Effect of Flow Rate and Filter Efficiency on Indoor PM2.5 in Ventilation and Filtration Control

Abstract

1. Introduction

2. Method

- (1)

- Describe an indoor particle model on the basis of a mass–balance equation.

- (2)

- Estimate parameters by experiments.

- (3)

- Validate estimated parameters using indoor particle model and independently measured data.

- (4)

- Determine the valid range of outdoor and indoor PM2.5 conditions in residential buildings.

- (5)

- Analyze combined effect of ventilation and filtration system control parameters using a simulation model and recommend a ventilation and filtration system operation according to the indoor and outdoor PM2.5 conditions.

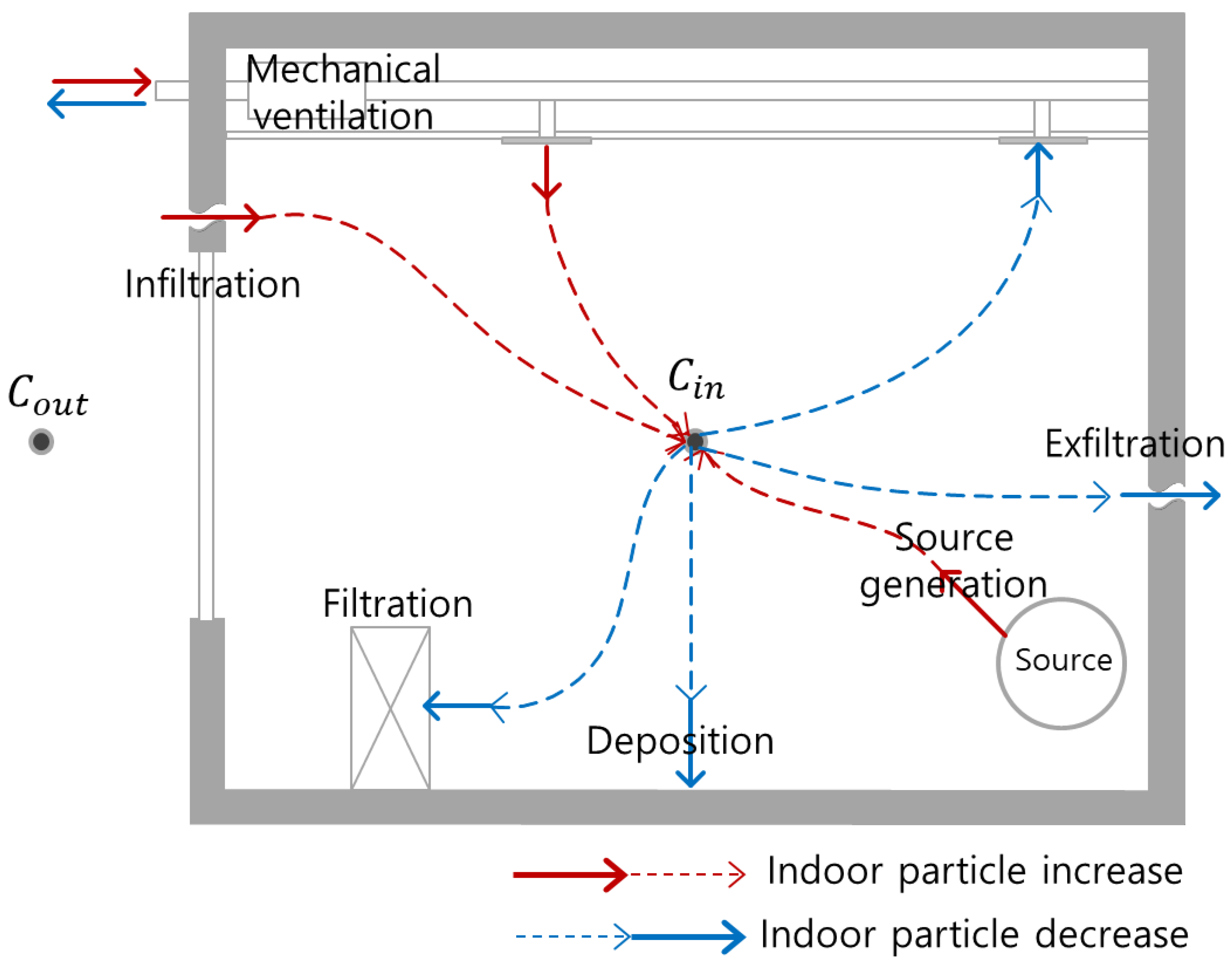

2.1. Mass–Balance Model

- : indoor particle concentration ();

- : outdoor–particle concentration ();

- : infiltration/exfiltration rate ();

- : penetration coefficient ();

- : particle removal efficiency of ventilation system ();

- : particle removal efficiency of filtration system ();

- : ventilation air-flow rate (m3/h);

- : filtration air-flow rate (m3/h);

- : indoor generation rate (/h);

- : deposition rate ();

- : room volume ();

- : time ().

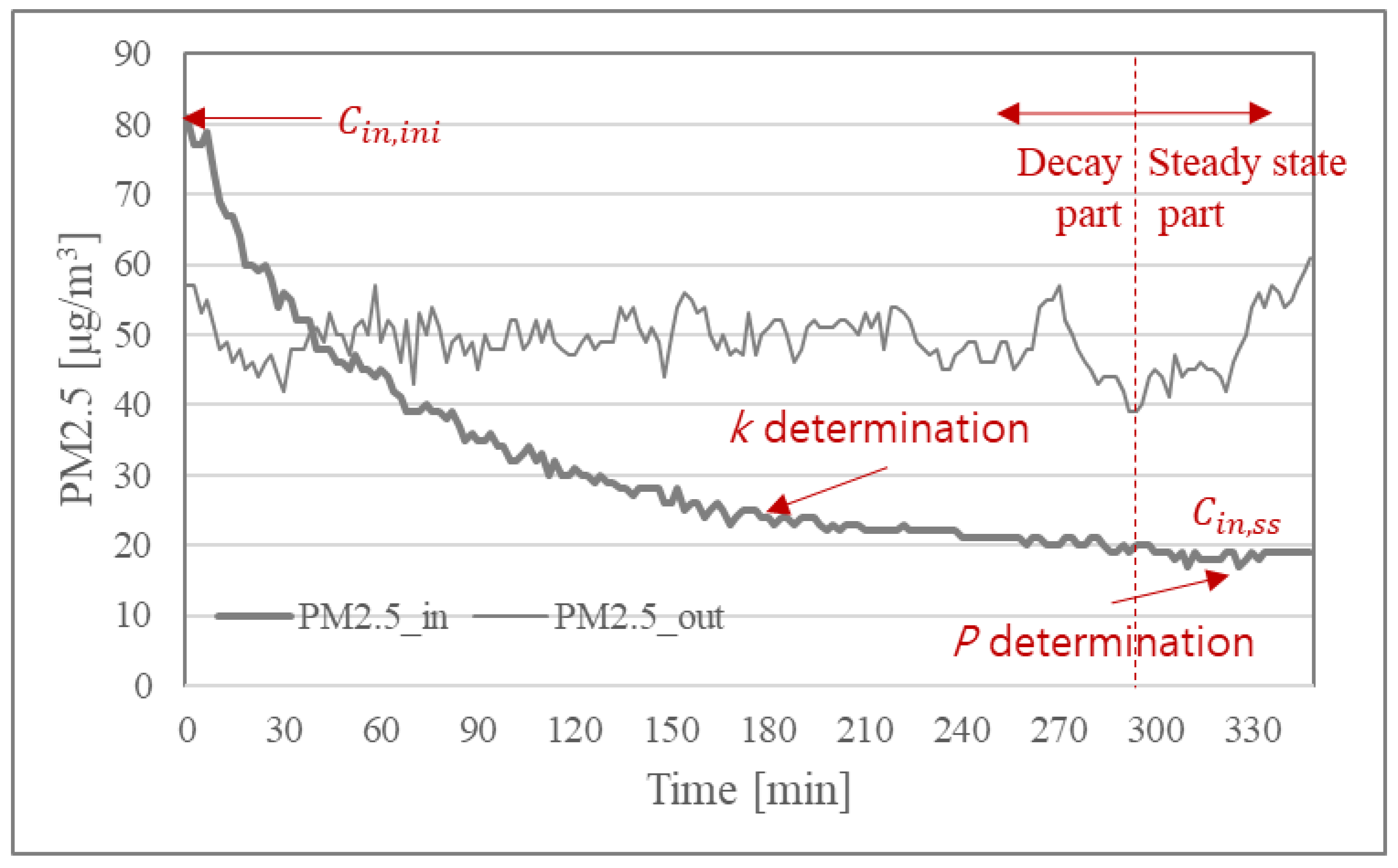

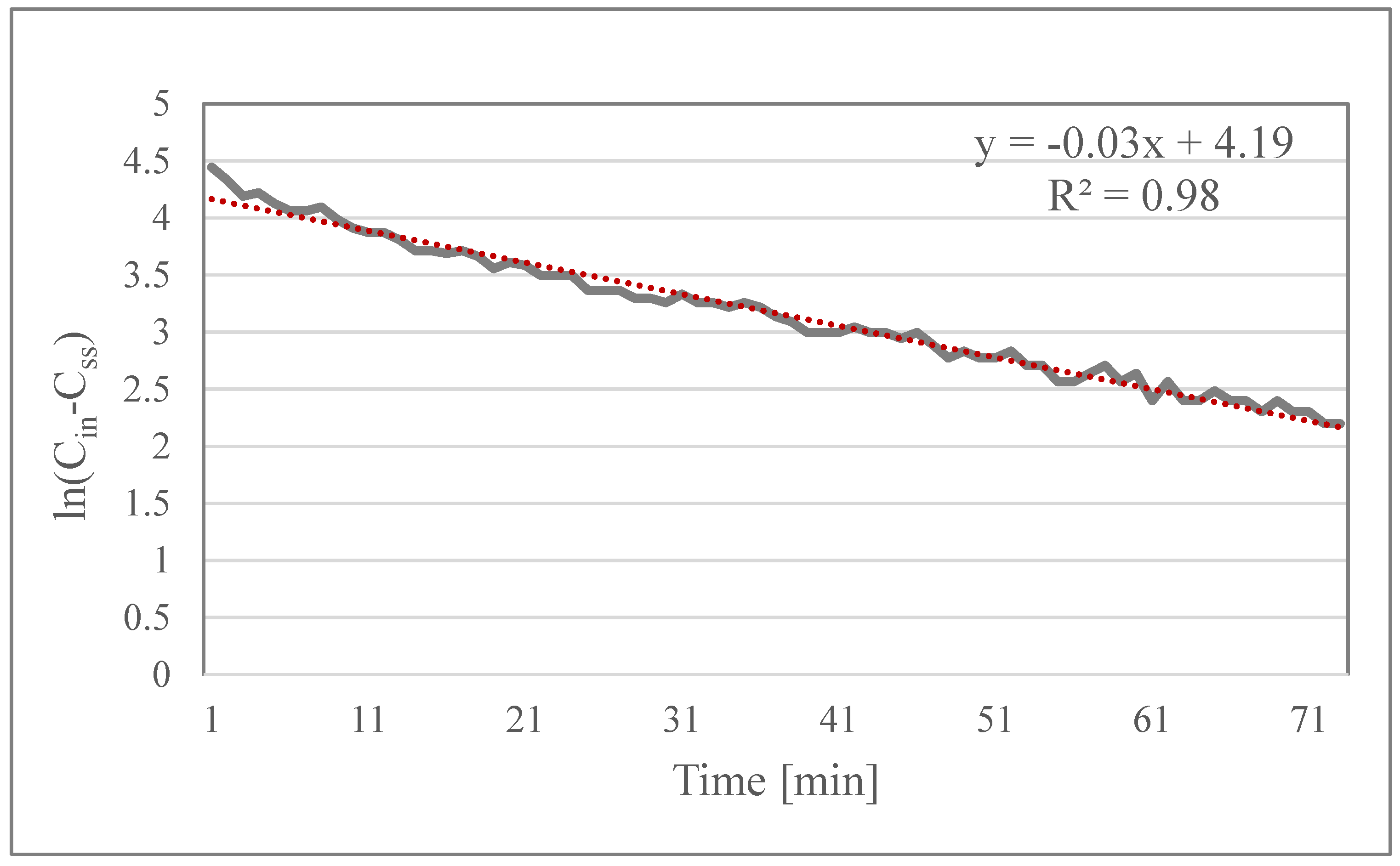

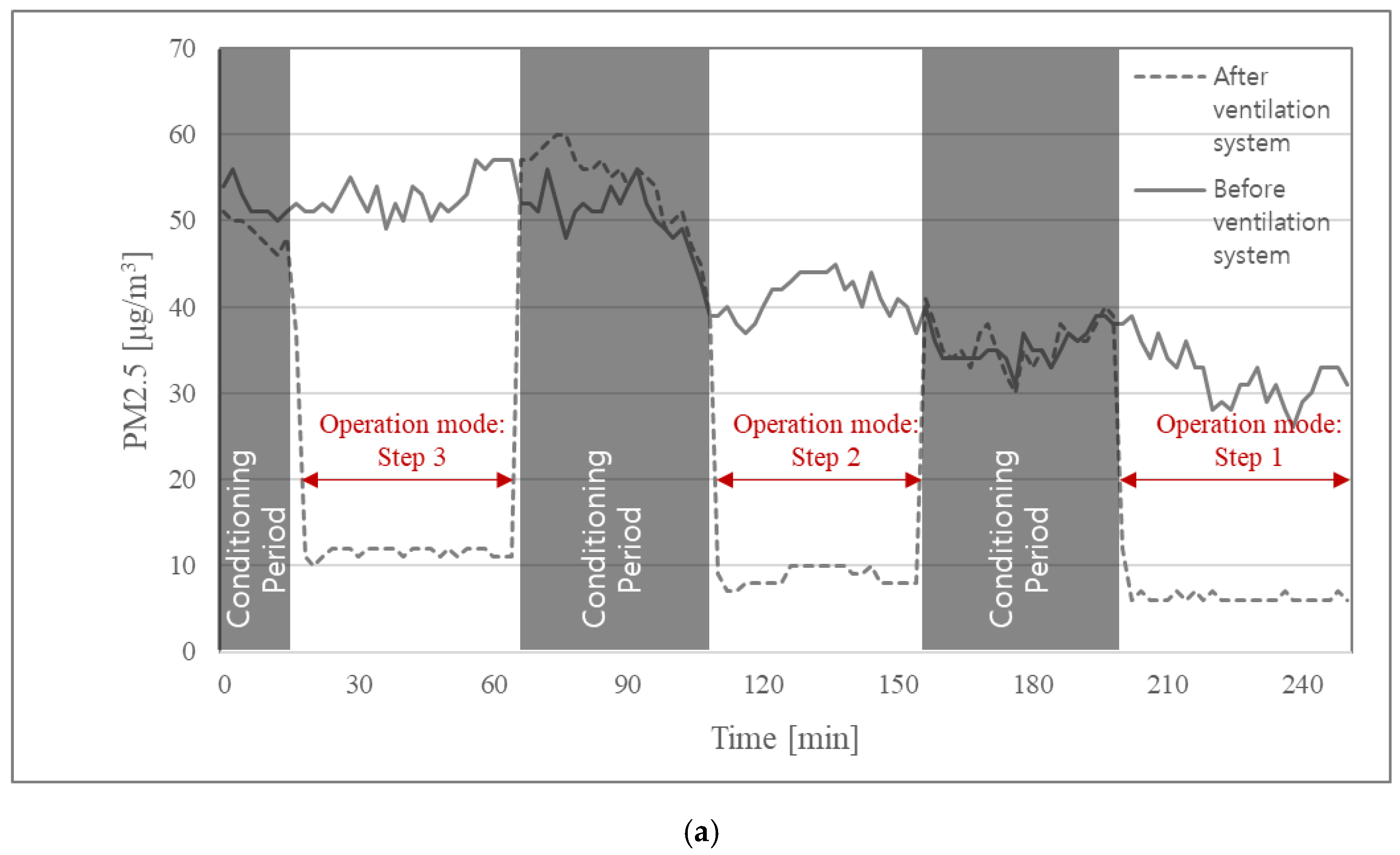

2.2. P, k, ηv, and ηf Estimation

- : indoor particle concentration at steady–state condition ();

- : initial indoor particle concentration ().

- : filter efficiency of ventilation system or filtration system ();

- : particle concentration of outlet of ventilation or filtration system ();

- : particle concentration of inlet of ventilation or filtration system ().

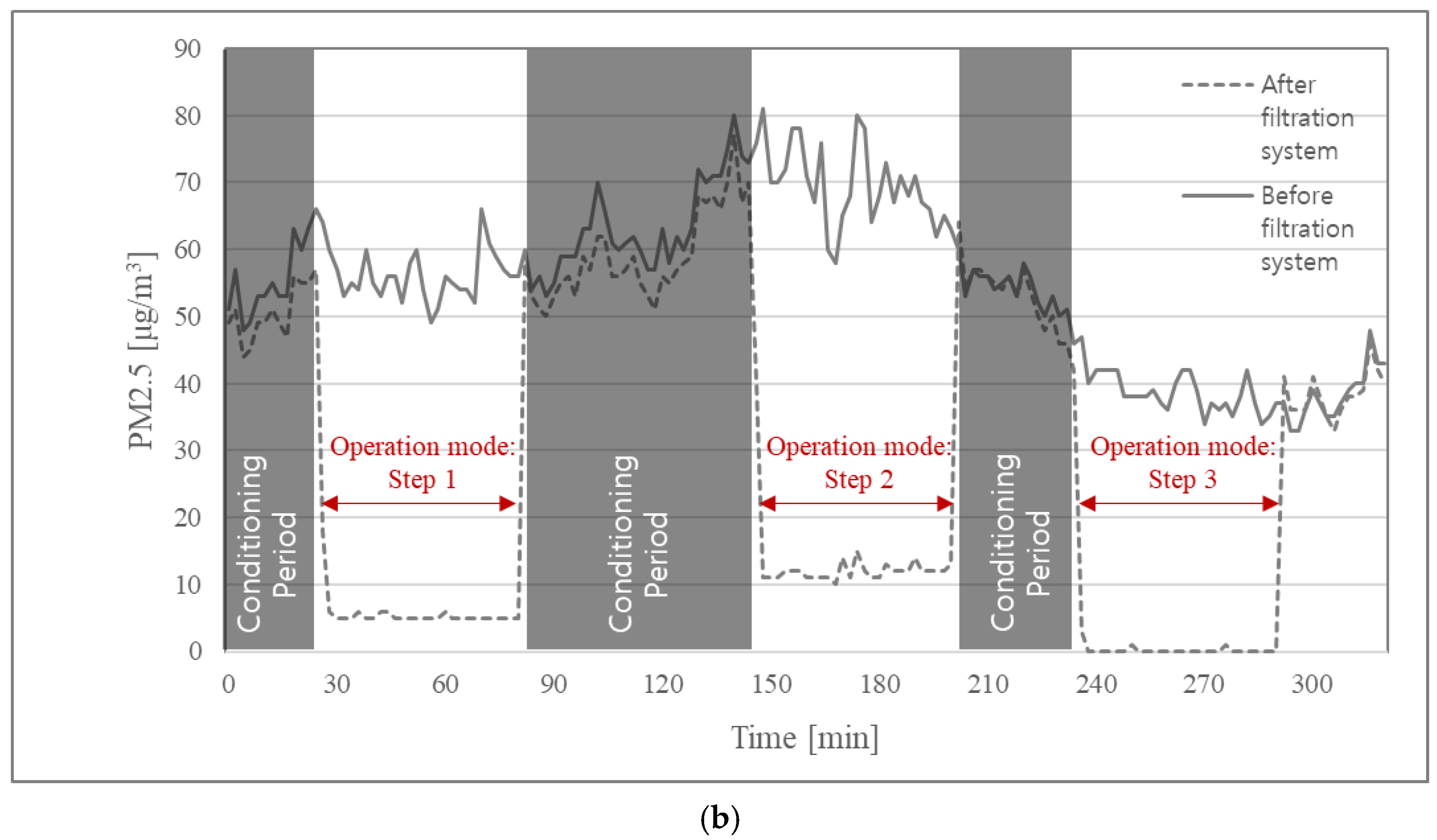

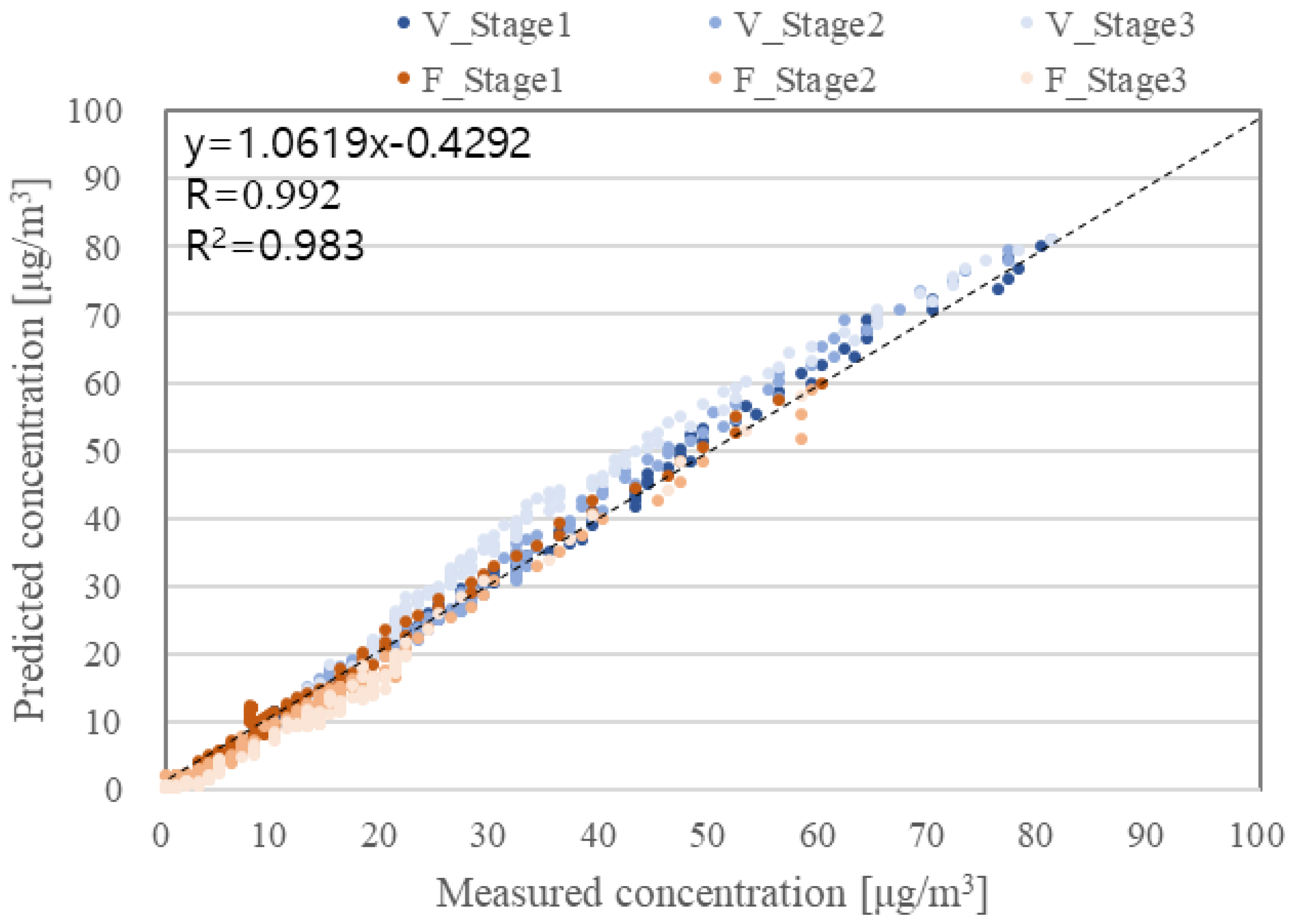

2.3. Validation

2.4. Determination of Evaluation Ranges and Simulation Cases

3. Results and Discussion

3.1. Ventilation Control Parameters

3.2. Filtration Control Parameters

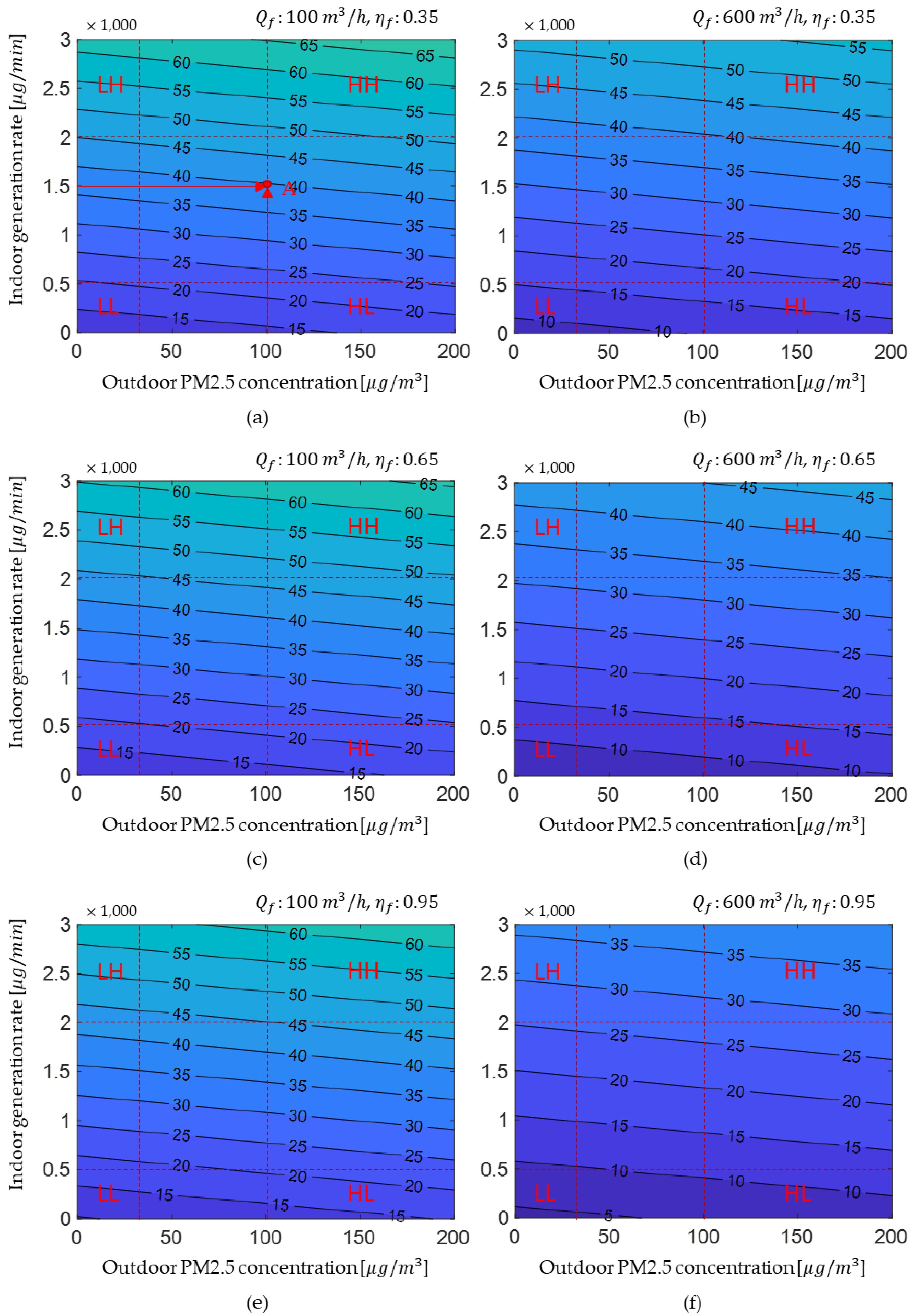

3.3. Comparison between Ventilation Control and Filtration Control

3.4. Combined Effect of Ventilation Control and Filtration Control

4. Conclusions

- (1)

- The effects of ventilation flow rate and filter efficiency on indoor PM2.5 concentration were analyzed. In the case of the HH (high outdoor PM2.5 and high indoor PM2.5 generation rate) condition, using higher efficiency of ventilation filter reduced indoor PM2.5 more effectively than increasing flow rate. Therefore, high flow rate + high efficiency filter or low flow rate + high efficiency filter was superior in reducing indoor PM2.5 concentration. On the other hand, ventilation flow rate was a more effective control parameter than ventilation filter efficiency of the LH (low outdoor PM2.5 and high indoor PM2.5 generation rate) condition. Therefore, regardless of filter efficiency, high flow rate was superior for reducing indoor PM2.5 concentration. High flow rate + high efficiency filter or low flow rate + high efficiency filter was superior for the HL (high outdoor PM2.5 and low indoor PM2.5 generation rate) condition. In this condition, ventilation flow rate should be minimized if filter efficiency was less than 0.65. In the case of LL (low outdoor PM2.5 and low indoor PM2.5 incidence) conditions, when filter efficiency of 0.65 or higher was applied, indoor PM2.5 was reduced as the ventilation volume increases.

- (2)

- The effects of the filtration flow rate and filter efficiency on indoor PM2.5 concentration were analyzed. When the filtration system was operated at a flow rate of 100 m3/h, the indoor PM2.5 concentration showed a reduction rate of up to 6 to 8% depending on the filtration efficiency. On the other hand, when the filter system operated at a flow rate of 600 m3/h, the indoor PM2.5 concentration showed a reduction rate of up to 29 to 38% depending on the filter efficiency. The simulation results also showed that the higher the CADR, the better the indoor PM2.5 concentration. Therefore, to improve indoor PM2.5 concentration by filtration control, a sufficient flow rate should be applied with a high-efficiency filter.

- (3)

- The indoor PM2.5 improved to a greater extent when filtration control was applied rather than ventilation control. Nevertheless, ventilation control is required for managing other indoor pollutants. Ventilation control should be applied carefully according to four different indoor and outdoor conditions. In the case of LL condition, if filtration system was operated at a high flow rate by using a filter with less than 0.65 efficiency, filtration control could reduce indoor PM2.5 by 17–28% more than ventilation control. However, the effects of filtration control and ventilation control were similar when the flow rate was low or the filter efficiency was high. In the case of LH conditions, ventilation control improved indoor PM2.5 as effectively as filtration control. Under HL conditions, which are the worst conditions for applying ventilation control, the indoor PM2.5 was found to be worse than uncontrolled condition if the ventilation filter efficiency was below 0.65. Finally, in the case of ventilation control under HH conditions using a filter with an efficiency of 0.95, indoor PM2.5 could be improved to a level similar to filtration control.

- (4)

- When operating the ventilation system and filtration system together, the control methods for managing indoor PM2.5 were presented in two aspects for each indoor and outdoor environmental conditions. One was the control method that can reduce indoor PM2.5 the most and the other was the recommended control method for maintaining indoor target concentration. In the case of LL conditions, the indoor PM2.5 was the lowest when the filtration flow rate was 600 m3/h, regardless of ventilation flow rate. However, since indoor PM2.5 control is not required in this condition, it is recommended to operate it with minimal ventilation considering pollutants generated from indoors. For LH conditions, the indoor PM2.5 concentration was the lowest when operated at a ventilation of 600 m3/h + filtration 600 m3/h, down 58% from no-control. If the ventilation flow rate was less than 200 m3/h, the filtration flow rate should be at least 400 m3/h, and if the filtration flow rate was less than 100 m3/h, the ventilation flow rate should be at least 400 m3/h to maintain the indoor target concentration. In the case of HL conditions, the indoor PM2.5 was the lowest when operated at ventilation 100 m3/h + filtration 600 m3/h, down 44% from no-control. The recommended control was to maintain the minimum ventilation flow rate for the management of other indoor pollutants and operate the filtration system at the flow rate that can maintain the indoor target PM2.5 concentration. Under HH conditions, operating ventilation 100 m3/h + filtration 600 m3/h was the best and the most recommended control method.

Author Contributions

Funding

Conflicts of Interest

References

- Hoek, G.; Krishnan, R.M.; Beelen, R.; Peters, A.; Ostro, B.; Brunekreef, B. Long–term air pollution exposure and cardiorespiratory mortality: A review. Environ. Health 2013, 12, 43. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.S.V.; Lee, K.K.; Mcallister, D.A.; Hunter, A.; Nair, H.; Whiteley, W.; Langlish, J.P.; Newby, D.E.; Mills, N.L. Short term exposure to air pollution and stroke: Systematic review and meta–analysis. Br. Med. J. 2015, 350, h1295. [Google Scholar] [CrossRef] [PubMed]

- Park, S.–K. Assessing the impact of ozone and particulate matter on mortality rate from respiratory disease in Seoul, Korea. Atmosphere 2019, 10, 685. [Google Scholar] [CrossRef]

- Wu, L.; Luo, X.–S.; Li, H.; Cang, L.; Yang, J.; Yang, J.; Zhao, Z.; Tang, M. Seasonal levels, sources, and health risks of heavy metals in atmospheric PM2.5 from four functional areas of Nanjing city, eastern China. Atmosphere 2019, 10, 419. [Google Scholar] [CrossRef]

- Franck, U.; Odeh, S.; Wiedensohler, A.; Wehner, B.; Herbarth, O. The effect of particle size on cardiovascular disorders—The smaller the worse. Sci. Total Environ. 2011, 409, 4217–4221. [Google Scholar] [CrossRef]

- Kim, K.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Fisk, W.J.; Faulkner, D.; Palonen, J.; Sepanen, O. Performance and costs of particle air filtration technologies. Indoor Air 2002, 12, 223–234. [Google Scholar] [CrossRef]

- Howard–Reed, C.; Wallace, L.; Emmerich, S. Effect of ventilation systems and air filters on decay rates of particles produced by indoor sources in an occupied townhouse. Atmos. Environ. 2003, 37, 5295–5306. [Google Scholar] [CrossRef]

- Jamriska, M.; Morawska, L.; Ensor, D. Control strategies for sub–micrometer particles indoors: Model study of air filtration and ventilation. Indoor Air 2003, 96–105. [Google Scholar] [CrossRef]

- Ben–David, T.; Waring, M.S. Interplay of ventilation and filtration: Differential analysis of cost function combining energy use and indoor exposure to PM2.5 and ozone. Build. Environ. 2018, 128, 320–335. [Google Scholar]

- Ruan, T.; Rim, D. Indoor air pollution in office buildings in mega–cities: Effects of filtration efficiency and outdoor air ventilation rates. Sustain. Cities Soc. 2019, 49, 101609. [Google Scholar] [CrossRef]

- Ren, J.; Liu, J.; Cao, X.; Hou, Y. Influencing factors and energy–saving control strategies for indoor fine particles in commercial office buildings in six Chinese cities. Energy Build. 2017, 149, 171–179. [Google Scholar] [CrossRef]

- Afshari, A.; Matson, U.; Ekberg, L.E. Characterization of indoor sources of fine and ultrafine particles: A study conducted in a fullscale chamber. Indoor Air 2005, 15, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Long, C.M.; Suh, H.H.; Koutrakis, P. Characterization of indoor particle sources using continuous mass and size monitors. J. Air Waste Manag. Assoc. 2000, 50, 1236–1250. [Google Scholar] [CrossRef] [PubMed]

- Wallace, L. Indoor sources of ultrafine and accumulation mode particles: Size distributions, size–resolved concentrations, and source strengths. Aerosol Sci. Technol. 2006, 40, 348–360. [Google Scholar] [CrossRef]

- Abt, E.; Suh, H.; Catalano, P.; Koutrakis, P. Relative contribution of outdoor and indoor particle sources to indoor concentrations. Environ. Sci. Technol. 2000, 34, 3579–3587. [Google Scholar] [CrossRef]

- MacNeill, M.; Kearney, J.; Wallace, L.; Gibson, M.; Heroux, M.E.; Kuchta, J.; Guernsey, J.R.; Wheeler, A.J. Quantifying the contribution of ambient and indoor–generated fine particles to indoor air in residential environments. Indoor Air 2014, 24, 362–375. [Google Scholar] [CrossRef]

- Ferro, A.R.; Kopperud, R.J.; Hildemann, L.M. Source strengths for indoor human activities that resuspend particulate matter. Environ. Sci. Technol. 2004, 38, 1759–1764. [Google Scholar] [CrossRef]

- Urso, P.; Cattaneo, A.; Garramone, G.; Peruzzo, C.; Cavallo, D.M.; Carrer, P. Identification of particulate matter determinants in residential homes. Build. Environ. 2015, 86, 61–69. [Google Scholar] [CrossRef]

- Zhong, X.; Wu, W.; Ridley, I.A. Assessing the energy and indoor PM2.5 exposure impacts of control strategies for residential energy recovery ventilators. J. Build. Eng. 2020, 29, 101137. [Google Scholar] [CrossRef]

- Allen, R.; Larson, T.; Sheppard, L.; Wallace, L.; Liu, L.J.S. Use of real–time light scattering data to estimate the contribution of infiltrated and indoor–generated particles to indoor air. Environ. Sci. Technol. 2003, 37, 3484–3492. [Google Scholar] [CrossRef] [PubMed]

- Long, C.M.; Suh, H.H.; Catalano, P.J.; Koutrakis, P. Using time–and size–resolved particulate data to quantify indoor penetration and deposition behavior. Environ. Sci. Technol. 2001, 35, 2089–2099. [Google Scholar] [CrossRef] [PubMed]

- Özkaynak, H.; Xue, J.; Spengler, J.; Wallace, L.; Pellizzari, E.; Jenkins, P. Personal exposure to airborne particles and metals: Results from the Particle TEAM study in Riverside, California. J. Expo. Sci. Environ. Epidemiol. 1996, 6, 57–78. [Google Scholar]

- Park, B.R.; Choi, D.H.; Kang, D.H. Seasonal Contribution of Indoor generated–and Outdoor Originating PM 2.5 to Indoor Concentration Depending on Airtightness of Apartment Units. J. Archit. Inst. Korea Struct. Constr. 2020, 36, 155–163. [Google Scholar]

- Thatcher, T.L.; Lunden, M.M.; Sextro, R.G.; Hering, S.; Brown, N.J. The effect of penetration factor, deposition, and environmental factors on the indoor concentration of PM2.5 sulfate, nitrate, and carbon. In Proceedings of the 9th International Conference on Indoor Air Quality and Climate, Monterey, CA, USA, 30 June–5 July 2002; Volume 1, pp. 846–851. [Google Scholar]

- Williams, R.; Suggs, J.; Rea, A.; Leovic, K.; Vette, A.; Croghan, C.; Sheldon, L.; Rodes, C.; Thornburg, J.; Ejire, A.; et al. The Research Triangle Park particulate matter panel study: PM mass concentration relationships. Atmos. Environ. 2003, 37, 5349–5363. [Google Scholar] [CrossRef]

- Zhao, H.; Stephens, B. Using portable particle sizing instrumentation to rapidly measure the penetration of fine and ultrafine particles in unoccupied residences. Indoor Air 2017, 27, 218–229. [Google Scholar] [CrossRef]

- Korean Statistical Information Service. Available online: http://kosis.kr/statisticsList/statisticsListIndex.do?menuId=M_01_01&vwcd=MT_ZTITLE&parmTabId=M_01_01#SelectStatsBoxDiv (accessed on 8 September 2020).

- Choi, D.H.; Kang, D.H. Infiltration of ambient PM2.5 through building envelope in apartment housing units in Korea. Aerosol Air Qual. Res. 2017, 17, 598–607. [Google Scholar] [CrossRef]

- Chao, C.Y.; Wan, M.P.; Cheng, E.C. Penetration coefficient and deposition rate as a function of particle size in non–smoking naturally ventilated residences. Atmos. Environ. 2003, 37, 4233–4241. [Google Scholar] [CrossRef]

- Tran, D.T.; Alleman, L.Y.; Coddeville, P.; Galloo, J.C. Indoor particle dynamics in schools: Determination of air exchange rate, size–resolved particle deposition rate and penetration factor in real–life conditions. Indoor Built Environ. 2017, 26, 1335–1350. [Google Scholar] [CrossRef]

- Vette, A.F.; Rea, A.W.; Lawless, P.A.; Rodes, C.E.; Evans, G.; Highsmith, V.R.; Sheldon, L. Characterization of indoor–outdoor aerosol concentration relationships during the Fresno PM exposure studies. Aerosol Sci. Technol. 2001, 34, 118–126. [Google Scholar] [CrossRef]

- Lee, J.; Lee, D.; Kim, J.; Yee, J. A field measuring study on airtight performance of apartment by building type. In Proceedings of the AIK 2019 Autumn Annual Conference, Daejeon, Korea, 24–25 October 2019; Volume 72, pp. 341–342. [Google Scholar]

- Korea Environment Corporation. Airkorea. Available online: www.airkorea.or.kr/web (accessed on 19 June 2020).

- Wallace, L.A. Indoor particles: A review. J. Air Waste Manag. Assoc. 1996, 46, 98–126. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Morawska, L.; Hitchins, J.; Gilbert, D. Contribution from indoor sources to particle number and mass concentrations in residential houses. Atmos. Environ. 2004, 38, 3405–3415. [Google Scholar] [CrossRef]

- Kleipis, N.; Ott, W.; Switzer, P.A. Multiple smoker model for predicting indoor air quality in public lounges. Environ. Sci. Technol. 1996, 30, 2813–2820. [Google Scholar] [CrossRef]

- Brauer, M.; Hirtle, R.; Lang, B.; Ott, W. Assessment of indoor fine aerosol contributions from environmental tobacco smoke and cooking with a portable nephelometer. J. Expo. Anal. Environ. Epidemiol. 2000, 10, 136–144. [Google Scholar] [CrossRef] [PubMed]

- Fazli, T.; Zeng, Y.; Stephens, B. Fine and ultrafine particle removal efficiency of new residential HVAC filters. Indoor air 2019, 29, 656–669. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Stephens, B. Estimates of HVAC filtration efficiency for fine and ultrafine particles of outdoor origin. Atmos. Environ. 2014, 98, 337–346. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Residential Air Cleaners: Portable Air Cleaners Furnace and HVAC Filters; EPA 402–F–09–002; U.S. Environmental Protection Agency: Washington, DC, USA, 2018.

| Description | |

|---|---|

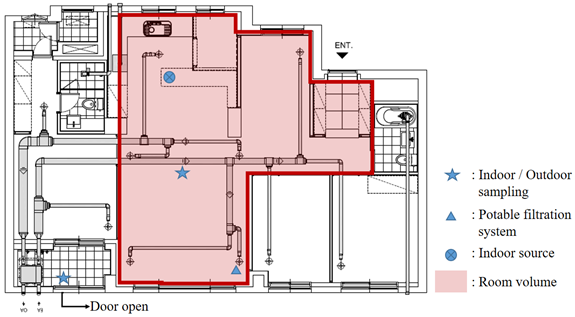

| layout |  |

| Location | Seoul, South Korea |

| Building type | Apartment building |

| Construction year | 2017 |

| Structure type | Reinforced concrete, Flat slab |

| Window type | Double window |

| Flow area | 84 m2 |

| Ceiling height | 2.3 m |

| Furniture | Basic built–in furniture |

| Number of bay | 4–bays |

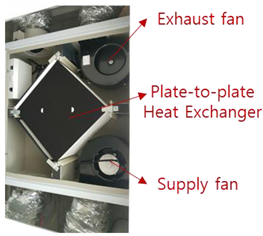

| Ventilation | Heat–recovery ventilation system |

| Ventilation System | Filtration System | |

|---|---|---|

| Picture |  |  |

| Type | Heat–recovery ventilation unit | Potable filtration device |

| Flow control | 3 stages | 3 steps |

| Flow rate (m3/h) | Rated: 100, Actual: 107 (stage 1) Rated: 150, Actual: 121 (stage 2) Rated: 200, Actual: 145 (stage 3) | Rated: 150, Actual: 125 (stage 1) Rated: 250, Actual: 245 (stage 2) Rated: 350, Actual: 305 (stage 3) |

| Pressure loss (Pa) | 100 | – |

| Power consumption (W) | 80 | 90 |

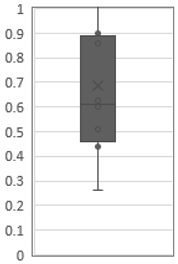

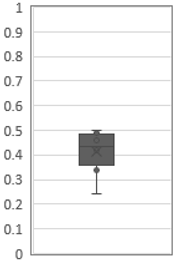

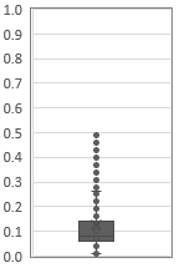

| Parameters | |||

|---|---|---|---|

| Distribution |  |  |  |

| Average () | 0.7 | 0.4 | 0.13 |

| Variance () | 0.0937 | 0.0065 | 0.0108 |

| Standard deviation () | 0.3060 | 0.0806 | 0.1041 |

| Operation Mode | |||

|---|---|---|---|

| Step 1 | Step 2 | Step 3 | |

| (–) | 0.60 ( = 107 m3/h) | 0.60 ( = 121 m3/h) | 0.70 ( = 145 m3/h) |

| (–) | 0.89 ( = 125 m3/h) | 0.80 ( = 245 m3/h) | 0.97 ( = 305 m3/h) |

| No. | ||||||||

|---|---|---|---|---|---|---|---|---|

| (–) | (–) | (h−1) | (m3) | (h−1) | (–) | (m3/h) | (–) | |

| V_Step 1 | 0.7 | 0.4 | 0.13 | 132 | 0.30 | 0.60 | – | – |

| V_Step 2 | 0.13 | 0.31 | 0.60 | – | – | |||

| V_Step 3 | 0.13 | 0.38 | 0.70 | – | – | |||

| F_Step 1 | 0.08 | – | – | 125 | 0.89 | |||

| F_Step 2 | 0.11 | – | – | 245 | 0.80 | |||

| F_Step 3 | 0.09 | – | – | 305 | 0.97 |

| Parameters | Range |

|---|---|

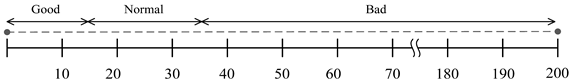

| Outdoor PM2.5 concentration () |  |

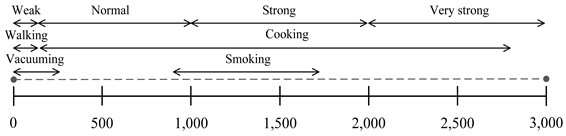

| Indoor PM2.5 generation rate ) |  |

| Case Index | G | P | k | V | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m3/h) | (–) | (m3/h) | (–) | (–) | (–) | (h−1) | ||||

| V100_0.35 | 100 | 0.35 | 0 | – | 0–200 | 0–3000 | 0.7 | 0.4 | 0.1 | 250 |

| V100_0.65 | 100 | 0.65 | 0 | – | ||||||

| V100_0.95 | 100 | 0.95 | 0 | – | ||||||

| V200_0.35 | 200 | 0.35 | 0 | – | ||||||

| V200_0.65 | 200 | 0.65 | 0 | – | ||||||

| V200_0.95 | 200 | 0.95 | 0 | – | ||||||

| V400_0.35 | 400 | 0.35 | 0 | – | ||||||

| V400_0.65 | 400 | 0.65 | 0 | – | ||||||

| V400_0.95 | 400 | 0.95 | 0 | – | ||||||

| V600_0.35 | 600 | 0.35 | 0 | – | ||||||

| V600_0.65 | 600 | 0.65 | 0 | – | ||||||

| V600_0.95 | 600 | 0.95 | 0 | – | ||||||

| F100_0.35 | 0 | – | 100 | 0.35 | ||||||

| F100_0.65 | 0 | – | 100 | 0.65 | ||||||

| F100_0.95 | 0 | – | 100 | 0.95 | ||||||

| F200_0.35 | 0 | – | 200 | 0.35 | ||||||

| F200_0.65 | 0 | – | 200 | 0.65 | ||||||

| F200_0.95 | 0 | – | 200 | 0.95 | ||||||

| F400_0.35 | 0 | – | 400 | 0.35 | ||||||

| F400_0.65 | 0 | – | 400 | 0.65 | ||||||

| F400_0.95 | 0 | – | 400 | 0.95 | ||||||

| F600_0.35 | 0 | – | 600 | 0.35 | ||||||

| F600_0.65 | 0 | – | 600 | 0.65 | ||||||

| F600_0.95 | 0 | – | 600 | 0.95 |

| Control Type | Flow Rate (m3/h) | Filter Eff. (–) | Indoor PM2.5 Concentration (μg/m3) (Fraction to Indoor Concentration When No Control Is Applied) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| : 30 μg/m3 (Low) G: 500 μg/min (Low) | : 30 μg/m3 (Low) G: 2000 μg/min (High) | : 100 μg/m3 (High) G: 500 μg/min (Low) | : 100 μg/m3 (High) G: 2000 μg/min (High) | |||||||

| No-control | – | – | 21.5 | (1.00) | 48.0 | (1.00) | 23.6 | (1.00) | 50.2 | (1.00) |

| Ventilation | 100 | 0.35 | 21.6 | (1.00) | 45.8 | (0.95) | 30.9 | (1.31) | 55.1 | (1.10) |

| 0.65 | 20.2 | (0.94) | 44.3 | (0.92) | 26.1 | (1.11) | 50.2 | (1.00) | ||

| 0.95 | 18.7 | (0.87) | 42.9 | (0.89) | 21.2 | (0.90) | 45.4 | (0.90) | ||

| 200 | 0.35 | 21.7 | (1.01) | 43.8 | (0.91) | 36.9 | (1.56) | 58.9 | (1.17) | |

| 0.65 | 19.0 | (0.88) | 41.1 | (0.86) | 28.1 | (1.19) | 50.1 | (1.00) | ||

| 0.95 | 16.4 | (0.76) | 38.5 | (0.80) | 19.2 | (0.81) | 41.3 | (0.82) | ||

| 400 | 0.35 | 21.7 | (1.01) | 40.3 | (0.84) | 45.8 | (1.94) | 64.4 | (1.28) | |

| 0.65 | 17.3 | (0.80) | 35.9 | (0.75) | 30.9 | (1.31) | 49.5 | (0.99) | ||

| 0.95 | 12.8 | (0.60) | 31.4 | (0.65) | 16.1 | (0.68) | 34.7 | (0.69) | ||

| 600 | 0.35 | 21.7 | (1.01) | 37.5 | (0.78) | 51.8 | (2.19) | 67.7 | (1.35) | |

| 0.65 | 16.0 | (0.74) | 31.8 | (0.66) | 32.8 | (1.39) | 48.7 | (0.97) | ||

| 0.95 | 10.3 | (0.48) | 26.1 | (0.54) | 13.8 | (0.58) | 29.6 | (0.59) | ||

| Filtration | 100 | 0.35 | 20.3 | (0.94) | 46.0 | (0.96) | 22.4 | (0.95) | 48.1 | (0.96) |

| 0.65 | 19.5 | (0.91) | 44.4 | (0.93) | 21.5 | (0.91) | 46.4 | (0.92) | ||

| 0.95 | 18.6 | (0.87) | 42.9 | (0.89) | 20.6 | (0.87) | 44.9 | (0.89) | ||

| 200 | 0.35 | 19.3 | (0.90) | 44.1 | (0.92) | 21.3 | (0.90) | 46.2 | (0.92) | |

| 0.65 | 17.7 | (0.82) | 41.2 | (0.86) | 19.6 | (0.83) | 43.1 | (0.86) | ||

| 0.95 | 16.2 | (0.75) | 38.4 | (0.80) | 18.0 | (0.76) | 40.3 | (0.80) | ||

| 400 | 0.35 | 17.4 | (0.81) | 40.7 | (0.85) | 19.3 | (0.82) | 42.6 | (0.85) | |

| 0.65 | 14.7 | (0.68) | 35.6 | (0.74) | 16.4 | (0.69) | 37.3 | (0.74) | ||

| 0.95 | 12.4 | (0.58) | 31.3 | (0.65) | 14.0 | (0.59) | 32.8 | (0.65) | ||

| 600 | 0.35 | 15.7 | (0.73) | 37.6 | (0.78) | 17.5 | (0.74) | 39.4 | (0.78) | |

| 0.65 | 12.3 | (0.57) | 31.0 | (0.65) | 13.8 | (0.58) | 32.5 | (0.65) | ||

| 0.95 | 9.7 | (0.45) | 25.9 | (0.54) | 11.0 | (0.47) | 27.2 | (0.54) | ||

| Control Type (Flow Rate (m3/h), Filter Efficiency (–)) | Indoor PM2.5 Concentration (μg/m3) (Percentage to Indoor Concentration When No Control Applied) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| : 30 μg/m3 (Low) G: 500 μg/min (Low) | : 30 μg/m3 (Low) G: 2000 μg/min (High) | : 100 μg/m3 (High) G: 500 μg/min (Low) | : 100 μg/m3 (High) G: 2000 μg/min (High) | ||||||

| No-control | 21.5 | (1.00) | 48.0 | (1.00) | 23.6 | (1.00) | 50.2 | (1.00) | |

| Ventilation (100, 0.65) | No filtration | 20.2 | (0.94) | 44.3 | (0.92) | 26.1 | (1.11) | 50.2 | (1.00) |

| Filtration (100, 0.95) | 17.6 | (0.82) | 39.8 | (0.83) | 23.1 | (0.98) | 45.2 | (0.90) | |

| Filtration (200, 0.95) | 15.5 | (0.72) | 35.9 | (0.75) | 20.5 | (0.87) | 40.9 | (0.81) | |

| Filtration (400, 0.95) | 12.1 | (0.56) | 29.5 | (0.61) | 16.4 | (0.69) | 33.8 | (0.67) | |

| Filtration (600, 0.95) | 9.6 | (0.45) | 24.7 | (0.51) | 13.3 | (0.56) | 28.3 | (0.56) | |

| Ventilation (200, 0.65) | No filtration | 19.0 | (0.88) | 41.1 | (0.86) | 28.1 | (1.19) | 50.1 | (1.00) |

| Filtration (100, 0.95) | 16.8 | (0.78) | 37.1 | (0.77) | 25.1 | (1.06) | 45.4 | (0.90) | |

| Filtration (200, 0.95) | 14.9 | (0.69) | 33.6 | (0.70) | 22.5 | (0.95) | 41.3 | (0.82) | |

| Filtration (400, 0.95) | 11.8 | (0.55) | 27.9 | (0.58) | 18.4 | (0.78) | 34.5 | (0.69) | |

| Filtration (600, 0.95) | 9.6 | (0.45) | 23.6 | (0.49) | 15.3 | (0.65) | 29.3 | (0.58) | |

| Ventilation (400, 0.65) | No filtration | 17.3 | (0.80) | 35.9 | (0.75) | 30.9 | (1.31) | 49.5 | (0.99) |

| Filtration (100, 0.95) | 15.5 | (0.72) | 32.7 | (0.68) | 28.1 | (1.19) | 45.3 | (0.90) | |

| Filtration (200, 0.95) | 13.9 | (0.65) | 29.9 | (0.62) | 25.7 | (1.09) | 41.6 | (0.83) | |

| Filtration (400, 0.95) | 11.4 | (0.53) | 25.3 | (0.53) | 21.6 | (0.92) | 35.5 | (0.71) | |

| Filtration (600, 0.95) | 9.6 | (0.45) | 21.7 | (0.45) | 18.5 | (0.78) | 30.7 | (0.61) | |

| Ventilation (600, 0.65) | No filtration | 16.0 | (0.74) | 31.8 | (0.66) | 32.8 | (1.39) | 48.7 | (0.97) |

| Filtration (100, 0.95) | 14.5 | (0.67) | 29.3 | (0.61) | 30.2 | (1.28) | 44.9 | (0.89) | |

| Filtration (200, 0.95) | 13.3 | (0.62) | 27.0 | (0.56) | 27.9 | (1.18) | 41.6 | (0.83) | |

| Filtration (400, 0.95) | 11.2 | (0.52) | 23.3 | (0.49) | 24.0 | (1.02) | 36.1 | (0.72) | |

| Filtration (600, 0.95) | 9.6 | (0.45) | 20.3 | (0.42) | 20.9 | (0.89) | 31.7 | (0.63) | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Yeo, M.-S. Effect of Flow Rate and Filter Efficiency on Indoor PM2.5 in Ventilation and Filtration Control. Atmosphere 2020, 11, 1061. https://doi.org/10.3390/atmos11101061

Kim J-H, Yeo M-S. Effect of Flow Rate and Filter Efficiency on Indoor PM2.5 in Ventilation and Filtration Control. Atmosphere. 2020; 11(10):1061. https://doi.org/10.3390/atmos11101061

Chicago/Turabian StyleKim, Ji-Hye, and Myoung-Souk Yeo. 2020. "Effect of Flow Rate and Filter Efficiency on Indoor PM2.5 in Ventilation and Filtration Control" Atmosphere 11, no. 10: 1061. https://doi.org/10.3390/atmos11101061

APA StyleKim, J.-H., & Yeo, M.-S. (2020). Effect of Flow Rate and Filter Efficiency on Indoor PM2.5 in Ventilation and Filtration Control. Atmosphere, 11(10), 1061. https://doi.org/10.3390/atmos11101061