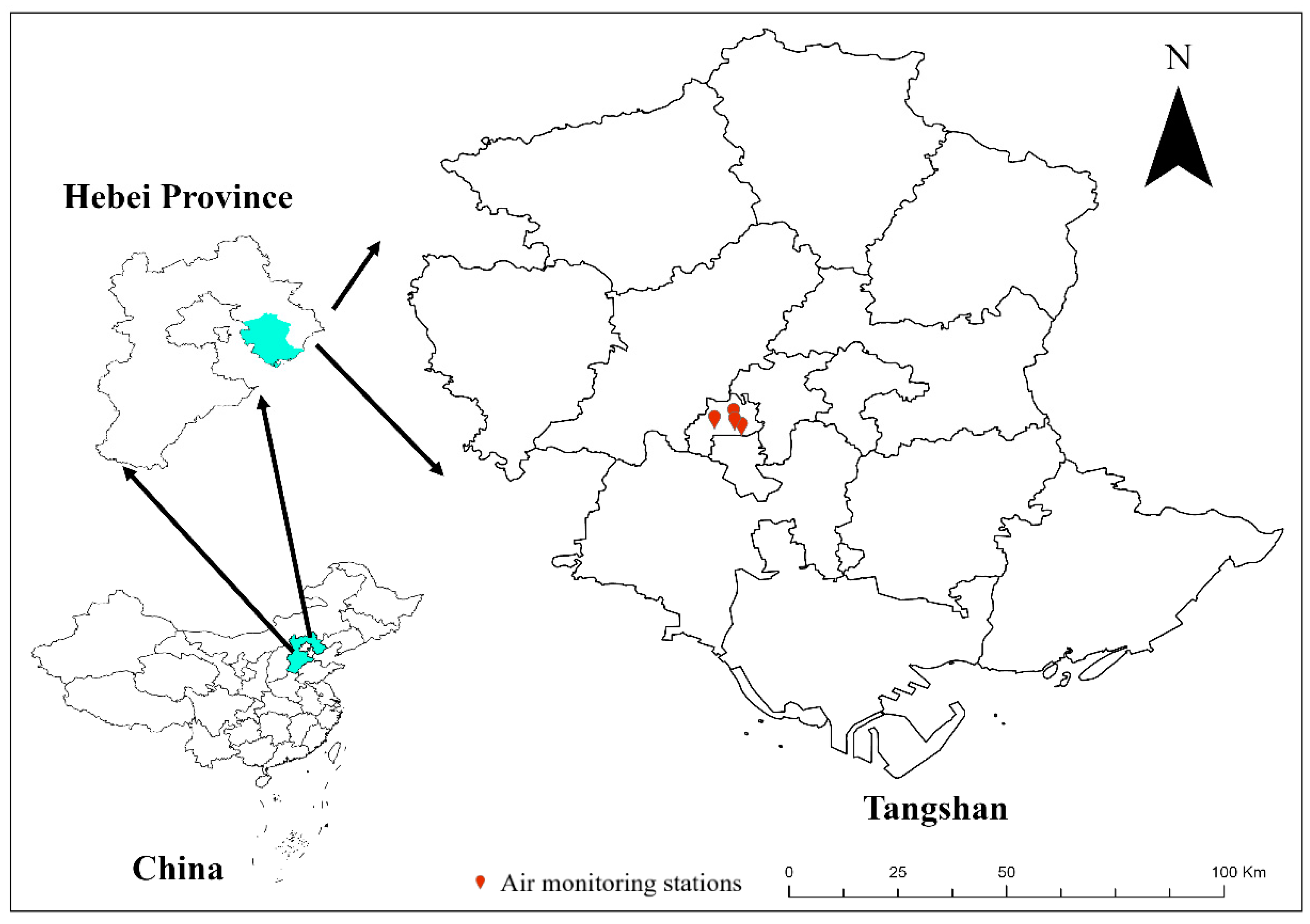

Improving the Air Quality Management: The Air Pollutant and Carbon Emission and Air Quality Model for Air Pollutant and Carbon Emission Reduction in the Iron and Steel Industries of Tangshan, Hebei Province, China

Abstract

:1. Introduction

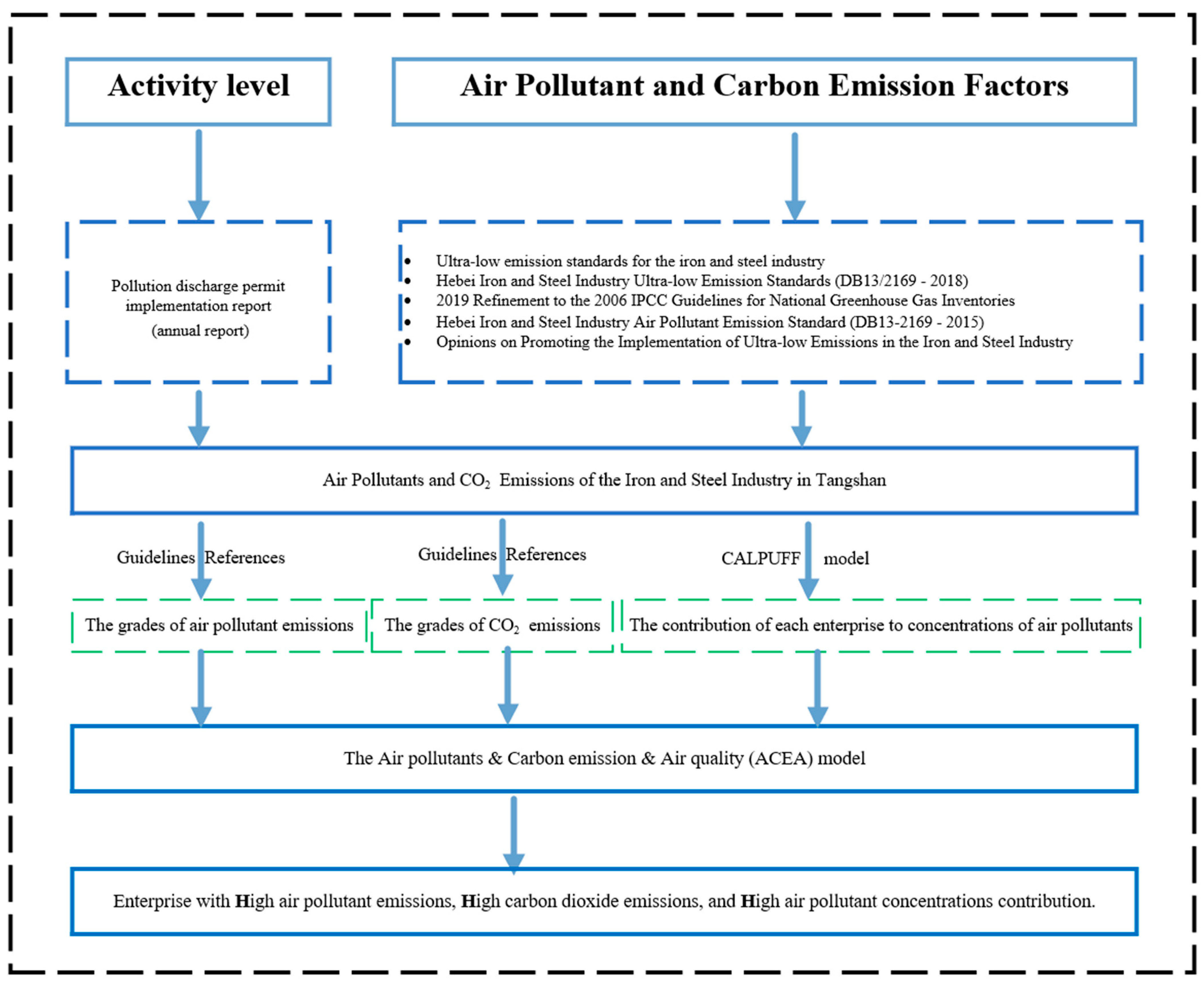

2. Methodology

2.1. The Technical Route of the Air Pollutant and Carbon Emission and Air Quality (ACEA) Model

2.2. The Establishment of Air Pollutant and Carbon Emission Inventories

2.3. The Determination of Emission Factors and the Grades of Emission Performance

2.3.1. The Emission Factors of Air Pollutants and the Corresponding Grades of Emission Performance

2.3.2. Emission Factors of CO2 and Grades of Emission Performance

2.3.3. Analysis of Uncertainty

2.4. The Settings of the CALPUFF Model

2.4.1. The Grade of Contributions to the Concentration of Air Pollutants

2.4.2. Model Verification

3. Results

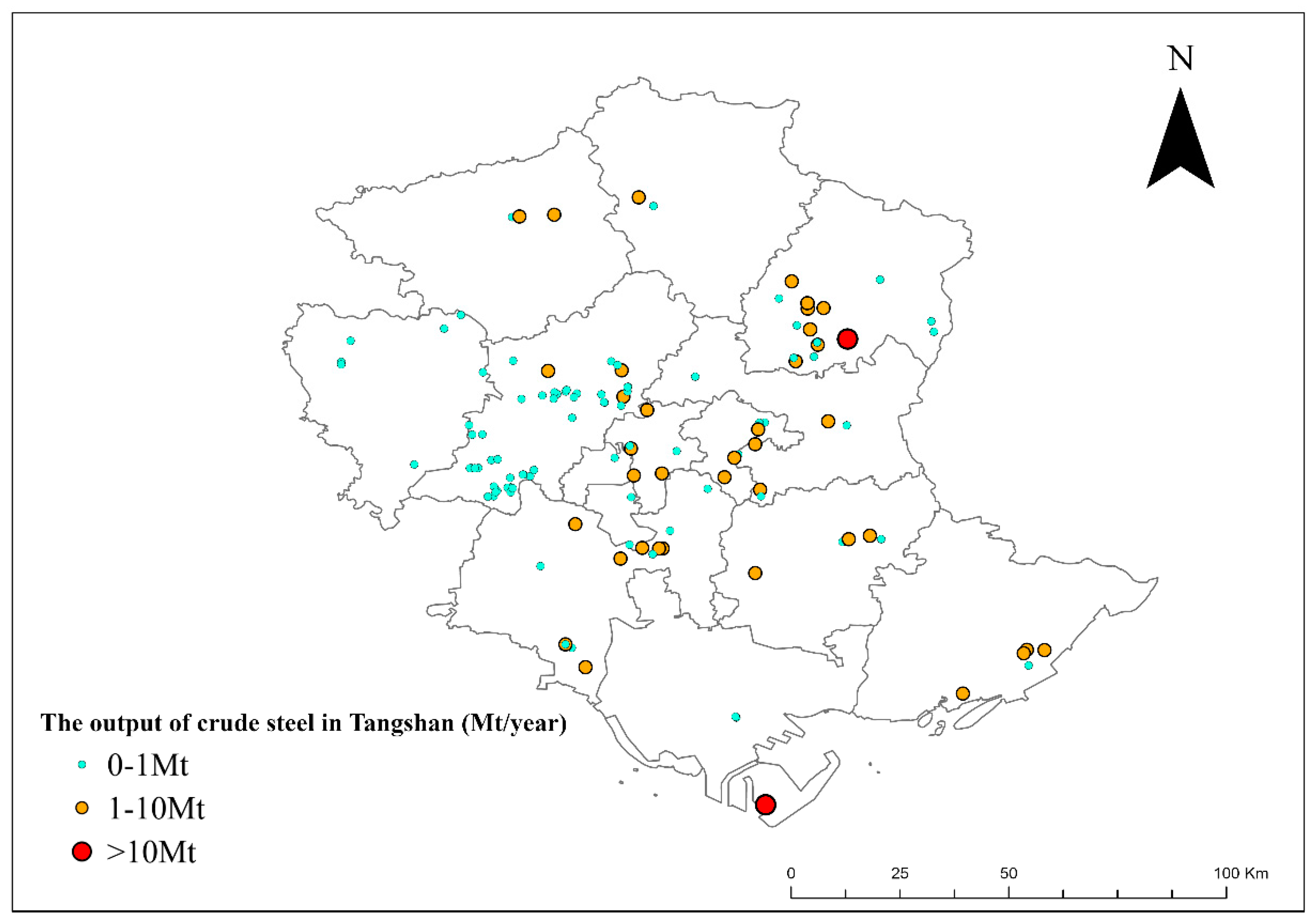

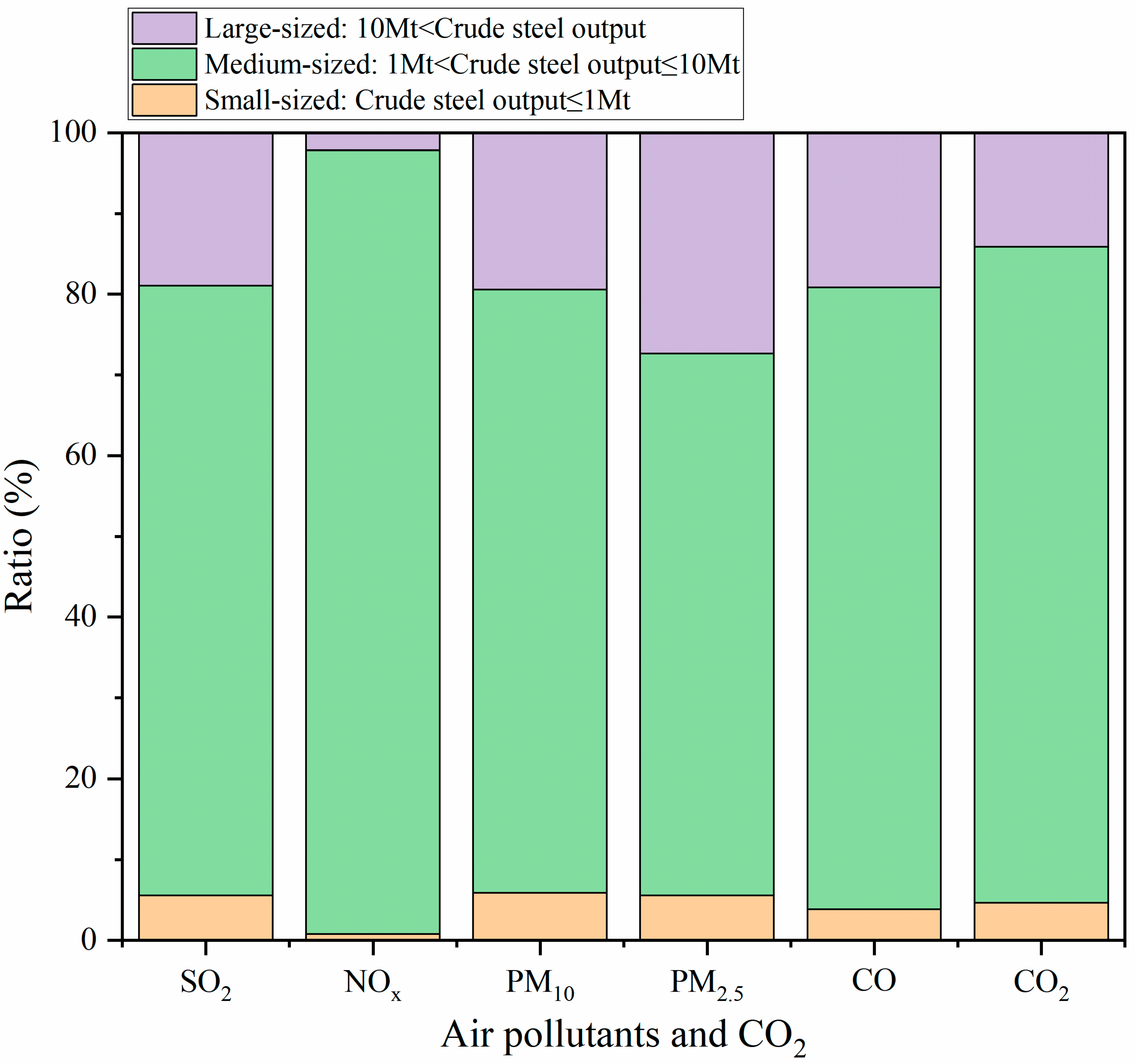

3.1. Emission Characteristics of Air Pollutant and CO2 in 2019 Tangshan

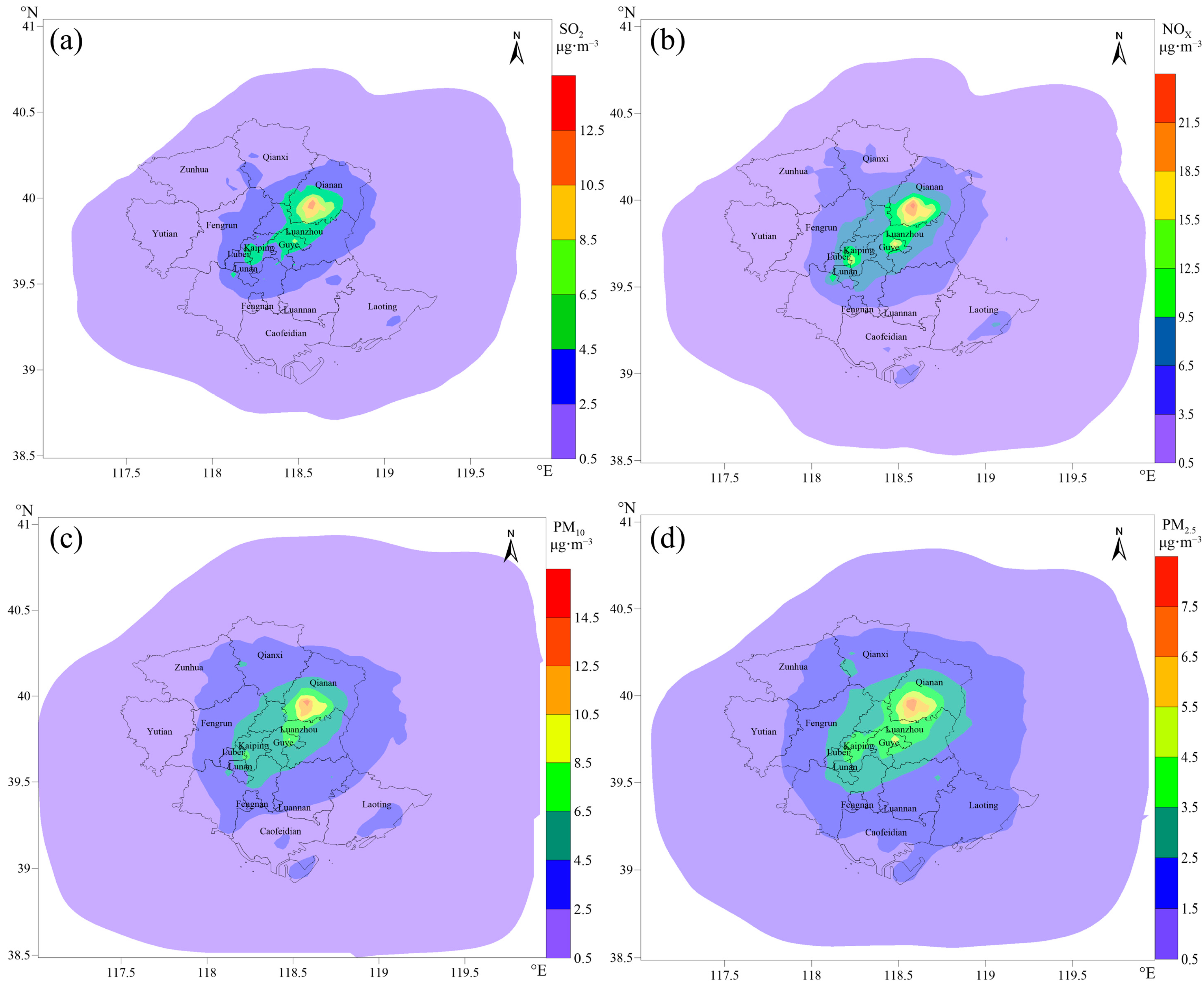

3.2. Air Quality Impacts

3.3. Identification Results of the ACEA Model for ISIs in Tangshan

3.4. Uncertainty Analysis of the ACEA Model

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- WorldSteel. World Steel Statistical Yearbook 2020; World Steel Association Network: Brussels, Belgium, 2020. [Google Scholar]

- National Bureau of Statistics of China. China Statistical Yearbook; National Bureau of Statistics Network: Beijing, China, 2020. (In Chinese)

- Liu, H.; Wu, B.; Liu, S.; Shao, P.; Liu, X.; Zhu, C.; Wang, Y.; Wu, Y.; Xue, Y.; Gao, J.; et al. A regional high-resolution emission inventory of primary air pollutants in 2012 for Beijing and the surrounding five provinces of North China. Atmos. Environ. 2018, 181, 20–33. [Google Scholar] [CrossRef]

- Statistics Bureau of Hebei Province. Hebei Statistical Yearbook; Statistics Bureau network of Hebei Province: Shijiazhuang, China, 2020. (In Chinese)

- Gao, Y.; Zhang, L.; Huang, A.; Kou, W.; Bo, X.; Cai, B.; Qu, J. Unveiling the spatial and sectoral characteristics of a high-resolution emission inventory of CO2 and air pollutants in China. Sci. Total Environ. 2022, 847, 157623. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Yang, R.; Li, Y. Synergizing the reduction of pollution and carbon emissions in cities: A case study of Tangshan city. World Environ. 2022, 4, 36–39. (In Chinese) [Google Scholar]

- Li, R.; Gao, Y.; Chen, Y.; Peng, M.; Zhao, W.; Wang, G.; Hao, J. Measurement report: Rapid changes of chemical characteristics and health risks for highly time resolved trace elements in PM2.5 in a typical industrial city in response to stringent clean air actions. Atmos. Chem. Phys. 2023, 23, 4709–4726. [Google Scholar] [CrossRef]

- Tang, L.; Jia, M.; Bo, X.; Xue, X.; Guo, J.; Tian, J.; Huang, M.; Wang, T.; Cui, L.; Dong, G. High resolution emission inventory and atmospheric environmental impact research in Chinese iron and steel industry. China Environ. Sci. 2020, 40, 1493–1506. [Google Scholar] [CrossRef]

- Yang, H.; Tao, W.; Liu, Y.; Qiu, M.; Liu, J.; Jiang, K.; Yi, K.; Xiao, Y.; Tao, S. The contribution of the Beijing, Tianjin and Hebei region’s iron and steel industry to local air pollution in winter. Environ. Pollut. 2019, 245, 1095–1106. [Google Scholar] [CrossRef] [PubMed]

- Xiang, S.; Liu, J.; Tao, W.; Yi, K.; Xu, J.; Hu, X.; Liu, H.; Wang, Y.; Zhang, Y.; Yang, H.; et al. Control of both PM2.5 and O3 in Beijing-Tianjin-Hebei and the surrounding areas. Atmos. Environ. 2020, 224, 117259. [Google Scholar] [CrossRef]

- China National Environmental Monitoring Centre. 2019 National Urban Air Quality Report. Available online: http://www.cnemc.cn/jcbg/kqzlzkbg/index_2.shtml (accessed on 25 September 2023). (In Chinese).

- Liu, S.; Hua, S.; Wang, K.; Qiu, P.; Liu, H.; Wu, B.; Shao, P.; Liu, X.; Wu, Y.; Xue, Y.; et al. Spatial-temporal variation characteristics of air pollution in Henan of China: Localized emission inventory, WRF/Chem simulations and potential source contribution analysis. Sci. Total Environ. 2018, 624, 396–406. [Google Scholar] [CrossRef]

- Yang, N.; Li, Y.; Lv, C.; Zhao, M.; Liu, Z.; Liu, H. Carbon mission accounting and peak forecasting of iron & steel industry in Tangshan. Env. Eng. 2020, 38, 44–52. (In Chinese) [Google Scholar]

- Yang, Y.; Dai, D. Analysis of energy consumption and carbon emissions in Tangshan. Co-Oper. Econ. Sci. 2016, 08, 46–47. (In Chinese) [Google Scholar] [CrossRef]

- Shan, W.; Chen, S.; Wang, G.; Li, J.; Bo, X. Clearing the Air: Assessing the Effectiveness of Emission Policy in Qinhuangdao’s Key Industries. Atmosphere 2023, 14, 1218. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, S.; Sang, M.; Wang, Z.; Bo, X.; You, Q. Air quality improvement through vehicle electrification in Hainan province, China. Chemosphere 2023, 316, 137814. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Xue, X.; Jia, M.; Jing, H.; Wang, T.; Zhen, R.; Huang, M.; Tian, J.; Guo, J.; Li, L.; et al. Iron and steel industry emissions and contribution to the air quality in China. Atmos. Environ. 2020, 237, 117668. [Google Scholar] [CrossRef]

- Zhu, S.; Gao, C.; Song, K.; Gao, W.; Guo, Y.; Gao, C. The changes in spatial layout of steel industry in China and associated pollutant emissions: A case of SO2. J. Environ. Manag. 2022, 302, 114034. [Google Scholar] [CrossRef] [PubMed]

- Tang, L.; Guo, j.; Guo, P.; Li, J.; Gan, D.; Jia, M.; Qu, J.; Bo, X. PCDD/Fs emission inventory and environmental impact of municipal solid waste incineration plants in Shandong Province. China Environ. Sci. 2023, 43, 735–747. (In Chinese) [Google Scholar] [CrossRef]

- Abdul-Wahab, S.; Fadlallah, S.; Al-Rashdi, M. Evaluation of the impact of ground-level concentrations of SO2, NOx, CO, and PM10 emitted from a steel melting plant on Muscat, Oman. Sustain. Cities Soc. 2018, 38, 675–683. [Google Scholar] [CrossRef]

- Li, S.; Xie, S. Spatial distribution and source analysis of SO2 concentration in Urumqi. Int. J. Hydrogen Energy 2016, 41, 15899–15908. [Google Scholar] [CrossRef]

- Li, M.; Liu, H.; Geng, G.; Hong, C.; Liu, F.; Song, Y.; Tong, D.; Zheng, B.; Cui, H.; Man, H.; et al. Anthropogenic emission inventories in China: A review. Natl. Sci. Rev. 2017, 4, 834–866. [Google Scholar] [CrossRef]

- Zheng, B.; Tong, D.; Li, M.; Liu, F.; Hong, C.; Geng, G.; Li, H.; Li, X.; Peng, L.; Qi, J.; et al. Trends in China’s anthropogenic emissions since 2010 as the consequence of clean air actions. Atmos. Chem. Phys. 2018, 18, 14095–14111. [Google Scholar] [CrossRef]

- Bo, X.; Jia, M.; Xue, X.D.; Tang, L.; Mi, Z.F.; Wang, S.Y.; Cui, W.G.; Chang, X.Y.; Ruan, J.H.; Dong, G.X.; et al. Effect of strengthened standards on Chinese ironmaking and steelmaking emissions. Nat. Sustain. 2021, 4, 811–820. [Google Scholar] [CrossRef]

- Tang, L.; Qu, J.B.; Mi, Z.F.; Bo, X.; Chang, X.Y.; Anadon, L.D.; Wang, S.Y.; Xue, X.D.; Li, S.B.; Wang, X.; et al. Substantial emission reductions from Chinese power plants after the introduction of ultra-low emissions standards. Nat. Energy 2019, 4, 929–938. [Google Scholar] [CrossRef]

- Tang, L.; Xue, X.; Bo, X.; Jia, M.; Guo, J.; Tian, J.; Huang, M.; Cui, W.; Wang, T.; Li, S.; et al. Contribution of Emissions from the Iron and Steel Industry to Air Quality in China. Environ. Sci. 2020, 41, 2981–2994. (In Chinese) [Google Scholar] [CrossRef]

- Department of Ecology and Environment of Hebei Province. Notice on the Issuance of the Performance Grading Results of Key Industries in Tangshan City’s Heavily Polluted Weather. Available online: https://news.mysteel.com/20/1112/16/3E7C9DDBFFCCA9B4.html (accessed on 25 September 2023). (In Chinese).

- Ministry of Ecology and Environment of the People’s Republic of China. Guidelines for the Development of Emergency Emission Reduction Measures for Heavily Polluted Weather (2020 Revision). Available online: http://new.tangshan.gov.cn/zhengwu/tsfengruzhengfuwenjian/20210608/1191203.html (accessed on 25 September 2023). (In Chinese)

- DB13/2169—2018; Ultra-Low Emission Standards for Air Pollutants in the Steel Industry. Department of Ecology and Environment of Hebei Province: Shijiazhuang, China, 2018. (In Chinese)

- DB 13/2196-2015; Emission Standard of Air Pollutants for Iron and Steel Industry. Department of Ecology and Environment of Hebei Province: Shijiazhuang, China, 2015. (In Chinese)

- HJ846-2017; Technical Specification for Application and Issuance of Pollutant Permit Iron and Steel Industry. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2017. (In Chinese)

- Ministry of Ecology and Environment of the People’s Republic of China. Opinions on Promoting the Implementation of Ultra-low Emissions in the Steel Industry. Available online: https://www.gov.cn/zhengce/zhengceku/2019-10/10/content_5438149.htm (accessed on 25 September 2023). (In Chinese)

- He, K. Technical Manual for the Preparation of Urban Air Pollutant Emission Inventory 2017; Tsinghua University: Beijing, China, 2017. [Google Scholar]

- Zhang, G. Emission Characteristics of Particulate Matter of Steel Plants; Northeastern University: Shenyang, China, 2015. (In Chinese) [Google Scholar]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/vol3.html (accessed on 25 September 2023).

- Wang, X.; Lei, Y.; Yan, L.; Liu, T.; Zhang, Q.; He, K. A unit-based emission inventory of SO2, NOx and PM for the Chinese iron and steel industry from 2010 to 2015. Sci. Total Environ. 2019, 676, 18–30. [Google Scholar] [CrossRef] [PubMed]

- Bo, X.; Ding, F.; Xu, H.; Li, S. Review of Atmospheric Diffusion Spersion Model CALPUFF Technology. Adm. Tech. Environ. Monit. 2009, 21, 9–13+47. (In Chinese) [Google Scholar]

- Bo, X.; Wang, G.; Wen, R.; He, Y.; Ding, F.; Wu, C.; Meng, F. Air pollution effect of the thermal power plants in Beijing-Tianjin-Hebei region. China Environ. Sci. 2015, 35, 364–373. (In Chinese) [Google Scholar]

- Bo, X.; Wu, Z.; Wang, G.; Hu, C.; Ding, F.; Wu, C.; Li, S. Study on the Standardized Application of CALPUFF Model. Environ. Sci. Technol. 2014, 37, 530–534. (In Chinese) [Google Scholar]

- Cui, J.; Lei, T.; Bo, X.; Wu, P.; Qu, J.; Gao, S.; Tian, F.; Li, S. Studies on air pollutant emission inventory and environmental impact in Hainan Province. Environ. Pollut. Control 2020, 42, 651–659+665. (In Chinese) [Google Scholar] [CrossRef]

- Tian, F.; Bo, X.; Xue, X.; Jia, Y.; Tang, Q.; Sun, H.; Li, S. Study on settlement of dioxin pollutants under complex terrain-weather conditions. China Environ. Sci. 2019, 39, 1678–1686. (In Chinese) [Google Scholar] [CrossRef]

- Wang, C.; Chu, Y.; Ruan, J.; Sang, M.; Cheng, J.; Wu, C.; Bo, X. Research on the influence of AERMOD model surface parameter update on simulation effect. China Environ. Sci. 2022, 42, 2070–2077. (In Chinese) [Google Scholar] [CrossRef]

- Bo, X.; Xu, J.; Du, X.; Guo, Q.; Zhen, R.; Tian, J.; Cai, B.; Wang, L.; Ma, F.; Zhou, B. Impacts assessment of steel plants on air quality over Beijing-Tianjin-Hebei area. China Environ. Sci. 2017, 37, 1684–1692. (In Chinese) [Google Scholar]

- Ministry of Ecology and Environment of the People’s Republic of China. Guidelines for Selection of Ambient Air Quality Models (Trial). Available online: https://www.mee.gov.cn/gkml/hbb/bgth/201508/W020150911488652824265.pdf (accessed on 25 September 2023). (In Chinese)

- IPCC. Climate Change 2001-Mitigation. Available online: https://www.ipcc.ch/report/ar3/wg3/ (accessed on 25 September 2023).

- Yang, R.; Wang, M.; Zhao, M.; Feng, X. Synergic Benefits of Air Pollutant Reduction, CO2 Emission Abatement, and Water Saving under the Goal of Achieving Carbon Emission Peak: The Case of Tangshan City, China. Int. J. Environ. Res. Public Health 2022, 19, 7145. [Google Scholar] [CrossRef] [PubMed]

- An, R.; Yu, B.; Li, R.; Wei, Y. Potential of energy savings and CO2 emission reduction in China’s iron and steel industry. Appl. Energy 2018, 226, 862–880. [Google Scholar] [CrossRef]

- Krzywanski, J.; Czakiert, T.; Nowak, W.; Shimizu, T.; Zylka, A.; Idziak, K.; Sosnowski, M.; Grabowska, K. Gaseous emissions from advanced CLC and oxyfuel fluidized bed combustion of coal and biomass in a complex geometry facility:A comprehensive model. Energy 2022, 251, 123896. [Google Scholar] [CrossRef]

- Yang, W.; Gong, J.; Wang, X.; Bao, Z.; Guo, Y.; Wu, Z. A Review on the Impact of SO2 on the Oxidation of NO, Hydrocarbons, and CO in Diesel Emission Control Catalysis. ACS Catal. 2021, 11, 12446–12468. [Google Scholar] [CrossRef]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G.; et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335–338. [Google Scholar] [CrossRef]

| Reference | Year | SO2 | NOx | CO | PM10 | PM2.5 | CO2 |

|---|---|---|---|---|---|---|---|

| Bo et al. [43] | 2012 | 186,892.1 | 228,576.9 | 59,986.4 | |||

| Yang et al. [9] | 2016 | 223,373.9 | 254,707.2 | ||||

| Yang et al. [13] | 2018 | 1.8 × 108 | |||||

| Yang et al. [46] | 2018 | 1.2 × 108 | 2.5 × 108 | 0.45 × 108 | 1.9 × 108 | ||

| This study | 2019 | 57,500 | 134,700 | 5,790,400 | 35,500 | 18,000 | 2.2 × 108 |

| Enterprise Number | SO2 (%) | NOx (%) | PM10 (%) | PM2.5 (%) | Average (%) |

|---|---|---|---|---|---|

| 6 | 1.632 | 2.137 | 0.459 | 0.552 | 1.195 |

| 14 | 1.096 | 0.73 | 0.282 | 0.326 | 0.609 |

| 21 | 0.742 | 0.645 | 0.236 | 0.289 | 0.478 |

| 13 | 0.531 | 0.493 | 0.148 | 0.205 | 0.344 |

| 19 | 0.635 | 0.321 | 0.177 | 0.225 | 0.34 |

| 10 | 0.522 | 0.352 | 0.139 | 0.185 | 0.3 |

| 26 | 0.377 | 0.297 | 0.107 | 0.129 | 0.228 |

| 1 | 0.402 | 0.253 | 0.104 | 0.118 | 0.219 |

| 7 | 0.303 | 0.225 | 0.084 | 0.095 | 0.177 |

| 8 | 0.253 | 0.168 | 0.1 | 0.113 | 0.159 |

| 15 | 0.216 | 0.176 | 0.063 | 0.08 | 0.134 |

| 22 | 0.186 | 0.154 | 0.072 | 0.094 | 0.127 |

| 17 | 0.188 | 0.155 | 0.056 | 0.072 | 0.118 |

| 12 | 0.185 | 0.13 | 0.067 | 0.084 | 0.117 |

| 27 | 0.182 | 0.1 | 0.069 | 0.087 | 0.11 |

| 3 | 0.181 | 0.105 | 0.066 | 0.085 | 0.109 |

| 5 | 0.189 | 0.094 | 0.053 | 0.066 | 0.101 |

| 2 | 0.136 | 0.065 | 0.071 | 0.096 | 0.092 |

| 28 | 0.131 | 0.085 | 0.042 | 0.057 | 0.079 |

| 20 | 0.133 | 0.061 | 0.039 | 0.046 | 0.07 |

| 18 | 0.101 | 0.083 | 0.032 | 0.038 | 0.064 |

| 23 | 0.093 | 0.058 | 0.029 | 0.04 | 0.055 |

| 11 | 0.076 | 0.042 | 0.022 | 0.029 | 0.042 |

| 25 | 0.054 | 0.029 | 0.023 | 0.033 | 0.035 |

| 16 | 0.047 | 0.028 | 0.018 | 0.021 | 0.029 |

| 24 | 0.039 | 0.023 | 0.018 | 0.024 | 0.026 |

| 31 | 0.015 | 0.049 | 0.01 | 0.016 | 0.023 |

| 9 | 0.005 | 0.004 | 0.002 | 0.003 | 0.004 |

| 30 | 0.002 | 0.005 | 0.001 | 0.002 | 0.003 |

| 32 | 0 | 0 | 0.001 | 0.001 | 0.001 |

| 4 | 0 | 0 | 0 | 0 | 0 |

| 29 | 0 | 0 | 0 | 0 | 0 |

| Pollutant | SO2 | NOx | PM10 | PM2.5 | CO | CO2 |

|---|---|---|---|---|---|---|

| Uncertainty | −4.7–4.9% | −4.5–4.5% | −3.1–3.0% | −4.5–4.6% | −4.9–4.9% | −5–5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Li, J.; You, Q.; Wang, Z.; Shan, W.; Bo, X.; Zhu, R. Improving the Air Quality Management: The Air Pollutant and Carbon Emission and Air Quality Model for Air Pollutant and Carbon Emission Reduction in the Iron and Steel Industries of Tangshan, Hebei Province, China. Atmosphere 2023, 14, 1747. https://doi.org/10.3390/atmos14121747

Chen S, Li J, You Q, Wang Z, Shan W, Bo X, Zhu R. Improving the Air Quality Management: The Air Pollutant and Carbon Emission and Air Quality Model for Air Pollutant and Carbon Emission Reduction in the Iron and Steel Industries of Tangshan, Hebei Province, China. Atmosphere. 2023; 14(12):1747. https://doi.org/10.3390/atmos14121747

Chicago/Turabian StyleChen, Shaobo, Jianhui Li, Qian You, Zhaotong Wang, Wanyue Shan, Xin Bo, and Rongjie Zhu. 2023. "Improving the Air Quality Management: The Air Pollutant and Carbon Emission and Air Quality Model for Air Pollutant and Carbon Emission Reduction in the Iron and Steel Industries of Tangshan, Hebei Province, China" Atmosphere 14, no. 12: 1747. https://doi.org/10.3390/atmos14121747

APA StyleChen, S., Li, J., You, Q., Wang, Z., Shan, W., Bo, X., & Zhu, R. (2023). Improving the Air Quality Management: The Air Pollutant and Carbon Emission and Air Quality Model for Air Pollutant and Carbon Emission Reduction in the Iron and Steel Industries of Tangshan, Hebei Province, China. Atmosphere, 14(12), 1747. https://doi.org/10.3390/atmos14121747