1. Introduction

The interest in renewable energies is increasing more and more due to the limited availability of conventional fossil fuels and to mitigate climate change by the reduction of CO

2 in the atmosphere. A promising technology for the conversion of biomass is the fluidized bed gasification. This is due to the high heat and mass transfer and good mixing properties as well as the suitability for scaling up. The resulting syngas (which is mainly composed of H

2, CO, CO

2 und CH

4) from biomass gasification is versatile and can be used for the production of synthetic fuels or the generation of heat as well as electricity, for instance [

1,

2,

3,

4]. By applying the principle of chemical looping, the emissions and costs can be further reduced compared to other gasification processes [

5]. The biomass chemical looping gasification (BCLG) is based on the circulation of an oxygen carrier (OC) between two interconnected reactors. Thereby, lattice oxygen for the oxidation of biomass and the heat for reactions is provided. In this process, the oxygen carrier is oxidized in the air reactor (AR) and reduced by the reaction with the biomass in the fuel reactor (FR). The two reactors are separated using loop-seals, which prevents the dilution of the syngas produced in the fuel reactor with flue gas from the air reactor and, thus, a high quality syngas is obtained. Furthermore, a low tar content in the syngas is obtained due to the presence of oxygen carriers underlining the advantage of BCLG compared to other processes for syngas production [

5,

6,

7,

8].

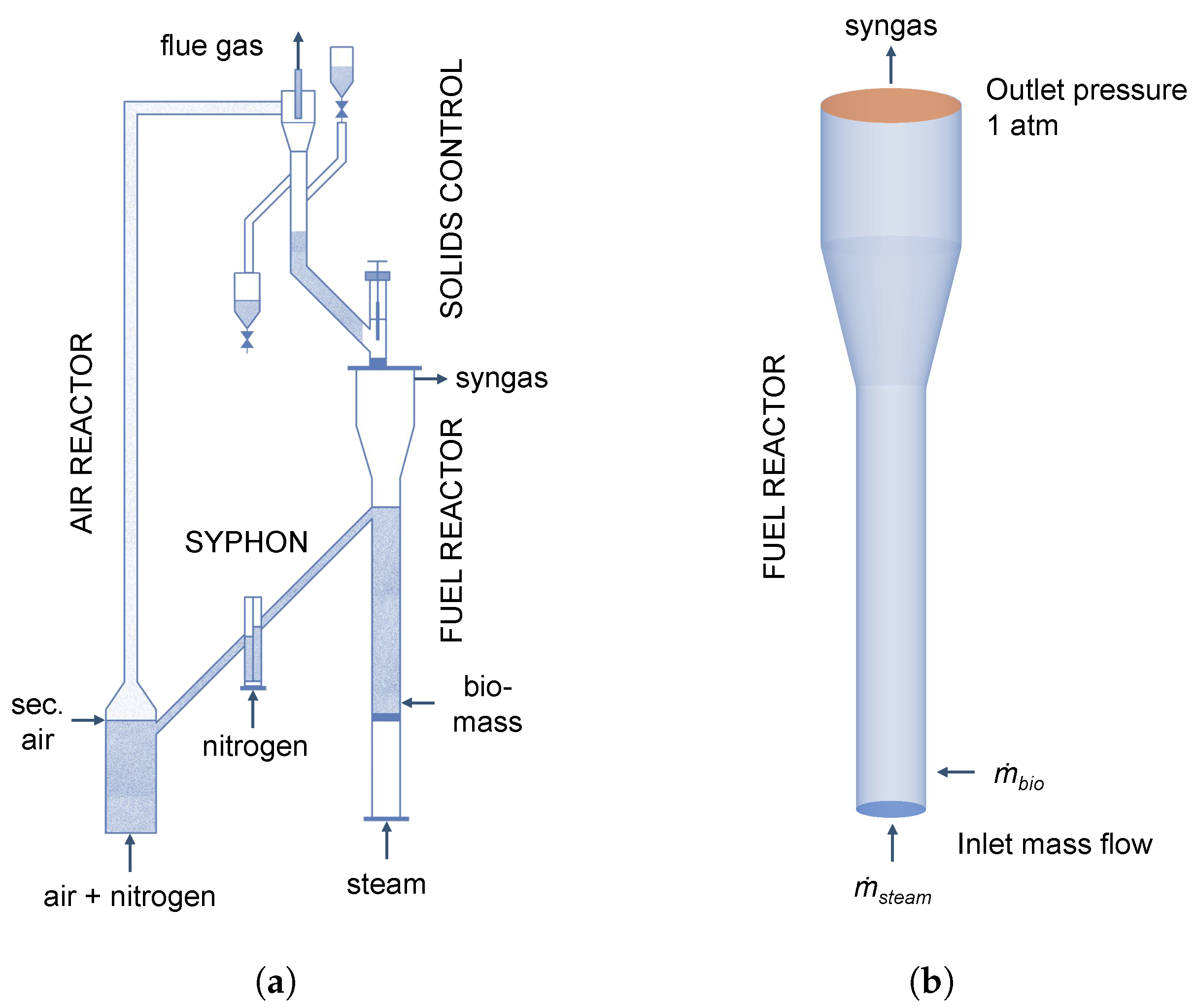

A similar carbon capture technology, namely the chemical looping combustion (CLC), can be applied to combust fuels such as biomass or coal to generate power. A product gas mainly composed of CO

2 and steam is obtained [

9,

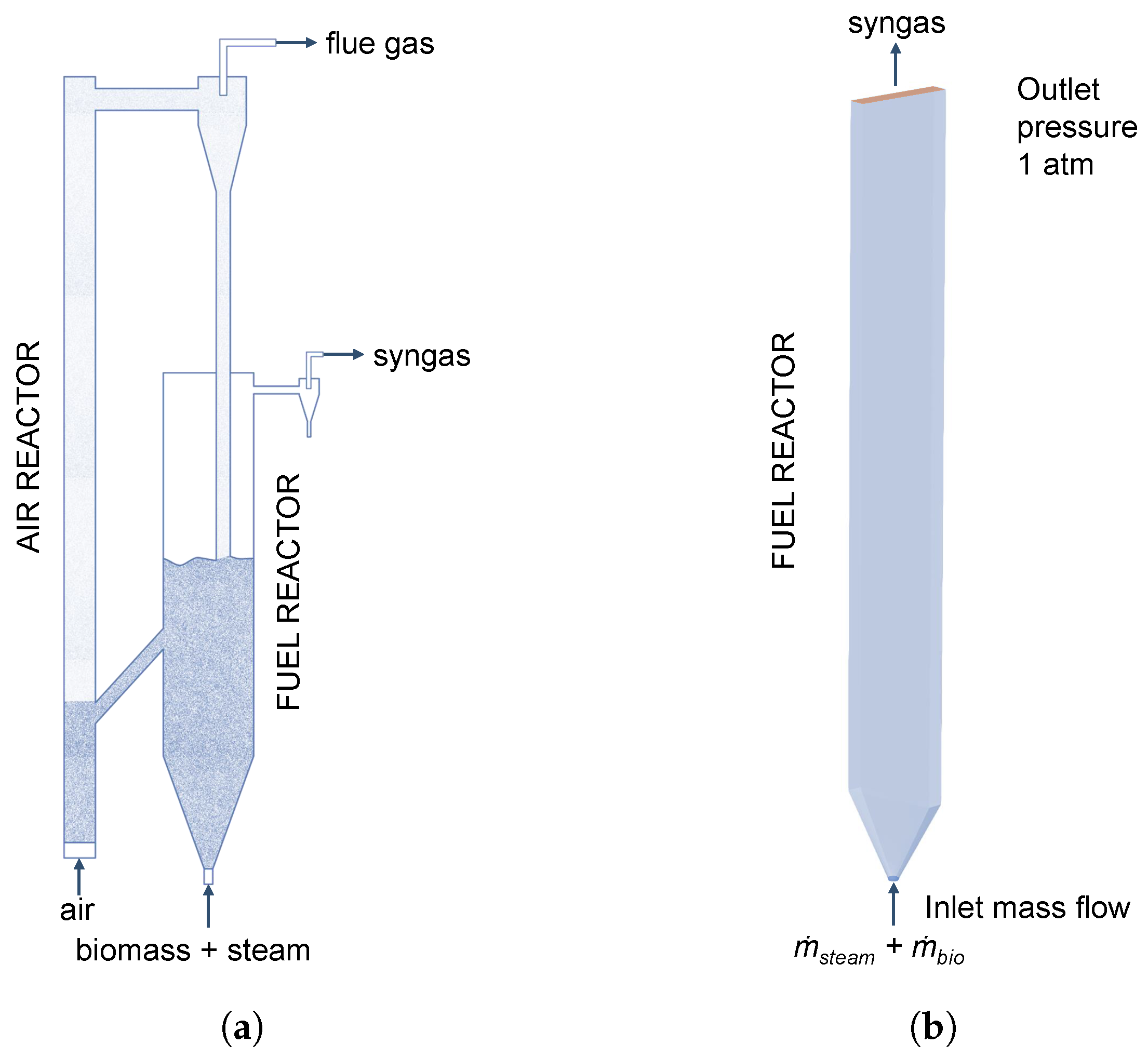

10] in contrast to BCLG, where the produced syngas can be used for a wide range of applications. A schematic representation of the chemical looping gasification (CLG) principle is shown in

Figure 1 and a detailed description of the CLG process is given in the work of Ge et al. [

11].

Several experimental studies regarding BCLG have been performed [

5,

11,

12,

13,

14,

15], but there is no consensus in the literature regarding the influence of the main operating parameters on syngas composition [

5]. Furthermore, the harsh conditions in CLG reactors only allow the measurement of mascroscopic quantities [

16]. For this matter and due to the increase in processing power, computational fluid dynamics (CFD) became an attractive tool for the optimization, operation, and design of fluidized beds. However, a compromise between accuracy of the model and computational effort has to be made for the simulation of industrial-size plants [

17,

18].

For the simulation of fluidized bed reactors, Euler–Euler and Euler–Lagrange approaches are typically used [

19]. Euler–Euler approaches (e.g., TFM or

two-fluid model) are mainly used for industrial-sized applications because of the high computational speed, but many closure equations are necessary, limiting the accuracy. This is due to the fact that in this approach both phases are considered as continua by treating the solid phase as a pseudo-fluid. Therefore, a new pseudo-phase has to be defined for every particle size for the implementation of particle size distributions, for instance, [

20,

21,

22]. Euler–Lagrange approaches (e.g., CFD–DEM or

computational fluid dynamics–discrete element method) solve the Newtonian equations of motion for the solid phase in contrast to the TFM, while the gas phase is modeled as a continuum. Due to the tracking of individual particles and resolving particle–particle interactions, the computational effort is significantly higher compared to the TFM, resulting in a limitation of the number of particles. Therefore, mainly lab-scale fluidized beds are investigated using CFD–DEM [

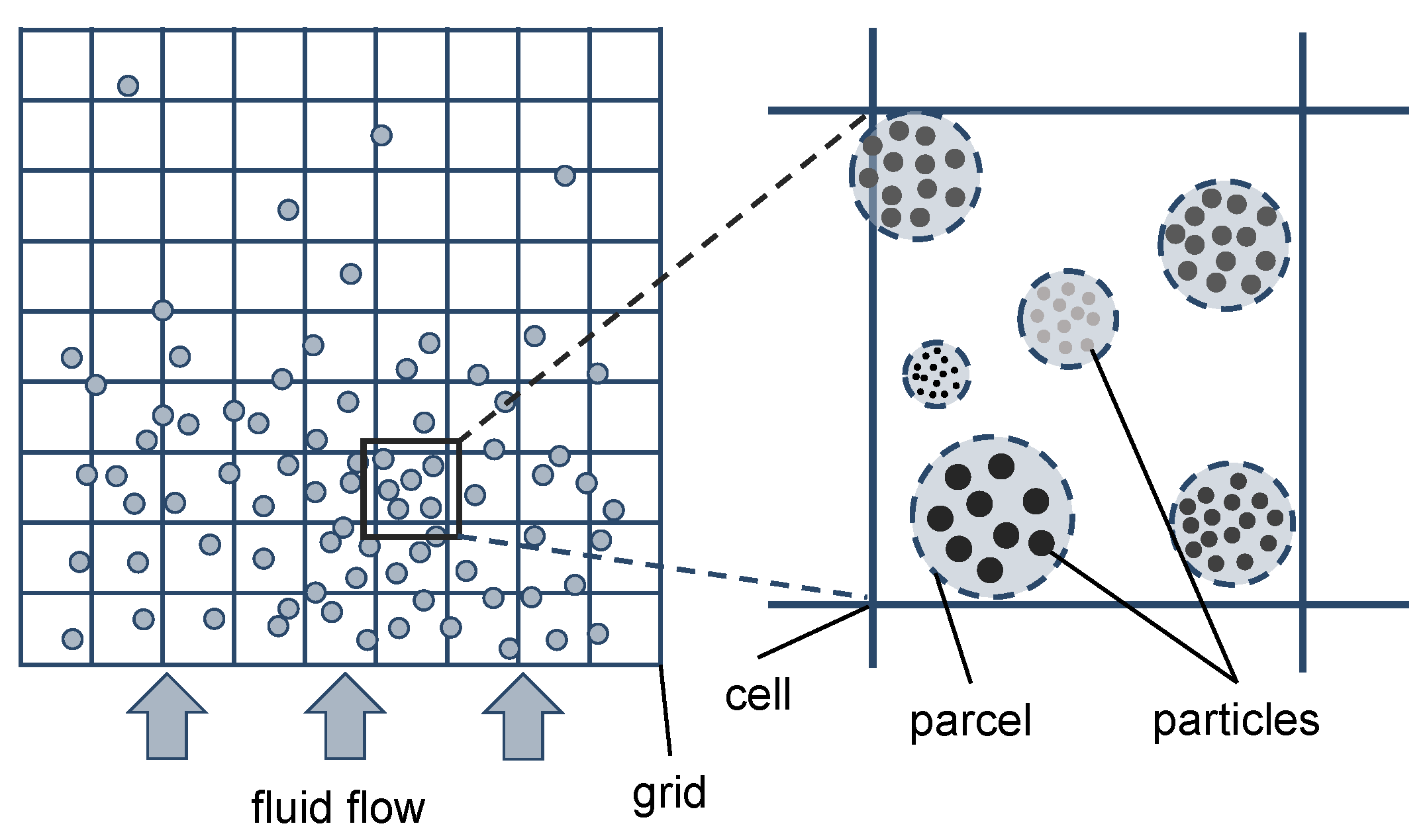

23]. The multiphase particle-in-cell (MP-PIC) method is based on the work of Andrews and O’Rourke [

24], which results from a modification of the Euler–Lagrange approach. In this approach, computational parcels are used to represent a defined number of particles with identical properties such as size, velocity, and location. Instead of resolving particle–particle collisions, the so-called

particle stress model is used to model the particle–particle interactions, resulting in a significant reduction of the computational effort compared to CFD–DEM. With this approach, simulations of industrial-sized circulating fluidized beds are feasible, as performed in literature [

4,

25]. A schematic representation of the MP-PIC method is shown in

Figure 2.

Biomass gasification has been numerically investigated by several authors and only a small selection will be named in this work. A detailed list of literature on CFD simulation of biomass gasification is given in the work of Ostermeier et al. [

27]. A CFD–DEM model was developed by Ku et al. [

28] in OpenFOAM

® to investigate the influence of the reactor temperature and steam-to-biomass ratio on the syngas composition. Their results show good agreement with literature data. A similar study was performed by Qi et al. [

29] using a coarse-grain CFD–DEM model in STAR-CCM

®. They obtained good results as well with reduced computational time. A CFD-DEM study was also performed by Wang and Shen [

16]. They found that the particle diameter of the biomass has an insignificant influence regarding the hydrogen concentration, while the biomass feeding position influences the syngas composition. Ostermeier et al. [

27] used a coarse-grain CFD–DEM model in ANSYS

® Fluent

® for the investigation of wood pellet evolution with a satisfying prediction of the gasifier behavior.

Furthermore, there are various studies incorporating reactions of solid fuel with oxygen carriers, mostly for the investigation of chemical looping combustion systems [

30,

31,

32,

33,

34]. However, few studies are available in the literature regarding the simulation of the biomass chemical looping gasification processes. Li et al. [

35] used a Euler–Euler approach for the simulation of BCLG with an Fe-based oxygen carrier and yielded good results in terms of the syngas composition. Whereas Wang et al. [

36] investigated the influence of the main operating parameters for the gasification of coal in a multi-fluid model and found that a smaller size of the oxygen carrier particles reduces the syngas production.

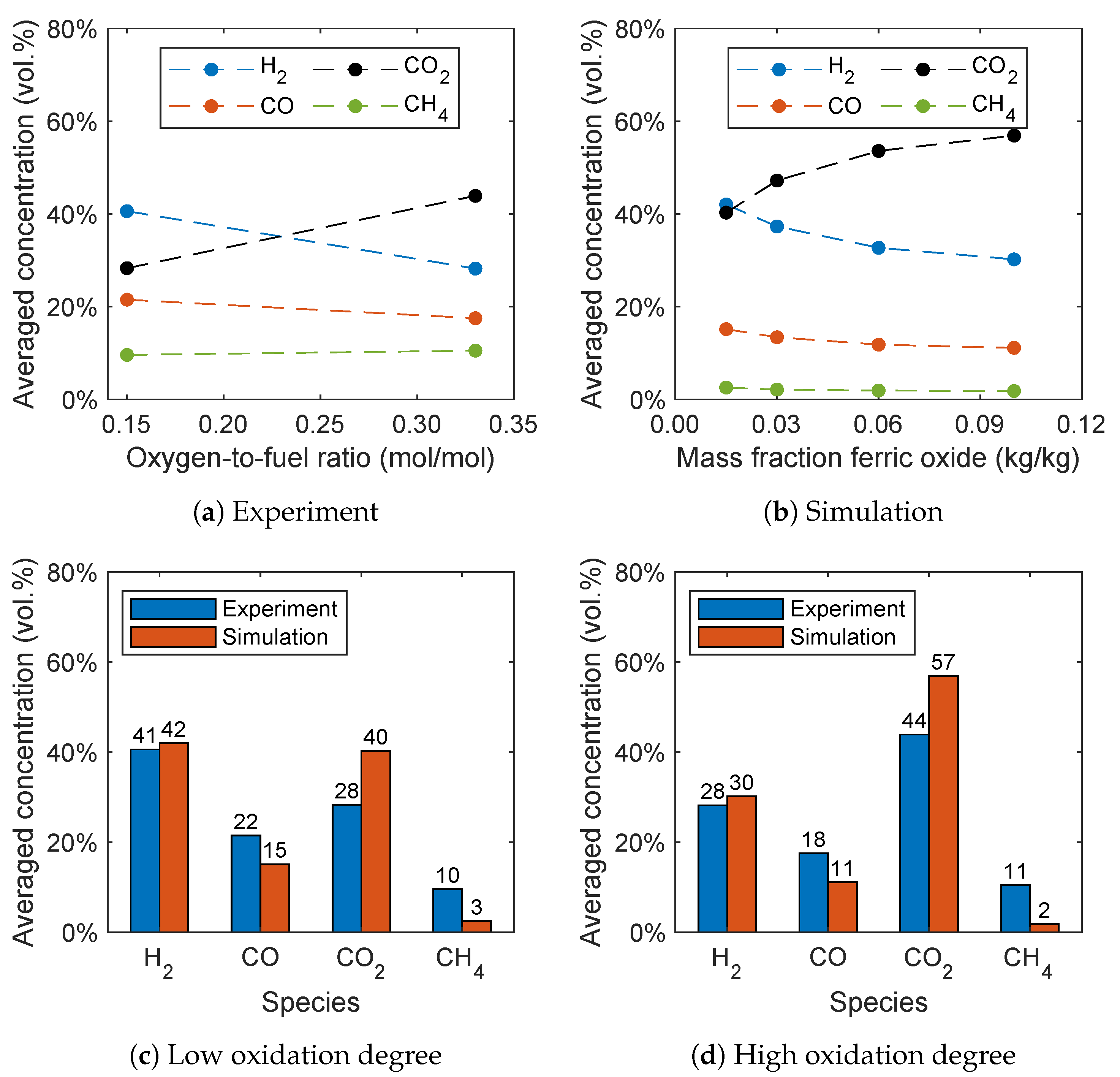

Controlling the availability of oxygen in the gasification process is crucial for adjusting the syngas composition. BCLG is hence expected to work with an oxygen carrier at lower oxidation degrees. Therefore, Condori et al. [

5] developed a novel method for controlling the oxidation of the OC ilmenite in the air reactor. Their results also showed the effectiveness of ilemnite.

However, limited numerical studies on biomass steam gasification using oxygen carriers are available. Furthermore, no study was found in the literature that numerically investigated the influence of the oxidation degree of the oxygen carrier on the syngas composition. Therefore, in this work, biomass steam gasification using ilmenite as an oxygen carrier is modeled using

Barracuda VR

® 21.0 as framework of the MP-PIC method. This is performed in two separate steps. At first, biomass gasification in a spouted bed is simulated using a reduced reaction network. The influence of the reactor temperature and steam-to-biomass ratio is investigated and compared with experimental data given by Song et al. [

6]. Second, the gasification of biomass is coupled with the reaction kinetics of ilmenite as an oxygen carrier proposed by Abad et al. [

37], and the influence of the reactor temperature and the oxidation degree is investigated and compared with experimental data obtained by Condori et al. [

5] in a lab-scale fluidized bed. The separation in two steps is performed to distinguish the deviations of the simulations compared to the experiments resulting from the two different reduced reaction networks.

5. Conclusions

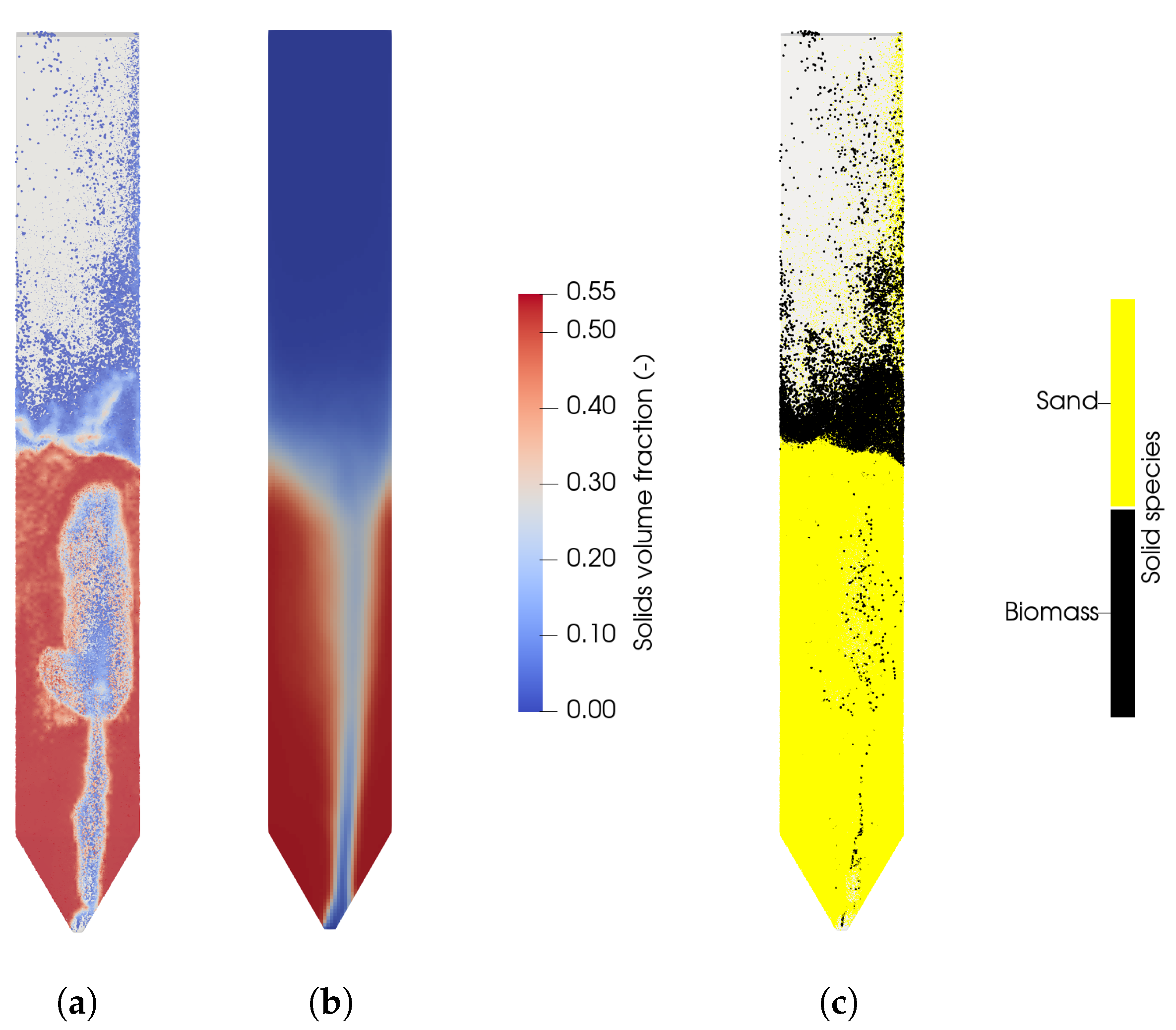

In this work, a model for the simulation of biomass steam gasification using ilmenite as an oxygen carrier was developed using the MP-PIC method in the framework of Barracuda VR® 21.0. This was performed in two separate steps.

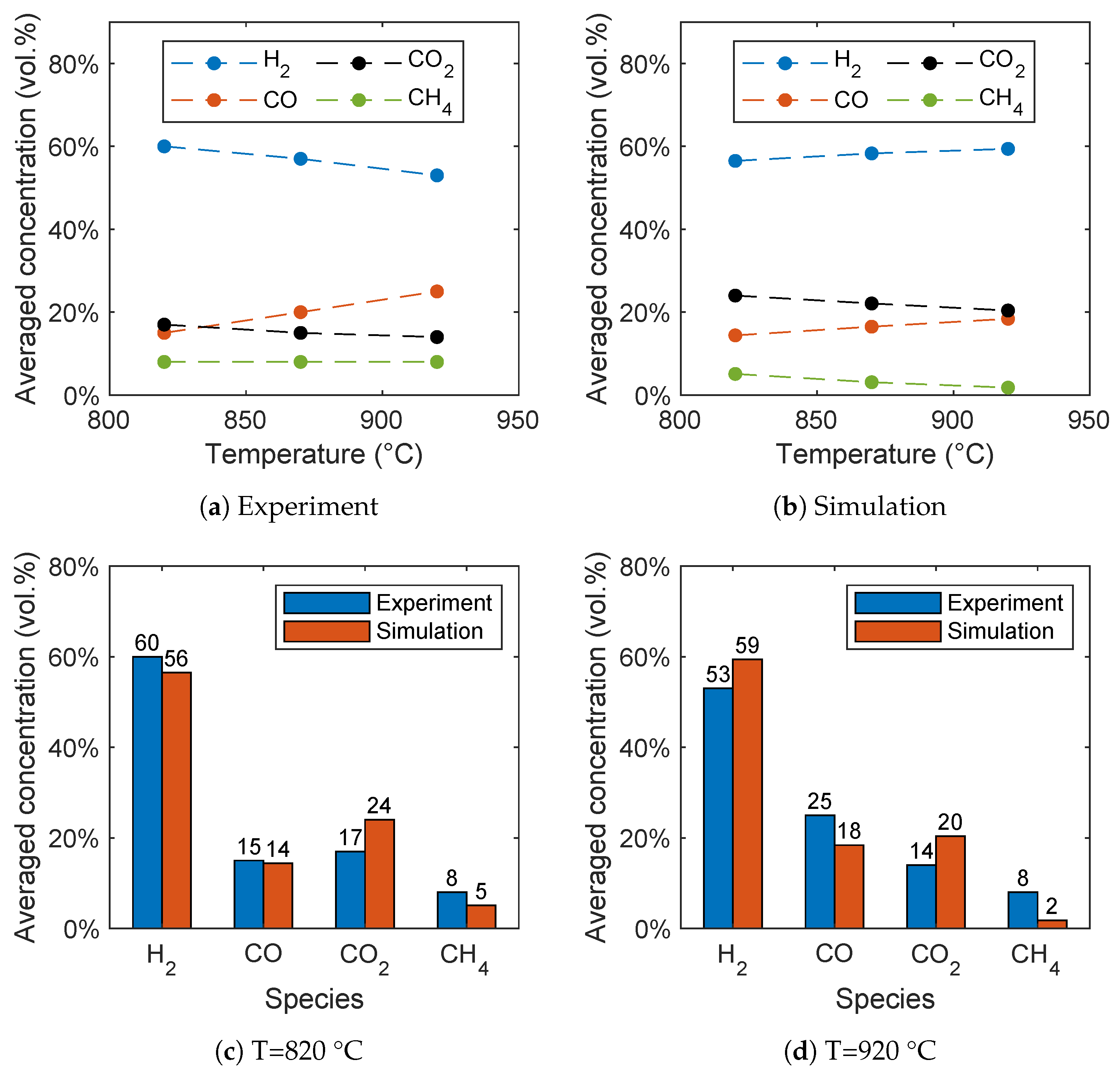

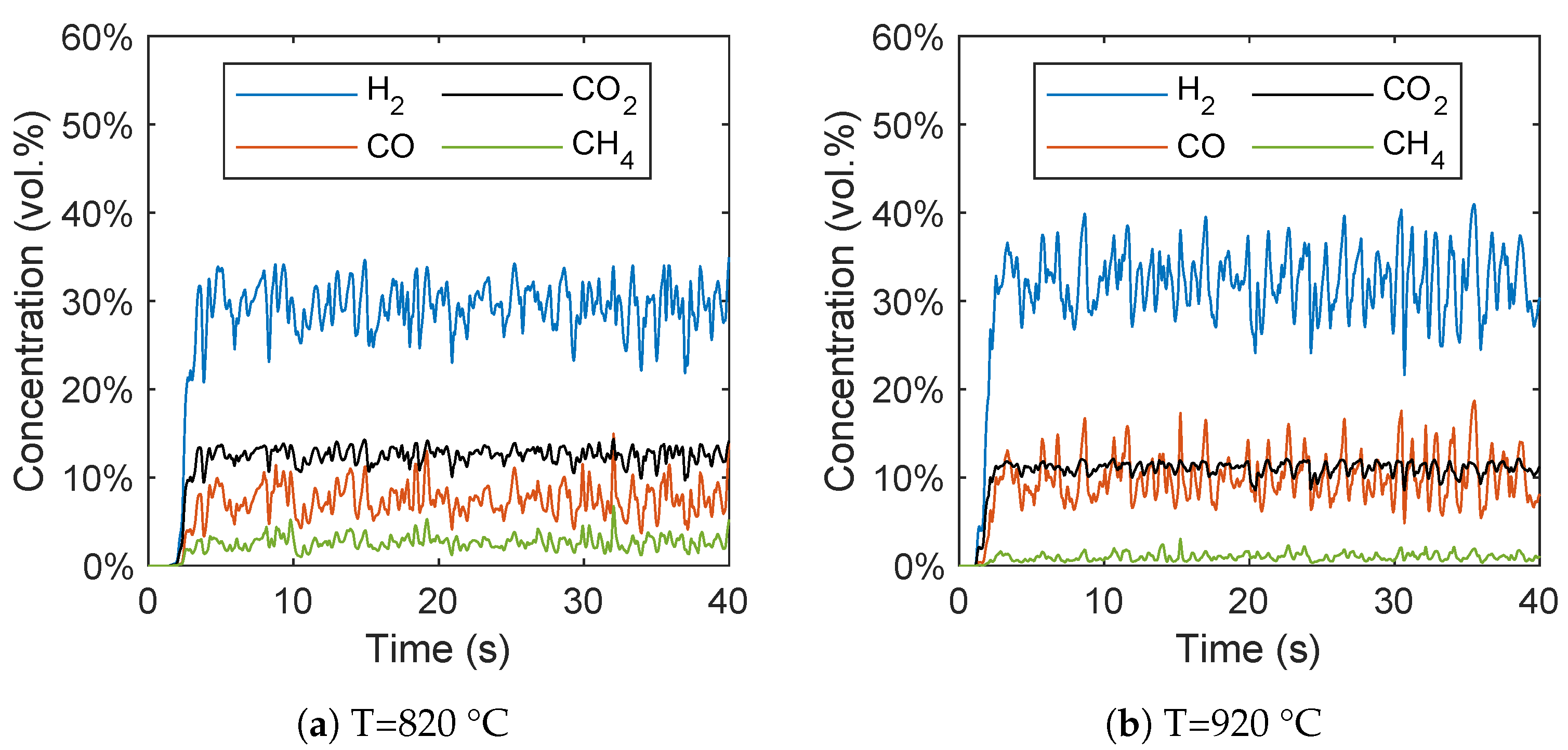

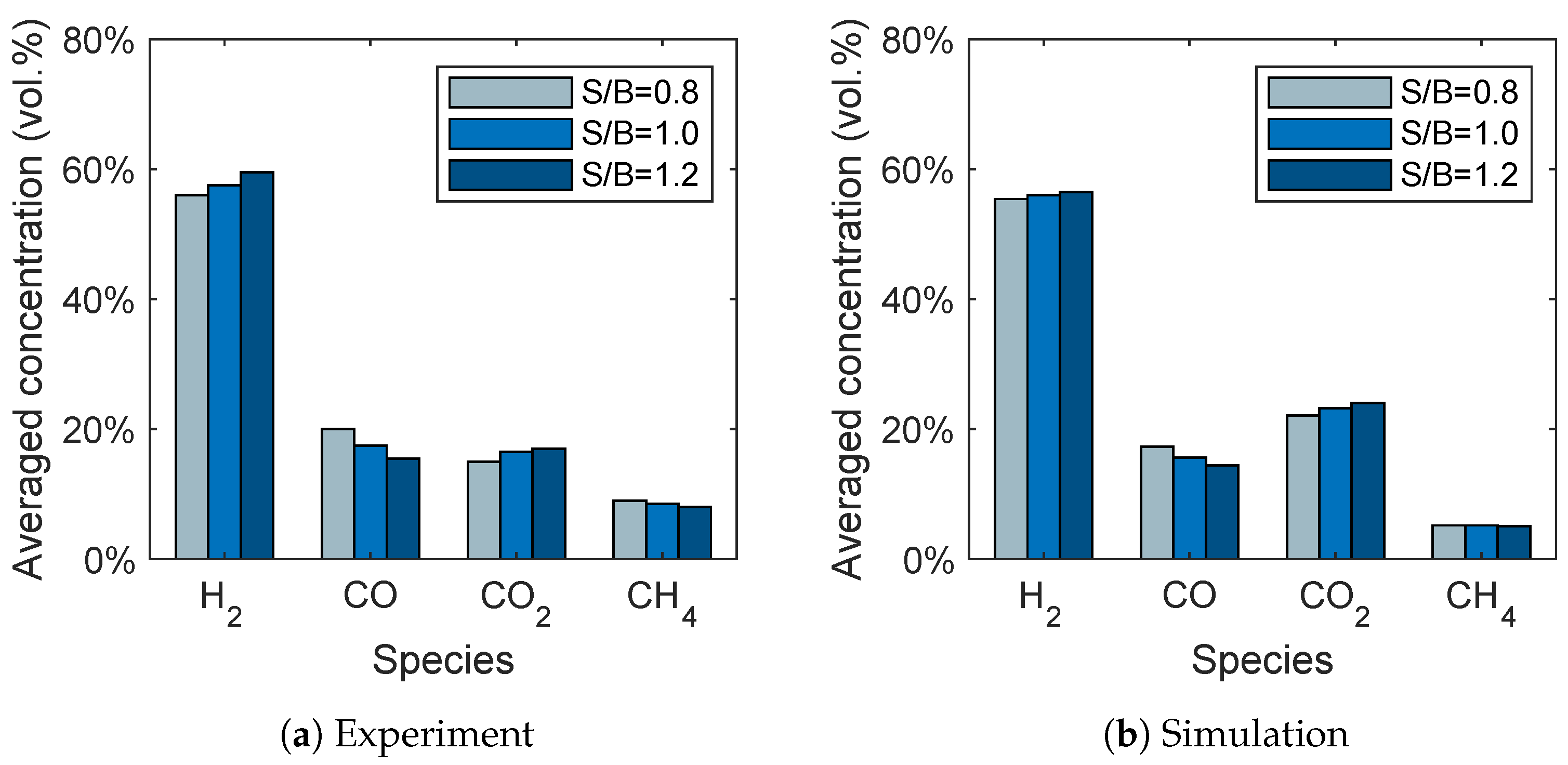

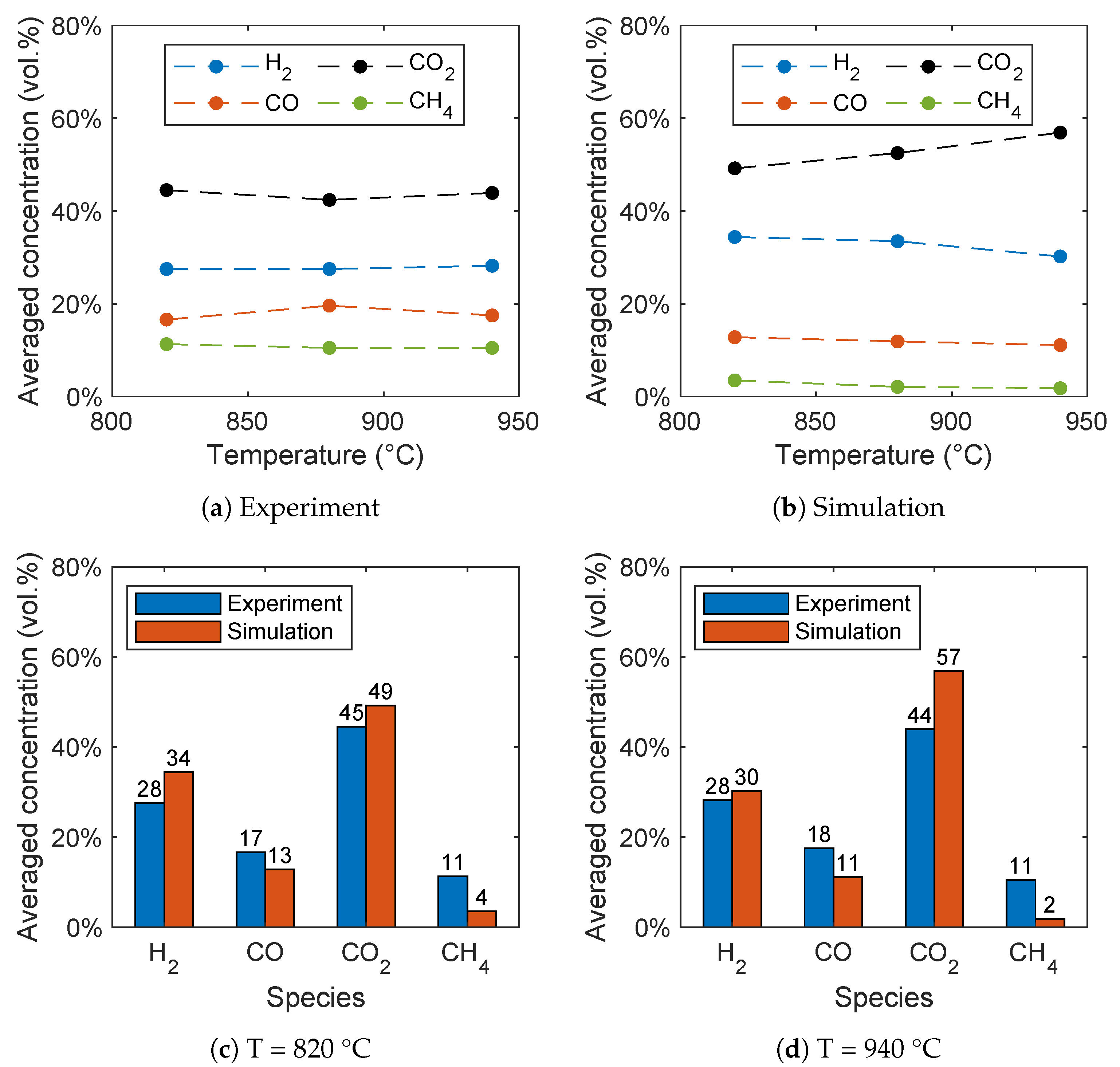

Firstly, a reduced reaction network for the gasification of biomass in a spouted bed was investigated and the results were compared with experimental data. The results show a good agreement despite the necessary simplifications. The influence of the steam-to-biomass ratio was successfully reproduced by simulations. For the influence of the temperature on the syngas composition, the trends for carbon monoxide and carbon dioxide were predicted correctly. The observed increase of the hydrogen concentration with increasing temperature is presumable due to an overprediction of the methane conversion by the methane reforming reaction. These findings are also in line with observations of similar studies in the literature [

16,

28,

29]. Furthermore, the influence of the bed mass was investigated showing that the hydrogen concentration decreases and methane concentration increases with increasing bed mass in the syngas due to a lower residence time of the syngas in the reactor.

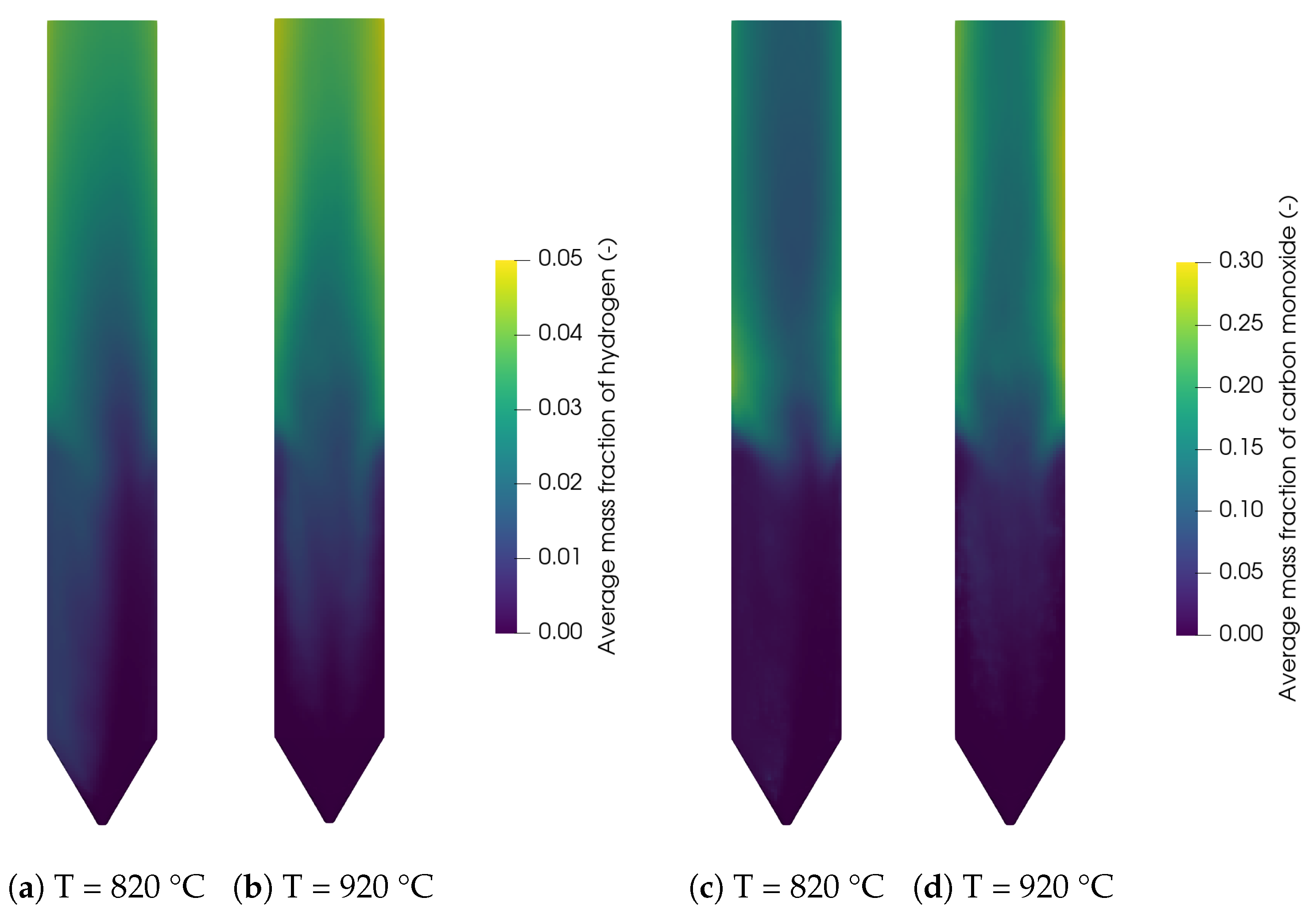

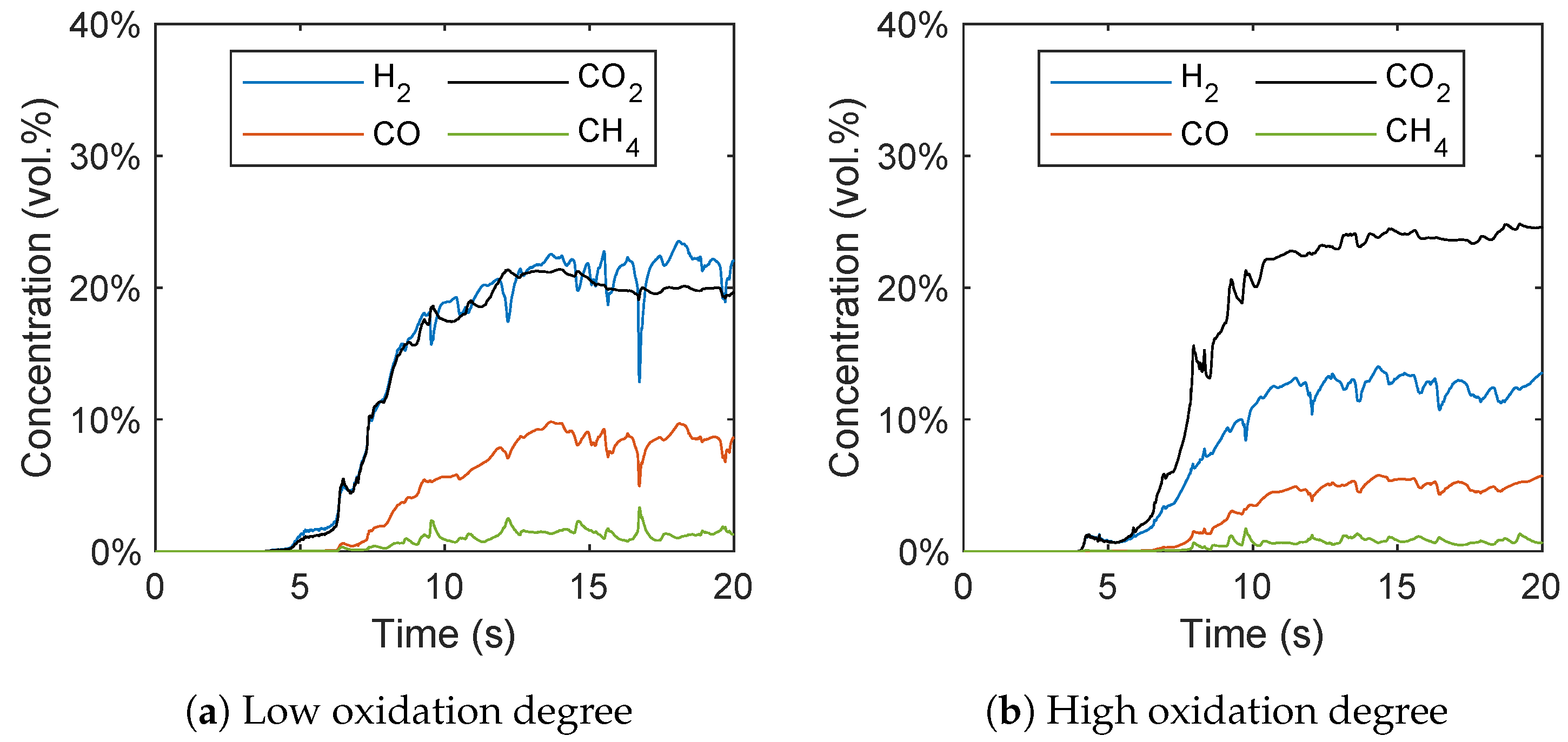

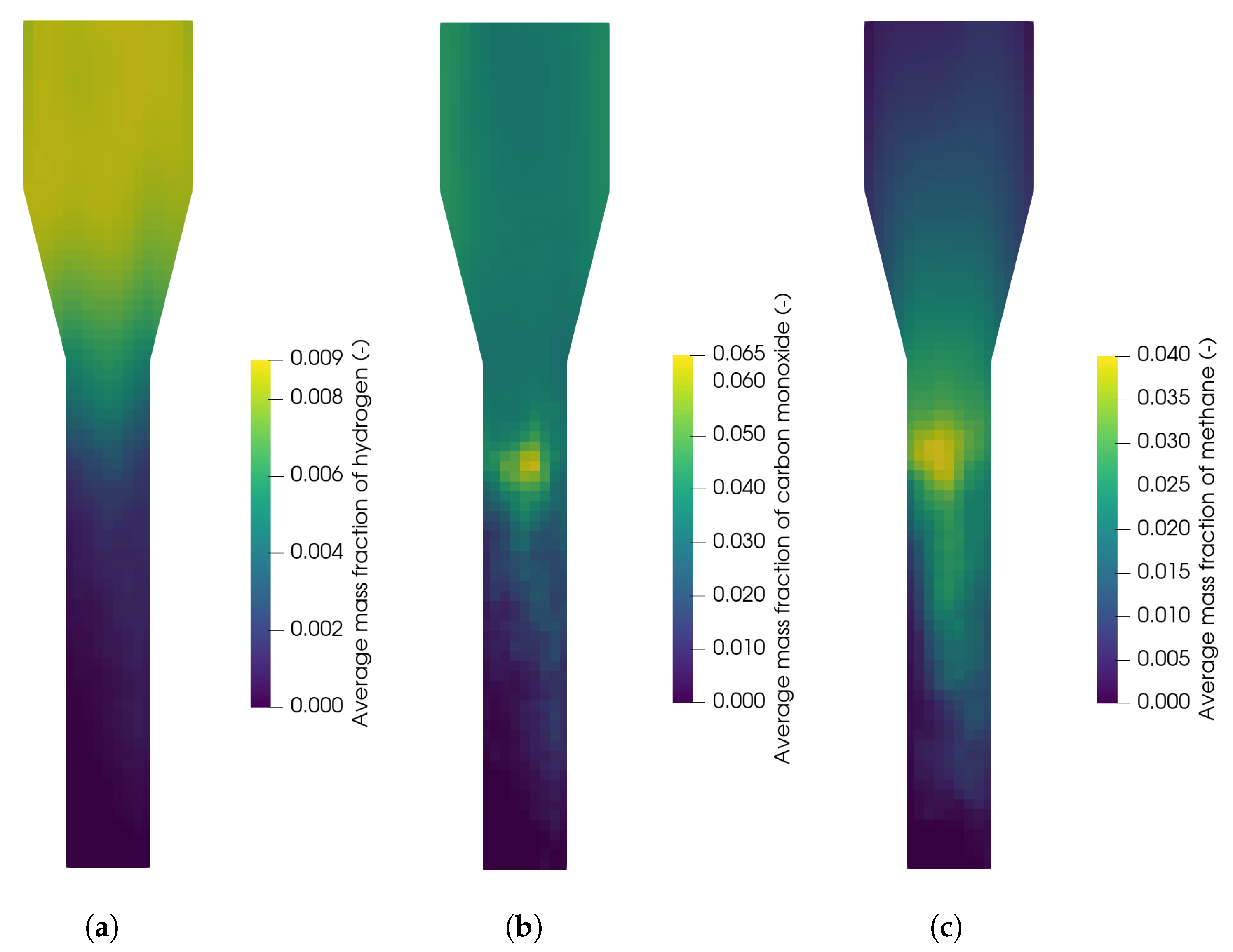

Secondly, the reduced reaction network was coupled with the reaction kinetics of ilmenite as an oxygen carrier for the simulation of BCLG in a lab-scale fluidized bed and compared with experimental data as well. In contrast to CLC processes, the oxygen carrier is present in a reduced state for BCLG and it was found that the oxidation degree of ilmenite has a significant influence on the syngas composition, which was also successfully captured by the simulations. However, the concentration of carbon dioxide was overpredicted, while the syngas yield was underpredicted. Furthermore, the simulations showed a significant increase of the carbon dioxide concentration with increasing temperature that was not observed in the experiments. This is presumable due to an overprediction of the oxidation reactions resulting from the reaction kinetics of the oxygen carrier that were measured in a fully oxidized state. However, there is no consensus in the literature regarding the influence of the reactor temperature on the syngas composition in BCLG.

In general, the simulation results are in good agreement with the experimental data. Thus, the model can be a useful tool for a better understanding of the complex biomass chemical looping gasification process and the influence of various operation parameters. The model can be used to predict the syngas composition of biomass gasification in fluidized beds influenced by operating parameters such as the reactor temperature and oxidation degree of the oxygen carrier for optimizing the plant design.