Abstract

Kura clover living mulch (KCLM) systems have been previously investigated for their incorporation into upper Midwestern row crop rotations to provide ecosystem services through continuous living cover. Reductions in soil erosion and nitrate loss to surface and groundwater have been reported, but factors affecting agronomic performance and nutrient management are not well defined. To achieve realized environmental benefits, research must develop agronomic management techniques, determine economic opportunities, and provide management recommendations for row crop production in KCLM systems. Two experiments were conducted in 2017 and 2018 to determine the response to N fertilizer application for maize production in KCLM. The first-year maize experiment followed forage management, and the second-year maize experiment followed maize after forage management. Eight fertilizer N treatments ranging from 0–250 kg N ha−1 were applied to each experiment and grain and stover yields were compared to conventionally managed maize hybrid trials that were conducted nearby. First-year maize did not need fertilizer N to maximize yield and profitability in either growing season, and second-year maize required a fertilizer N rate near local University guidelines for maize following soybean. The net economic return from maize grain and stover in the KCLM averaged over first and second-year maize experiments and 2017 and 2018 growing seasons were $138 ha−1 greater than the conventional comparison.

Keywords:

kura clover; living mulch; cover crop; perennial; conservation; nitrogen; forage; economics 1. Introduction

Kura clover (Trifolium ambiguum M. bieb), a rhizatomous perennial legume forage, is well suited for incorporation into upper Midwestern row-cropping systems as a perennial cover crop or living mulch [1]. Kura clover’s dense rhizome system holds large stores of metabolite energy that allow for perennial persistence and rapid reestablishment after intensive agronomic management [2]. In the U.S. Midwest, maize (Zea mays) and soybean (Glycine max) have been successfully grown in a kura clover living mulch (KCLM), and clover forage productivity recovered in the following growing season [1,3,4]. Living cover and active root uptake during the fall and spring months reduce soil erosion and nitrate leaching from maize production by up to three-quarters in the KCLM system compared to conventional management [5,6].

Maize production in KCLM requires stover harvest to prevent smothering of kura clover by crop residues [1]. Maize silage and stover are important forage and bedding materials in livestock operations and were harvested from 7% of maize acres in the central and eastern U.S. in 2010 [7,8]. While harvest of maize residue in conventional production systems can increase soil erosion and negatively affects soil carbon, structure, and fertility [9,10], soil physical and chemical properties were unaffected by 5–7 years of continuous maize stover removal under KCLM management in the upper Midwest [11]. Improved protection from soil erosion and increased carbon input to soils from living cover maintains soil quality and reduces environmental and economic costs of stover harvest by increasing the sustainable stover removal rate [12]. Higher stover removal rates will reduce the land area impacted by stover harvest, thus reducing harvest cost and increasing the sustainability of stover removal in upper Midwestern livestock production systems.

Disparities in the literature exist regarding the agronomic productivity between KCLM and conventional maize systems, where grain and forage yields are either reduced [3,4,5,6,13] or maintained [1,2,14,15]. Previous research comparing maize grain yield in KCLM and conventional management systems are sometimes confounded by nitrogen (N) management, where living mulch treatments were granted legume N credits of 67–146 kg N ha−1 [5,6,13]. Limited understanding of biological N fixation and cycling in KCLM systems has left researchers with little baseline information on N management guidelines, limiting the quantification and understanding of agronomic, environmental, and economic attributes of KCLM systems. Defining more robust N management recommendations for KCLM-row cropping systems requires identification of environmental and agronomic factors that affect in-season N contributions and availability. Recent work to isolate factors affecting in-season N contributions from KCLM identified rotary zone tillage as an important factor in promoting N mineralization from disturbed and incorporated clover residues [16]. This aligns with previous studies that identified rotary zone tillage as a promising strategy to reduce living mulch competition with the emerging row crop [14,17,18].

It is necessary to develop N management guidelines based on crop rotations and scenarios that may be utilized by growers to quantify the economic and environmental potentials of KCLM-maize management systems. The potential reduction of fertilizer N requirements for maize through in-season N contributions from KCLM may reduce management costs and improve economic competitiveness with other cropping systems. The objectives of this research were to determine the effect of N fertilizer management on the productivity of maize and kura clover in a KLCM-maize system and assess the economic performance of this system. Greater understanding of N cycling in KCLM systems will facilitate innovation and adoption of perennial-annual intercropping systems that reduce environmental impacts of agriculture while providing economic benefits to crop and livestock growers.

2. Materials and Methods

2.1. Site Description

Field experiments were conducted in 2017 and 2018 at the University of Minnesota Research and Outreach Center in Rosemont, MN (44.73° N, 93.09° W) on a Waukegan silt loam (Fine-silty over sandy or sandy-skeletal, mixed, super active, mesic Typic Hapludolls). Soils at the site contained 20.5 g kg−1 organic carbon and were 5.7 pH in the 0–30 cm layer. Endura kura clover was established at the site in 2006–2007 and used as a living mulch for maize and soybean from 2008–2009. Rhizomes were dug from the experimental site in 2010 using a potato (Solanum tuberosum) harvester for a vegetative repropagation study [19] and kura clover recovered before resuming as a living mulch for maize in 2011 and 2013 and soybean in 2012 and 2014. Phosphorous (P) and potassium (K) fertilizers were applied according to soil test values and University of Minnesota guidelines in 2015 [20] and clover was harvested for hay once each year in 2015 and 2016.

Daily precipitation and minimum and maximum air temperature from 1 April to 31 October were obtained from National Weather Service Cooperative Observer Station No. 217107. Daily weather observations were averaged over 1981–2010 to represent the climatic normal. Daily minimum and maximum temperature were used to calculate cumulative growing degree days with a base and upper limit of 10 and 30 °C, respectively, beginning on 12 May for the climatic average and the planting date of the corresponding growing seasons in these experiments.

2.2. Experimental Design

Two studies, each conducted over two growing seasons (2017 and 2018), investigated fertilizer N management for maize in KCLM (Table 1). The ‘first-year’ experiment was maize seeded into kura clover that was managed as forage since the 2015 growing season. The ‘second-year’ experiment was maize seeded into kura clover that had been planted to maize in the previous growing season and was previously managed as forage since the 2015 growing season. In the 2011–2014 growing seasons, the kura clover was managed as a living mulch in a maize-soybean rotation. First-year maize production in preparation for the second-year maize experiment received 150 kg N ha−1 as liquid urea-ammonium nitrate banded 10 cm from the center of the row at the six-leaf collar stage of maize phenological development. The second growing season of each study was placed adjacent to the first to maintain the crop rotation treatments; therefore, treatments were not applied to the same plots in both growing seasons. The studies investigated fertilizer N rate, where an unfertilized control was compared to plots that received a split application of urea containing urease and nitrification inhibitors (SuperU, Koch Agronomic Services, Wichita, KS, USA) at 40, 80, 120, 180, or 250 kg N ha−1. SuperU was surface-banded at 40 kg N ha−1 onto the center of the tilled row and incorporated with a second pass of the rotary zone tillage tool prior to planting. The remainder of treatment fertilizer N was surface banded 5 cm from the center of the row at the four-leaf collar stage of maize phenological development. Two additional fertilizer N treatments applied urea instead of SuperU, either in a single application of 120 kg N ha−1 at planting or as a split application of 40 and 80 kg N ha−1 at planting and the four-leaf collar stage of maize phenological development, respectively. Plots were 4.7 m (6 rows) wide by 15.2 m long and the first- and second-year maize experiments were arranged as two 4 × 2 randomized complete blocks with four replications of the eight fertilizer N treatments.

Table 1.

Crop rotations for first- and second-year maize experiments.

2.3. Agronomic Management

Prior to spring clover management, triple superphosphate, potash, and gypsum fertilizers were broadcast over the entire experimental area in both growing seasons based on soil test values and university guidelines [20]. Clover was cut with a flail mower to 5 cm prior to row establishment in 2017 and in the first-year maize experiment in 2018. Rows were established with a rotary zone tillage tool (Northwest Tillers, Yakima, WA, USA) that tilled 30-cm-wide rows every 76 cm on 11 May 2017 and 22 May 2018 [16,17]. Fertilizer N applications at planting were applied with a garden seeder (Earthway, Bristol, IN, USA) in the center of the tilled strip before incorporation with a second pass of the rotary zone tillage tool. Maize (Pioneer P0157AMX, Pioneer Dupont, Johnston, IA, USA) was planted in 76-cm rows in the center of the tilled strips at 86,000 seeds ha−1 with a John Deere 7000 planter (John Deere, Moline, IA, USA) on 12 May 2017 and 22 May 2018. An additional clover mowing 15 days after planting (DAP) was necessary in 2017 to reduce clover encroachment into maize rows, but mowing was not needed in the 2018 experiments. Herbicide suppression was used in both growing seasons to reduce clover encroachment into maize rows and was achieved with a broadcast application of 2.3 L a.e. ha−1 (N-(phosphonomethyl) glycine) (glyphosate) 39 and 31 DAP in 2017 and 2018, respectively [5,6,16].

2.4. Crop Sampling and Analysis

Clover biomass was sampled at 160 and 133 DAP maize in 2017 and 2018 by placing a 0.5-m2 quadrat between the center two maize rows and cutting clover biomass to a 1 cm height [16]. Maize was harvested at physiological maturity by hand harvesting ears and cutting stalks to a 15 cm height from 4.6 m in two rows in each plot. Maize stover was weighed in the field before a six-stalk subsample was ground with a biomass chipper, collected, and weighed. Maize ears, stalks, and clover were dried at 60 °C for 3 d until reaching a constant mass. Dry stover subsamples were weighed to determine field moisture content to correspond with in-field measurements. Maize ears were shelled before dry grain and cobs were weighed. Subsamples of grain, cob, stover, and kura clover were ground to < 0.1 mm and analyzed for organic carbon and N with the Dumas dry combustion method in an elemental analyzer (Elementar, Langenselbold, DE) [21]. The N content of crop components were combined with corresponding dry biomass measurements to determine maize N uptake. Stover and cob yield and N content were summed and are herein referred to as stover yield and N content, respectively.

2.5. Residual Soil Nitrogen

Post-harvest soil samples were collected with a 41-mm i.d. hydraulic coring device. Soils were collected from the 0–30 and 30–60 cm soil layers in 2017 and 2018. Samples were homogenized and weighed before a 10-g subsample of wet soil was added to 38 mL of 2M KCl, shaken at 120 rpm for 1 h, and filtered through 11-μm filter paper. The filtered extractant was analyzed for NO3-N (sum of NO2-N and NO3-N) and NH4-N with the Greiss–Ilosvay with cadmium reduction and the sodium salicylate-nitroprusside methods, respectively, each modified for flow-through injection analysis [22] (Lachat, Loveland, CO, USA). A 5-g subsample of wet soil was dried at 105 °C until constant mass to determine gravimetric water content. Core volume and mass were used to determine soil bulk density, and soil N content was the product of soil N concentration and soil bulk density.

2.6. Economic Calculations

The partial net economic return was determined with a partial budget analysis of this study’s KCLM experiments and conventionally managed maize hybrid trials, where maize hybrids followed soybean and were greater than 99-day relative maturity, similar to the 102-day relative maturity hybrid used in the KCLM experiments. Maize hybrid trials were conducted at Rosemount, MN, USA in 2017 (n = 27) and 2018 (n = 28) [23,24], and trial yields were compared to the corresponding growing season of the KCLM experiments. Agronomic management costs that differed between conventional and KCLM cropping systems included fertilizer N rate, spring tillage, spring mowing, fall tillage, and baling operations. Baling operations included raking, round baling, bale transportation, bale storage [25,26], and nutrient replacement costs associated with stover removal (1.65 kg P Mg−1 and 6.65 kg K Mg−1 dry stover) [27]. Management for conventional maize production was assumed as spring field cultivation and fall disk-chiseling, while management for the KCLM system was based on agronomic practices performed on experimental treatments with spring and in-season mowing, rotary zone tillage, and baling operations with the associated nutrient replacement cost [17,26,27]. All other costs, including land, P and K fertilization excluding stover nutrient removal replacement, seed, planting, pesticide and application of pesticide, harvest costs, and miscellaneous costs were assumed equal across treatments and conventional comparisons [26]. Net return from grain in the variety trials and the KCLM experiments were the product of grain yield at the economic optimum fertilizer N rate (EONR), which was determined from grain yield estimates of the fitted quadratic regression equations where N cost was $0.86 kg−1 and the grain valued at $133 Mg−1 at 155 g kg−1 moisture. When there was no grain yield response to fertilizer N, the EONR was set at 0 kg N ha−1. Net return from stover in KCLM experiments was the product of stover yield at the EONR and stover value ($79.37 Mg−1) at 200 g kg−1 moisture [28]. A comparison of system performance was based on parameter estimates of the fitted linear or quadratic regression of the response variables at the EONR when grain yield was affected by fertilizer N and the average response of the unfertilized treatment when grain yield was not affected by fertilizer N.

2.7. Data Analysis

Data were analyzed separately for first- and second-year maize experiments, where the first-year maize experiment was maize following forage management and the second-year maize experiment was maize following maize after forage management. Dependent variables were evaluated using restricted maximum likelihood in mixed effect models in the lme4 version 1.1-19 package of R version 3.5.2 [29], where growing season and N fertilizer treatment were considered fixed effects and block was considered a random effect. Scatter and quantile-quantile plots of predicted versus residual values were evaluated for homogeneity of variance and normality [30]. The requirements of normality and common variance were met for all dependent variables except residual NH4-N, NO3-N, and total inorganic N (NH4-N + NO3-N, TIN), which were therefore logarithm base 10 transformed and subsequently evaluated for normality and common variance using the aforementioned procedures. The requirements of homogeneity of variance and normality were met for NH4-N, NO3-N, and TIN following logarithm base 10 transformation. The significance of fixed effects were determined with analysis of variance at p < 0.05. When the main effect of growing season was significant, means were compared at p < 0.05 using pairwise comparisons with the emmeans version 1.3.3 package of R [31]. When the main effect of fertilizer N treatment or the growing season-by-fertilizer N treatment interaction was significant, means of the three treatments receiving a total of 120 kg N ha−1 were compared at p < 0.05 using pairwise comparisons with the emmeans package of R. Regression of the non-transformed parameter response to fertilizer N rate was conducted using the unfertilized treatment and the split SuperU N rate treatments with the lme4 package of R, where quadratic and linear regression functions were evaluated using analysis of variance and the quadratic function was used when p < 0.05.

3. Results

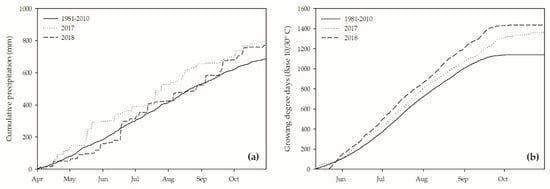

The 30-year (1981–2010) cumulative precipitation between 1 April and 31 October was 689 mm, and actual precipitation was 798 and 772 mm in 2017 and 2018, respectively (Figure 1a). Accumulated growing degree days were 1141, 1362, and 1435 for the climatic normal, 2017, and 2018, respectively (Figure 1b).

Figure 1.

(a) cumulative precipitation between 1 April and 31 October and (b) accumulated growing degree days (base 10 °C and upper limit 30 °C) following planting for the 1981–2010 historic average and the 2017 and 2018 experiment growing seasons.

3.1. First-Year Maize

First-year maize grain yield was not affected by growing season or fertilizer N treatment (Table 2). Grain N yield was 9% greater in 2018 than in 2017. Stover and stover N yields were 25 and 34% greater in 2018 than in 2017, respectively, and late-season clover yield was reduced by 77% in 2018 compared to 2017.

Table 2.

Growing season and treatment means, standard error, and statistical significance of dependent variables for first-year maize.

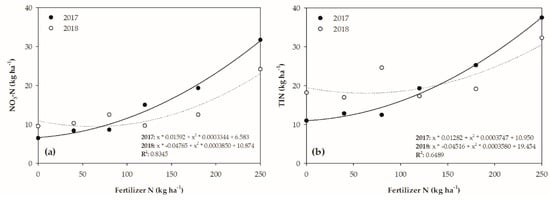

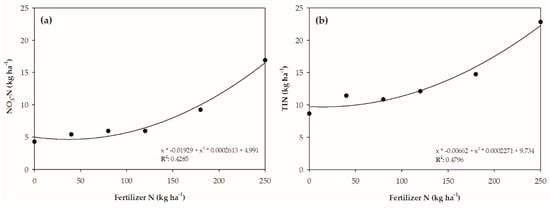

Post-harvest soil NO3-N and total inorganic N (NO3-N + NH4-N, TIN) in the 0–0.6 m layer were affected by the interaction between growing season and treatment (Table 2, Figure 2a,b). Significant differences among 120 kg N ha−1 treatments differing in N source and/or timing were found for NO3-N and TIN. Residual NO3-N and TIN did not differ between treatments in 2018 but were greater in the 120 kg N ha−1 SuperU and pre-plant urea treatments relative to the split-urea treatment in 2017.

Figure 2.

(a) response of post-harvest soil NO3-N and (b) total inorganic nitrogen (NO3-N + NH4-N, TIN) to fertilizer nitrogen (N) rate for first-year maize in 2017 and 2018.

3.2. Second-Year Maize

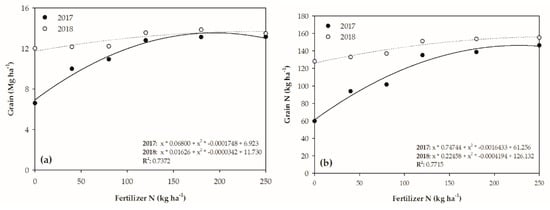

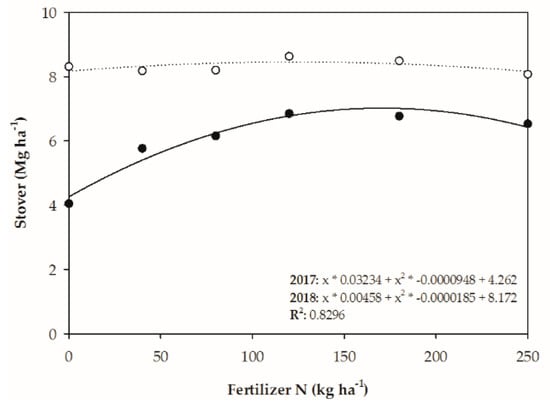

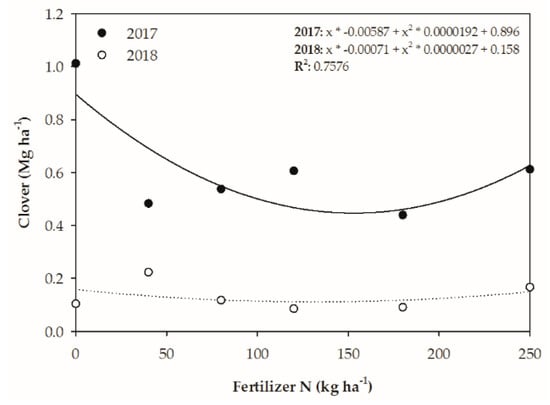

There was a significant growing season-by-treatment interaction effect for maize grain, grain N, and stover yields (Table 3, Figure 3a,b, Figure 4), but N rate and timing treatments were not significantly different within a growing season. Late-season clover biomass responded negatively to fertilizer N application in 2017 and biomass was reduced in 2018 relative to 2017. Clover biomass was not significantly different between fertilizer N rate treatments in 2018 (Figure 5).

Table 3.

Growing season and treatment means, standard error, and statistical significance of dependent variables for second-year maize.

Figure 3.

(a) response of grain yield and (b) grain N to fertilizer nitrogen (N) rate for second-year maize in 2017 and 2018.

Figure 4.

Response of stover yield to fertilizer nitrogen (N) rate for second-year maize in 2017 and 2018.

Figure 5.

Response of late season clover biomass yield to fertilizer nitrogen (N) rate for second-year maize in 2017 and 2018.

Post-harvest soil NO3-N and TIN were significantly affected by growing season and treatment, with greater soil N in 2018 than 2017 and increased residual N content with fertilizer N application (Figure 6a,b). Nitrate-N and TIN did not differ between source and timing treatments within a growing season.

Figure 6.

(a) response of post-harvest soil NO3-N and (b) total inorganic nitrogen (NO3-N + NH4-N, TIN) to fertilizer nitrogen (N) rate for second-year maize, across 2017 and 2018.

3.3. Economic Performance

Fertilizer N was needed to maximize economic return from grain production in second-year maize (Table 3). The EONR was 0 kg N ha−1 for first-year maize in both growing seasons, and 177 and 146 kg N ha−1 for second-year maize in 2017 and 2018, respectively. At the EONR, crop and soil N variables were consistent, with approximately 13 Mg maize grain ha−1 and < 20 kg ha−1 of post-harvest TIN in the 0–0.6 m layer (Table 4).

Table 4.

Level of dependent variables in first- and second-year maize at the economic optimum nitrogen rate (EONR) in 2017 and 2018.

Partial management cost, the sum of agronomic management costs that corresponded with treatment management and yield at the EONR for the KCLM experiments and the conventional comparison, were greater in the KCLM system than conventionally managed maize (Table 5). High spring tillage and stover harvest, handling, and nutrient replacement costs (1.65 kg P Mg−1 + 7.65 kg K Mg−1, $6 Mg−1 dry stover) [27] increased the partial management cost in the KCLM system by $101–303 ha−1 relative to conventional management. Nitrogen costs were reduced by $132 ha−1 in first-year maize, while the cost of fertilizer N for second-year maize was similar to the conventional comparison.

Table 5.

Partial management cost (in U.S. $ ha−1) for maize produced conventionally and in KCLM in 2017 and 2018.

Net return from maize grain was reduced in the KCLM system compared to conventional management due to reduced yield and increased partial management cost. Net return was greater in 2018 than 2017 due to greater stover yields in first- and second-year maize. Additional revenue from stover harvest increased the partial economic net return of the KCLM system averaged between first- and second-year maize to $-42 ha−1 and $318 ha−1 in 2017 and 2018, respectively (Table 6).

Table 6.

Economic return (in U.S. $ ha−1) for maize produced conventionally and in KCLM in 2017 and 2018.

4. Discussion

Results from this study demonstrate that kura clover living mulch may be integrated into current cropping systems to provide economic and environmental benefits. Net economic return at the EONR in the KCLM system was similar or superior to the conventional comparison for first- and second-year maize in both growing seasons. Maize grain yield was reduced and management costs were increased in the KCLM system relative to the conventional comparison, but the added value from maize stover maintained or increased economic net return. With KCLM, residual soil TIN was <20 kg N ha−1 in the 0–0.6 m soil layer at the EONR in first- and second-year maize in both growing seasons. Additionally, KCLM has been shown to protect soils from erosion, decreasing the risk of degradation to soil and water resources during vulnerable fall and spring months when soils under conventional management are fallow [33,34].

Maintaining clover vigor in a KCLM system is challenging since spring clover regrowth is affected by variable weather conditions, maize production requires intensive clover suppression management, and shade from maize limits mid- and late-season clover growth [4]. Snowfall (25 cm) at the study site on 16 April 2018 delayed spring clover growth and development relative to 2017 and eliminated the need for mowing prior to row establishment in second-year maize. Following row establishment and maize planting, rapid growing degree day accumulation and maize development shaded the clover canopy before a second mowing was needed to manage competition between clover and maize. Less aggressive in-season suppression management in 2018 reduced mechanical clover disturbance, but late-season clover biomass was reduced by three-quarters relative to 2017 due to heavy shading. Management to mitigate reductions in clover biomass and vigor due to shading is limited, but may be important to reduce clover recovery time in the following spring [1,4].

Agronomic management preceding row crop production in KCLM influences N contributions during the maize year. Second-year maize grain yield was affected by the interaction between growing season and treatment, where grain yield for non-N-fertilized maize in 2018 was 4.8 Mg ha−1 greater and increased more gradually with applied N than in 2017. These differences may be attributed to differences in weather during the growing season or grain yield level. However, cumulative precipitation and growing degree day accumulation were similar in both growing seasons, and first-year maize did not respond to treatment, growing season, or the interaction of these factors. Thus, it is most likely that the number of years in forage management prior to treatment application was the main factor affecting maize yield response to fertilizer N in second-year maize experiment, confirming previous findings for maize following alfalfa (Medicago sativa) [35,36].

Forage legumes increase the soil labile N pool relative to fertilized maize systems [37,38]. Forage stands ≥3 yr. old at termination often accumulate enough labile organic N to eliminate the need for fertilizer N in first-year maize [35] and in many cases second-year maize [36,39]. While labile N accumulates under forage legume production, intensive grazing or harvest of sole kura clover reduces root and shoot biomass productivity over time [40,41]. The intensity of mechanical and chemical suppression of KCLM in the spring disturbs root and shoot tissues [17], while maize reduces late-season clover biomass due to competition for light and plant resources [42]. The translocation of metabolites from root biomass during the spring flush of clover growth and limited opportunity for biomass recovery in living mulch management is likely to exacerbate the decline of root biomass, spring vigor, and clover health. Rapid root accumulation after the establishment year has been observed in other forage legumes, where root biomass doubled between the first and second year of establishment [43]. The additional year of forage management preceding treatment application in 2018 relative to 2017 may have allowed for greater recovery of root biomass and accumulation of labile N. The magnitude of these accumulated N pools was large enough to reduce fertilizer N requirements for two years of maize production when the clover was managed as forage for ≥2 yr.

The relationships between clover forage production, maize production, and N contributions from the KCLM-maize cropping system add complexity to the current understanding of N management in these systems. Early studies found that KCLM systems supply most or all of the N requirements for maize [1], suggesting that N contributions from KCLM are supplied in the same year as biological N fixation. Although the response to fertilizer N in second-year maize may have been partially influenced by fall and spring growing conditions and maize development, both of which influence clover growth, early-season clover growth and vigor are closely linked to clover root biomass [40]. The number of years in forage preceding first-year maize is likely an important factor for re-accumulation of root biomass that is translocated to shoots in early spring, linking clover root biomass, spring vigor, and mineralized clover biomass N following suppression management. This study suggests that the N contribution from the living mulch is supplied in-season following row establishment and suppression management, and that mineralized N is sourced from labile and biomass N pools accumulated during forage management. First-year maize following ≥ 2yr of forage management does not need fertilizer N and second-year maize requires fertilizer N near University guidelines for maize following soybean. Additional research is needed to confirm these relationships with a greater number of rotation management variables, and to quantify the effect of KCLM management on root biomass pools. Optimization of crop rotation in KCLM systems may balance the health of the clover and the row crop to realize sustainable N contributions over a greater number of growing seasons.

5. Conclusions

Maize grown in KCLM was economically similar or superior to that produced conventionally due to additional income from maize stover harvest. Kura clover living mulch reduced the fertilizer N requirement for first-year maize in both growing seasons and second-year maize in 2018 relative to the conventional comparison. These benefits promote the use of KCLM systems for continuous maize production; however, further optimization is needed to reduce adoption barriers of KCLM-maize systems. Barriers to adoption of KCLM systems for maize production include slow clover establishment, which may take land out of production for a full growing season, the need for specialized row establishment equipment, suppression management operations that require multiple passes during the spring planting season and required maize stover harvest that can be challenging during wet fall conditions. These adoption barriers may be offset by agronomic benefits of KCLM systems, including the potential to reduce P and K application rates by up to one-half through band application with the rotary zone tillage tool relative to broadcasting [44,45]. Additionally, increased water infiltration in KCLM systems [11] may distribute precipitation over the landscape more evenly, reducing areas affected by flooding and reducing the time from rainfall until field conditions are suitable for field operations. Potential avenues for system optimization may include research to speed clover establishment, utilization of strip-tillage equipment that is more readily available than the rotary zone tillage tool, suppression techniques to reduce root and rhizome biomass disturbance, and alternative row-crop rotations. Alterations in agronomic management should consider potential impacts on mineralization of accumulated organic N pools and how this may affect the fertilizer N requirement of row crops. Research to address these constraints may improve the competitiveness of KCLM systems with conventional cropping systems, leading to increased adoption and realized environmental and economic benefits of KCLM systems. Kura clover living mulch-row crop systems may be an important strategy for reducing the negative impacts of agricultural production on water quality and soil health through improved water infiltration into soils, reduced residual soil N following row crops, increased protection against soil erosion, and increased gross crop productivity.

Author Contributions

Conceptualization, J.B., R.V. and J.C.; Data curation, J.A.; Formal analysis, J.A.; Funding acquisition, J.B. and R.V; Investigation, J.A., J.B., R.V. and J.C.; Methodology, J.A., J.B., R.V and J.C.; Project administration, J.B. and R.V; Resources, J.B. and R.V; Supervision, J.B., R.V. and J.C.; Validation, J.A and J.C.; Visualization, J.A; Writing—original draft, J.A; Writing—review and editing, J.A., J.B., R.V and J.C.

Funding

This research was funded by the Minnesota Corn Research and Promotion Council, Grant No. 4097-13SP.

Acknowledgments

The authors thank Michael Dolan, William Breiter, Cody Winker, Ryan Felton, and Seiya Wakahara for technical assistance with field sampling and laboratory analysis. The use of trade, firm, or corporation names in this publication is for the information and convenience of the reader. Such use does not constitute an official endorsement or approval by the United States Department of Agriculture or the Agricultural Research Service of any product or service to the exclusion of others that may be suitable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Fixed costs associated with grain production in conventional and KCLM systems.

Table A1.

Fixed costs associated with grain production in conventional and KCLM systems.

| Input (Unit) | $ unit−1 | $ ha−1 † |

|---|---|---|

| Land | - | 500 |

| Fertilizer P ‡ (kg) | 0.86 | 57.84 |

| Fertilizer K ║ (kg) | 0.60 | 32.28 |

| Fertilizer Application | - | 8.90 |

| Seed (1000 seeds) | 3.26 | 280.36 |

| Planting | - | 26.69 |

| Herbicide | - | 69.19 |

| Insecticide | - | 57.58 |

| Spraying | - | 10.38 |

| Harvest | - | 73.14 |

| Labor | - | 96.87 |

| Miscellaneous | - | 22.24 |

| Total | 1235.47 |

† Estimates were obtained from Plastina, 2018. ‡ Phosphorous (P). ║ Potassium (K).

References

- Zemenchik, R.A.; Albrecht, K.A.; Boerboom, C.M.; Lauer, J.G. Corn production with kura clover as a living mulch. Agron. J. 2000, 92, 698–705. [Google Scholar] [CrossRef]

- Affeldt, R.P.; Albrecht, K.A.; Boerboom, C.M.; Bures, E.J. Integrating Herbicide-Resistant Corn Technology in a Kura Clover Living Mulch System. Agron. J. 2004, 96, 247–251. [Google Scholar] [CrossRef]

- Pedersen, P.; Bures, E.J.; Albrecht, K.A. Soybean production in a kura clover living mulch system. Agron. J. 2009, 101, 653–656. [Google Scholar] [CrossRef]

- Grabber, J.H.; Jokela, W.E.; Lauer, J.G. Soil nitrogen and forage yields of corn grown with clover or grass companion crops and manure. Agron. J. 2014, 106, 952–961. [Google Scholar] [CrossRef]

- Siller, A.R.S.; Albrecht, K.A.; Jokela, W.E. Soil erosion and nutrient runoff in corn silage production with Kura clover living mulch and winter rye. Agron. J. 2016, 108, 989–999. [Google Scholar] [CrossRef]

- Ochsner, T.E.; Albrecht, K.A.; Schumacher, T.W.; Baker, J.M.; Berkevich, R.J. Water balance and nitrate leaching under corn in kura clover living mulch. Agron. J. 2010, 102, 1169–1178. [Google Scholar] [CrossRef]

- Schmer, M.R.; Brown, R.M.; Jin, V.L.; Mitchell, R.B.; Redfearn, D.D. Corn Residue Use by Livestock in the United States. Agric. Environ. Lett. 2017, 2, 1–4. [Google Scholar] [CrossRef]

- USDA National Agricultural Statistics Service. Quick Stats; USDA: Washington, DC, USA, 2018.

- Wilhelm, W.W.; Johnson, J.M.F.; Karlen, D.L.; Lightle, D.T. Corn stover to sustain soil organic carbon further constrains biomass supply. Agron. J. 2007, 99, 1665–1667. [Google Scholar] [CrossRef]

- Johnson, J.M.F.; Strock, J.S.; Tallaksen, J.E.; Reese, M. Corn stover harvest changes soil hydrology and soil aggregation. Soil Tillage Res. 2016, 161, 106–115. [Google Scholar] [CrossRef]

- Baker, J.M. Long Term Affects of Kura Clover Living Mulch on Soil Physical Properties; Working Paper; University of Minnesota: St. Paul, MN, USA, 2019. [Google Scholar]

- Pratt, M.R.; Tyner, W.E.; Muth, D.J.; Kladivko, E.J. Synergies between cover crops and corn stover removal. Agric. Syst. 2014, 130, 67–76. [Google Scholar] [CrossRef]

- Ochsner, T.E.; Schumacher, T.W.; Venterea, R.T.; Feyereisen, G.W.; Baker, J.M. Soil Water Dynamics and Nitrate Leaching Under Corn–Soybean Rotation, Continuous Corn, and Kura Clover. Vadose Zo. J. 2017, 17, 1. [Google Scholar] [CrossRef]

- Pearson, C.H.; Brummer, J.E.; Beahm, A.T.; Hansen, N.C. Kura clover living mulch for furrow-irrigated corn in the intermountain west. Agron. J. 2014, 106, 1324–1328. [Google Scholar] [CrossRef]

- Sawyer, J.E.; Pedersen, P.; Barker, D.W.; Ruiz Diaz, D.A.; Albrecht, K. Intercropping corn and kura clover: Response to nitrogen fertilization. Agron. J. 2010, 102, 568–574. [Google Scholar] [CrossRef]

- Alexander, J.R.; Venterea, R.T.; Baker, J.M.; Coulter, J.A. Kura Clover Living Mulch: Spring Management Effects on Nitrogen. Agronomy 2019, 9, 69. [Google Scholar] [CrossRef]

- Dobbratz, M.; Baker, J.M.; Grossman, J.; Wells, M.S.; Ginakes, P. Rotary zone tillage improves corn establishment in a kura clover living mulch. Soil Tillage Res. 2019, 189, 229–235. [Google Scholar] [CrossRef]

- Ricks, N.R. Corn and Soybean Production on Irrigated Coarse-Textured Soils: Integrating Winter Rye and Kura Clover to Reduce Nitrate Leaching. Master’s Thesis, University of Minnesota, Minneapolis, MN, USA, 2019. [Google Scholar]

- Baker, J.M. Vegetative propagation of kura clover: A field-scale test. Can. J. Pln. Sci. 2012, 1245–1251. [Google Scholar] [CrossRef]

- Kaiser, D.E.; Lamb, J.A.; Eliason, R. Fertilizer Guidelines for Agronomic Crops in Minnesota; University of Minnesota Extension: St. Paul, MN, USA, 2011; Volume 1, pp. 1–44. [Google Scholar]

- Bremner, J.M.; Mulvaney, C.S. Nitrogen—Total. In Methods of Soil Analysis; Sparks, D., Ed.; American Society of Agronomy: Madison, WI, USA, 1982; pp. 1085–1089. [Google Scholar]

- Mulvaney, R.L. Nitrogen—Inorganic Forms. In Methods of Soil Analysis Part 3: Chemical Methods; Sparks, D.L., Ed.; American Society of Agronomy: Madison, WI, USA, 1996; pp. 1123–1184. [Google Scholar]

- Hoverstad, T.; Ihlenfeld, W.; Coulter, J.; Reese, C.; Quiring, S.; Hanson, M. Varietal Trial Results: Corn Grain; University of Minnesota Extension: St. Paul, MN, USA, 2017; p. 6. [Google Scholar]

- Hoverstad, T.; Ihlenfeld, W.; Coulter, J.; Reese, C.; Quiring, S.; Hanson, M. Varietal Trial Results: Corn Grain; University of Minnesota Extension: St. Paul, MN, USA, 2018; p. 6. [Google Scholar]

- Edwards, W. Estimating a Value for Corn Stover; Ag Decision Maker—Iowa State University Extension and Outreach: Ames, IA, USA, 2014; Volume 1, pp. 1–4. [Google Scholar]

- Plastina, A. Estimating Costs of Crop Production in 2018; Ag Decision Maker—Iowa State University Extension and Outreach: Ames, IA, USA, 2018; Volume 1, pp. 1–13. [Google Scholar]

- Sawyer, J.E.; Mallarino, A.P. Nutrient Considerations with Corn Stover Harvest; Iowa State University (ISU) Extension and Outreach, ISU: Ames, IA, USA, 2014; pp. 1–3. [Google Scholar]

- Battaglia, M.; Groover, G.; Thomason, W. Harvesting and nutrient replacement costs associated with corn stover removal in Virginia; Virginia Cooperative Extension: Petersburg, VA, USA, 2018; pp. 1–9. [Google Scholar]

- Bates, D.; Maechler, M.; Bolker, B.; Walker, S.; Christensen, R.H.B.; Singmann, H.; Dai, B.; Eigen, C. Package “lme4”. Compr. R Arch. Netw. 2014, 1–123. [Google Scholar]

- Kutner, M.H.; Nachtsheim, C.J.; Neter, J. Applied Linear Regression Models, 4th ed.; McGraw-Hill: New York, NY, USA, 2004; pp. 107–152. [Google Scholar]

- Lenth, R.; Singmann, H.; Love, J.; Buerkner, P.; Herve, M. Package “emmeans”: Estimated Marginal Means, aka Least-Squares Means. Compr. R Arch. Netw. 2019, 1–67. [Google Scholar]

- Plastina, A.; Johanns, A.; Wynne, G. 2019 Iowa Farm Custom Rate Survey. Ag Decis. Mak. 2019, 1–5. [Google Scholar]

- Helmers, M.J.; Lawlor, P.A.; Baker, J.L.; Melvin, S.W.; Lemke, D.W. Temporal Subsurface Flow Patterns from Fifteen Years in North-Central Iowa. Soc. Eng. Agri. Food Bio. Sys. Conf. Proc. 2005, 1–13. [Google Scholar]

- Qi, Z.; Helmers, M.J.; Christianson, R.D.; Pederson, C.H. Nitrate-Nitrogen Losses through Subsurface Drainage under Various Agricultural Land Covers. J. Environ. Qual. 2011, 40, 1578. [Google Scholar] [CrossRef] [PubMed]

- Yost, M.A.; Russelle, M.P.; Coulter, J.A.; Schmitt, M.A.; Sheaffer, C.C.; Randall, G.W. Stand age affects fertilizer nitrogen response in first-year corn following alfalfa. Agron. J. 2015, 107, 486–494. [Google Scholar] [CrossRef]

- Yost, M.A.; Morris, T.F.; Russelle, M.P.; Coulter, J.A. Second-Year Corn after Alfalfa Often Requires No Fertilizer Nitrogen. Agron. J. 2014, 106, 659–669. [Google Scholar] [CrossRef]

- Carpenter-Boggs, L.; Pikul, J.L.; Vigil, M.F.; Riedell, W.E. Soil Nitrogen Mineralization Influenced by Crop Rotation and Nitrogen Fertilization. Soil Sci. Soc. Am. J. 2000, 64, 2038. [Google Scholar] [CrossRef]

- Singh, G.; Schoonover, J.E.; Williard, K.W.J.; Kaur, G.; Crim, J. Carbon and Nitrogen Pools in Deep Soil Horizons at Different Landscape Positions. Soil Sci. Soc. Am. J. 2018, 82, 1512. [Google Scholar] [CrossRef]

- Yost, M.A.; Russelle, M.P.; Coulter, J.A. Field-specific fertilizer nitrogen requirements for first-year corn following alfalfa. Agron. J. 2014, 106, 645–658. [Google Scholar] [CrossRef]

- Peterson, P.R.; Sheaffer, C.C.; Jordan, R.M.; Christians, C.J. Responses of kura clover to sheep grazing and clipping: II. Below-ground morphology, persistence, and total nonstructural carbohydrates. Agron. J. 1994, 86, 660–667. [Google Scholar] [CrossRef]

- Peterson, P.R.; Sheaffer, C.C.; Jordan, R.M.; Christians, C.J. Responses of kura clover to sheep grazing and clipping: I. Yield and forage quality. Agron. J. 1994, 86, 655–660. [Google Scholar] [CrossRef]

- Baributsa, D.N.; Foster, E.F.; Thelen, K.D.; Kravchenko, A.N.; Mutch, D.R.; Ngouajio, M. Corn and cover crop response to corn density in an interseeding system. Agron. J. 2008, 100, 981–987. [Google Scholar] [CrossRef]

- Bolinder, M.A.; Angers, D.A.; Bélanger, G.; Michaud, R.; Laverdière, M.R. Root biomass and shoot to root ratios of perennial forage crops in eastern Canada. Can. J. Plant Sci. 2011, 82, 731–737. [Google Scholar] [CrossRef]

- Kaiser, D.E.; Pagliari, P. Understanding phosphorus fertilizers|UMN Extension. Available online: https://extension.umn.edu/phosphorus-and-potassium/understanding-phosphorus-fertilizers#corn-624160 (accessed on 2 June 2019).

- Kaiser, D.E.; Rosen, C.J. Potassium for crop production|UMN Extension. Available online: https://extension.umn.edu/phosphorus-and-potassium/potassium-crop-production#corn-and-small-grain-603411 (accessed on 2 June 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).