Study on Volatile Organic Compound (VOC) Emission Control and Reduction Potential in the Pesticide Industry in China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Objects

2.2. Data Collection

2.3. Methodology

2.3.1. Collection Rate of Exhaust Gas

2.3.2. Facility Removal Rate

2.3.3. Facility Commissioning Rate

2.3.4. Comprehensive Facility Removal Rate

2.4. Design Scenario

3. Results and Discussion

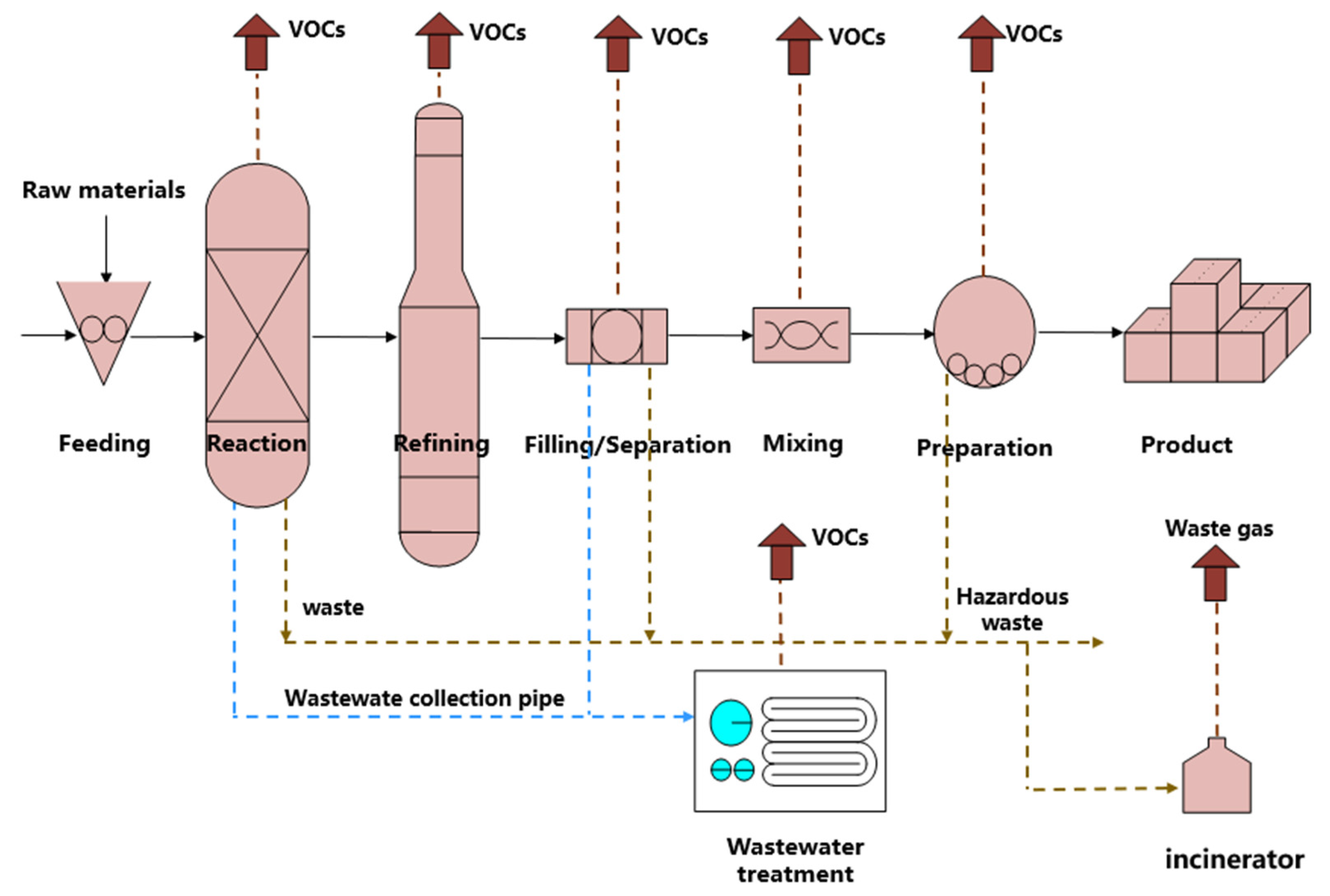

3.1. Characteristics of VOC Pollution in the Pesticide Manufacturing Industry

3.2. List of Key VOC Substances in Pesticide Manufacturing Industry

3.3. VOC Treatment Technologies in Pesticide Manufacturing Industry

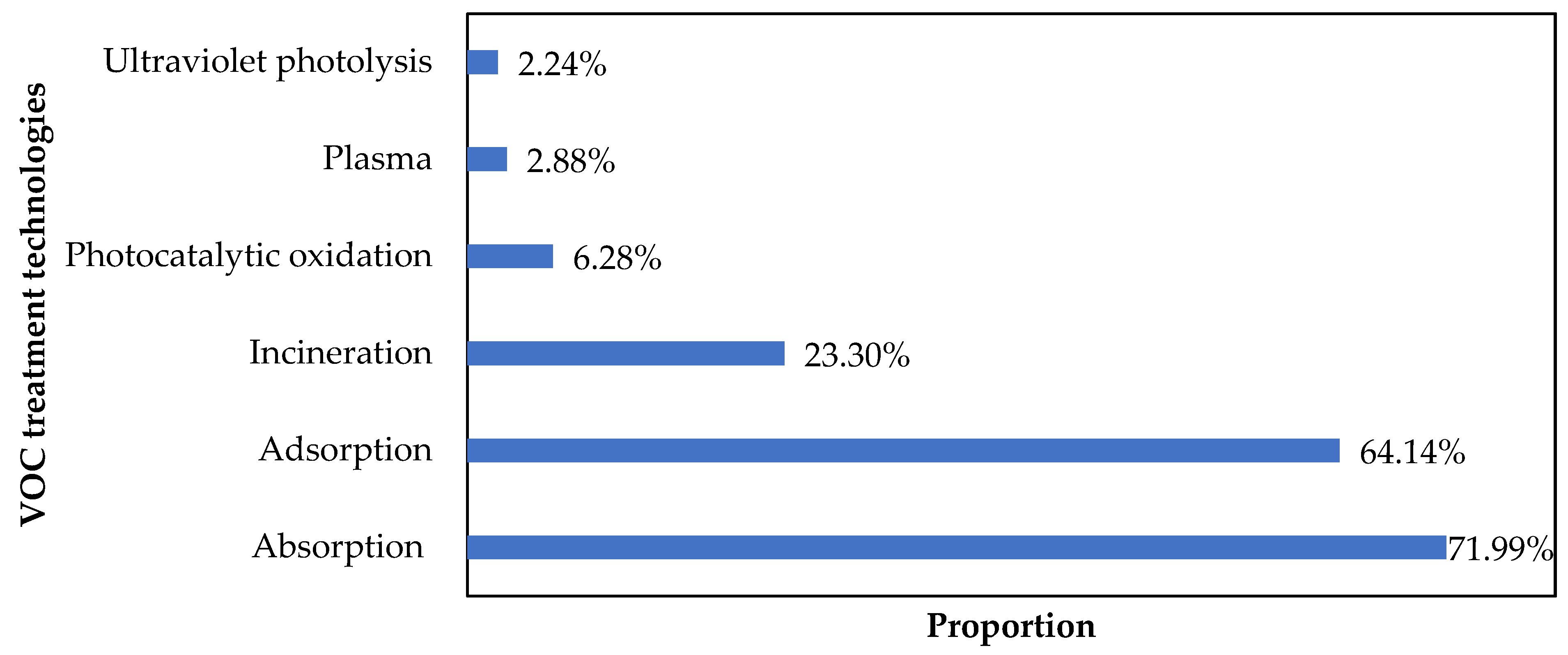

3.3.1. Proportion of VOC Treatment Technologies Used

3.3.2. Facility Removal Rates of VOCs

3.3.3. Collection Rate of Exhaust Gas

3.3.4. Emission Reduction Benefit and Economic Evaluation

3.4. VOC Emission Reduction Potential of the Pesticide Manufacturing Industry

4. Conclusions and Prospects

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Yan, F.; Hua, H.; Yuan, Z. Identifying hotspots based on high-resolution emission inventory of volatile organic compounds: A case study in China. J. Environ. Manag. 2021, 288, 112419. [Google Scholar] [CrossRef] [PubMed]

- A Practical Handbook on Volatile Organic Compounds Management, 2nd ed; China Environment Publishing Group: Beijing, China; ISBN 9787511147509.

- Song, C.; He, J.; Wu, L.; Jin, T.; Chen, X.; Li, R.; Ren, P.; Zhang, L.; Mao, H. Health burden attributable to ambient PM2.5 in China. Environ. Pollut. 2017, 223, 575–586. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Wu, L.; Xie, Y.; He, J.; Chen, X.; Wang, T.; Lin, Y.; Jin, T.; Wang, A.; Liu, Y.; et al. Air pollution in China: Status and spatiotemporal variations. Environ. Pollut. 2017, 227, 334–347. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xue, L.; Brimblecombe, P.; Lam, Y.F.; Li, L.; Zhang, L. Ozone pollution in China: A review of concentrations, meteorological influences, chemical precursors, and effects. Sci. Total Environ. 2017, 575, 1582–1596. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Su, G.; Li, C.; Liu, P.; Zhao, X.; Zhang, C.; Sun, X.; Mu, Y.; Wu, M.; Wang, Q.; et al. An investigation into the role of VOCs in SOA and ozone production in Beijing, China. Sci. Total Environ. 2020, 720, 137536. [Google Scholar] [CrossRef]

- Xiang, S.; Liu, J.; Tao, W.; Yi, K.; Xu, J.; Hu, X.; Liu, H.; Wang, Y.; Zhang, Y.; Yang, H.; et al. Control of both PM2.5 and O3 in Beijing-Tianjin-Hebei and the surrounding areas. Atmos. Environ. 2020, 224, 117259. [Google Scholar] [CrossRef]

- Guo, X.; Shen, Y.; Liu, W.; Chen, D.; Liu, J. Estimation and Prediction of Industrial VOC Emissions in Hebei Province, China. Atmosphere 2021, 12, 530. [Google Scholar] [CrossRef]

- Wang, H.L.; Sun, S.M.; Nie, L.; Zhang, Z.S.; Li, W.P.; Hao, Z.P. A review of whole-process control of industrial volatile organic compounds in China. J. Environ. Sci. 2022. [Google Scholar] [CrossRef]

- He, D.C.; Li, F.H.; Wu, M.; Luo, H.L.; Qiu, L.Q.; Ma, X.R.; Lu, J.W.; Liu, W.R.; Ying, G.G. Emission of volatile organic compounds (VOCs) from application of commercial pesticides in China. J. Environ. Manag. 2022, 314, 115069. [Google Scholar] [CrossRef]

- Wang, R.; Wang, X.; Cheng, S.; Wang, K.; Cheng, L.; Zhu, J.; Zheng, H.; Duan, W. Emission Characteristics and Reactivity of Volatile Organic Compounds from Typical High-Energy-Consuming Industries in North China. Sci. Total Environ. 2022, 809, 151134. [Google Scholar] [CrossRef]

- Lewis, A.C.; Hopkins, J.R.; Carslaw, D.C.; Hamilton, J.F.; Nelson, B.S.; Stewart, G.; Dernie, J.; Passant, N.; Murrells, T. An increasing role for solvent emissions and implications for future measurements of volatile organic compounds. Phil. Trans. Math. Phys. Eng. Sci. 2020, 378, 20190328. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.M.; Zhao, W.J.; Nie, L.; Shao, X.; Dang, H.Y.; Zhang, W.Q.; Wang, D. A new classification approach to enhance future VOCs emission policies: Taking solvent-consuming industry as an example. Environ. Pollut. 2021, 268, 115868. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.S.; Cheng, W.H.; Huang, H.Y. Spatiotemporal distribution characteristics and potential sources of VOCs at an industrial harbor city in southern Taiwan: Three year VOCs monitoring data analysis. J. Environ. Manag. 2022, 303, 114259. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.Y.; Liu, F.M.; Wang, J.; Peng, Q.R. Research progress on substitution of harmful organic solvent in pesticide emulsifiable concentrates. Chin. J. Pesticide Sci. 2020, 22, 925–932. [Google Scholar]

- OWD (Our World in Data). Pesticides—Our World in Data. 2021. Available online: https://ourworldindata.org/pesticides (accessed on 18 May 2022).

- Habeebullah, T.M. Risk assessment of exposure to BTEX in the Holy City of Makkah. Arab. J. Geosci. 2015, 8, 1155–1162. [Google Scholar] [CrossRef]

- Bari, M.A.; Kindzierski, W.B. Concentrations, sources and human health risk of inhalation exposure to air toxics in Edmonton. Chemosphere 2017, 173, 160–171. [Google Scholar] [CrossRef]

- Masih, A.; Lall, A.S.; Taneja, A.; Singhvi, R. Exposure levels and health risk assessment of ambient BTX at urban and rural environments of a Terai region of Northern India. Environ. Pollut. 2018, 242, 1678–1683. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.N.; Yang, C.Q.; Hao, Z.P.; Sun, H.K.; Li, Y. Countermeasures for priority control of toxic VOC pollution. Environ. Sci. 2011, 32, 3469–3475. [Google Scholar]

- Wei, W. Study on Current and Future Anthropogenic Emission of Volatile Organic Compounds in China. Ph.D. Thesis, Tsinghua University, Beijing, China, 2009. (In Chinese). [Google Scholar]

- Liu, J.F.; Zhao, J.; Li, T.T.; Bai, Y.H.; Liu, Z.R. Establishment of Chinese Anthropogenic Source Volatile Organic Compounds Emission Inventory. China Environ. Sci. 2008, 28, 496–500. (In Chinese) [Google Scholar]

- Zhao, B.; Wang, P.; Ma, J.Z.; Zhu, S.; Pozzer, A.; Li, W. A high-resolution emission inventory of primary pollutants for the Huabei region, China. Atmos. Chem. Phys. 2012, 12, 481–501. [Google Scholar] [CrossRef] [Green Version]

- Hua, H.; Jiang, S.; Sheng, H.; Zhang, Y.; Liu, X.; Zhang, L.; Yuan, Z.; Chen, T. A high spatial-temporal resolution emission inventory of multi-type air pollutants for Wuxi city. J. Clean. Prod. 2019, 229, 278–288. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Zheng, B.; Tong, D.; Lei, Y.; Liu, F.; Hong, C.; Kang, S.; Yan, L.; Zhang, Y.; et al. Persistent growth of anthropogenic non-methane volatile organic compound (NMVOC) emissions in China during 1990–2017: Drivers, speciation and ozone formation potential. Atmos. Chem. Phys. 2019, 19, 8897–8913. [Google Scholar] [CrossRef] [Green Version]

- “Emission Standard of Air Pollutants for Pesticide Industry” (GB 39727-2020). 2020. Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqgdwrywrwpfbz/202012/t20201225_814812.shtml (accessed on 20 May 2022). (In Chinese)

- “Stationary Source Emission-Determination of Total Hydrocarbons, Methane and Nonmethane Hydrocarbons-Gas Chromatography” (HJ38-2017). 2017. Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/jcffbz/201801/t20180108_429313.shtml (accessed on 20 May 2022). (In Chinese)

- Zheng, H.C.; Dang, X.Q.; Li, S.J.; Cao, L.; Tan, X.Y.; Xu, J. Selection and optimization of VOCs exhaust gas collection method in printing process. Chin. J. Environ. Eng. 2020, 14, 2786–2795. (In Chinese) [Google Scholar]

- Liu, H.; Huang, Y.; Zhou, J.R.; Qiu, P.P.; Duan, Y.X. Measured analysis of volatile organic compounds pollution control efficiency in key industries in Wuhan. J. Gre. Sci. Tech. 2022, 24, 214–218. (In Chinese) [Google Scholar]

- Chen, Y. Study on Current and Future Industrial Emission of Volatile Organic Compounds in China. Master’s Thesis, South China University of Technology, Guangzhou, China, 2011. (In Chinese). [Google Scholar]

- Shao, Y.X. Study on Emission Characteristics and Emission Reduction Potential of Volatile Organic Compounds from Typical Industries. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Sha, Q.; Zhu, M.; Huang, H.; Wang, Y.; Huang, Z.; Zhang, X.; Tang, M.; Lu, M.; Chen, C.; Shi, B.; et al. A newly integrated dataset of volatile organic compounds (VOCs) source profiles and implications for the future development of VOCs profiles in China. Sci. Total Environ. 2021, 793, 148348. [Google Scholar] [CrossRef]

- Huang, Y.; Xiu, G.; Lu, Y.; Gao, S.; Li, L.; Chen, L.; Huang, Q.; Yang, Y.; Che, X.; Chen, X.; et al. Application of an emission profile-based method to trace the sources of volatile organic compounds in a chemical industrial park. Sci. Total Environ. 2021, 768, 144694. [Google Scholar] [CrossRef] [PubMed]

- Carter, W.P.L. Development of ozone reactivity scales for volatile organic compounds. J. Air Waste Manag. 1994, 44, 881–899. [Google Scholar] [CrossRef] [Green Version]

- American. FINAL Regulation Order: Tables of Maximum Incremental and Reactivity (MIR) Values [Z], 94700. Available online: https://vdocument.in/final-regulation-order-tables-of-maximum-incremental-reactivity-mir-of-maximum.html?page=1 (accessed on 17 May 2022).

- Li, Z.M. Discussion on Determination of Non-methane Hydrocarbons. Adv. Mat. Res. 2015, 1073–1076, 562–566. [Google Scholar] [CrossRef]

| Target Levels | Proportion of Factories (%) | ||

|---|---|---|---|

| Benchmark | Moderate | Poor | |

| Low | 20 | 65 | 15 |

| Moderate | 30 | 60 | 10 |

| High | 40 | 58 | 2 |

| Process | Generating Point | Cause | Emission Characteristics | Emission Form | Discharge Concentration after Collection and Treatment (mg/m3) |

|---|---|---|---|---|---|

| Feeding | Feeding port | The feeding port is connected to the reactor | Normal temperature and pressure, intermittent discharge | Organized/fugitive emissions | <10 |

| Reaction | Reactor, washing kettle, etc. | Displacement, purging and other processes | High temperature, atmospheric or high pressure, intermittent discharge | Organized emissions | 5~110 |

| Refining | Distillation tower, rectification tower, crystallization tank, etc. | Discharge during replacement, purging, material in- and outflow, etc. | High temperature, atmospheric pressure, intermittent discharge | Organized emissions | 5~110 |

| Separation | Filter presses, stratification facilities | Processes such as open filter presses | Normal temperature, normal pressure, intermittent discharge | Organized/fugitive emissions | 5~110 |

| Filling | Discharge port, product filling, etc. | Product discharge | Normal temperature, normal pressure, intermittent discharge | Organized/fugitive emissions | <10 |

| Storage | Breathing valve of the organic liquid storage tank at atmospheric pressure | Tank breathing | Normal temperature, normal pressure, intermittent discharge | Organized/fugitive emissions | <10 |

| Wastewater treatment | Open liquid surface in wastewater treatment facilities | Liquid escape | Normal temperature, normal pressure, continuous discharge | Organized/fugitive emissions | <10 |

| Loading | Open mouths of tankers etc. | Exhaust gas discharge due to internal and external gas phase balance | Normal temperature, normal pressure, intermittent discharge | Organized/fugitive emissions | <10 |

| Hazardous waste storage | Hazardous waste warehouse, raw material warehouse | Escape caused by poor packaging | Normal temperature, normal pressure, continuous discharge | Organized/fugitive emissions | <10 |

| Vacuum system | Wet vacuum system, circulating water tank | VOC escape from circulating water | Normal temperature, normal pressure, continuous discharge | Organized/fugitive emissions | Fugitive emissions caused by improper management >3000 |

| Circulating water system | Open circulating water equipment | VOC escape from circulating water | Normal temperature, normal pressure, continuous discharge | Fugitive emissions | High VOC emissions caused by improper management |

| Type | Key VOC Substances | Origins | Screening Evidence |

|---|---|---|---|

| Alkanes | Cyclohexane, n-hexane, n-heptane, methylcyclohexane | Intermediates, raw materials | Refer to active substance lists [30,31,32,33] |

| Olefins | Acrylonitrile | Raw materials | High MIR value [34,35]; pungent odour |

| Propylene, isoprene, ethylene, 1-pentene, cyclopentene, trans-3-heptene, trans-1,3-dichloropropene, cyclohexene, styrene, isopentene | Intermediates, raw materials | Refer to active substance lists [30,31,32,33] | |

| Aromatic hydrocarbons | Benzene series (benzene, toluene, xylene) | Raw materials, solvents, contaminants | Benzene: carcinogenicity class I (high toxicity) Toluene: high MIR value; large amount used as solvent Xylene: high MIR value; large amount used as solvent [34,35] |

| m/p-xylene, o-xylene, m-diethylbenzene, naphthalene | Intermediates, raw materials | Refer to active substance lists [30,31,32,33] | |

| Oxygenated hydrocarbons | Formaldehyde | Raw materials and byproducts | Carcinogenicity class I; high MIR value; inhalation toxicity class I; low olfactory threshold [34,35] |

| Glyoxal, propionaldehyde, acrolein, n-butyraldehyde, n-butanol, n-hexanal, 3-methoxy-1-butanol, methyl isobutyl ketone, ethanol, cyclohexanone, n-propyl acetate, Methyl tert-butyl ether, methanol, ethyl acetate, isopropanol | Intermediates, raw materials | Refer to active substance lists [30,31,32,33] | |

| Halogenated olefins | Trichloroethylene | Intermediates, raw materials | Refer to active substance lists [30,31,32,33] |

| Phenols | Phenols | Raw materials | Industry standard requirements, no MIR value yet |

| Chlorobenzenes | Chlorobenzenes | Byproduct | Industry standard requirements, no MIR value yet |

| Facility | Coverage Rate | Facility Removal Rates of VOCs (In Terms of Total Nonmethane Hydrocarbons) (%) | ||

|---|---|---|---|---|

| Concentration I (>250 mg/m3) | Concentration II (20~250 mg/m3) | Concentration III (<20 mg/m3) | ||

| Incineration (RTO) | 23.3% | 98 | 82 | 53 |

| Multistage absorption and adsorption | 64.14% | 95 | 65 | 35 |

| Multistage absorption | 71.99% | 85 | 51 | 16 |

| Specific Pollutants | Recommended Combination Process | Removal Rate/% |

|---|---|---|

| Benzene | One-stage alkali absorption + RTO | 99 |

| Acrylonitrile | Alkali absorption | 95 |

| Xylene | Two-stage falling film + two-stage lye absorption + one-stage activated carbon adsorption | 90 |

| Two-stage 5 °C water-cooled treatment +activated carbon adsorption and desorption | 90 | |

| One-stage absorption with water spray + one-stage alkali absorption + one-stage activated carbon adsorption | 95 | |

| Phosgene | Alkali absorption + RTO | 99 |

| Two-stage absorption with falling water film + two-stage hot water catalytic light breaking absorption + one-stage absorption with falling water film + one-stage alkali absorption in packed tower | 95 | |

| Toluene | Activated carbon adsorption | 98 |

| Condensation absorption | 80 | |

| Secondary falling film absorption + activated carbon adsorption | 95 | |

| Formaldehyde | One-stage alkali absorption + RTO | 98 |

| Water absorption | 90 | |

| Secondary falling film absorption + activated carbon adsorption | 95 |

| Collection Method | Coverage Rate % | Collection Rate % | The Conditions that Must Be Met to Reach the Upper Limit Efficiency, Otherwise the Limit Is Calculated |

|---|---|---|---|

| Direct connection to the exhaust gas outlet of the equipment | Approximately 80% | 80~95 | The equipment has a fixed discharge pipe (or port) directly connected to the air duct. The equipment is completely sealed, leaving only the product inlet and outlet open, and there are exhaust gas collection measures at the inlet and outlet. When the collection system is running, hardly any VOCs are emitted around it. |

| Confined collection in workshop or closed room | Approximately 40% | 80~95 | The roof is cast in place, and the surrounding walls, doors, and windows have good airtightness. The total air volume collected ensures a slight negative pressure at the opening (the suction wind speed at the open section is not less than 0.5 m/s), and exhaust gas is not leaked. |

| Semi-closed hood or fume hood | Approximately 60% | 65~85 | At the point (surface) of pollutant generation, the controlled wind speed towards the suction port shall not be less than 0.5 m/s. |

| Hot upper suction hoods | Approximately 30% | 30~60 | At the point (surface) of pollutant generation, the controlled wind speed towards the suction port shall not be less than 0.5 m/s. “Hot” refers to the temperature of the gas emitted by the pollution source, which must be ≥60 °C. |

| Cold upper suction hoods | >90% | 20~50 | At the point (surface) of pollutant generation, the controlled wind speed towards the suction port shall not be less than 0.5 m/s. “Cold” refers to the temperature of the gas emitted by the pollution source, which must be <60 °C. |

| Side suction hoods | >90% | 20~40 | At the point (surface) of pollutant generation, the controlled wind speed towards the suction port shall not be less than 0.5 m/s, and the distance between the suction hood and the far end of the pollution source shall not be greater than 0.6 m. |

| Technology | Depreciation Cost (Ten Thousand US Dollars) | Operating Cost (Ten Thousand US Dollars) | Comprehensive Cost (Ten Thousand US Dollars) | VOC Treatment Amount (t/a) | Unit VOC Reduction Cost (US dollars/ton) |

|---|---|---|---|---|---|

| RTO (low cost) | 31.08 | 8.88 | 39.96 | 88.2 | 4530.28 |

| RTO (high cost) | 68.08 | 34.04 | 102.12 | 187.51 | 5446.40 |

| Multistage absorption and adsorption | 6.66 | 3.7 | 10.36 | 32.47 | 3190.88 |

| Multistage absorption | 5.92 | 0.74 | 6.66 | 20.06 | 3319.64 |

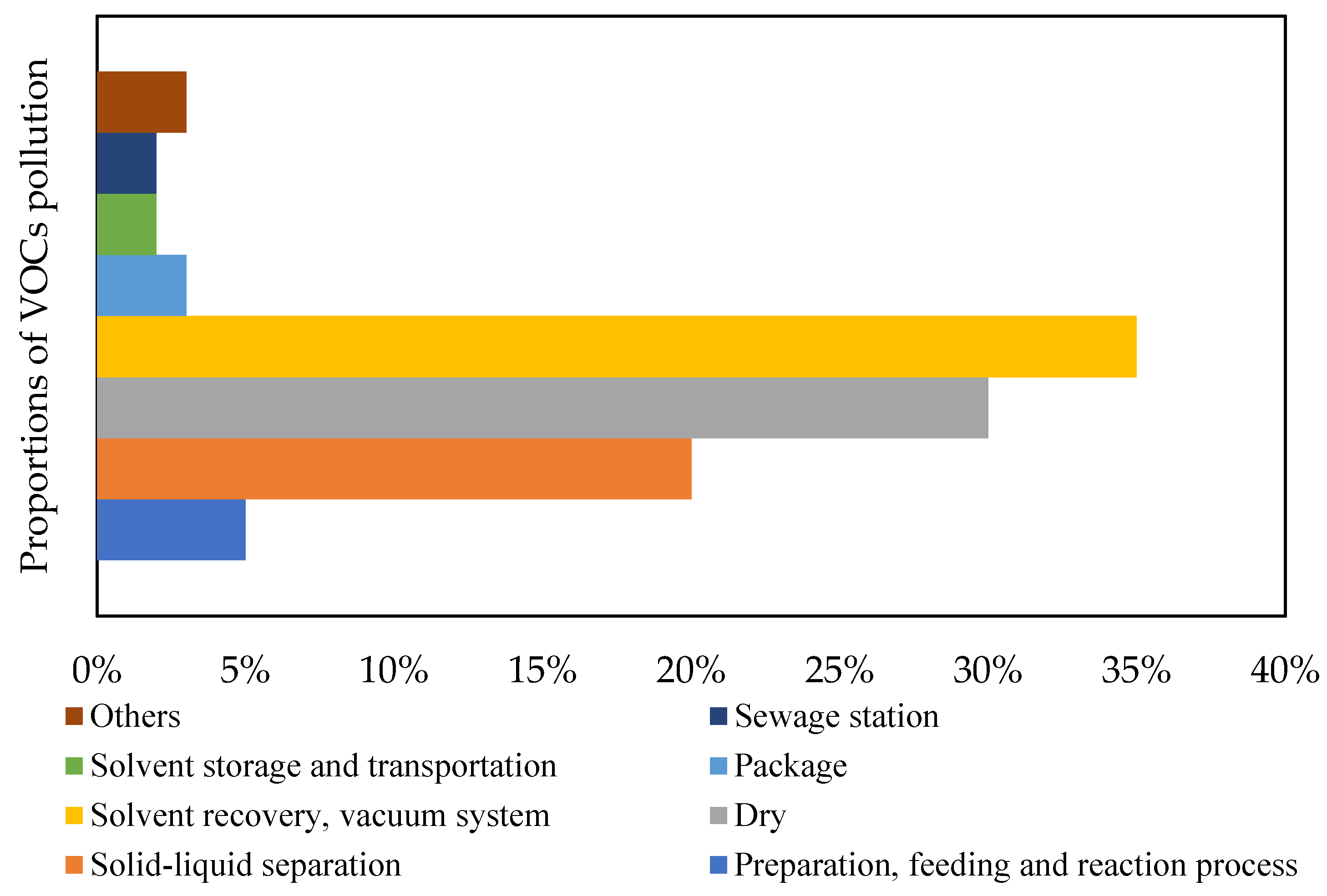

| Evaluation Node | Proportion of VOC Pollution | Estimated Exhaust Gas Collection Rate/Type of Factory | Estimated Facility Commissioning Rate/Type of Factory | Estimated Facility Removal Rate/Type of Factory | Estimated Comprehensive Removal Rate/Type of Factory | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | M | P | B | M | P | B | M | P | B | M | P | ||

| Preparation, feeding and reaction process | 5% | 95% | 75% | 0 | 95% | 80% | 50% | 95% | 75% | 30% | 86% | 45% | 0% |

| Solid–liquid separation | 20% | 95% | 75% | 60% | 95% | 80% | 50% | 95% | 75% | 30% | 86% | 45% | 9% |

| Drying | 30% | 95% | 85% | 75% | 95% | 80% | 50% | 95% | 75% | 30% | 86% | 51% | 11% |

| Solvent recovery, vacuum system | 35% | 98% | 95% | 85% | 95% | 80% | 50% | 95% | 75% | 30% | 88% | 57% | 13% |

| Packaging | 3% | 95% | 85% | 0 | 95% | 80% | 50% | 95% | 75% | 30% | 86% | 51% | 0% |

| Solvent storage and transportation | 2% | 95% | 75% | 50% | 95% | 80% | 50% | 95% | 95% | 0 | 86% | 57% | 0% |

| Sewage station | 2% | 90% | 75% | 10% | 95% | 80% | 50% | 90% | 60% | 30% | 77% | 36% | 2% |

| Others | 3% | 90% | 75% | 0 | 95% | 80% | 50% | 95% | 60% | 30% | 81% | 36% | 0% |

| Whole plant evaluation | 86% | 51% | 10% | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Shi, M.; Wu, S.; Guo, X.; Zhang, X.; Ni, N.; Sha, S.; Zhang, H. Study on Volatile Organic Compound (VOC) Emission Control and Reduction Potential in the Pesticide Industry in China. Atmosphere 2022, 13, 1241. https://doi.org/10.3390/atmos13081241

Wang N, Shi M, Wu S, Guo X, Zhang X, Ni N, Sha S, Zhang H. Study on Volatile Organic Compound (VOC) Emission Control and Reduction Potential in the Pesticide Industry in China. Atmosphere. 2022; 13(8):1241. https://doi.org/10.3390/atmos13081241

Chicago/Turabian StyleWang, Na, Mali Shi, Shengmin Wu, Xinyan Guo, Xiaohui Zhang, Ni Ni, Sha Sha, and Houhu Zhang. 2022. "Study on Volatile Organic Compound (VOC) Emission Control and Reduction Potential in the Pesticide Industry in China" Atmosphere 13, no. 8: 1241. https://doi.org/10.3390/atmos13081241

APA StyleWang, N., Shi, M., Wu, S., Guo, X., Zhang, X., Ni, N., Sha, S., & Zhang, H. (2022). Study on Volatile Organic Compound (VOC) Emission Control and Reduction Potential in the Pesticide Industry in China. Atmosphere, 13(8), 1241. https://doi.org/10.3390/atmos13081241