Influence of Disc Temperature on Ultrafine, Fine, and Coarse Particle Emissions of Passenger Car Disc Brakes with Organic and Inorganic Pad Binder Materials

Abstract

1. Introduction

- 1.

- Is it possible to prevent nucleation processes or to increase the critical temperature by replacing organic compounds in the brake pad e.g., organic binder materials?

- 2.

- How does thermal decomposition processes of pad materials influence the reproducibility of nucleation events?

- 3.

- How can the influence of disc temperature on PM10 emissions be quantified on a full-scale dynamometer setup?

- 4.

- How does thermal decomposition processes of pad materials affect the temperature dependency of PM10 emissions?

- 5.

- How does thermal decomposition processes of pad materials influence the reproducibility of the measurement of emission maps for PM10 depending on temperature?

2. Methodology

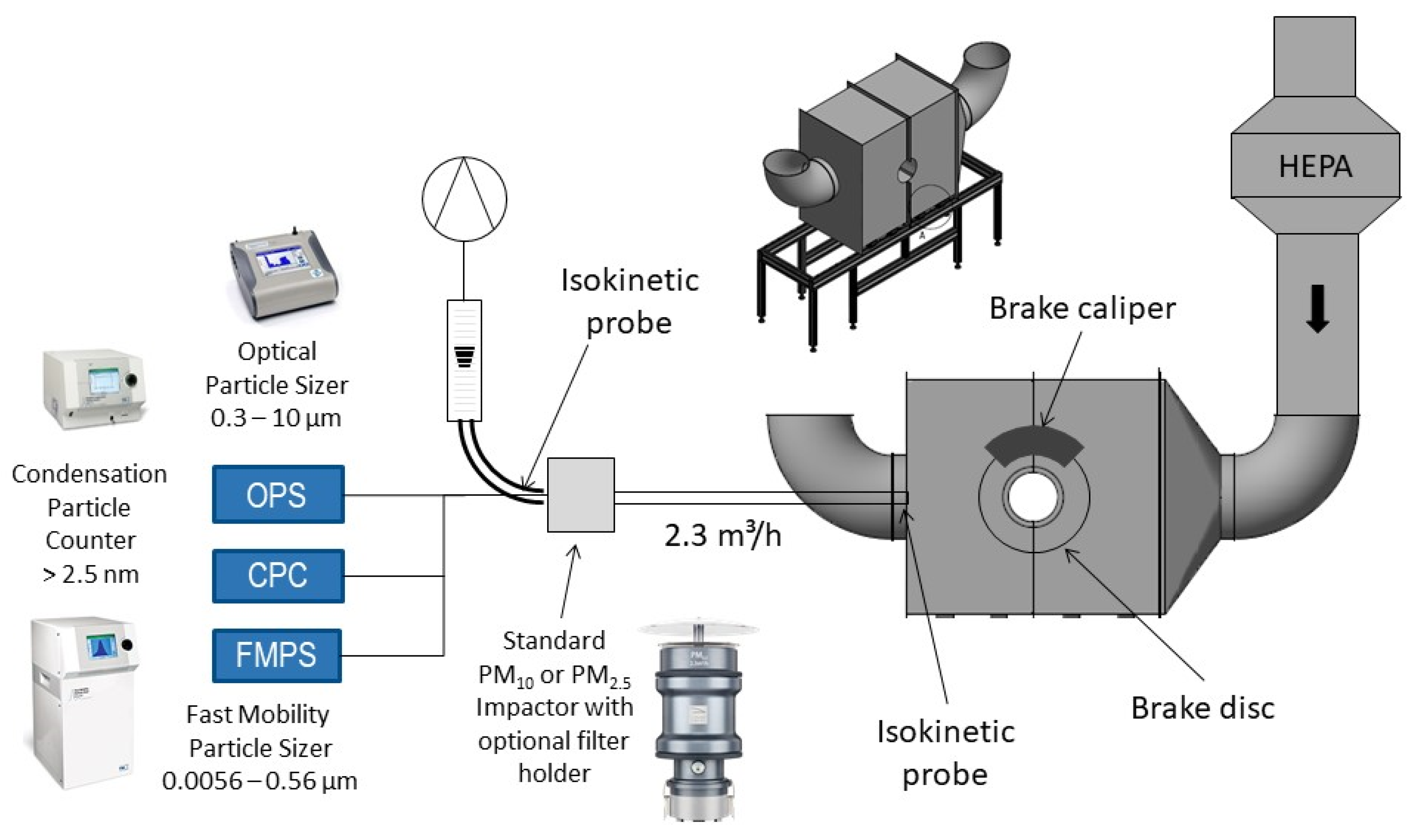

2.1. Experimental Setup

- Serial ECE pad material (FER8104) with a conventional organic phenolic resin binder

- Prototypical pads with an inorganic binder based on a silicate, which is thermally stable up to 800 °C

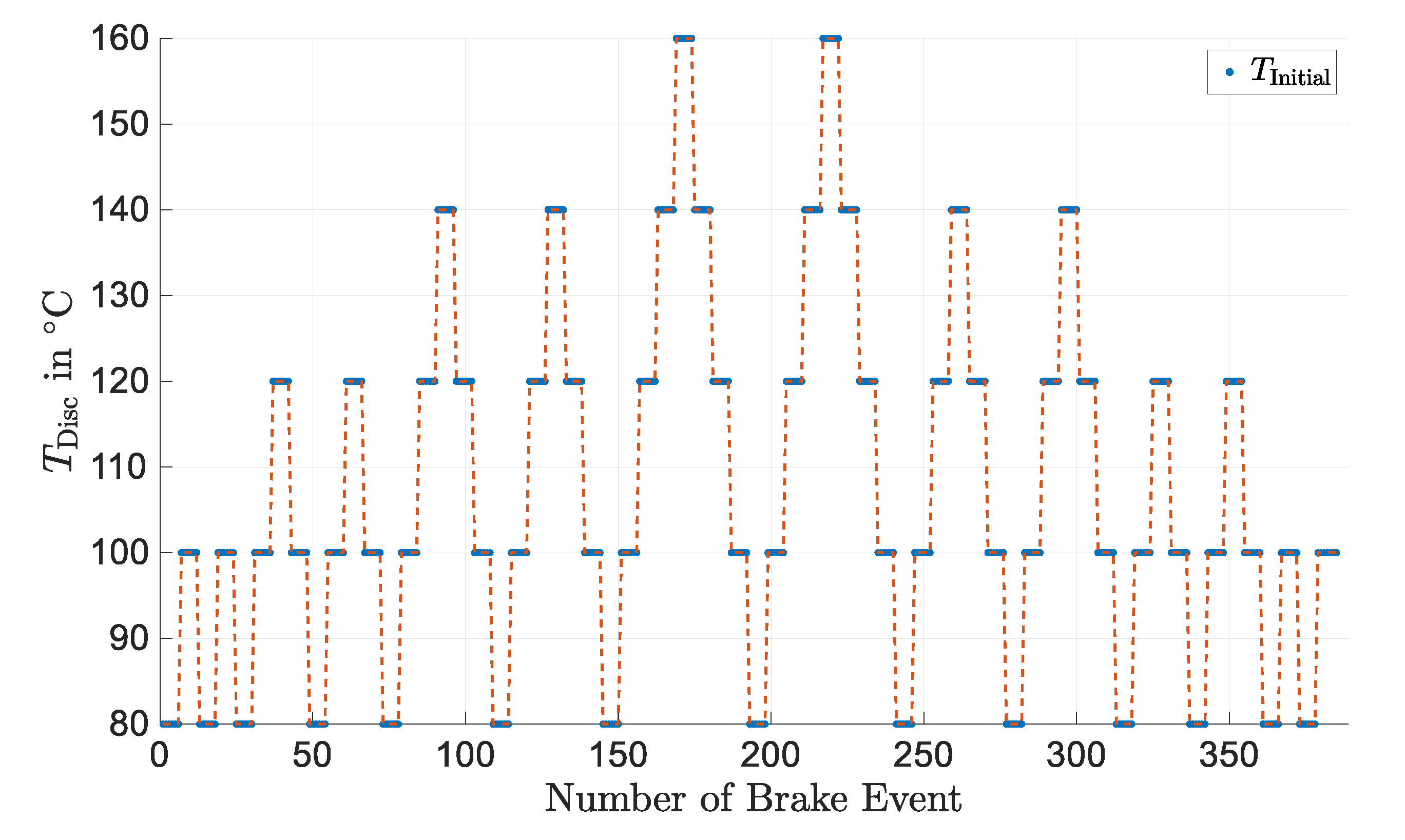

2.2. Ultrafine Particles (Research Questions 1 & 2)

2.3. Fine and Coarse Particles (PM10) (Research Questions 3, 4, & 5)

3. Results

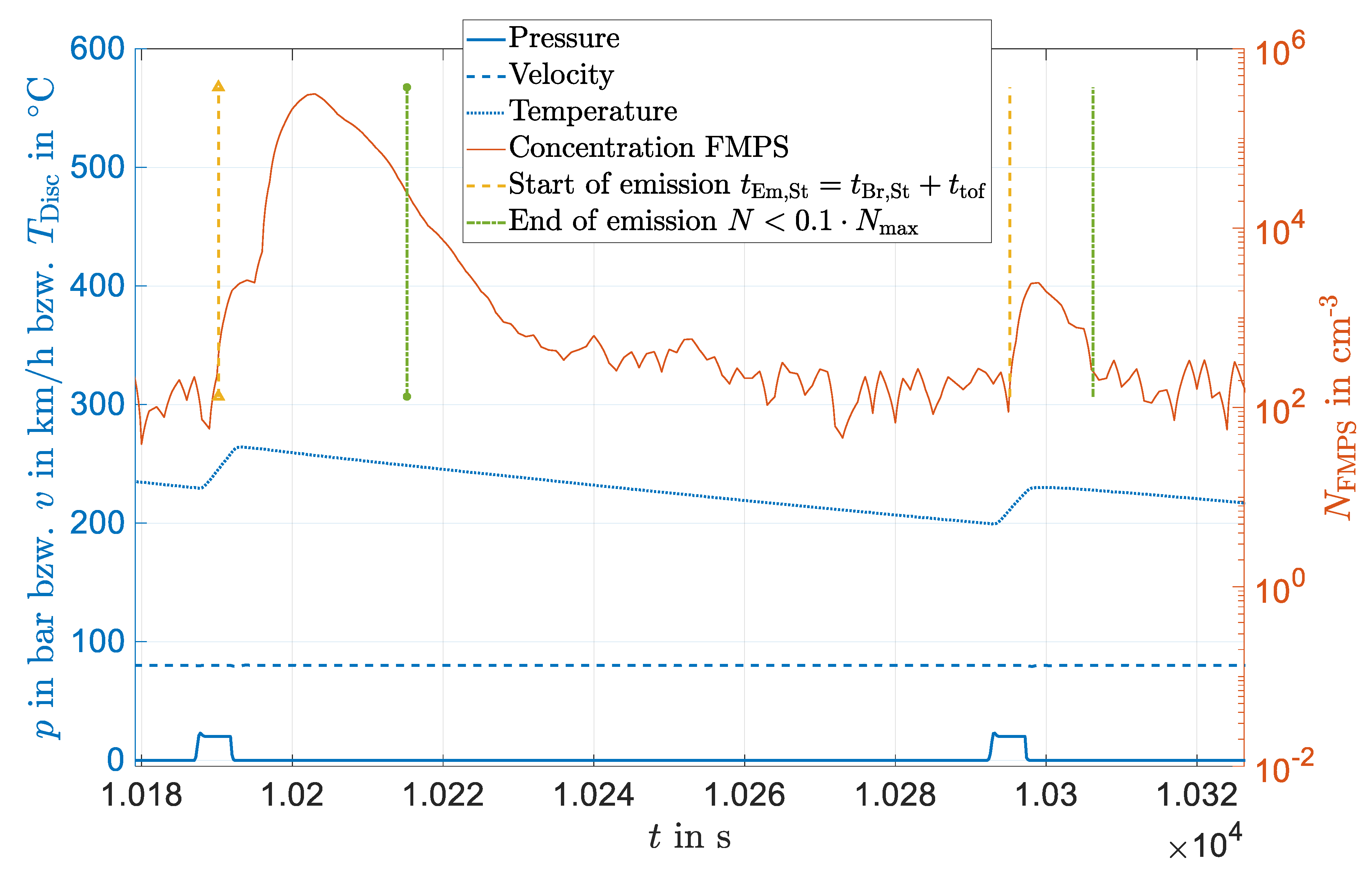

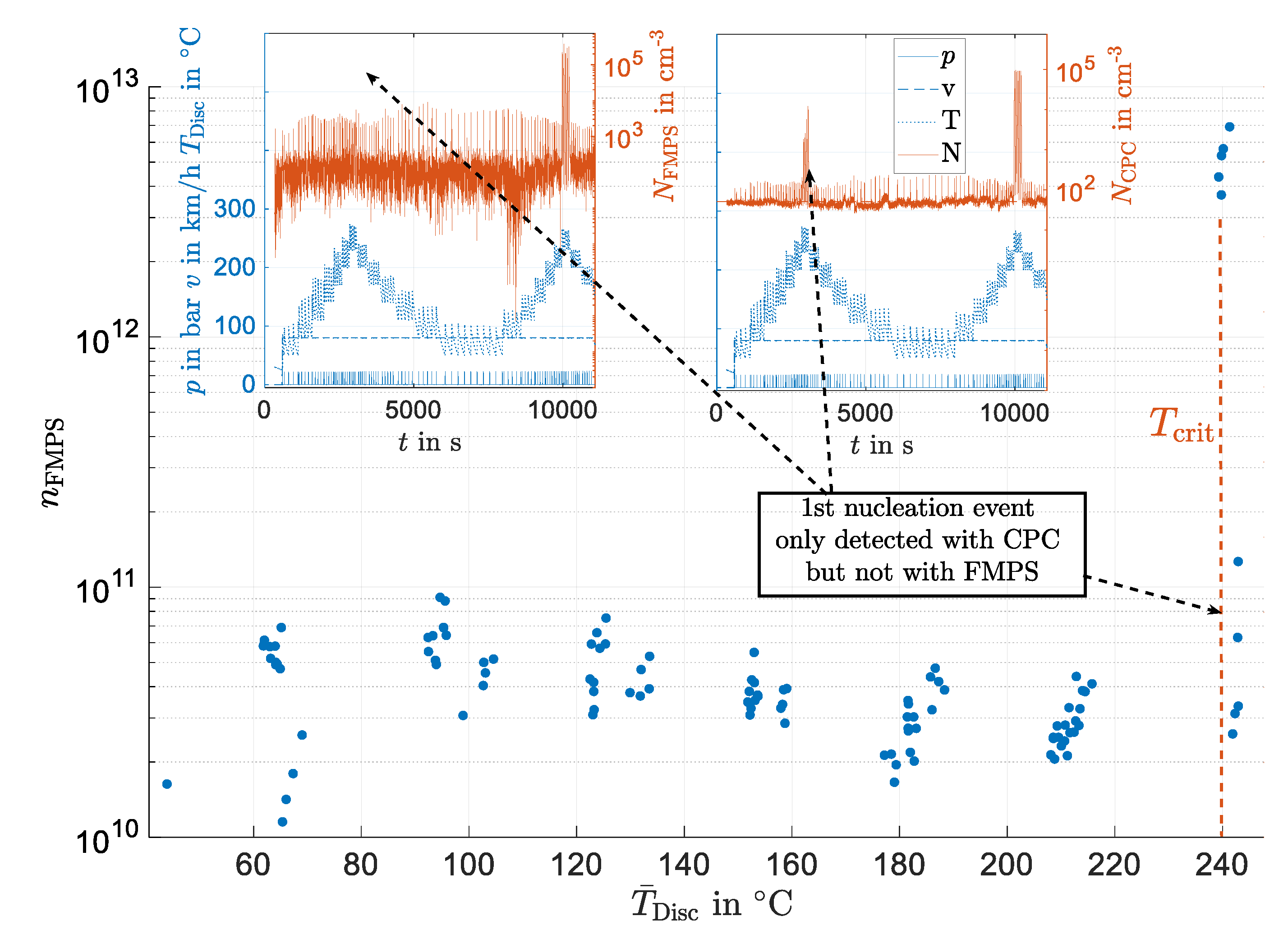

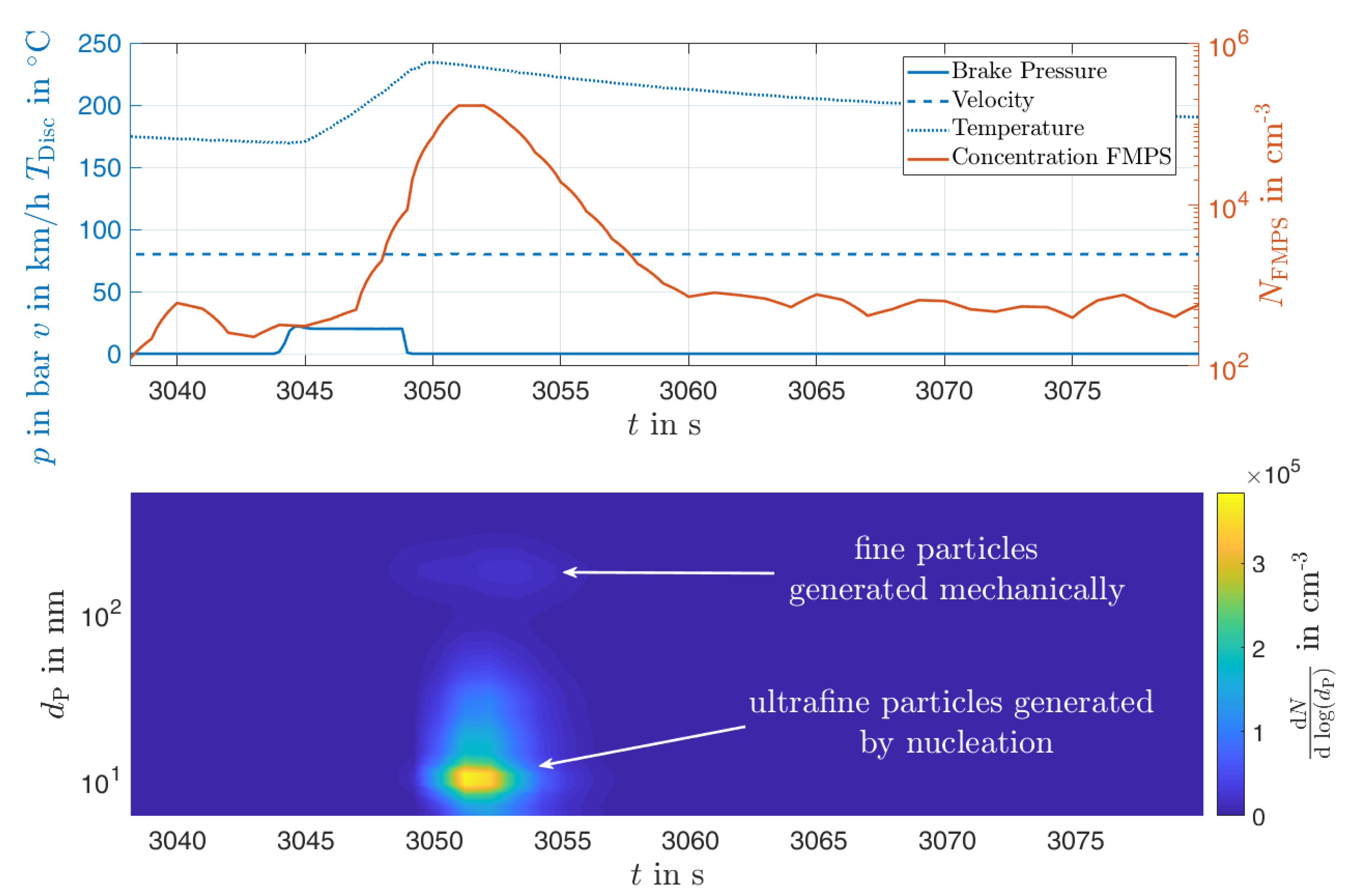

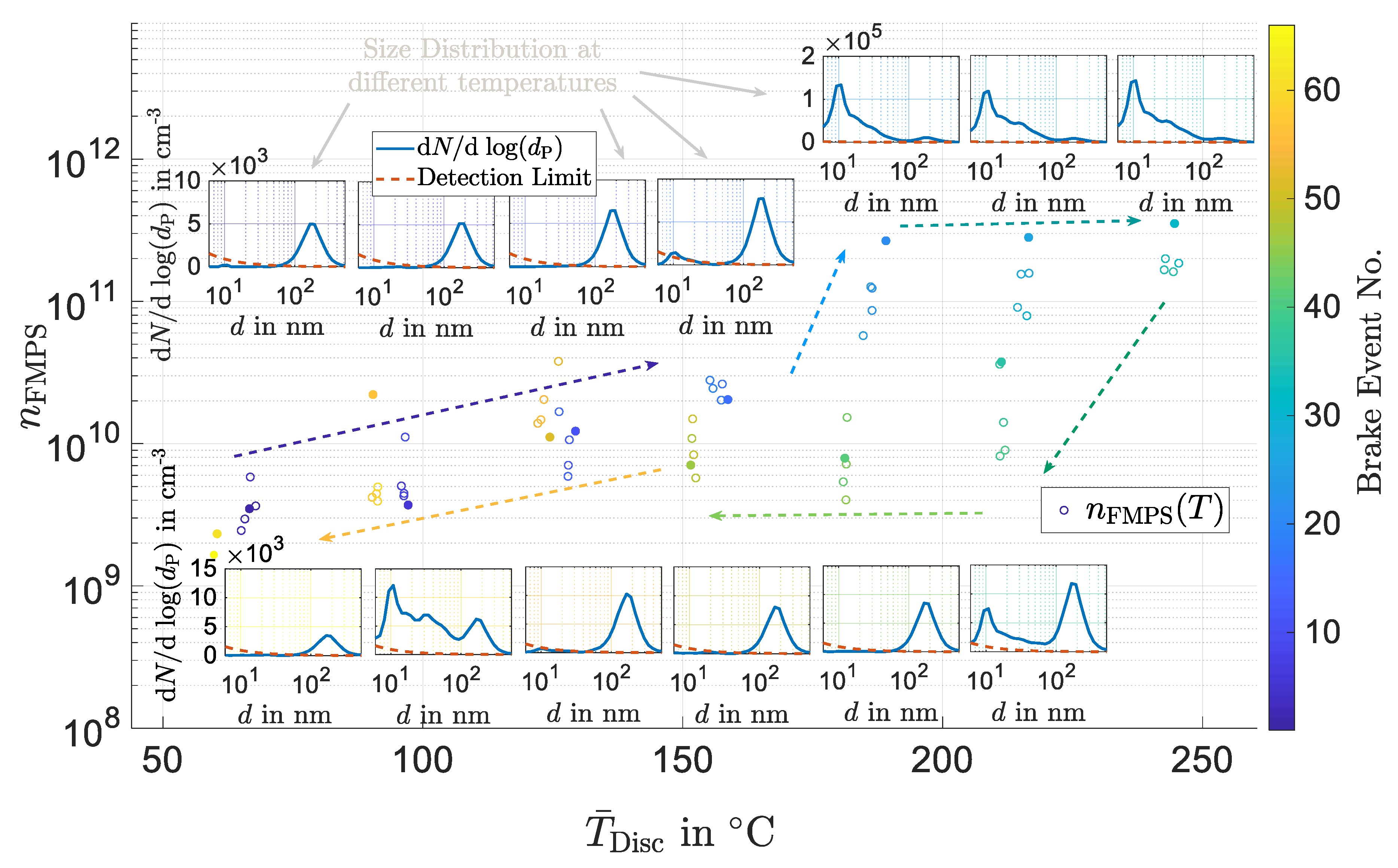

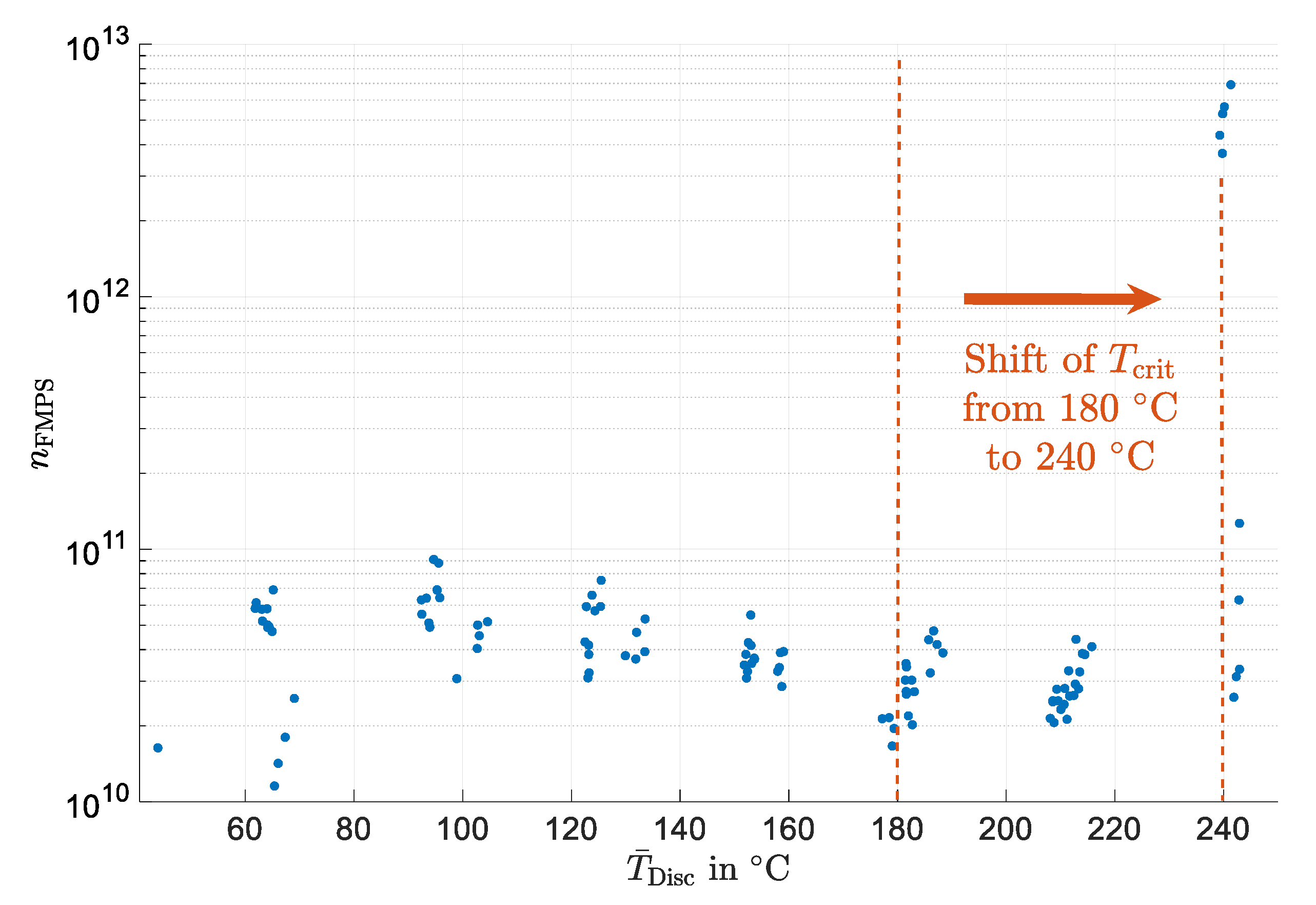

3.1. Ultrafine Particles

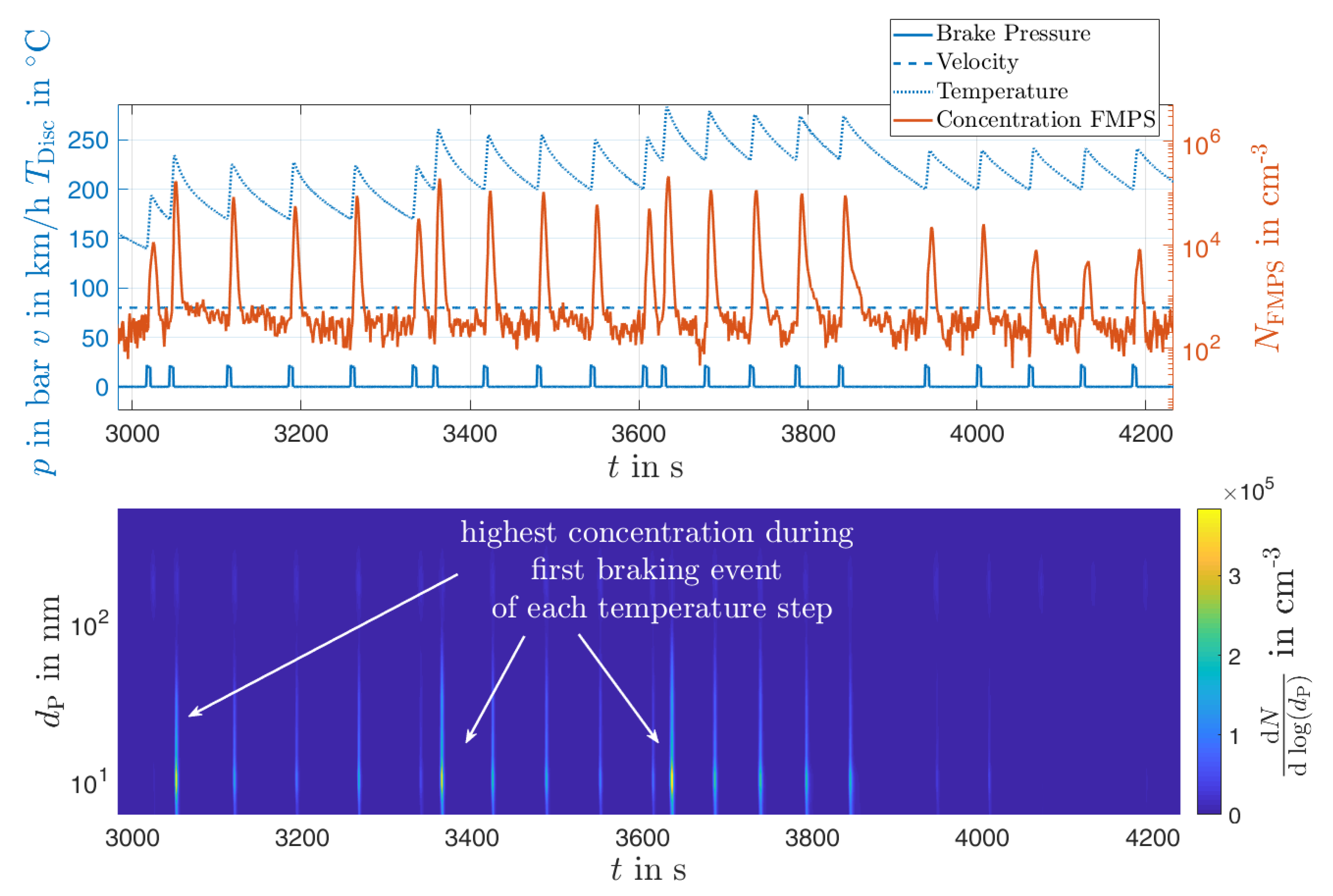

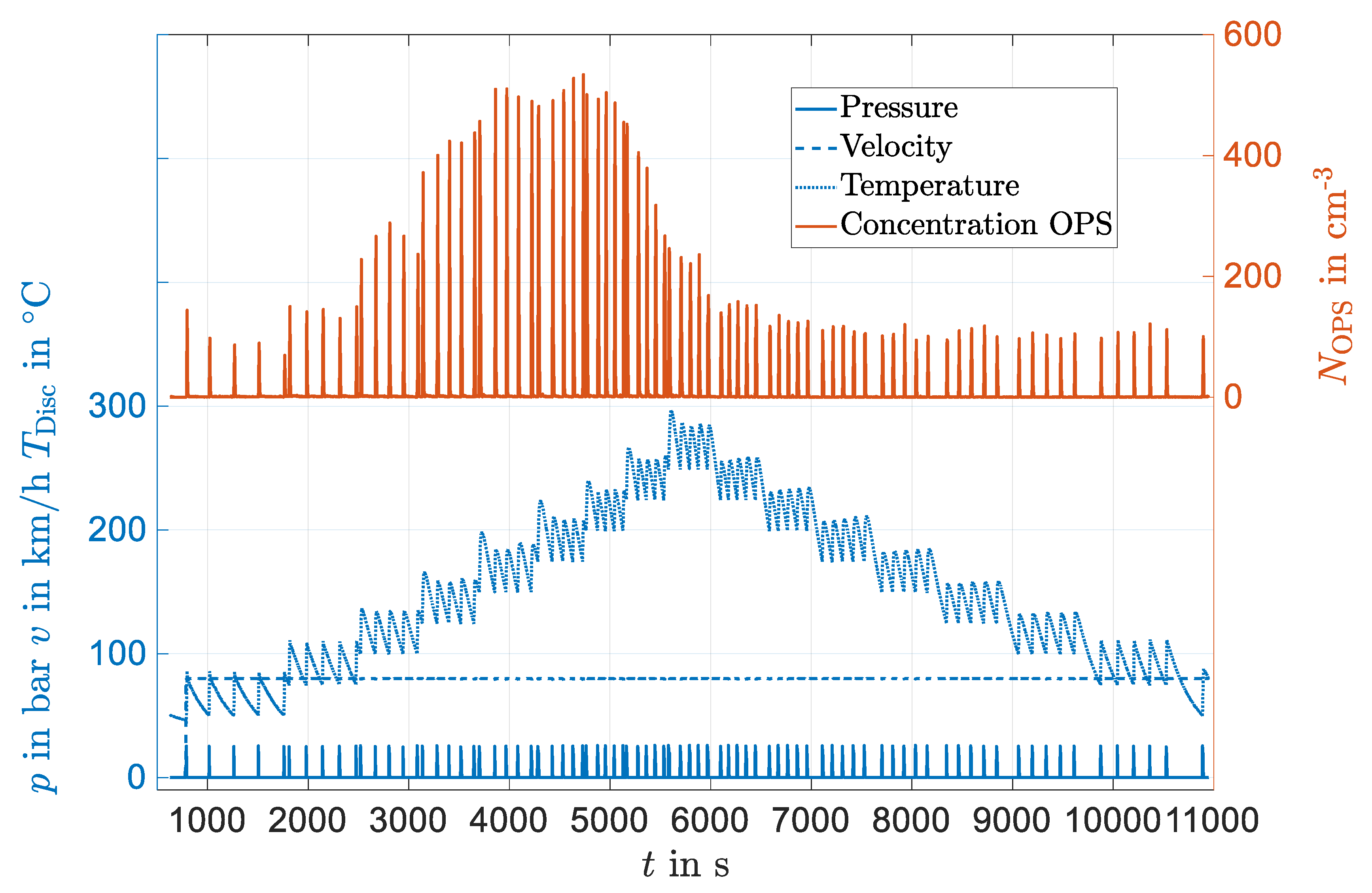

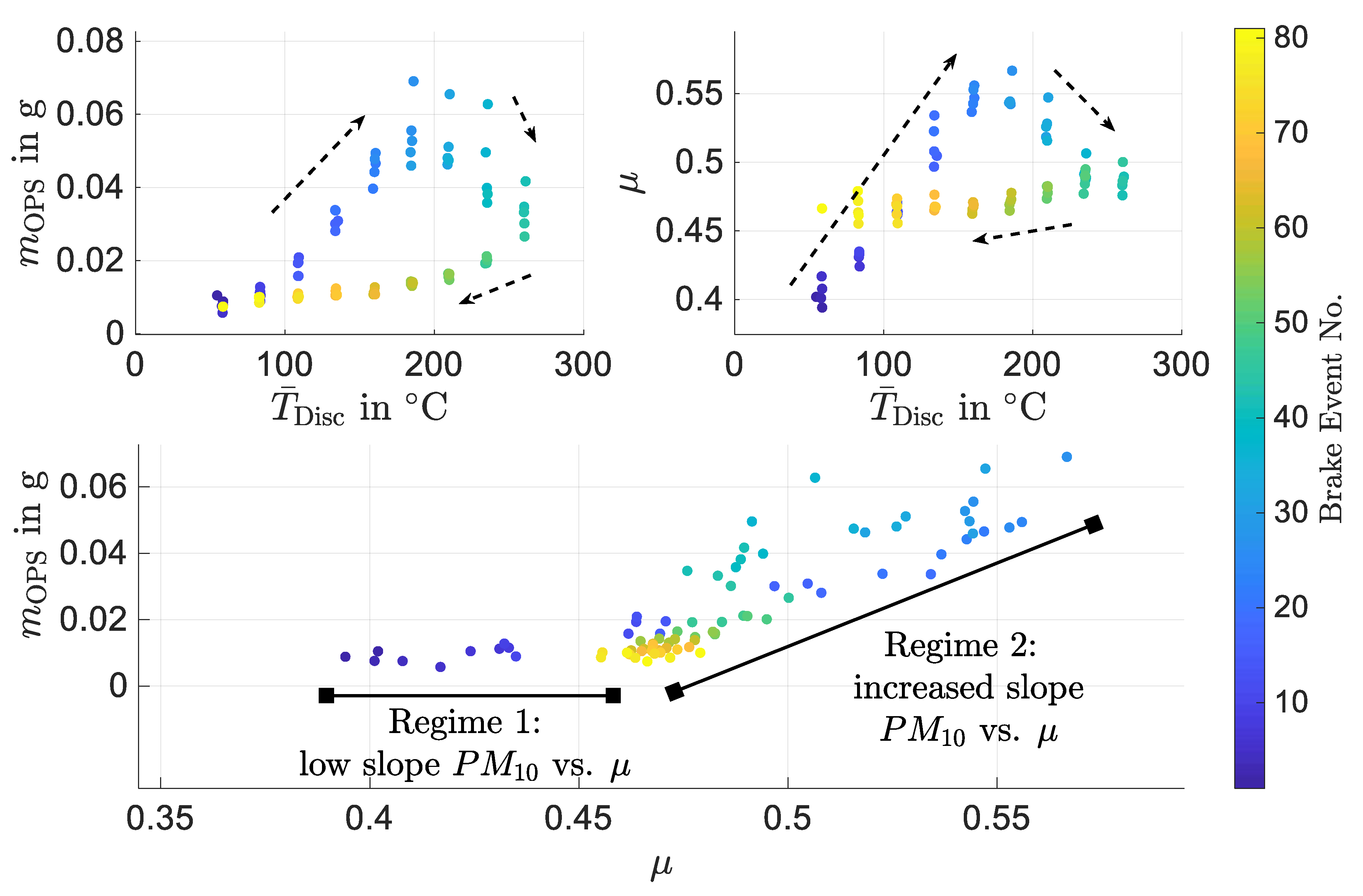

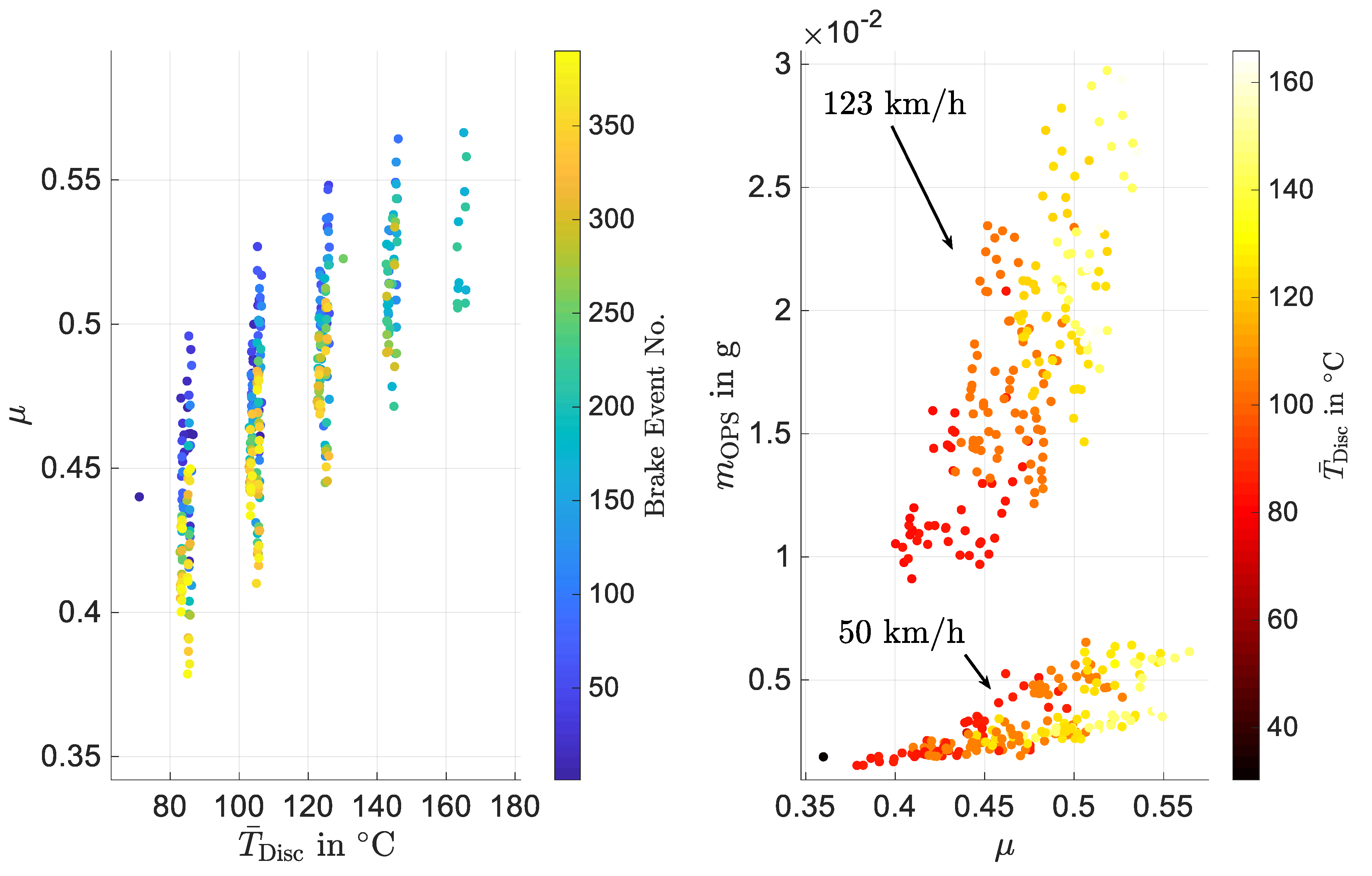

3.2. Fine and Coarse Particles (Part 1: Single Triangle Test Signal)

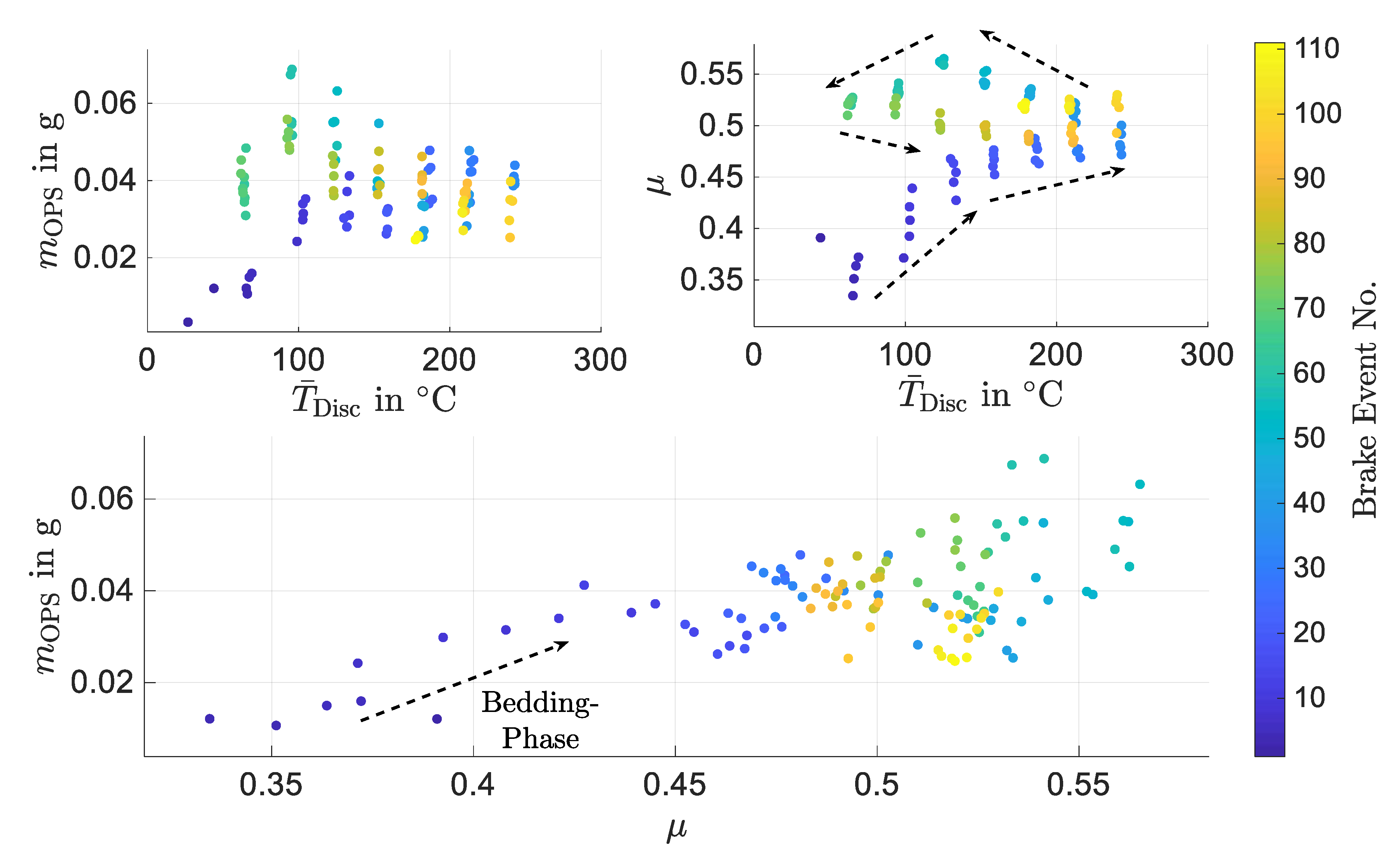

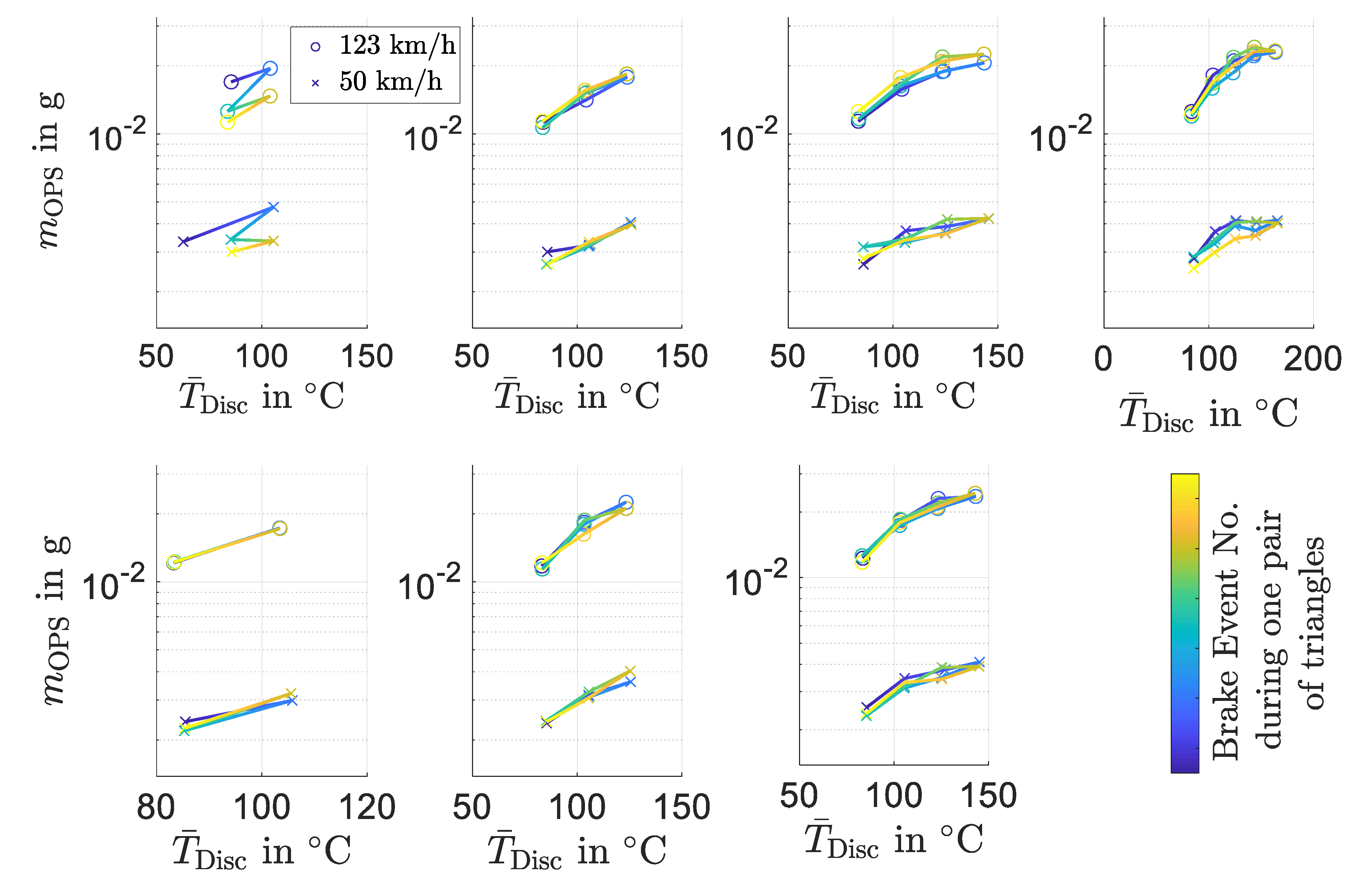

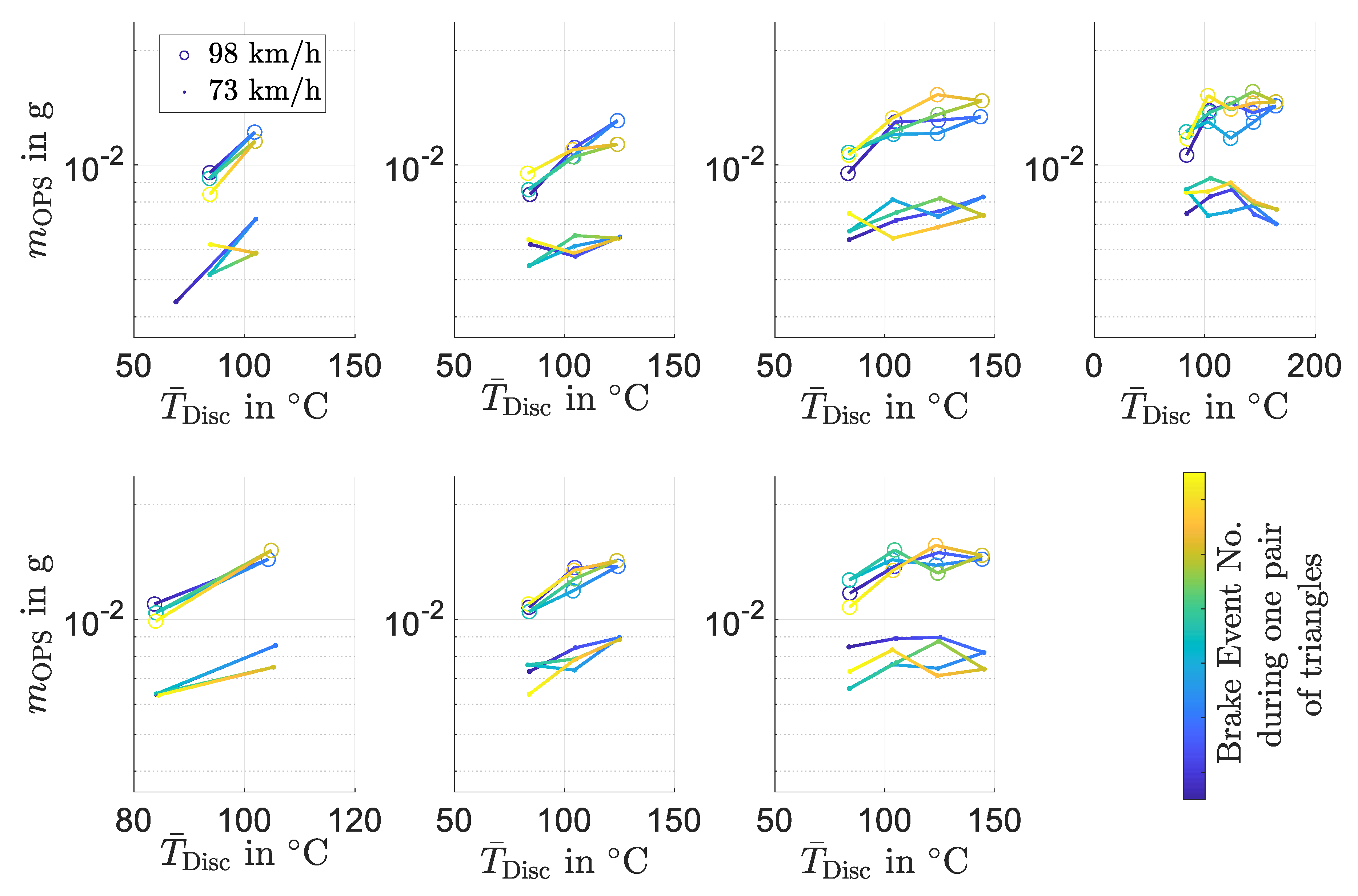

3.3. Fine and Coarse Particles (Part 2: Multiple Triangle Test Signals)

4. Discussion

5. Conclusions

5.1. Ultrafine Particles

5.2. Fine and Coarse Particles/PM10 Emission

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. Int. 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [PubMed]

- Zum Hagen, F.H.F.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. Study of Brake Wear Particle Emissions: Impact of Braking and Cruising Conditions. Environ. Sci. Technol. 2019, 53, 5143–5150. [Google Scholar] [CrossRef] [PubMed]

- Asbach, C.; Todea, M.A.; Zessinger, M.; Kaminski, H.; Mayer, R. Entstehung und Möglichkeiten zur Messung von Feinund Ultrafeinstaub beim Bremsen. In XXXVII. Internationales μ-Symposium 2018 Bremsen-Fachtagung; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Namgung, H.G.; Kim, J.B.; Woo, S.H.; Park, S.; Kim, M.; Kim, M.S.; Bae, G.N.; Park, D.; Kwon, S.B. Generation of Nanoparticles from Friction between Railway Brake Disks and Pads. Environ. Sci. Technol. 2016, 50, 3453–3461. [Google Scholar] [CrossRef] [PubMed]

- Ramousse, S.; Høj, J.W.; Sørensen, O.T. Thermal Characterisation of Brake Pads. J. Therm. Anal. Calorim. 2001, 64, 933–943. [Google Scholar] [CrossRef]

- Nosko, O.; Alemani, M.; Olofsson, U. Temperature effect on emission of airborne wear particles from car brakes. In Proceedings of the Europe’s Braking Conference and Exhibition, Dresden, Germany, 4–6 May 2015. [Google Scholar]

- Nosko, O.; Olofsson, U. Quantification of ultrafine airborne particulate matter generated by the wear of car brake materials. Wear 2017, 374, 92–96. [Google Scholar] [CrossRef]

- Nosko, O.; Vanhanen, J.; Olofsson, U. Emission of 1.3–10 nm airborne particles from brake materials. Aerosol Sci. Technol. 2017, 51, 91–96. [Google Scholar] [CrossRef]

- Alemani, M.; Wahlström, J.; Olofsson, U. On the influence of car brake system parameters on particulate matter emissions. Wear 2018, 396, 67–74. [Google Scholar] [CrossRef]

- Perricone, G.; Matějka, V.; Alemani, M.; Valota, G.; Bonfanti, A.; Ciotti, A.; Olofsson, U.; Söderberg, A.; Wahlström, J.; Nosko, O.; et al. A concept for reducing PM10 emissions for car brakes by 50%. Wear 2018, 396, 135–145. [Google Scholar] [CrossRef]

- Sachse, H. Untersuchungen zu geeigneten Messmethoden und Prüfverfahren für die Bewertung bremseninduzierter Emissionen. In Proceedings of the XXXVII Internationales µ-Symposium, Bad Neuenahr, Germany, 26 October 2018. [Google Scholar]

- Agudelo, C. Systematic assessment of the influence of test setup, test procedure and friction material on brake emissions during inertia dynamometer tests. In Proceedings of the Europe’s Braking Conference and Exhibition, Milan, Italy, 13–15 June 2016. [Google Scholar]

- Kukutschová, J.; Moravec, P.; Tomášek, V.; Matějka, V.; Smolík, J.; Schwarz, J.; Seidlerová, J.; Safářová, K.; Filip, P. On airborne nano/micro-sized wear particles released from low-metallic automotive brakes. Environ. Pollut. 2011, 159, 998–1006. [Google Scholar] [CrossRef] [PubMed]

- Zum Hagen, F.H.F. Investigation of Brake Wear Particle Emissions on the Dynamometer and the Vehicle under Real-Driving Simulation. Ph.D. Thesis, Bergische Universität, Wuppertal, Germany, 2019. Available online: https://doi.org/10.25926/f1j5-fp87 (accessed on 14 September 2020).

- Zum Hagen, F.H.F.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. On-road vehicle measurements of brake wear particle emissions. Atmos. Environ. 2019, 217, 116943. [Google Scholar] [CrossRef]

- Mathissen, M.; Grochowicz, J.; Schmidt, C.; Vogt, R.; zum Hagen, F.H.F.; Grabiec, T.; Steven, H.; Grigoratos, T. A novel real-world braking cycle for studying brake wear particle emissions. Wear 2018, 414, 219–226. [Google Scholar] [CrossRef]

- Niemann, H.; Winner, H.; Asbach, C.; Kaminski, H.; Zessinger, M. System Identification Method for Brake Particle Emission Measurements of Passenger Car Disc Brakes on a Dynamometer; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2018. [Google Scholar]

- Eriksson, M.; Bergman, F.; Jacobson, S. On the nature of tribological contact in automotive brakes. Wear 2002, 252, 26–36. [Google Scholar] [CrossRef]

- Ostermeyer, G.P.; Müller, M. Surface Topography and Wear Dynamics of Brake Pads. In SAE Technical Paper Series 2006-01-3202, 24th Annual Brake Colloquium & Exhibition; SAE: Warrendale, PA, USA, 2006. [Google Scholar]

- Ostermeyer, G.-P.; Wilkening, L. Experimental Investigations of the Topography Dynamics in Brake Pads. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 1398–1407. [Google Scholar] [CrossRef]

- UNECE. PMP Web Conference 20 May. Non-Exhaust Brake Emissions—Aboratory Testing—Part 1: Inertia Dynamometer Protocol to Measure and Characterise Brake Emissions Using the WLTP-Brake Cycle: INFORMAL DOCUMENT GRPE-81-XX. Available online: https://wiki.unece.org/display/trans/PMP+Web+Conference+20+May (accessed on 21 August 2020).

- Niemann, H.; Winner, H.; Asbach, C.; Kaminski, H.; Zessinger, M. Untersuchung des Partikelemissionsverhaltens von Scheibenbremsen unter Transienten Lasten; VDI-Bericht 2356. In Proceedings of the VDI-Fachtagung Reifen-Fahrwerk-Fahrbahn 2019, Hannover, Germany, 16–17 October 2019. [Google Scholar]

- Niemann, H.; Winner, H.; Asbach, C.; Kaminski, H.; Zessinger, M. Application of a sampling enclosure for the identification of the influencing parameters on brake wear particle emissions. In Proceedings of the European Aerosol Conference, Göteborg, Sweden, 25–30 August 2019. [Google Scholar]

- Niemann, H.; Winner, H.; Asbach, C.; Kaminski, H.; Zessinger, M.; Brandau, M. Map based simulation of brake wear particle emissions. In Proceedings of the EuroBrake, Barcelona, Spain, 2–4 June 2020. [Google Scholar] [CrossRef]

| Operating Point | Brake Torque M in Nm | Velocity v in km/h |

|---|---|---|

| 1 | 1120 | 50 |

| 2 | 753 | 74 |

| 3 | 568 | 98 |

| 4 | 455 | 123 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niemann, H.; Winner, H.; Asbach, C.; Kaminski, H.; Frentz, G.; Milczarek, R. Influence of Disc Temperature on Ultrafine, Fine, and Coarse Particle Emissions of Passenger Car Disc Brakes with Organic and Inorganic Pad Binder Materials. Atmosphere 2020, 11, 1060. https://doi.org/10.3390/atmos11101060

Niemann H, Winner H, Asbach C, Kaminski H, Frentz G, Milczarek R. Influence of Disc Temperature on Ultrafine, Fine, and Coarse Particle Emissions of Passenger Car Disc Brakes with Organic and Inorganic Pad Binder Materials. Atmosphere. 2020; 11(10):1060. https://doi.org/10.3390/atmos11101060

Chicago/Turabian StyleNiemann, Hartmut, Hermann Winner, Christof Asbach, Heinz Kaminski, Georg Frentz, and Roman Milczarek. 2020. "Influence of Disc Temperature on Ultrafine, Fine, and Coarse Particle Emissions of Passenger Car Disc Brakes with Organic and Inorganic Pad Binder Materials" Atmosphere 11, no. 10: 1060. https://doi.org/10.3390/atmos11101060

APA StyleNiemann, H., Winner, H., Asbach, C., Kaminski, H., Frentz, G., & Milczarek, R. (2020). Influence of Disc Temperature on Ultrafine, Fine, and Coarse Particle Emissions of Passenger Car Disc Brakes with Organic and Inorganic Pad Binder Materials. Atmosphere, 11(10), 1060. https://doi.org/10.3390/atmos11101060