Abstract

Due to the intensification and concentration of agriculture and the interpenetration of residential and agricultural areas, odours are an important air pollutant. The changes taking place in rural areas mean that not all inhabitants of these areas are involved in agricultural activities, and there are new people looking for an idyllic life in the countryside. In recent years, there has been an increase in the number of complaints concerning odour emissions from agricultural sources. The aim of the study was to compare odour emissions from selected livestock buildings for various animal species in the Great Poland Voivodeship. The assessment of odour concentrations was made in accordance with EN 13725: 2003 using the TO 8 olfactometer in the accredited olfactometric laboratory of the Institute of Technology and Life Sciences National Research Institute in Poznań. The fattening house showed the highest odour burden for the surroundings (mean odour concentration and odour emission factor: 450 ouE·m3 and 0.419 ouE·s−1·kg−1, respectively). In the case of buildings for poultry and dairy cows, the differences in the emission factors were not large. The emission factor for poultry (0.232 ouE·s−1·kg−1) was 22% higher than that for dairy cows (0.190 ouE·s−1·kg−1). Conversely, the mean concentration in the hen house (281 ouE·m3) was 18% lower than that in the dairy cow barn (342 ouE·m3).

Keywords:

odour concentration; odour emission factor; pigs; dairy cows; poultry; livestock buildings 1. Introduction

Air quality is receiving increasing attention. It has a direct impact on people’s health and the everyday comfort of their lives. Over the past two decades, many initiatives have been undertaken to improve air quality in the European Union (EU) and a specific EU policy has been pursued in this area. Despite these activities, the negative impact of human activities can still be observed, which poses threats to human health and the environment resulting from the emission of pollutants into the air [1,2].

The main air pollutants include ammonia (NH3), sulphur dioxide (SO2), nitrogen oxides (NOx), non-methane volatile organic compounds (NMVOC) and particulate matter, especially PM2.5. However, odour emissions are also an important form of air pollutant affecting air quality. The problems of odour nuisance are becoming increasingly common, especially in the era of developing economic activity, migration of people from cities to rural areas, and spatial expansion of cities, which results in settlements being closer to rural areas or industrial zones (factories and production buildings). An additional factor is the growing social awareness and the will to live in a clean and friendly natural environment [3,4,5,6]. Due to the intensification and concentration of agriculture and the interpenetration of residential and agricultural areas, odours are an important air pollutant, which are leading to an increase in the number of complaints concerning odour emissions from agricultural sources.

The perception of odours is an individual feature because the same smell can cause different reactions that depend on the kind of the odour source or the personal sensitivity. Therefore, defining unambiguous odour criteria is extremely difficult. There is no doubt that odours can have a negative impact on people’s health and well-being. It has been found that long-term exposure to odour can cause many ailments, such as: insomnia, stress, apathy, irritability, depression, migraines, cough, runny nose, chest cramps, stuffy nose and other respiratory ailments, or inflammatory and allergic reactions [7,8].

Odours are emitted from natural and anthropogenic sources. Most of these are related to human activities. Agriculture causes unpleasant odours at almost every stage of production. Their source is primarily the processes of fermentation and rotting of litter, decomposition of faeces, urine and feed residues, and, to a lesser extent, animal respiration and evaporation from their skin [9,10]. Taking into consideration the location, we can indicate three areas of odour emission: livestock buildings, natural fertiliser storage areas and arable fields after the application of natural fertilisers. Livestock buildings, as point or line emission sources, constitute the greatest nuisance to the environment. This is due to their constant high level of odour emissions and, often, their distance to residential buildings. The emission of odours from livestock buildings depends on the species of animals and the housing system, and on the construction and equipment of the building [11,12,13,14].

The aim of the study was to compare odour emissions from selected livestock buildings for various animal species in the Great Poland Voivodeship.

2. Materials and Methods

The research was carried out in three buildings where farm animals were kept. All studied objects were in the Greater Poland Voivodeship, in Poland. The measurements were made one day per each month for one year.

2.1. Studied Buildings

2.1.1. Breeding Hens

The measurements for poultry were conducted in a hen house in Siąszyce. It was a deep-litter/slatted-floor building, where breeding hens (ROSS 308 line) from 18 to 58 weeks of age were housed. The object, 110.4 m by 15.2 m, was settled by 11,800 hens (11,000 hens and 800 cocks). The ratio of the litter area (rye or wheat-rye straw) to the slatted-floor area was 2:1. The slatted floor with nests (automatic egg collection) was in the central part of the building along its axis. The droppings and manure were removed after the end of the production cycle. The animals were fed ad libitum, and the feeding and watering process was automated. The poultry house was heated by a 250 kW water boiler for solid fuels (coal dust or pea coal) and 6 heat exchangers (water–air) with a heating power of 45 kW each (Figure 1).

Figure 1.

The studied poultry house (authors photo).

2.1.2. Fattening Pigs

The research on odour concentrations and emissions for pigs was carried out in a deep-litter piggery for fattening pigs, in the village of Charcice (the building’s nominal stock was 480 pigs). There were 8 pens, each with an area of 45 m2 and designed for 60 fattening pigs. During the measurements, pigs differed in the age and the body mass, from weaners weighing 20 kg to fattening pigs with a final weight of 105 kg. The animals were fed ad libitum with dry fodder. The litter was made of wheat, rye or wheat-rye straw. The pens were bedded every three days, and the used bedding was removed from pens after the production cycle. The studied fattening house did not have a heating system (in Polish conditions, with full stocking, it is not required to maintain appropriate microclimatic conditions) (Figure 2).

Figure 2.

The studied piggery for fattening pigs (authors photo).

2.1.3. Dairy Cows

The odour measurements for cows were in a half-open barn in Libartów, where 240 dairy cows were kept. The average mass of the animals is about 650 kg. It was a frame building, and the side walls were half brick and half made of curtains. The corridors had a solid floor and cubicles were littered in most of the litter from maize straw. Bedding took place every 4 days, and the manure was removed daily using a front loader. The studied dairy barn was not heated (Figure 3).

Figure 3.

The studied barn for dairy cattle (authors photo).

2.2. Ventilation Rate

Due to the differences in ventilation systems in the studied buildings, air exchange was determined according to individual methodologies for each facility.

2.2.1. Breeding Hens

The studied poultry house was equipped with a negative pressure mechanical ventilation. The air was removed from the building by 4 roof fans (Big Dutchman FC080-6E), each with a nominal efficiency of 23,000 m3·h−1 and 4 wall fans (Big Dutchman Air Master EM 50), each with a nominal efficiency of 37,430 m3·h−1. The fresh air was provided by 70 wall inlets with regulation of flow rate. The microclimate controller (Big Dutchman Viper) (Table 1) managed the work of fans and the degree of opening of the air inlets, based on the temperature of the air inside the poultry house and according to user settings.

Table 1.

The user setting of fans (c—operating mode on/off; f—continuous operation; •—fan off).

The microclimate controller was not equipped with an output for recording devices. Therefore, the ventilation rate was determined based on temperature measurements, the user setting of fans and the characteristics of the used ventilation fans. During each 24 h measurement series, the air temperature inside the poultry house was measured every 5 min by a Testo 175 H2 logger. This was located close to the temperature sensor of the microclimate controller.

2.2.2. Fattening Pigs

The studied fattening house was equipped with a mechanical vacuum ventilation system. It was equipped with two fans with a diameter of d = 520 mm and nominal efficiency of 24,000 m3·h−1, with temperature regulation. The ventilation rate was determined based on the instantaneous percentage efficiency of the fans provided by the SK-1D2M microclimate controller (Wesstron, Poland) and the fan characteristics. The air temperature inside the piggery was measured using a Testo 175 H2 logger.

2.2.3. Dairy Cows

The dairy cow barn was naturally ventilated. Therefore, the ventilation rate was determined in accordance with the CIGR methodology [15]. This method is based on comparing the carbon dioxide (CO2) concentration inside and outside a building. To calculate the ventilation rate, it was necessary to measure the CO2 concentration inside and outside the building (INNOVA Multi Gas Monitor 1312 photo-acoustic spectrometer), the indoor and outdoor temperature, and the atmospheric pressure (Testo 435-4 multi-function measuring instrument). The outdoor CO2 concentration was measured at least 10 m from the windward side of the building, at the height of the air inlets in the side walls. The concentration of CO2 inside the facility was measured during each air sample collection, along the axis of the building at a height of at least 2/3 of the total height of the building above the side inlets. The ventilation rate (m3·h−1) was calculated from Equation (1):

where VR is ventilation rate (m3·h−1), n is number of cows, PCO2 is the amount of CO2 produced by cow (mg·h−1·cow−1), Cin is the concentration inside the building (mg·m−3), and Cout is the concentration outside the building (mg·m−3).

The amount of carbon dioxide produced by one cow was calculated based on the heat flux needed to maintain vital functions (ql), pregnancy (qp) and milk production (qm). These values were calculated from Equations (2)–(4):

where m is cow mass (kg), p is number of days after insemination (day) and y is milk yield (kg·day−1). The values p, m, y necessary to calculate heat fluxes were taken from databases of herd management systems. The total heat flux (qt), is the sum of the above-mentioned fluxes, Equation (5):

The value (qt) is related to the inside temperature equal to 20 °C, so the corrected heat flux (qcor) to the measured temperature was calculated from Equations (6) and (7):

where tin is inside temperature (°C) and CF is correction coefficient.

The amount of CO2 produced by cow (PCO2) was calculated from Equation (8) [16,17]:

2.2.4. Odour Concentration and Emission

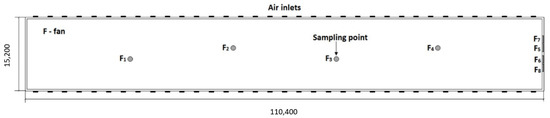

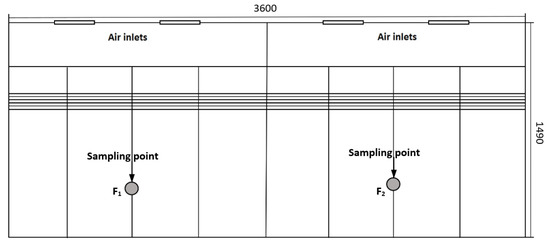

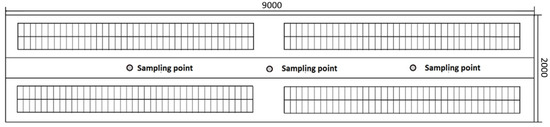

Air samples for olfactometric analysis were collected at the sampling points presented in Figure 4, Figure 5 and Figure 6. Two samples were taken at each point. In the poultry house, the air sample to determine the odour concentration was collected at one point. The building had no internal partitions, and it was tight and well ventilated; thus, it was assumed that the air in the entire volume of the building was a homogeneous mixture. The fattening house was divided into two chambers, where animals of different body mass could be kept during the fattening. The air samples were collected at two points, one in each chamber. In the dairy barn, it was decided to collect the air samples at 3 points, which resulted from the structure of the object. The solid gable walls limited air exchange in some parts of the building.

Figure 4.

Sampling points in the poultry house.

Figure 5.

Sampling points in the piggery.

Figure 6.

Sampling points in the dairy cow barn.

A CSD30 by ECOMA sampler and 8-litre disposable bags made of Nalophan (PET) material were used for sampling. This allowed minimising the diffusion of pollutants from the bags into the atmospheric air, thus limiting the change in the chemical composition of the sample from the moment of collection to testing. Odour concentration was determined within 24 h from the time of odour collection and was carried out in the accredited olfactometric laboratory of the Institute of Technology and Life Sciences National Research Institute in Poznań. The odour concentration was determined by dynamic olfactometry in accordance with EN 13725:2003 using the TO 8 olfactometer [18]. The odour concentration was determined by the same team of four experts, selected based on the individual odour threshold determination using n-butanol as an indicator gas. The yes/no method was used to assess the odour concentration. The momentary odour emission (Eod) was calculated according to Equation (9):

where VR is ventilation rate (m3·s−1) and cod is odour concentration (ouE·m−3).

The value of the odour concentration was the geometric mean of two samples. The calculated momentary odour emission was the gross value (the outside odour concentration was negligible). The determined concentrations and odour emission factors were statistically analysed in Statistica 12.

3. Results

3.1. Breeding Hens

Table 2 shows the average odour concentrations and odour emission factors from the poultry house for breeding hens for eggs.

Table 2.

Mean odour concentration and odour emission factor for breeding hens for eggs.

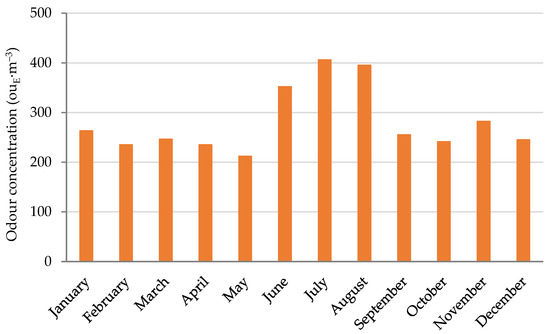

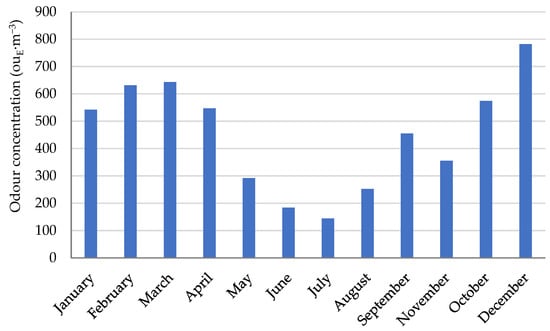

The mean value of the odour concentration during the study was 281 ouE·m−3 and it was characterised by low variability for olfactometric tests (coefficient of variation 22.5%). Analysing the changes of concentration during the year (Figure 7), a comparable level of odour concentration during the year was noted, excluding the summer months. The increased concentration of odours during this period was due to the high temperature in the building, which helps (promotes) the release of odours.

Figure 7.

Mean odour concentration for breeding hens for eggs.

In the literature, there are no studies on odour emissions from a poultry house for breeding hens for eggs, but results are available for other production groups. Lim et al. [19], conducting research in a battery cage house for laying hens in the spring, found an average odour concentration similar to the results of this study, amounting to 281 ouE·m−3. Concentration measurements in a deep pit house for laying hens and in a battery system with a ventilated manure belt were studied by Valli et al. [11], and they measured mean values of 233 and 143 ouE·m−3, respectively. Huang and Guo [20] also measured the odour concentration in the building for laying hens in a cage system and the recorded mean odour concentration was 583 ± 216 ouE·m−3.

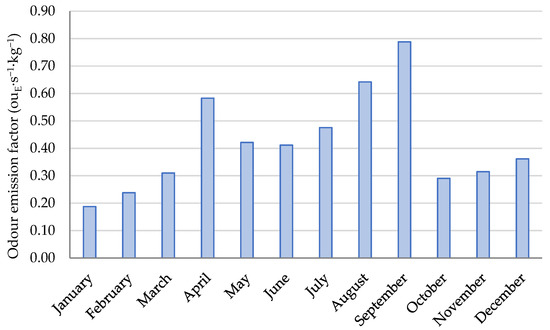

The mean odour emission factor from the house containing breeding hens for eggs in the studied period was 0.237 ouE·s−1·kg−1, and its variability was higher than in odour concentrations. The coefficient of variation was 39%. On the other hand, the nature of the changes during the year was similar to the changes in the odour concentration. Moreover, for the odour emission factors, higher values were observed in the summer period, which are the result of higher odour concentrations and higher air exchange. Outside of this period, the factors have similar values (Figure 8).

Figure 8.

Odour emission factors for breeding hens for eggs.

Studies in a battery cage hen house for laying hens, in the period from March to May, were conducted by Lim et al. [19]. They determined the mean odour emission factor to be equal to 0.06 ouE·s−1·kg−1. Hayes et al. [21] analysed the odour emissions from two hen houses. The first of these, a battery cage hen house, was studied in the spring and the mean odour emission factor was 0.26 ouE·s−1·kg−1. In the second, having a deep-litter/slatted floor, the mean odour emission factor was higher in the summer season, and was equal to 0.67 ouE·s−1·kg−1. Comparative studies in three poultry houses with different manure removal and storage systems—deep-litter pit, manure belt with natural drying and manure belt with forced drying—were conducted by Fournel et al. [22]. They obtained the following odour emission factors: 0.166, 0.096 and 0.105 ouE·s−1·kg−1, respectively. Summarising, the odour emission factor for breeding hens for eggs calculated in this study falls within the scope of the published research results.

3.2. Fattening Pigs

The values of odour concentrations observed in the fattening house and the determined odour emission factors are included in Table 3.

Table 3.

Mean odour concentration and odour emission factors for fattening pigs Adapted from [23] own study.

The mean odour concentration in the fattening house was 450 ouE·m−3 and was higher than for breeding hens. The range of changes in the observed concentrations was also higher, as evidenced by the value of the coefficient of variation equal to 43%. Odour concentrations in the summer season, when the ventilation rate was the highest, were much lower than in the periods when the air exchange was at a low level (Figure 9). In addition to large changes in the ventilation rate, resulting mainly from the lack of a heating system (this is a typical solution for Polish conditions), other factors influencing the odour concentration were the animal stock, which varied during the research period, and the quality of litter and frequency of bedding.

Figure 9.

Mean odour concentration for fattening pigs.

Many research teams have analysed the odour concentration in fattening houses. Guo et al. [24], conducting research in a non-litter, fully slatted-floor piggery for fattening pigs with a manure deep pit, recorded higher mean odour concentrations in the summer season, ranging from 397 to 655 ouE·m−3. By comparison, during one year of measurements made by Guo et al. [25] in the same building, the mean odour concentrations were higher and ranged from 1390 to 2025 ouE·m−3. Studies in the fall–winter and summer seasons in a fully slatted-floor fattening house were conducted by Sun et al. [26]. They obtained much higher results, and mean odour concentrations ranged from 728 to 3821 ouE·m−3 and from 404 to 570 ouE·m−3, respectively. A similar range of odour concentrations in a non-litter, slatter floor fattening house was obtained by Akdeniz et al. [13], of 1500 to 3500 ouE·m−3. Romain et al. [27] carried out research in a non-litter piggery for finishers during the autumn–winter season. The odour concentrations determined by them ranged from 50 to 1570 ouE·m−3. Research for both fully slatted-floor and deep-litter systems in laboratory conditions was undertaken by Wang et al. [12]. They obtained lower mean odour concentrations, ranging from 89.6 to 119.3 ouE·m−3 and from 60.5 to 73.6 ouE·m−3, respectively.

The determined mean odour emission factor was 0.419 ouE·s−1·kg−1, which is almost twice as high as the emission factor for breeding hens at a comparable level of variability (coefficient of variation 41%). This may be related to the area of odour release. In a fattening house, manure covers almost all of the area of the pens, whereas in a poultry house, most of the manure is under the slatted floor, which is a small part of the poultry house area. The highest values of the emission factor were observed in the summer, and the lowest in the winter, which resulted mainly from the ventilation rate (Figure 10). The odour emission factor ranged from 0.188 to 0.788 ouE·s−1·kg−1 and is within the published values. During daily studies in the summer season, in a fully slatted-floor fattening house, Guo et al. [24] obtained a mean odour emission factor equal to 0.18 ouE·s−1·kg−1. During autumn–winter and summer studies in the same fattening house, Sun et al. [26] obtained odour emission factors ranging from 0.08 to 0.49 ouE·s−1·kg−1. From fall measurements in a non-litter fattening house, Romain et al. [27] determined the odour emission factor to range from 0.03 to 0.31 ouE·s−1·kg−1. Research on deep litter was carried out in laboratory conditions by Wang et al. [12], comprising two, two-week measurements made in December and January. They obtained odour emission factors equal to 0.038 and 0.104 ouE·s−1·kg−1, respectively. These factors are much lower than the results of this work; however, they may result from differences between production and laboratory conditions. During the research, Wang et al. [12] bedded the pens each day, which is not practiced in industrial production. Additionally, the pen area per pig was 1.7 times bigger than that in industrial conditions.

Figure 10.

Odour emission factors for fattening pigs.

3.3. Dairy Cows

Table 4 presents odour concentrations and emission factors for dairy cows housed in a semi-open litter barn.

Table 4.

Mean odour concentration and odour emission factor for dairy cows.

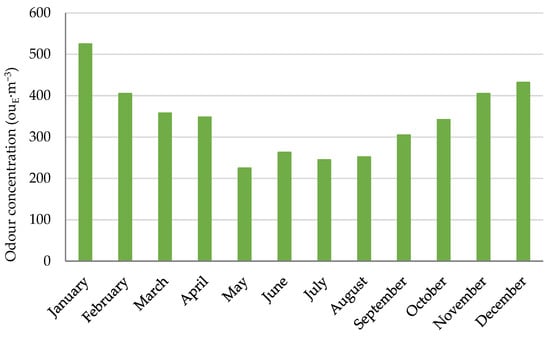

The mean odour concentration in the tested barn for dairy cows was 342 ouE·m−3 and was lower than for fattening pigs, but higher than for breeding hens. It was characterised by low variability, as evidenced by the coefficient of variation amounting to 25%. As in the case of the fattening house, the concentration of odours was lower in the summer and higher in the winter (Figure 11). This is due to a smaller stream of fresh air entering the building. In the period of low temperatures, air vents in the side walls of the building were covered with curtains.

Figure 11.

Mean odour concentration for dairy cows.

The measured odour concentrations were in the range of the published results. The lowest odour concentration was obtained by Zhao et al. [28]. Conducting research in a free-stall dairy cattle barn with a solid floor, they observed concentrations from 79 to 142 ouE·m−3 during the warm and hot season. Concentrations in a similar range (9–163 ouE·m−3) were determined by Valli et al. [11]. These are the mean values of three dairy cow barns: a tied barn, a free-stall barn with a slatted-floor, and a free-stall barn on deep-litter. Akdeniz et al. [13] obtained comparable values of odour concentration ranging from 170 to 300 ouE·m−3. The measurements were made in two free-stall barns for dairy cows. Higher odour concentrations were observed by Maasikmets et al. [29]. During measurements in two types of barns—a tied barn with a solid manure system and a free-stall barn with a liquid manure system—the mean odour concentrations were 642 and 1483 ouE·m−3, respectively. Keck et al. [30] measured the odour concentration in a free-stall barn for dairy cows with a solid floor and littered cubicles, and recorded a mean odour concentration of 870 ouE·m−3. This is the average result of multi-point measurements carried out just above the floor surface and at a height of 3 m from the three, communication, feed area, and cubicle areas.

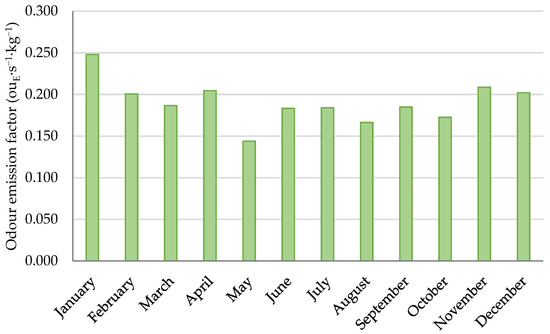

The mean odour emission factors were characterised by low variability during the research period. The coefficient of variation was 13%. In contrast to fattening pigs and breeding hens, lower odour emission factors were observed in the summer (Figure 12). However, the differences in the values of emission factors between the seasons were not as large as for poultry and pigs. The mean value of the odour emission factor for the whole year was 0.190 ouE·s−1·kg−1. This is comparable to the results published by Akdeniz et al. [13], who determined the odour emission factor based on studies conducted in two free-stall dairy barns, ranging from 0.024 to 0.128 ouE·s−1·kg−1. Much lower values were found by Maasikmets et al. [30], both in a tied barn with a solid manure system—0.004 ouE·s−1·kg−1—and in a free-stall barn with a liquid manure system—0.031 ouE·s−1·kg−1.

Figure 12.

Odour emission factors for dairy cows.

3.4. Comparison of Odour Concentrations and Emission Factors

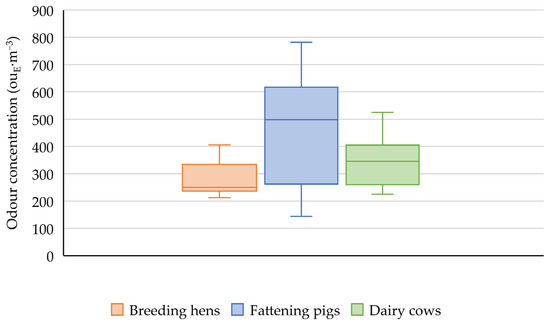

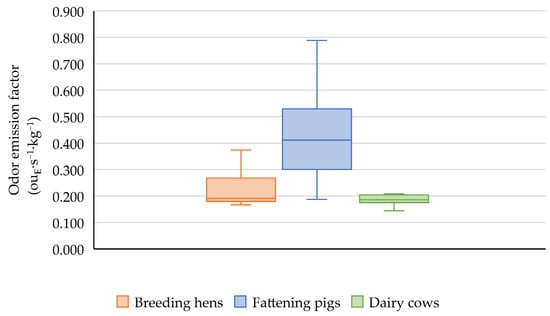

Figure 13 and Figure 14 present the collective results for the studied buildings regarding the odour concentration and odour emission factors. The line inside the box represents the median (Me), the top and bottom lines are the upper (Q3) and lower (Q1) quartiles, respectively, and the so-called whiskers are the minimum and maximum values.

Figure 13.

Odour concentration.

Figure 14.

Odour emission factor.

Statistical analysis showed significant differences in odour concentrations between studied buildings (α = 0.05). Comparing the values of odour concentrations in the tested objects, the highest concentrations of odours were observed in the fattening house (Me = 499 ouE·m−3), and the lowest in the breeding hen house (Me = 281 ouE·m−3). In the building for dairy cows, the odour concentration was between these values (Me = 342 ouE·m−3). Apart from the differences between the median and mean values, differences also occurred in the range of typical concentrations, expressed by the value of the quartile range (Q3 − Q1), which includes 50% of all observations. For poultry and dairy cows, typical odour concentration values changed in relatively narrow ranges of 233–334 ouE·m−3 and 255–405 ouE·m−3, respectively. For pigs, the range was 262–617 ouE·m−3. For all groups of animals, there were incidental odour concentrations that exceeded the median value.

Moreover, for the odour emission factor, the statistical analysis showed significant differences for all groups of animals (α = 0.05). As in the case for odour concentrations, the highest factor was for fattening pigs (Me = 0.412 ouE·s−1·kg−1), and 50% of observations ranged from 0.300 to 0.529 ouE·s−1·kg−1. The median of odour emission factors for dairy cows and poultry were similar and amounted to 186 and 191 ouE·s−1·kg−1, respectively. However, the range of changes for poultry (0.180 and 0.268 ouE·s−1·kg−1) was larger than for dairy cows (0.175 and 0.204 ouE·s−1·kg−1). For pigs and poultry, odour emission factors periodically exceeded twice the median value. Such large deviations did not occur for dairy cows.

4. Conclusions

Based on the results of this research, The following conclusions were formulated:

- Odor concentration in fattening house ranged from 144 ouE·m−3 to 782 ouE·m−3 (mean value 450 ouE·m−3), and odor emission factor was from 0.188 ouE·s−1·kg−1 to 0.788 ouE·s−1·kg−1 (mean value 0.419 ouE·s−1·kg−1). The values were the highest among studied facilities.

- Lower odor concentration (mean value 342 ouE·m−3) and emission factor (mean value 0.190 ouE·s−1·kg−1) were noted in free-stall barn. The range of odor concentration and emission factor was from 225 ouE·m−3 to 435 ouE·m−3 and from 0.144 ouE·s−1·kg−1 to 0.248 ouE·s−1·kg−1, respectively

- Mean odor concentration in the hen house (281 ouE·m−3) was 18% lower than in the dairy cow barn. It ranged from 212 ouE·m−3 to 406 ouE·m−3. The emission factor for poultry was from 0.167 ouE·s−1·kg−1 to 0.455 ouE·s−1·kg−1 (mean value 0.232 ouE·s−1·kg−1)

It can be concluded that both the odour concentrations and the odour emission factor differ for individual animal species, and they varied during the year. These are the values measured in three specific buildings and should not be generalized, because odour emission is a very complex process, which is influenced by many factors, including: building construction, type of ventilation system, type and dose of feed, manure removal system and storage facilities, topography, weather conditions and others. The result of this study may be helpful in planning, above all, suburban housing estates and selecting the location of new livestock buildings. Most people migrating from cities to rural areas identify the countryside with an idyllic land, not a place where agricultural production is carried out. This knowledge will allow to avoid many problems and conflicts arising at the meeting point of town and village in the future.

Author Contributions

Conceptualization, W.R. and P.M.-B.; methodology, W.R. and P.M.-B.; formal analysis, W.R. and P.M.-B.; investigation, W.R. and P.M.-B.; resources, W.R. and P.M.-B.; writing—original draft preparation, W.R. and P.M.-B.; writing—review and editing, W.R. and P.M.-B.; visualization, W.R. and P.M.-B.; supervision, W.R. and P.M.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Communication from the Commission to the Council and the European Parliament. Thematic Strategy on air pollution. Brussels, Belgium, 21 September 2005. [Google Scholar]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Clean Air Programme for Europe. Brussels, Belgium, 18 December 2013. [Google Scholar]

- Bibbiani, C.; Russo, C. Odour emission from intensive livestock production system: Approaches for emission abatement and evaluation of their effectiveness. Large Animal Rev. 2012, 18, 135–138. [Google Scholar]

- Peters, G.; Murphy, K.; Adamsen, A.P.S.; Bruun, S.; Svanström, M.; Hoeve, M.T. Improving odour assessment in LCA—the odour footprint. Int. J. Life Cycle Assess. 2014, 19, 1891–1900. [Google Scholar] [CrossRef]

- Strohmaier, C.; Krommweh, M.S.; Büscher, W. Suitability of Different Filling Materials for a Biofilter at a Broiler Fattening Facility in Terms of Ammonia and Odour Reduction. Atmosphere 2019, 11, 13. [Google Scholar] [CrossRef]

- Schauberger, G.; Piringer, M.; Wu, C.; Koziel, J.A. Environmental Odour. Atmosphere 2021, 12, 1293. [Google Scholar] [CrossRef]

- Palmiotto, M.; Fattore, E.; Paiano, V.; Celeste, G.; Colombo, A.; Davoli, E. Influence of a municipal solid waste landfill in the surrounding environment: Toxicological risk and odor nuisance effects. Environ. Int. 2014, 68, 16–24. [Google Scholar] [CrossRef]

- Blanes-Vidal, V. Air pollution from biodegradable wastes and non-specific health symptoms among residents: Direct or annoyance-mediated associations? Chemosphere 2015, 120, 371–377. [Google Scholar] [CrossRef]

- Ubeda, Y.; López-Jiménez, P.A.; Nicolas, J.; Calvet, S. Strategies to control odours in livestock facilities: A critical review. Span. J. Agric. Res. 2013, 11, 1004. [Google Scholar] [CrossRef]

- Dunlop, M.W.; Blackall, P.J.; Stuetz, R. Odour emissions from poultry litter—A review litter properties, odour formation and odorant emissions from porous materials. J. Environ. Manag. 2016, 177, 306–319. [Google Scholar] [CrossRef] [PubMed]

- Valli, L.; Moscatelli, G.; Labartino, N. Odour emissions from livestock production facilities. Chem. Eng. Trans. 2008, 15, 239–246. [Google Scholar]

- Wang, K.; Wei, B.; Zhu, S.; Ye, Z. Ammonia and odour emitted from deep litter and fully slatted floor systems for growing-finishing pigs. Biosyst. Eng. 2011, 109, 203–210. [Google Scholar] [CrossRef]

- Akdeniz, N.; Jacobson, L.D.; Hetchler, B.P.; Bereznicki, S.D.; Heber, A.J.; Koziel, J.A.; Cai, L.; Zhang, S.; Parker, D.B. Odor and Odorous Chemical Emissions from Animal Buildings: Part 2. Odor Emissions. Trans. ASABE 2012, 55, 2335–2345. [Google Scholar] [CrossRef]

- Mielcarek, P.; Rzeźnik, W. Odor Emission Factors from Livestock Production. Pol. J. Environ. Stud. 2015, 24, 27–35. [Google Scholar] [CrossRef]

- CIGR. 4th Report of working group on climatisation of animalhouses: Heat and moisture production at animal and house levels. Commission Internationale du Génie Rural: Horsens, Denmark, 2002. [Google Scholar]

- Albright, L.D. Environment control for animals and Plants, 1st ed.; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1990. [Google Scholar]

- Lindley, J.A.; Whitaker, J.H. Agricultural buildings and structures. Rev. 96; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1996. [Google Scholar]

- European Committee for Standardization CEN. Air Quality—Determination of Odour Concentration by Dynamic Olfactometry; EN 13725:2003; CEN: Brussels, Belgium, 2003. [Google Scholar]

- Lim, T.T.; Heber, A.J.; Ni, J.Q. Air quality measurements at a laying hen house: Odor and hydrogen sulfide emissions. In Proceedings of the International Symposium on Control of Gaseous and Odor Emissions from Animal Production Facilities, Horsens, Denmark, 1–4 June 2003; Danish Institute of Agricultural Sciences: Foulum, Denmark, 2003; pp. 273–282. [Google Scholar]

- Huang, D.; Guo, H. Relationships between odor properties and determination of odor concentration limits in odor impact criteria for poultry and dairy barns. Sci. Total Environ. 2018, 630, 1484–1491. [Google Scholar] [CrossRef] [PubMed]

- Hayes, E.; Curran, T.; Dodd, V. Odour and ammonia emissions from intensive poultry units in Ireland. Bioresour. Technol. 2006, 97, 933–939. [Google Scholar] [CrossRef] [PubMed]

- Fournel, S.; Pelletier, F.; Godbout, S.; Lagacé, R.; Feddes, J. Odour emissions, hedonic tones and ammonia emissions from three cage layer housing systems. Biosyst. Eng. 2012, 112, 181–191. [Google Scholar] [CrossRef]

- Rzeźnik, W.; Mielcarek, P.; Rzeźnik, I. Odour emission from deep litter farming system for fattening pigs. Probl. Agri-Cult. Eng. 2014, 1, 91–99. (In Polish) [Google Scholar]

- Guo, H.; Dehod, W.; Agnew, J.; Feddes, J.R.; Lague, C.; Pang, S. Daytime Odor Emission Variations from Various Swine Barns. Trans. ASABE 2007, 50, 1365–1372. [Google Scholar] [CrossRef]

- Guo, H.; Dehod, W.; Agnew, J.; Lague, C.; Feddes, J.R.; Pang, S. Annual odor emission rate from different types of swine production buildings. Trans. ASABE 2006, 49, 517–525. [Google Scholar] [CrossRef][Green Version]

- Sun, G.; Guo, H.; Peterson, J. Seasonal Odor, Ammonia, Hydrogen Sulfide, and Carbon Dioxide Concentrations and Emissions from Swine Grower-Finisher Rooms. J. Air Waste Manag. Assoc. 2010, 60, 471–480. [Google Scholar] [CrossRef]

- Romain, A.-C.; Nicolas, J.; Cobut, P.; Delva, J.; Nicks, B.; Philippe, F.-X. Continuous odour measurement from fattening pig units. Atmos. Environ. 2013, 77, 935–942. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Brugger, M.F.; Manuzon, R.B.; Arnold, G.; Imerman, E. Variations in Air Quality of New Ohio Dairy Facilities with Natural Ventilation Systems. Appl. Eng. Agric. 2007, 23, 339–346. [Google Scholar] [CrossRef]

- Maasikmets, M.; Teinemaa, E.; Kaasik, A.; Kimmel, V. Measurement and analysis of ammonia, hydrogen sulphide and odour emissions from the cattle farming in Estonia. Biosyst. Eng. 2015, 139, 48–59. [Google Scholar] [CrossRef]

- Keck, M.; Schmidlin, A.; Zeyer, K.; Emmenegger, L.; Schrade, S. Odour concentration and emission from naturally ventilated dairy loose housings with an outdoor exercise area. Chem. Eng. Trans. 2010, 23, 195–200. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).