Marine Air Pollution in Israel: Extent, Proposed Mitigation Targets, Benefits and Feasibility

Abstract

:1. Introduction

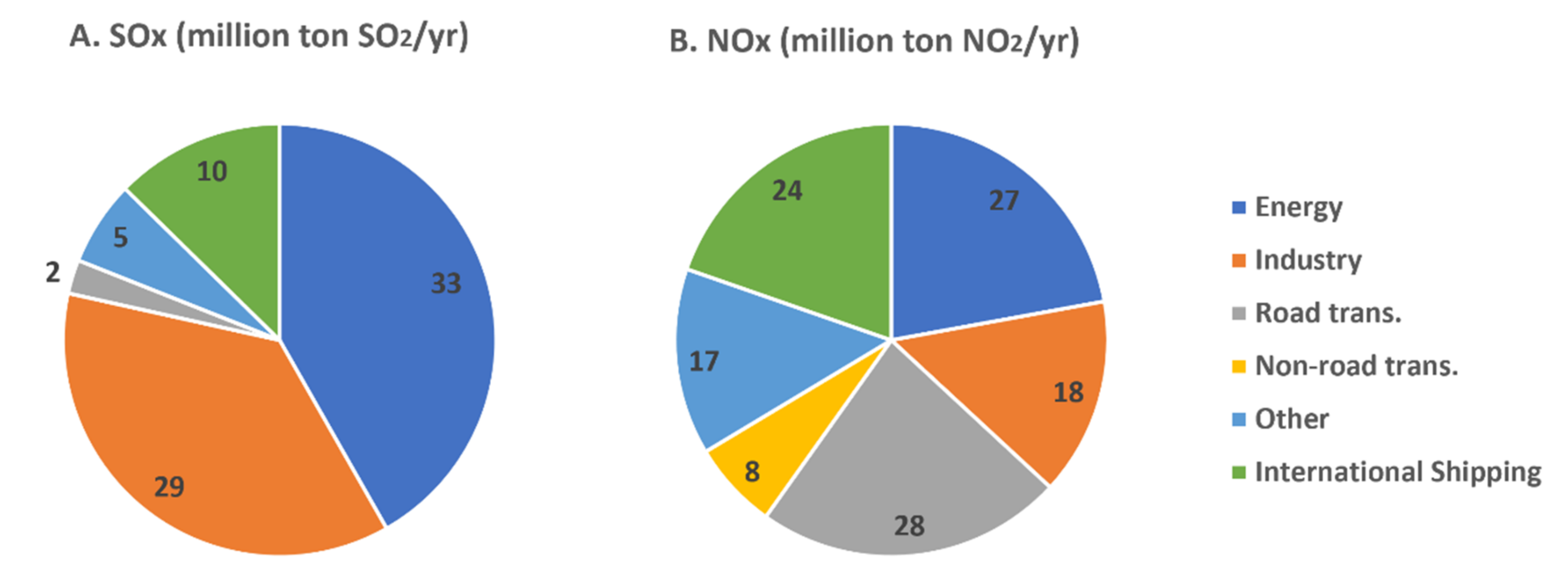

1.1. Global Marine Air Pollution

1.2. Marine Air Pollution in Israel

1.3. Are Marine Emissios in Isreal Higher Than Previously Esimated, and What Can Be Done to Combat the Problem?

2. Materials and Methods

2.1. Calculation of 2018 Marine Emissions in the Haifa and Ashdod Ports

2.1.1. Calculation of NOx, SOx, PM2.5, CO and VOCs Emissions

2.1.2. Calculation of Average Nickel Concentration in Total Suspended Particulate (TSP) Monitored by Air Quality Monitoring Stations

2.1.3. Calculation of Different Marine Activities Share in NOx Emissions

2.1.4. Calculation of Visiting Ships Manufacturing Year-Range Distribution, for the Haifa and Ashdod Ports

2.2. Marine Emission Mitigation

2.2.1. Marine Emission Feasibility Assessment of Mitigation Techniques

2.2.2. Calculation of Future Emission Scenarios for 2030

- (a)

- Reviewing various mitigation techniques that can be applied on ships to reduce NOx, SOx, PM2.5, CO and VOCs emissions. This was carried out while considering that some new ships manufactured since 2016 have to meet more strict emission standards [23,75], and yet as suggested in this paper, their portion in fleets is expected to be limited even by year 2030. So, the MPS focused on techniques that can be used on existing ships (up to Tier II). Additionally, other non-technological “soft” management methods were considered. For example: port congestion management, control on ship speeds, imposing green levies related to specific emissions and other types of management and operational aspects that can affect air pollution performance around ports areas.

- (b)

- Determining the feasibility of each technique, based on if the technique has been well proven as a technically feasible method (used in ships) while considering its emission reduction effectiveness and cost-efficiency.

- (c)

- Calculating emission scenario after implementation of a mitigation plan, based on creating different sub-emission reduction scenarios which rely on varying portions of incorporation of the different available mitigation techniques. The MPS assumes that one holistic policy framework is implemented to require and/or incentivize the techniques incorporation, while considering that there are different ways (combinations of techniques) that can lead to a general mitigation outcome (‘mitigation scenario’). The outcome of the mitigation scenario assumed the following key elements: (1) All ships at each port would comply with MARPOL VI concerning use of fuel with sulfur content of up to 0.5%; (2) A total of 70% of the current most polluting ships at each port would install NOx reduction technologies, would use LNG (liquefied natural gas) as alternative fuel, or would convert hoteling engines to electric auxiliary engines powered by ESP (electric shore power); (3) The other 30% of these ships would allow stand-by for porting at distance of at least 5 km from each port/ shore; see Appendix D.

2.3. Calculation of Emissions’ Environmental-Health Damage Cost and the Potential Benefits of MPS

3. Results and Discussion

3.1. Marine Vessels Air Pollution Emissions in and Adjacent to the Haifa and Ashdod Ports for 2018

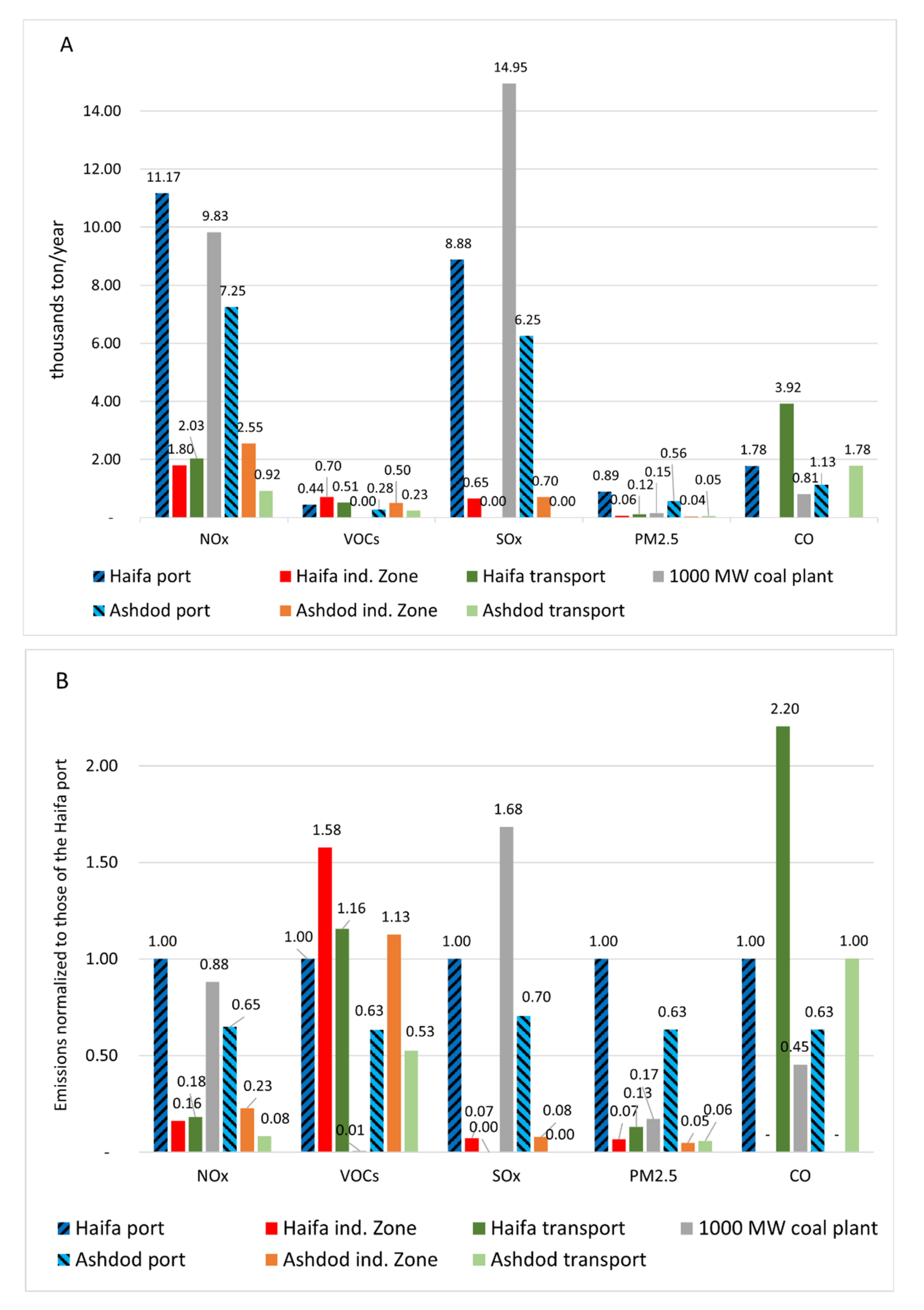

3.1.1. Total NOx, SOx, PM2.5, C, and VOCs Emissions from Marine Activity

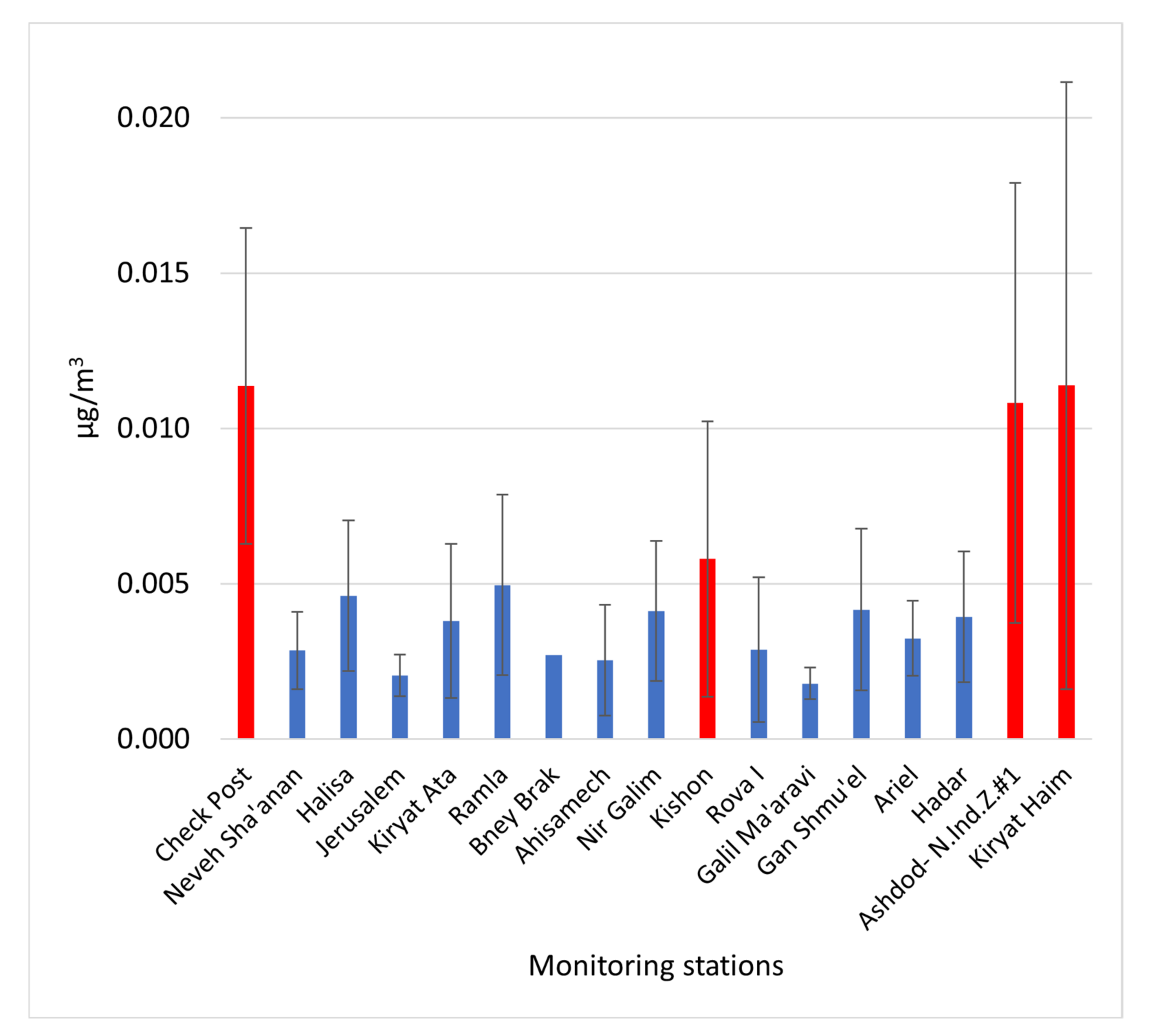

3.1.2. Relatively High Nickel Concentration in TSP (Total Suspended Particulate) was Measured Only Relatively Close to the Haifa and Ashdod Ports

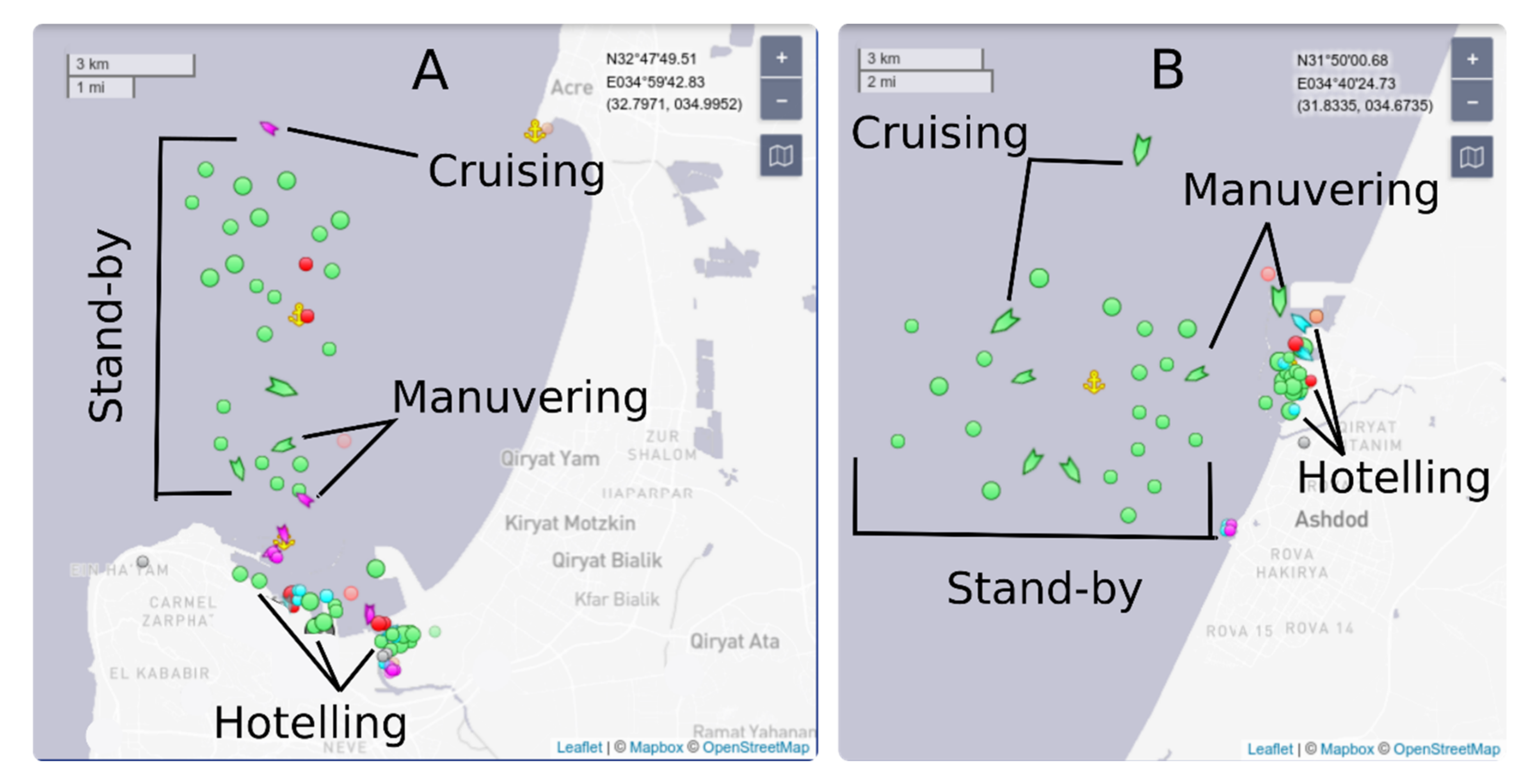

3.1.3. Share of Different Marine Activities in NOx Emissions

3.1.4. Distribution of Visiting Ships Manufacturing Year, for the Haifa and Ashdod Ports

3.2. Marine Emission Mitigation in Israel

3.2.1. Emission Mitigation Techniques and Their Feasibility in Israel

3.2.2. Emission Mitigation Scenario for 2030

3.3. Haifa and Ashdod Ports Air Polution Damage Cost and Mitigation Benefits

3.4. Israeli Marine Emission Mitigation Feasibility

4. Conclusions

- Compared to the industrial and land transportation sectors in these cities, the marine sectors in Haifa and Ashdod emit 3–12 times more NOx, 10 times more SOx than the industrial zones (the land transportation sectors do not emit any SOx) and 4–20 times more PM2.5.

- Relatively high average concentrations of nickel (a signature air pollutant for marine air emissions) as a fraction of TSP were found in Israel only around the Haifa and Ashdod ports, which indicates that the marine air pollution reaches the shore and therefore poses a risk to the surrounding populations.

- Air quality monitoring stations in, near and around the Haifa and Ashdod ports should be installed to properly understand the impact of marine air pollution in these cities.

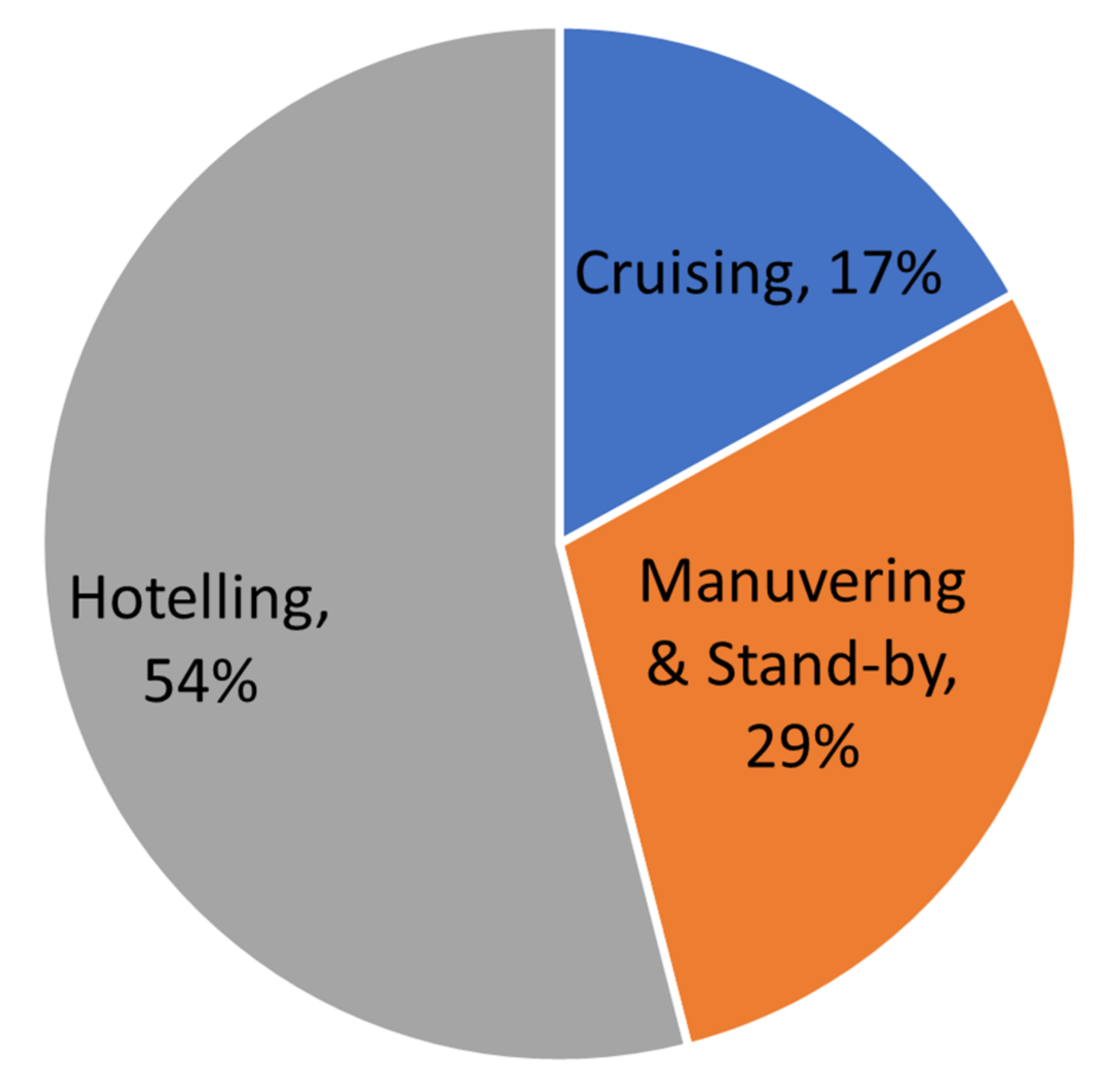

- Of the total marine NOx emissions, 54% are emitted during the ships’ hoteling, while 29% and 17% are attributed to the maneuvering and stand-by and cruising navigation phases, respectively. The share of the maneuvering and stand-by phase is unusually high, due to the long average stand-by duration in these ports.

- Due to the slow replacement of international fleets, reduction in marine NOx emissions is improbable in the next decade.

- The most feasible marine emission mitigation techniques for Israel are distancing stand-by location (all emissions), SCR (selective catalytic reduction: NOx), EGR (exhaust gas recirculation: NOx), EGCS (exhaust gas cleaning systems: SOx and PM2.5), ULSD (low or ultra-lowc sulfur diesel: SOx and PM2.5) and ESP (electric shore power- all emissions).

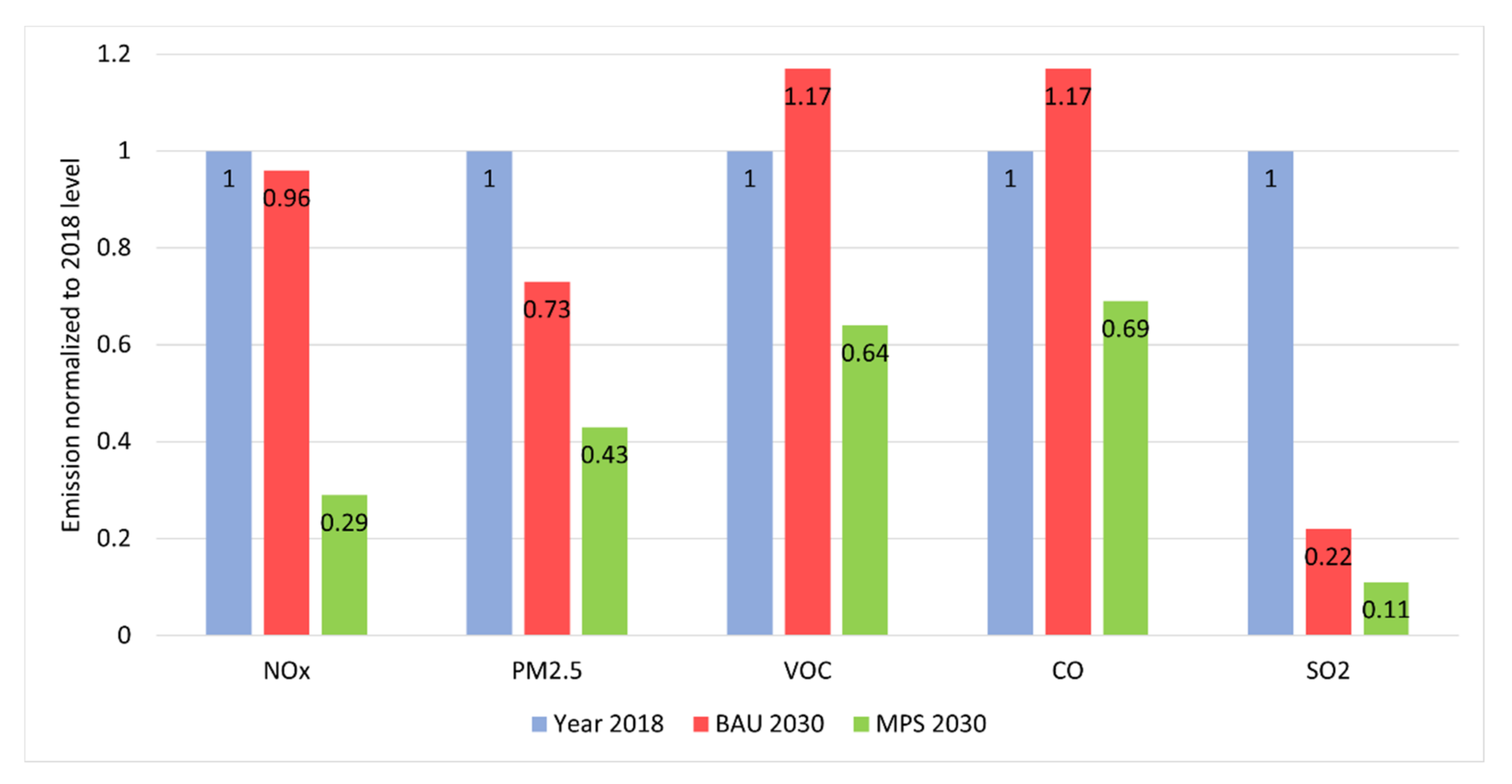

- In the BAU 2030 (business as usual) scenario, NOx emissions will hardly change, PM2.5 will drop by 27%, VOCs and CO will rise by 17% and SOx will drop by 78% (if the MARPOL VI will be fully implemented). However, in the MPS 2030 (Mitigation Plan Scenario), NOx will drop by 71%, PM2.5 will drop by 57%, VOCs will drop by 36%, CO will drop by 31% and SOx will drop by 89%.

- The most important and beneficial policy step to mitigate the marine emissions is first to have a strong and effective local enforcement of MARPOL VI regulation for reducing SOx and PM emissions.

- Since it was found that current NOx emissions are the highest of all emissions examined and are unlikely to significantly decrease in the next decade, decision makers in Israel should consider establishing a local mitigation plan focused on NOx. This plan can achieve significant reduction for other air pollutants, including NMVOCs and CO as well as further reduction of SOx, PM2.5 and other pollutants

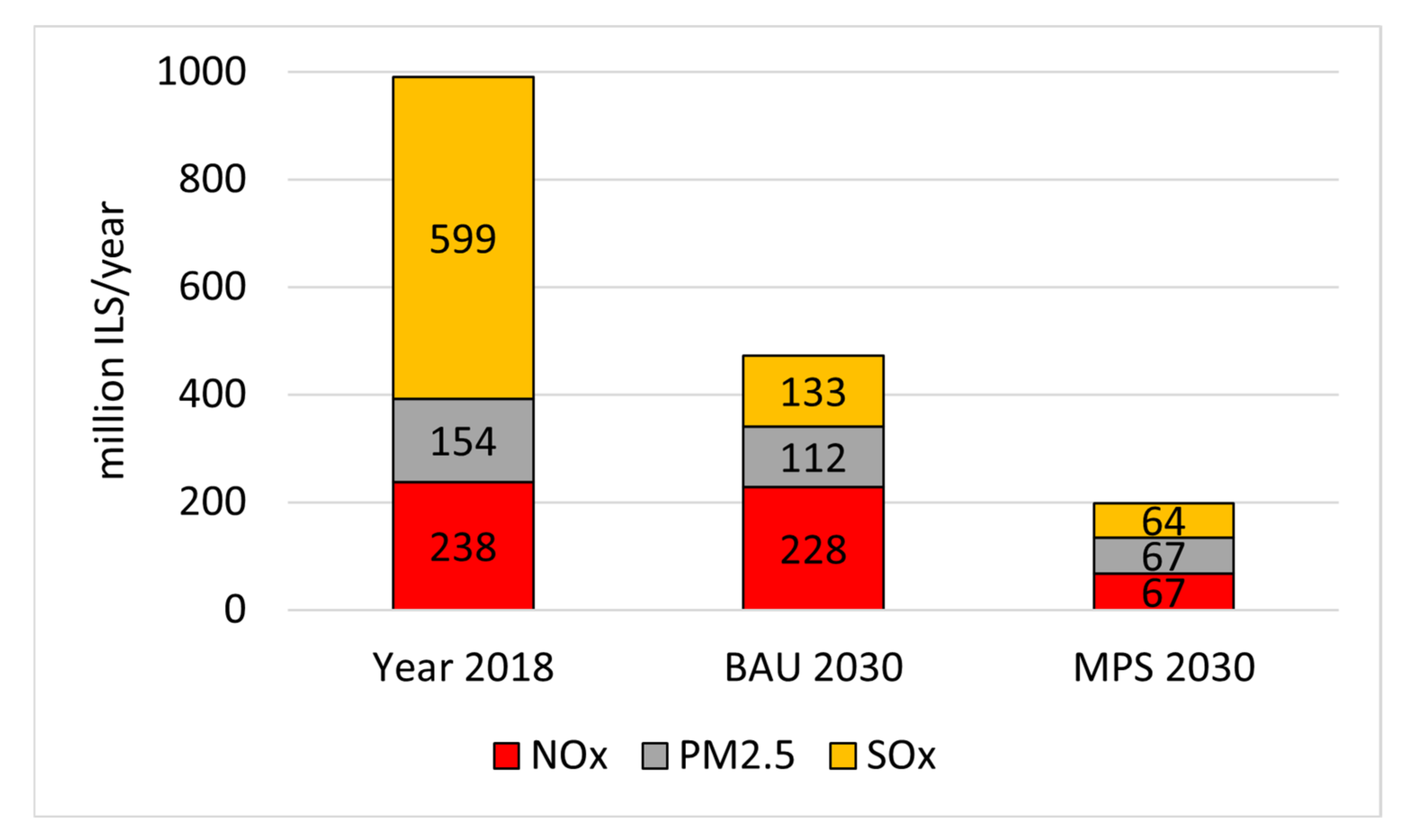

- A preliminary calculation shows that the marine sectors in Haifa and Ashdod externalities are at least ILS 991 million (EUR 253 million) per year. The BAU 2030 scenario can lower them by ILS 518 million (EUR 132 million) and the MPS 2030 scenario can lower them by ILS 793 million (EUR 202 million) per year.

- Israeli marine emissions mitigation is feasible from technological and regulatory aspects.

- As of today, and increasingly more going forward, most of the large marine vessels are subjected to stricter NOx and SOx regulation at least in one of the ports in their route (North America, Europe, China); it is suggested that regulation will make it more feasible for countries to restrict their emissions, including small countries, such as Israel.

- It is highlighted that although implementation of a local emission mitigation plan, as suggested in this paper, is a feasible step with probably more benefits than costs, it is also associated with significant economic and regulatory challenges. As most of all imports to Israel takes place by marine shipping [108], policy makers in Israel should consider the potential economic risks of imposing new costly environmental standards. The latter should be especially considered in light of the recent trend in price increase of various goods in Israel and elsewhere [106,107], which is to some extent attributed to the increase in marine shipping costs. However, since most of the global marine traffic is already (or will be in a few years) under SOx and NOx emissions restriction (North America, Europe, China), many ships have invested or are investing in complying with emissions restrictions.

- It is recommended to examine the expected costs and other strategic implications of an ambitious marine emissions reduction plan, including legal and financial ways for promoting it. It is also recommended to examine other potential public benefits of such plan, for example, opportunities for real estate development and increase of the land value around areas currently affected by marine air pollution in Haifa and Ashdod. The overall benefits of such a plan will probably outweigh its costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Marine Emission Sources in 2018

| Source | Engine | Phase | Engine Type | Fuel Type |

|---|---|---|---|---|

| Vessels: Cruise, Passenger shuttle, Panamax, Oil tanker, Bunker, General cargo ship, Tugboat, I.N.S, ect. | main | cruise | gas turbine | BFO |

| MDO/MGO | ||||

| high-speed diesel | BFO | |||

| MDO/MGO | ||||

| medium-speed diesel | BFO | |||

| MDO/MGO | ||||

| slow-speed diesel | BFO | |||

| MDO/MGO | ||||

| steam turbine | BFO | |||

| MDO/MGO | ||||

| manoeuvring/hoteling | gas turbine | BFO | ||

| MDO/MGO | ||||

| high-speed diesel | BFO | |||

| MDO/MGO | ||||

| medium-speed diesel | BFO | |||

| MDO/MGO | ||||

| slow-speed diesel | BFO | |||

| MDO/MGO | ||||

| steam turbine | BFO | |||

| MDO/MGO | ||||

| auxiliary | cruise/manoeuvring/hoteling | high-speed diesel | BFO | |

| MDO/MGO | ||||

| medium-speed diesel | BFO | |||

| MDO/MGO | ||||

| Trucks | main | travel | 4-stroke gasoline | gasoline |

| diesel | diesel | |||

| waiting | 4-stroke gasoline | gasoline | ||

| diesel | diesel | |||

| Locomotives | main | travel | diesel | diesel |

| waiting | ||||

| Cranes | main | travel | diesel | diesel |

| loading | ||||

| Forklifts | main | travel | 4-stroke gasoline | gasoline |

| diesel | diesel | |||

| loading | 4-stroke gasoline | gasoline | ||

| diesel | diesel | |||

| Bulldozers | main | travel | diesel | diesel |

| loading |

Appendix B. Emission Factors

- Evessel = overall emission from a vessel (g)

- LF = engine load factor (%)

- P = engine nominal power (kW)

- T = time (hour)

- ec = engine category (main/auxiliary)

- i = pollutant (NOx/CO/VOC/PM2.5/SOx)

- f = fuel type (BFO/MDO/MGO)

- e = engine type (slow-/medium-/high- speed diesel or gas turbine)

- p = phase of the navigation (cruise, maneuvering, hoteling)

| Engine | Phase | Engine Type | Fuel Type | NOx EF (g/kWh) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Entec 2000 | Entec 2005 | Entec 2010 | EPA Standard TIER I | EPA Standard TIER II | EPA Standard TIER III | EPA Standard TIER IV | ||||

| Main | cruise | gas turbine | BFO | 6.1 | 5.9 | 5.7 | 1.8 | |||

| MDO/MGO | 5.7 | 5.5 | 5.3 | |||||||

| high-speed diesel | BFO | 12.7 | 12.3 | 11.8 | ||||||

| MDO/MGO | 12 | 11.6 | 11.2 | |||||||

| medium-speed diesel | BFO | 14 | 13.5 | 13 | ||||||

| MDO/MGO | 13.2 | 12.8 | 12.3 | |||||||

| slow-speed diesel | BFO | 18.1 | 17.5 | 16.9 | ||||||

| MDO/MGO | 17 | 16.4 | 15.8 | |||||||

| steam turbine | BFO | 2.1 | 2 | 2 | ||||||

| MDO/MGO | 2 | 1.9 | 1.9 | |||||||

| manoeuvring/hoteling | gas turbine | BFO | 3.1 | 3 | 2.9 | |||||

| MDO/MGO | 2.9 | 2.8 | 2.7 | |||||||

| high-speed diesel | BFO | 10.2 | 9.9 | 9.5 | ||||||

| MDO/MGO | 9.6 | 9.3 | 8.9 | |||||||

| medium-speed diesel | BFO | 11.2 | 10.8 | 10.4 | ||||||

| MDO/MGO | 10.6 | 10.2 | 9.9 | |||||||

| slow-speed diesel | BFO | 14.5 | 14 | 13.5 | ||||||

| MDO/MGO | 13.6 | 13.1 | 12.7 | |||||||

| steam turbine | BFO | 1.7 | 1.6 | 1.6 | ||||||

| MDO/MGO | 1.6 | 1.6 | 1.5 | |||||||

| Auxiliary | cruise/manoeuvring/hoteling | high-speed diesel | BFO | 11.6 | 11.2 | 10.8 | ||||

| MDO/MGO | 10.9 | 10.5 | 10.2 | |||||||

| medium-speed diesel | BFO | 14.7 | 14.2 | 13.7 | ||||||

| MDO/MGO | 13.9 | 13.5 | 13 | |||||||

| Engine | Phase | Engine Type | Fuel Type | VOC EF (g/kWh) | PM2.5 EF (g/kWh) | CO EF (g/kWh) | SOx EF (g/kWh) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Entec 2000–2010 | EU Emission Directive | Entec 2000–2010 | EPA Standard | Lloyd’s Register | EPA Standard | Lloyd’s Register | ||||

| Main | cruise | gas turbine | BFO | 0.1 | 0.1 | 0.1–0.8 | 1.6 | 5 | ||

| MDO/MGO | 0.1 | 0 | ||||||||

| high-speed diesel | BFO | 0.2 | 0.8 | |||||||

| MDO/MGO | 0.2 | 0.3 | ||||||||

| medium-speed diesel | BFO | 0.5 | 0.8 | |||||||

| MDO/MGO | 0.5 | 0.3 | ||||||||

| slow-speed diesel | BFO | 0.6 | 1.7 | |||||||

| MDO/MGO | 0.6 | 0.3 | ||||||||

| steam turbine | BFO | 0.1 | 0.8 | |||||||

| MDO/MGO | 0.1 | 0.3 | ||||||||

| manoeuvring/ hoteling | gas turbine | BFO | 0.5 | 1.5 | ||||||

| MDO/MGO | 0.5 | 0.5 | ||||||||

| high-speed diesel | BFO | 0.6 | 2.4 | |||||||

| MDO/MGO | 0.6 | 0.9 | ||||||||

| medium-speed diesel | BFO | 1.5 | 2.4 | |||||||

| MDO/MGO | 1.5 | 0.9 | ||||||||

| slow-speed diesel | BFO | 1.8 | 2.4 | |||||||

| MDO/MGO | 1.8 | 0.9 | ||||||||

| steam turbine | BFO | 0.3 | 2.4 | |||||||

| MDO/MGO | 0.3 | 0.9 | ||||||||

| Auxiliary | cruise/manoeuvring/hoteling | high-speed diesel | BFO | 0.4 | 0.8 | |||||

| MDO/MGO | 0.4 | 0.3 | ||||||||

| medium-speed diesel | BFO | 0.4 | 0.8 | |||||||

| MDO/MGO | 0.4 | 0.3 | ||||||||

| Regulation | In Force from Year: | Sulfur Content in Fuel Oil (%) | |

|---|---|---|---|

| Marpol Annex VI | SECA | 2010 | 1 |

| 2015 | 0.1 | ||

| Global | 2012 | 3.5 | |

| 2020 | 0.5 | ||

| EU Directive 2005/33 [94] | SECA | 2007 | 1.5 |

| Global | None | None | |

| Parameter | Uncertainties of Emission Factors | ||

|---|---|---|---|

| Cruising | Manoeuvring | Hotelling | |

| NOx | ±20% | ±40% | ±30% |

| SOx | ±10% | ±30% | ±20% |

| VOC | ±25% | ±50% | ±40% |

| PM2.5 | ±25% | ±50% | ±40% |

| Fuel Consumption | ±10% | ±30% | ±20% |

| Parameter | Value | Units |

|---|---|---|

| Vessel velocity | 10 | Knot |

| 18.5 | km/hr | |

| Cruising distance | 19.2 | km |

| Cruising time | 1 | hr |

| Manoeuvring time | 1 | hr |

| Stand-by time | 3 | hr |

| Hoteling time | 84 | hr |

| Specific fuel Consumption | 218 | g/kWh |

Appendix C. Ships Tracking of Typical Movements and Location around the Ports during 2018

| Haifa Port | Ashdod Port | |||||

|---|---|---|---|---|---|---|

| Number of Ships at Hoteling Position | Number of Ships at Waiting in-Line Position | Total Number of Ships Positioning at Distance of 0–4 km from the Port | Number of Ships at Hoteling Position | Number of Ships at Waiting in-Line Position | Total Number of Ships Positioning at Distance of 0–4 km from the Port | |

| Average value | 45.18 | 22.74 | 67.91 | 36.21 | 13.26 | 49.47 |

| Maximum value | 60 | 35 | 78 | 49 | 28 | 65 |

| Minimum value | 32 | 14 | 55 | 29 | 7 | 45 |

| Std N = 34 (days) | 5.5 | 5.2 | 6.6 | 4.7 | 5.3 | 6.3 |

| Weekly average number of ships entering or leaving the port in 24 h | Movement per hour | Weekly average number of ships entering or leaving the port in 24 h | Movement per hour | |||

| N = 6 (weeks) | 82.725 | 3.45 | 41.36 | 1.72 | ||

Appendix D. Emissions Scenarios for 2018, 2025 and 2030

- Passive renovation of vessels;

- Current global regulation;

- Increased vessels congestion;

- Reduction of hoteling time;

- New “HaMifratz”/”HaDarom” port.

- Electric shore power for 30% of the vessels;

- Reduction of stand-by time by 30%.

- 50% of the old vessels are replaced with new ones, or SCR is installed in them;

- Reduction of stand-by time by 30%.

- MPS A1 2025 and MPS A2 2025 together.

- Passive renovation of vessels;

- Current global regulation;

- Increased vessels congestion;

- Reduction of hoteling time.

- Electric shore power for 50% of vessels;

- Reduction of stand-by time by 60%.

- 70% of old vessels are replaced with new ones or with SCR is installed in them;

- Reduction of stand-by time by 60%.

- MPS A1 2030 and MPS A2 2030 together.

| Vessel Type | Instantaneous Emissions (g/s) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering | Hoteling | |||||||||||||

| NOx | PM2.5 | VOC | CO | SOx | NOx | PM2.5 | VOC | CO | SOx | NOx | PM2.5 | VOC | CO | SOx | |

| Large cruise | 114.3 | 6.5 | 1.6 | 40.8 | 124.6 | 53.4 | 3.1 | 1.9 | 19.2 | 58.6 | 26.7 | 1.54 | 0.77 | 9.60 | 29.3 |

| Passenger vessel | 19.1 | 1.1 | 0.7 | 6.8 | 20.9 | 6.9 | 0.4 | 0.2 | 2.5 | 7.5 | 6.9 | 0.39 | 0.20 | 2.47 | 7.5 |

| Panamax (containers) | 111.7 | 6.4 | 1.6 | 39.9 | 121.8 | 38.1 | 2.4 | 1.5 | 14.9 | 45.5 | 4.7 | 0.28 | 0.14 | 1.75 | 5.3 |

| Panamax (grains) | 32.1 | 0.7 | 0.5 | 11.5 | 35.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.1 | 0.05 | 0.06 | 0.77 | 2.3 |

| Oil tanker 180 m | 25.3 | 0.4 | 0.4 | 9.7 | 29.7 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.8 | 0.03 | 0.05 | 0.67 | 2.0 |

| Chemical tanker 100 m | 13.3 | 0.3 | 0.2 | 4.8 | 14.5 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.0 | 0.04 | 0.06 | 0.73 | 2.2 |

| Bunker 120 m | 6.8 | 0.1 | 0.1 | 2.4 | 7.4 | 0.5 | 0.01 | 0.02 | 0.2 | 0.5 | 0.5 | 0.01 | 0.01 | 0.17 | 0.5 |

| General cargo ship 120 m | 6.8 | 0.1 | 0.1 | 2.4 | 7.4 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.5 | 0.01 | 0.01 | 0.17 | 0.5 |

| I.N.S | 18.5 | 1.1 | 0.7 | 6.8 | 20.9 | 6.7 | 0.4 | 0.2 | 2.5 | 7.5 | 6.7 | 0.39 | 0.20 | 2.47 | 7.5 |

| Tugboat | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 4.2 | 0.1 | 0.2 | 1.8 | 5.4 | 1.8 | 0.03 | 0.05 | 0.67 | 2.0 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1946 | 17% | 3228 | 29% | 5993 | 54% | 11,167 |

| PM2.5 | 156 | 18% | 304 | 34% | 429 | 48% | 889 |

| VOC | 39 | 9% | 190 | 43% | 214 | 48% | 444 |

| CO | 312 | 18% | 608 | 34% | 857 | 48% | 1778 |

| SO2 | 460 | 5% | 1891 | 21% | 6526 | 74% | 8877 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 2069 | 19% | 3375 | 30% | 5676 | 51% | 11,119 |

| PM2.5 | 120 | 19% | 233 | 36% | 286 | 45% | 638 |

| VOC | 48 | 9% | 232 | 46% | 229 | 45% | 509 |

| CO | 383 | 19% | 745 | 36% | 915 | 45% | 2042 |

| SO2 | 113 | 6% | 463 | 24% | 1392 | 71% | 1968 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 2069 | 24% | 2569 | 30% | 4011 | 46% | 8648 |

| PM2.5 | 120 | 24% | 178 | 36% | 202 | 40% | 499 |

| VOC | 48 | 12% | 177 | 46% | 162 | 42% | 387 |

| CO | 383 | 24% | 568 | 36% | 647 | 40% | 1598 |

| SO2 | 113 | 8% | 356 | 25% | 984 | 68% | 1453 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1360 | 20% | 1684 | 25% | 3757 | 55% | 6801 |

| PM2.5 | 120 | 21% | 178 | 30% | 286 | 49% | 583 |

| VOC | 48 | 11% | 177 | 39% | 229 | 50% | 454 |

| CO | 383 | 21% | 568 | 30% | 915 | 49% | 1865 |

| SO2 | 113 | 6% | 356 | 19% | 1392 | 75% | 1861 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1360 | 24% | 1684 | 29% | 2694 | 47% | 5738 |

| PM2.5 | 120 | 24% | 178 | 36% | 202 | 40% | 499 |

| VOC | 48 | 12% | 177 | 46% | 162 | 42% | 387 |

| CO | 383 | 24% | 568 | 36% | 647 | 40% | 1598 |

| SO2 | 113 | 8% | 356 | 25% | 984 | 68% | 1453 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 2066 | 19% | 3347 | 31% | 5327 | 50% | 10,740 |

| PM2.5 | 126 | 19% | 245 | 38% | 280 | 43% | 650 |

| VOC | 50 | 10% | 244 | 47% | 224 | 43% | 518 |

| CO | 402 | 19% | 783 | 38% | 896 | 43% | 2080 |

| SO2 | 118 | 6% | 487 | 25% | 1363 | 69% | 1969 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 2066 | 33% | 1909 | 31% | 2192 | 36% | 6167 |

| PM2.5 | 126 | 33% | 140 | 37% | 116 | 30% | 382 |

| VOC | 50 | 18% | 140 | 50% | 92 | 33% | 283 |

| CO | 402 | 33% | 449 | 37% | 370 | 30% | 1221 |

| SO2 | 118 | 12% | 284 | 29% | 562 | 58% | 964 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1088 | 22% | 986 | 20% | 2892 | 58% | 4966 |

| PM2.5 | 126 | 23% | 140 | 26% | 280 | 51% | 546 |

| VOC | 50 | 12% | 140 | 34% | 224 | 54% | 414 |

| CO | 402 | 23% | 449 | 26% | 896 | 51% | 1746 |

| SO2 | 118 | 7% | 284 | 16% | 1363 | 77% | 1766 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1088 | 33% | 986 | 30% | 1190 | 36% | 3263 |

| PM2.5 | 126 | 33% | 140 | 37% | 116 | 30% | 382 |

| VOC | 50 | 18% | 140 | 50% | 92 | 33% | 283 |

| CO | 402 | 33% | 449 | 37% | 370 | 30% | 1221 |

| SO2 | 118 | 12% | 284 | 29% | 562 | 58% | 964 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 973 | 13% | 1614 | 22% | 4661 | 64% | 7248 |

| PM2.5 | 78 | 14% | 152 | 27% | 333 | 59% | 564 |

| VOC | 20 | 7% | 95 | 34% | 167 | 59% | 281 |

| CO | 156 | 14% | 304 | 27% | 667 | 59% | 1127 |

| SO2 | 230 | 4% | 946 | 15% | 5076 | 81% | 6251 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1034 | 14% | 1687 | 23% | 4493 | 62% | 7215 |

| PM2.5 | 60 | 15% | 116 | 29% | 226 | 56% | 402 |

| VOC | 24 | 7% | 116 | 36% | 181 | 56% | 321 |

| CO | 191 | 15% | 372 | 29% | 724 | 56% | 1288 |

| SO2 | 56 | 4% | 232 | 17% | 1102 | 79% | 1390 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1034 | 19% | 1325 | 24% | 3171 | 57% | 5531 |

| PM2.5 | 60 | 19% | 92 | 29% | 160 | 51% | 311 |

| VOC | 24 | 10% | 91 | 38% | 128 | 53% | 243 |

| CO | 191 | 19% | 293 | 29% | 512 | 51% | 996 |

| SO2 | 56 | 6% | 183 | 18% | 778 | 76% | 1018 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 680 | 15% | 869 | 19% | 2974 | 66% | 4523 |

| PM2.5 | 60 | 16% | 92 | 24% | 226 | 60% | 378 |

| VOC | 24 | 8% | 91 | 31% | 181 | 61% | 296 |

| CO | 191 | 16% | 293 | 24% | 724 | 60% | 1208 |

| SO2 | 56 | 4% | 183 | 14% | 1102 | 82% | 1342 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 680 | 19% | 869 | 24% | 2099 | 58% | 3648 |

| PM2.5 | 60 | 19% | 92 | 29% | 160 | 51% | 311 |

| VOC | 24 | 10% | 91 | 38% | 128 | 53% | 243 |

| CO | 191 | 19% | 293 | 29% | 512 | 51% | 996 |

| SO2 | 56 | 6% | 183 | 18% | 778 | 76% | 1018 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1043 | 15% | 1690 | 24% | 4194 | 61% | 6927 |

| PM2.5 | 63 | 16% | 123 | 30% | 220 | 54% | 407 |

| VOC | 25 | 8% | 123 | 38% | 176 | 54% | 325 |

| CO | 203 | 16% | 395 | 30% | 705 | 54% | 1303 |

| SO2 | 60 | 4% | 246 | 18% | 1073 | 78% | 1379 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 1043 | 28% | 964 | 26% | 1726 | 46% | 3733 |

| PM2.5 | 63 | 28% | 71 | 31% | 91 | 40% | 225 |

| VOC | 25 | 15% | 71 | 42% | 73 | 43% | 169 |

| CO | 203 | 28% | 227 | 31% | 291 | 40% | 721 |

| SO2 | 60 | 9% | 143 | 22% | 442 | 69% | 646 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 544 | 17% | 502 | 15% | 2209 | 68% | 3255 |

| PM2.5 | 63 | 18% | 71 | 20% | 220 | 62% | 355 |

| VOC | 25 | 9% | 71 | 26% | 176 | 65% | 272 |

| CO | 203 | 18% | 227 | 20% | 705 | 62% | 1135 |

| SO2 | 60 | 5% | 143 | 11% | 1073 | 84% | 1276 |

| Pollutant | Emissions (Ton/Year) | ||||||

|---|---|---|---|---|---|---|---|

| Cruising | Maneuvering + Stand-By | Hoteling | Total | ||||

| NOx | 544 | 28% | 502 | 26% | 909 | 46% | 1955 |

| PM2.5 | 63 | 28% | 71 | 31% | 91 | 40% | 225 |

| VOC | 25 | 15% | 71 | 42% | 73 | 43% | 169 |

| CO | 203 | 28% | 227 | 31% | 291 | 40% | 721 |

| SO2 | 60 | 9% | 143 | 22% | 442 | 69% | 646 |

Appendix E. Emissions from the Haifa and Ashdod Industrial Zones, Land Transportation and from a 1000 MW Coal Power Plant

| Pollutant (Ton/Year) | Year | Yearly Average | Proportional Annual Emission for a 1000 MW Coal Plant | |||

|---|---|---|---|---|---|---|

| 2012 | 2013 | 2014 | 2015 | |||

| NOx | 25,489 | 22,873 | 19,473 | 20,610 | 22,111 | 9827 |

| PM10 | 622 | 533 | 373 | 766 | 574 | 255 |

| PM2.5 | 373.2 | 319.8 | 223.8 | 459.6 | 344 | 153 |

| NMVOC | 30 | 0 | 0 | 0 | 8 | 3 |

| CO | 628 | 611 | 1340 | 4684 | 1816 | 807 |

| SO2 | 35,222 | 34,402 | 31,396 | 33,501 | 33,630 | 14,947 |

| Sources | NOx | VOCs | SOx | PM2.5 | CO | |

|---|---|---|---|---|---|---|

| Haifa | Port | 11,167 | 444 | 8877 | 889 | 1778 |

| Industrial Zone | 1800 | 700 | 650 | 60 | ||

| Transport | 2031 | 513 | 4 | 116 | 3919 | |

| 1000 MW coal plant | 9827 | 3 | 14,947 | 153 | 807 | |

| Ashdod | Port | 7248 | 281 | 6251 | 564 | 1127 |

| Ind. Zone | 2550 | 500 | 700 | 42 | ||

| Transport | 923 | 233 | 2 | 53 | 1781 | |

Appendix F. External Costs and Benefits from the Haifa and Ashdod Ports Air Pollution and Mitigation Scenarios

| Air Pollutant | Present Costs (ILS/Year) | BAU Costs 2030 (ILS/Year) | MPS Costs 2030 (ILS/Year) | BAU–Present Cost Difference (ILS/Year) | BAU–MPS Cost Difference (ILS/Year) |

|---|---|---|---|---|---|

| NOx | 237,978,819 | 228,314,928 | 67,435,308 | −9,663,891 | −160,879,620 |

| PM2.5 | 153,952,512 | 112,018,816 | 67,447,579 | −41,933,696 | −44,571,238 |

| SOx | 599,492,589 | 132,658,465 | 63,815,301 | −466,834,124 | −68,843,165 |

| Total | 991,423,921 | 472,992,209 | 198,698,187 | −518,431,711 | −274,294,022 |

Appendix G. Marine Air Pollution Mitigation Techniques

Appendix G.1. Holistic Mitigation Techniques

Appendix G.1.1. Electric Shore Power (ESP) for Marine Vessels

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

| Costs | Port of Göteborg, EUR09 * | ||

|---|---|---|---|

| Bunker price USD16/metric ton | USD 640 | ||

| Ship auxiliary engine | Bunker/fuel | 277,316/year | |

| Maintenance | 0 | ||

| CO2 | 0 | ||

| Externalities | 0 | ||

| Sum | 277,316 | ||

| Shore power | Ship | Retrofit | 400,000 |

| Capital cost | 54,347/year | ||

| Electricity | 297,024/year | ||

| Maintenance | 0/year | ||

| Port | number of quays | 2 | |

| Investment for all quays | 280,000 | ||

| Capital cost | 38,043/year | ||

| Maintenance | 0/year | ||

| Sum shore power | 389,414/year | ||

| Total cost/saving | −112,099/year | ||

| Vessel Type | Container and Bulk Cargo (USD) | Tankers and Vehicle Carriers (USD) | Cruise (USD) | |

|---|---|---|---|---|

| Costs | Vessel retrofit (thousand USD/vessel/year) | −41 | −38 | −59 |

| Berth retrofit (thousand USD/berth/year) | −732 | −219 | −327 | |

| Benefits (thousand USD/vessel/year) | Fuel savings | 13 | 21 | 140 |

| Total environmental benefits (NOx, SO2, PM2.5, CO2) | 124 (EASIUR and APEEP) | 67 (EASIUR)61 (APEEP) | 368 (EASIUR)138 (APEEP) | |

| Net private benefit (vessel fuel savings minus retrofit cost) (thousand USD/vessel/year) | −28 | −17 | 81 | |

Cost Effectiveness

| Port | TEU (Million Units/Year) | Volume (Million Metric Tons/Year) | EASIUR (Millions USD/Year) | APEEP (Millions USD/Year) | ||

|---|---|---|---|---|---|---|

| Maximize Net Total Benefit | Maximize Total Benefit | Maximize Net Total Benefit | Maximize Total Benefit | |||

| Oakland | 2.3 | 17 | 10 | 11 | 9 | 11 |

| Charleston | 2 | 17.3 | 1 | 1 | 1 | 1 |

| Ashdod | 1.3 | 19.6 | ||||

| Haifa | 1.2 | 24 | ||||

| Miami | 0.9 | - | 7 | 10 | 6 | 7 |

| Port Everglades | 0.9 | 19.1 | 8 | 17 | 4 | 8 |

| Jacksonville | 0.9 | 14 | 1 | 1 | 1 | 1 |

Feasibility

Appendix G.1.2. Repowering Vessels with Natural Gas or Dual-Fuel Engines

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.1.3. Ship Onboard Incineration (SOI)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.1.4. Oceangoing Vessels Speed Reduction (VSR)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.1.5. Reduce Hotelling Time (RHT)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.1.6. Distancing Stand-By Location

Appendix G.2. SOx Mitigation Techniques

Appendix G.2.1. Low-Sulfur Marine Gas Oil (MGO) Diesel Fuel

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.2.2. On-Road Diesel

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.2.3. Gas to Liquid (GTL) Fuel

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.2.4. Exhaust Gas Cleaning Systems (EGCS, “Scrubbers”)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3. NOx Mitigation Techniques

Appendix G.3.1. Emulsified Diesel Fuel (EDF)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3.2. Direct Water Injection (DWI)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3.3. Fumigation

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3.4. Exhaust Gas Recirculation (EGR)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3.5. Repowering with US EPA Tier II, III and IV Engines

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.3.6. Selective Catalytic Reduction (SCR)

Technique’s Description

General Potential of Emissions Reduction

Inputs and Costs

Cost Effectiveness

Feasibility

Appendix G.4. Mitigation Techniques Summary

| Technique Name | Emission Mitigation Potential | Cost (USD) | Sufficiency and Relative Cost Effectiveness (NIS/Ton Reduced Pollutant) | Remarks | |||

|---|---|---|---|---|---|---|---|

| SOx | PM | VOC | NOx | ||||

| ESP—Electric Shore power | 100% | 100% | 100% | 100% | 300,000–200,000 per vessel 400,000–5,000,000 per berth 0–5,000,000 per electric net. 0–600,000 for O and M [29,33,98] | Highly sufficient. Medium to high cost-efficiency [38,98]. | Eliminate all pollutants during hoteling time (the biggest operation-regime contributor to air pollution from the Haifa and Ashdod ports). |

| Natural gas/dual fuel | 99% | 94% | 90% | 90% | 240,000–4,625,000$ per vessel (184/kW) [29]. LNG price is usually within 15% of HFO price [99,100] 50,000,000 per LNG facility [101]. | Highly sufficient. Medium to high cost-efficiency [99]. | Emission mitigation applies for all operational regimes (natural gas), or when close to shore (dual fuel). LNG fuel is still not widely available. |

| SOI—Ship onboard incineration | - | Some | - | Highly cost-effective, but not sufficient as a standalone technique | Does not affect the main emission source (the engine). | ||

| VSR—Vessel Speed reduction | 70% | 70% | 55% | Highly cost effective, but not sufficient as a standalone technique | Mitigation is only for sailing. 80–90% of vessels within 25 nautical miles of Israeli ports, usually sail at low speed. | ||

| RHT—Reduced Hoteling Time | Highly cost effective, but not sufficient as a standalone technique | Mitigation is only for hoteling phase. | |||||

| Distancing stand-by location | ~90% | ~90% | ~90% | ~90% | No cost | Not sufficient as a stand-alone technique, but very high cost-effectiveness. | Mitigation is only for the stand-by and maneuvering phase. Very relevant for Israel, as dozens of ships always wait in-line outside the ports. |

| Technique Name | Emission Mitigation Potential | Cost (USD) | Sufficiency and And Relative Cost- Effectiveness (NIS/Ton Reduced Pollutant) | Remarks | ||

|---|---|---|---|---|---|---|

| SOx | PM | NOx | ||||

| MGO | 90% | 85% | New build 34,000–90,000 (1.5–8/kW) Retrofitting 45,000–100,000 (2–10/kW) [103] MGO price is usually 60% more expensive than HFO [100] | Highly sufficient. Medium to high cost-efficiency [29] | ||

| On-road diesel | 90% | 87% | 6% | Vessel modifications 50,000 [29] More expensive than MGO. | Highly sufficient. Medium to high cost-efficiency | |

| GTL | 100% | 87% | 13% | Vessel modifications 50,000 [29] GTL facility CAPEX is very high: 5–20 billion [131] GTL is more expensive than MGO. | Highly sufficient. low cost-efficiency | The substantial environmental impact of a GTL plant should also be considered [142] |

| EGCS | 80–99% | 400,000–7,000,000 or 35–94/kW (more expensive for retrofitting) [103,136] | Highly sufficient. Can be more cost-effective than switching to MGO | Open systems can cause SOx and heavy metals sea pollution [135] | ||

| Technique Name | NOx Emissions Mitigation | Cost (USD) Per Vessel (or Per kW) | Cost-Effectiveness ($/Ton of Reduced NOx) | Remarks |

|---|---|---|---|---|

| EDF | 10–50% | 86,000–210,000 (4–19/kW) [103] | Low to medium sufficiency. Low to medium cost-efficiency | Compatible with Tier II. |

| DWI | 50–60% | 185,000–1115,000 (23–41/kW) [103] | Medium sufficiency. Low to medium cost-efficiency | Compatible with Tier II. |

| Fumigation | 50–70% | 170,000–1085,000 (22–42/kW) [103] | Medium sufficiency. Low to medium cost-efficiency | Compatible with Tier II–III. |

| EGR | 70% | 86,000–251,000 (5–19/kW) [103] | Medium to high sufficiency. High cost-efficiency [99,140] | Compatible with Tier III. Some experience in marine vessels. |

| SCR | 70–98% | 500,000–1300,000 retrofit (112/kW) [104] 390,000–2080,000 new (39–87/kW) [103] | Highly sufficient. Medium to high cost-efficiency [99] | Compatible with Tier III–IV. Plenty of experience in marine vessels. |

| Engine retrofitting from Tier I to II, III. | Tier II 20% Tier III 80% Tier IV 90% [29,109,141] | Retrofitting to Tier II: 8000–260,000$ (0.3–17/kW) [103] Replacing to Tier II: 7500–310,000 [29] Retrofitting to Tier III: 52,000–130,000 (3–12/kW) (not including adding SCR or EGR) [103] | Low to high sufficiency. Medium to high cost-efficiency | Full replacement to Tier III engine is more expensive. New Tier III engines include SCR, EGR or LNG technologies. |

References

- Merk, O. Shipping Emissions in Ports; OECD: Paris, France, 2011. [Google Scholar]

- Rodrigue, J.-P. The Geography of Transport Systems, 5th ed.; Routledge: New York, NY, USA, 2020; ISBN 9780367364625. [Google Scholar]

- International Maritime Organization. Third IMO GHG Study 2014 Executive Summary and Final Report; International Maritime Organization: London, UK, 2015. [Google Scholar]

- Concawe. Marine Fuel Facts; Concawe: Brussels, Belgium, 2017. [Google Scholar]

- Vaishnav, P.; Fischbeck, P.S.; Morgan, M.G.; Corbett, J.J. Shore Power for Vessels Calling at U.S. Ports: Benefits and Costs. Environ. Sci. Technol. 2016, 50, 1102–1110. [Google Scholar] [CrossRef] [PubMed]

- Van Erp, J.; Spapens, T.; Van Wingerde, K. Legal and extralegal enforcement of pollution by seagoing vessels. In Hazardous Waste and Pollution; Wyatt, T., Ed.; Springer International Publishing: Berlin/Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2016; pp. 163–176. ISBN1 978-3-319-18080-9. ISBN2 978-3-319-18081-6. [Google Scholar]

- Winkel, R.; Weddige, U.; Johnsen, D.; Hoen, V.; Papaefthimiou, S. Shore Side Electricity in Europe: Potential and environmental benefits. Energy Policy 2016, 88, 584–593. [Google Scholar] [CrossRef]

- Jasper, F.; Shinichi, H.; Zhang, S.; Paula, P.; Comer, B.; Hauerhof, E.; van der Loeff, W.S.; Smith, T.; Zhang, Y.; Kosaka, H.; et al. Fourth Greenhouse Gas Study 2020; International Maritime Organization: London, UK, 2021. [Google Scholar]

- McDuffie, E.E.; Smith, S.J.; O’Rourke, P.; Tibrewal, K.; Venkataraman, C.; Marais, E.A.; Zheng, B.; Crippa, M.; Brauer, M.; Martin, R.V. A global anthropogenic emission inventory of atmospheric pollutants from sector- And fuel-specific sources (1970–2017): An application of the Community Emissions Data System (CEDS). Earth Syst. Sci. Data 2020, 12, 3413–3442. [Google Scholar] [CrossRef]

- Olmer, N.; Comer, B.; Roy, B.; Mao, X.; Rutherford, D. Greenhouse Gas Emissions from Global Shipping, 2013–2015; International Council on Clean Transportation: Washington, DC, USA, 2015. [Google Scholar]

- Viana, M.; Hammingh, P.; Colette, A.; Querol, X.; Degraeuwe, B.; de Vlieger, I.; van Aardenne, J. Impact of maritime transport emissions on coastal air quality in Europe. Atmos. Environ. 2014, 90, 96–105. [Google Scholar] [CrossRef]

- Endresen, Ø. Emission from international sea transportation and environmental impact. J. Geophys. Res. 2003, 108, 4560. [Google Scholar] [CrossRef]

- Neumann, B.; Vafeidis, A.T.; Zimmermann, J.; Nicholls, R.J. Future Coastal Population Growth and Exposure to Sea-Level Rise and Coastal Flooding—A Global Assessment. PLoS ONE 2015, 10, e0118571. [Google Scholar] [CrossRef] [Green Version]

- NASA Gridded Population of the World (GPW), v4. Available online: https://sedac.ciesin.columbia.edu/data/collection/gpw-v4# (accessed on 8 March 2021).

- Rouïl, L.; Ratsivalaka, C.; André, J.; Allemand, N. ECAMED—Conclusions of the Technical Feasibility Study on Implementing an Emissions Control Area (ECA) for Ships in the Mediterranean; INERIS: Verneuil-en-Halatte, France, 2019. [Google Scholar]

- Cofala, J.; Amann, M.; Borken-Kleefeld, J.; Gomez Sanabria, A.; Heyes, C.; Kiesewetter, G.; Sander, R.; Schöpp, W.; Holland, M.; Fagerli, H.; et al. The Potential for Cost-Effective Air Emission Reductions from International Shipping through Designation of Further Emission Control Areas in EU Waters with Focus on the Mediterranean Sea; IIASA: Laxenburg, Austria, 2018. [Google Scholar]

- Corbett, J.J.; Winebrake, J.J.; Green, E.H.; Kasibhatla, P.; Eyring, V.; Lauer, A. Mortality from Ship Emissions: A Global Assessment. Environ. Sci. Technol. 2007, 41, 8512–8518. [Google Scholar] [CrossRef]

- Anenberg, S.; Miller, J.; Henze, D.; Minjares, R. A Global Snapshot of the Air Pollution-Related Health Impacts of Transportation Sector Emissions in 2010 and 2015; International Council on Clean Transportation: Washington, DC, USA, 2019. [Google Scholar]

- Caumette, G.; Lienemann, C.-P.; Merdrignac, I.; Bouyssiere, B.; Lobinski, R. Element speciation analysis of petroleum and related materials. J. Anal. At. Spectrom. 2009, 24, 263–276. [Google Scholar] [CrossRef]

- Corbin, J.C.; Mensah, A.A.; Pieber, S.M.; Orasche, J.; Michalke, B.; Zanatta, M.; Czech, H.; Massabò, D.; de Mongeot, F.B.; Mennucci, C.; et al. Trace Metals in Soot and PM2.5 from Heavy-Fuel-Oil Combustion in a Marine Engine. Environ. Sci. Technol. 2018, 52, 6714–6722. [Google Scholar] [CrossRef] [Green Version]

- Burgess, J.; Foulkes, L.; Jones, P.; Merighi, M.; Murray, S.; Whitacre, J. Law of the Sea; A Policy Primer: Medford, MA, USA, 2017. [Google Scholar]

- United Nations United Nations Convention on the Law of the Sea; UNCLOS: Montego Bay, Jamaica, 1982.

- International Maritime Organization Emission Control Areas (ECAs). Designated under MARPOL Annex VI. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Emission-Control-Areas-(ECAs)-designated-under-regulation-13-of-MARPOL-Annex-VI-(NOx-emission-control).aspx (accessed on 10 February 2021).

- Chang, C.-C.; Wang, C.-M. Evaluating the effects of green port policy: Case study of Kaohsiung harbor in Taiwan. Transp. Res. Part D Transp. Environ. 2012, 17, 185–189. [Google Scholar] [CrossRef]

- International Maritime Organization. International Convention for the Prevention of Pollution from Ships (MARPOL). Available online: http://www.imo.org/en/About/Conventions/ListOfConventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx (accessed on 13 September 2018).

- Matthias, V.; Bewersdorff, I.; Aulinger, A.; Quante, M. The contribution of ship emissions to air pollution in the North Sea regions. Environ. Pollut. 2010, 158, 2241–2250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seyler, A.; Wittrock, F.; Kattner, L.; Mathieu-Üffing, B.; Peters, E.; Richter, A.; Schmolke, S.; Burrows, J.P. Monitoring shipping emissions in the German Bight using MAX-DOAS measurements. Atmos. Chem. Phys. 2017, 17, 10997–11023. [Google Scholar] [CrossRef] [Green Version]

- International Maritime Organization. Prevention of Air Pollution from Ships. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Air-Pollution.aspx (accessed on 10 February 2021).

- Environ. Cold Ironing Cost Effectiveness Study Volume I—Report; Environ: Los Angeles, CA, USA, 2004. [Google Scholar]

- EMSA. Legislative Texts—Directive 2012/33/EU—EMSA—European Maritime Safety Agency; EMSA: Lisbon, Portugal, 2012; p. 13. [Google Scholar]

- Doves, S. Alternative Maritime Power in the Port of Rotterdam; Port of Rotterdam Authority: Rotterdam, Netherlands, 2006. [Google Scholar]

- CALSTART. Passenger Ferries, Air Quality, and Greenhouse Gases: Can System Expansion Result in Fewer Emissions in the San Francisco Bay Area? CALSTART: Pasadena, CA, USA, 2002. [Google Scholar]

- Wilske, Å. Examining the Commercial Viability of Cold Ironing; Port of Göteborg: Göteborg, Sweden, 2009. [Google Scholar]

- Khan, M.Y.; Agrawal, H.; Ranganathan, S.; Welch, W.A.; Miller, J.W.; Cocker, D.R. Greenhouse Gas and Criteria Emission Benefits through Reduction of Vessel Speed at Sea; California Air Resources Board: Sacramento, CA, USA, 2012. [Google Scholar]

- CARB. Regulatory Advisory: Ships-at-Berth Regulation; California Air Resources Board: Sacramento, CA, USA, 2013. [Google Scholar]

- CARB. Almanac Emission Projection Data. Available online: https://www.arb.ca.gov/app/emsinv/2013/emssumcat_query.php?F_DIV=-4&F_DD=Y&F_YR=2012&F_SEASON=A&SP=2013&F_AREA=CO&F_CO=19 (accessed on 29 May 2018).

- California Air Resources Board. Oceangoing Ship Onboard Incineration. Available online: https://www.arb.ca.gov/ports/shipincin/shipincin.htm (accessed on 22 August 2018).

- Board, C.A.R. Technical Support Document: Initial Statement of Reasons for the Proposed Rulemaking; California Air Resources Board: Sacramento, CA, USA, 2007. [Google Scholar]

- Uno, V.; Gordon, M.; Batarse, A.A.; Calloway, P.; Head, J.W.; Katzoff, K.S.; Mcclure, M.; Benjamin, O.R.; Waring, D.; Wong, J.K.; et al. Maritime Air Quality Improvement Plan (MAQIP)—Port of Oakland; Port of Oakland: Oakland, CA, USA, 2009. [Google Scholar]

- EMSA. Air Emissions—Air Pollution—Sulphur Directive—EMSA—European Maritime Safety Agency; EMSA: Lisbon, Portugal, 2012. [Google Scholar]

- Chen, J.; Wan, Z.; Zhang, H.; Liu, X.; Zhu, Y.; Zheng, A. Governance of Shipping Emission of SOx in China’s Coastal Waters: The SECA Policy, Challenges, and Directions. Coast. Manag. 2018, 46, 191–209. [Google Scholar] [CrossRef]

- DieselNet China Designates Emission Control Areas Near Major Ports; ECOpoint Inc.: Mississauga, ON, Canada, 2015.

- Khasawneh, R. China’s Stricter Rules on Shipping Emissions a Boon for IMO 2020 Compliance: Woodmac; Reuters: London, UK, 2018. [Google Scholar]

- Liu, H.; Jin, X.; Wu, L.; Wang, X.; Fu, M.; Lv, Z.; Morawska, L.; Huang, F.; He, K. The impact of marine shipping and its DECA control on air quality in the Pearl River Delta, China. Sci. Total Environ. 2018, 625, 1476–1485. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, Y.; Liu, Y.; Zhao, J.; Zhou, Y.; Wang, X.; Yang, X.; Zou, Z.; Zhang, C.; Fu, Q.; et al. Changes in the SO2 Level and PM2.5 Components in Shanghai Driven by Implementing the Ship Emission Control Policy. Environ. Sci. Technol. 2019, 53, 11580–11587. [Google Scholar] [CrossRef] [PubMed]

- United Nations Conference On Trade And Development (UNCTAD). Reflecting on the Past, Exploring the Future Transport and Trade Facilitation; Series No.11; UNCTAD: Geneva, Switzerland, 2018. [Google Scholar]

- Asariotis, R.; Assaf, M.; Benamara, H.; Hoffmann, J.; Premti, A.; Rodríguez, L.; Weller, M.; Youssef, F.; Bradford, G.; Crowe, T.; et al. Review of Maritime Transport 2018; UNCTAD: Geneva, Switzerland, 2018; p. 116. [Google Scholar]

- Dinu, O.; Ilie, A.M. Maritime vessel obsolescence, life cycle cost and design service life. In Proceedings of the Modern Technologies in Industrial Engineering (ModTech2015), Mamaia, Romania, 17–20 June 2015; Volume 95, p. 012067. [Google Scholar]

- Maluch, H.; Hibner, V. Estimation of Emission from Air and Sea Traffic and Ways for Reduction of Air Pollution; Meteo-tech: Bnei Brak, Israel, 2010. (In Hebrew) [Google Scholar]

- Israeli Central Bureau of Statistics (CBS). Local Municipalities in Israel—2018; Publication #1797; CBS: Jerusalem, Israel, 2020. (In Hebrew) [Google Scholar]

- Ashdod-Yavneh Region Environmental Union. Ashdod-Yavneh Region Environmental Union. Available online: https://www.env.org.il/he/אודות/רשויות-החברות-באיגוד/ (accessed on 24 July 2021). (In Hebrew).

- Haifa Bay Cities Environmental Union. Haifa Bay Cities Environmental Union. Available online: http://www.envihaifa.org.il/רשויות-מקומיות (accessed on 24 July 2021). (In Hebrew).

- Svechkina, A.; Portnov, B.A. Spatial identification of environmental health hazards potentially associated with adverse birth outcomes. Environ. Sci. Pollut. Res. 2018, 26, 3578–3592. [Google Scholar] [CrossRef]

- Davarashvili, S.; Zusman, M.; Keinan-Boker, L.; Rybnikova, N.; Kaufman, Z.; Silverman, B.G.; Dubnov, J.; Linn, S.; Portnov, B.A. Application of the double kernel density approach to the analysis of cancer incidence in a major metropolitan area. Environ. Res. 2016, 150, 269–281. [Google Scholar] [CrossRef]

- Zusman, M.; Dubnov, J.; Barchana, M.; Portnov, B.A. Residential proximity to petroleum storage tanks and associated cancer risks: Double Kernel Density approach vs. zonal estimates. Sci. Total Environ. 2012, 441, 265–276. [Google Scholar] [CrossRef]

- Negev, M. Air Pollution Policy in Israel. Atmosphere 2020, 11, 1065. [Google Scholar] [CrossRef]

- Israeli Ministry of Environmental Protection. Annual 2019 Pollutant Release and Transfer Register (PRTR) Report; Israeli Ministry of Environmental Protection: Jerusalem, Israel, 2020. (In Hebrew) [Google Scholar]

- Becker, N.; Agai-Shai, K.; Erel, Y.; Schaffer, G.; Greenfeld, A. Economic Cost of the Health Burden Caused by Selected Pollutants in the Haifa Bay Area; Tel-Hai College: Tel-Hai, Israel, 2020. [Google Scholar]

- International Maritime Organization. Ships Face Lower Sulphur Fuel Requirements in Emission Control Areas from 1 January 2015. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/Pages/44-ECA-sulphur.aspx (accessed on 10 February 2021).

- Regional Marine Pollution Emergency Response Centre for the Mediterranean Sea (REMPEC). Med SOx ECA. Available online: https://www.rempec.org/en/our-work/pollution-prevention/hop-topics/med-eca/med-sox-eca-introduction (accessed on 10 February 2021).

- Viana, M.; Fann, N.; Tobías, A.; Querol, X.; Rojas-Rueda, D.; Plaza, A.; Aynos, G.; Conde, J.A.; Fernández, L.; Fernández, C. Environmental and Health Benefits from Designating the Marmara Sea and the Turkish Straits as an Emission Control Area (ECA). Environ. Sci. Technol. 2015, 49, 3304–3313. [Google Scholar] [CrossRef]

- Ministry Of Transport—Administration of Shipping & Ports. Total Traffic Cargo in Israeli Ports 2018; Israeli Ministry of Transport: Jerusalem, Israel, 2019. [Google Scholar]

- Israeli Ministry of Transport Report on Shipment Activity in Israel’s Ports for 2020. Available online: http://asp.mot.gov.il/he/chargers/2245-cargo-2020 (accessed on 10 March 2021).

- Israel Port Company (IPC). Israel Port Company (IPC)—Annual Report for Year 2019; IPC: Tel Aviv-Yafo, Israel, 2020. (In Hebrew) [Google Scholar]

- Israel Planning Administration (IPA). Israel National Outline Plan 13/b/1/1 for Building Port Hamifrats. Available online: https://mavat.iplan.gov.il/SV4/1/99008403/310 (accessed on 13 March 2021). (In Hebrew)

- Israel Planning Administration (IPA). Israel National Outline Plan 13/b/2/1 for Building the Hadarom Container Terminal. Available online: https://mavat.iplan.gov.il/SV4/1/99006968/310 (accessed on 13 March 2021). (In Hebrew)

- MarineTraffic.com MarineTraffic: Global Ship Tracking Intelligence|AIS Marine Traffic. Available online: https://www.marinetraffic.com/en/ais/home/centerx:34.5/centery:32.4/zoom:8 (accessed on 8 March 2021).

- OpenStreetMap OpenStreetMap. Available online: https://www.openstreetmap.org/copyright (accessed on 24 July 2021).

- Israel Ports Company. HaMifratz Port Environmental Impact Assessments; Israel Ports Company: Haifa, Israel, 2018. (In Hebrew) [Google Scholar]

- Whall, C.; Stavrakaki, A.; Ritchie, A.; Green, C.; Shialis, T.; Minchin, W.; Cohen, A.; Stokes, R. Ship Emissions Inventory—Mediterranean Sea, Final Report for Concawe; Entec UK Limited: London, UK, 2007. [Google Scholar]

- US EPA. Compilation of Air Pollutant Emission Factors: Volume II: Mobile Sources—Vessels AP-42, 4th ed.; US EPA, Ed.; US EPA: Washington, DC, USA, 1985. [Google Scholar]

- US EPA. Compilation of Air Pollutant Emission Factors: Mobile Sources—Vessels AP-42, 5th ed.; EPA, Ed.; US EPA: Washington, DC, USA, 2011. [Google Scholar]

- The Israeli Ministry of Environmental Protection. The Israeli Air Quality Monitoring Portal. Available online: https://www.svivaaqm.net/ (accessed on 3 November 2021). (In Hebrew).

- Israeli Ministry of Environmental Protection. Air Quality in Israel Report—2018–2019; Israeli Ministry of Environmental Protection: Jerusalem, Israel, 2020. (In Hebrew) [Google Scholar]

- US EPA, OARO. International Standards to Reduce Emissions from Marine Diesel Engines and Their Fuels. Available online: https://www.epa.gov/regulations-emissions-vehicles-and-engines/international-standards-reduce-emissions-marine-diesel (accessed on 13 September 2018).

- Beker, N.; Grossman, M.; Barak, Y.; Charuvi, N. Green Book: Estimating and Measuring External Costs of Air Pollution and Greenhouse Gas Emissions; Ministry of Environmental Protection: Jerusalem, Israel, 2020. [Google Scholar]

- European Central Bank Israeli Shekel (ILS) to Euro Exchange Reference Rate 2020. Available online: https://www.ecb.europa.eu/stats/policy_and_exchange_rates/euro_reference_exchange_rates/html/eurofxref-graph-ils.en.html (accessed on 3 August 2021).

- Sherlock, R.H.; Lesher, E.J. Role of Chimney Design in dispersion of Waste Gases. J. Air Waste Manage. Assoc. 1954, 4, 13–23. [Google Scholar] [CrossRef]

- Nelson, F.; Shenfeld, L. Economics, Engineering and Air Pollution in the Design of Large Chimneys. J. Air Waste Manage. Assoc. 1965, 15, 355–361. [Google Scholar] [CrossRef]

- The Israeli Ministry of Transport—Administration of Shipping & Ports. Containers in Israeli Ports for 2018; Israeli Ministry of Transport: Jerusalem, Israel, 2019. [Google Scholar]

- Progiou, A.G.; Bakeas, E.; Evangelidou, E.; Kontogiorgi, C.; Lagkadinou, E.; Sebos, I. Air pollutant emissions from Piraeus port: External costs and air quality levels. Transp. Res. Part D Transp. Environ. 2021, 91, 102586. [Google Scholar] [CrossRef]

- Tzannatos, E. Ship emissions and their externalities for the port of Piraeus—Greece. Atmos. Environ. 2010, 44, 400–407. [Google Scholar] [CrossRef]

- Israel Shipping and Ports Authority. Shipping and Sea Ports—2018 Statistical Report; Israel Shipping and Ports Authority: Haifa, Israel, 2019. (In Hebrew) [Google Scholar]

- Kotchenruther, R.A. The effects of marine vessel fuel sulfur regulations on ambient PM2.5 along the west coast of the U.S. Atmos. Environ. 2015, 103, 121–128. [Google Scholar] [CrossRef]

- Kotchenruther, R.A. The effects of marine vessel fuel sulfur regulations on ambient PM2.5 at coastal and near coastal monitoring sites in the U.S. Atmos. Environ. 2017, 151, 52–61. [Google Scholar] [CrossRef]

- Moreno, T.; Querol, X.; Alastuey, A.; de la Rosa, J.; Sánchez de la Campa, A.M.; Minguillón, M.C.; Pandolfi, M.; González-Castanedo, Y.; Monfort, E.; Gibbons, W. Variations in vanadium, nickel and lanthanoid element concentrations in urban air. Sci. Total Environ. 2010, 408, 4569–4579. [Google Scholar] [CrossRef] [PubMed]

- UK Department for Environment, Food & Rural Affairs. UK Report on Measures for 2014 Exceedance of the Target Value for Nickel; UK Department for Environment: London, UK, 2016. [Google Scholar]

- Israeli Ministry of Environmental Protection. Pollutant Release and Transfer Register (PRTR) Report—2018; Israeli Ministry of Environmental Protection: Jerusalem, Israel, 2019. (In Hebrew) [Google Scholar]

- Nesher Israel Cement Enterprises. Nesher Israel Cement Enterprises—2016 Corporate Social Responsibility (CSR) Report; Nesher Israel Cement Enterprises: Ramla, Israel, 2017. (In Hebrew) [Google Scholar]

- Israeli Ministry of Environmental Protection Industrial Pollution Reduction by Technological Means. Available online: https://www.gov.il/he/departments/general/using_technological_means_to_reduce_pollution (accessed on 19 November 2021). (In Hebrew)

- Israeli Ministry of Agriculture AgriMeteo—PllutantRose. Available online: https://www.meteo.co.il/Report/PollutantRose (accessed on 3 November 2021).

- European Parliament and European Council. Directive 2004/107/EC of the European Parliament and of the Council of 15 December 2004 Relating to Arsenic, Cadmium, Mercury, Nickel and Polycyclic Aromatic Hydrocarbons in Ambient Air—EUR-Lex—32004L0107—EN—EUR-Lex; European Parliament and European Council: Brussels, Belgium, 2015. [Google Scholar]

- The Israeli Ministry of Environmental Protection. A Draft for the Updated Air Pollutants Environmental Values, Accourding to the new WHO Guidelines 2021; The Israeli Ministry of Environmental Protection: Jerusalem, Israel, 2021. (In Hebrew) [Google Scholar]

- World Health Organization (WHO). WHO Global Air Quality Guidelines—Particulate Matter (PM2.5 and PM10), Ozone, Nitrogen Dioxide, Sulfur Dioxide and Carbon Monoxide; World Health Organization (WHO): Geneva, Switzerland, 2021. [Google Scholar]

- International Marine Organization (IMO). Nitrogen Oxides (NOx)—Regulation 13; International Maritime Organization (IMO): London, UK, 2010. [Google Scholar]

- Paltiel, A.; Sepulchre, M.; Kornilenko, I.; Maldonado, M. Long-Range Population Projections for Israel: 2009–2059; Israeli Central Bureau of Statistics (CBS): Jerusalem, Israel, 2012. (In Hebrew) [Google Scholar]

- Data Commons Israel—Place Explorer—Data Commons. Available online: https://datacommons.org/place/country/ISR?utm_medium=explore&mprop=count&popt=Person&hl=en (accessed on 15 June 2021).

- Wang, H.; Mao, X.; Rutherford, D. Costs and Benefits of Shore Power at the Port of Shenzhen; ICCT: Washington, DC, USA, 2015. [Google Scholar]

- Winnes, H.; Fridell, E.; Yaramenka, K.; Nelissen, D.; Faber, J.; Ahdour, S. NOx Controls for Shipping in EU Seas; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2016. [Google Scholar]

- Lindstad, H.E.; Eskeland, G.S. Environmental regulations in shipping: Policies leaning towards globalization of scrubbers deserve scrutiny. Transp. Res. Part D Transp. Environ. 2016, 47, 67–76. [Google Scholar] [CrossRef] [Green Version]

- International Maritime Organization. Studies on the Feasibility and Use of LNG as a Fuel for Shipping; International Maritime Organization: London, UK, 2016. [Google Scholar]

- Merk, O.; Dang, T. Efficiency of World Ports in Container and Bulk Cargo (Oil, Coal, Ores and Grain); OECD: Paris, France, 2012. [Google Scholar]

- EPA, I.I. Costs of Emission Reduction Technologies for Category 3 Marine Engines; US EPA: Washington, DC, USA, 2009. [Google Scholar]

- Yaramenka, K.; Winnes, H.; Åström, S.; Fridell, E. Cost-Benefit Analysis of NOx Control for Ships in the Baltic Sea and the North Sea; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2017. [Google Scholar]

- World Bank Group. GDP (current US$)—Israel|Data. Available online: https://data.worldbank.org/indicator/NY.GDP.MKTP.CD?locations=IL (accessed on 28 April 2021).

- International Monetary Fund (IMF). World Economic Outlook, October 2021; International Monetary Fund (IMF): Washington, DC, USA, 2021. [Google Scholar]

- Global-rates.com Inflation 2021, International Inflation Figures from 2021. Available online: https://www.global-rates.com/en/economic-indicators/inflation/2021.aspx (accessed on 19 November 2021).

- Israel Ports Company The Israeli Marine Ports Sector. Available online: https://israports.co.il/he/PortIsrael/Pages/default.aspx (accessed on 19 November 2021). (In Hebrew).

- Yang, J.; Johnson, K.C.; Miller, J.W.; Durbin, D.T.; Jiang, Y.; Karavalakis, G.; Cocker, D.R.I. Marine Scrubber Efficiency and NOx Emission from Large Ocean Going Vessels. In Proceedings of the 2017 International Emissions Inventory Conference, Baltimore, MD, USA, 14–18 August 2017; p. 29. [Google Scholar]

- Trozzi, C. Update of Emission Estimate Methodology for Maritime Navigation—Techne Consulting Report ETC.EF.10 DD; Techne Consulting: Rome, Italy, 2010. [Google Scholar]

- Barak, Y.; Razi-Yanuv, E.; Madar, D.; Na’im, O. Feasibility Study for Reducing Marine Vessels’ Air Pollution at Haifa and Ashdod Ports; AVIV AMCG Ltd.: Rosh Haayin, Israel, 2019. [Google Scholar]

- European Environment Agency (EEA). Air Pollution in Europe 1990–2004—European Environment Agency; European Environment Agency (EEA): Copenhagen, Denmark, 2007. [Google Scholar]

- Zha, H.; Wang, R.; Feng, X.; An, C.; Qian, J. Spatial characteristics of the PM 2.5/PM 10 ratio and its indicative significance regarding air pollution in Hebei Province, China. Environ. Monit. Assess. 2021, 193, 486. [Google Scholar] [CrossRef]

- Haifa Bay Cities Environmental Union. 2018 Annual Report; Haifa Bay Cities Environmental Union: Haifa, Israel, 2019. (In Hebrew) [Google Scholar]

- Israeli Ministry of Environmental Protection. Rotenberg Coal Power Plant PRTR 2012. Available online: https://www.gov.il/apps/sviva/airq/atar_svivati_emission_details?layer=divuchim2012&atarsvivati=52258 (accessed on 3 August 2021). (In Hebrew)

- Israeli Ministry of Environmental Protection. Rotenberg Coal Power Plant PRTR 2013. Available online: https://www.gov.il/apps/sviva/airq/atar_svivati_emission_details?layer=divuchim2013&atarsvivati=52258 (accessed on 3 August 2021). (In Hebrew)

- Israeli Ministry of Environmental Protection. Rotenberg Coal Power Plant PRTR 2014. Available online: https://www.gov.il/apps/sviva/airq/atar_svivati_emission_details?layer=divuchim2014&atarsvivati=52258 (accessed on 3 August 2021). (In Hebrew)

- Israeli Ministry of Environmental Protection. Rotenberg Coal Power Plant PRTR 2015. Available online: https://www.gov.il/apps/sviva/airq/atar_svivati_emission_details?layer=divuchim2015&atarsvivati=52258 (accessed on 3 August 2021). (In Hebrew)

- US EPA, OAR, OTAQ. Northwest Ports Achievements in Reducing Emissions and Improving Performance; US EPA, OAR, OTAQ: Washington, DC, USA, 2017. [Google Scholar]

- US EPA, OAR, OTAQ. Shore Power Technology Assessment at U.S. Ports; US EPA, OAR, OTAQ: Washington, DC, USA, 2017. [Google Scholar]

- The American Association of Port Authorities. World Port Rankings—Top 100 Ports in the World in 2015; The American Association of Port Authorities: Washington, DC, USA, 2015. [Google Scholar]

- Port of Portland Port of Portland Air Quality Improvement and Emission Reduction Strategies. Available online: https://www.oregonlegislature.gov/dembrow/workgroupitems/7-19PortofPortlandEmissionReductions.pdf (accessed on 19 November 2021).

- US EPA, OAR, OTAQ. EPA and Port Everglades Partnership: Emission Inventories and Reduction Strategies; US EPA, OAR, OTAQ: Washington, DC, USA, 2018. [Google Scholar]

- Shell Global IMO 2020: What’s Next?—Shell Global. Available online: https://propertibazar.com/article/imo-2020-whats-next-shell-global_5a5533c2d64ab2962ffa6b4b.html (accessed on 16 September 2018).

- DNV GL. Alternative Fuels Insight—LNG. Available online: https://afi.dnvgl.com/Statistics?repId=1 (accessed on 6 January 2019).

- Ship and Bunker. CMA CGM’s New 22,000 TEU Mega-Box Ships to Use LNG Bunkers; Ship and Bunker: Vancouver, BC, Canada, 2017. [Google Scholar]

- Sea LNG. Bunkering Infrastructure—Sea LNG. Available online: https://sea-lng.org/lng-as-a-marine-fuel/bunkering-infrastructure/ (accessed on 6 January 2019).

- LNG Bunkering World Map|WPCI—LNG Bunkering. Available online: http://lngbunkering.org/lng/map/node (accessed on 6 January 2019).

- EPCM Holdings LNG as Marine Bunkering Fuel—EPCM Holdings. Available online: https://www.epcmholdings.com/lng-as-marine-bunkering-fuel/#Infrastructure_required (accessed on 6 January 2019).

- Carr, E.W.; Corbett, J.J. Ship Compliance in Emission Control Areas: Technology Costs and Policy Instruments. Environ. Sci. Technol. 2015, 49, 9584–9591. [Google Scholar] [CrossRef]

- Shell Pearl GTL—Overview|Shell Global. Available online: https://www.shell.com/about-us/major-projects/pearl-gtl/pearl-gtl-an-overview.html (accessed on 25 June 2018).

- Ou, X.; Zhang, X.X.; Zhang, X.X.; Zhang, Q. Life Cycle GHG of NG-Based Fuel and Electric Vehicle in China. Energies 2013, 6, 2644–2662. [Google Scholar] [CrossRef] [Green Version]

- Jaramillo, P.; Griffin, W.M.; Matthews, H.S. Comparative Analysis of the Production Costs and Life-Cycle GHG Emissions of FT Liquid Fuels from Coal and Natural Gas. Environ. Sci. Technol. 2008, 42, 7559–7565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Vliet, O.P.R. Feasibility of Alternatives to Driving on Diesel and Petrol; Utrecht University: Utrecht, Netherlands, 2010. [Google Scholar]

- Endres, S.; Maes, F.; Hopkins, F.; Houghton, K.; Mårtensson, E.M.; Oeffner, J.; Quack, B.; Singh, P.; Turner, D. A New Perspective at the Ship-Air-Sea-Interface: The Environmental Impacts of Exhaust Gas Scrubber Discharge. Front. Mar. Sci. 2018, 5, 139. [Google Scholar] [CrossRef] [Green Version]

- Grimmer, R.J. IMO 2020: A Sea Change is Coming; Stillwater Associates LLC: Irvine, CA, USA, 2018; p. 38. [Google Scholar]

- Abadie, L.M.; Goicoechea, N.; Galarraga, I. Adapting the shipping sector to stricter emissions regulations: Fuel switching or installing a scrubber? Transp. Res. Part D Transp. Environ. 2017, 57, 237–250. [Google Scholar] [CrossRef]

- World Maritime News. Wärtsilä Cashes in on 2020 Sulphur Cap Countdown; Navingo BV: Schiedam, The Netherlands, 2018. [Google Scholar]

- Sahu, S. Compliance to the IMO 2020 Rule to Be “Quite High” Post-2020 Despite Concerns: MECL MD|S& P Global Platts. Available online: https://www.spglobal.com/platts/en/market-insights/latest-news/shipping/041018-compliance-to-the-imo-2020-rule-to-be-quite-high-post-2020-despite-concerns-mecl-md (accessed on 16 September 2018).

- Alfa Laval. Reducing NOx Emissions from Ship Exhaust; Alfa Laval: Lund, Sweden, 2020. [Google Scholar]

- International Agency for Research on Cancer. Annex: Emission standards for light- and heavy-duty vehicles. In Diesel and Gasoline Engine Exhausts and Some Nitroarenes; International Agency for Research on Cancer: Lyon, France, 2014; p. 702. ISBN 9789283213284. [Google Scholar]

- Ayalon, O.; Lev-On, M.; Madar, D.; Lev-On, P.; Shapira, N. A Comparative Study of the Carbon Capture Alternatives in the Production of Natural Gas-based Transportation Fuels; Samuel Neaman Institute: Haifa, Israel, 2018. [Google Scholar]

| Technique Name | Compared to Tier I, Emission Mitigation by: | Cost | Maturity | Installation Time | Prevalence | Cost-Efficiency | Feasibility in Israel | ||

|---|---|---|---|---|---|---|---|---|---|

| SOx | PM | NOx | |||||||

| Engine retrofitting from Tier I to Tier III/IV | Tier III 70% Tier IV 90% | ++ | +++++ | ++ | + | + | + | ||

| Selective catalytic reduction (SCR) | 70–98% | +++ | +++++ | +++ | ++++ | ++ | ++++ | ||

| Exhaust gas recirculation (EGR) | 70% | ++++ | +++++ | ++++ | +++ | +++ | ++++ | ||

| Exhaust gas cleaning systems (EGCS) (“scrubbers”) | 90–99% | 0–20% | +++ | +++++ | +++ | ++++ | ++ | ++++ | |

| Low or ultra-low sulfur diesel (ULSD) | 70–90% | 25–60% | ++++ | +++++ | +++ | ++++ | +++ | ++++ | |

| Electric shore power (ESP) | 100% during hoteling 50–70% over the 3 phases of navigation | ++ | +++++ | ++ | +++ | ++ | +++ | ||

| Liquid natural gas (LNG)/dual fuel | 99% | 94% | 90% | + | +++++ | + | + | + | + |

| Distancing stand-by location | 70–90% of emissions during stand-by phase. 15%–25% over all phases of navigation | +++++ | +++++ | +++++ | + | +++++ | +++++ | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razy-Yanuv, E.; Barak, Y.; Noam, O.; Madar, D. Marine Air Pollution in Israel: Extent, Proposed Mitigation Targets, Benefits and Feasibility. Atmosphere 2022, 13, 241. https://doi.org/10.3390/atmos13020241

Razy-Yanuv E, Barak Y, Noam O, Madar D. Marine Air Pollution in Israel: Extent, Proposed Mitigation Targets, Benefits and Feasibility. Atmosphere. 2022; 13(2):241. https://doi.org/10.3390/atmos13020241

Chicago/Turabian StyleRazy-Yanuv, Eyal, Yogev Barak, Oran Noam, and Daniel Madar. 2022. "Marine Air Pollution in Israel: Extent, Proposed Mitigation Targets, Benefits and Feasibility" Atmosphere 13, no. 2: 241. https://doi.org/10.3390/atmos13020241

APA StyleRazy-Yanuv, E., Barak, Y., Noam, O., & Madar, D. (2022). Marine Air Pollution in Israel: Extent, Proposed Mitigation Targets, Benefits and Feasibility. Atmosphere, 13(2), 241. https://doi.org/10.3390/atmos13020241