Quantitative Analysis of the Impacts of Ash from Lubricating Oil on the Nanostructure of Diesel Particulate Matter

Abstract

1. Introduction

2. Materials and Methods

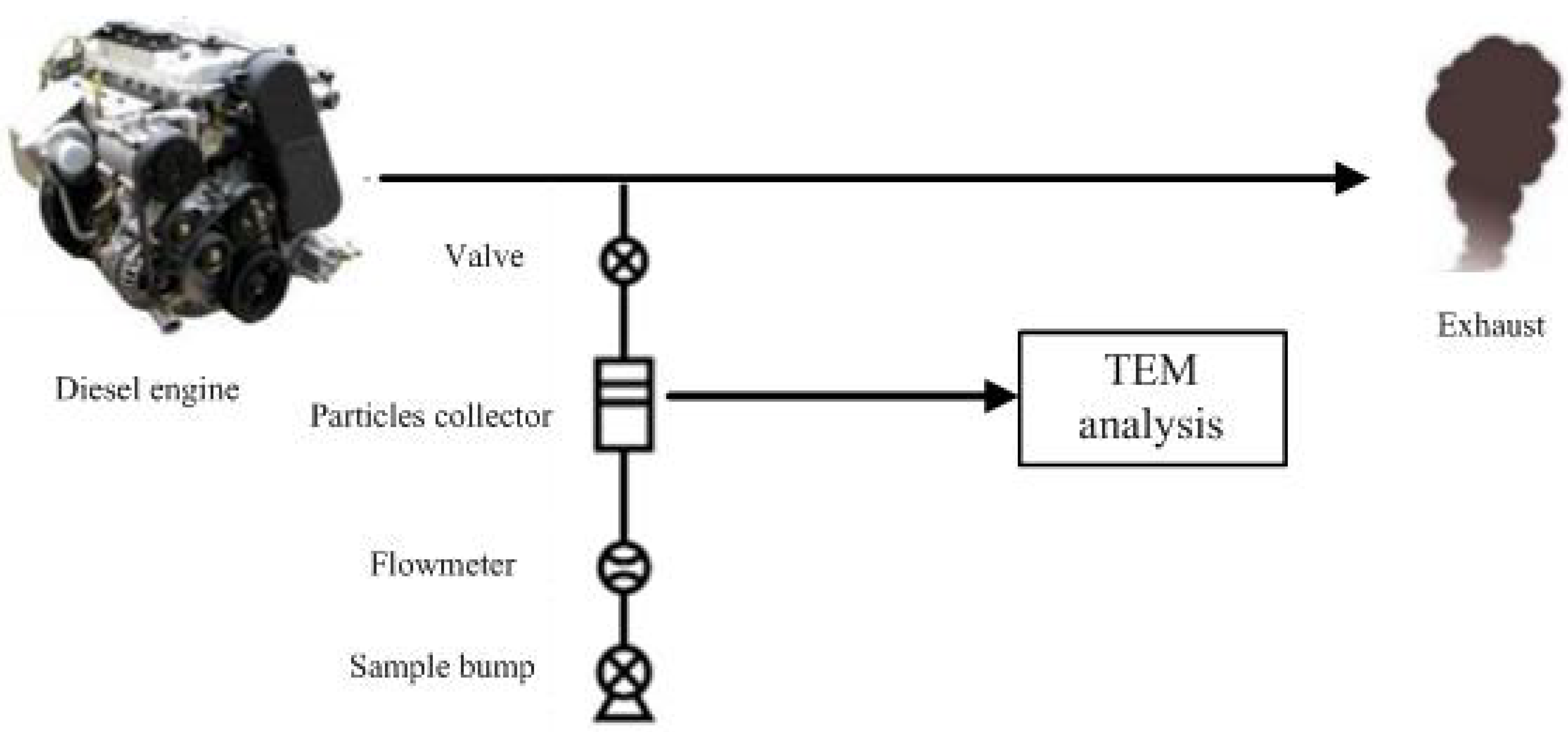

2.1. Experiment Apparatus and Sampling

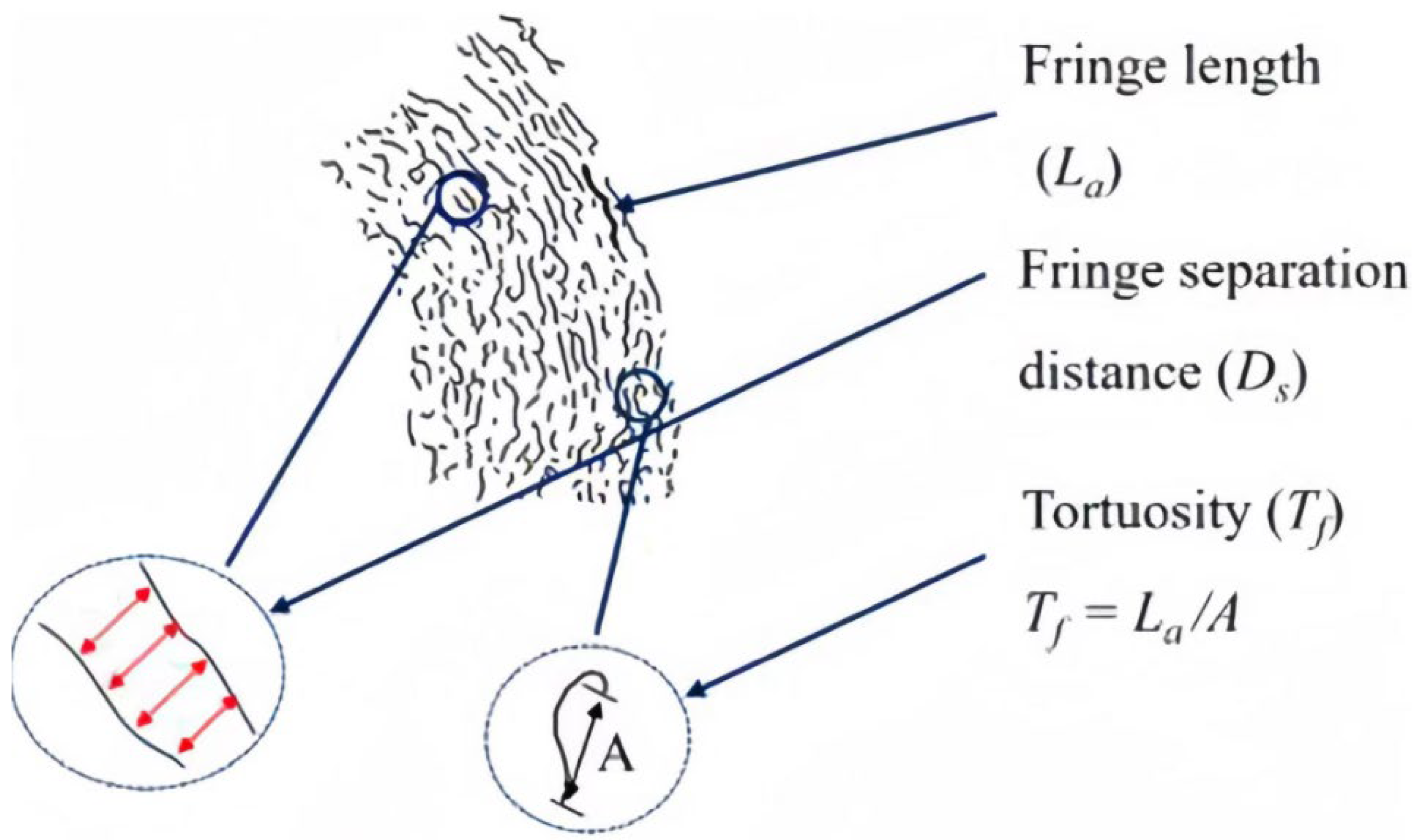

2.2. Analytical Method

3. Results and Discussion

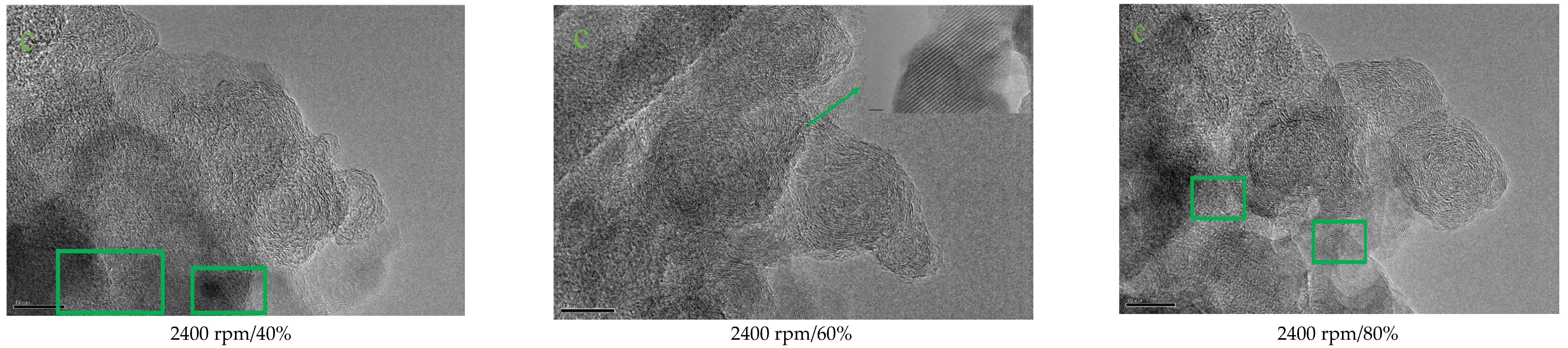

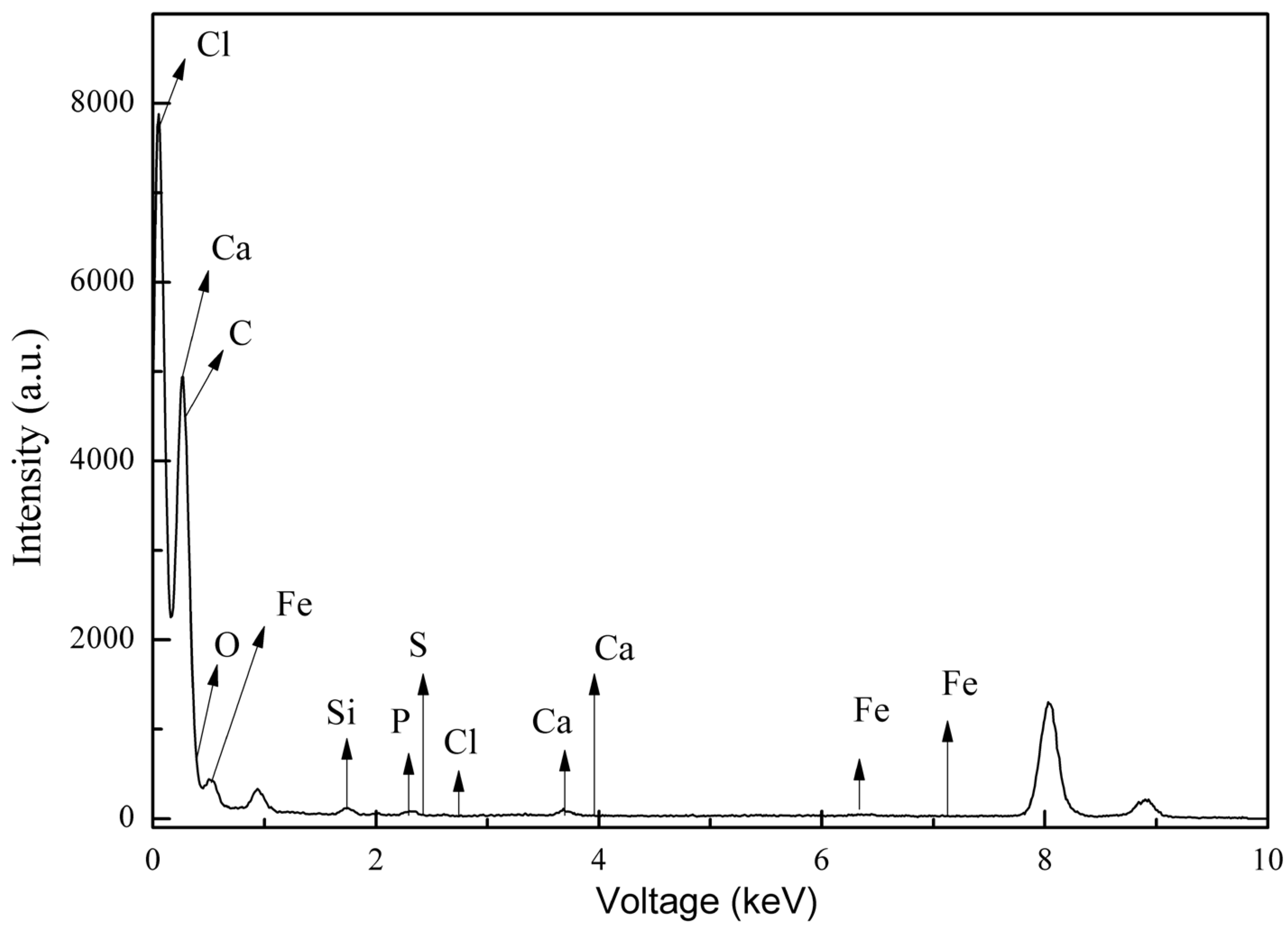

3.1. Nanomorphology Analysis

3.2. Nanostructure Parameters Analysis

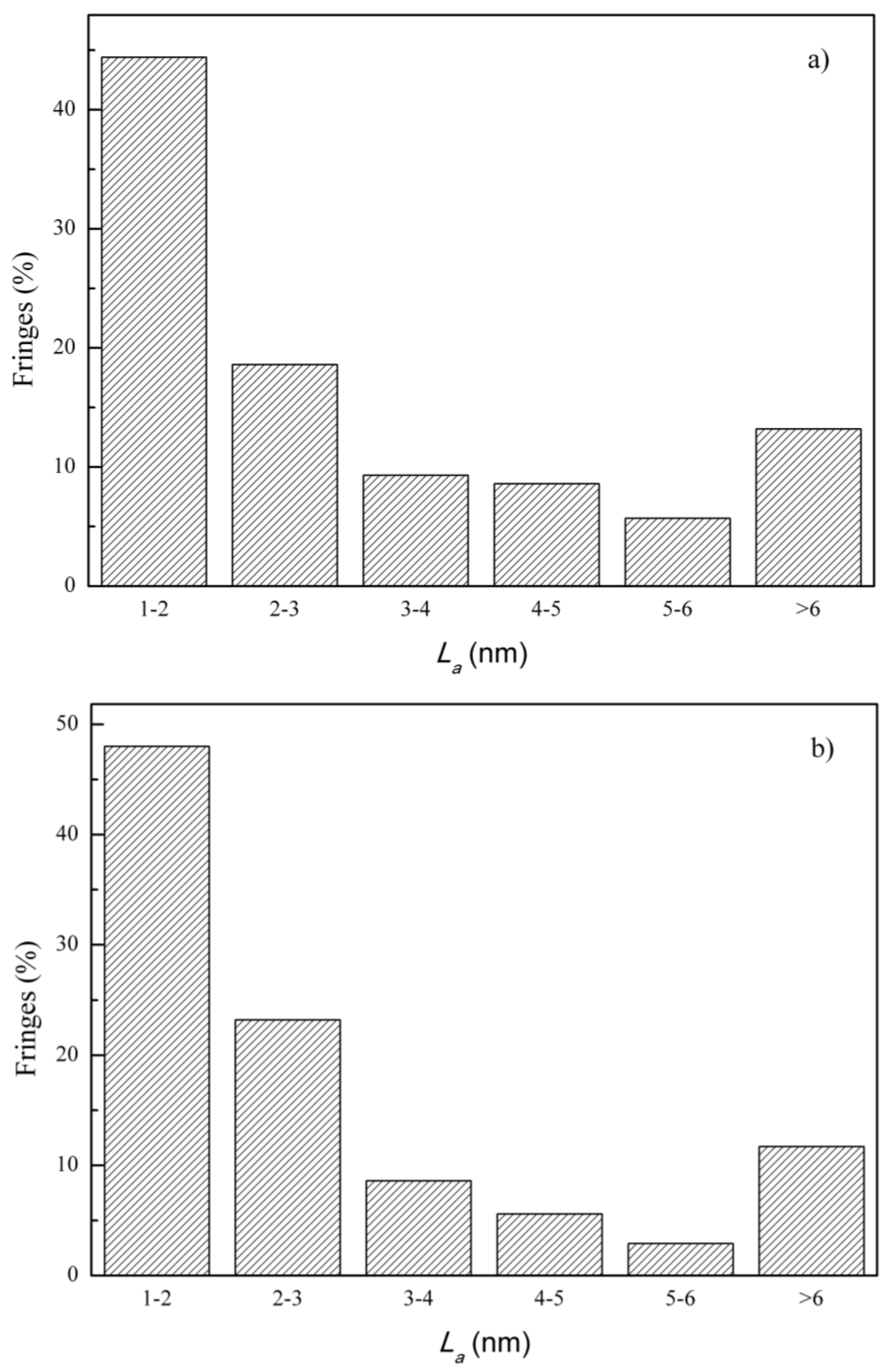

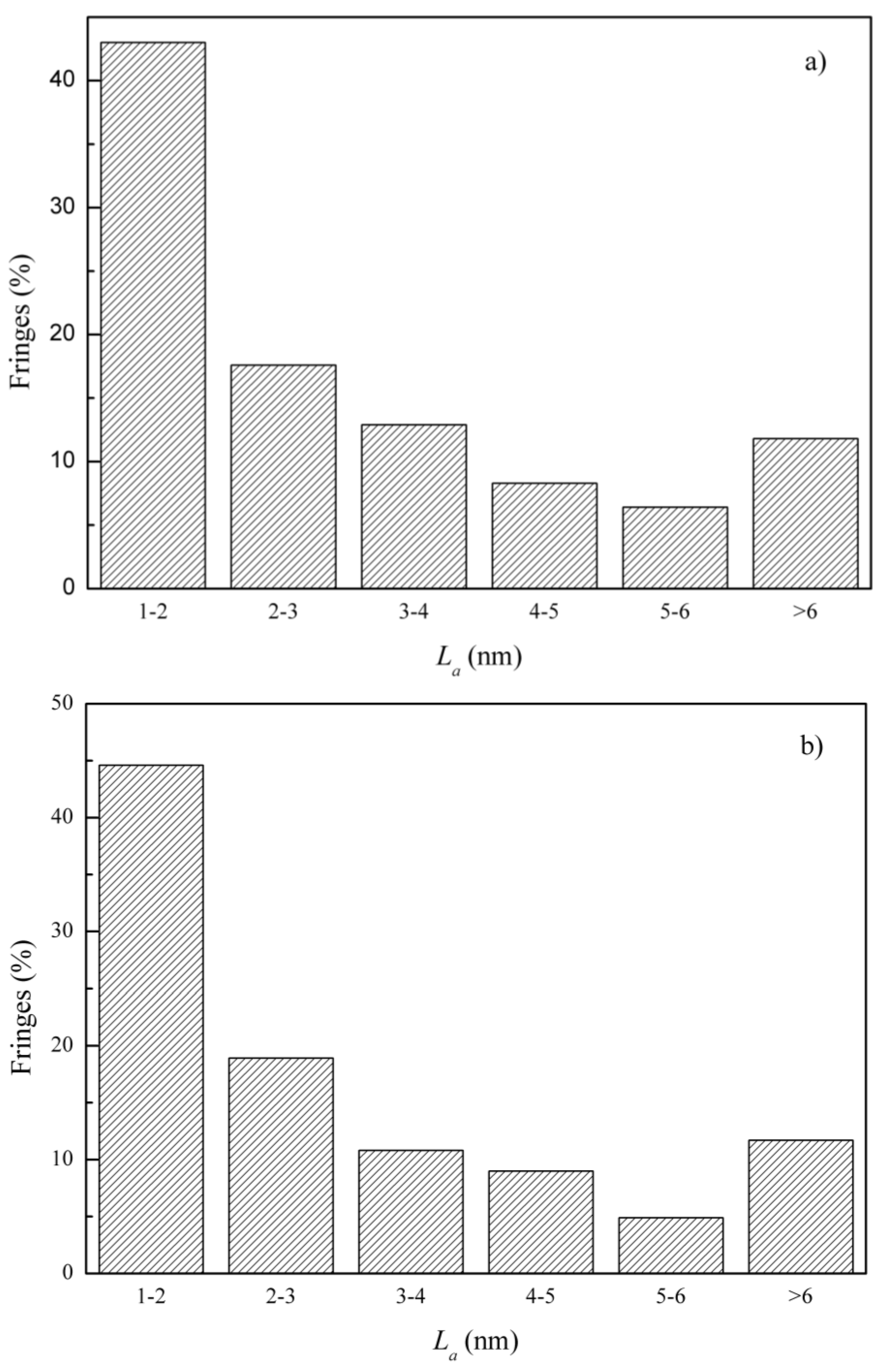

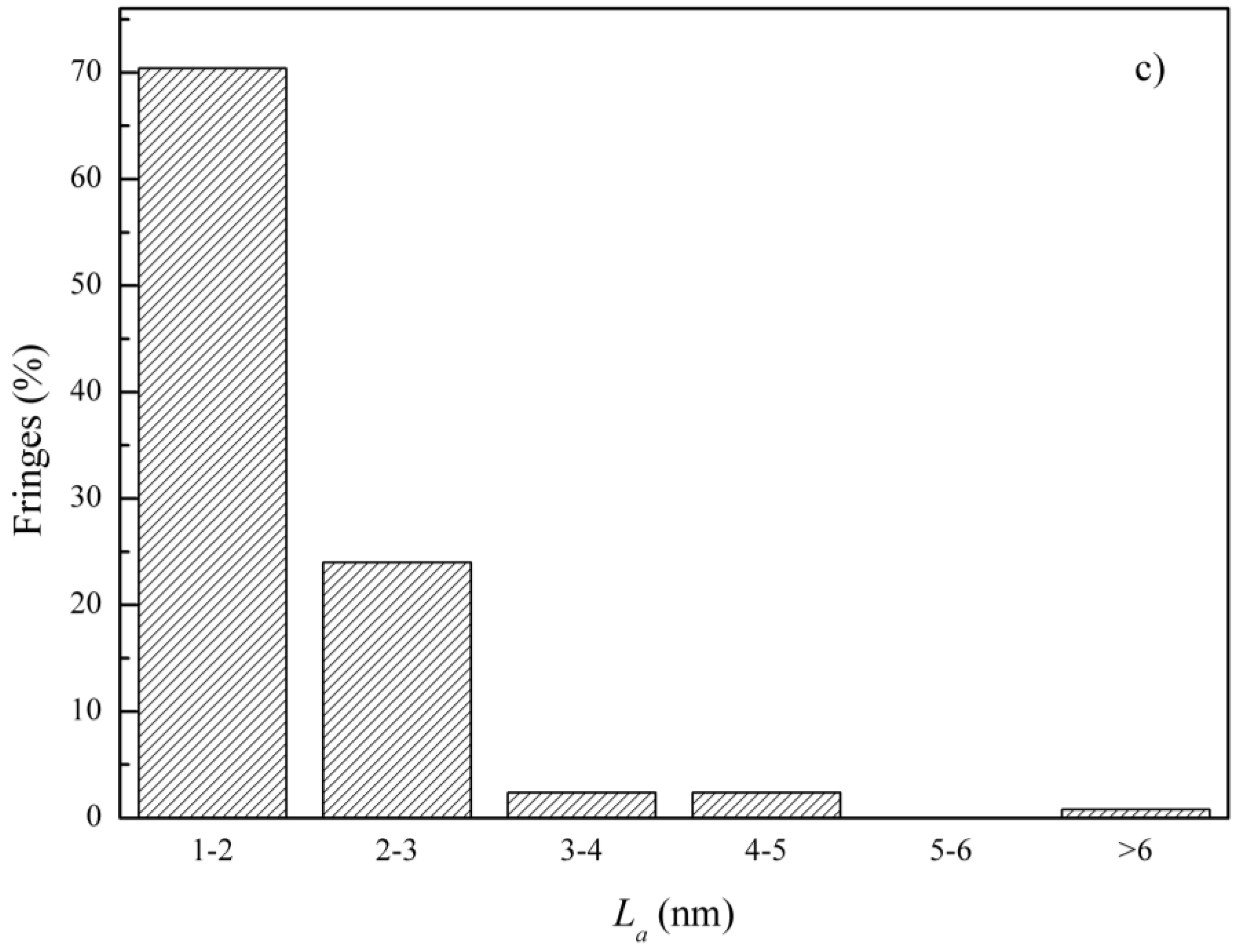

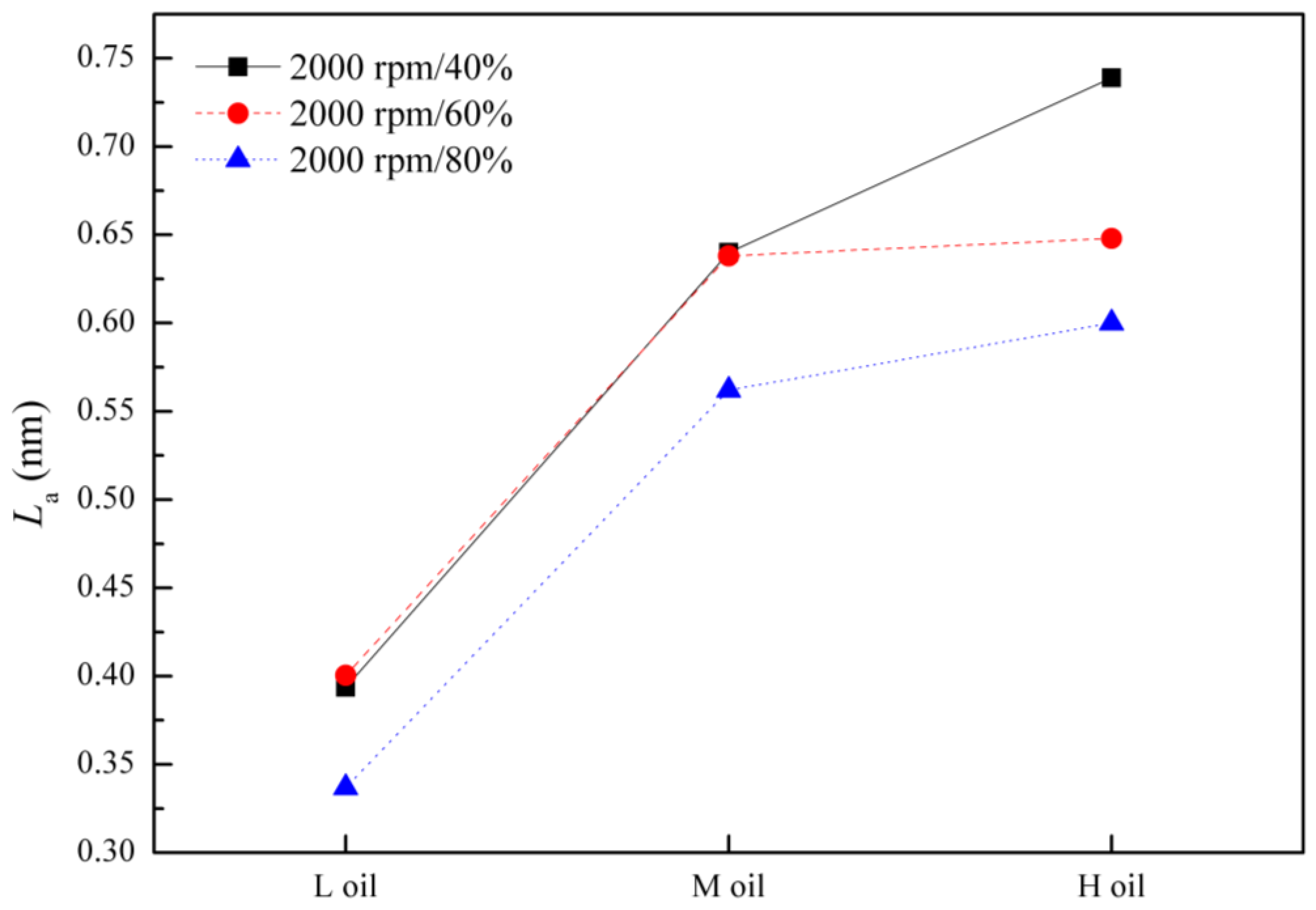

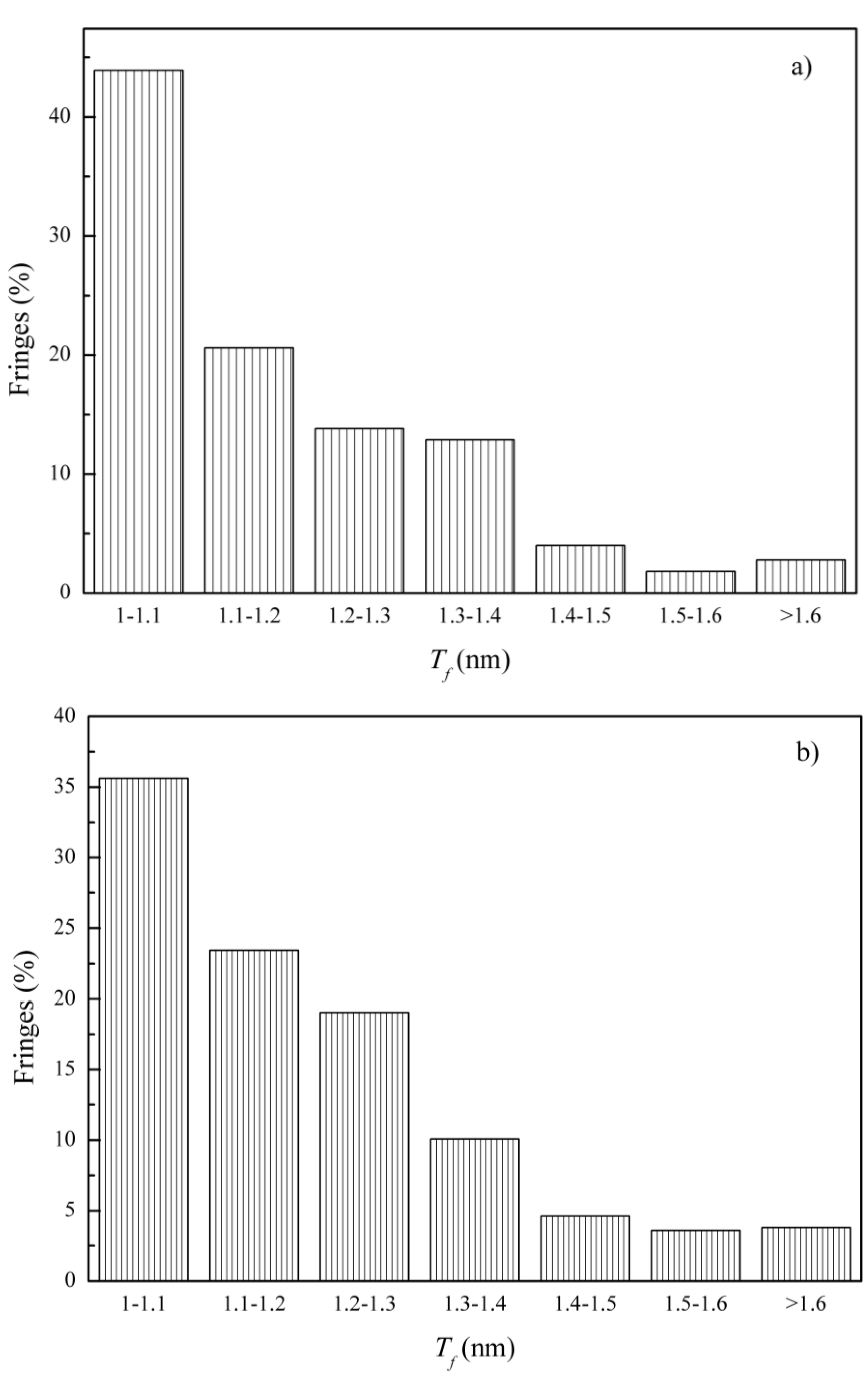

3.2.1. Fringe Length

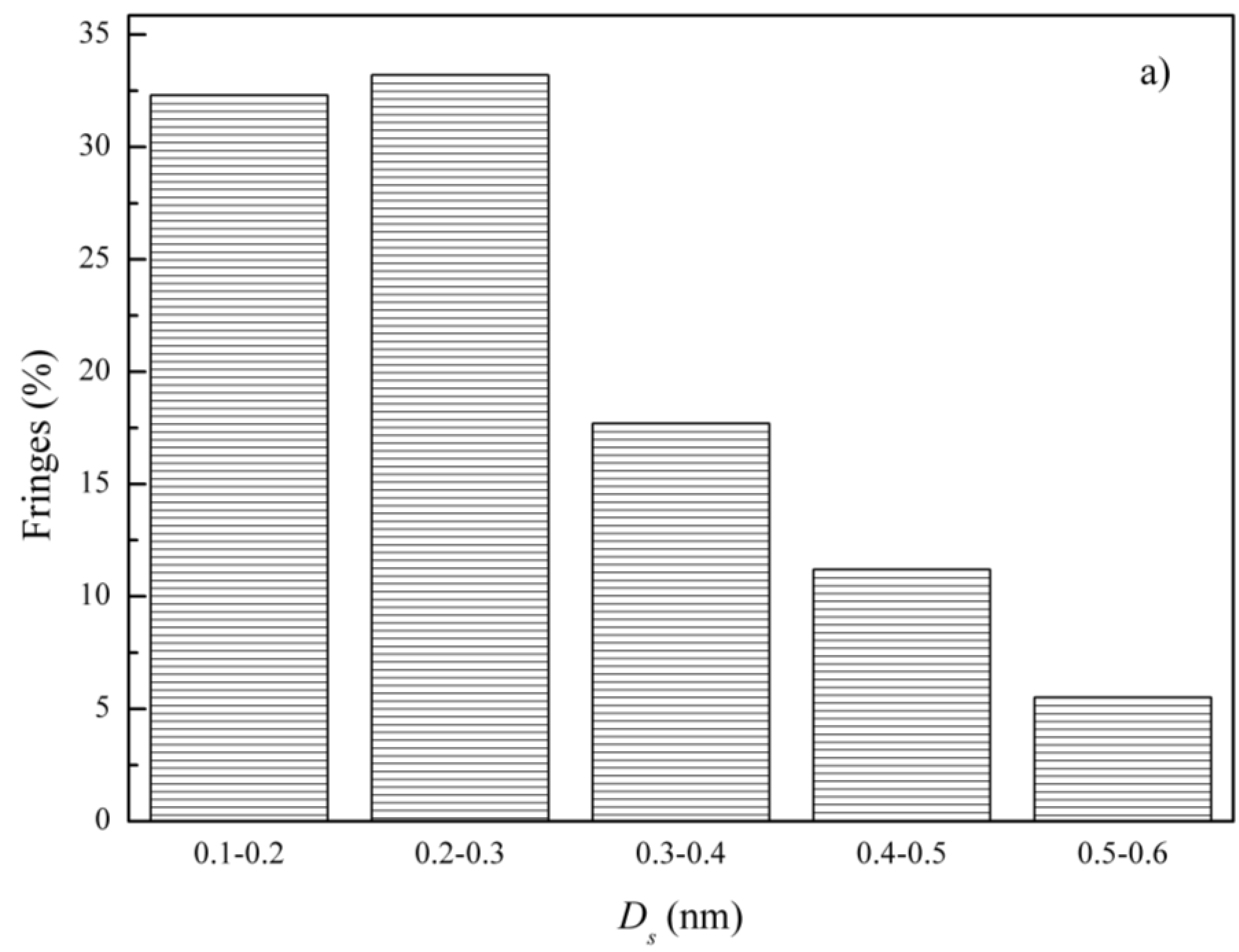

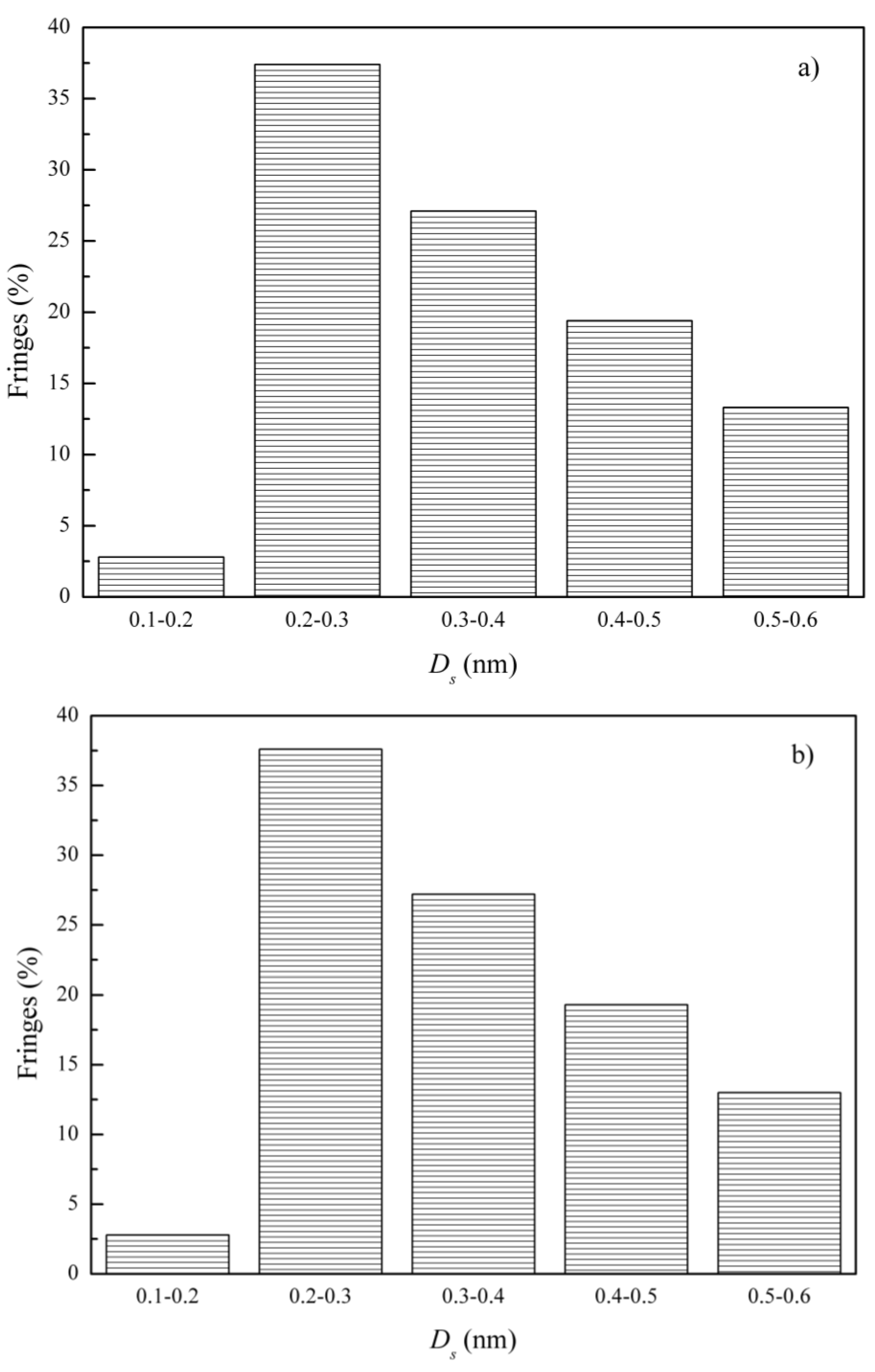

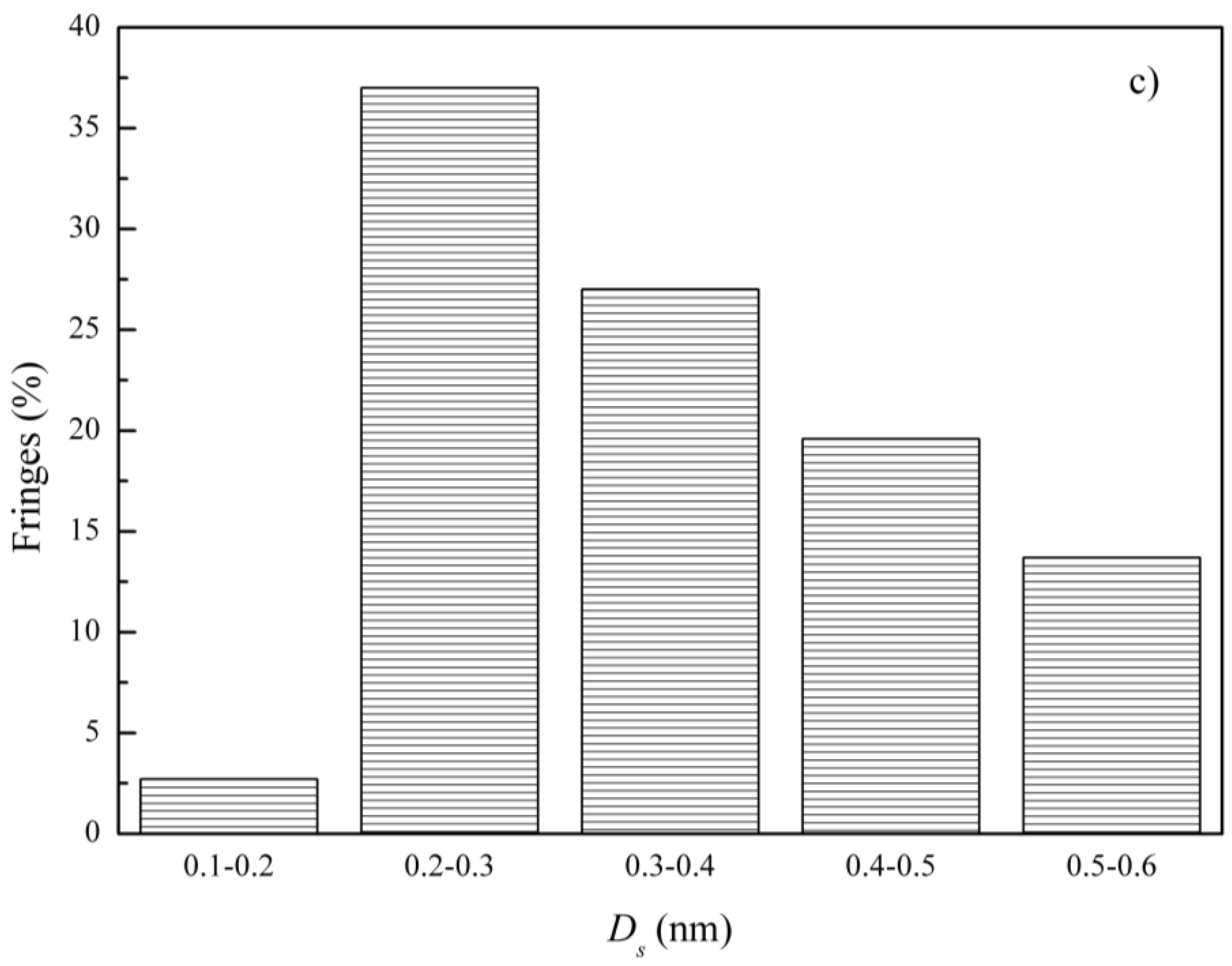

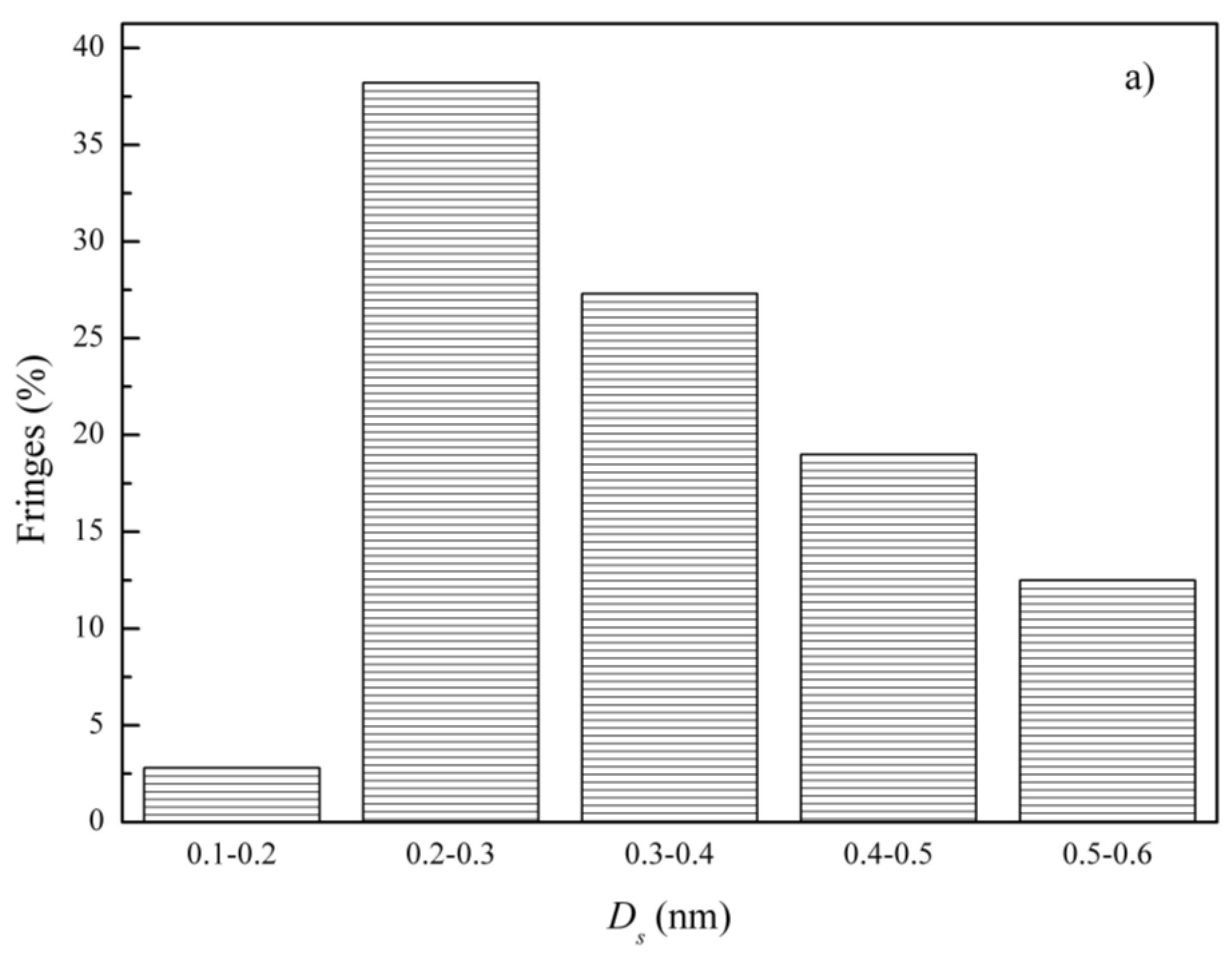

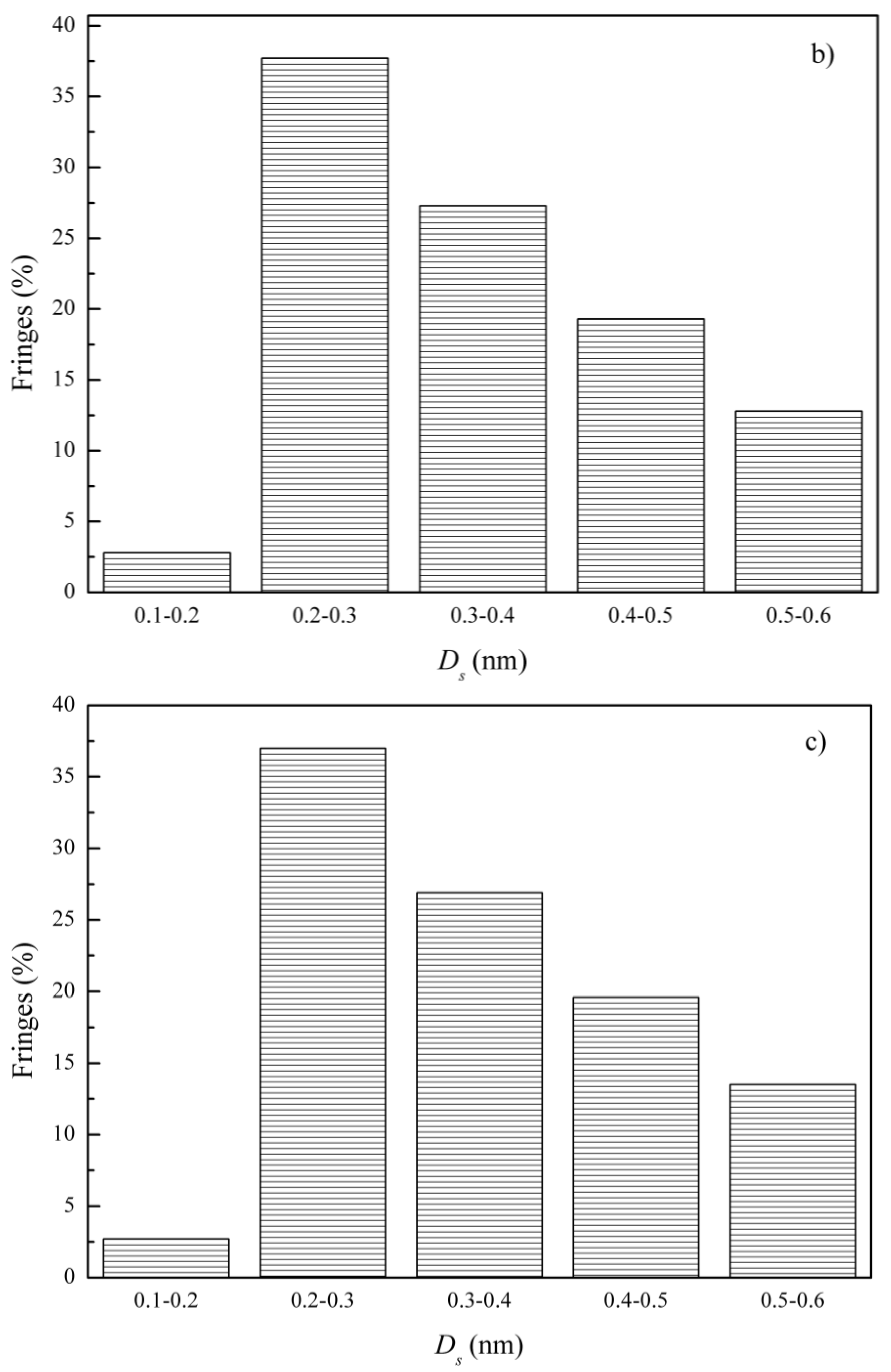

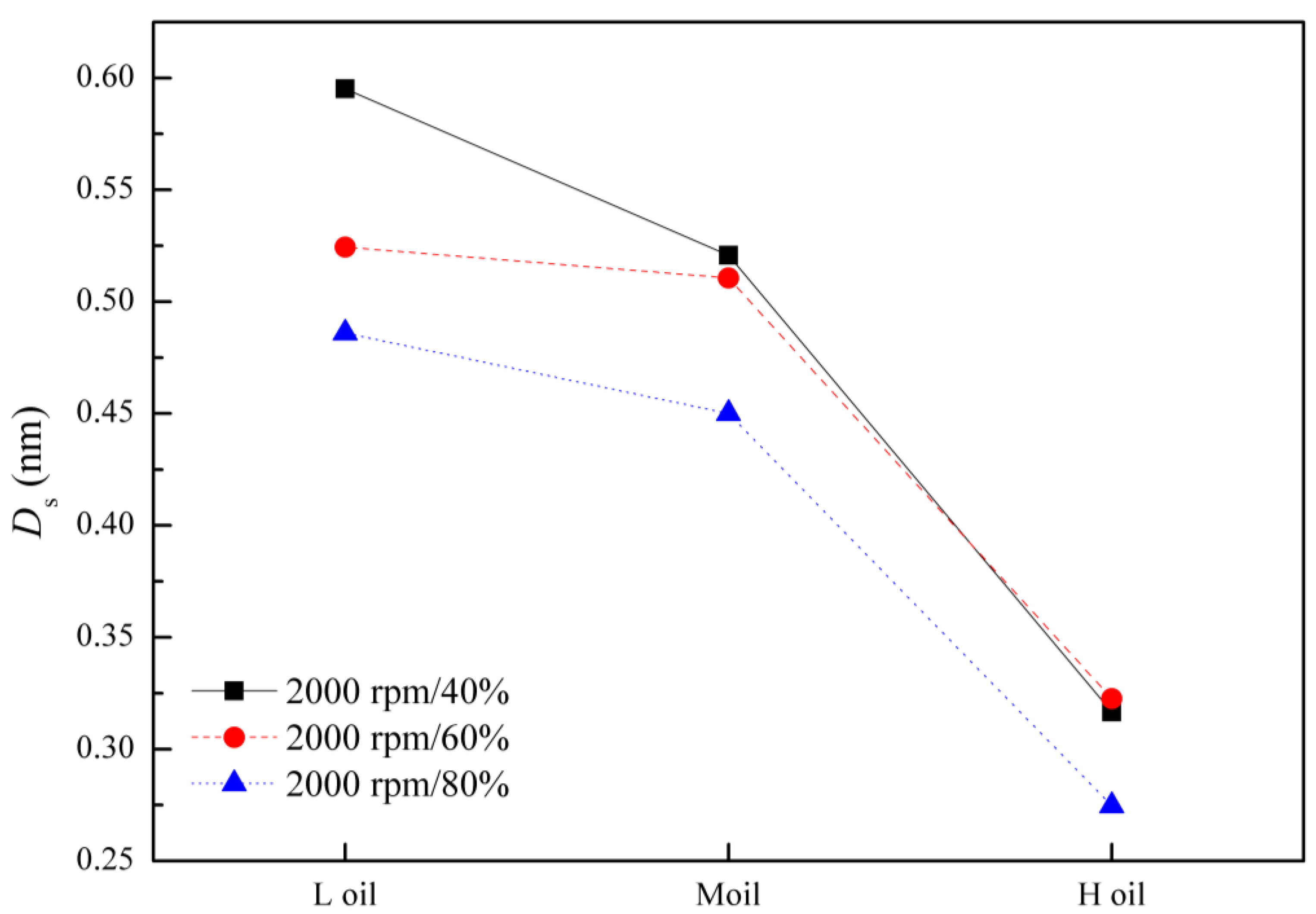

3.2.2. Fringe Separation Distance

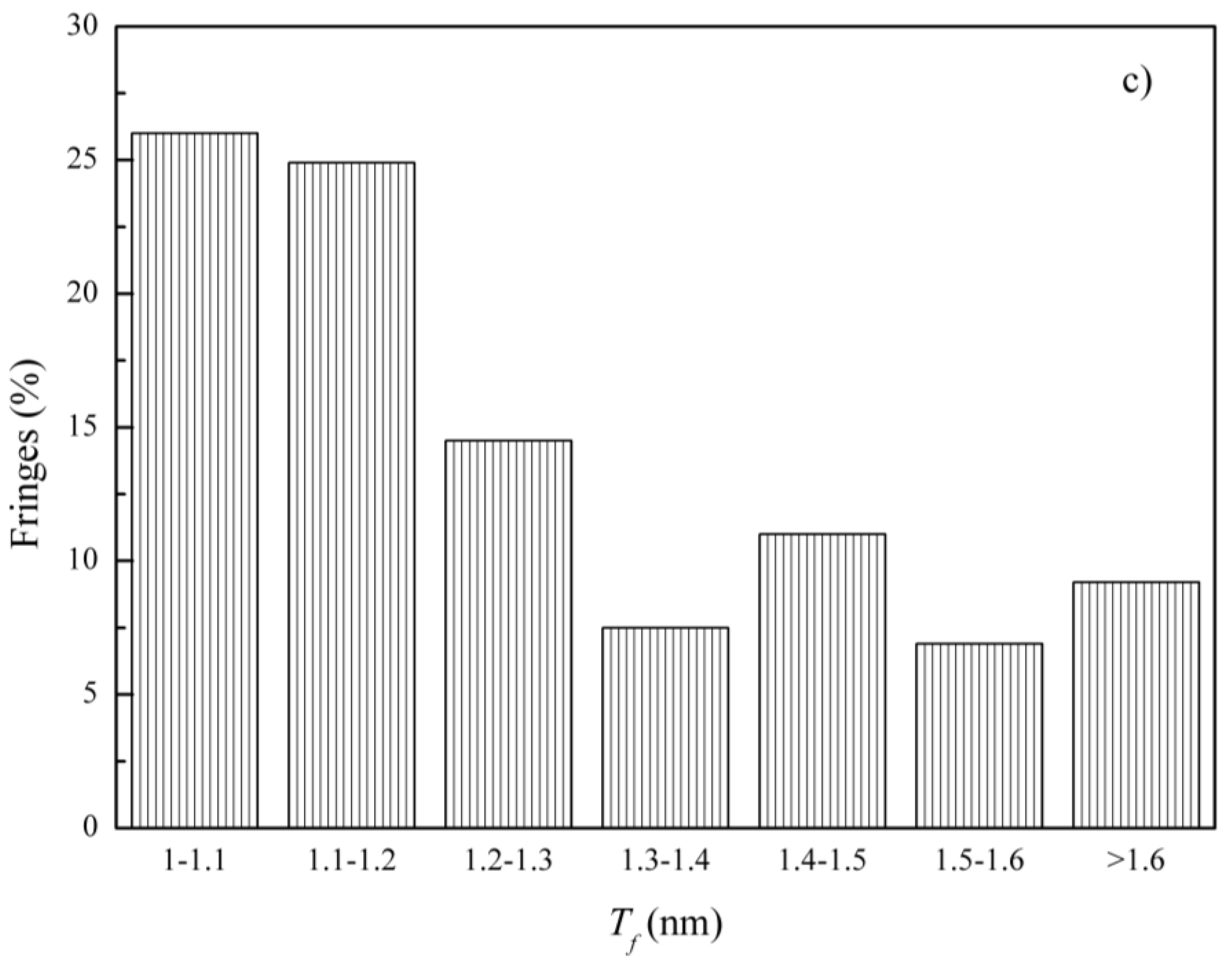

3.2.3. Fringe Tortuosity

| Property | Method | H oil | M oil | L oil |

|---|---|---|---|---|

| Density at 20 °C (kg/m3) | SH/T0604-2000 [28] | 858.1 | 872.5 | 860.4 |

| Viscosity at 40 °C (mm2/s) | GB/T265-88 [29] | 72.78 | 114.1 | 95.3 |

| Viscosity at 100 °C (mm2/s) | GB/T265-88 | 12.3 | 15.2 | 13.5 |

| Viscosity index (-) | - | 156 | 158 | 157 |

| Viscosity grade | - | 15W-40 | 5W-40 | 10W-40 |

| API service classification | - | CJ-4 | CJ-4 | CK-4 |

| Carbon content (%) | SH/T0656-1988 (2004) [30] | 83.99 | 85.16 | 85.11 |

| Hydrogen content (%) | SH/T0656-1988 (2004) | 13.85 | 13.82 | 13.84 |

| Ash content (%) | GB/T2433-2001 [31] | 1.92 | 1.21 | 0.92 |

| Sulfur content (%) | SH/T0689-2000 [32] | 0.41 | 0.44 | 0.40 |

| Ca content (%) | ICP-MS | 0.11 | 0.14 | 0.47 |

| Zn content (%) | 0.13 | 0.11 | 0.11 | |

| P content (%) | 0.12 | 0.12 | 0.11 | |

| Si content (%) | 0.00031 | 0.00083 | 0.0005 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Symbols

| DPF | Diesel particulate filter |

| DOC | Diesel oxidation catalyst |

| EGR | Exhaust gas recirculation |

| GDI | Gasoline direct-injection |

| HRTEM | High-resolution transmission electron microscopy |

| PM | Particulate matter |

| TEM | Transmission electron microscopy |

| Ds | Fringe separation distance |

| La | Fringe length |

| Tf | Fringe tortuosity |

References

- Liati, A.; Dimopoulos Eggenschwiler, P.; Müller Gubler, E.; Schreiber, D.; Aguirre, M. Investigation of diesel ash particulate matter: A scanning electron microscope and transmission electron microscope study. Atmos. Environ. 2012, 49 (Suppl. C), 391–402. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Ma, C.; Chen, J.; Huang, L. Physicochemical property changes during oxidation process for diesel PM sampled at different tailpipe positions. Fuel 2018, 219, 62–68. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, Y.X.; Li, X.; Ji, L.; Chen, Y.; Wang, W. Evolution of diesel particulate physicochemical properties using nonthermal plasma. Fuel 2019, 253, 1292–1299. [Google Scholar] [CrossRef]

- Bao, J.H.; Qu, P.P.; Wang, H.Y.; Zhou, C.Y.; Zhang, L.; Shi, C. Implementation of various bowl designs in an HPDI natural gas engine focused on performance and pollutant emissions. Chemosphere 2022, 303, 135275. [Google Scholar] [CrossRef]

- Bao, J.H.; Wang, H.H.; Wang, R.F.; Wang, Q.X.; Di, L.M.; Shi, C. Comparative experimental study on macroscopic spray characteristics of various oxygenated diesel fuels. Energy Sci. Eng. 2023, 11, 1579–1588. [Google Scholar] [CrossRef]

- Wang, H.H.; Ge, Y.S.; Tan, J.W.; Hao, L.; Wu, L.; Yang, J.; Du, Q.; Zhang, H.; Huang, Y.; Chen, Y.; et al. Ash deposited in diesel particular filter: A review. Energ. Source. Part A 2018, 41, 2184–2193. [Google Scholar] [CrossRef]

- Gao, J.B.; Ma, C.; Xing, S.; Sun, L.; Huang, L. Nanostructure analysis of particulate matter emitted from a diesel engine equipped with a NTP reactor. Fuel 2017, 192, 35–44. [Google Scholar] [CrossRef]

- Shi, C.; Chai, S.; Wang, H.Y.; Ji, C.W.; Ge, Y.S.; Di, L.M. An insight into direct water injection applied on the hydrogen-enriched rotary engine. Fuel 2023, 339, 127352. [Google Scholar] [CrossRef]

- Fang, J.; Meng, Z.W.; Li, J.; Pu, Y.F.; Du, Y.H.; Li, J.S.; Jin, Z.X.; Chen, C.; Chase, G.G. The influence of ash on soot deposition and regeneration processes in diesel particular filter. Appl. Therm. Eng. 2017, 124, 633–640. [Google Scholar] [CrossRef]

- Tan, P.Q.; Duan, L.S.; Li, E.F.; Hu, Z.Y.; Lou, D.M. Experimental study on the temperature characteristics of a diesel particulate filter during a drop to idle active regeneration process. Appl. Therm. Eng. 2020, 178, 115628. [Google Scholar] [CrossRef]

- Ji, L.; Cai, Y.; Shi, Y.; Fan, R.; Wang, W.; Chen, Y. Effects of Nonthermal Plasma on Microstructure and Oxidation Characteristics of Particulate Matter. Environ. Sci. Technol. 2020, 54, 2510–2519. [Google Scholar] [CrossRef] [PubMed]

- Bai, S.; Wang, C.; Li, D.; Wang, G.; Li, G. Influence of the idle-up strategy on the thermal management of diesel particulate filter regeneration during a drop to the idle process. Appl. Therm. Eng. 2018, 141, 976–980. [Google Scholar] [CrossRef]

- Gao, J.B.; Ma, C.; Xing, S.; Sun, L.; Huang, L. A review of fundamental factors affecting diesel PM oxidation behaviors. Sci. China Technol. Sci. 2018, 61, 330–345. [Google Scholar] [CrossRef]

- Gao, J.B.; Ma, C.C.; Tian, G.H.; Chen, J.Y.; Xing, S.K.; Huang, L.Y. Oxidation Activity Restoration of Diesel Particulate Matter by Aging in Air. Energy Fuel 2018, 32, 2450–2457. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Ge, Y.S.; Wang, X.; Peng, Z.; Tan, J.; Hao, L.; Lv, L.; Wang, C. An investigation into the impact of burning diesel/lubricant oil mixtures on the nature of particulate emissions: Implications for DPF ash-loading acceleration method. J. Energy Inst. 2020, 93, 1207–1215. [Google Scholar] [CrossRef]

- Chen, T.; Wu, Z.; Gong, J.; E, J.Q. Numerical Simulation of Diesel Particulate Filter Regeneration Considering Ash Deposit. Flow Turbul. Combust. 2016, 97, 849–864. [Google Scholar] [CrossRef]

- Du, Y.H.; Meng, Z.W.; Fang, J.; Qin, Y.; Jiang, Y.; Li, S.; Li, J.; Chen, C.; Bai, W. Characterization of soot deposition and oxidation process on catalytic diesel particulate filter with ash loading through an optimized visualized method. Fuel 2019, 243, 251–261. [Google Scholar] [CrossRef]

- Choi, S.; Seong, H. Oxidation characteristics of gasoline direct-injection (GDI) engine soot: Catalytic effects of ash and modified kinetic correlation. Combust. Flame 2015, 162, 2371–2389. [Google Scholar] [CrossRef]

- Tan, P.Q.; Wang, D.Y. Effects of Sulfur Content and Ash Content in Lubricating Oil on the Aggregate Morphology and Nanostructure of Diesel Particulate Matter. Energ. Fuels 2018, 32, 713–724. [Google Scholar] [CrossRef]

- Tan, P.Q.; Li, Y.; Shen, H.Y. Exhaust particle properties from a light duty diesel engine using different ash content lubricating oil. J. Energy Inst. 2018, 91, 55–64. [Google Scholar] [CrossRef]

- Wang, H.H.; Tan, J.W.; Ge, Y.S.; Li, J.; Yan, X. Pore morphology and fractal dimension of ash deposited in catalyst diesel particulate filter. Environ. Sci. pollut. R. 2020, 27, 11026–11037. [Google Scholar] [CrossRef] [PubMed]

- Vander Wal, R.L. Soot Nanostructure: Definition, Quantification and Implications; SAE International: Warren-dale, PA, USA, 2005. [Google Scholar]

- Zhang, Y.; Kim, D.; Rao, L.; Zhang, R.; Kook, S.; Kim, K.S.; Kweon, C.B. The soot particle formation process inside the piston bowl of a small-bore diesel engine. Combust. Flame 2017, 185, 278–291. [Google Scholar] [CrossRef]

- Hurt, R.H.; Crawford, G.P.; Shim, H.S. Equilibrium nanostructure of primary soot particles. Proc. Combust. Inst. 2000, 28, 2539–2546. [Google Scholar] [CrossRef]

- Wang, Y.S.; Liang, X.Y.; Tang, G.; Chen, Y.; Dong, L.H.; Shu, G.Q. Impact of lubricating oil combustion on nanostructure, composition and graphitization of diesel particles. Fuel 2017, 190, 237–244. [Google Scholar] [CrossRef]

- Botero, M.L.; Chen, D.; González-Calera, S.; Jefferson, D.; Kraft, M. HRTEM evaluation of soot particles produced by the non-premixed combustion of liquid fuels. Carbon 2016, 96, 459–473. [Google Scholar] [CrossRef]

- Wal, R.L.V. Initial investigation of effects of fuel oxygenation on nanostructure of soot from a direct-injection diesel engine. Energ. Fuel 2006, 20, 2364–2369. [Google Scholar]

- Zhang, W.; Song, C.; Lyu, G.; Bi, F.; Wang, T.; Liu, Y.; Qiao, Y. Petroleum and Fischer-Tropsch diesel soot: A comparison of morphology, nanostructure and oxidation reactivity. Fuel 2021, 283, 118919. [Google Scholar] [CrossRef]

- SH/T0604-2000; Crude Petroleum and Petroleum Products-Determination of Density-Oscillating U-tube Method. China Petroleum & Chemical Corporation Research Institute of Petroleum: Beijing, China, 2001.

- GB/T265-88; Petroleum Products—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. China Petroleum & Chemical Corporation Research Institute of Petroleum: Beijing, China, 1989.

- SH/T0656-1988; Determination of Carbon, Hydrogen, Nitrogen in Petroleum Products and Lubricants (Elemental Analyzer Method). 2004.

- GB/T2433-2001; Petroleum Products—Lubricating Oils and Additives—Determination of Sulphated Ash. China Petroleum & Chemical Corporation Research Institute of Petroleum: Beijing, China, 2002.

| Property | Value | Property | Value |

|---|---|---|---|

| Number of cylinders | 4 | Rated power (kW/(r/min)) | 105/3600 |

| Bore × diameter × stroke (mm) | 4 × 92 × 94 | Maximum torque ((N·m)/(r/min)) | 360/1600~2800 |

| Displacement (L) | 2.499 | Fuel System | Common rail |

| Lube consumption | ≤0.2% | Intake System | Turbocharged EGR |

| Compression ratio | 16.6:1 | Aftertreatment | DOC + DPF |

| Property | Value | |

|---|---|---|

| Distillation | 50% recovery temperature °C | 257.5 |

| 90% recovery temperature °C | 333.0 | |

| 95% recovery temperature °C | 351.0 | |

| Cetane number | - | 55.7 |

| Viscosity at 20 °C | mm2/s | 3.72 |

| Density at 20 °C | Kg/m3 | 821.3 |

| PAH content | % | 2.57 |

| Sulfur content | ppm | 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Yang, J.; Wang, H.; Yang, D.; Ge, Y.; Ning, P. Quantitative Analysis of the Impacts of Ash from Lubricating Oil on the Nanostructure of Diesel Particulate Matter. Atmosphere 2024, 15, 130. https://doi.org/10.3390/atmos15010130

Wu L, Yang J, Wang H, Yang D, Ge Y, Ning P. Quantitative Analysis of the Impacts of Ash from Lubricating Oil on the Nanostructure of Diesel Particulate Matter. Atmosphere. 2024; 15(1):130. https://doi.org/10.3390/atmos15010130

Chicago/Turabian StyleWu, Legang, Jia Yang, Haohao Wang, Dongxia Yang, Yunshan Ge, and Ping Ning. 2024. "Quantitative Analysis of the Impacts of Ash from Lubricating Oil on the Nanostructure of Diesel Particulate Matter" Atmosphere 15, no. 1: 130. https://doi.org/10.3390/atmos15010130

APA StyleWu, L., Yang, J., Wang, H., Yang, D., Ge, Y., & Ning, P. (2024). Quantitative Analysis of the Impacts of Ash from Lubricating Oil on the Nanostructure of Diesel Particulate Matter. Atmosphere, 15(1), 130. https://doi.org/10.3390/atmos15010130