 2013, 256–257, 1–9. [Google Scholar] [CrossRef]

- Cimo, G.; Kucerik, J.; Berns, A.E.; Schaumann, G.E.; Alonzo, G.; Conte, P. Effect of Heating Time and Temperature on the Chemical Characteristics of Biochar from Poultry Manure. J. Agric. Food Chem. 2014, 62, 1912–1918. [Google Scholar] [CrossRef] [Green Version]

- Bekiaris, G.; Peltre, C.; Jensen, L.S.; Bruun, S. Using FTIR-photoacoustic spectroscopy for phosphorus speciation analysis of biochars. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 168, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Kalderis, D.; Hawthorne, S.B.; Clifford, A.A.; Gidarakos, E. Interaction of soil, water and TNT during degradation of TNT on contaminated soil using subcritical water. J. Hazard. Mater. 2008, 159, 329–334. [Google Scholar] [CrossRef] [PubMed]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 2014, 11, 6613–6621. [Google Scholar] [CrossRef] [Green Version]

- Haddad, K.; Jellali, S.; Jaouadi, S.; Benltifa, M.; Mlayah, A.; Hamzaoui, A.H. Raw and treated marble wastes reuse as low cost materials for phosphorus removal from aqueous solutions: Efficiencies and mechanisms. C. R. Chim. 2015, 18, 75–87. [Google Scholar] [CrossRef]

- Cao, X.; Harris, W. Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour. Technol. 2010, 101, 5222–5228. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Y.; Cheng, L.; Andserson, B.; Zhao, X.; Wang, D.; Ding, A. ScienceDirect Review on utilization of biochar for metal-contaminated soil and sediment remediation. J. Environ. Sci. 2017, 63, 156–173. [Google Scholar] [CrossRef]

- Novais, S.V.; Zenero, M.D.O.; Barreto, M.S.C.; Montes, C.R.; Cerri, C.E.P. Phosphorus removal from eutrophic water using modified biochar. Sci. Total Environ. 2018, 633, 825–835. [Google Scholar] [CrossRef]

- Novak, J.M.; Busscher, W.J.; Laird, D.L.; Ahmedna, M.; Watts, D.W.; Niandou, M.A.S. Impact of Biochar Amendment on Fertility of a Southeastern Coastal Plain Soil. Soil Sci. 2009, 174, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Cantrell, K.B.; Hunt, P.G.; Uchimiya, M.; Novak, J.M.; Ro, K.S. Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 2012, 107, 419–428. [Google Scholar] [CrossRef]

- Chen, X.; Lin, Q.; He, R.; Zhao, X.; Li, G. Hydrochar production from watermelon peel by hydrothermal carbonization. Bioresour. Technol. 2017, 241, 236–243. [Google Scholar] [CrossRef]

- Domingues, R.R.; Trugilho, P.F.; Silva, C.A.; De Melo, I.C.N.A.; Melo, L.C.A.; Magriotis, Z.M.; Sánchez-Monedero, M.A. Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS ONE 2017, 12, e0176884. [Google Scholar] [CrossRef] [PubMed]

- Enders, A.; Hanley, K.; Whitman, T.; Joseph, S.; Lehmann, J. Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour. Technol. 2012, 114, 644–653. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Cao, C.; Guo, L.; Jin, H.; Dargusch, M.; Bernhardt, D.; Yao, X. Hydrogen production from supercritical water gasification of chicken manure. Int. J. Hydrogen Energy 2016, 41, 22722–22731. [Google Scholar] [CrossRef]

- Mau, V.; Quance, J.; Posmanik, R.; Gross, A. Phases’ characteristics of poultry litter hydrothermal carbonization under a range of process parameters. Bioresour. Technol. 2016, 219, 632–642. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Hoon, S.; Jung, S.; Ryu, C.; Jeon, J.; Shin, M.; Park, Y. Production and utilization of biochar: A review. J. Ind. Eng. Chem. 2016, 40, 1–15. [Google Scholar]

- Xiao, R.; Wang, J.J.; Gaston, L.A.; Zhou, B.; Park, J.H.; Li, R.; Dodla, S.K.; Zhang, Z. Biochar produced from mineral salt-impregnated chicken manure: Fertility properties and potential for carbon sequestration. Waste Manag. 2018, 78, 802–810. [Google Scholar] [CrossRef]

- Halajnia, A.; Oustan, S.; Najafi, N.; Khataee, A.R.; Lakzian, A. Adsorption-desorption characteristics of nitrate, phosphate and sulfate on Mg-Al layered double hydroxide. Appl. Clay Sci. 2013, 80–81, 305–312. [Google Scholar] [CrossRef]

- Peak, D.; Sims, J.T.; Sparks, D.L. Solid-state speciation of natural and alum-amended poultry litter using XANES spectroscopy. Environ. Sci. Technol. 2002, 36, 4253–4261. [Google Scholar] [CrossRef]

- Barca, C.; Gérente, C.; Meyer, D.; Chazarenc, F.; Andrès, Y. Phosphate removal from synthetic and real wastewater using steel slags produced in Europe. Water Res. 2012, 46, 2376–2384. [Google Scholar] [CrossRef]

- Mukherjee, A.; Zimmerman, A.R. Organic carbon and nutrient release from a range of laboratory-produced biochars and biochar-soil mixtures. Geoderma 2013, 193, 122–130. [Google Scholar] [CrossRef]

- Liu, G.; Zotarelli, L.; Li, Y.; Dinkins, D.; Wang, Q. Controlled-Release and Slow-Release Fertilizers as Nutrients Management Tools; UF/IFAS Extension: Gainesville, FL, USA, 2017. [Google Scholar]

- Sun, K.; Qiu, M.; Han, L.; Jin, J.; Wang, Z.; Pan, Z.; Xing, B. Speciation of phosphorus in plant- and manure-derived biochars and its dissolution under various aqueous conditions. Sci. Total Environ. 2018, 634, 1300–1307. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schulz, H.; Glaser, B. Effects of biochar compared to organic and inorganic fertilizers on soil quality and plant growth in a greenhouse experiment. J. Plant Nutr. Soil Sci. 2012, 175, 410–422. [Google Scholar] [CrossRef]

| Physico-Chemical Property | RPM | B400 | B600 |

|---|---|---|---|

| Grains Size Distribution | |||

| d10 (mm) | 0.21 | 0.16 | 0.19 |

| d50 (mm) | 0.48 | 0.43 | 0.31 |

| d60 (mm) | 0.57 | 0.44 | 0.33 |

| Uniformity coefficient (UC = d60/d10) | 2.71 | 2.75 | 1.74 |

| Surface area (m2 g−1) | |||

| BET | 0.88 | 4.30 | 5.34 |

| Charges density | |||

| pHZC | 9.09 ± 0.03 a | 10.87 ± 0.008 b | 11.47 ± 0.015 c |

| Ultimate Analysis (%)* | |||

| C | 25.56 ± 1.39 b | 22.04 ± 1.75 ab | 21.22 2.30a |

| H | 3.27 ± 0.79 b | 0.87 ± 0.015 a | 0.54 ± 0.04 a |

| N | 2.19 ± 0.17 b | 0.95 ± 0.19 a | 0.64 ± 0.11 a |

| S | 0.69 ± 0.0.17 a | 0.68 ± 0.46 a | 0.66 ± 0.005 a |

| O | 69.35± 2.43 a | 75.45 ± 2.31 b | 76.90 ± 2.38 b |

| C/H | 6.87 ± 1.85 a | 25.33 ± 1.59 b | 35.53 ± 7.61 c |

| Mineral Composition (mg g−1) | |||

| Al | 15.97 | 18.30 | 23.22 |

| Fe | 2.24 | 3.46 | 3.68 |

| K | 38.12 | 71.95 | 66.23 |

| Mg | 4.62 | 6.64 | 7.11 |

| Na | 18.98 | 20.17 | 28.67 |

| P | 17.00 | 20.33 | 43.17 |

| Si | 265.81 | 277.85 | 390.95 |

| Ti | 0.37 | 0.39 | 0.51 |

| Proximate Analysis (%)* | |||

| Moisture | 16.69 ± 0.04 b | 0.76 ± 0.09 a | 0.80 ± 0.04 a |

| Ash | 51.35 ± 0.38 a | 78.64 ± 0.62 b | 79.74 ± 0.18 c |

| Volatile matter | 36.34 ± 0.18 b | 4.08 ± 0.12 a | 3.95 ± 0.13 a |

| Fixed carbon | 11.99 ± 0.05 a | 17.72 ± 0.13 c | 16.18 ± 0.24 b |

| Solid Support | Pseudo-First-Order Model (PFO) | Pseudo-Second-Order Model (PSO) | ||||

|---|---|---|---|---|---|---|

| K1.PFO (h−1) | R2PFO | APEPFO (%) | K2.PSO (g mg −1 h−1) | R2PSO | APEPSO (%) | |

| RPM | 3.238 | 0.786 | 23.714 | 2.318 | 0.867 | 14.467 |

| B400 | 3.242 | 0.822 | 23.431 | 1.435 | 0.879 | 17.766 |

| B600 | 1.688 | 0.734 | 29.566 | 4.602 | 0.836 | 19.860 |

| Solid Support | Pseudo-First-Order Model (PFO) | Pseudo-Second-Order Model (PSO) | ||||

|---|---|---|---|---|---|---|

| K1.PFO (h−1) | R2PFO | APEPFO (%) | K2.PSO (g mg−1 h−1) | R2PSO | APEPSO (%) | |

| RPM | 3.618 | 0.474 | 27.130 | 1.087 | 0.743 | 17.837 |

| B400 | 2.886 | 0.668 | 26.199 | 0.150 | 0.750 | 19.517 |

| B600 | 0.039 | 0.422 | 56.748 | 0.109 | 0.995 | 1.737 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadroug, S.; Jellali, S.; Leahy, J.J.; Kwapinska, M.; Jeguirim, M.; Hamdi, H.; Kwapinski, W. Pyrolysis Process as a Sustainable Management Option of Poultry Manure: Characterization of the Derived Biochars and Assessment of their Nutrient Release Capacities. Water 2019, 11, 2271. https://doi.org/10.3390/w11112271

Hadroug S, Jellali S, Leahy JJ, Kwapinska M, Jeguirim M, Hamdi H, Kwapinski W. Pyrolysis Process as a Sustainable Management Option of Poultry Manure: Characterization of the Derived Biochars and Assessment of their Nutrient Release Capacities. Water. 2019; 11(11):2271. https://doi.org/10.3390/w11112271

Chicago/Turabian StyleHadroug, Samar, Salah Jellali, James J. Leahy, Marzena Kwapinska, Mejdi Jeguirim, Helmi Hamdi, and Witold Kwapinski. 2019. "Pyrolysis Process as a Sustainable Management Option of Poultry Manure: Characterization of the Derived Biochars and Assessment of their Nutrient Release Capacities" Water 11, no. 11: 2271. https://doi.org/10.3390/w11112271

APA StyleHadroug, S., Jellali, S., Leahy, J. J., Kwapinska, M., Jeguirim, M., Hamdi, H., & Kwapinski, W. (2019). Pyrolysis Process as a Sustainable Management Option of Poultry Manure: Characterization of the Derived Biochars and Assessment of their Nutrient Release Capacities. Water, 11(11), 2271. https://doi.org/10.3390/w11112271