In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cooking Events

2.2. Stoves and Fuels

2.3. Description of Seasons

2.4. Emission Sampling

2.5. Data Analysis Methods

3. Results and Discussion

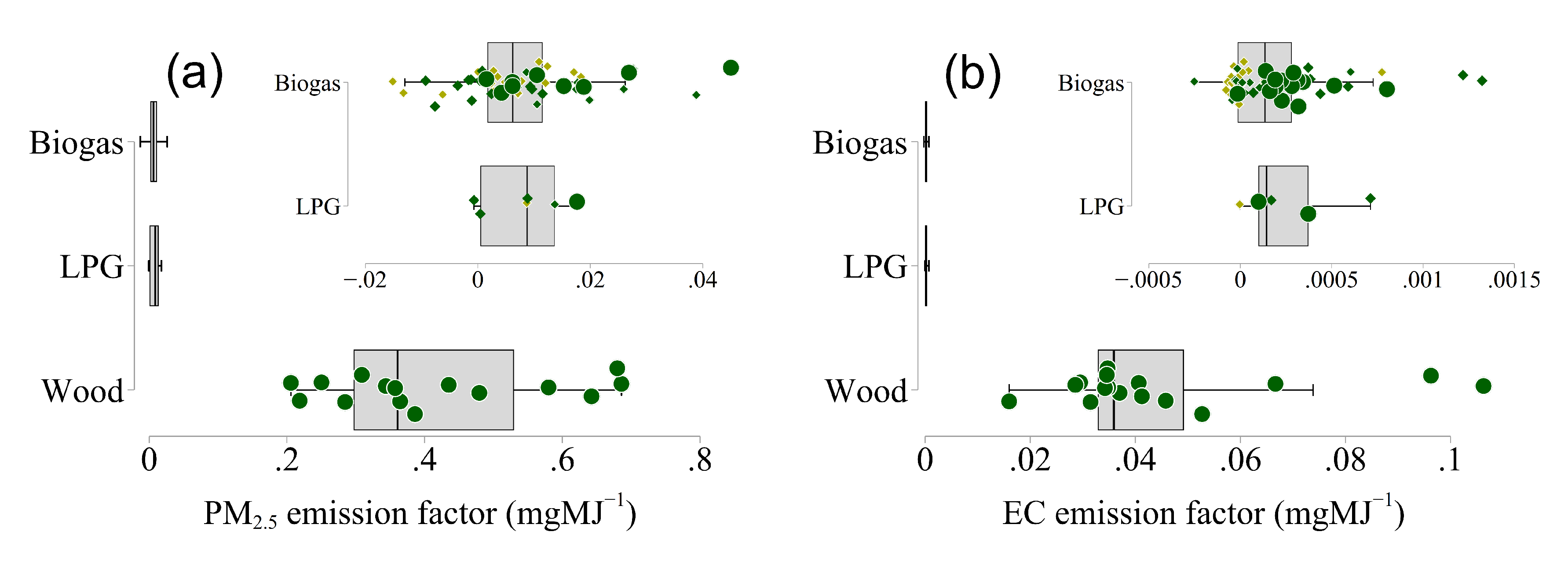

3.1. Wood Stove Emission Factors

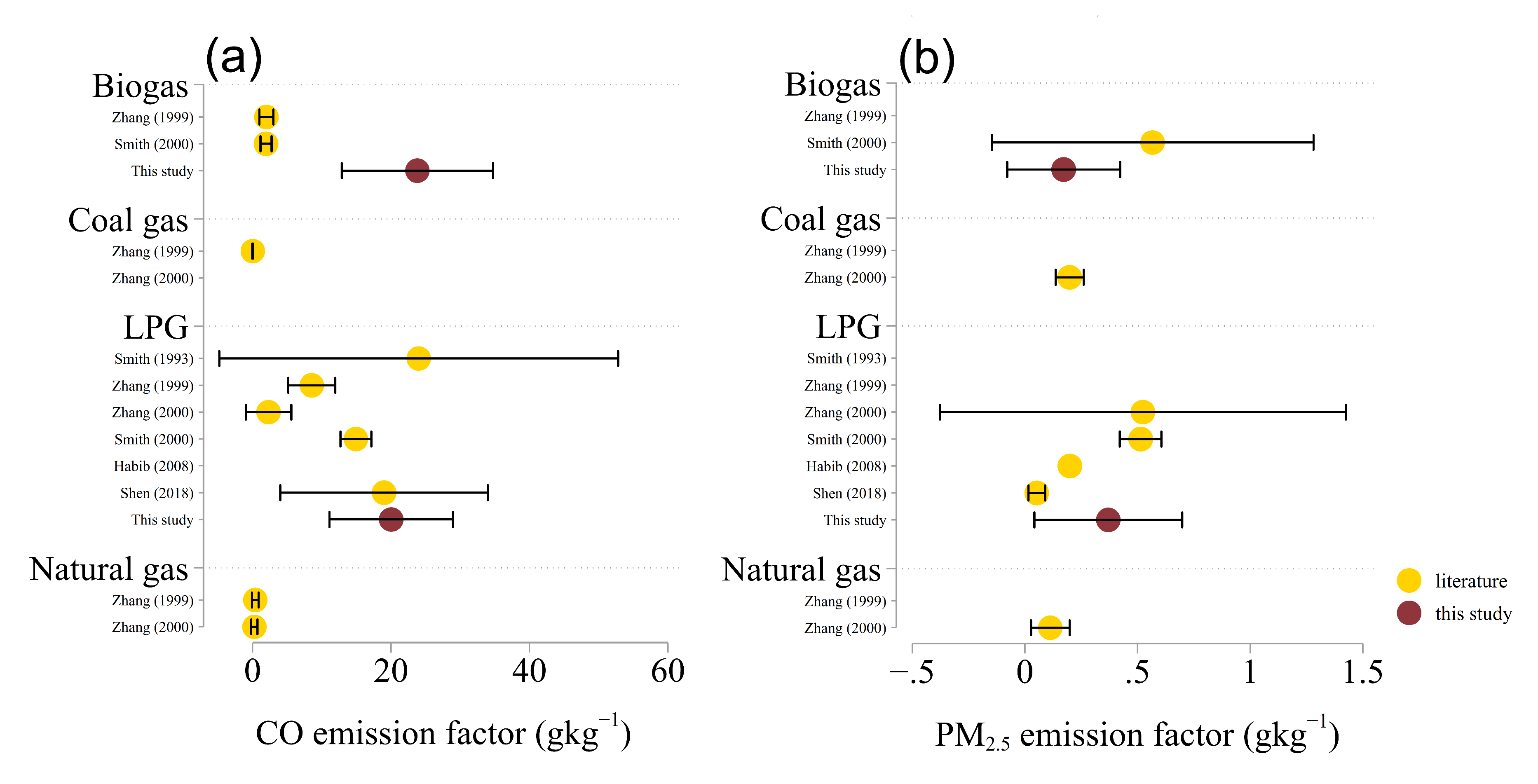

3.2. Biogas and LPG: Carbon Monoxide

3.3. Biogas and LPG: Particulate Matter

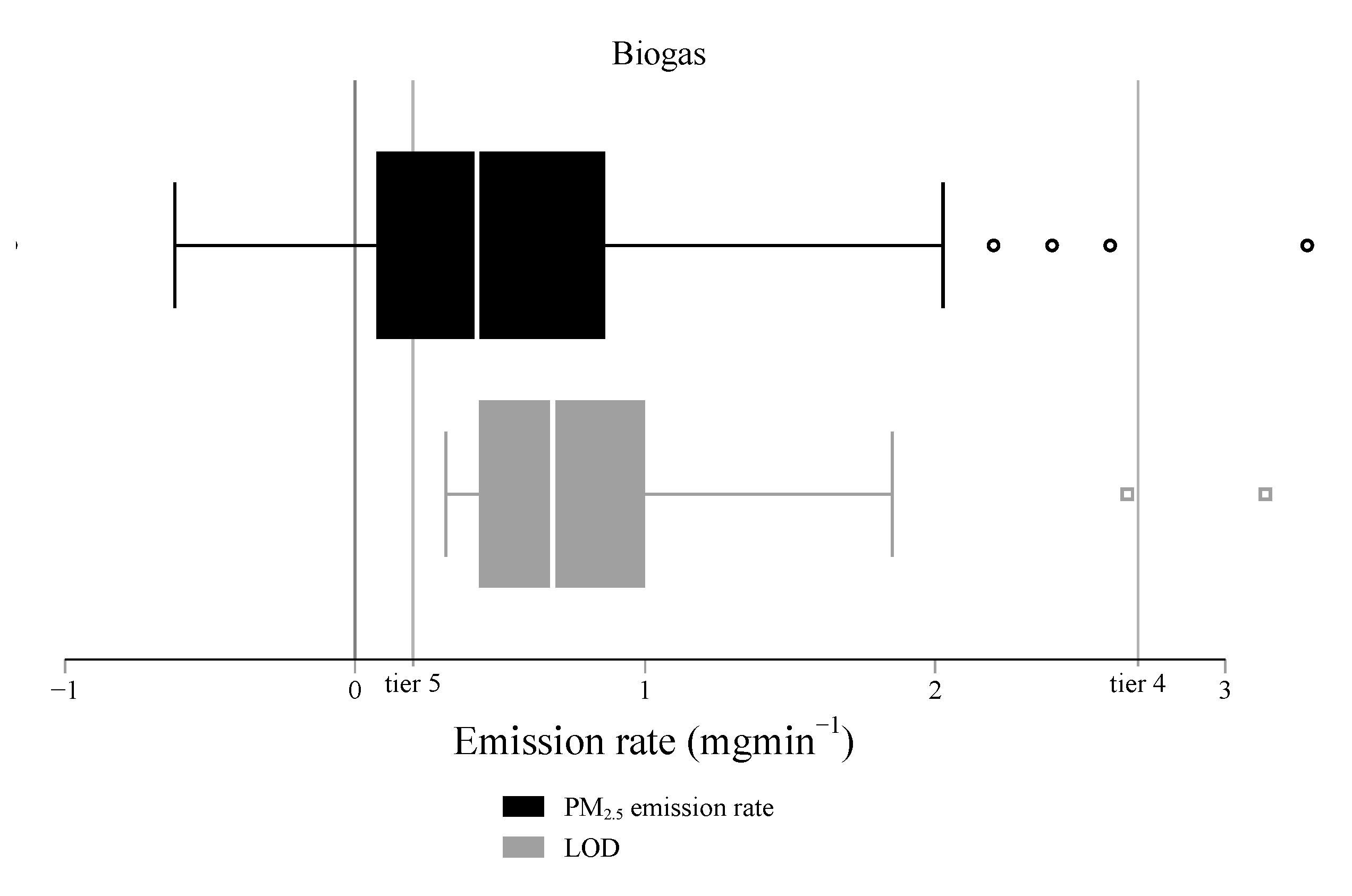

3.4. Biogas and LPG: Elemental and Organic Carbon

3.5. Cooking System Emissions

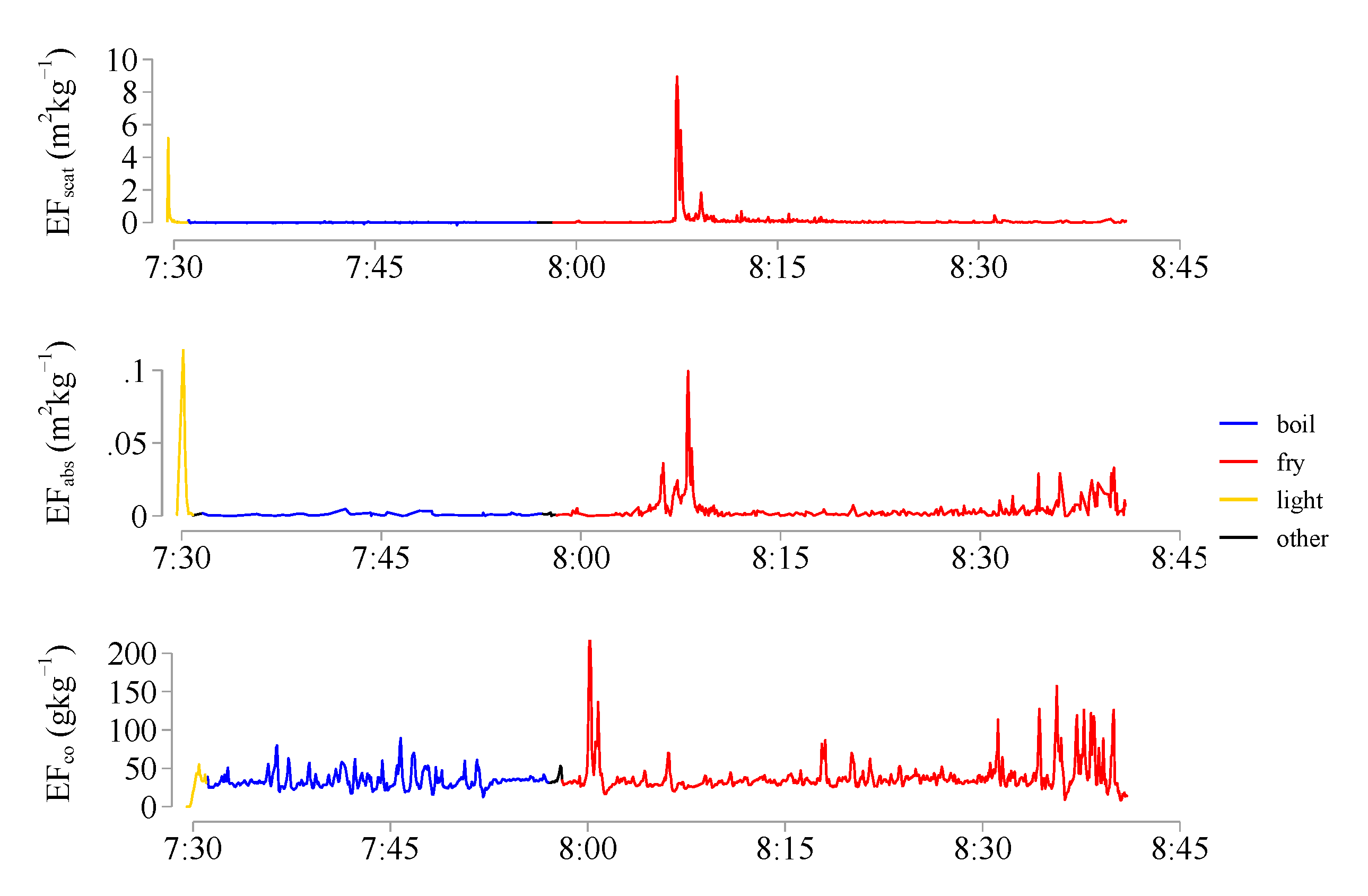

3.6. Sources of Variability

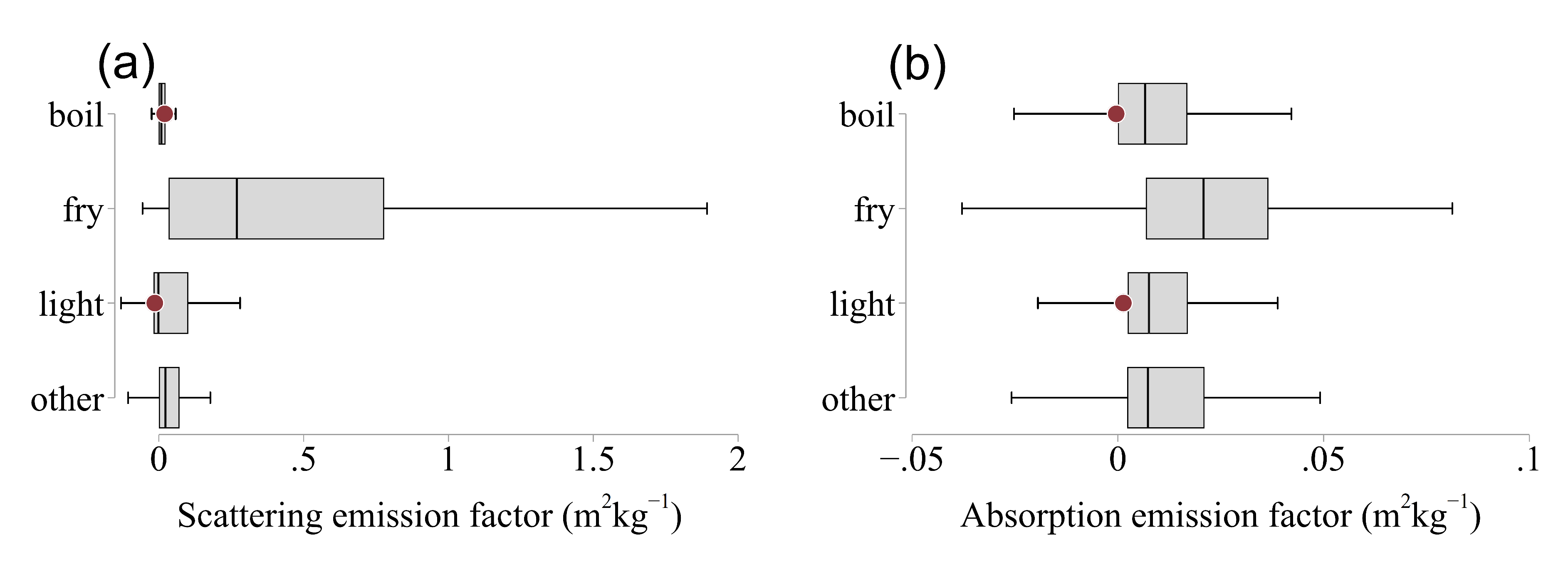

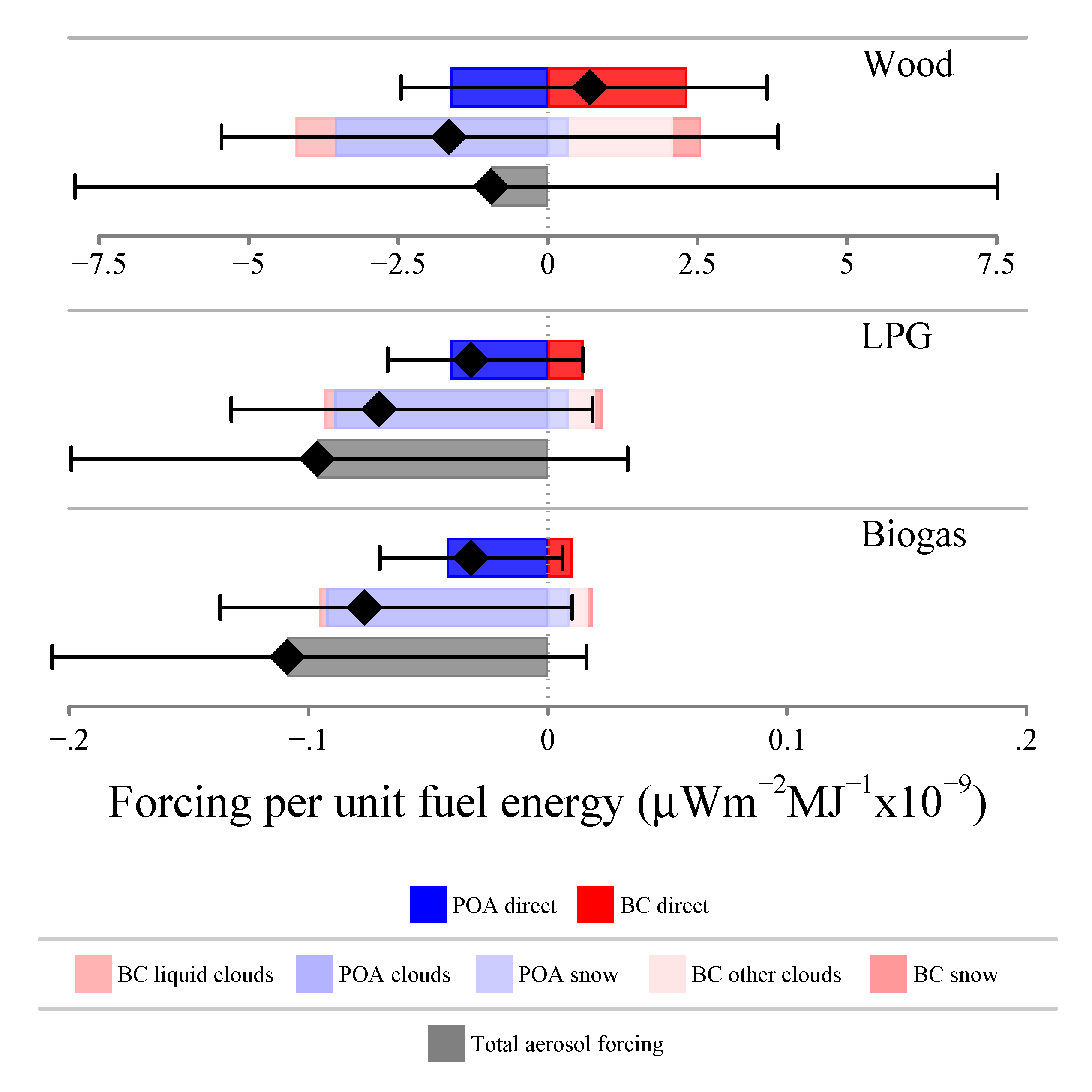

3.7. Climate Forcing by Aerosols from Cooking Fuels

3.8. Comparison with ISO Performance Tiers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| LPG | Liquified petroleum gas |

| EC | Elemental carbon |

| OC | Organic carbon |

| PM | Particulate matter with aerodynamic diameter smaller than 2.5 m |

| CO | Carbon monoxide |

| CO | Carbon dioxide |

| BC | Black carbon |

| LOD | Limit of detection |

| EF | Emission factor |

| ISO | International standards organization |

References

- Legros, G.; Havet, I.; Bruce, N.; Bonjour, S.; Rijal, K.; Takada, M. The Energy Access Situation in Developing Countries: A Review Focusing on the Least Developed Countries and Sub-Saharan Africa; World Health Organization and UNDP: Geneva, Switzerland, 2009. [Google Scholar]

- Gakidou, E.; Afshin, A.; Abajobir, A.A.; Abate, K.H.; Abbafati, C.; Abbas, K.M.; Abd-Allah, F.; Abdulle, A.M.; Abera, S.F.; Aboyans, V. Global, regional, and national comparative risk assessment of 84 behavioural, environmental and occupational, and metabolic risks or clusters of risks, 1990–2016: A systematic analysis for the Global Burden of Disease Study 2016. Lancet 2017, 390, 1345–1422. [Google Scholar] [CrossRef]

- International Standards Organization. Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols —Part 3: Voluntary Performance Targets for Cookstoves Based on Laboratory Testing; International Standards Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Burnett, R.T.; Pope, C.A., III; Ezzati, M.; Olives, C.; Lim, S.S.; Mehta, S.; Shin, H.H.; Singh, G.; Hubbell, B.; Brauer, M. An integrated risk function for estimating the global burden of disease attributable to ambient fine particulate matter exposure. Environ. Health Perspect. 2014, 122, 397. [Google Scholar] [CrossRef] [PubMed]

- Smith, K.R.; Peel, J.L. Mind the gap. Environ. Health Perspect. 2010, 118, 1643. [Google Scholar] [CrossRef] [PubMed]

- Aung, T.W.; Baumgartner, J.; Jain, G.; Sethuraman, K.; Reynolds, C.; Marshall, J.D.; Brauer, M. Effect on blood pressure and eye health symptoms in a climate-financed randomized cookstove intervention study in rural India. Environ. Res. 2018, 166, 658–667. [Google Scholar] [CrossRef] [PubMed]

- Nightingale, R.; Lesosky, M.; Flitz, G.; Rylance, S.J.; Meghji, J.; Burney, P.; Balmes, J.; Mortimer, K. Noncommunicable Respiratory Disease and Air Pollution Exposure in Malawi (CAPS). A Cross-Sectional Study. Am. J. Respir. Crit. Care Med. 2019, 199, 613–621. [Google Scholar] [CrossRef]

- Mortimer, K.; Ndamala, C.B.; Naunje, A.W.; Malava, J.; Katundu, C.; Weston, W.; Havens, D.; Pope, D.; Bruce, N.G.; Nyirenda, M. A cleaner burning biomass-fuelled cookstove intervention to prevent pneumonia in children under 5 years old in rural Malawi (the Cooking and Pneumonia Study): A cluster randomised controlled trial. Lancet 2017, 389, 167–175. [Google Scholar] [CrossRef]

- Smith, K.R.; Sagar, A. Making the clean available: Escaping India’s Chulha Trap. Energy Policy 2014, 75, 410–414. [Google Scholar] [CrossRef]

- Gould, C.F.; Urpelainen, J. LPG as a clean cooking fuel: Adoption, use, and impact in rural India. Energy Policy 2018, 122, 395–408. [Google Scholar] [CrossRef]

- Office of the Registrar General and Census Commissioner, India Ministry of Home Affairs, Government of India. India National Census. 2011. Available online: http://censusindia.gov.in/2011-Common/CensusData2011.html (accessed on 20 November 2019).

- Khandelwal, M.; Hill, M.E., Jr.; Greenough, P.; Anthony, J.; Quill, M.; Linderman, M.; Udaykumar, H. Why have improved cook-stove initiatives in India failed? World Dev. 2017, 92, 13–27. [Google Scholar] [CrossRef]

- Smith, K.; Uma, R.; Kishore, V.; Zhang, J.; Joshi, V.; Khalil, M. Greenhouse implications of household stoves: An analysis for India. Annu. Rev. Energy Environ. 2000, 25, 741–763. [Google Scholar] [CrossRef]

- Zhang, J.; Smith, K.; Uma, R.; Ma, Y.; Kishore, V.; Lata, K.; Khalil, M.; Rasmussen, R.; Thorneloe, S. Carbon monoxide from cookstoves in developing countries: 1. Emission factors. Chemosp.-Glob. Chang. Sci. 1999, 1, 353–366. [Google Scholar] [CrossRef]

- Smith, K.; Khalil, M.; Rasmussen, R.; Thorneloe, S.; Manegdeg, F.; Apte, M. Greenhouse gases from biomass and fossil fuel stoves in developing countries: A Manila pilot study. Chemosphere 1993, 26, 479–505. [Google Scholar] [CrossRef]

- Global Alliance for Clean Cookstove Partners. The Water Boiling Test Version 4.2.3 Cookstove Emissions and Efficiency in a Controlled Laboratory Setting. 2014. Available online: https://www.cleancookingalliance.org/binary-data/DOCUMENT/file/000/000/399-1.pdf (accessed on 20 November 2019).

- Roden, C.A.; Bond, T.C.; Conway, S.; Pinel, A.B.O. Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environ. Sci. Technol. 2006, 40, 6750–6757. [Google Scholar] [CrossRef] [PubMed]

- Weyant, C.L.; Chen, P.; Vaidya, A.; Li, C.; Zhang, Q.; Thompson, R.; Ellis, J.; Chen, Y.; Kang, S.; Shrestha, G.R.; et al. Emission measurements from traditional biomass cookstoves in South Asia and Tibet. Environ. Sci. Technol. 2019, 56, 3306–3314. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.; Li, J.; Weyant, C.; Edwards, R.; Lan, Q.; Rothman, N.; Hu, W.; Dang, J.; Dang, A.; Smith, K.R.; et al. Field Emission Measurements of Solid Fuel Stoves in Yunnan, China Demonstrate Dominant Causes of Uncertainty in Household Emission Inventories. Environ. Sci. Technol. 2019, 56, 3323–3330. [Google Scholar] [CrossRef] [PubMed]

- Bond, T.; Doherty, S.; Fahey, D.; Forster, P.; Berntsen, T.; Deangelo, B.; Flanner, M.; Ghan, S.; Kärcher, B.; Koch, D.; et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. D Atmos. 2013, 118, 5380–5552. [Google Scholar] [CrossRef]

- Bond, T.C.; Zarzycki, C.; Flanner, M.; Koch, D. Quantifying immediate radiative forcing by black carbon and organic matter with the Specific Forcing Pulse. Atmos. Chem. Phys. 2011, 11, 1505–1525. [Google Scholar] [CrossRef]

- Smith, K.; Uma, R.; Kishore, V.; Lata, K.; Zhang, J.; Joshi, V.; Rasumussen, R.; Khalil, M. Greenhouse Gases from Small-Scale Combustion Devices in Developing Countries Phase IIa: Household Stoves in India. EPA-600/R-00-052. 2000. Available online: https://pdfs.semanticscholar.org/2b25/79be3535c4b984d1f6c0858726eb09360eab.pdf?_ga=2.108327111.431936412.1574241126-292403031.1574241126 (accessed on 20 November 2019).

- Ko, Y.C.; Lin, T.H. Emissions and efficiency of a domestic gas stove burning natural gases with various compositions. Energy Convers. Manag. 2003, 44, 3001–3014. [Google Scholar] [CrossRef]

- Shen, G.; Hays, M.D.; Smith, K.R.; Williams, C.; Faircloth, J.W.; Jetter, J.J. Evaluating the performance of household liquefied petroleum gas cookstoves. Environ. Sci. Technol. 2018, 52, 904–915. [Google Scholar] [CrossRef]

- Zhang, J.; Smith, K.; Ma, Y.; Ye, S.; Jiang, F.; Qi, W.; Liu, P.; Khalil, M.; Rasmussen, R.; Thorneloe, S. Greenhouse gases and other airborne pollutants from household stoves in China: a database for emission factors. Atmos. Environ. 2000, 34, 4537–4549. [Google Scholar] [CrossRef]

- Shen, G.; Chen, Y.; Xue, C.; Lin, N.; Huang, Y.; Shen, H.; Wang, Y.; Li, T.; Zhang, Y.; Su, S. Pollutant emissions from improved coal-and wood-fuelled cookstoves in rural households. Environ. Sci. Technol. 2015, 49, 6590–6598. [Google Scholar] [CrossRef] [PubMed]

- Wathore, R.; Mortimer, K.; Grieshop, A.P. In-use emissions and estimated impacts of traditional, natural-and forced-draft cookstoves in rural Malawi. Environ. Sci. Technol. 2017, 51, 1929–1938. [Google Scholar] [CrossRef] [PubMed]

- Jetter, J.; Zhao, Y.; Smith, K.R.; Khan, B.; Yelverton, T.; DeCarlo, P.; Hays, M.D. Pollutant emissions and energy efficiency under controlled conditions for household biomass cookstoves and implications for metrics useful in setting international test standards. Environ. Sci. Technol. 2012, 46, 10827–10834. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.A.; Garland, C.R.; Jagoe, K.; Edwards, R.; Ndemere, J.; Weyant, C.; Patel, A.; Kithinji, J.; Wasirwa, E.; Nguyen, T. In-Home Emissions Performance of Cookstoves in Asia and Africa. Atmosphere 2019, 10, 290. [Google Scholar] [CrossRef]

- Habib, G.; Venkataraman, C.; Bond, T.C.; Schauer, J.J. Chemical, microphysical and optical properties of primary particles from the combustion of biomass fuels. Environ. Sci. Technol. 2008, 42, 8829–8834. [Google Scholar] [CrossRef]

- Venkataraman, C.; Habib, G.; Eiguren-Fernandez, A.; Miguel, A.; Friedlander, S. Residential biofuels in South Asia: Carbonaceous aerosol emissions and climate impacts. Science 2005, 307, 1454–1456. [Google Scholar] [CrossRef] [PubMed]

- Grieshop, A.P.; Jain, G.; Sethuraman, K.; Marshall, J.D. Emission factors of health-and climate-relevant pollutants measured in home during a carbon-finance-approved cookstove intervention in rural India. GeoHealth 2017, 1, 222–236. [Google Scholar] [CrossRef]

- International Standards Organization. Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part 1: Standard Test Sequence for Emissions and Performance, Safety and Durability; International Standards Organization: Geneva, Switzerland, 2018. [Google Scholar]

| Group | N | EF | EF | EF | EF | MSC | |

|---|---|---|---|---|---|---|---|

| g MJ | mg MJ | mg MJ | mg MJ | m g | |||

| Wood stove | |||||||

| Monsoon | 7 | 4.6 (1.4) | 390 (176) | 36.8 (15.8) | 189.0 (109.6) | 1.3 (0.3) | |

| Winter | 5 | 5.1 (1.5) | 461 (206) | 37.6 (3.2) | 234.5 (114.6) | 1.1 (0.3) | |

| Spring | 4 | 5.4 (0.7) | 372 (49) | 71.0 (36.6) | 190.5 (19.9) | 0.9 (0.1) | |

| Average wood | 16 | 5.1 (1.3) | 408 (160) | 45.6 (24.5) | 203.6 (94.1) | 1.2 (0.3) | |

| Biogas stove | |||||||

| Monsoon | 19 | 1.1 (0.6) | 9.9 (8.6) | 0.06 (0.20) | 4.4 (5.4) | 1.3 (0.8) | |

| Winter | 19 | 1.1 (0.5) | 4.5 (9.4) | 0.20 (0.27) | 1.9 (4.9) | 1.9 (1.4) | |

| Spring | 19 | 1.0 (0.5) | 7.9 (13.8) | 0.31 (0.36) | 9.2 (11.7) | 1.2 (0.6) | |

| Average biogas | 57 | 1.1 (0.5) | 7.4 (10.9) | 0.20 (0.30) | 5.3 (8.6) | 1.5 (1.0) | |

| LPG stove | |||||||

| Monsoon | 2 | 0.4 (0.1) | 11.0 (3.6) | 0.05 (0.08) | 6.7 (4.0) | 1.3 (–) | |

| Winter | 1 | 0.1 (–) | 17.3 (–) | 0.44 (–) | 8.5 (–) | 0.5 (–) | |

| Spring | 3 | 0.5 (0.2) | 4.1 (6.7) | 0.40 (0.26) | 3.0 (2.8) | – (–) | |

| Average LPG | 6 | 0.4 (0.2) | 9.5 (6.8) | 0.29 (0.25) | 5.1 (3.5) | 0.9 (0.6) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weyant, C.L.; Thompson, R.; Lam, N.L.; Upadhyay, B.; Shrestha, P.; Maharjan, S.; Rai, K.; Adhikari, C.; Fox, M.C.; Pokhrel, A.K. In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves. Atmosphere 2019, 10, 729. https://doi.org/10.3390/atmos10120729

Weyant CL, Thompson R, Lam NL, Upadhyay B, Shrestha P, Maharjan S, Rai K, Adhikari C, Fox MC, Pokhrel AK. In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves. Atmosphere. 2019; 10(12):729. https://doi.org/10.3390/atmos10120729

Chicago/Turabian StyleWeyant, Cheryl L., Ryan Thompson, Nicholas L. Lam, Basudev Upadhyay, Prabin Shrestha, Shovana Maharjan, Kaushila Rai, Chija Adhikari, Maria C. Fox, and Amod K. Pokhrel. 2019. "In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves" Atmosphere 10, no. 12: 729. https://doi.org/10.3390/atmos10120729

APA StyleWeyant, C. L., Thompson, R., Lam, N. L., Upadhyay, B., Shrestha, P., Maharjan, S., Rai, K., Adhikari, C., Fox, M. C., & Pokhrel, A. K. (2019). In-Field Emission Measurements from Biogas and Liquified Petroleum Gas (LPG) Stoves. Atmosphere, 10(12), 729. https://doi.org/10.3390/atmos10120729