Abstract

Prior studies suggest brick workers in Nepal may be chronically exposed to hazardous levels of fine particulate matter (PM2.5) from ambient, occupational, and household sources. However, findings from these studies were based on stationary monitoring data, and thus may not reflect a worker’s individual exposures. In this study, we used RTI International’s MicroPEMs to collect 24 h PM2.5 personal breathing zone (PBZ) samples among brick workers (n = 48) to estimate daily exposures from ambient, occupational, and household air pollution sources. Participants were sampled from five job categories at one kiln. The geometric mean (GM) PM2.5 exposure across all participants was 116 µg/m3 (95% confidence interval [CI]: 94.03, 143.42). Job category was significantly (p < 0.001) associated with PBZ PM2.5 concentrations. There were significant pairwise differences in geometric mean (GM) PBZ PM2.5 concentrations among workers in administration (GM: 47.92, 95% CI: 29.81, 77.03 µg/m3) vs. firemen (GM: 163.46, 95 CI: 108.36, 246.58 µg/m3, p = 0.003), administration vs. green brick hand molder (GM: 163.35, 95% CI: 122.15, 218.46 µg/m3, p < 0.001), administration vs. top loader (GM: 158.94, 95% CI: 102.42, 246.66 µg/m3, p = 0.005), firemen vs. green brick machine molder (GM: 73.18, 95% CI: 51.54, 103.90 µg/m3, p = 0.03), and green brick hand molder vs. green brick machine molder (p = 0.008). Temporal exposure trends suggested workers had chronic exposure to hazardous levels of PM2.5 with little to no recovery period during non-working hours. Multi-faceted interventions should focus on the control of ambient and household air pollution and tailored job-specific exposure controls.

1. Introduction

Brick manufacturing is a major industry in the Kathmandu Valley, Nepal, which consists of the districts of Bhaktapur, Lalitpur, and Kathmandu. More than 120 of Nepal’s approximately 1700 brick kilns operate in the valley and employ more than 30,000 workers annually [1,2,3]. Most of the brick manufacturing process in the Kathmandu Valley occurs outdoors where workers are exposed to high levels of ambient fine particulate matter (PM2.5) that originates from fugitive dust, vehicle exhaust, burning of biomass, trash and coal, and regional pollutant transport (Figure 1) [4,5,6,7]. Studies also provide evidence that there may be a potentially significant occupational component to brick workers’ daily PM2.5 exposures [8,9]. However, these studies are based on stationary sampling methods that may not accurately reflect workers’ true exposures. In addition to contributions from ambient and occupational PM2.5, brick workers likely experience exposure to high levels of household air pollution during non-working hours. It is customary for brick workers to live in poorly constructed housing at or near the brick factory, and to cook indoors with open wood fires or with liquefied petroleum gas (LPG) cookstoves [10,11,12]. One prior study showed indoor PM2.5 levels in brick workers’ homes were significantly higher than outdoor levels, and in some cases exceeded 500 µg/m3 depending on the type of cooking fuel used in the home [10,11]. Brick workers in the Kathmandu Valley may be chronically exposed to high levels of PM2.5 during work with no recovery period during non-working hours.

Figure 1.

Ambient air pollution in Bhaktapur, Nepal, March 2023. Photograph by Jaren Wilkey, University Communications, Brigham Young University, Provo, UT, USA.

Currently, inhalation of PM2.5 is thought to be the most significant environmental health issue globally [13]. Ambient PM2.5 exposure is responsible for more than four million deaths and more than 100 million disability-adjusted life years (DALYs) annually, with ischemic heart disease, chronic obstructive pulmonary disease (COPD), lung cancer, stroke, and lower respiratory infections being the primary contributors [14,15,16,17]. Studies show brick workers around the globe suffer from high rates of respiratory symptoms that, in addition to inhalation of brick dust, may be explained by PM2.5 exposure. These symptoms include cough, shortness of breath, wheezing, chronic phlegm, and symptoms consistent with a diagnosis of chronic obstructive pulmonary disease (COPD) [18,19,20]. In Nepal, one prior study documented the significantly higher self-reported prevalence of respiratory symptoms among brick workers compared to a control group of grocery workers in the same community [21]. These health effects warrant investigation of brick workers’ overall daily inhaled PM2.5 burden from all sources, including ambient, occupational, and household exposures.

Limitations in our current knowledge of Nepalese brick workers’ PM2.5 exposures include (1) prior studies of both ambient and household air pollution relying on data from stationary monitors, and (2) job-specific exposure data are generally not available. Ambient pollution levels are influenced by several factors, including location, type, and density of pollution sources, geography, and weather patterns [22,23]. Similarly, household air pollution levels measured with stationary monitors do not necessarily show a home occupant’s overall exposure because individuals are not likely to stay indoors and close to the monitor and/or pollution source(s) during the entire data collection period. Thus, a major disadvantage of stationary monitoring is that it does not account for the movement of people in and out of high-pollution areas during the sampling period. Several studies show low correlations between stationary monitors and personal breathing zone (PBZ) exposures [24,25,26]. Understanding brick workers’ total PM2.5 exposure is complicated because workers are mobile, and there are multiple local contributing sources, including smoke from the brick kiln and its chimney, ambient air pollution, brick dust, and household air pollution. The lack of data on job-specific exposures during brick manufacturing further obfuscates a clear understanding of workers’ daily inhaled PM2.5 burden.

Some limitations of stationary monitoring can be overcome by collecting PBZ samples, although this strategy is labor intensive. The recent development of miniaturized, wearable devices, such as the MicroPEM (RTI International, Research Triangle Park, NC, USA) allows for PBZ sampling of environmental PM2.5 aerosols using both filter-based (gravimetric) and nephelometer-based (real-time, data logged) readings. PBZ sampling provides an innovative method for understanding how aerosol concentrations fluctuate based on location and time as workers move through microenvironments. In the case of brick workers, wearable monitors may be used to capture the triadic (ambient, household, and occupational) nature of their daily PM2.5 exposures more accurately than stationary monitors. The purpose of this study, therefore, was to monitor workers’ 24 h PM2.5 exposures across job categories and during work and non-work activities using PBZ sampling. A clearer understanding of brick workers’ daily PM2.5 exposures may be useful for the development of future intervention strategies to limit workers’ exposures and ultimately improve their lung health.

2. Materials and Methods

2.1. Study Design

In this cross-sectional, observational study, we evaluated breathing zone PM2.5, temperature (°C), and relative humidity (%) exposures among adult brick workers (n = 48) from five job categories at one brick factory. The brick factory, located in Bhaktapur, Nepal, was categorized as an induced-draught zigzag kiln (IDZK). All samples were collected during a seven-day period from 13 to 20 March 2023. Participants were selected based on convenience sampling. Written informed consent was given by all participants prior to data collection by using native-language translations and having bilingual interpreters on site to answer participant questions. In most cases, wearable sampling instruments were placed on workers in the morning (before noon) and collected approximately 24 h later. Participants also completed a questionnaire about demographics, lifestyle, health, and work history that was modified for use in this study [27]. The questionnaire was modified specifically by adding nine questions related to pregnancy complications (data not reported here). Participants completed a second questionnaire about the characteristics of their homes that were modified to improve clarity [10]. The five job categories that were included in this study were administration (management and office personnel), green brick hand molders (workers who formed green bricks using hand molds), green brick machine molders (workers who ran brick molding machinery and workers who moved bricks formed by machinery), firemen (workers who added coal to bricks during the firing process), and top loaders (workers who removed soil from the top of the brick kiln after the firing process). This study was reviewed and approved by the Brigham Young University (BYU) Institutional Review Board (IRB) and by the Nepal Health Research Council (NHRC).

2.2. Personal Breathing Zone Monitoring

The RTI MicroPEMs V3.2A were used to collect PBZ PM2.5, temperature, and relative humidity samples. The MicroPEM offers the capability of both gravimetric sampling, which utilizes filters, and real-time data collection, which uses light-scattering technology from an onboard 780 nm infrared laser. PBZ samples were collected by placing the MicroPEM in a mesh pocket sewn to a reflective running vest worn by the worker. The vest and pocket were both 100% polyester. The vest pocket was zip-tied in place to prevent blockage of the MicroPEM inlet during sampling (Figure 2). Participants were instructed to wear the sampling vest for the entire 24 h period except while sleeping, when they were asked to place the vest and the attached MicroPem next to them. Study personnel checked on participants periodically during daytime hours to verify that they were wearing the sampling vest/MicroPEM as instructed.

Figure 2.

Placement of MicroPEM monitor in brick worker’s personal breathing zone. The brick worker in this photo was categorized as a green brick hand molder. Photograph by Jaren Wilkey, University Communications, Brigham Young University, Provo, UT, USA.

2.3. MicroPEM Preparation

MicroPEMs were prepared according to RTI standard operating procedures [28]. Before sampling, all previously stored data was deleted from the MicroPEMs. MicroPEMs were fitted with a two-stage mini-impactor assembly with a first-stage cut point at 4.0 µm and a final-stage cut point at 2.5 µm. The mini-impactor assemblies were oiled prior to sample collection by RTI International personnel. A new, pre-weighed 3.0 µm PTFE 25 mm filter (Zefon International, Ocala, FL, USA) was placed in the filter cassette before sampling, and the filter cassette was placed in the MicroPEM. Instrument date/time, nephelometer offset, and pump flow rate were set in the field on each instrument using Docking Station software version 2.0 (RTI International, Research Triangle Park, NC, USA). The nephelometer offset was adjusted to zero while HEPA-filtered air was being drawn through the instrument. A TSI model 4140 flow meter (TSI, Shoreview, MN, USA) was used to calibrate the MicroPEM flow rate to 0.5 L per minute.

2.4. Filter Preparation and Handling

Both pre- and post-collection filter weighing occurred in a temperature and humidity-controlled laboratory room on the campus of Brigham Young University in Provo, Utah, USA. Before weighing, filters were conditioned for 24 h by placing a filter in an SKC filter keeper (SKC, Inc., Eighty Four, PA, USA). Filter keepers were loosely closed to prevent dust from falling onto the filters while allowing laboratory air to circulate inside the filter keeper. This was accomplished by fastening the clamshell filter keeper together with a binder clip, but not snapping the circular ring together, which would have prevented the enclosed filters from equilibrating to laboratory temperature and relative humidity. Temperature was maintained by the building’s heating, ventilation, and air conditioning system. Humidity in the weighing room was maintained using a humidifier filled with deionized water. Temperature and humidity were measured during pre- and post-filter conditioning periods using an Extech SD500 datalogger (Extech Instruments, Nashua, NH, USA). Mean temperature and relative humidity during pre-conditioning were 21.75 °C (SD = 1.77 °C) and 29.73% (SD = 7.61%), respectively. Mean temperature and relative humidity during post-conditioning were 21.20 °C (SD = 1.21 °C) and 27.74% (SD = 9.96%), respectively. All weighing was completed using a Mettler Toledo (Mettler Toledo, Columbus, OH, USA) model XP2U microbalance. When handling the filters, we used Teflon-coated tweezers (Mettler Toledo Columbus, OH, USA). Additionally, a Haug (Haug North America, Williamsville, NY, USA) U-bar deionizer was employed to eliminate static electricity from each filter prior to weighing. Each filter was weighed three times and the mean of these measurements was recorded as the filter pre-weight. This same procedure was used to post weigh the filters after our return from Nepal. Filters were stored in SKC filter keepers when not in use. Filter keepers were snapped closed after filter conditioning to prevent contamination.

2.5. Statistical Analyses

We performed all data management and statistical analysis with SAS version 9.4 (SAS Institute, Inc., Cary, NC, USA). When we reviewed the MicroPEM nephelometer data, we discovered some negative readings for some participants, which may indicate the nephelometer laser had drifted (perhaps because of temperature changes or the MicroPEM was dropped) or the optics needed to be cleaned. Therefore, we corrected the drift/negative values to match the overall patterns in the nephelometer data for these participants. We then corrected the nephelometer data for all participants using the gravimetric results as explained previously [11,28].

We calculated summary statistics including frequencies, percentages, arithmetic means (AM), standard deviations (SD), minimums, first quartiles, medians, third quartiles, maximums, geometric means (GM), and 95% confidence intervals (CI) for demographic, job, and housing characteristics and PBZ PM2.5 concentrations, temperature, and relative humidity. The distributions of PBZ PM2.5 concentrations and temperature were right skewed, so we used intercept-only linear regression models of the natural logarithm transformed values to calculate the overall GM and 95% CI. We used intercept-only linear regression models of the original values to calculate the overall AM and 95% CI for PBZ relative humidity.

We calculated the Akaike Information Criterion (AIC) for several versions (e.g., linear; linear and quadratic; linear, quadratic, and cubic; categorical; restricted quadratic regression splines) of the continuous job and housing characteristics and used the versions with the lowest AIC for subsequent analyses [29,30]. We used separate simple (i.e., unadjusted) linear regression models of the natural logarithm transformed values to calculate GM or geometric mean ratios (GMR), 95% CI, and p-values for associations between individual job and housing characteristics and PBZ PM2.5 concentrations and temperature. We used separate simple (i.e., unadjusted) linear regression models of the original values to calculate AM or change in AM, 95% CI, and p-values for associations between individual job and housing characteristics and PBZ relative humidity. We scaled calculated GMR or change in AM and 95% CI to interquartile range (IQR) increases in continuous job or housing characteristics to make them easier to interpret. For job and housing characteristics that had three or more categories and p-values for associations with PBZ PM2.5 concentrations, temperature, or relative humidity less than a significance level of α = 0.05, we conducted pairwise comparisons of GM or AM for each category and used the Tukey–Kramer method to adjust for multiple comparisons.

We thought job category might be a potential confounder of associations between other job and housing characteristics and PBZ PM2.5 concentrations, temperature, and relative humidity, so we used separate multivariable linear regression models of the natural logarithm transformed values to calculate p-values for associations between individual job and housing characteristics and PBZ PM2.5 concentrations and temperature adjusted for job category. We also used separate multivariable linear regression models of the original values to calculate p-values for associations between individual job and housing characteristics and PBZ relative humidity adjusted for job category.

We conducted two sensitivity analyses. First, we repeated analyses for PBZ PM2.5 concentrations after excluding data for one participant because we had dropped the MicroPEM filter on a concrete floor at the end of data collection and were worried the sample might have been contaminated (i.e., we were worried the PBZ PM2.5 concentration was too high). Second, we repeated analyses for PBZ temperature after excluding data for one participant because there was an approximately 3.5 h increase in temperature that did not seem realistic (i.e., the temperature reached almost 260 °C during the 3.5 h increase).

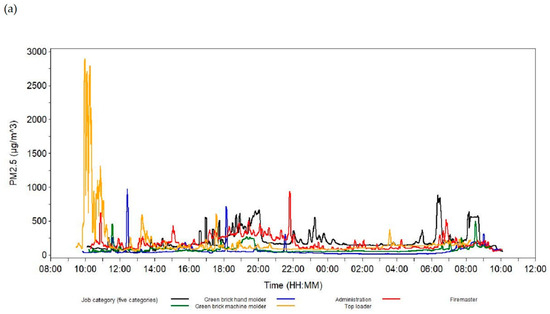

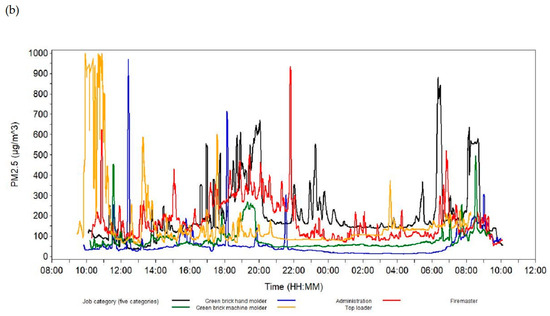

We used line graphs to investigate temporal trends in five-minute moving averages of AM PBZ PM2.5 concentrations, temperature, and relative humidity by job category (i.e., we averaged PBZ PM2.5 concentrations, temperature, and relative humidity across workers in each category and then calculated five-minute moving averages of the AMs).

3. Results

For the 48 workers for which we obtained PBZ air samples, the median age was 28.42 (IQR: 11.37) years, 48% were male, and 74% had completed elementary school (grades 1–8) or less (Table 1). The workers worked in the following job categories: administration (13%), firemen (17%), green brick hand molder (33%), green brick machine molder (23%), and top loader (15%; Table 2). The AM internal house area was 10.75 (SD: 4.66) m2, the median internal house volume was 17.75 (IQR: 12.43) m3, and the median time lived in the house was five (IQR: 19.50) months. Nineteen percent of workers lived in firemen’s homes and 23%, 23%, and 54% lived in the same house, a different house in the Kathmandu Valley, and a different house outside the Kathmandu Valley, respectively, during summer monsoon months when brick kilns are shut down. The median people, adults, children under 18 years of age, and children under 6 years of age who lived in the house were 4.00 (IQR: 2.50), 2.50 (IQR: 2.00), 1.00 (IQR: 2.00), and 0.50 (IQR: 1.00), respectively. The median occupant density was 34.40 (IQR: 26.34) residents/100 m2 and 94% of workers cooked inside the home. The primary fuel used for cooking was liquid petroleum gas (LPG) only for 98% of workers and 2% had a stove or other cooking source vented to the outdoors with a chimney. Twenty-one percent of workers had a heating source in their homes. Thirteen percent of workers used a cooking fire and 8% used an electric heater as the heating source in the home. Ten percent of workers used the heating source in the home less than once per day, whereas 10% used the heating source in the home once per day or more. Ninety-eight percent of workers used electricity for light when it was dark outside and 52% had smokers living in the home. The median number of smokers living in the home was one (IQR: one) and the median number of smokers living in the home who regularly smoke inside the home was zero (IQR: one).

Table 1.

Demographic information for workers a at a brick kiln in Bhaktapur, Nepal, March 2023.

Table 2.

Job and housing characteristics for workers a at a brick kiln in Bhaktapur, Nepal, March 2023.

The median PBZ air sampling time was 21.86 (IQR: 3.39) hours and the GM PBZ PM2.5 concentration was 116.13 (95% CI: 94.03, 143.42) µg/m3 (Table 3). The GM PBZ temperature was 24.76 (95% CI: 23.48, 26.10) °C and the AM PBZ relative humidity was 48.11% (95% CI: 45.99, 50.23).

Table 3.

Summary statistics for mean personal breathing zone PM2.5 concentrations, temperature, and relative humidity among workers a at a brick kiln in Bhaktapur, Nepal, March 2023.

Job category was significantly (p < 0.001) associated with PBZ PM2.5 concentrations (Table 4). There were significant pairwise differences in PBZ PM2.5 concentrations among workers in administration (GM: 47.92, 95% CI: 29.81, 77.03 µg/m3) vs. firemen (GM: 163.46, 95 CI: 108.36, 246.58 µg/m3, p = 0.003), administration vs. green brick hand molder (GM: 163.35, 95% CI: 122.15, 218.46 µg/m3, p < 0.001), administration vs. top loader (GM: 158.94, 95% CI: 102.42, 246.66 µg/m3, p = 0.005), firemen vs. green brick machine molder (GM: 73.18, 95% CI: 51.54, 103.90 µg/m3, p = 0.03), and green brick hand molder vs. green brick machine molder (p = 0.008). There was a significant (p = 0.02) inverse association between a 20-month increase in how long workers lived in their house and PBZ PM2.5 concentrations (GMR: 0.91, 95% CI: 0.84, 0.98). Where workers live during summer monsoon months when brick kilns are shut down was significantly (p = 0.02) associated with PBZ PM2.5 concentrations. There were significant pairwise differences in PBZ PM2.5 concentrations among workers in the same house (GM: 67.75, 95% CI: 44.91, 102.22 µg/m3) vs. different house in the Kathmandu Valley (GM: 144.47, 95% CI: 95.76, 217.95 µg/m3, p = 0.03) and same house vs. different house outside the Kathmandu Valley (GM: 132.99, 95% CI: 101.78, 173.77 µg/m3, p = 0.02). Having a heating source in the home was significantly associated (p = 0.01) with PBZ PM2.5 concentrations (no: GM: 132.44, 95% CI: 105.85, 165.72 µg/m3; yes: GM: 70.47, 95% CI: 45.52, 109.08 µg/m3). How often is the heating source in the home used was significantly (p = 0.03) associated with PBZ PM2.5 concentrations. There was a significant (p = 0.04) pairwise difference in PBZ PM2.5 concentrations among workers who never used a heating source in the home (GM: 132.44, 95% CI: 105.79, 165.82 µg/m3) vs. those who used the heating source in the home once per day or more (GM: 57.92, 95% CI: 31.17, 107.62 µg/m3).

Table 4.

Associations between job and housing characteristics and mean personal breathing zone PM2.5 concentrations among workers a at a brick kiln in Bhaktapur, Nepal, March 2023.

PBZ temperature was significantly (p < 0.001) associated with job category (Table S1). There were significant pairwise differences in PBZ temperature among workers in administration (GM: 23.56, 95% CI: 20.88, 26.59 °C) vs. top loader (GM: 31.90, 95% CI: 28.52, 35.68 °C, p = 0.005), green brick hand molder (GM: 23.80, 95% CI: 22.10, 25.63 °C) vs. top loader (p < 0.001), and green brick machine molder (GM: 22.23, 95% CI: 20.33, 24.30 °C) vs. top loader (p < 0.001).

Job category was significantly (p < 0.001) associated with PBZ relative humidity (Table S2). There were significant pairwise differences in PBZ relative humidity among workers in administration (AM: 45.19, 95% CI: 49.42, 53.65%) vs. firemen (AM: 37.05, 95% CI: 40.71, 44.37%, p = 0.02), administration vs. top loader (AM: 37.31, 95% CI: 41.23, 45.15%, p = 0.05), firemen vs. green brick hand molder (AM: 46.85, 95% CI: 49.45, 52.04%, p = 0.003), firemen vs. green brick machine molder (AM: 52.08, 95% CI: 55.21, 58.33%, p < 0.001), green brick hand molder vs. green brick machine molder (p = 0.05), green brick hand molder vs. top loader (p = 0.008), and green brick machine molder vs. top loader (p < 0.001). There were significant positive associations between PBZ relative humidity and a 5.70 m2 increase in internal house area (change in AM: 3.69, 95% CI: 1.06, 6.33%, p = 0.007) and a 12.43 m3 increase in internal house volume (change in AM: 2.83, 95% CI: 0.53, 5.13%, p = 0.02). Whether a firemen’s home was significantly associated (p = 0.003) with PBZ relative humidity (no: AM: 47.38, 95% CI: 49.54, 51.70%; yes: AM: 37.39, 95% CI: 41.90, 46.40%). How many people live in the house was significantly (p = 0.04) associated with PBZ relative humidity. There was a significant (p = 0.03) pairwise difference in PBZ relative humidity among workers who had 3–4 people who lived in the house (AM: 48.14, 95% CI: 51.52, 54.91%) vs. 5–11 (AM: 42.21, 95% CI: 45.41, 48.61%). There was a significant (p = 0.02) inverse association between an increase in occupant density of 26.34 residents/100 m2 and PBZ relative humidity (change in AM: −2.84, 95% CI: −5.19, −0.50%).

After adjusting all estimated associations between job and housing characteristics and PBZ PM2.5 concentrations, temperature, and relative humidity for job category, we found that job category remained significantly associated with PBZ PM2.5 concentrations (Table 5), temperature (Table S3), and relative humidity (Table S4). However, the only other significant associations after adjusting for job category were between PBZ PM2.5 concentrations and heating source in the home (p = 0.02) and how often is the heating source in the home used (p = 0.05). Results were similar after we conducted the two aforementioned sensitivity analyses (not shown).

Table 5.

Associations between housing characteristics and mean personal breathing zone PM2.5 concentrations adjusted for job category among workers a at a brick kiln in Bhaktapur, Nepal, March 2023.

Line graphs of temporal trends in five-minute moving averages indicated PBZ PM2.5 concentrations for administration workers were fairly stable over the sampling period with a few isolated increases, whereas firemen had several increases in PBZ PM2.5 concentrations throughout the day, but a decrease at night (Figure 3). For green brick hand molders and green brick machine molders, PBZ PM2.5 concentrations increased around mealtimes, although these increases were of greater magnitude for green brick hand molders than for green brick machine molders. Top loaders had multiple increases in PBZ PM2.5 concentrations throughout the working period of the day including a very large increase in the morning. For workers in all five job categories, PBZ temperature generally increased in the morning, was stable during the afternoon, and decreased at night, although these temperature changes were much greater among top loaders than among workers in the other four job categories (Figure S1). PBZ relative humidity generally decreased in the morning, was stable during the afternoon, and increased at night for workers in all five job categories (Figure S1).

Figure 3.

Line graphs of temporal trends in five-minute moving averages of arithmetic mean personal breathing zone PM2.5 concentrations among workers a at a brick kiln in Bhaktapur, Nepal, March 2023: (a) PM2.5, (b) PM2.5 (0 to 1000 µg/m3). Abbreviations: PM2.5, particulate matter with an aerodynamic diameter less than 2.5 µm. a Two samples were missing because one of the 50 workers enrolled in the study declined to participate in the personal breathing zone air sampling, and a MicroPEM malfunctioned for another worker, so we could not obtain personal breathing zone information for that worker.

4. Discussion

Our findings add to a growing body of literature about particulate matter pollution exposures associated with clay brick manufacturing. Raza et al. (2014) reported mean PM2.5 and PM10 concentrations of 412 µg/m3 and 1193 µg/m3, respectively, for various sections of brick kilns in the Gujrat district, Pakistan [8]. Berumen-Rodríquez et al. (2023) found PM2.5 concentrations ranged from 42–3542 µg/m3 (mean = 276 µg/m3) at brick kilns in the San Lois Potosí municipality in Mexico [9]. Recent studies also show the potential for high exposures to PM2.5 in brick worker housing well above the World Health Organization’s (WHO) air quality guideline (AQG) of 15.0 µg/m3 for a 24 hr period [10,12,31]. Thygerson et al. (2019) found an average daytime concentration of 182.80 µg/m3 for indoor PM2.5 in brick workers’ homes [10]. Johnston et al. (2020) reported 24 h PM2.5 concentrations ranging from a GM of 79.32 µg/m3 for homes that used LPG cookstoves to a GM of 541.14 µg/m3 for homes that used open wood cooking fires [11]. Furthermore, 24 h indoor samples collected by Johnston et al. (2021) had PM2.5 chemical constituents, including aluminum, calcium, copper, iron, silicon, and titanium, above concentrations known to cause deleterious health effects [12]. One major drawback to these prior studies is that results were based on stationary monitoring data, which may not accurately reflect brick workers’ true exposures. In this study, we aimed to characterize brick workers’ PM2.5 exposures over a 24 h period using personal breathing zone sampling. This sampling strategy allowed us to capture participants’ PM2.5 exposures from multiple sources over the sampling period. In general, our participants’ 24 h PM2.5 exposures (GM = 116 µg/m3) were lower than the average stationary indoor and outdoor measures cited above. However, our findings suggest brick workers in the Kathmandu Valley experience almost constant exposure to harmful concentrations of PM2.5 with little to no recovery period during non-working hours.

A substantial fraction of PM2.5 exposure among our participants likely came from ambient air pollution in the Kathmandu Valley. Globally, high ambient PM2.5 levels are predominantly found in low- and middle-income countries in South, East, and Southeast Asia, Central and West Africa, and Central and South America [13]. In 2021, the average ambient PM2.5 level in Nepal was 51.7 µg/m3, placing Nepal among the four countries in the world with the worst air pollution [13]. Ambient PM2.5 in the Kathmandu Valley is generally higher than in other parts of Nepal due to higher population density and the bowl-shaped topography of the valley. In winter and springtime seasons, when brick manufacturing occurs, PM2.5 levels in the valley average more than 70 µg/m3 [32]. During the brick-making season in Nepal, workers are almost exclusively outdoors during work hours. This pattern held true for participants in our study except for administration workers. Administration workers, the group with the lowest GM PM2.5 exposures among the five job categories sampled, appeared to split their time between indoor and outdoor tasks. There appeared to be a relatively small occupational component to administration workers’ aerosol exposures; however, some in this group spent intermittent time on top of the kiln. It is possible that administration offices served as a protective envelope from outdoor air pollution, which resulted in lower exposures among this group. Conversely, it is also plausible that office spaces provided little protection, and PM2.5 exposures among administration workers largely reflected combined exposures from infiltration of ambient PM2.5 into office spaces, ambient exposure when administration workers were outdoors, and household air pollution exposure during non-working hours.

After adjusting for housing characteristics, job category remained significantly associated with PM2.5 exposure. While all participants were exposed, presumably, to similar concentrations of ambient air pollution during sampling, we observed some specific tasks that may help explain differences in PM2.5 exposure by job category. For example, firemen had the highest GM PM2.5 exposure among the job categories sampled. One of their primary tasks was to add fuel to the kiln. This was carried out by removing fuel feed hole covers and pouring coal or a sawdust/coal mixture into fuel feed holes on top of the kiln. Smoke that escaped from the fuel feed holes likely contributed to the firemen’s exposures. Top loaders, as a group, had a similarly high GM PM2.5 exposure. Their primary job task was to remove the layer of soil and the top layer of bricks from the kiln after the bricks were fired. The soil/brick removal process is quite dusty. In addition, removing the layer of soil and bricks allowed residual smoke from the firing process to escape, which potentially exposed top loaders to PM2.5 aerosols. Green brick hand molders did not work on top of the kiln and were thus less likely to be exposed like the firemen and top loaders. We were surprised to find high PM2.5 exposures in this group because green bricks were molded with wet clay. In addition to contributions from ambient and household sources, green brick hand molders may have had a significant occupational component to their PM2.5 exposure from the release agent used during brick molding. During hand molding, workers regularly applied a fine coat of dry dust to the inside of the brick mold. This dust coat prevented the freshly molded green brick from sticking to the inside of the wooden mold. There was a visible cloud of dust near the workers’ breathing zone when they coated the mold, which may explain their relatively high exposure. Much of this dust is presumably larger than 2.5 µm, and a substantial fraction of the dust is likely too large to be inhaled or is captured by inertial impaction on the back of the worker’s throat upon inhalation, therefore not reaching the lungs. Nevertheless, our findings suggest the release agent contains dust particles in the respirable range, which contributed to green brick hand molders’ overall PM2.5 exposure. An assessment of particle sizes in the release agent may help determine the fraction of dust that, when aerosolized, will be in the respirable range. A comparison of chemical components in PM2.5 samples by job category may help elucidate sources of exposures between firemen, top loaders, and green brick hand molders.

Among the five job categories sampled, green brick machine molders had the second lowest GM PM2.5 exposure. Green brick machine molders’ primary job tasks were to remove bricks from the brick molding machine, wheel the bricks on a cart to the drying area, and lay the bricks on the ground to dry. Most of their work occurred outdoors or under outdoor canopies where the bricks were air dried, but they did regularly enter the opening to the building where bricks were being machine molded. Machinery exhaust or dust generated in the building may have contributed an occupational component to their overall PM2.5 exposure.

Contrary to what we would have predicted, participants who had a heating source in the home had lower GM PM2.5 levels than participants who did not have a heating source in the home. Similarly, participants who used the heating source in the home at least once per day had lower GM PM2.5 levels than participants who did not have a heating source in the home or who used it less often. Of the 10 participants who used a heating source in the home, 2 were green brick hand molders, 3 were green brick machine molders, and 2 were administration workers. Of the five people who used the heating source in the home at least once per day, one was a green brick hand molder, two were green brick machine molders, and two were administration workers. Among the job categories sampled, green brick machine molders and administration workers had the lowest overall GM PM2.5 levels. However, we adjusted for job category and still found a significant association between the heating source in the home, how often the heating source in the home was used, and GM PM2.5 levels. One possible explanation is that the association between having a heating source in the home and GM PM2.5 levels is due to sample size. In this study, a relatively small number of participants had and used a heating source in the home. Studies with larger sample sizes are needed to understand this relationship more fully. It may also help to distinguish between outdoor, occupational, and indoor exposures using activity diaries or other methods of tracking workers’ time/activity patterns.

Temporal trends in PM2.5 exposure over the sampling period had intermittent exposure peaks among all job categories, which often exceeded 1000 µg/m3. This finding was particularly pronounced for top loaders during morning and afternoon hours and is consistent with our observations of participants in this work group having visibly high dust exposures. We also identified exposure peaks among various job categories during approximately 18:00–21:00 h and approximately 07:00–09:00 h, which coincide with evening and morning meals. Participants in our study almost exclusively used LPG fuel for cooking. In the study by Johnston et al. (2020), exposure peaks were observed at mealtimes in homes of brick workers that used wood cooking fires, but not in those that used LPG cookstoves [11]. Cooking differences between kiln workers may help explain this result. For example, stir fry cooking creates a tremendous amount of aerosol compared to stewing and boiling methods [33]. It is possible that workers at this particular kiln tended to use frying methods more than participants at the kiln referenced by Johnston et al. Unfortunately, we did not ask workers about cooking practices, which we recommend doing for future studies that consider brick workers’ indoor exposures.

One strength of this study was the use of PBZ sampling across job categories. This strategy provided a clearer, more integrated understanding of workers’ daily PM2.5 exposures and accounted for contributions from ambient, occupational, and household sources. Additionally, the MicroPEM is equipped with both filter-based and optical sampling methods. This allowed us to use the corrected, and hence more accurate, nephelometer measures, something that has been lacking in previous studies [8]. This study was limited to assessing exposures to a single type of pollutant at a single brick kiln. Results from this study may not be generalizable to workers at other brick kilns in the Kathmandu Valley, or other brick kilns globally. While the PBZ sampling strategy provided a more accurate assessment of workers’ daily PM2.5 exposures, we did not collect activity diaries or other measures of workers’ spatial movements between work and home. Thus, we were not able to estimate contributions from ambient, occupational, and household pollution sources to their daily exposures.

5. Conclusions

In addition to the well-recognized ambient air quality problems in the Kathmandu Valley, our findings suggest brick workers’ daily PM2.5 exposure burden has significant occupational and household components. Our findings related to job-specific differences in exposure suggest additional assessments are needed to confirm and complement our results and these assessments should be conducted at multiple kilns, and across multiple job categories. The high PM2.5 exposures found in this study also warrant additional research on brick workers’ health. Based on the known health consequences associated with PM2.5 exposure, we recommend focusing future studies on lung and cardiovascular health. Workplace-led interventions focused on smoking cessation and cleaner fuels for cooking and heating may also provide workers and their families with substantive relief from chronically high air pollution exposures during non-working hours [34,35].

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/atmos14121783/s1, Table S1: associations between job and housing characteristics and mean personal breathing zone temperature among workers at a brick kiln in Bhaktapur, Nepal, March 2023; Table S2: associations between job and housing characteristics and mean personal breathing zone relative humidity among workers at a brick kiln in Bhaktapur, Nepal, March 2023; Table S3: associations between housing characteristics and mean personal breathing zone temperature adjusted for job category among workers at a brick kiln in Bhaktapur, Nepal, March 2023; Table S4: associations between housing characteristics and mean personal breathing zone relative humidity adjusted for job category among workers at a brick kiln in Bhaktapur, Nepal, March 2023; Figure S1: line graphs of temporal trends in five-minute moving averages of arithmetic mean personal breathing zone temperature and relative humidity among workers at a brick kiln in Bhaktapur, Nepal, March 2023.

Author Contributions

Conceptualization, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F. and J.D.B.; methodology, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F., R.T.C., L.N.L., J.H.L., M.S.P., S.S. and J.D.B.; validation, J.D.J., R.T.C. and J.D.B.; formal analysis, J.D.J., R.T.C., J.H.L., M.S.P. and J.D.B.; investigation, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F., L.N.L., J.H.L., M.S.P. and J.D.B.; resources, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F. and J.D.B.; data curation, J.D.J., S.C.C., R.T.C. and J.D.B.; writing—original draft preparation, J.D.J., S.C.C., L.N.L., J.H.L., M.S.P. and J.D.B.; writing—review and editing, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F., R.T.C., L.N.L., J.H.L., M.S.P., S.S. and J.D.B.; visualization, J.D.B.; supervision, J.D.J., S.C.C., J.D.L., N.E.P., P.R.R., J.A.A., A.J.S., C.B.F. and J.D.B.; project administration, J.D.J., S.S. and J.D.B.; funding acquisition, J.D.J., J.D.L., N.E.P., P.R.R. and J.D.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by BYU’s Simmons Research Endowment as an Interdisciplinary Research (IDR) Origination Award. This work was supported in part by a John A. Widtsoe Innovative Research Grant from BYU and the Roger and Victoria Sant Educational Endowment for a Sustainable Environment, which is managed by BYU’s College of Life Sciences. This work was also supported in part by College Undergraduate Research Awards from BYU’s College of Life Sciences.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board of Brigham Young University (protocol number IRB 2022-370, approved 25 October 2022) and by the Nepal Health Research Council (protocol number 554-2022, approved 13 March 2023).

Informed Consent Statement

Written informed consent was obtained from all subjects involved in this study.

Data Availability Statement

The data presented in this study are openly available in Open Science Framework at https://osf.io/9gpws/.

Acknowledgments

This work could not have been accomplished without the expert help of our friend and guide, Jagat Lama, and his team. The data enumerators and interpreters are heartily acknowledged. Our special thanks also to the BYU Kennedy Center for their knowledge and in-country logistical support. We are also especially grateful to the brick kiln owner and his staff, and the brick kiln workers, for their support of this research.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Eil, A.; Li, J.; Baral, P.; Saikawa, E. Dirty Stacks, High Stakes: An Overview of Brick Sector in South Asia; World Bank Group: Washington, DC, USA, 2020; Available online: http://documents.worldbank.org/curated/en/685751588227715919/Dirty-Stacks-High-Stakes-An-Overview-of-Brick-Sector-in-South-Asia (accessed on 21 November 2023).

- Haack, B.N.; Khatiwada, G. Rice and bricks: Environmental issues and mapping of the unusual crop rotation pattern in the Kathmandu Valley, Nepal. Environ. Manag. 2007, 39, 774–782. [Google Scholar] [CrossRef] [PubMed]

- ENPHO—Environment and Public Health Organisation. A Study on Status of Brick Industry in the Kathmandu Valley; ENPHO: Kathmandu, Nepal, 2001. [Google Scholar]

- Shakya, K.M.; Rupakheti, M.; Shahi, A.; Maskey, R.; Pradhan, B.; Panday, A.; Puppala, S.P.; Lawrence, M.; Peltier, R.E. Near-road sampling of PM2.5, BC, and fine-particle chemical components in Kathmandu Valley, Nepal. Atmos. Chem. Phys. 2017, 17, 6503–6516. [Google Scholar] [CrossRef]

- Saud, B.; Paudel, G. The threat of ambient air pollution in Kathmandu, Nepal. J. Environ. Public Health 2018, 2018, 1504591. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Li, T.; Mahata, K.; Khanal, N.; Werden, B.; Giordano, M.R.; Praveen Puppala, S.; Dhital, N.B.; Gurung, A.; Saikawa, E. Wintertime Air Quality across the Kathmandu Valley, Nepal: Concentration, Composition, and Sources of Fine and Coarse Particulate Matter. ACS Earth Space Chem. 2022, 6, 2955–2971. [Google Scholar] [CrossRef] [PubMed]

- Khanal, S.; Pokhrel, R.P.; Pokharel, B.; Becker, S.; Giri, B.; Adhikari, L.; LaPlante, M.D. An episode of transboundary air pollution in the central Himalayas during agricultural residue burning season in North India. Atmos. Pollut. Res. 2022, 13, 101270. [Google Scholar] [CrossRef]

- Raza, A.; Qamer, M.F.; Afsheen, S.; Adnan, M.; Naeem, S.; Atiq, M. Particulate matter associated lung function decline in brick kiln workers of Jalalpur Jattan, Pakistan. Pak. J. Zool. 2014, 46, 237–243. [Google Scholar]

- Berumen-Rodríguez, A.A.; Alcántara-Quintana, L.E.; Pérez-Vázquez, F.J.; Zamora-Mendoza, B.N.; Díaz de León-Martínez, L.; Díaz Barriga, F.; Flores-Ramírez, R. Assessment of inflammatory cytokines in exhaled breath condensate and exposure to mixtures of organic pollutants in brick workers. Environ. Sci. Pollut. Res. 2023, 30, 13270–13282. [Google Scholar] [CrossRef]

- Thygerson, S.M.; Beard, J.D.; House, M.J.; Smith, R.L.; Burbidge, H.C.; Andrus, K.N.; Weber, F.X.; Chartier, R.; Johnston, J.D. Air-Quality Assessment of On-Site Brick-Kiln Worker Housing in Bhaktapur, Nepal: Chemical Speciation of Indoor and Outdoor PM2.5 Pollution. Int. J. Environ. Res. Public Health 2019, 16, 4114. [Google Scholar] [CrossRef]

- Johnston, J.D.; Hawks, M.E.; Johnston, H.B.; Johnson, L.A.; Beard, J.D. Comparison of Liquefied Petroleum Gas Cookstoves and Wood Cooking Fires on PM2.5 Trends in Brick Workers’ Homes in Nepal. Int. J. Environ. Res. Public Health 2020, 17, 5681. [Google Scholar] [CrossRef]

- Johnston, J.D.; Beard, J.D.; Montague, E.J.; Sanjel, S.; Lu, J.H.; McBride, H.; Weber, F.X.; Chartier, R.T. Chemical composition of PM2.5 in wood fire and lpg cookstove homes of Nepali brick workers. Atmosphere 2021, 12, 911. [Google Scholar] [CrossRef]

- Greenstone, M.; Hasenkopf, C. Air Quality Life Index (AQLI) “Annual Update”; Energy Policy Institute at the University of Chicago (EPIC): Chicago, IL, USA, 2023; Available online: https://aqli.epic.uchicago.edu/reports/ (accessed on 21 November 2023).

- Bu, X.; Xie, Z.; Liu, J.; Wei, L.; Wang, X.; Chen, M.; Ren, H. Global PM2.5-attributable health burden from 1990 to 2017: Estimates from the Global Burden of disease study 2017. Environ. Res. 2021, 197, 111123. [Google Scholar] [CrossRef] [PubMed]

- Sang, S.; Chu, C.; Zhang, T.; Chen, H.; Yang, X. The global burden of disease attributable to ambient fine particulate matter in 204 countries and territories, 1990–2019: A systematic analysis of the Global Burden of Disease Study 2019. Ecotoxicol. Environ. Saf. 2022, 238, 113588. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhang, T.; Zhang, Y.; Chen, H.; Sang, S. Global burden of COPD attributable to ambient PM2.5 in 204 countries and territories, 1990 to 2019: A systematic analysis for the Global Burden of Disease Study 2019. Sci. Total Environ. 2021, 796, 148819. [Google Scholar] [CrossRef] [PubMed]

- Cohen, A.J.; Brauer, M.; Burnett, R.; Anderson, H.R.; Frostad, J.; Estep, K.; Balakrishnan, K.; Brunekreef, B.; Dandona, L.; Dandona, R. Estimates and 25-year trends of the global burden of disease attributable to ambient air pollution: An analysis of data from the Global Burden of Diseases Study 2015. Lancet 2017, 389, 1907–1918. [Google Scholar] [CrossRef] [PubMed]

- Monga, V.; Singh, L.P.; Bhardwaj, A.; Singh, H. Respiratory health in brick kiln workers. Int. J. Phys. Soc. Sci. 2012, 2, 226–244. [Google Scholar]

- Raza, A.; Ali, Z. Impact of air pollution generated by brick kilns on the pulmonary health of workers. J. Health Pollut. 2021, 11, 210906. [Google Scholar] [CrossRef]

- Berumen-Rodríguez, A.A.; Díaz de León-Martínez, L.; Zamora-Mendoza, B.N.; Orta-Arellanos, H.; Saldaña-Villanueva, K.; Barrera-López, V.; Gómez-Gómez, A.; Pérez-Vázquez, F.J.; Díaz-Barriga, F.; Flores-Ramírez, R. Evaluation of respiratory function and biomarkers of exposure to mixtures of pollutants in brick-kilns workers from a marginalized urban area in Mexico. Environ. Sci. Pollut. Res. 2021, 28, 67833–67842. [Google Scholar] [CrossRef]

- Sanjel, S.; Khanal, S.N.; Thygerson, S.M.; Carter, W.S.; Johnston, J.D.; Joshi, S.K. Respiratory symptoms and illnesses related to the concentration of airborne particulate matter among brick kiln workers in Kathmandu valley, Nepal. Ann. Occup. Environ. Med. 2017, 29, 1–12. [Google Scholar] [CrossRef]

- Gulliver, J.; Briggs, D. Personal exposure to particulate air pollution in transport microenvironments. Atmos. Environ. 2004, 38, 1–8. [Google Scholar] [CrossRef]

- Park, Y.M.; Kwan, M.-P. Individual exposure estimates may be erroneous when spatiotemporal variability of air pollution and human mobility are ignored. Health Place 2017, 43, 85–94. [Google Scholar] [CrossRef]

- Avery, C.L.; Mills, K.T.; Williams, R.; McGraw, K.A.; Poole, C.; Smith, R.L.; Whitsel, E.A. Estimating error in using residential outdoor PM2.5 concentrations as proxies for personal exposures: A meta-analysis. Environ. Health Perspect. 2010, 118, 673–678. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, A.J.; Xu, X.; Kulka, R.; You, H.; Wallace, L.; Mallach, G.; Ryswyk, K.V.; MacNeill, M.; Kearney, J.; Rasmussen, P.E. Windsor, Ontario exposure assessment study: Design and methods validation of personal, indoor, and outdoor air pollution monitoring. J. Air Waste Manag. Assoc. 2011, 61, 324–338. [Google Scholar] [CrossRef] [PubMed]

- Oglesby, L.; Künzli, N.; Röösli, M.; Braun-Fahrländer, C.; Mathys, P.; Stern, W.; Jantunen, M.; Kousa, A. Validity of ambient levels of fine particles as surrogate for personal exposure to outdoor air pollution—Results of the European EXPOLIS-EAS Study (Swiss Center Basel). J. Air Waste Manag. Assoc. 2000, 50, 1251–1261. [Google Scholar] [CrossRef]

- Schubauer-Berigan, M.K.; Dahm, M.M.; Erdely, A.; Beard, J.D.; Eileen Birch, M.; Evans, D.E.; Fernback, J.E.; Mercer, R.R.; Bertke, S.J.; Eye, T. Association of pulmonary, cardiovascular, and hematologic metrics with carbon nanotube and nanofiber exposure among US workers: A cross-sectional study. Part. Fibre Toxicol. 2018, 15, 22. [Google Scholar] [CrossRef] [PubMed]

- Rodes, C. Standard Operating Procedure MicroPEM v 3.2 A [Gates Foundation Version] Aerosol Exposure SOP M-300: Setup, Preparation, Calibration, Deployment; RTI International, Engineering and Technology Unit, Center for Aerosols and Nanomaterials Technologies: Research Triangle Park, NC, USA, 2013; pp. 1–46. [Google Scholar]

- Akaike, H. A new look at the statistical model identification. IEEE Trans. Autom. Control 1974, 19, 716–723. [Google Scholar] [CrossRef]

- Howe, C.J.; Cole, S.R.; Westreich, D.J.; Greenland, S.; Napravnik, S.; Eron, J.J., Jr. Splines for trend analysis and continuous confounder control. Epidemiology 2011, 22, 874. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. WHO Guidelines for Indoor Air Quality: Household Fuel Combustion; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Karki, K.B.; Dhakal, P.; Shrestha, S.L.; Joshi, H.D.; Aryal, K.K.; Poudyal, A.; Puri, S.; Verma, S.C.; Pokhrel, A.; Lohani, G.R. Situation Analysis of Ambient Air Pollution and Respiratory Health Effects in Kathmandu Valley; Nepal Health Research Council: Kathmandu, Nepal, 2016.

- Lu, F.; Shen, B.; Yuan, P.; Li, S.; Sun, Y.; Mei, X. The emission of PM2.5 in respiratory zone from Chinese family cooking and its health effect. Sci. Total Environ. 2019, 654, 671–677. [Google Scholar] [CrossRef]

- Mehta, S.; Shahpar, C. The health benefits of interventions to reduce indoor air pollution from solid fuel use: A cost-effectiveness analysis. Energy Sustain. Dev. 2004, 8, 53–59. [Google Scholar] [CrossRef]

- Hwang, G.S.; Jung, H.S.; Yi, Y.; Yoon, C.; Choi, J.W. Smoking cessation intervention using stepwise exercise incentives for male workers in the workplace. Asia Pac. J. Public Health 2012, 24, 82–90. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).