Numerical Simulation on Particulate Matter Emissions from a Layer House during Summer in Northeast China

Abstract

1. Introduction

2. Materials and Methods

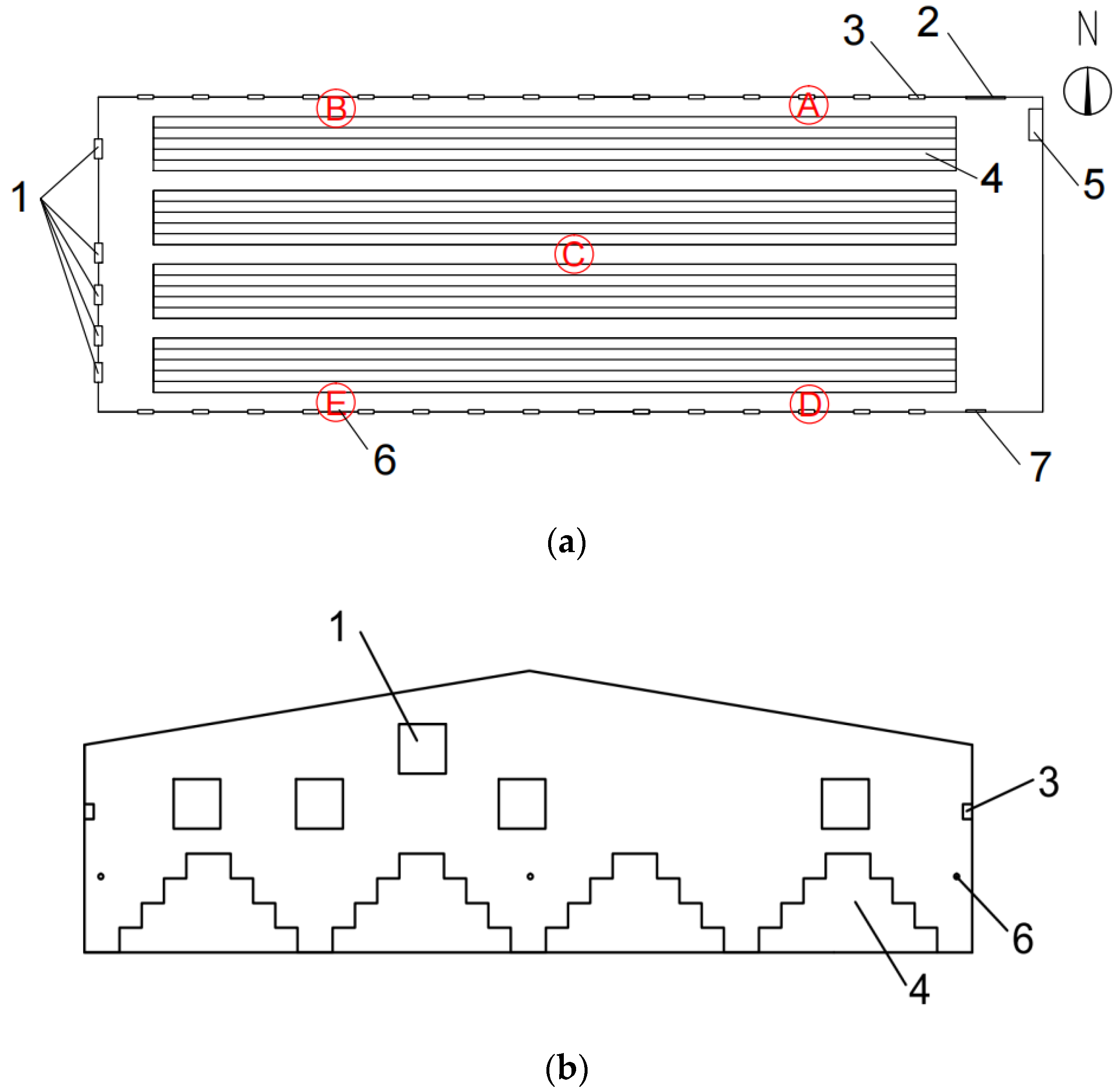

2.1. Layer House

2.2. Field Measurement

2.3. Numerical Simulation

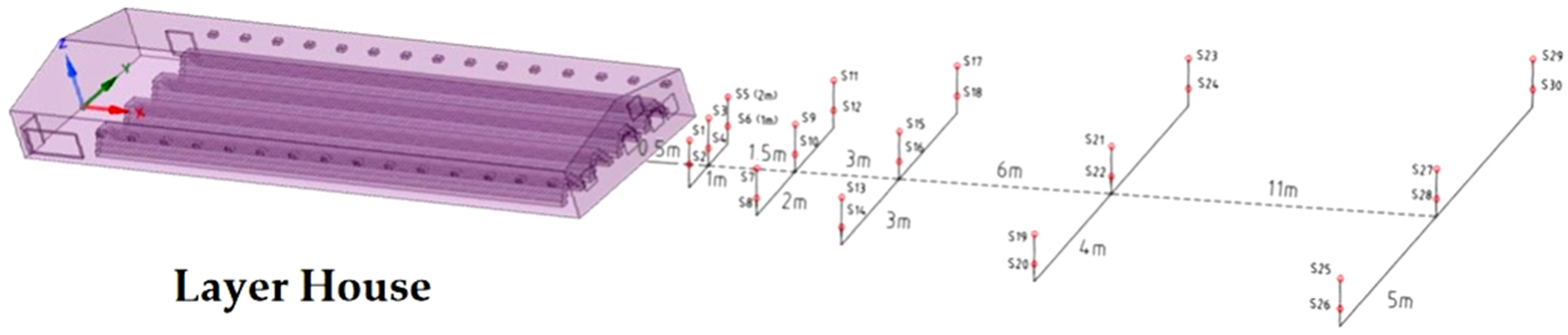

2.3.1. Layer House Model

2.3.2. Grid

2.4. Boundary Conditions

2.5. Fundamental Conservation Equation

2.6. Turbulence Model

2.7. Force Analysis of Particles in the Flow Field

2.8. Data Analysis

3. Results and Discussions

3.1. Analysis of Measured Data

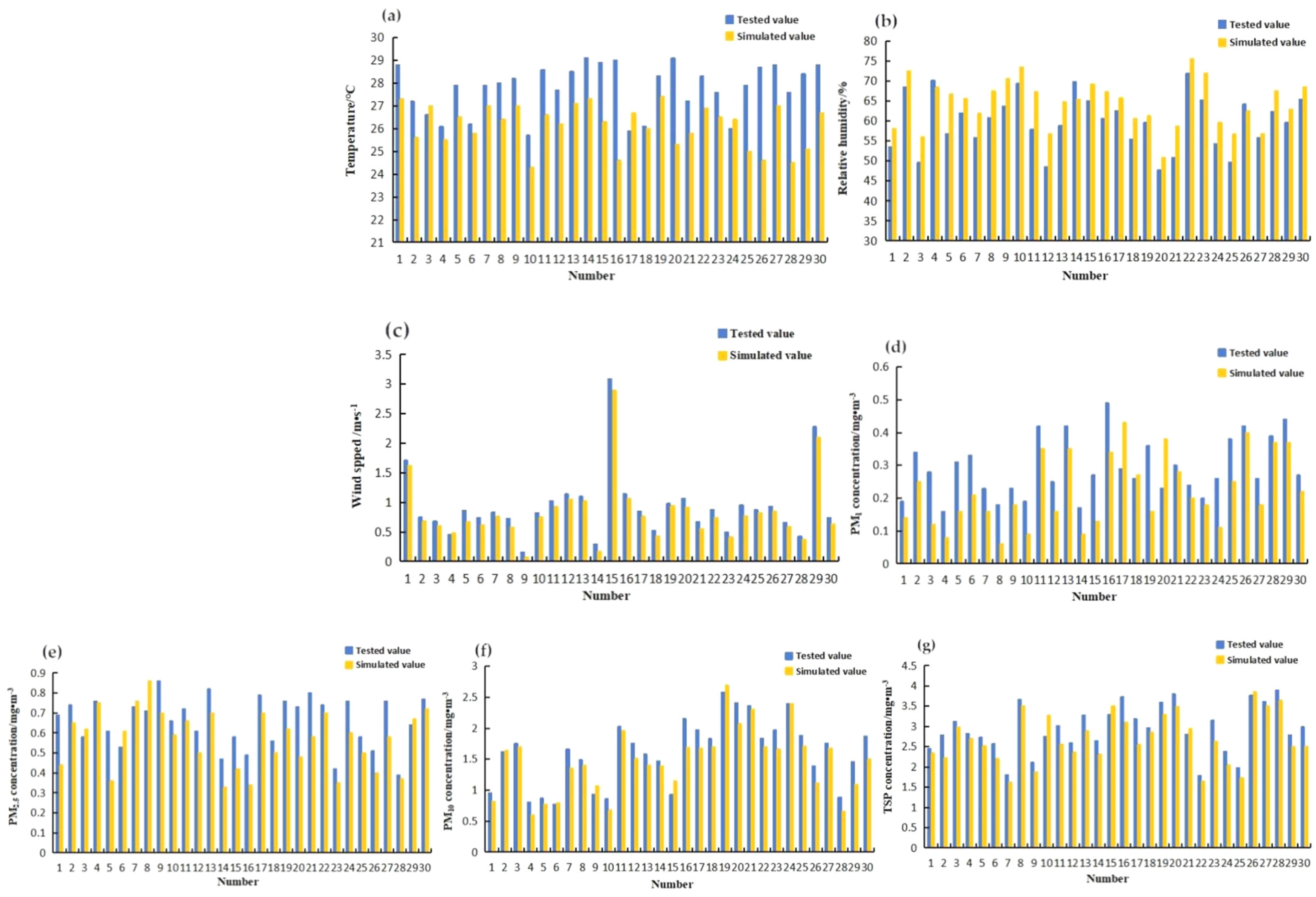

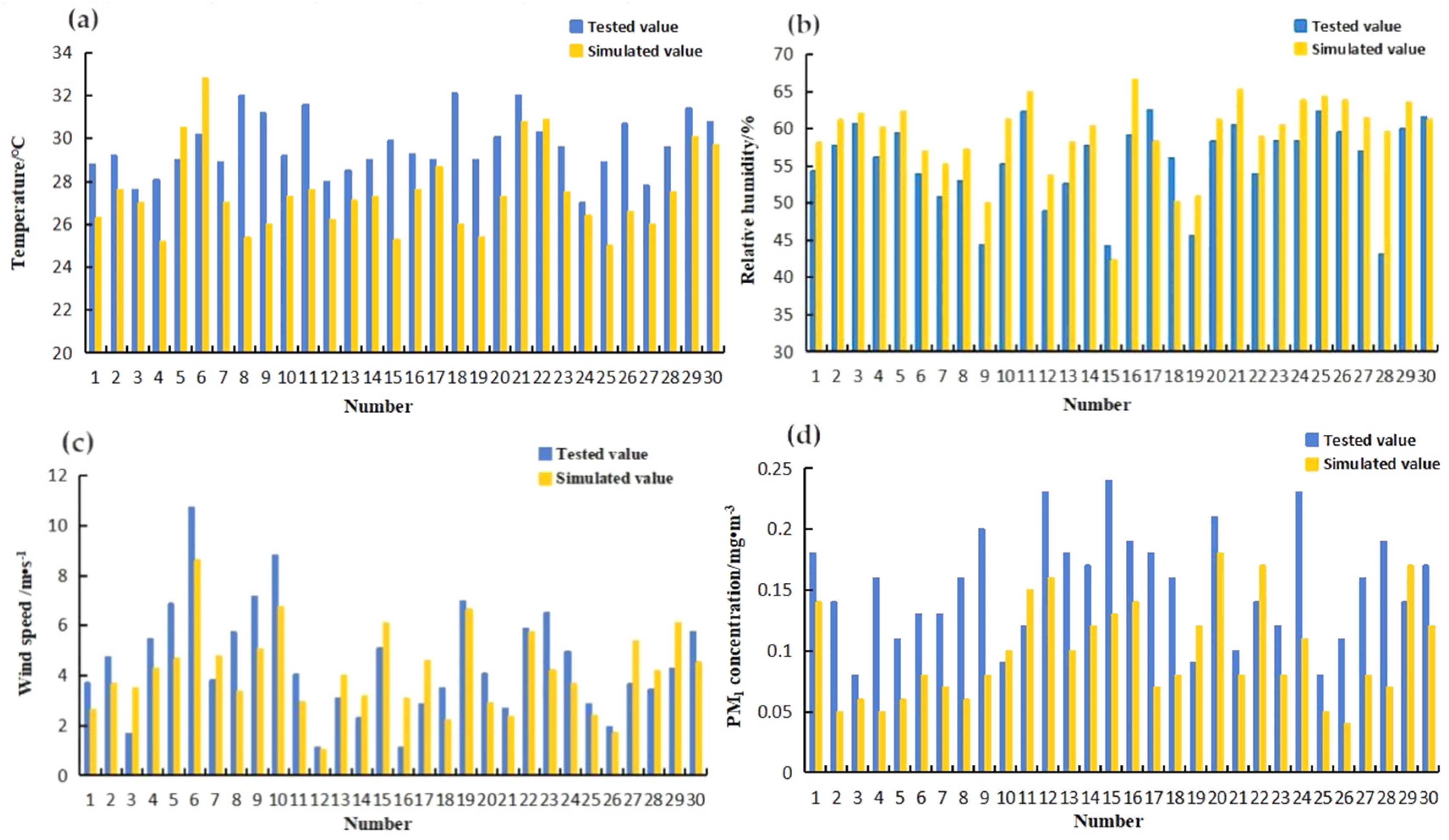

3.2. Comparison of Simulated and Measured Data

3.3. Evaluation of Simulation Results

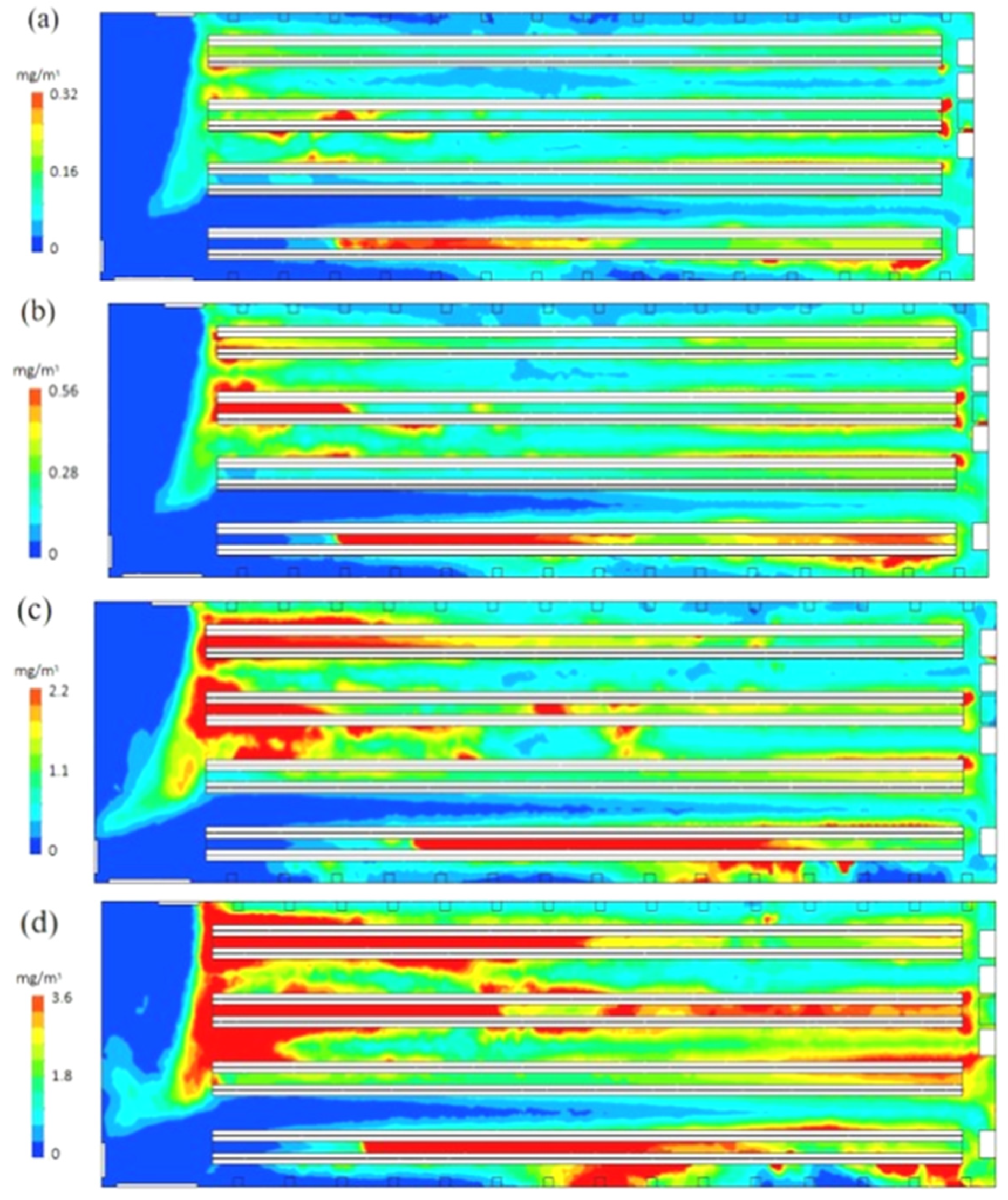

3.3.1. PM Concentration Measurements and Profiles Indoor

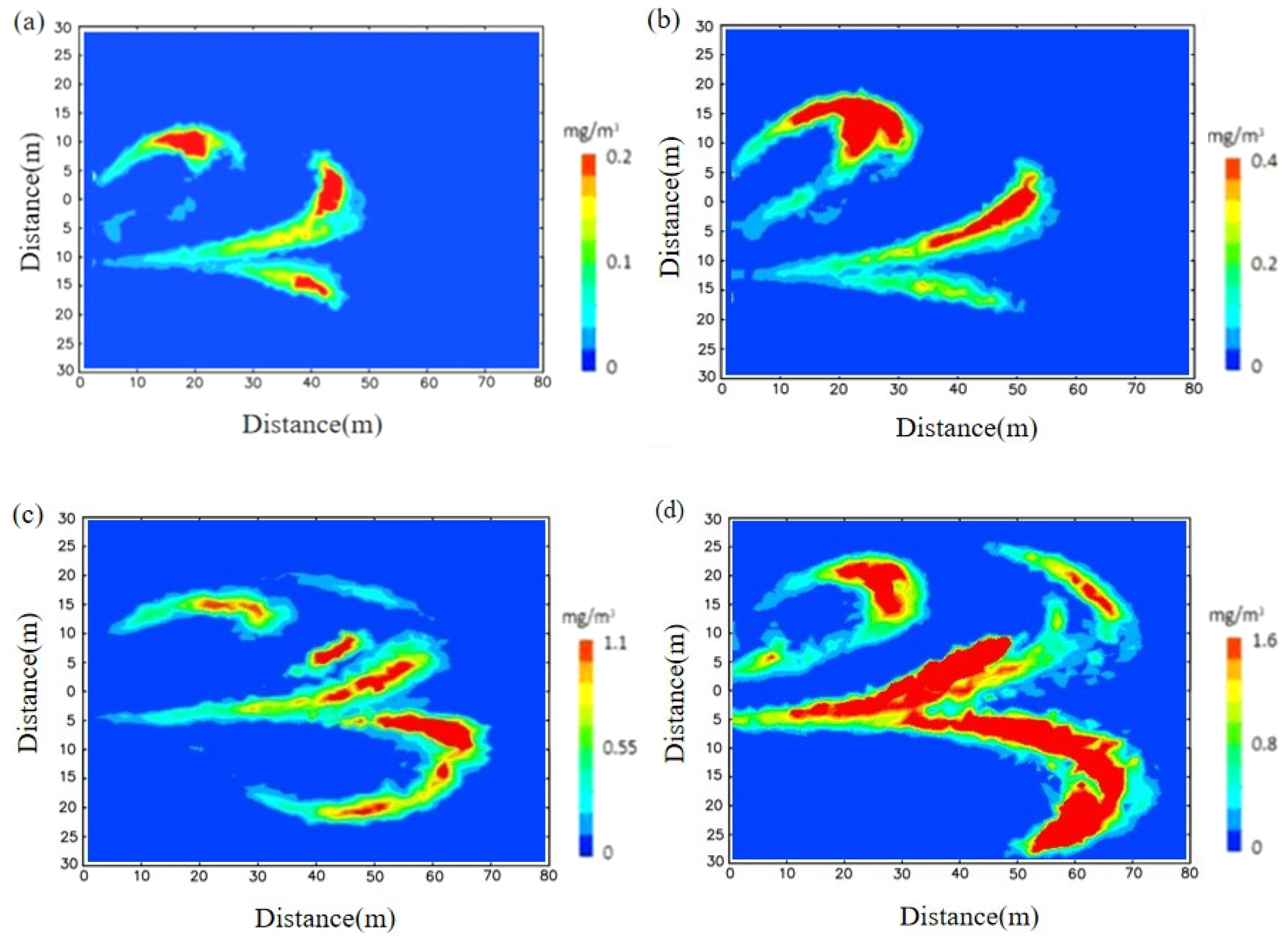

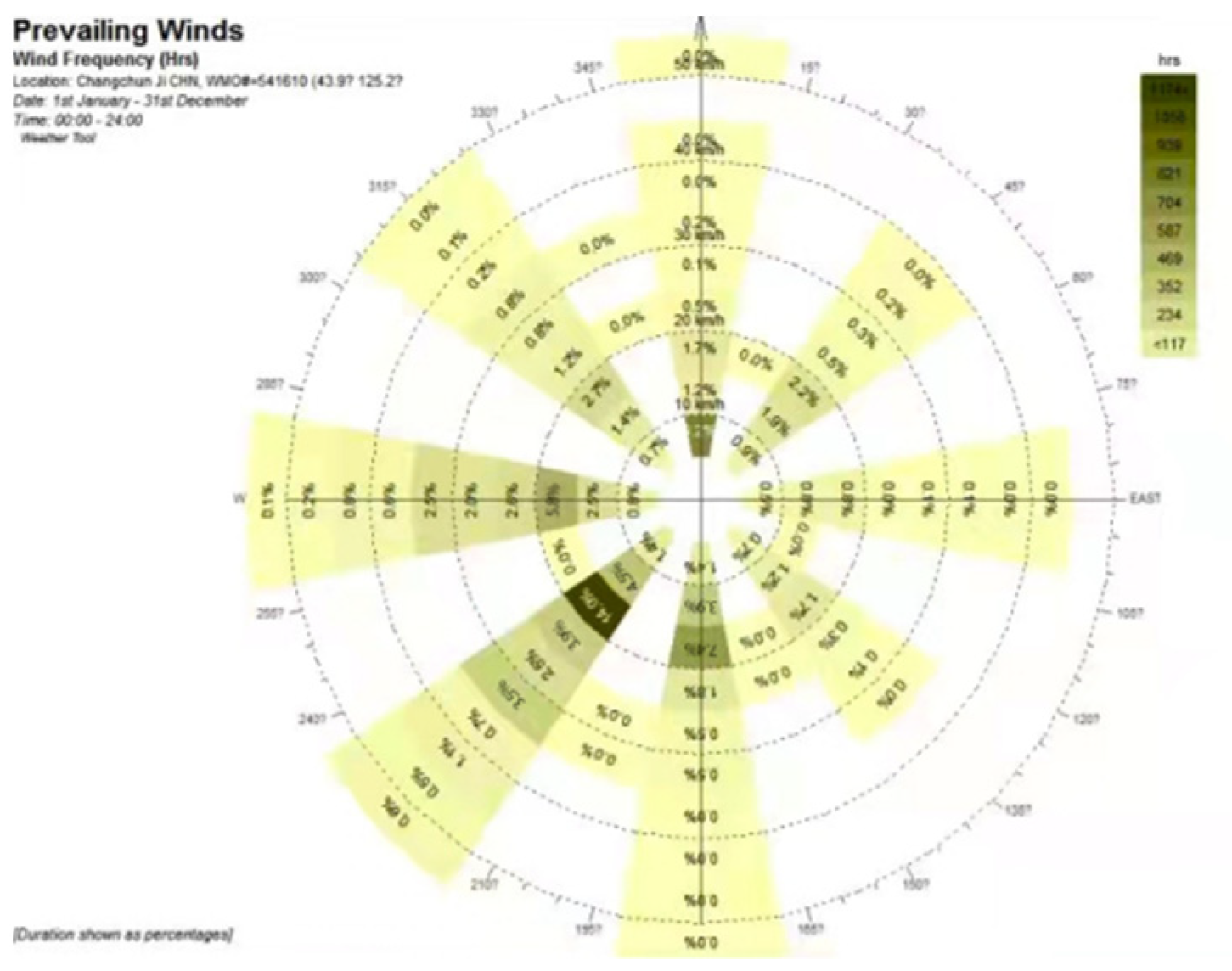

3.3.2. PM Concentration Measurements and Profiles Outdoor

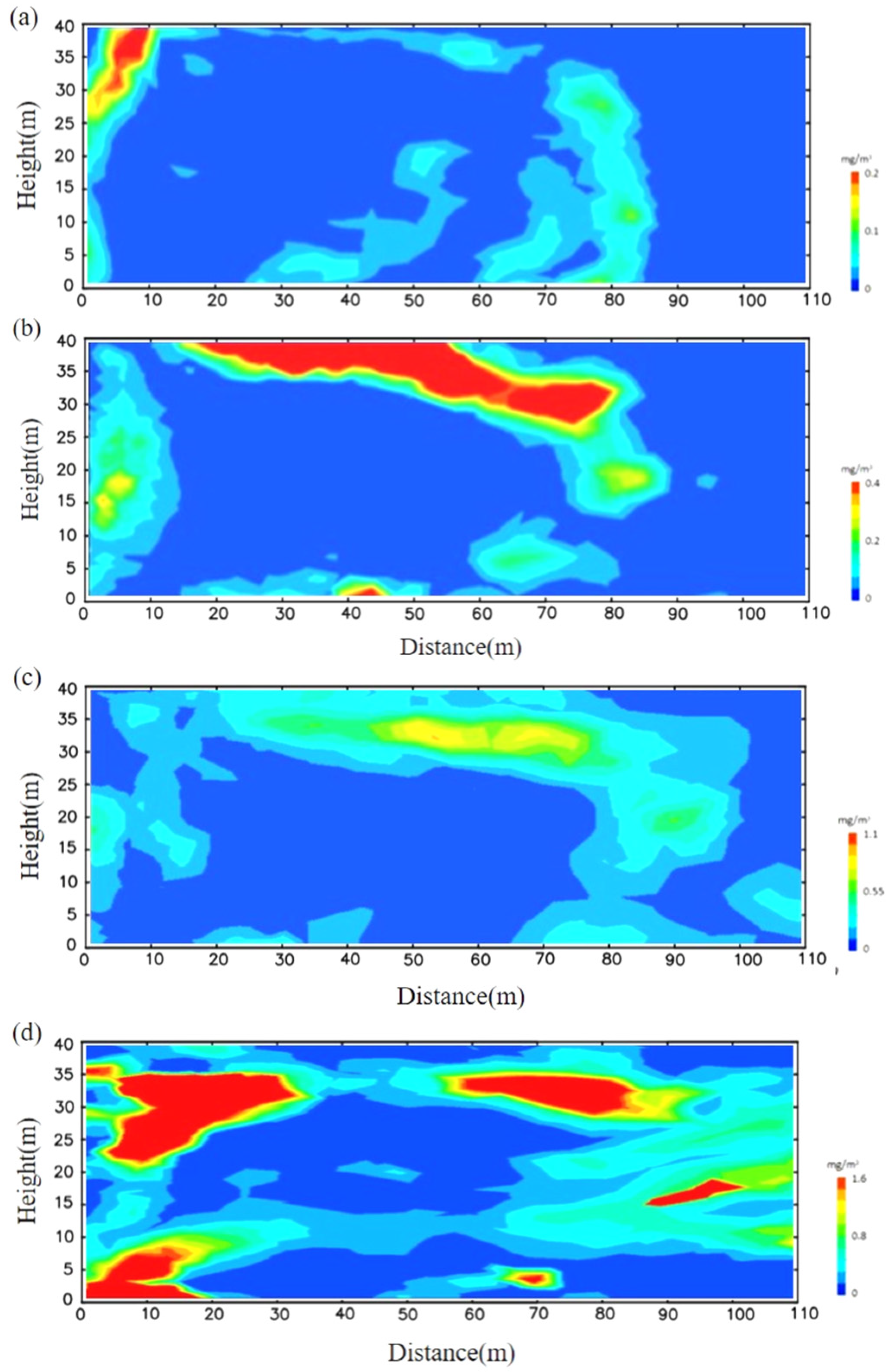

3.3.3. Simulated Diffusion Diagram of PM to Increase the Height of the Fan

4. Conclusions

- (1)

- Through correlation analysis, it was found that temperature was positively correlated with PM1 and PM2.5, and relative humidity and wind speed are negatively correlated with PM, which has a greater impact on PM10 and TSP. The correlation between PM10 and TSP was strong, and the correlation between PM1 and PM2.5 was strong. The concentration of PM in the atmosphere at nighttime was lower than daytime.

- (2)

- NMSE and relative error were used to calculate the accuracy of the model, and the relative error and NMSE values are within an acceptable range. The relative error value and the NMSE value outside the house are both larger than those in the house because the atmospheric environment outside the house was more complicated than that in the house, and the turbulence phenomenon was more obvious, which leads to an increase in the simulation error. The PM concentration value obtained by the simulation was basically consistent with the data value measured by the experiment. The concentration on the north side was slightly higher than that on the south side.

- (3)

- The larger the particle size, the longer the diffusion distance in the atmosphere, and the transmission height was dominated by the atmospheric turbulence and the direction of the measured PM emission plumes was dominated by the airflow rate and the orientation from the mechanical ventilation. The horizontal plume shape of PM10 in the nighttime was longer than daytime and when the wind direction was the same as the diffusion direction of the PM, the PM spread farther than other wind directions. Appropriately increasing the height of the release source helps to reduce the concentration of PM when it diffuses to the ground, because the PM is diluted as it descends, effectively improving the environmental quality around the livestock and poultry houses, and reducing the harm of PM to the health of residents.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, Y.M.; Wang, H. Development and Application of Information Technology in Dairy Farming. Agric. Technol. 2017, 37, 143. [Google Scholar]

- National Bureau of Statistics of People’s Republic of China. China Statistical Yearbook; National Bureau of Statistics of People’s Republic of China: Beijing, China, 2020. [Google Scholar]

- Nielsen, O.K.; Plejdrup, M.; Winther, M.; Mikkelsen, M.H.; Albrektsen, R.; Nielsen, M.; Fauser, P.; Hoffmann, L.; Hjelgaard, K.; Gyldenkærne, S. Projection of SO2, NOx, NH3 and Particle Emissions-2010–2030; Technical Report from DCE–Danish Centre for Environment and Energy: Aarhus, Denmark, 2012. [Google Scholar]

- Carey, J.B.; Lacey, R.E.; Mukhtar, S. A review of literature concerning odors, ammonia, and dust from broiler production facilities: 2. Flock and house management factors. Appl. Poult. Res. 2004, 13, 509–513. [Google Scholar] [CrossRef]

- Zhong, Z.B.; Wang, N. The Size Distrition and Health Risk Assessment of Microbe Bacterial Aerosol in Livestock and Poultry House. China Anim. Quar. 2014, 31, 101–105. [Google Scholar]

- Bakutis, B.; Monstviliene, E.; Januskeviciene, G. Analyses of airborne contamination with bacteria, endotoxins and dust in livestock barns and poultry houses. Acta Vet. Brun. 2004, 73, 283–289. [Google Scholar] [CrossRef][Green Version]

- Cai, L.; Koziel, J.A.; Lo, Y.C. Characterization of volatile organic compounds and odorants associated with swine barn particulate matter using solid-phase microextraction and gas chromatography-mass spectrometry-olfactometry. J. Chromatogr. A 2006, 1102, 60–72. [Google Scholar] [CrossRef]

- Guo, L.; Zhao, D.S.; Zhao, B.; Ma, S.L.; Liu, X.L.; Li, M.; Liu, X. Seasonal variations and spatial distribution of particulate matter emissions from a ventilated laying hen house in Northeast China. Int. J. Agric. Biol. Eng. 2020, 13, 57–63. [Google Scholar] [CrossRef]

- Redwine, J.S.; Lacey, R.E.; Mukhtar, S.; Carey, J. Concentration and emissions of ammonia and particulate matter in tunnel–ventilated broiler houses under summer conditions in Texas. Trans. ASAE 2002, 45, 1101–1109. [Google Scholar] [CrossRef]

- Huang, Q.; Chen, C.H.; Huang, J.G. Comparison of some stability classifications and the corresponding diffusion parameters. J. Lanzhou Univ. (Nat. Sci.) 1996, 32, 147–154. [Google Scholar]

- Yu, X.M.; Cao, L.; Yan, J.D. A simulation of atmospheric pollution based on multi-phase particle-in-cell method. Sci. Technol. Eng. 2020, 20, 5856–5863. [Google Scholar]

- Jiang, W.M.; Sun, J.N.; Cao, W.J. Course of Air Pollution Meteorology; China Meteological Press: Beijing, China, 2004. [Google Scholar]

- Guo, D.P.; Zhao, P.; Wang, R.; Yao, R.T.; Hu, J.M. Numerical simulations of the flow field and pollutant dispersion in an idealized urban area under different atmospheric stability conditions. Process Saf. Environ. Prot. 2020, 136, 310–323. [Google Scholar] [CrossRef]

- Wang, Y.W.; Zhai, X.F.; Qi, D.L.; Huang, L.; Chen, L. Simulation of the land-use change effect on urban local thermodynamic circulation. Sci. Technol. Eng. 2017, 17, 16–28. [Google Scholar]

- Jiang, X.M.; Zhang, Y.L.; Zhang, X.G.; Huang, L.; Li, F.H.; Wang, J.; Li, H.; Li, M. CFD-based studies on transitional ventilation of closed hen house with semi ladder coop. J. Huazhong Agric. Univ. 2017, 36, 113–120. [Google Scholar]

- Roache, P.J. Quantification of uncertainty in computational fluid dynamics. Annu. Rev. Fluid Mech. 1997, 29, 123–160. [Google Scholar] [CrossRef]

- Dai, P.Y.; Shen, D.; Tang, Q. Research progress on characteristics of particulate matter in livestock houses and its harmful effects on respiratory tract health of livestock and poultry. Sci. Agric. Sin. 2018, 51, 3214–3225. [Google Scholar]

- Seo, I.H.; Lee, I.B.; Moon, O.K. Modelling of internal environmental conditions in a full-scale commercial pig house containing animals. Biosyst. Eng. 2012, 111, 91–106. [Google Scholar] [CrossRef]

- Seo, I.H.; Lee, I.B.; Moon, O.K. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Lee, I.; Sase, S.; Sung, S. Evaluation of CFD accuracy for the ventilation study of a naturally ventilated broiler house. JARQ 2007, 41, 53–64. [Google Scholar] [CrossRef]

- Zhi, S. A new centrifugal correction drag force model for gas solid-particle two-phase flow. Powder Technol. 2016, 303, 124–129. [Google Scholar]

- Chung, J.N.; Troutt, T.R. Simulation of particle dispersion in an axisymmetric jet. J. Fluid Mech. 1988, 186, 199–222. [Google Scholar] [CrossRef]

- Sbrizzai, F.; Verzicco, R.; Pidria, M.F.; Soldati, A. Mechanisms for selective radial dispersion of microparticles in the transition region of a confined turbulent round jet. Int. J. Multiph. Flow 2004, 30, 1389–1417. [Google Scholar] [CrossRef]

- Peter, H. Understanding normalized mean squared error in power amplifier linearization. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 1047–1049. [Google Scholar]

- Saraz, J.A.O.; Velasque, H.J.C.; Bedoya, A.E. Thermal evaluation and validati-on of a computational model to unrefined sugar (panela) burner GP150. DYNA 2010, 77, 237–247. [Google Scholar]

- Du, X.Y.; Teng, G.H.; Du, X.D.; Liu, M.L.; Wang, C.Y. Comprehensive evaluation of environmental comfort in layer poultry house using radar graph. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2020, 36, 202–209. [Google Scholar]

- Bony, S.; Stevens, B.; Frierson, D.M.W. Clouds, circulation and climate sensitivity. Nat. Geosci. 2015, 8, 261–268. [Google Scholar] [CrossRef]

- Chen, W.; Dong, B. Anthropogenic impacts on recent decadal change in temperature extremes over China: Relative roles of greenhouse gases and anthropogenic aerosols. Clim. Dyn. 2018, 52, 3643–3660. [Google Scholar] [CrossRef]

- Guo, L.; Wang, C.; Ma, S.L.; Chen, D.H.; Tong, J.; Ren, L.L. Characterization and influencing factors analysis of indoor and outdoor particulate matter for caged laying hen house with mechanical ventilation. Trans. Chin. Soc. Agric. Mach. 2018, 49, 276–282. [Google Scholar]

- Ma, J.; Liu, Z.Y. CFD simulation and optimization of environmental parametersin closed hen house. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2020, 40, 1–9. [Google Scholar]

- Deng, S.H.; Shi, Z.X.; Li, B.M.; Zhao, S.M.; Ding, T.; Zheng, W.P. CFD simulation of airflow distribution in low profile cross ventilated dairy cattle barn. Trans. Chin. Soc. Agric. Eng. 2014, 30, 139–146. [Google Scholar]

- Flagan, R.C.; Seinfeld, J.H. Fundamentals of Air Pollution Engineering; Courier Corporation: North Chemsford, MA, USA, 2012. [Google Scholar]

- Lin, Z.; Hahm, T.S. Turbulence spreading and transport scaling in global gyrokinetic particle simulations. Phys. Plasmas 2004, 11, 1099–1108. [Google Scholar] [CrossRef]

- Yao, Q.; Yang, Z.J.; Li, H.; Buser, M.D.; Wanjura, J.D.; Downey, P.M.; Zhang, C.; Craige, C.; Torrents, A.; McConnell, L.L.; et al. Assessment of particulate matter and ammonia emission concentrations and respective plume profiles from a commercial poultry house. Environ. Pollut. 2018, 238, 10–16. [Google Scholar] [CrossRef]

- Roumeliotis, T.S.; Van Heyst, B.J. Summary of ammonia and particulate matter emission factors for poultry operations. J. Appl. Poult. Res. 2018, 17, 305–314. [Google Scholar] [CrossRef]

- Kim, J.J.; Baik, J.J. A numerical study of the effects of ambient wind direction on flow and dispersion in urban street canyons using the RNG k-ε turbulence model. Atmos. Environ. 2004, 38, 3039–3048. [Google Scholar] [CrossRef]

- Yook, S.J.; Ahn, K.H. Gaussian diffusion sphere model to predict transfer due to diffusional particle deposition on a flat surface in laminar flow regime. Appl. Phys. Lett. 2009, 94, 215. [Google Scholar] [CrossRef]

- Chen, P.Q. Oblique Gaussian Diffusion-Deposition Model and Effect of Gravitational Settlement on Ground Concentration. Environ. Sci. 1982, 1, 61–67. [Google Scholar]

- Sun, T.; Wang, G.B. Discussion on the design of exhaust venting chimney using Gaussian plume model. Chem. Eng. Des. 2018, 1, 12–15. [Google Scholar]

- Fuller, E.N.; Schettler, P.D.; Giddings, J.C. New method for prediction of binary gas-phase diffusion coefficients. Ind. Eng. Chem. 1966, 58, 18–27. [Google Scholar] [CrossRef]

| Boundary Condition | Boundary | Option | Numerical Value |

|---|---|---|---|

| Side window | Pressure inlet | Temperature | North: 25 °C |

| South: 31 °C | |||

| Pressure | Hydrostatic: 0 | ||

| Total pressure: 101.325 kpa | |||

| Fan | Fan | Temperature | 22 °C |

| Velocity | 3.48 m/s | ||

| Door | Velocity inlet | Temperature | 26 °C |

| Velocity | 3.6 m/s | ||

| North wet curtain | Velocity inlet | Temperature | 22 °C |

| Velocity | 1 m/s | ||

| South wet curtain | Velocity inlet | Temperature | 27 °C |

| Velocity | 1 m/s | ||

| Building envelope | Non-slip boundary | Temperature | Roof: 29 °C |

| Ground: 23 °C | |||

| East: 28 °C | |||

| West: 27 °C | |||

| South: 31 °C | |||

| North: 25 °C | |||

| Layer hen | Non-slip boundary | Temperature | 42 °C |

| Experiment Date | Temperature (°C) | Relative Humidity (%) | Wind Speed (m/s) | PM1 (mg/m3) | PM2.5 (mg/m3) | PM10 (mg/m3) | TSP (mg/m3) | |

|---|---|---|---|---|---|---|---|---|

| Daytime inside | 7.12 | 23.6 | 62.3 | 1.65 | 0.42 | 0.65 | 2.39 | 3.78 |

| 7.13 | 24.3 | 59.9 | 1.37 | 0.49 | 0.87 | 2.47 | 3.49 | |

| 7.14 | 23.1 | 65.4 | 1.42 | 0.36 | 0.54 | 1.88 | 2.93 | |

| 7.15 | 22.8 | 67.1 | 1.59 | 0.28 | 0.42 | 1.53 | 2.64 | |

| 7.16 | 24.4 | 65.9 | 1.35 | 0.39 | 0.48 | 1.04 | 2.48 | |

| 7.17 | 21.7 | 66.5 | 1.56 | 0.17 | 0.26 | 0.97 | 2.07 | |

| 7.18 | 23 | 64.4 | 1.52 | 0.31 | 0.33 | 0.73 | 1.85 | |

| 7.19 | 23.7 | 63.2 | 1.46 | 0.34 | 0.67 | 1.31 | 2.32 | |

| 7.20 | 24.4 | 60.8 | 1.71 | 0.43 | 0.62 | 2.01 | 3.62 | |

| 7.21 | 25.2 | 60.2 | 1.43 | 0.48 | 0.71 | 2.69 | 4.02 | |

| Daytime outside | 7.12 | 25.3 | 57.8 | 3.46 | 0.19 | 0.37 | 1.06 | 1.52 |

| 7.13 | 26.8 | 53.6 | 2.65 | 0.13 | 0.32 | 1.18 | 1.76 | |

| 7.14 | 25 | 56.1 | 2.89 | 0.27 | 0.41 | 0.94 | 1.58 | |

| 7.15 | 24.9 | 59.3 | 3.11 | 0.22 | 0.36 | 0.77 | 1.61 | |

| 7.16 | 26.8 | 57.2 | 3.27 | 0.23 | 0.39 | 0.82 | 1.69 | |

| 7.17 | 24.3 | 62.3 | 3.63 | 0.13 | 0.21 | 0.69 | 1.45 | |

| 7.18 | 25.4 | 60.7 | 2.48 | 0.15 | 0.32 | 0.51 | 1.37 | |

| 7.19 | 26.1 | 46.8 | 3.34 | 0.24 | 0.43 | 0.74 | 1.52 | |

| 7.20 | 26.5 | 52.9 | 2.66 | 0.16 | 0.35 | 1.01 | 1.86 | |

| 7.21 | 26.3 | 51.3 | 2.95 | 0.17 | 0.33 | 1.2 | 1.87 | |

| Nighttime outside | 7.12 | 21.3 | 73.7 | 1.32 | 0.11 | 0.21 | 0.62 | 1.03 |

| 7.13 | 22.8 | 64.3 | 1.56 | 0.08 | 0.11 | 0.54 | 0.98 | |

| 7.14 | 20.4 | 81.3 | 1.03 | 0.18 | 0.23 | 0.57 | 0.86 | |

| 7.15 | 20.9 | 74.1 | 0.82 | 0.09 | 0.16 | 0.42 | 0.81 | |

| 7.16 | 21.7 | 66.2 | 1.68 | 0.11 | 0.23 | 0.53 | 0.95 | |

| 7.17 | 20.6 | 73.9 | 1.53 | 0.09 | 0.13 | 0.39 | 0.82 | |

| 7.18 | 22.9 | 79 | 1.26 | 0.1 | 0.19 | 0.36 | 0.74 | |

| 7.19 | 23.1 | 53.6 | 1.15 | 0.13 | 0.26 | 0.41 | 0.89 | |

| 7.20 | 22.5 | 64.2 | 1.79 | 0.09 | 0.19 | 0.62 | 1.2 | |

| 7.21 | 22.2 | 69.4 | 0.72 | 0.12 | 0.18 | 0.68 | 1.3 |

| Temperature | Relative Humidity | Wind Speed | PM1 | PM2.5 | PM10 | TSP | |

|---|---|---|---|---|---|---|---|

| PM1 | 0.523 * | −0.378 * | −0.22 | 1 | |||

| PM2.5 | 0.564 * | −0.492 * | −0.29 | 0.91 ** | 1 | ||

| PM10 | 0.361 | −0.587 ** | −0.473 * | 0.68 * | 0.74 * | 1 | |

| TSP | 0.208 | −0.525 ** | −0.546 * | 0.53 * | 0.69 * | 0.83 ** | 1 |

| Temperature | Relative Humidity | Wind Speed | PM1 | PM2.5 | PM10 | TSP | |

|---|---|---|---|---|---|---|---|

| Relative error | 1.02~6.23% | 6.19~13.83% | 2.48~9.75% | 4.26~32.47% | 7.16~29.64% | 5.67~30.32% | 6.86~43.29% |

| NMSE | 0.015 | 0.034 | 0.027 | 0.032 | 0.029 | 0.048 | 0.073 |

| Temperature | Relative Humidity | Wind Speed | PM1 | PM2.5 | PM10 | TSP | |

|---|---|---|---|---|---|---|---|

| Relative error | 3.49~9.76% | 9.77~18.42% | 7.81~26.35% | 6.19~39.76% | 8.28~37.64% | 7.27~42.85% | 9.61~47.93% |

| NMSE | 0.018 | 0.039 | 0.043 | 0.052 | 0.036 | 0.057 | 0.083 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhou, L.; Jia, L.; Li, J.; Liu, B.; Yuan, Y. Numerical Simulation on Particulate Matter Emissions from a Layer House during Summer in Northeast China. Atmosphere 2022, 13, 435. https://doi.org/10.3390/atmos13030435

Zhang S, Zhou L, Jia L, Li J, Liu B, Yuan Y. Numerical Simulation on Particulate Matter Emissions from a Layer House during Summer in Northeast China. Atmosphere. 2022; 13(3):435. https://doi.org/10.3390/atmos13030435

Chicago/Turabian StyleZhang, Shuo, Lina Zhou, Lexin Jia, Jinsheng Li, Biying Liu, and Yueming Yuan. 2022. "Numerical Simulation on Particulate Matter Emissions from a Layer House during Summer in Northeast China" Atmosphere 13, no. 3: 435. https://doi.org/10.3390/atmos13030435

APA StyleZhang, S., Zhou, L., Jia, L., Li, J., Liu, B., & Yuan, Y. (2022). Numerical Simulation on Particulate Matter Emissions from a Layer House during Summer in Northeast China. Atmosphere, 13(3), 435. https://doi.org/10.3390/atmos13030435