Gaseous Emissions from a Seagoing Ship under Different Operating Conditions in the Coastal Region of China

Abstract

1. Introduction

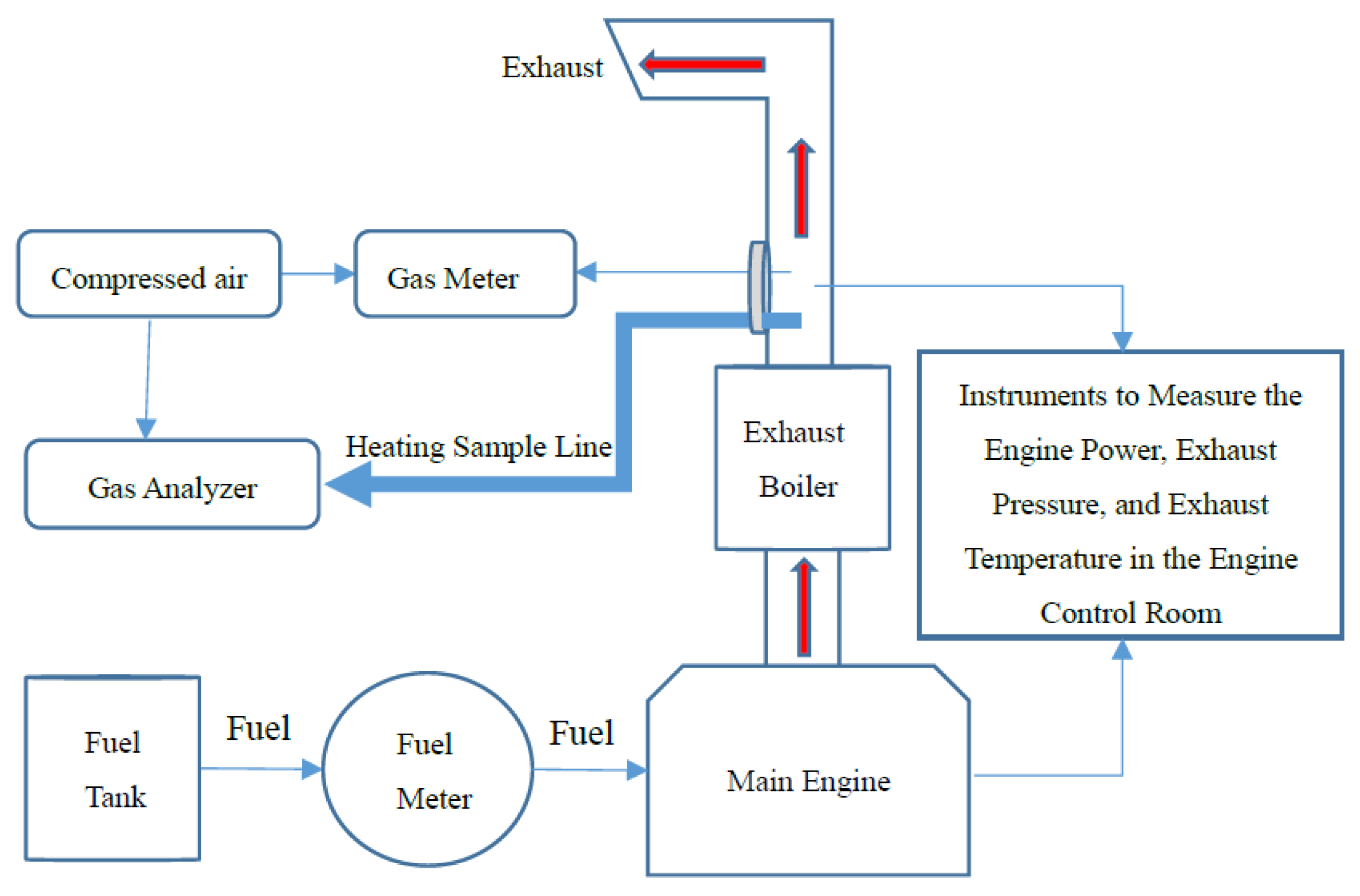

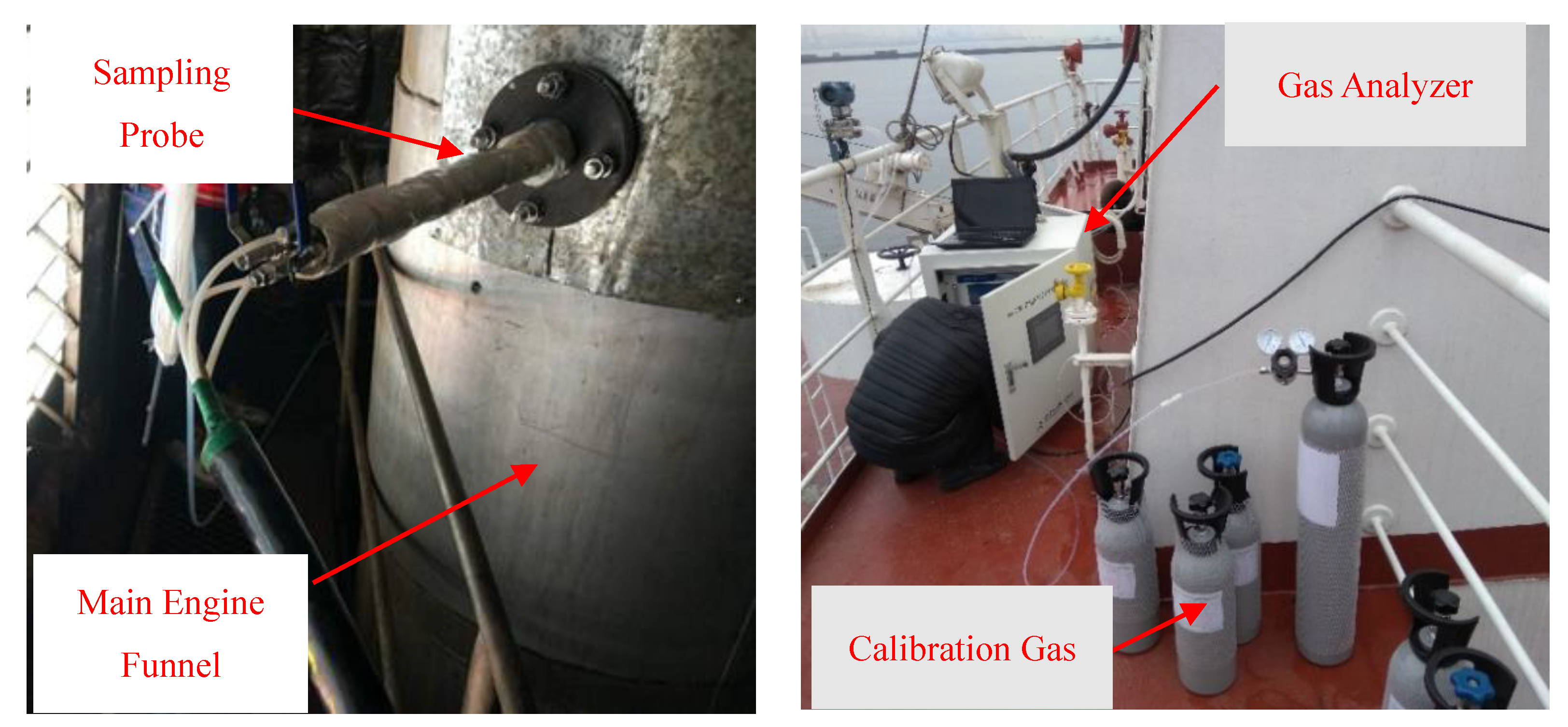

2. Experimental Section

2.1. Ship and Equipment

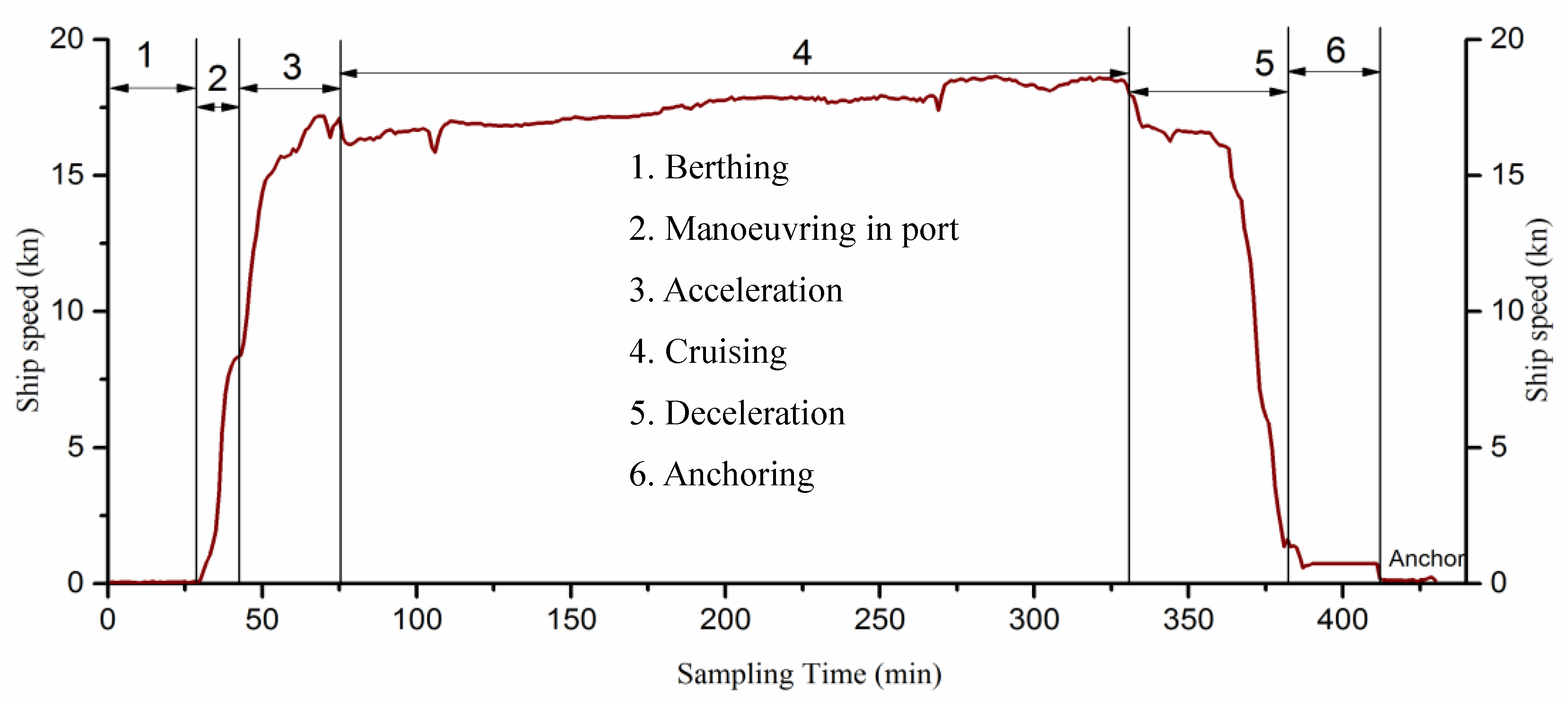

2.2. Data Collection and Processing

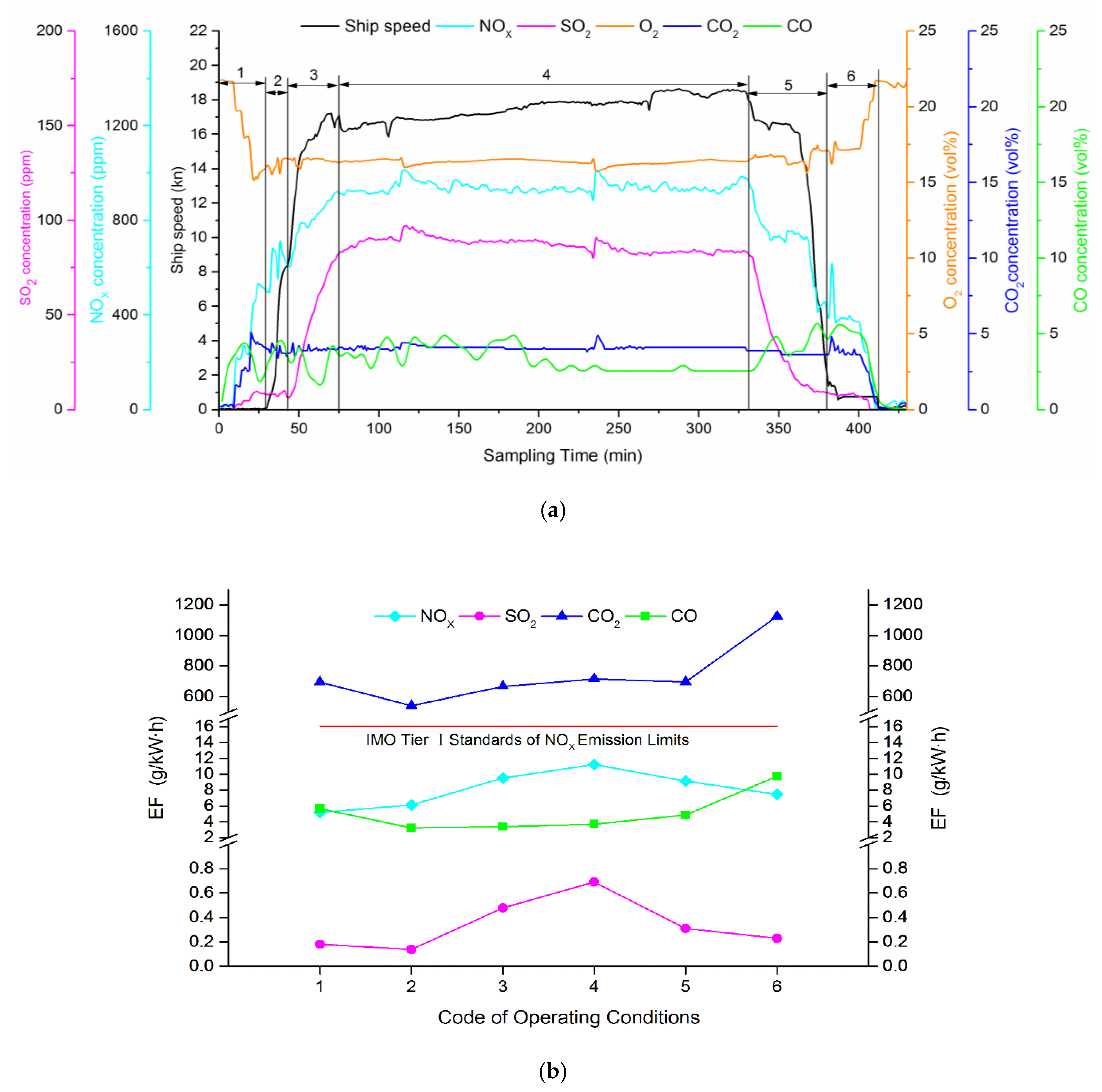

3. Results and Discussion

3.1. Gaseous Emissions

3.1.1. O2

3.1.2. NOX

3.1.3. SO2

3.1.4. CO2

3.1.5. CO

3.2. Comparison and Analysis of Gaseous Emissions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eyring, V.; Isaksen, I.S.A.; Berntsen, T.; Collins, W.J.; Corbett, J.J.; Endresen, O.; Grainger, R.G.; Moldanova, J.; Schlager, H.; Stevenson, D.S. Transport impacts on atmosphere and climate: Shipping. Atmos. Environ. 2010, 44, 4735–4771. [Google Scholar] [CrossRef]

- Shang, F.; Chen, D.; Guo, X.; Lang, J.; Zhou, Y.; Li, Y.; Fu, X. Impact of Sea Breeze Circulation on the Transport of Ship Emissions in Tangshan Port, China. Atmosphere 2019, 10, 723. [Google Scholar] [CrossRef]

- Merico, E.; Dinoi, A.; Contini, D. Development of an integrated modelling-measurement system for near-real-time estimates of harbour activity impact to atmospheric pollution in coastal cities. Transp. Res. Part D Transp. Environ. 2019, 73, 108–119. [Google Scholar] [CrossRef]

- Lauer, A.; Eyring, V.; Hendricks, J.; Jockel, P.; Lohmann, U. Global model simulations of the impact of ocean-going ships on aerosols, clouds, and the radiation budget. Atmos. Chem. Phys. 2007, 7, 5061–5079. [Google Scholar] [CrossRef]

- IMO. Annex VI of Marpol 73/78—Regulations for the Prevention of Air Pollution from Ships; IMO: London, UK, 1997. [Google Scholar]

- Chu Van, T.; Zare, A.; Jafari, M.; Bodisco, T.A.; Surawski, N.; Verma, P.; Suara, K.; Ristovski, Z.; Rainey, T.; Stevanovic, S.; et al. Effect of cold start on engine performance and emissions from diesel engines using IMO-Compliant distillate fuels. Environ. Pollut. 2019, 255, 113260. [Google Scholar] [CrossRef]

- Cheng, Y.L.; Wang, S.S.; Zhu, J.; Guo, Y.L.; Zhang, R.F.; Liu, Y.M.; Zhang, Y.; Yu, Q.; Ma, W.C.; Zhou, B. Surveillance of SO2 and NO2 from ship emissions by MAX-DOAS measurements and the implications regarding fuel sulfur content compliance. Atmos. Chem. Phys. 2019, 19, 13611–13626. [Google Scholar] [CrossRef]

- MOT. Implementation Scheme of the Domestic Emission Control Areas for Atmospheric Pollution from Vessels; MOT, Ed.; MOT: Beijing, China, 2018. [Google Scholar]

- Wan, Z.; Zhang, Q.; Xu, Z.; Chen, J.; Wang, Q. Impact of emission control areas on atmospheric pollutant emissions from major ocean-going ships entering the Shanghai Port, China. Mar. Pollut. Bull. 2019, 142, 525–532. [Google Scholar] [CrossRef]

- Kowalski, J. An experimental study of emission and combustion characteristics of marine diesel engine with fuel pump malfunctions. Appl. Therm. Eng. 2014, 65, 469–476. [Google Scholar] [CrossRef]

- Kowalski, J. An Experimental Study of Emission and Combustion Characteristics of Marine Diesel Engine with Fuel Injector Malfunctions. Pol. Marit. Res. 2016, 23, 77–84. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Tan, Q.M.; Geng, P. Combustion and emissions investigation on low-speed two-stroke marine diesel engine with low sulfur diesel fuel. Pol. Marit. Res. 2019, 26, 153–161. [Google Scholar] [CrossRef]

- Chu Van, T.; Rainey, T.; Ristovski, Z.; Pourkhesalian, A.; Garaniya, V.; Abbassi, R.; Yang, L.; Brown, R. Emissions from a Marine Auxiliary Diesel Engine at Berth Using Heavy Fuel Oil. In Proceedings of the 10th Australasian Heat and Mass Transfer Conference: Selected, Peer Reviewed Papers, Brisbane, Australia, 14–15 July 2016. [Google Scholar]

- Winnes, H.; Fridell, E. Emissions of NOX and particles from manoeuvring ships. Transp. Res. Part D Transp. Environ. 2010, 15, 204–211. [Google Scholar] [CrossRef]

- Cooper, D.A. Exhaust emissions from ships at berth. Atmos. Environ. 2003, 37, 3817–3830. [Google Scholar] [CrossRef]

- Winnes, H.; Fridell, E. Particle emissions from ships: Dependence on fuel type. J. Air Waste Manag. Assoc. 2009, 59, 1391–1398. [Google Scholar] [CrossRef] [PubMed]

- Winnes, H.; Moldanova, J.; Anderson, M.; Fridell, E. On-board measurements of particle emissions from marine engines using fuels with different sulphur content. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 45–54. [Google Scholar] [CrossRef]

- Fridell, E.; Salo, K. Measurements of abatement of particles and exhaust gases in a marine gas scrubber. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 154–162. [Google Scholar] [CrossRef]

- Moldanova, J.; Fridell, E.; Popovicheva, O.; Demirdjian, B.; Tishkova, V.; Faccinetto, A.; Focsa, C. Characterisation of particulate matter and gaseous emissions from a large ship diesel engine. Atmos. Environ. 2009, 43, 2632–2641. [Google Scholar] [CrossRef]

- Fu, M.L.; Ding, Y.; Ge, Y.S.; Yu, L.X.; Yin, H.; Ye, W.T.; Liang, B. Real-world emissions of inland ships on the Grand Canal, China. Atmos. Environ. 2013, 81, 222–229. [Google Scholar] [CrossRef]

- Yin, H.; Ding, Y.; Ge, Y.-S.; Ye, W.-T.; Wang, J.-F.; Bai, T.; Qian, L.-Y. Emissions characteristics of diesel engines for inland waterway vessels in China. Res. Environ. Sci. 2014, 27, 470–476. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, Y.; Tan, J.; Fu, M.; Shah, A.N.; Li, L.; Ji, Z.; Ding, Y. Emission characteristics of offshore fishing ships in the Yellow Bo Sea, China. J. Environ. Sci. (China) 2018, 65, 83–91. [Google Scholar] [CrossRef]

- Huang, C.; Hu, Q.; Wang, H.; Qiao, L.; Jing, S.; Wang, H.; Zhou, M.; Zhu, S.; Ma, Y.; Lou, S.; et al. Emission factors of particulate and gaseous compounds from a large cargo vessel operated under real-world conditions. Environ. Pollut. 2018, 242, 667–674. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Y.; Tian, C.; Lou, D.; Li, J.; Zhang, G.; Matthias, V. Emission factors for gaseous and particulate pollutants from offshore diesel engine vessels in China. Atmos. Chem. Phys. 2016, 16, 6319–6334. [Google Scholar] [CrossRef]

- Wang, C.; Hao, L.; Ma, D.; Ding, Y.; Lv, L.; Zhang, M.; Wang, H.; Tan, J.; Wang, X.; Ge, Y. Analysis of ship emission characteristics under real-world conditions in China. Ocean Eng. 2019, 194. [Google Scholar] [CrossRef]

- Chu-Van, T.; Ristovski, Z.; Pourkhesalian, A.M.; Rainey, T.; Garaniya, V.; Abbassi, R.; Jahangiri, S.; Enshaei, H.; Kam, U.S.; Kimball, R.; et al. On-board measurements of particle and gaseous emissions from a large cargo vessel at different operating conditions. Environ. Pollut. 2018, 237, 832–841. [Google Scholar] [CrossRef] [PubMed]

- Cooper, D.; Gustafsson, T. Methodology for Calculating Emissions from Ships: 1. Update of Emission Factors; Swedish Methodology for Environmental Data: Uppsala, Sweden, 2004. [Google Scholar]

- UNCTAD. Review of Maritime Transport 2018; United Nations Conference on Trade and Development: New York, NY, USA, 2018. [Google Scholar]

- MOT. Domestic Coastal Cargo Ship Capacity Analysis Report in 2018; Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- Cao, Y.-L.; Wang, X.; Yin, C.-Q.; Xu, W.-W.; Shi, W.; Qian, G.-R.; Xun, Z.-M. Inland Vessels Emission Inventory and the emission characteristics of the Beijing-Hangzhou Grand Canal in Jiangsu province. Process. Saf. Environ. Prot. 2018, 113, 498–506. [Google Scholar] [CrossRef]

- Sun, X.; Tian, Z.; Malekian, R.; Li, Z.X. Estimation of Vessel Emissions Inventory in Qingdao Port Based on Big Data Analysis. Symmetry 2018, 10, 452. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Brown, R.; Yang, L.; Morawska, L.; Ristovski, Z.; Fu, Q.; Huang, C. Shipping emissions and their impacts on air quality in China. Sci. Total Environ. 2017, 581, 186–198. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Y.; Ma, W.; Ma, H.; Feng, J.; Yu, Q.; Yang, X.; Ng, S.; Fu, Q.; Chen, L. Spatial and Seasonal Dynamics of Ship Emissions over the Yangtze River Delta and East China Sea and Their Potential Environmental Influence. Environ. Sci. Technol. 2015, 50. [Google Scholar] [CrossRef]

- IMO. Amendments to the Annex of the Protocol of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from Ships, 1973, As Modified by the Protocol of 1978 Relating Thereto, MEPC 58/23/Add.1 ed.; International Maritime Organization: London, UK, 2008. [Google Scholar]

- ISO. ISO 8178-2 Reciprocating Internal Combustion Engines—Exhaust Emission Measurement. In Part 2: Measurement of Gaseous and Particulate Exhaust Emissions under Field Conditions; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Entec. Quantification of Emissions from Ships Associated with Ship Movements Between Ports in the European Community; European Commission: Brussel, Belgium, 2002. [Google Scholar]

- IMO. Third IMO GHG Study 2014; International Maritime Organization: London, UK, 2014. [Google Scholar]

- IMO. Second IMO GHG Study 2009; International Maritime Organization: London, UK, 2009. [Google Scholar]

- Nunes, R.A.O.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. The activity-based methodology to assess ship emissions—A review. Environ. Pollut. 2017, 231, 87–103. [Google Scholar] [CrossRef]

| Tier | Total Weighted Cycle Emission Limit (g/kWh) n = engine’s rated speed (rpm) | ||

|---|---|---|---|

| n < 130 | 130 ≤ n < 2000 | n ≥ 2000 | |

| Tier I standards | 17.0 | 45·n−0.2 | 9.8 |

| Tier II standards | 14.4 | 44·n−0.23 | 7.7 |

| Tier III standards | 3.4 | 9·n−0.2 | 2.0 |

| Area | Compliance Date (Year. Month) | Sulfur Limit in Fuel (m/m) | NOX Emission Limit | |

|---|---|---|---|---|

| Global | 2000.01 | 4.5% | Tier I standards | |

| 2011.01 | - | Tier II standards | ||

| 2012.01 | 3.5% | - | ||

| 2020.01 | 0.5% | - | ||

| Emission Control Areas | 2000.01 | 1.5% | - | |

| 2010.07 | 1.0% | - | ||

| 2015.01 | 0.1% | - | ||

| 2016.01 | - | Tier III standards | ||

| China (Domestic Emission Control Areas) | Coastal Control Areas | 2015.03 | - | Tier II standards * |

| 2019.01 | 0.5% | - | ||

| 2022.01 (Hainan waters) | 0.1% | Tier III standards * | ||

| 2025.01 (Assessed) | 0.1% | Tier III standards * | ||

| Inland River Control Areas | 2015.03 | - | Tier II standards * | |

| 2019.01 | 0.5% | - | ||

| 2020.01 | 0.1% | - | ||

| 2022.01 | - | Tier III standards * | ||

| Ship Specifications | Particulars |

|---|---|

| Build year | 2006 |

| Gross tonnage | 6106 |

| Length | 116.00 m |

| Breadth | 18.00 m |

| Draft | 5.40 m |

| Main engine type | MAN B&W 6S35MC-C |

| Maximum continuous power of main engine | 4440 kW |

| Maximum engine’s rated speed | 173 r/min |

| Fuel consumption rate | 186.7 g/kW·h |

| Maximum design speed | 17.2 kn |

| Sulfur content of the fuel | 0.02% (m/m) and 0.437% (m/m) |

| Study | Ship Type/Main Engine Power (kW) | Operating Condition | Sulfur % (m/m) | EFs (g/kW·h) | |||

|---|---|---|---|---|---|---|---|

| NOX | SO2 | CO2 | CO | ||||

| This study | Special-purpose ship/4440 | Berthing | 0.02 | 5.19 | 0.18 | 694.25 | 5.66 |

| Manoeuvring in port | 6.12 | 0.14 | 540.91 | 3.25 | |||

| Acceleration | 0.02/0.437 * | 9.53 | 0.48 | 665.81 | 3.37 | ||

| Cruising | 0.437 | 11.23 | 0.69 | 715.22 | 3.70 | ||

| Deceleration | 0.437/0.02 * | 9.13 | 0.31 | 695.42 | 4.88 | ||

| Anchoring | 0.02 | 7.47 | 0.23 | 1124.51 | 9.74 | ||

| Huang et al. (2018) [23] | Bulk carrier/7948 | Departure Main Engine load (0%–50%) | 1.12 | 10.50 | - | 722.75 | 3.35 |

| Cruising Main Engine load (74%) | 7.73 | - | 607.39 | 2.09 | |||

| Arrival Main Engine load (50%–0%) | 15.05 | - | 601.7 | 6.78 | |||

| Zhang et al. (2015) [24] | Engineering vessel/700 | - | 0.0798 | 23.9 | 0.36 | 635 | 6.92 |

| Research vessel/3200 | - | 0.0458 | 7.14 | 0.18 | 631 | 1.39 | |

| Research vessel/500 | - | 0.13 | 6.97 | 0.57 | 697 | 2.01 | |

| Cooper (2004) [27] | - | Manoeuvring | 0.4 | 13.6 | - | 647 | 1 |

| Cruising | 17.0 | - | 588 | 0.5 | |||

| Entec (2002) [36] | - | Manoeuvring (in port) | 0.5 | 13.6 | 1.0 | 647 | - |

| Cruising | 17.0 | 0.9 | 588 | - | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, C.; Li, Y.; Liu, B.; Zhang, Z.; Wu, P. Gaseous Emissions from a Seagoing Ship under Different Operating Conditions in the Coastal Region of China. Atmosphere 2020, 11, 305. https://doi.org/10.3390/atmos11030305

Bai C, Li Y, Liu B, Zhang Z, Wu P. Gaseous Emissions from a Seagoing Ship under Different Operating Conditions in the Coastal Region of China. Atmosphere. 2020; 11(3):305. https://doi.org/10.3390/atmos11030305

Chicago/Turabian StyleBai, Chunjiang, Ying Li, Bingxin Liu, Zhaoyi Zhang, and Peng Wu. 2020. "Gaseous Emissions from a Seagoing Ship under Different Operating Conditions in the Coastal Region of China" Atmosphere 11, no. 3: 305. https://doi.org/10.3390/atmos11030305

APA StyleBai, C., Li, Y., Liu, B., Zhang, Z., & Wu, P. (2020). Gaseous Emissions from a Seagoing Ship under Different Operating Conditions in the Coastal Region of China. Atmosphere, 11(3), 305. https://doi.org/10.3390/atmos11030305