The Effect of Wood Species on Fine Particle and Gaseous Emissions from a Modern Wood Stove

Abstract

1. Introduction

2. Materials and Methods

2.1. Combustion Facility

2.2. Combustion Appliance

2.3. Operational Practices and Characteristics of Wood Species

2.4. Emission Measurements and Analyses

2.4.1. Particle Sampling, Measurement and Analysis

2.4.2. Gas Analysis

2.5. Data Analysis

3. Results and Discussion

3.1. Combustion Conditions, Temperatures and Thermal Efficiency

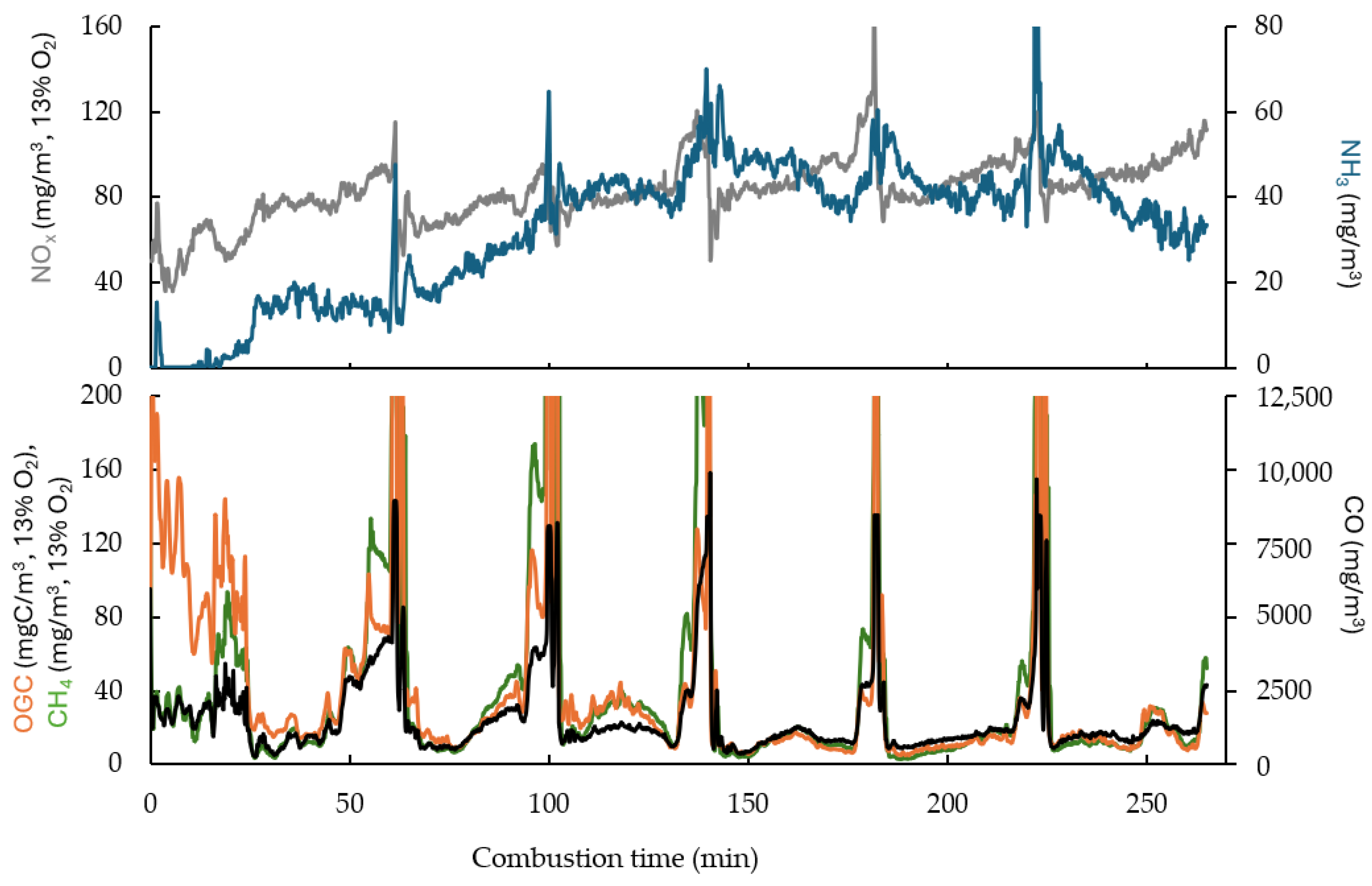

3.2. Gaseous Emissions

3.2.1. Carbon Monoxide

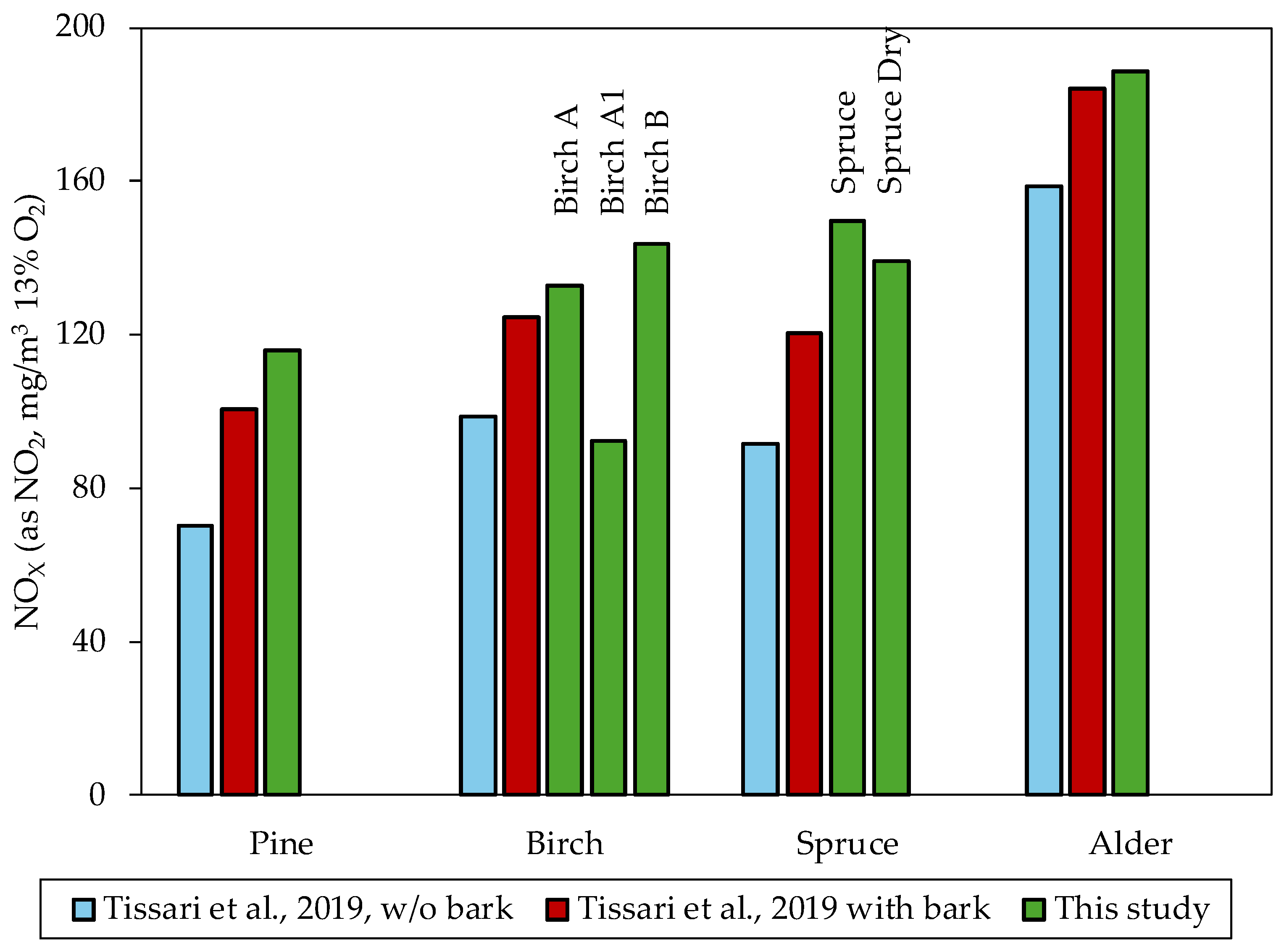

3.2.2. Nitrogen Oxides and Ammonium

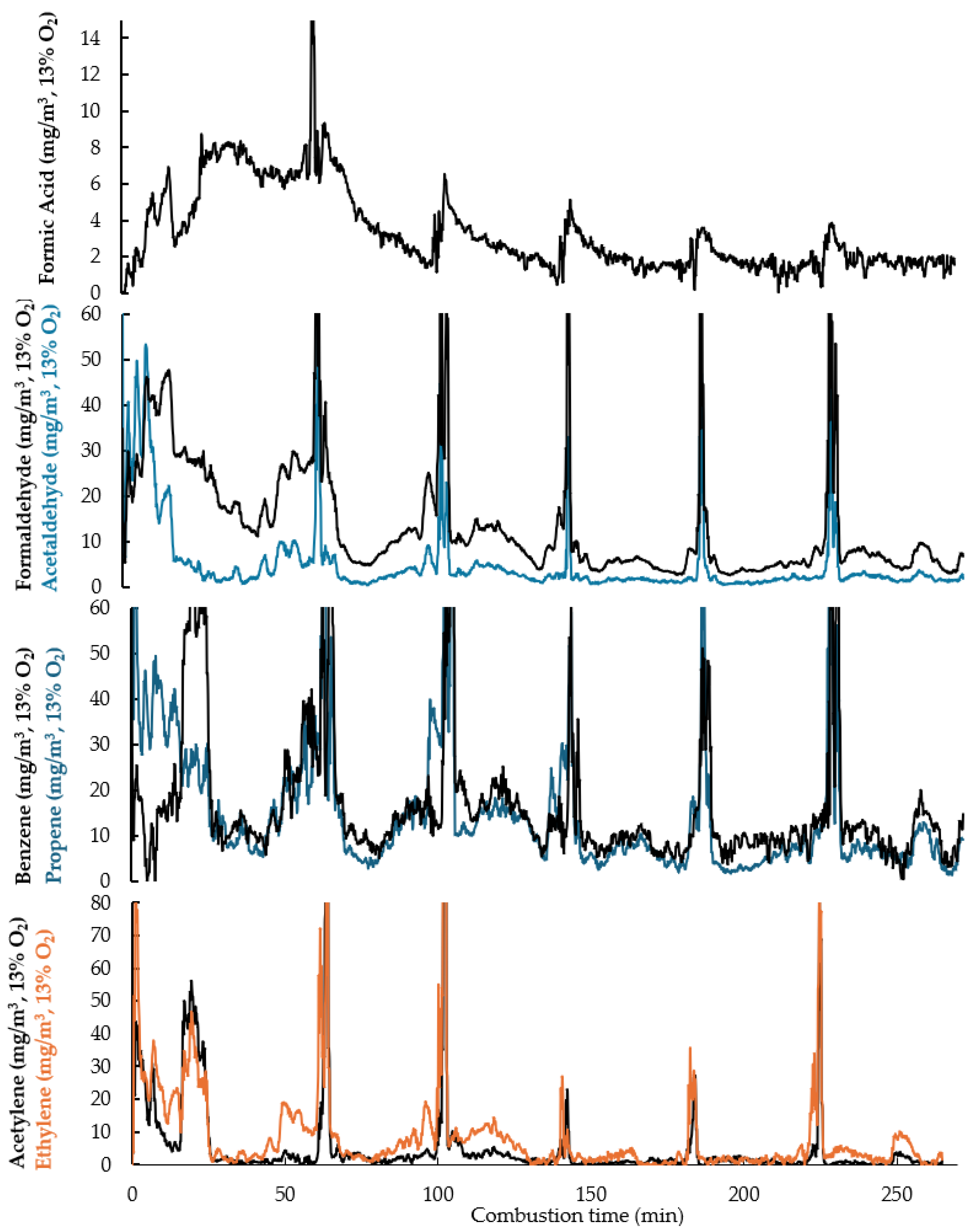

3.2.3. Organic Gaseous Compounds and Single VOC Compounds

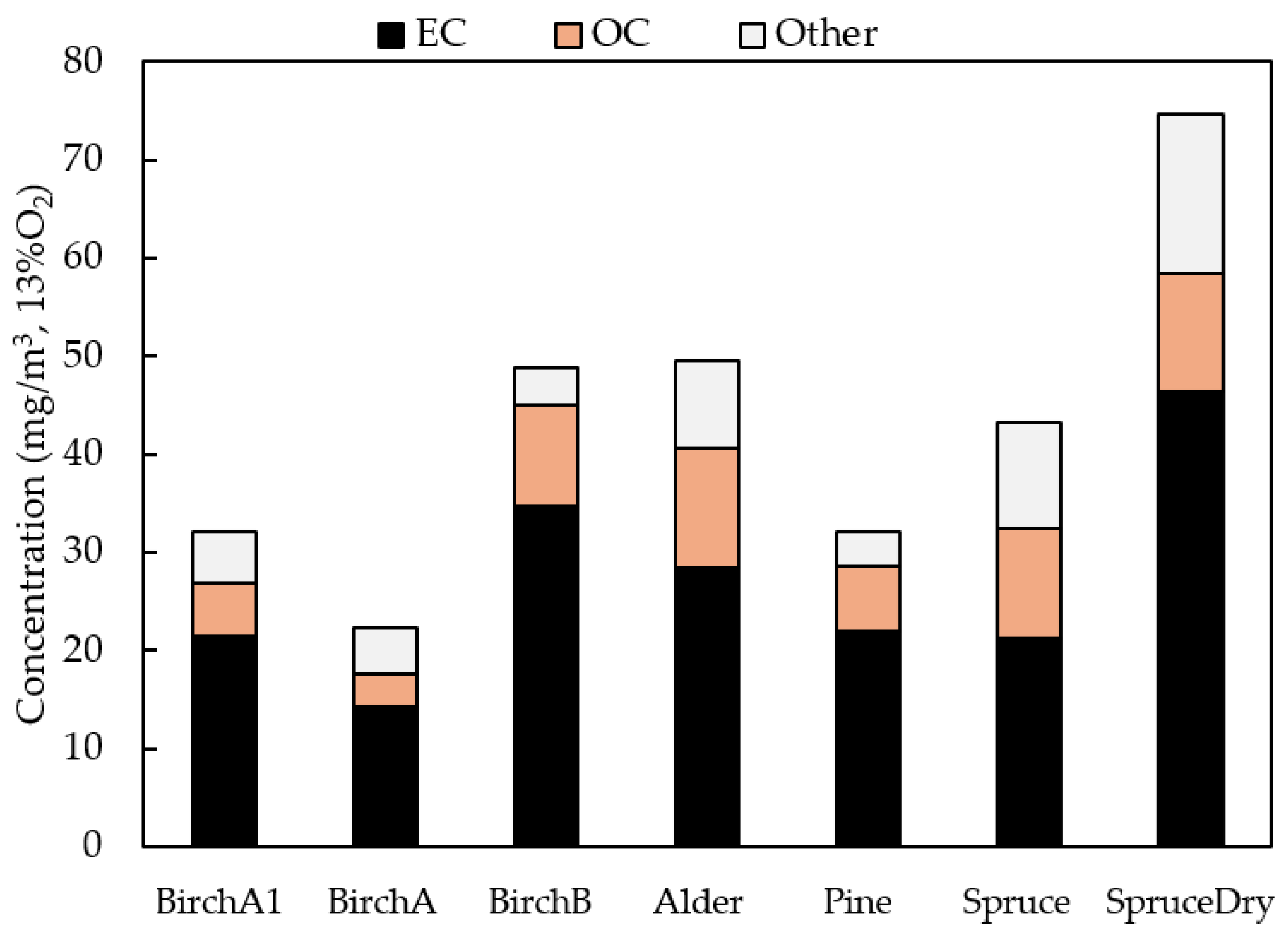

3.3. Fine Particles

3.3.1. Average Values of Particle Parameters

3.3.2. Behavior of Particle Concentration between Different Batches

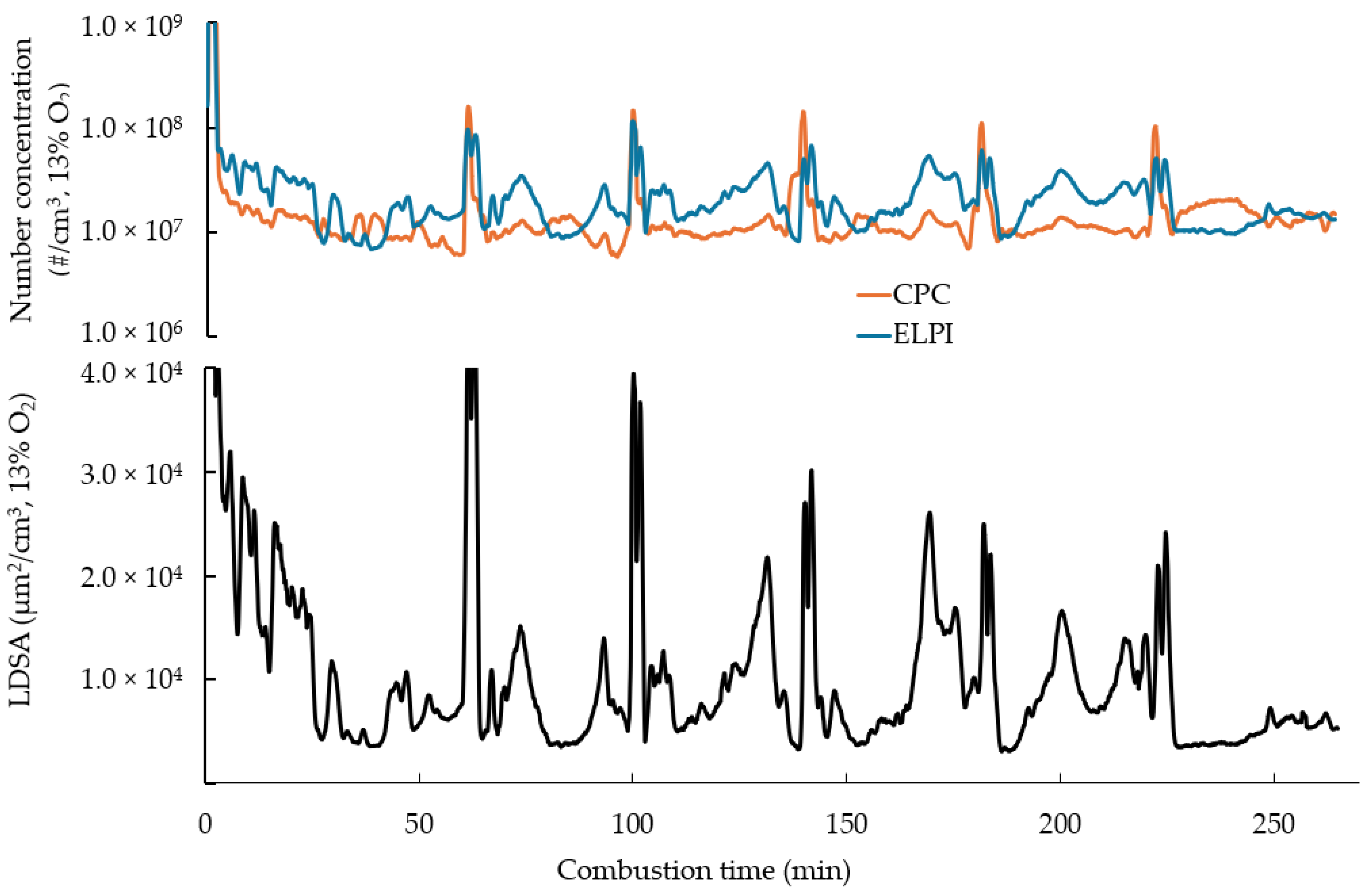

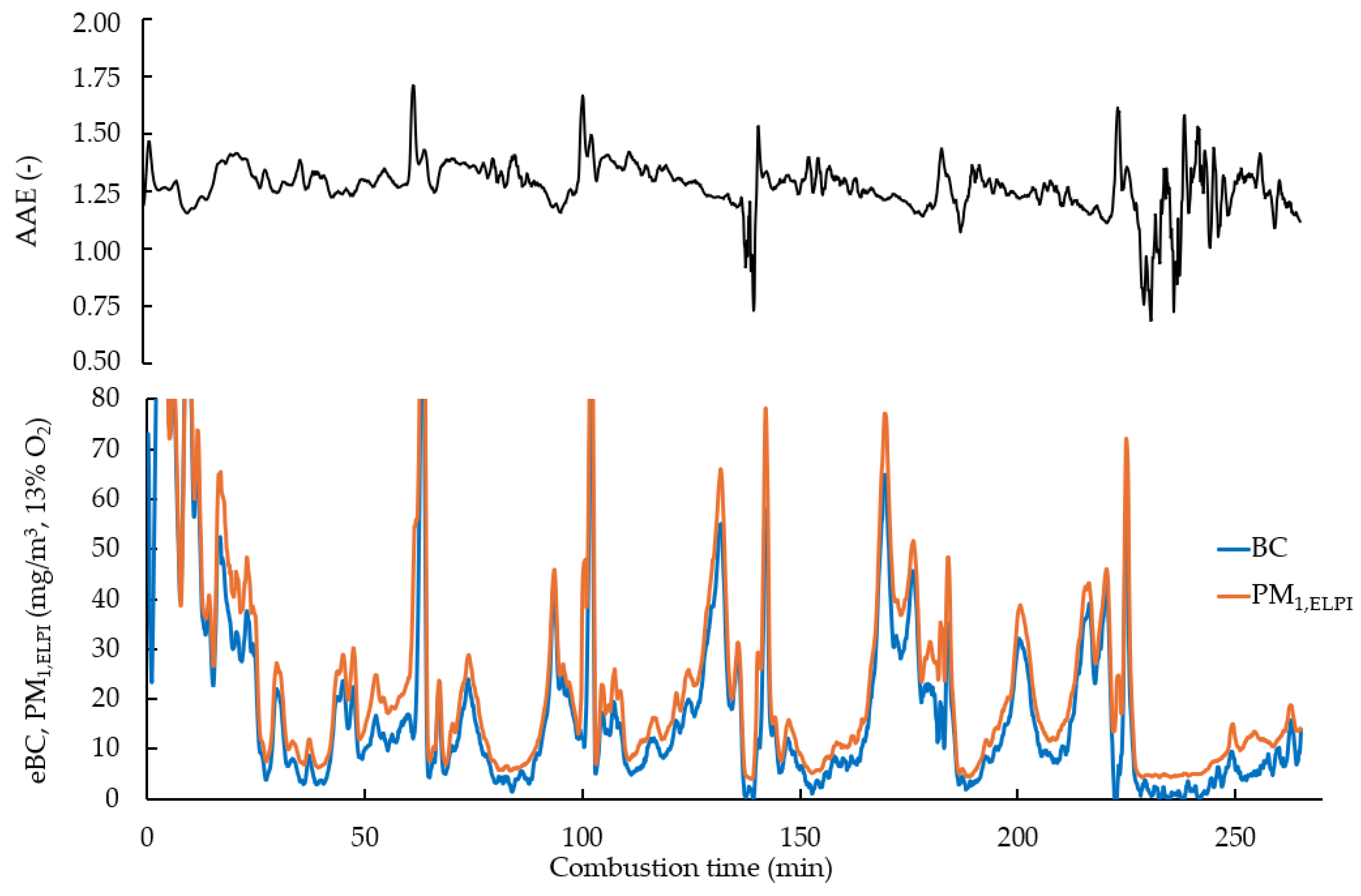

3.3.3. Real-Time Particle Concentrations

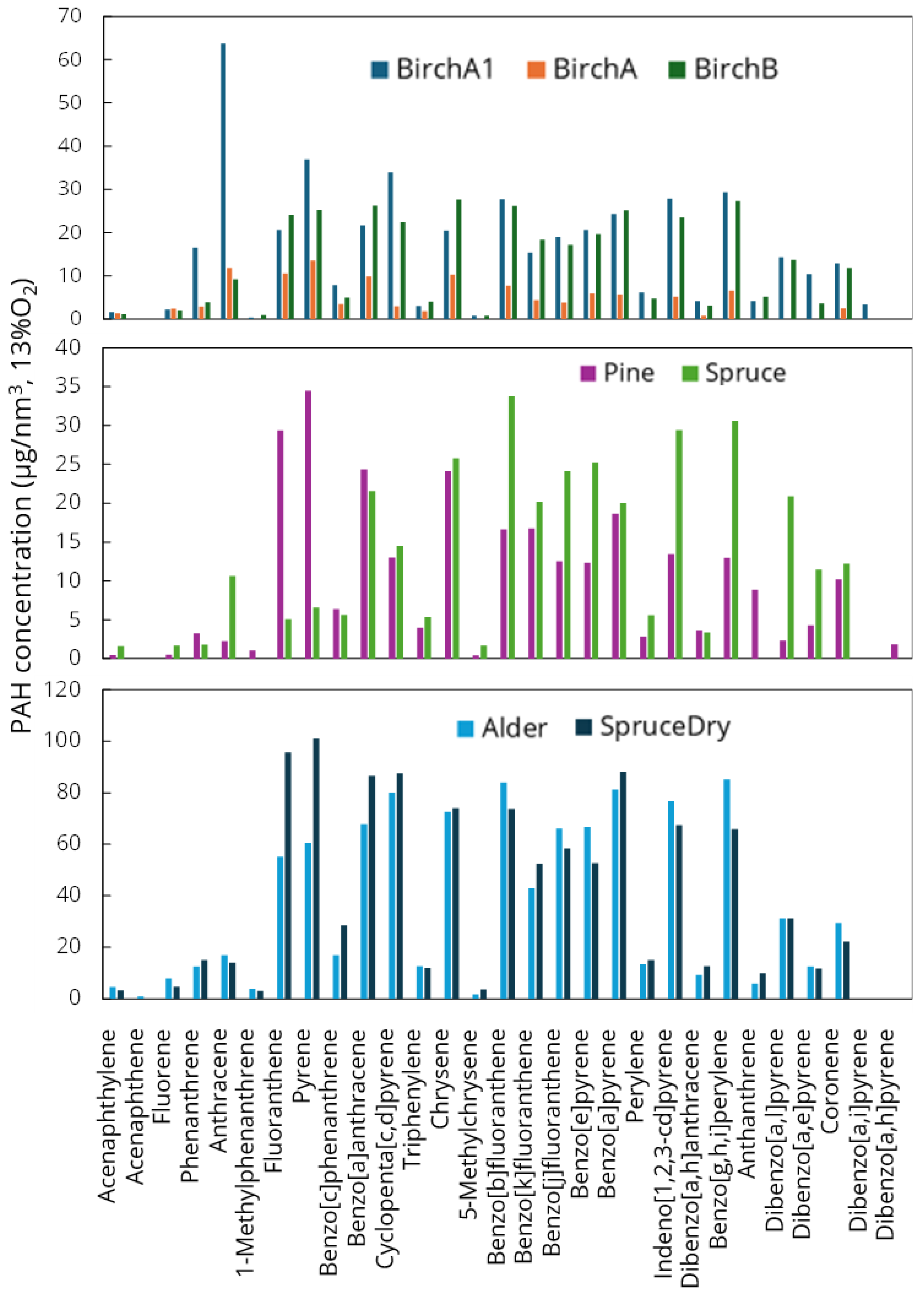

3.3.4. PAH Concentrations

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deutsche Umwelthilfe. Residential Wood Burning—Environmental Impact and Sustainable Solutions. Background Paper of Clean Heat-Project 2016. Available online: https://www.clean-heat.eu/en/actions/info-material/download/background-paper-residential-/ (accessed on 12 June 2024).

- Vicente, E.D.; Alves, C.A. An overview of particulate emissions from residential biomass combustion. Atmos. Res. 2018, 199, 159–185. [Google Scholar] [CrossRef]

- Savolahti, M.; Karvosenoja, N.; Soimakallio, S.; Kupiainen, K.; Tissari, J.; Paunu, V.-V. Near-term climate impacts of Finnish residential wood combustion. Energy Policy 2019, 133, 110837. [Google Scholar] [CrossRef]

- Allen, S.A.A.; Ree, A.G.; Ayodeji, S.A.M.; Deborah, S.A.E.; Ejike, O.M. Secondary inorganic aerosols: Impacts on the global climate system and human health. Biodivers. Int. J. 2019, 3, 249–259. [Google Scholar] [CrossRef]

- Bruns, E.A.; El Haddad, I.; Slowik, J.G.; Kilic, D.; Klein, F.; Baltensperger, U.; Prévôt, A.S.H. Identification of significant precursor gases of secondary organic aerosols from residential wood combustion. Sci. Rep. 2016, 6, 27881. [Google Scholar] [CrossRef] [PubMed]

- Hartikainen, A.; Tiitta, P.; Ihalainen, M.; Yli-Pirilä, P.; Orasche, J.; Czeck, H.; Kortelainen, M.; Lamberg, H.; Suhonen, H.; Koponen, H.; et al. Photochemical transformation of residential wood combustion emissions: Dependence of organic aerosol composition on OH exposure. Atmos. Chem. Phys. 2020, 20, 6357–6378. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Residential Heating with Wood and Coal: Health Impacts and Policy Options in Europe and North America. WHO Publication 2015. Available online: https://iris.who.int/bitstream/handle/10665/153671/9789289050760-eng.pdf?sequence=3 (accessed on 13 June 2024).

- Naeher, L.P.; Brauer, M.; Lipsett, M.; Zelikoff, J.T.; Simpson, C.D.; Koenig, J.Q.; Smith, K.R. Woodsmoke health effects: A review. Inhal. Toxicol. 2007, 19, 67–106. [Google Scholar] [CrossRef] [PubMed]

- Guercio, V.; Doutsi, A.; Exley, K.S. A systematic review on solid fuel combustion exposure and respiratory health in adults in Europe, USA, Canada, Australia and New Zealand. Int. J. Hyg. Environ. Health 2022, 241, 113926. [Google Scholar] [CrossRef] [PubMed]

- Olsen, Y.; Nøjgaard, J.K.; Olesen, H.R.; Brandt, J.; Sigsgaard, T.; Pryor, S.C.; Ancelet, T.; Viana, M.d.M.; Querol, X.; Hertel, O. Emissions and source allocation of carbonaceous air pollutants from wood stoves in developed countries: A review. Atmos. Pollut. Res. 2020, 11, 234–251. [Google Scholar] [CrossRef]

- Uski, O.; Jalava, P.I.; Happo, M.S.; Leskinen, J.; Sippula, O.; Tissari, J.; Mäki-Paakkanen, J.; Jokiniemi, J.; Hirvonen, M.-R. Different toxic mechanisms are activated by emission PM depending on combustion efficiency. Atmos. Environ. 2014, 89, 623–632. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Europe’s Air Quality Status 2024. Report 2024. Available online: https://www.eea.europa.eu//publications/europes-air-quality-status-2024 (accessed on 13 June 2024).

- Jakobson, M.Z. Short-term effects of controlling fossil-fuel soot, biofuel soot and gases, and methane on climate, Arctic ice, and air pollution health. J. Geophys. Res. 2010, 115, D14209. [Google Scholar] [CrossRef]

- Tissari, J. Fine Particle Emissions from Residential Wood Combustion. Ph.D. Thesis, University of Kuopio, Kuopio, Finland, 2008. [Google Scholar]

- Kortelainen, M.; Jokiniemi, J.; Tiitta, P.; Tissari, J.; Lamberg, H.; Leskinen, J.; Rodriguez, J.G.-L.; Koponen, H.; Antikainen, S.; Nuutinen, I.; et al. Time-resolved chemical composition of small-scale batch combustion emissions from various wood species. Fuel 2018, 233, 224–236. [Google Scholar] [CrossRef]

- Väätäinen, S.; Leskinen, J.; Lamberg, H.; Koponen, H.; Kortelainen, M.; Sippula, O.; Tissari, J. The effects of air staging and combustion air control on black carbon and other particulate and gaseous emissions from a sauna stove. Fuel 2023, 331, 125769. [Google Scholar] [CrossRef]

- Tissari, J.; Hytönen, K.; Sippula, O.; Jokiniemi, J. The effects of operating conditions on emissions from masonry heaters and sauna stoves. Biomass Bioenergy 2009, 33, 513–520. [Google Scholar] [CrossRef]

- Shen, G.; Xue, M.; Wei, S.; Chen, Y.; Zhao, Q.; Li, B.; Wu, H.; Tao, S. Influence of fuel moisture, charge size, feeding rate and air ventilation conditions on the emissions of PM, OC, EC, parent PAHs, and their derivatives from residential wood combustion. J. Environ. Sci. 2013, 25, 1808–1816. [Google Scholar] [CrossRef]

- McDonald, J.D.; Zielinska, B.; Fujita, E.M.; Sagebiel, J.C.; Chow, J.C.; Watson, J.G. Fine particle and gaseous emission rates from residential wood combustion. Environ. Sci. Technol. 2000, 34, 2080–2091. [Google Scholar] [CrossRef]

- Rogge, W.F.; Hildemann, L.M.; Mazurek, M.A.; Cass, G.R. Sources of fine organic aerosol. 9. pine, oak, and synthetic log combustion in residential fireplaces. Environ. Sci. Technol. 1998, 32, 13–22. [Google Scholar] [CrossRef]

- Morin, B.; Allen, G.; Marin, A.; Rector, L.; Ahmadi, M. Impacts of wood species and moisture content on emissions from residential wood heaters. J. Air Waste Manag. Assoc. 2022, 72, 647–661. [Google Scholar] [CrossRef]

- Amaral, S.S.; de Carvalho Junior, J.A.; Costa, M.A.M.; Neto, T.G.S.; Dellani, R.; Leite, L.H.S. Comparative study for hardwood and softwood forest biomass: Chemical characterization, combustion phases and gas and particulate matter emissions. Bioresour. Technol. 2014, 164, 55–63. [Google Scholar] [CrossRef]

- Cereceda-Balic, F.; Toledo, M.; Vidal, V.; Guerrero, F.; Diaz-Robles, L.A.; Petit-Breuilh, X.; Lapuerta, M. Emission factors for PM2.5, CO, CO2, NOX, SO2 and particle size distributions from the combustion of wood species using a new controlled combustion chamber 3CE. Sci. Total Environ. 2017, 584–585, 901–910. [Google Scholar] [CrossRef]

- Fernandes, A.P.; Alves, C.A.; Gonalves, C.; Tarelho, L.; Pio, C.; Schimdl, C.; Bauer, H. Emission factors from residential combustion appliances burning Portuguese biomass fuels. J. Environ. Monit. 2011, 13, 3196–3206. [Google Scholar] [CrossRef]

- Gonçalves, C.; Alves, C.; Fernandes, A.P.; Monteiro, C.; Tarelho, L.; Evtyugina, M.; Pio, C. Organic compounds in PM2.5 emitted from fireplace and woodstove combustion of typical Portuguese wood species. Atmos. Environ. 2011, 45, 4533–4545. [Google Scholar] [CrossRef]

- Nyström, R.; Lindgren, R.; Avagyan, R.; Westerholm, R.; Lundstedt, S.; Boman, C. Influence of wood species and burning conditions on particle emission characteristics in a residential wood stove. Energy Fuels 2017, 31, 5514–5524. [Google Scholar] [CrossRef]

- Tissari, J.; Väätäinen, S.; Leskinen, J.; Savolahti, M.; Lamberg, H.; Kortelainen, M.; Karvosenoja, N.; Sippula, O. Fine particle emissions from sauna stoves: Effects of combustion appliance and fuel, and implications for the finnish emission inventory. Atmosphere 2019, 10, 775. [Google Scholar] [CrossRef]

- Ihantola, T.; Di Bucchianico, S.; Happo, M.; Ihalainen, M.; Uski, O.; Bauer, S.; Kuuspalo, K.; Sippula, O.; Tissari, J.; Oeder, S.; et al. Influence of wood species on toxicity of log-wood stove combustion aerosols: A parallel animal and air-liquid interface cell exposure study on spruce and pine smoke. Part. Fibre Toxicol. 2020, 17, 27. [Google Scholar] [CrossRef] [PubMed]

- Zou, L.Y.; Zhang, W.; Atkiston, S. The characterisation of polycyclic aromatic hydrocarbons emissions from burning of different firewood species in Australia. Environ. Pollut. 2003, 124, 283–289. [Google Scholar] [CrossRef] [PubMed]

- Wardoyo, A.Y.P.; Morawska, L.; Ristovski, Z.D.; Marsh, J. Quantification of particle number and mass emission factors from combustion of Queensland trees. Environ. Sci. Technol. 2006, 40, 5696–5703. [Google Scholar] [CrossRef] [PubMed]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Gani, A.; Naruse, I. Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew. Energy 2007, 32, 649–661. [Google Scholar] [CrossRef]

- Reda, A.A.; Czech, H.; Schnelle-Kreis, J.; Sippula, O.; Orasche, J.; Weggler, B.; Abbaszade, G.; Arteaga-Salas, J.M.; Kortelainen, M.; Tissari, J.; et al. Analysis of gas-phase carbonyl compounds in emissions from modern wood combustion appliances: Influence of wood type and combustion appliance. Energy Fuels 2015, 29, 3897–3907. [Google Scholar] [CrossRef]

- Grishin, A.M.; Yakimov, A.S. Mathematical modeling of the wood ignition process. Thermophys. Aeromech. 2013, 20, 463–475. [Google Scholar] [CrossRef]

- EN 16510-1:2022; Residential Solid Fuel Burning Appliances. Part 1: General Requirements and Test Methods. The European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- Sulg, M.; Konist, A.; Järvik, O. Characterization of different wood species as potential feedstocks for gasification. Agron. Res. 2021, 19, 276–299. [Google Scholar]

- Sippula, O.; Hytönen, K.; Tissari, J.; Raunemaa, T.; Jokiniemi, J. Effect of wood fuel on the emissions from a top-feed pellet stove. Energy Fuels 2007, 21, 1151–1160. [Google Scholar] [CrossRef]

- Sonmez, T.; Keles, S.; Tilki, F. Effect of aspect, tree age and tree diameter on bark thickness of Picea orientalis. Scan. J. Forest Res. 2007, 22, 193–197. [Google Scholar] [CrossRef]

- Komán, S.; Feher, S. Basic density of hardwoods depending on age and site. Wood Res. 2015, 60, 907–912. [Google Scholar]

- Rabaçal, M.; Costa, M. Particulate emissions from the combustion of biomass pellets. In Biomass Pelletization: Standards and Production; Garcia-Maraver, A., Perez-Jimenez, J.A., Eds.; WIT Press: Billerica MA, USA, 2015; pp. 101–135. [Google Scholar]

- Fine, P.M.; Cass, G.R.; Simoneit, B.R.T. Chemical characterization of cine particle emissions from the fireplace combustion of wood types grown in the Midwestern and Western United States. Environ. Eng. Sci. 2004, 21, 387–409. [Google Scholar] [CrossRef]

- SFS-EN ISO 18125:2017; Solid Biofuels. Determination of Calorific Value. International Organization for Standardization: Geneva, Switzerland; European Committee for Standardization: Brussels, Belgium, 2017.

- Helin, A.; Virkkula, A.; Backman, J.; Pirjola, L.; Sippula, O.; Aakko-Saksa, P.; Väätäinen, S.; Mylläri, F.; Järvinen, A.; Bloss, M.; et al. Variation of absorption ångström exponent in aerosols from different emission sources. J. Geophys. Res. 2021, 126, e2020JD034094. [Google Scholar] [CrossRef]

- Lamberg, H.; Nuutinen, K.; Tissari, J.; Ruusunen, J.; Yli-Pirilä, P.; Sippula, O.; Tapanainen, M.; Jalava, P.; Makkonen, U.; Teinilä, K.; et al. Physicochemical characterization of fine particles from small-scale wood combustion. Atm. Environ. 2011, 45, 7635–7643. [Google Scholar] [CrossRef]

- IEA Bioenergy. Inventory of National Strategies for Reducing the Impact on Air Quality from Residential Wood Combustion. Report, 2022. Available online: https://task32.ieabioenergy.com/wp-content/uploads/sites/24/2022/10/NationalStrategies_Report-final.pdf (accessed on 15 July 2024).

- Vicente, E.D.; Duarte, M.A.; Calvo, A.I.; Nunes, T.F.; Tarelho, L.; Alves, C.A. Emission of carbon monoxide, total hydrocarbons and particulate matter during wood combustion in a stove operating under distinct conditions. Fuel Process. Technol. 2015, 131, 182–192. [Google Scholar] [CrossRef]

- Pettersson, E.; Boman, C.; Westerholm, R.; Boström, D.; Nordin, A. Stove performance and emission characteristics in residential wood log and pellet combustion, Part 1: Pellet stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Li, P.-W.; Chyang, C.-S. A comprehensive study on NOX emission and fuel nitrogen conversion of solid biomass in bubbling fluidized beds under staged combustion. J. Energy Inst. 2020, 93, 324–334. [Google Scholar] [CrossRef]

- Koppejan, J.; Schmidl, C. Nitrogen Flows in Biomass Combustion Systems. A Parametric Scoping Study Aimed at Optimising Nitrogen Flows in Biomass Combustion. IEA Bioenergy Reports 2022. Available online: https://www.ieabioenergy.com/wp-content/uploads/2023/02/Task32_Nitrogencycle_I_final.pdf (accessed on 13 June 2024).

- Hesch, T.; Biedermann, F.; Brunner, T.; Obernberger, I. Reduction of NOX and PM1 emissions from automated boilers by advanced air staging. In Proceedings of the 19th European Biomass Conference & Exhibition, Berlin, Germany, 6–10 June 2011. [Google Scholar]

- Mladenović, M.; Paprika, M.; Marinković, A. Denitrification techniques for biomass combustion. Renew. Sus. Energy Rev. 2018, 82, 3350–3364. [Google Scholar] [CrossRef]

- Price-Allison, A.; Lea-Langton, A.R.; Mitchell, E.J.S.; Gudka, B.; Jones, J.M.; Mason, P.E.; Williams, A. Emissions performance of high moisture wood fuels burned in a residential stove. Fuel 2019, 239, 1038–1045. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, J.; Cai, S.; Zhou, W.; Wang, S.; Duan, L.; Hao, J. Gaseous ammonia emissions from coal and biomass combustion in household stoves with different combustion efficiencies. Environ. Sci. Technol. Lett. 2016, 3, 98–103. [Google Scholar] [CrossRef]

- Nuutinen, K.; Jokiniemi, J.; Sippula, O.; Lamberg, H.; Sutinen, J.; Horttanainen, P.; Tissari, J. Effect of air staging on fine particle, dust and gaseous emissions from masonry heaters. Biomass Bioenergy 2014, 67, 167–178. [Google Scholar] [CrossRef]

- Frenklach, M. Reaction mechanism of soot formation in flames. Phys. Chem. Chem. Phys. 2002, 4, 2028–2037. [Google Scholar] [CrossRef]

- Fine, P.M.; Cass, G.R.; Simoneit, B.R.T. Chemical characterization of fine particle emissions from fireplace combustion of woods grown in the Northeastern United States. Environ. Sci. Technol. 2001, 35, 2665–2675. [Google Scholar] [CrossRef]

- Basnet, S.; Hartikainen, A.; Virkkula, A.; Yli-Pirilä, P.; Kortelainen, M.; Suhonen, H.; Kilpeläinen, L.; Ihalainen, M.; Väätäinen, S.; Louhisalmi, J.; et al. Contribution of brown carbon to light absorption in emissions of European residential biomass combustion appliances. Atm. Chem. Phys. 2024, 24, 3197–3215. [Google Scholar] [CrossRef]

- Sandradewi, J.; Prévôt, A.S.H.; Szidat, S.; Perron, N.; Alfarra, M.R.; Lanz, V.A.; Weingartner, E.; Baltensperger, U. Using aerosol light absorption measurements for the quantitative determination of wood burning and traffic emission contributions to particulate matter. Environ. Sci. Technol. 2008, 42, 3316–3323. [Google Scholar] [CrossRef]

- Liu, C.; Chung, C.E.; Yin, Y.; Schnaiter, M. The absorption Ångström exponent of black carbon: From numerical aspects. Atmos. Chem. Phys. 2018, 18, 6259–6273. [Google Scholar] [CrossRef]

- Virkkula, A. Modeled source apportionment of black carbon particles coated with a light-scattering shell. Atmos. Meas. Tech. 2006, 14, 3707–3719. [Google Scholar] [CrossRef]

- Tissari, J.; Lyyränen, J.; Hytönen, K.; Sippula, O.; Tapper, U.; Frey, A.; Saarnio, K.; Pennanen, A.; Hillamo, R.; Salonen, R.; et al. Fine particle and gaseous emissions from normal and smouldering wood combustion in a conventional masonry heater. Atmos. Environ. 2008, 42, 7862–7873. [Google Scholar] [CrossRef]

- Michelsen, H.A. Probing soot formation, chemical and physical evolution, and oxidation: A review of in situ diagnostic techniques and needs. Proc. Combust. Inst. 2017, 36, 717–735. [Google Scholar] [CrossRef]

- Achten, C.; Beer, F.T.; Stader, C.; Brinkhaus, S.G. Wood-specific polycyclic aromatic hydrocarbon (PAH) patterns in soot using gas chromatography-atmospheric pressure laser ionization-mass spectrometry (GC-APLI-MS). Environ. Forensics 2015, 16, 42–50. [Google Scholar] [CrossRef]

- Avagyan, R.; Nyström, R.; Lindgren, R.; Boman, C.; Westerholm, R. Particulate hydroxy-PAH emissions from a residential wood log stove using different fuels and burning conditions. Atmos. Environ. 2016, 140, 1–9. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Selected Non-heterocyclic Polycyclic Hydrocarbons. In WHO International Programme on Chemical Safety (IPCS); Environmental Health Criteria 202; WHO: Geneva, Switzerland, 1998. [Google Scholar]

| BirchA1 | BirchA | BirchB | Alder | Pine | Spruce | SpruceDry | ||

|---|---|---|---|---|---|---|---|---|

| Lower heating value 1 | MJ/kg | 18.74 | 18.74 | 18.72 | 18.68 | 19.19 | 19.13 | 19.13 |

| Calorific heating value 1 | MJ/kg | 15.87 | 15.87 | 16.25 | 15.75 | 15.66 | 15.88 | 17.70 |

| Moisture content | % | 15.3 | 15.3 | 13.2 | 15.7 | 18.4 | 17.0 | 7.5 |

| Density, dry | kg/m3 | 621 | 621 | 673 | 446 | 478 | 350 | 350 |

| Log size | kg | 0.500 | 0.500 | 0.485 | 0.500 | 0.515 | 0.515 | 0.450 |

| Batch size | kg | 3.000 | 1.500 | 1.455 | 1.500 | 1.545 | 1.545 | 1.350 |

| Batch volume | dm3 | 4.2 | 2.1 | 1.9 | 2.9 | 2.7 | 3.8 | 3.6 |

| Batch energy | MJ | 47.6 | 23.8 | 23.6 | 23.6 | 24.2 | 24.5 | 23.9 |

| Unit | BirchA1 | BirchA | BirchB | Alder | Pine | Spruce | SpruceDry | |

|---|---|---|---|---|---|---|---|---|

| Time 1 | [min] | 62.3 ± 5.8 | 40.5 ± 1.8 | 39.9 ± 5.9 | 39.6 ± 3.2 | 44.1 ± 3.0 | 45.7 ± 2.6 | 40.8 ± 4.4 |

| Burning rate | [kg/h] | 2.92 ± 0.28 | 2.23 ± 0.10 | 2.24 ± 0.31 | 2.29 ± 0.17 | 2.12 ± 0.15 | 2.04 ± 0.12 | 2.00 ± 0.22 |

| Draught | [Pa] | 11.9 ± 0.4 | 12.1 ± 0.1 | 12.0 ± 0.1 | 12.1 ± 0.2 | 12.1 ± 0.3 | 11.9 ± 0.1 | 12.0 ± 0.1 |

| Temperature 2 | [°C] | 148 ± 14 | 234 ± 17 | 231 ± 21 | 239 ± 20 | 239 ± 13 | 244 ± 11 | 232 ± 20 |

| Λ 3 | [-] | 2.95 ± 0.27 | 2.97 ± 0.11 | 2.77 ± 0.21 | 2.77 ± 0.18 | 2.99 ± 0.20 | 3.02 ± 0.18 | 2.70 ± 0.29 |

| Efficiency | [%] | 85.0 ± 1.5 | 76.7 ± 1.0 | 78.3 ± 2.8 | 76.6 ± 1.5 | 76.0 ± 1.4 | 74.6 ± 1.2 | 78.1 ± 1.6 |

| Unit | BirchA1 | BirchA | BirchB | Alder | Pine | Spruce | SpruceDry | |

|---|---|---|---|---|---|---|---|---|

| CO2 | % | 6.9 ± 0.7 | 6.9 ± 0.3 | 7.3 ± 0.6 | 7.3 ± 0.5 | 6.8 ± 0.5 | 6.7 ± 0.4 | 7.6 ± 0.8 |

| H2O | %, wet | 7.8 ± 1.0 | 7.4 ± 0.3 | 8.0 ± 0.6 | 7.0 ± 0.4 | 6.2 ± 1.5 | 6.8 ± 0.5 | 6.8 ± 0.7 |

| CO | mg/m3 | 2190 ± 590 | 1270 ± 240 | 1430 ± 340 | 2710 ± 450 | 1880 ± 460 | 4280 ± 1080 | 2720 ± 550 |

| NOx | mg/m3 | 92.4 ± 12.6 | 132.8 ± 9.6 | 143.8 ± 13.5 | 188.8 ± 11.2 | 115.9 ± 8.7 | 149.5 ± 15.0 | 139.1 ± 14.9 |

| NH3 | mg/m3 | 0.8 ± 0.2 | 2.3 ± 0.6 | 2.9 ± 0.9 | 7.1 ± 3.2 | 2.7 ± 0.5 | 6.5 ± 0.3 | 3.8 ± 1.8 |

| OGC | mgC/m3 | 83.8 ± 42.0 | 21.8 ± 12.1 | 52.0 ± 34.5 | 98.9 ± 33.2 | 49.1 ± 22.1 | 142.4 ± 56.9 | 84.3 ± 46.3 |

| Methane | mg/m3 | 56.7 ± 25.1 | 28.2 ± 14.8 | 34.4 ± 12.5 | 56.1 ± 22.2 | 46.7 ± 18.4 | 69.6 ± 14.2 | 64.4 ± 23.3 |

| Pentane | mg/m3 | 32.8 ± 7.8 | 7.9 ± 4.4 | 11.0 ± 2.3 | 11.9 ± 3.5 | 14.7 ± 6.2 | 21.2 ± 5.4 | 14.7 ± 8.7 |

| Acetylene | mg/m3 | 14.2 ± 10.7 | 3.7 ± 2.1 | 11.5 ± 10.0 | 20.5 ± 10.6 | 7.9 ± 6.1 | 8.8 ± 0.1 | 15.9 ± 11.6 |

| Ethylene | mg/m3 | 22.5 ±13.2 | 5.1 ± 3.2 | 14.6 ± 11.5 | 24.7 ± 9.3 | 16.7 ± 8.4 | 21.2 ± 3.9 | 22.1 ± 12.0 |

| Propene | mg/m3 | 29.4 ± 12.9 | 9.1 ± 4.1 | 16.3 ± 8.9 | 25.6 ± 7.4 | 18.1 ± 7.5 | 25.4 ± 4.6 | 25.8 ± 9.1 |

| 1,3-Butadiene | mg/m3 | 13.4 ± 8.5 | 7.9 ± 1.6 | 8.4 ± 2.6 | 14.6 ± 6.7 | 15.8 ± 9.4 | 7.8 ± 0.3 | 6.3 ± 2.3 |

| Benzene | mg/m3 | 30.1 ± 13.5 | 11.8 ± 4.7 | 24.2 ± 15.7 | 36.8 ± 12.8 | 28.8 ± 10.4 | 30.3 ± 2.0 | 38.3 ± 22.0 |

| Formic Acid | mg/m3 | 4.7 ± 1.6 | 2.3 ± 1.1 | 2.2 ± 0.7 | 1.9 ± 1.1 | 2.4 ± 1.3 | 2.3 ± 1.0 | 2.4 ± 1.5 |

| Acetic Acid | mg/m3 | 75.4 ± 26.5 | 11.2 ± 5.8 | 13.9 ± 5.0 | 13.9 ± 10.0 | 10.7 ± 7.5 | 14.9 ± 6.2 | 15.4 ± 10.2 |

| Formaldehyde | mg/m3 | 29.8 ± 10.2 | 8.6 ± 2.6 | 10.9 ± 2.8 | 14.2 ± 4.6 | 15.4 ± 7.5 | 23.6 ± 6.7 | 18.0 ± 7.7 |

| Acetaldehyde | mg/m3 | 13.7 ± 7.3 | 2.9 ± 0.8 | 3.9 ± 1.2 | 4.3 ± 2.1 | 6.3 ± 3.5 | 8.9 ± 3.8 | 7.3 ± 4.0 |

| Methanol | mg/m3 | 15.7 ± 9.6 | 1.0 ± 0.5 | 1.6 ± 1.0 | 1.5 ± 0.3 | 2.0 ± 2.2 | 2.2 ± 1.8 | 1.9 ± 1.4 |

| Unit | BirchA1 | BirchA | BirchB | Alder | Pine | Spruce | SpruceDry | |

|---|---|---|---|---|---|---|---|---|

| Sample | °C | 21.7 ± 1.7 | 26.4 ± 4.5 | 28.5 ± 3.9 | 25.6 ± 3.9 | 27.0 ± 2.5 | 29.9 ± 2.0 | 25.4 ± 2.6 |

| DR | - | 90.3 ± 0.3 | 89.8 ± 0.1 | 89.0 ± 2.3 | 89.7 ± 0.1 | 89.8 ± 0.1 | 89.8 ± 0.1 | 89.8 ± 0.1 |

| PM2.5 | mg/m3 | 32.0 ± 6.1 | 22.4 ± 4.7 | 48.8 ± 16.5 | 49.6 ± 16.4 | 32.2 ± 10.5 | 43.2 ± 10.6 | 74.6 ± 36.1 |

| OC | mg/m3 | 5.5 ± 1.0 | 3.3 ± 1.8 | 10.3 ± 6.0 | 12.1 ± 5.2 | 6.7 ± 3.7 | 11.1 ± 3.2 | 9.6 ± 7.4 |

| EC | mg/m3 | 21.4 ± 6.0 | 14.3 ± 3.9 | 34.6 ± 11.0 | 28.5 ± 9.3 | 22.0 ± 8.7 | 21.3 ± 8.6 | 46.4 ± 29.4 |

| PM1,ELPI | mg/m3 | 36.4 ± 8.1 | 25.4 ± 7.4 | 42.2 ± 14.0 | 45.3 ± 10.3 | 35.6 ± 15.3 | 30.7 ± 1.9 | ND |

| GMDELPI | µm | 0.050 ± 0.023 | 0.072 ± 0.005 | 0.100 ± 0.010 | 0.098 ± 0.012 | 0.077 ± 0.010 | 0.076 ± 0.015 | ND |

| eBC | mg/m3 | 26.0 ± 4.0 | 13.1 ± 4.6 | 28.6 ± 9.3 | 18.6 ± 4.5 | 19.7 ± 7.7 | 14.6 ± 7.6 | 34.7 ± 23.6 |

| AAE | - | 1.27 ± 0.02 | 1.25 ± 0.07 | 1.18 ± 0.12 | 1.30 ± 0.11 | 1.26 ± 0.04 | 1.47 ± 0.16 | 1.19 ± 0.10 |

| PNELPI | 1 × 107 #/cm3 | 7.7 ± 5.3 | 1.8 ± 0.4 | 2.1 ± 0.4 | 2.5 ± 0.3 | 2.3 ± 0.4 | 2.9 ± 0.4 | ND |

| PNCPC | 1 × 107 #/cm3 | 16.6 ± 14.9 | 1.2 ± 0.2 | 1.5 ± 0.5 | 1.7 ± 0.2 | 1.2 ± 0.2 | 2.2 ± 0.5 | 1.4 ± 0.2 |

| LDSA | 1 × 104 µm2/cm3 | 1.8 ± 0.5 | 0.7 ± 0.2 | 1.1 ± 0.3 | 1.2 ± 0.2 | 0.9 ± 0.2 | 1.0 ± 0.1 | 1.2 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rinta-Kiikka, H.; Dahal, K.; Louhisalmi, J.; Koponen, H.; Sippula, O.; Krpec, K.; Tissari, J. The Effect of Wood Species on Fine Particle and Gaseous Emissions from a Modern Wood Stove. Atmosphere 2024, 15, 839. https://doi.org/10.3390/atmos15070839

Rinta-Kiikka H, Dahal K, Louhisalmi J, Koponen H, Sippula O, Krpec K, Tissari J. The Effect of Wood Species on Fine Particle and Gaseous Emissions from a Modern Wood Stove. Atmosphere. 2024; 15(7):839. https://doi.org/10.3390/atmos15070839

Chicago/Turabian StyleRinta-Kiikka, Henna, Karna Dahal, Juho Louhisalmi, Hanna Koponen, Olli Sippula, Kamil Krpec, and Jarkko Tissari. 2024. "The Effect of Wood Species on Fine Particle and Gaseous Emissions from a Modern Wood Stove" Atmosphere 15, no. 7: 839. https://doi.org/10.3390/atmos15070839

APA StyleRinta-Kiikka, H., Dahal, K., Louhisalmi, J., Koponen, H., Sippula, O., Krpec, K., & Tissari, J. (2024). The Effect of Wood Species on Fine Particle and Gaseous Emissions from a Modern Wood Stove. Atmosphere, 15(7), 839. https://doi.org/10.3390/atmos15070839