1. Introduction

The operational efficiency and precision of boom sprayers, as indispensable equipment for field crop protection worldwide, directly impact food security, agricultural production costs, and ecological sustainability [

1,

2,

3,

4,

5]. In the context of precision agriculture, achieving uniform chemical application is fundamental to enhancing crop yields and ensuring ecological safety, an objective that hinges on maintaining boom stability during operation. Severe boom vibration not only leads to practical issues like missed spraying, double spraying, and pesticide drift [

6,

7,

8,

9], which waste expensive chemicals and potentially harm crops, but it has also become a critical bottleneck for cutting-edge applications. For advanced visual technologies like “spot spraying,” for instance, the violent motion of the boom can render image acquisition and target recognition systems completely ineffective [

10]. However, achieving absolute boom stability is a complex task, as the suspension system design must constantly grapple with a fundamental technical contradiction: to effectively isolate high-frequency vehicle vibrations caused by uneven terrain while precisely following large-scale, low-frequency slope variations across the field [

9,

11]. The powerful driving force behind resolving this core contradiction stems from its substantial economic benefits. Research has shown that combining precision navigation with automated boom control technology significantly reduces overlap, saving farmers substantial input costs, particularly in irregularly shaped fields [

12]. Despite these clear technical objectives and economic incentives, the technology’s evolution and application level remain markedly uneven globally. In developed agricultural markets characterized by large-scale farms, the technological path has advanced from traditional passive suspensions to high-performance active balancing systems becoming standard equipment. In contrast, passive systems remain dominant in many small-to-medium-sized farms or cost-sensitive markets, where the associated advanced control technologies are still in development or have yet to achieve widespread adoption [

1,

13].

To address this context and provide a structured overview for a complex and evolving field, this paper presents a comprehensive and systematic survey of boom self-balancing technology. Our contribution is fourfold. First, we provide a foundational dynamic analysis of the root causes of boom instability, moving beyond a simple problem statement to explore the underlying physical mechanisms. Second, we uniquely categorize existing balancing solutions based on their core “design philosophies,” offering a novel perspective on technology’s evolutionary path. Third, we present a detailed synthesis of the progression in both sensing and control strategies, tracing their development from classical methods to the latest AI-driven approaches. Finally, by identifying current challenges and outlining future trends, this survey serves not only as a retrospective summary but also as a forward-looking roadmap intended to guide and inspire future research and development in this critical area.

2. Dynamics of Spray Booms

2.1. Forms and Quantification of Boom Instability

The movement of spray booms during field operations constitutes a complex three-dimensional dynamic phenomenon, with their unstable motion patterns directly impacting spray quality. These motions are typically decomposed into several primary modes. Among them, the most direct and significant effects on spray uniformity stem from overall vertical bouncing and rolling motions around the travel axis [

10,

14]. Movements within the horizontal plane are equally significant, particularly yaw around the vertical axis and fore-aft sway along the travel direction. These have also been confirmed as key factors causing uneven spray distribution [

6]. To deeply understand the detrimental effects of these motions, extensive research has focused on their precise quantification through field trials. Studies indicate that under typical field conditions, the height variation at the end of a large boom can easily exceed 50 cm, with roll angles surpassing 3° [

14]. By deploying triaxial accelerometers at critical locations—such as the chassis, boom center, and both ends—researchers can capture the structural transmission and response of vibrations [

15]. On a more demanding test track simulating field obstacles, the boom exhibited extreme dynamic responses: its vertical height variation at the end could exceed 3 m while enduring instantaneous accelerations as high as 20.7 g [

4]. These precisely quantified, high-intensity transient motions are the direct physical causes of the aforementioned issues, including uneven spraying and pesticide drift.

2.2. Vibration Sources and Resonance Mechanisms

The vibration of the spray boom is not a spontaneous occurrence, but rather a response to external excitation sources. This amplification of vibration is caused by resonance, which is a core physical mechanism. These excitation sources can be divided into two main types: random excitation from the ground surface and periodic excitation from the vehicle body itself. The uneven ground is the most significant disturbance source, with the majority of excitation energy concentrated in the low-frequency range of 0–1 Hz. As the driving speed increases, the intensity of excitation also increases [

15]. However, higher-frequency excitation from the vehicle body can also be detrimental, especially unbalanced inertial forces from the engine. Modal analysis has shown that wide spray booms typically have low-order natural frequencies below 120 Hz. In the case of a specific 24 m spray boom, the second-order inertial force frequency of the engine closely matches the third-order bending mode natural frequency [

16]. When the frequency of the excitation source coincides with or is close to a structural mode frequency, resonance occurs. This can result in significant vibration responses in the boom, even with minor excitation inputs. In addition to direct excitation sources, factors such as liquid sloshing within the tank can also contribute to the amplification of boom vibration responses [

16]. Therefore, it is essential to have a thorough understanding of the frequency characteristics of excitation sources, accurately identify the modal parameters of the boom, and analyze the risk of resonance between the two. These are necessary prerequisites and foundations for designing suspension vibration reduction and implementing active control measures.

2.3. Hazards of Unstable Motion

The severe disruption of spray uniformity caused by boom instability is a well-documented issue with a clear physical mechanism. Laboratory studies have systematically unraveled the specific impacts of different motion modes on spray distribution by decoupling complex boom movements. For example, roll motion directly disrupts spray distribution by altering the vertical distance between nozzles on opposite sides of the boom and the target, leading to over-application on one side and under-application on the other [

17]. On the other hand, yaw motion influences dose distribution by altering the horizontal movement speed of nozzles relative to the target. This can be particularly problematic at the velocity inflection point of boom oscillation, where extremely low instantaneous horizontal speeds can cause severe localized overapplication of spray solution. In addition to movement patterns, the physical properties of the droplets themselves, such as droplet size, play a crucial role in regulating spray distribution. Field trials have clearly demonstrated that small droplets are highly sensitive to boom dynamics. For instance, when using 255 μm droplets, spray coverage exhibits a significant negative correlation with instantaneous boom height—higher boom positions yield poorer coverage, with a coefficient of variation (CV) reaching up to 55%. In contrast, 588 μm droplets show negligible coverage variation with boom height changes. This is because small droplets, being lighter and settling more slowly, are more susceptible to turbulence induced by boom movement, thereby exacerbating spray distribution irregularities [

4,

17]. Therefore, the detrimental effects of boom instability are not constant but rather result from the complex interaction between kinematic characteristics and droplet aerodynamics.

2.4. Kinematic Modeling and Parameter Optimization

Precise dynamic modeling and parameter optimization [

18,

19] elevate the design of boom suspension from a “trial-and-error” approach to a more scientific “model-guided” approach. This process involves creating a mathematical model that accurately reflects the system’s dynamic behavior and using it to identify the optimal combination of parameters. Researchers have explored various technical pathways, with early work focusing on linear system relationships through transfer functions [

13] or using 3D CAD software for kinematic analysis. More recent research has adopted multibody dynamics theories, such as the Lagrangian method, to construct nonlinear models that consider factors like vehicle body coupling, friction, and other variables [

20]. To improve the realism of these models, researchers have also developed hybrid approaches that combine analytical equations with experimental data identification [

8,

21]. Currently, the most accurate model is the rigid-flexible coupling model, which uses co-simulation software to account for both rigid body motion and elastic deformation [

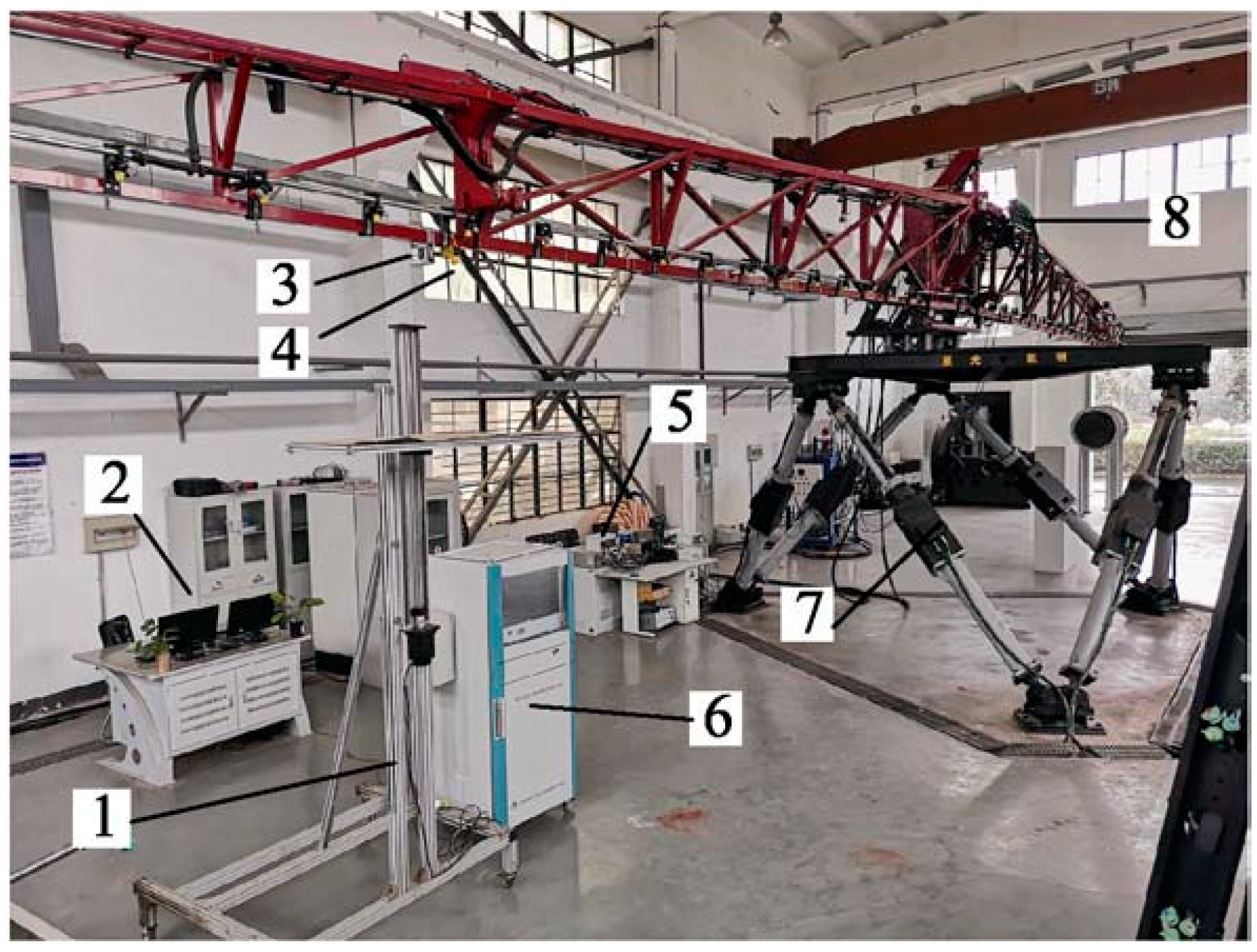

22]. However, all models must undergo experimental validation to prove their effectiveness, and laboratory testing platforms are crucial for this purpose. For example, Cui et al. developed a complex six-degree-of-freedom motion platform (

Figure 1) capable of replicating real-world field movement data. Through frequency response testing, they were able to minimize the error between the model’s predictions and experimental values, confirming its accuracy [

22]. The Herbst team took a different approach, using a static test rig to simulate ground conditions by moving a target beneath a stationary sprayer. This method allows for the independent evaluation of the system’s elevation and leveling performance, providing a reference for establishing standardized testing procedures [

23,

24].

For parameter optimization, there are currently two primary approaches: model-driven optimization and data-driven optimization. The first is model-driven optimization, which involves analyzing how different parameters affect system performance [

25]. This can range from basic applications to more complex ones that use a comprehensive intelligent optimization workflow. This workflow includes efficient sampling techniques such as optimal Latin hypercube sampling, running high-fidelity simulations, creating fast-computing surrogate models using neural networks, and identifying global optima using multi-objective optimization tools such as genetic algorithms [

22]. The second approach is data-driven optimization, which bypasses complex models and directly analyzes real-world field data, such as from orthogonal experiments, to determine optimal parameters [

19]. Lardoux et al. also propose a hybrid approach that combines both model-driven and data-driven optimization. They measure motion responses as the device navigates a standard obstacle and input these into a validated spray distribution model for simulation evaluation. This approach strikes a balance between testing efficiency and realism [

26]. These modeling, validation, and optimization methods collectively form the core technological framework of modern boom suspension design.

3. Self-Balancing Boom Solutions

3.1. Passive Stabilization Approach

Passive stabilization is the most commonly used design approach for boom suspension systems. It relies on mechanical structures and components to stabilize the boom without the need for external energy input. This method is cost-effective and widely used in the market for small-to-medium-sized and mounted sprayers. Traditional passive suspension structures include pendulum-type and trapezoidal linkage designs. According to FROST’s model simulations, these suspensions effectively utilize the gravity-return principle and linkage constraints to reduce high-frequency vibrations from the vehicle body [

9]. However, FROST’s research also revealed a fundamental limitation of passive suspension: it is unable to adapt to large-scale, low-frequency slope variations in the field, resulting in poor performance on inclined terrain.

Despite its limitations, researchers are still actively exploring new innovations and optimizations for passive structures. For example, Sobotka et al. proposed a unique passive stabilization system that uses self-balancing through the center of gravity of a suspended boom frame on bearing shafts. Their goal was to improve stability purely through mechanical means [

27]. At the same time, there is a growing focus on maximizing the performance of existing passive suspensions by precisely matching parameters such as spring stiffness and damper damping coefficients. Zhuang et al. used an orthogonal experimental design to identify the optimal combination of parameters for vibration-reducing components through field trials. As a result, they were able to achieve a 4% increase in the proportion of stabilized sprayer roll angles within a 0.6° range after optimization [

19]. Anthonis and Ramon’s research highlights the crucial role of accurately identifying and optimizing components like dampers when dealing with strong nonlinearities [

6]. Therefore, passive solutions, with their simple structure and ongoing optimization efforts, continue to be an essential aspect of boom balancing technology.

3.2. Active Control Solutions

To fundamentally overcome the performance limitations of passive suspension, active control solutions have emerged. These solutions involve introducing external energy sources and using sensing, control, and actuation units to intelligently adjust the boom posture. This technical approach has evolved into distinct tiers based on design objectives and cost positioning.

The first tier, known as “Assistive Active,” does not aim to completely eliminate all disturbances. Instead, it utilizes affordable and energy-efficient active components to specifically target the most crucial issues of passive suspension. A notable example in this field is the “slow-active” suspension [

28], which was proposed and extensively studied by Deprez et al. They recognized that the main limitation of passive suspension is its inability to automatically adjust to gradual changes in ground slope. To address this, they ingeniously incorporated a low-power DC motor as an active actuator into a cable-based passive suspension system. The primary purpose of this active system is not to improve bump response, but rather to automatically make low-frequency slope adjustments that previously required manual operation. Additionally, it provides extra active damping to the entire suspension system. With minimal added cost and energy consumption, it effectively compensates for the fundamental shortcomings of passive suspension [

8,

28].

A higher-order approach is considered the most advanced control scheme for boom balancing technology, known as the “fully active” approach. It is designed to effectively suppress disturbances across a wide range of frequencies. This approach, first introduced by FROST through his pioneering simulation research, involves real-time sensing of the relative position between the strut and the ground using sensors. The controller then uses this information to actively adjust the suspension geometry through actuators, effectively suppressing disturbances across a wide range of frequencies. This approach allows for precise and rapid tracking of low-frequency slope changes without compromising the high-frequency isolation capabilities, resolving the main technical challenge of passive suspension [

9]. In terms of specific mechanical implementation, researchers have developed active control solutions based on various suspension designs. Sun and Miao integrated an electrohydraulic self-leveling system into a passive four-bar linkage suspension, forming a hybrid system combining passive and active elements. Dynamic analysis and simulation results demonstrate that the passive component achieves excellent self-balancing within a small tilt range, while the active component provides rapid compensation responses to large disturbances [

29]. Another example is the work of Fang Li et al., who developed a CAN-based distributed control system for the more advanced double-pendulum active suspension. Simulation and experimental validation confirmed its high efficiency under PSO-optimized fuzzy PID control [

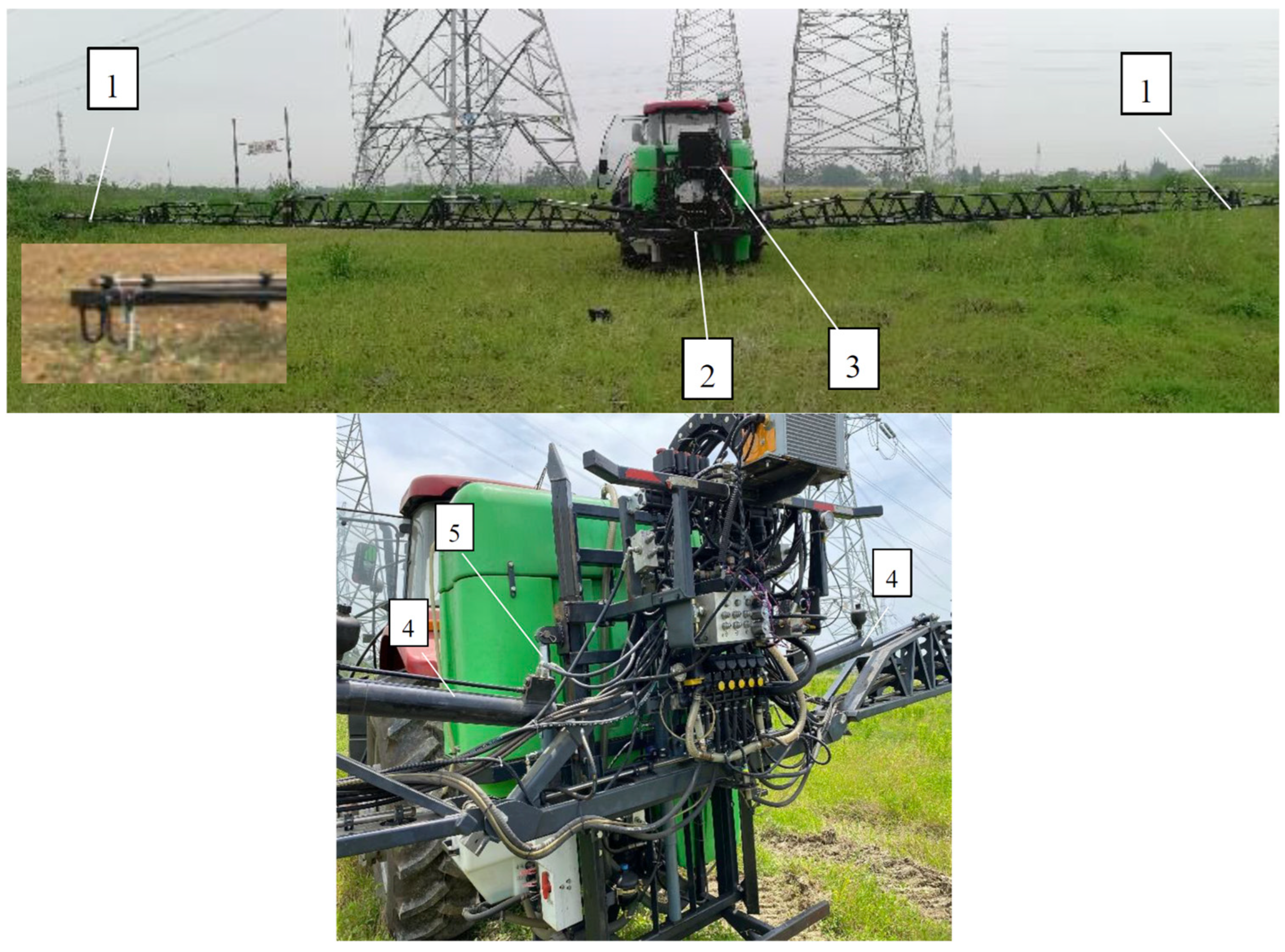

30]. Similarly, Li Jinyang et al. also successfully designed and validated an active control scheme for the widely used trapezoidal suspension (

Figure 2). Field test results compellingly demonstrated the powerful capabilities of active control: under severe conditions where the chassis reached a maximum roll angle of 3.896°, the maximum boom tilt angle was successfully suppressed to 0.453° [

7]. These solutions commonly employ high-response electro-hydraulic servo systems or high-precision electric actuators as actuators, providing the most reliable physical platform for achieving the most uniform spray distribution.

3.3. Disruptive Structural Solutions

Beyond passive and active suspension approaches, a paradigm shift emerged by transcending traditional mechanical linkage frameworks. This exploration fundamentally reimagined spray boom support and balancing mechanisms, giving rise to disruptive structural and dynamic solutions. Zhou Zhiyan et al. proposed the “rotor-suspended boom”. This solution insightfully recognized the physical limitations of traditional ultra-long truss booms—namely their weight, complexity, and detrimental impact on vehicle maneuverability—particularly in challenging environments like paddy fields. To address this, they innovatively integrated drone technology with ground machinery by mounting rotors at both ends of the boom. The active lift generated by these rotors “suspends” the boom in mid-air. This approach fundamentally decouples the mechanical connection between the boom, vehicle body, and ground, transforming complex mechanical vibration damping into a purer flight attitude control problem based on dual-sensor fusion of gyroscopes and LiDAR. Field trials demonstrated that, using fuzzy PID control algorithms, the hovering spray boom exhibits exceptional levelness (standard deviation < 0.11 m) and height stability (coefficient of variation < 1.5%), fully validating the feasibility of this novel operational approach [

31]. However, it is crucial to address the practical constraints of this disruptive design philosophy before considering it for commercial deployment. The primary challenge lies in its high energy consumption, as the power required to generate continuous aerodynamic lift is considerably greater than that of conventional active suspensions. Furthermore, the reliability and safety of the rotor systems present another significant hurdle. A failure in a motor or propeller during operation could lead to immediate boom instability, posing risks to both the crop and the machine. Therefore, while this concept offers an imaginative and promising new direction for the future development of ultra-wide, lightweight spray booms—especially for niche applications like paddy fields where conventional machines struggle—it still faces substantial challenges in energy efficiency and system robustness that must be overcome through further research.

4. Perception and Measurement Technology

Precise and reliable sensing is an absolute prerequisite for achieving automatic boom balancing and height adjustment. The core task of the sensing system is to continuously capture the boom’s own posture and its relative positional relationship with the target, providing decision-making basis for the control system. With technological advancement, boom sensing technology has undergone a profound evolution from single, discrete measurements to multi-source, fused form perception. This chapter systematically outlines the development path of sensing technology, delves into the data processing workflow of advanced sensing systems, and introduces precision measurement instruments used for mechanism research and system validation.

4.1. Perception Technology

The development of sensing technology for boom balancing systems has evolved over time, resulting in improved dimensional target information. This progress can be divided into two main stages. The first and most commonly used approach involves single-point height measurement. In this method, sensors are placed at critical points on the spray boom to measure the vertical distance from that point to the target. Ultrasonic sensors are the most prevalent in this stage due to their technical maturity and low cost. For example, Zhang et al. utilized ultrasonic sensors in their STM32-based electronic control system to provide real-time height feedback [

32]. Similarly, Tan Haoran et al. designed a hydraulic closed-loop control system using ultrasonic sensors and thoroughly tested its dynamic performance [

33]. Sun Xing et al. integrated three ultrasonic sensors and an inclinometer into a more complex system [

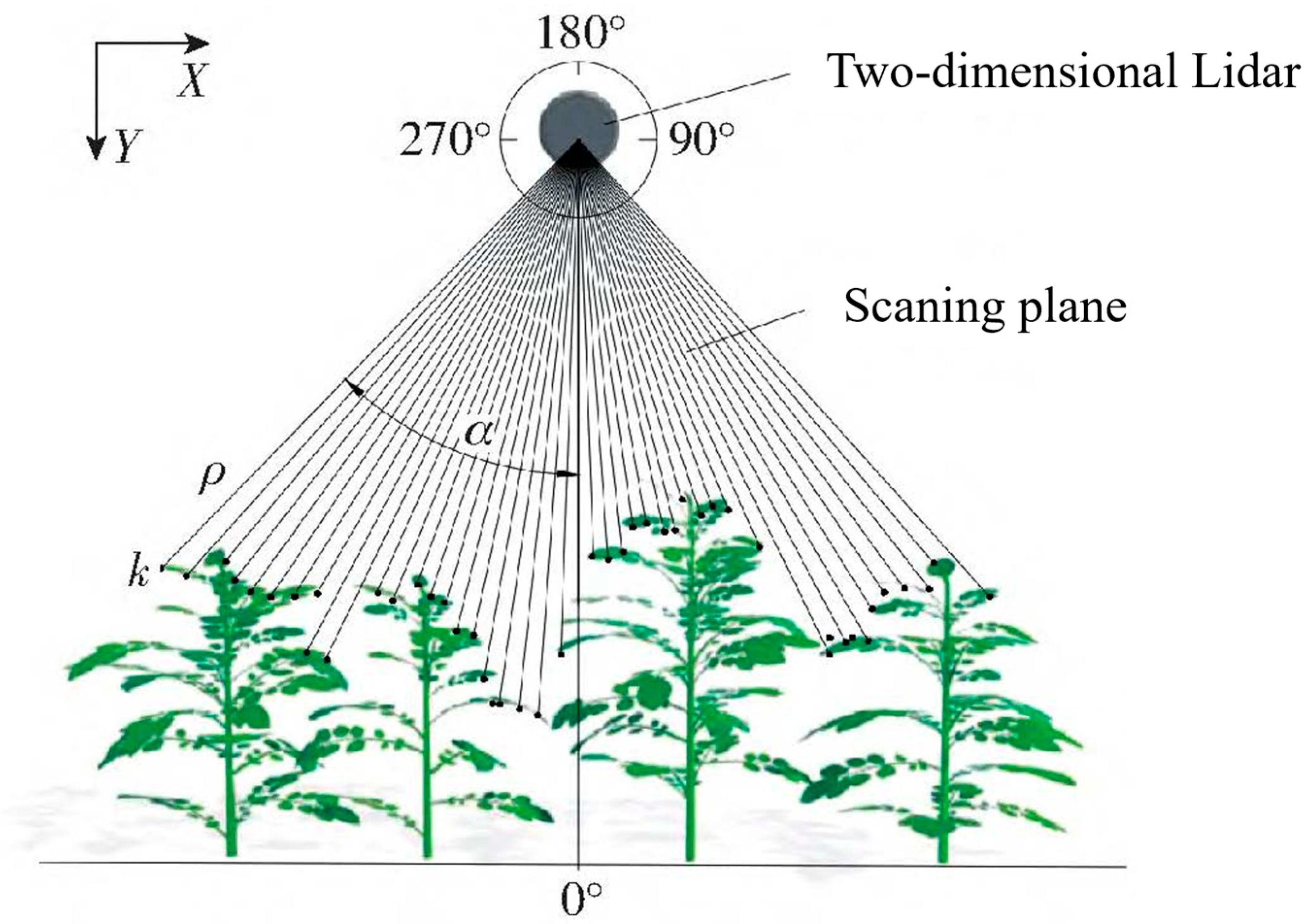

34]. However, ultrasonic sensors are susceptible to interference from dust and fog droplets, and may also misdetect the ground in sparse crop areas or inter-row regions. To address these limitations, some studies have explored alternative solutions. For instance, Dou et al. developed a low-cost LiDAR sensor based on single-point ranging principles (

Figure 3). Comparative experiments with ultrasonic sensors showed that the LiDAR sensor’s accuracy in detecting wheat stubble roots exceeded 95%, with an error margin of less than 5%. However, its performance in detecting crop canopies was significantly affected by driving speed [

35]. Whether using ultrasonic sensors or single-point LiDAR, perception at this stage essentially involves taking one-dimensional, discrete height measurements.

A more advanced approach involves canopy profile scanning and morphological sensing. This is especially important when dealing with crops such as potatoes, which have highly irregular canopy structures. Single-point height data alone is insufficient for precise contour control in such cases. To address this issue, researchers have elevated sensing technology to a new dimension. Pioneering work by Wang Xiangyou et al. demonstrated the potential of using 2D LiDAR to scan crop canopies (

Figure 4). Through point cloud processing and attitude data correction, they achieved real-time calculation of the vertical distance between the spray boom and the canopy top, with an average relative detection error of 3.95% [

36]. This marked a significant advancement in perception technology, moving from “point” to “line” detection. In his dissertation, Qu et al. further refined this technical approach by comparing multiple point cloud processing algorithms. He demonstrated the superior performance of 2D LiDAR in precisely capturing the height of potato canopy tops. Ultimately, he employed the k-means-Alpha-shapes algorithm to control the average relative error at 4.34% [

5]. This evolutionary phase signifies that spray boom sensing technology is advancing from simple distance measurement toward more intelligent machine perception with higher information dimensions.

4.2. Data Processing in Perception Technology

Acquiring raw sensor data is merely the first step in perception. More critically, a series of advanced data processing algorithms are required to extract stable, reliable, and precise state information from noisy and uncertain raw signals. The complexity of data processing is closely tied to the perception technology approach.

For single-point sensors, the core tasks of data processing are filtering and noise reduction. The most fundamental methods employ traditional digital signal processing techniques such as clipping filters and moving average filters to eliminate sudden disturbances in raw ultrasonic signals [

11,

34]. To further enhance accuracy, Dou et al. introduced the K-means clustering algorithm from machine learning into ultrasonic data processing. By grouping data points into clusters of valid signals and noise, they intelligently filtered out outliers, significantly improving sensor detection precision [

14].

When perception technology advances to the “canopy profile scanning” stage, data processing evolves into a more complex point cloud processing workflow. Due to the installation of 2D LiDAR on a moving spray boom, its inherent vibration causes distortion in the scanned point cloud. To address this, Wang Xiangyou et al. proposed that attitude sensor data must first be fused to perform coordinate transformation and attitude correction on the raw point cloud. This eliminates motion blur, yielding the true canopy profile in a global coordinate system [

36]. After obtaining precise point clouds, regions of interest are typically delineated and canopy units segmented based on crop planting patterns to exclude interference from ground surfaces and other irrelevant information. Finally, data fitting is employed to precisely extract canopy top information. Research by Wang Xiangyou and Qu Junzhe demonstrates that curve-fitting algorithms like moving least squares, or clustering-based methods such as k-means-Alpha-shapes, can effectively generate smooth, continuous canopy top contours from discrete, chaotic point clouds. This provides controllers with precise height reference points [

5,

36]. To enhance the intelligence and adaptability of perception systems, Xu Jing designed distinct data filtering methods in her dissertation specifically for broad-leaved and narrow-leaved crops—two types with vastly different morphologies. She quantified the differences in measurement accuracy between these methods, pioneering the research direction of adaptive perception tailored to specific agronomic traits [

13].

4.3. Multi-Sensor Fusion and Feedforward

To obtain more comprehensive and robust system state information, multi-sensor information fusion techniques are widely used in boom attitude control systems to overcome the limitations of single sensors. Information fusion strategies primarily manifest at two levels: state estimation fusion and feedforward control decision-making.

At the state estimation fusion level, the main concept is to combine sensor information from different types and characteristics to achieve state estimates that are better than those from a single sensor. Sun Xing et al. proposed a common configuration where three ultrasonic sensors were used simultaneously in a single system to measure height, along with a dual-axis tilt sensor mounted on the spray boom to measure roll attitude [

34]. By creating a fusion algorithm based on optimal weighting, the measurements from multiple sensors can be averaged with specific weights, resulting in a more stable and reliable estimate of height or attitude [

11,

34]. Zhou Zhiyan et al. utilized a “gyroscope + LiDAR” fusion approach in the more advanced “rotor-based hovering” spray boom. By utilizing high-frequency attitude data from the IMU and precise altitude information from LiDAR, they provided comprehensive and robust state feedback for the flight control system [

31].

At the feedforward layer of control decision-making, information fusion is used to proactively suppress disturbances. This involves deploying additional sensors to anticipate potential disruptions, which are then fed directly into the controller as a feedforward signal. This allows for faster responses. For example, Sun Xing et al. not only installed an inclination sensor on the spray boom, but also on the vehicle chassis. This continuous monitoring of the vehicle’s attitude changes allows the controller to predict how disturbances will affect the spray boom and take corrective actions in advance [

34]. Xu Jing took this concept a step further by using a model-based approach. By establishing a transfer function between the vehicle’s roll angle and the boom’s swing angle, he was able to predict the pose of the boom [

13]. This fusion of perception and prediction represents a significant advancement in control systems, moving from reactive compensation to proactive prediction.

5. Control System and Strategy

The primary function of the control system is to process real-time information from the perception system, generate decision commands based on predetermined control objectives and algorithms, and transmit these commands to the actuators through drive circuits, creating a complete closed-loop feedback circuit. With the rapid development of computer technology, control theory, and artificial intelligence, spray boom control strategies have evolved from simple to complex and from classical to intelligent. This chapter will first examine the progression of control algorithms in this field, explore the combined application and optimization of various algorithms, introduce active control modes designed to meet diverse operational requirements, and analyze the underlying system architecture and hardware implementation that support these advancements.

5.1. Control Algorithms

The development of boom balancing control algorithms is a clear reflection of the evolution of automatic control theory from classical to modern and then to artificial intelligence. The driving force behind this development has always been the pursuit of higher control accuracy and robustness in increasingly complex systems.

The most widely applied and fundamental control method in this field is PID, which is favored for its simplicity, high reliability, and ease of implementation. Yin et al. successfully developed a high-performance automatic leveling system by employing an incremental PID algorithm and optimizing response thresholds and filter parameters through field trials [

37]. To further enhance performance, researchers have incorporated feedforward control into PID systems. Studies by Cui et al. and Li et al. have demonstrated that velocity feedforward PID effectively improves low-frequency tracking performance [

7,

11]. Another class of simple yet effective classical strategies includes switch-mode control, such as threshold control triggered by preset error thresholds [

32,

36], and hysteresis control designed to prevent frequent oscillations near the setpoint [

38].

In the 1990s, Ramon and De Baerdemaeker utilized LQG/LTR methods from optimal control theory to design controllers based on linearized multibody dynamics models of the entire machine [

20]. Anthonis and Ramon also employed the H∞ control method from robust control theory to suppress horizontal boom vibration, using an innovative iterative procedure to address strong nonlinearities such as Coulomb friction in the system [

6]. In recent years, a significant body of work has emerged to address these challenges with more advanced strategies, with the team led by Longfei Cui conducting systematic and pioneering work in this field. To specifically tackle disturbances and hydraulic nonlinearities, they designed and implemented a nonlinear robust controller based on a disturbance observer (DOBC) [

39]. This recent approach is particularly noteworthy as the observer actively estimates and compensates for total system uncertainty, including the uncompensated friction and external disturbances that are notoriously difficult to model in hydraulic systems. Furthermore, they successfully applied other advanced strategies, such as Adaptive Robust Control (ARC), to the active suspension [

21]. These studies have experimentally demonstrated that such controllers can guarantee prescribed transient performance and tracking accuracy even in the presence of parametric uncertainties and unknown disturbances. Experimental comparisons confirmed that these advanced controllers comprehensively outperform traditional PID or PI controllers in handling these complex nonlinearities and uncertainties.

Artificial intelligence control takes a different approach, as it does not rely on precise mathematical models. Instead, it attempts to mimic human knowledge, experience, or biological intelligence for decision-making. This offers new possibilities for handling highly uncertain and nonlinear spray boom systems. For example, Li Maoyuan et al. [

40] have designed adaptive fuzzy controllers, while Zhou Zhiyan and Fang Li et al. [

30,

31] have adopted fuzzy PID controllers, both of which have demonstrated superior adaptability and robustness in simulations or experiments. Additionally, Tahmasebi et al. have incorporated artificial neural networks [

41] and iterative learning control [

42] into their simulation studies on boom vibration suppression. The results of simulation comparisons show that these AI algorithms outperform traditional approaches such as fuzzy PID in terms of performance.

5.2. Strategy Modes in Active Control

To accommodate varying operator preferences and diverse field operation requirements, modern high-performance active control systems typically avoid rigid, single-mode control logic. Instead, they integrate multiple control modes for user selection. These modes represent distinct control objectives and sensing strategies, significantly enhancing system adaptability and practicality. In their DSP-based electronic control system development, Cui et al. systematically designed and compared three mainstream control modes [

43].

The first mode is the roll control mode, which aims to stabilize the overall roll attitude of the boom, ensuring that it maintains a horizontal orientation. This mode typically utilizes an inertial measurement unit (IMU) or inclinometer as the primary sensor, and employs closed-loop feedback control by directly measuring the absolute angle of the boom. Field tests have shown that this mode is highly effective in isolating disturbances from the chassis, successfully reducing chassis roll angles from over 4° to within 0.841°.

The second mode is the wing-tip height control mode. Unlike the roll mode, which focuses on maintaining a specific attitude, this mode’s main goal is ground contouring. It independently controls both wing-tips to keep a constant, predetermined height in relation to the target surface, whether it be the ground or a crop canopy. To achieve this, it utilizes distance sensors such as ultrasonic or LiDAR as its primary sensor. Laboratory tests using sine wave tracking have shown that this mode has a tracking accuracy of 93.0%, slightly surpassing that of the roll mode.

The third mode is the hybrid control mode, which aims to combine the benefits of roll control and wing tip height control in order to achieve superior overall performance. This mode utilizes information from both the IMU and distance sensors and employs more complex fusion algorithms for decision-making. Laboratory step response tests have clearly demonstrated its superiority, with the hybrid mode restoring stability to the boom in just 2.35 s after a step disturbance. This is a 58.84% reduction in response time compared to the 5.71 s required by the pure roll mode, significantly improving response speed. This functional and selectable control mode design is a defining feature of modern commercial active balancing systems, representing a shift in control system design from single-technology implementation to a more demand-oriented and scenario-based functional approach.

6. Technology Integration and Application

With the advancement of precision agriculture technology, spray boom self-balancing technology has evolved beyond its role as a standalone vibration control solution. It now serves as a platform enabling higher-level intelligent applications and achieving core precision agriculture objectives. A stable, predictable spray boom platform provides the physical foundation for realizing and maximizing the effectiveness of advanced functions such as Variable Rate Application (VRC), automated navigation and section control, and even precision-targeted spraying.

6.1. Integration with Precision Agriculture Applications

Boom self-balancing technology does not exist in isolation; its true value lies in deep integration with other precision agriculture technologies. As a stable physical platform, a steady boom supports a series of more advanced intelligent applications such as variable rate application, automatic navigation, and machine vision.

A common example is its synergy with variable rate control, where both technologies collectively ensure spraying precision. The self-balancing system maintains a fixed geometric distance between nozzles and crops, ensuring consistent coverage area; the VRC system adjusts flow rates based on GPS speed or electronic prescription maps to control chemical application rates per unit area. Researchers like Wang Rong integrated both systems onto a single machine, enabling automatic matching of application rates to varying travel speeds and achieving uniform variable-rate operations [

3].

Further integration combines GPS navigation with automatic section control. This feature is designed to prevent overlapping spraying at field head turns and plot boundaries. GPS not only guides the path but also records previously treated areas. When a spray boom section enters a treated zone, the ASC system automatically switches it off and switches it back on again upon departure. The economic analysis by Battea et al. precisely calculates how much pesticide this technology saves on irregularly shaped fields [

12]. However, if the boom shakes excessively, the spray boundaries become relatively blurred, which significantly reduces the precision of section control.

More advanced applications include machine vision and precision spraying. As Bjørnsson et al. discovered in the “Smart Boom” project, installing a camera on the spray boom for real-time weed identification requires the camera to remain vibration-free at a fundamental level. Field tests confirmed that severe vertical vibrations of the boom can completely disable image capture and target recognition systems [

10]. Although formal stability thresholds for on-boom vision systems have yet to be established, the performance of state-of-the-art active systems provides a de facto benchmark. The ability of some advanced systems to limit the boom roll angle’s standard deviation to a mere 0.40° under field conditions exemplifies the level of precision that is now achievable and likely required [

11]. Quantifying this stability relies on metrics from both the time and frequency domains. While time-domain statistics like Root Mean Square Deviation (RMSD) and Standard Deviation (SD) assess overall positional and orientational error, frequency-domain analysis using Power Spectral Density (PSD) is particularly crucial for identifying and suppressing the high-frequency vibrations that directly cause image blur. Reaching this “quasi-static” level of stability is where Artificial Intelligence (AI) becomes essential, operating on two distinct but synergistic fronts. AI is not only the ‘brain’ within the vision system, often employing deep learning for real-time weed identification, but it also serves as the ‘reflex’ within the control system itself. AI-driven control strategies, such as the fuzzy PID, adaptive robust, and neural network controllers discussed previously, are what enable the suspension to deliver the ultra-stable physical platform [

21,

30,

41]. In essence, one form of AI (the controller) creates the necessary conditions for another form of AI (the vision system) to succeed. This highlights that a high-performance active balancing system is not merely an enhancement, but the fundamental enabling platform for this next generation of vision-based precision spraying technology.

6.2. Control Strategies Integrated with Agronomy

On the path of technological convergence, a more forward-thinking approach is emerging. This approach seeks to integrate the decision-making logic of control strategies with the agronomic characteristics of crops, thereby achieving a higher level of scene-adaptive intelligence.

In his research on potato sprayer control systems, Qu Junzhe observed significant differences in the core requirements for boom posture control differ significantly across potato growth stages. During early growth stage, potato plants are short and have not yet formed a continuous canopy that is suitable for effective sensor detection. At this stage, attempting to contour the canopy lacks physical basis and may instead trigger erroneous actions when sensors detect exposed furrows. Therefore, the optimal strategy is self-balancing mode, where maintaining the absolute horizontal level of the boom serves as the control objective. As the potatoes enter the growth phase, the plants mature and develop dense canopies. At this stage, spraying hinges on maintaining an optimal nozzle-to-canopy distance to ensure pesticide penetration and uniform coverage. At this stage, the system should switch to canopy contouring mode, using the canopy top contour detected by sensors such as LiDAR as the control reference. This design intelligently switches between control modes and sensing strategies based on crop growth, significantly enhancing the system’s adaptability and robustness throughout the entire crop growth cycle. It also embodies the design philosophy of letting agronomic needs define engineering objectives [

5].

7. Commercial System Applications and Comparisons

Boom self-leveling technology is commercially mature, but solutions from different manufacturers do not perform identically in real-world field conditions. A rigorous comparative evaluation by Burgers et al. [

44] identified three mainstream commercial systems available on the North American market: John Deere’s BoomTrac Pro™, Raven’s AutoBoom

® XRT, and Norac’s UC5™ Passive Roll™. Comprehensive comparative tests were conducted across three tracks of varying roughness levels and at multiple speeds. To quantify performance, the study employed multiple key metrics including root mean square deviation, the Herbst-modified Hockley index, and the percentage of spray boom height points within ±10 cm and ±25 cm of the target (see

Table 1).

The evaluation results were unequivocal: across 216 comparisons, Raven’s AutoBoom® XRT system outperformed the other two products in every metric, including sensor position, speed, and terrain type, with only four exceptions. The data revealed that when traveling at 26 km/h on moderately bumpy terrain, the RMS deviation for BoomTrac Pro and UC5 systems exceeded that of AutoBoom® XRT by 174% and 107%, respectively. Conversely, the latter system achieved a proportion of boom heights within ±25 cm of the target height that was 56% and 21% higher than that of the other two systems. These figures clearly demonstrate significant disparities among commercial systems in terms of maintaining boom proximity to target height and minimizing height variability.

These performance differences among commercial systems also reflect variations in their internal control strategies and functional designs. The study noted that different systems offer distinct operating modes to adapt to terrain, such as John Deere’s “Flat” and “Hilly” modes, and Norac’s “Soil” mode. These commercial functional options align conceptually with modes categorized in academic research, such as roll control and wing tip height control [

43].

These significant performance disparities raise a crucial question: what are the underlying technical reasons for this performance gap? While the proprietary algorithms of commercial systems are not public, a close examination of the system configurations reported by Burgers et al., combined with the control principles discussed in this survey, offers strong insights. The advantage of the Raven AutoBoom® XRT system likely stems from a synergistic combination of factors, with a superior sensing strategy playing a pivotal role. A key architectural differentiator is that the Raven system incorporated an independent, chassis-mounted Inertial Measurement Unit (IMU) on both test platforms. This provides the control system with crucial feedforward information regarding the vehicle’s roll motion, allowing it to proactively compensate for disturbances before they fully impact the boom. This approach aligns with the advanced control strategies discussed earlier, which leverage feedforward signals for faster and more precise responses. In contrast, the John Deere system, in that specific test configuration, lacked an independent chassis sensor. While the Norac system also featured a chassis roll sensor, the consistently superior performance of the Raven system suggests a more sophisticated fusion algorithm and control law are at play, better leveraging the rich data from both the chassis and the boom. Ultimately, it is the seamless integration of this advanced sensing architecture with a well-tuned, high-response control algorithm and capable hydraulic hardware that likely explains its top-tier performance.

8. Practical Recommendations for Evaluation and Optimization

While comprehensive system evaluation requires sophisticated laboratory equipment, the principles derived from scientific research can be adapted into a simplified, practical workflow for operators and farm technicians to evaluate and optimize their own boom balance systems. The goal is to provide a baseline for performance assessment and a methodical approach to tuning system settings. The following table outlines a recommended minimum set of metrics and corresponding test conditions.

Table 2 shows the practical evaluation and optimization details for boom balance.

By systematically conducting these tests, operators and technicians can gain objective, data-driven insights into their system’s performance, moving beyond subjective “feel.” The “Overall Stability” test serves as a general-purpose benchmark for performance under typical operating conditions. The “Response to Sudden Disturbance” test is particularly crucial as it directly evaluates the system’s high-frequency isolation capability, its ability to absorb sharp, sudden impacts without excessive reaction. Conversely, the “Low-Frequency Slope Following” test assesses the system’s ability to accurately track large-scale terrain changes, which is the other half of the core technical challenge.

The true value of these tests lies in their application for optimization, particularly for tuning the system’s “sensitivity” settings. For example, an operator can run the “bump test” with a low, medium, and high sensitivity setting. A setting that is too high might cause the boom to overreact, leading to a large maximum deviation and prolonged oscillation (poor high-frequency isolation). A setting that is too low might make the system sluggish, resulting in a long settling time. The optimal setting would be the one that minimizes both the peak deviation and the settling time, achieving a balance between responsiveness and stability. By using this methodical approach, operators can tailor their machine’s performance to specific field conditions and their own operational needs, thereby practically implementing the optimization principles discussed in this review.

9. Discussion

Self-balancing boom technology has made significant strides over the past decades and has been widely commercialized. However, as precision agriculture advances towards greater dimensions and higher accuracy, this technology still faces a series of profound challenges. These challenges stem not only from the pursuit of extreme performance metrics and disruptive demands arising from new application scenarios. Nevertheless, the convergence of multidisciplinary technologies indicates a clear development path for overcoming these limitations and developing the next generation of boom balancing technology. This chapter first analyzes the core challenges facing current technology and, based on this foundation, explores several of the most promising core development trends for the future.

9.1. Current Key Challenges

Although spray boom self-balancing technology has reached a certain level of maturity, significant challenges remain in terms of achieving higher operational precision and adapting to more complex field environments. At the perception level, sensing complex, non-uniform canopies robustly remains a major hurdle. Traditional ultrasonic sensors are prone to outputting erroneous height information when encountering highly irregular canopy structures, such as those found in potato crops or during the early stages of crop growth. This occurs when the sensors detect bare soil or canopy gaps, which leads to misjudgments by the control system [

5]. Even with more advanced 2D LiDAR technology, rapidly and accurately segmenting and fitting the effective canopy top contour from cluttered point clouds remains a significant challenge in terms of algorithm robustness and computational efficiency [

36]. At the control level, effectively handling and compensating for strong nonlinear factors within the system is a key bottleneck for improving control performance. Boom balancing systems, particularly those using hydraulic drives, commonly exhibit strong nonlinear characteristics stemming due to Coulomb friction, valve dead zones, and fluid pressure-flow nonlinearity [

6]. These nonlinearities are difficult to model precisely, which significantly degrades the performance of traditional linear controllers and fundamentally hinders the system’s ability to balance fine adjustments with rapid response. At the application level, the challenge lies in providing a stable physical platform for more advanced intelligent crop protection applications. As noted by Bjørnsson et al., traditional boom stability standards are inadequate for visual applications [

10]. This implies that the vibration suppression requirements for the next generation boom balancing systems may increase exponentially compared to current standards. Achieving this “quasi-static” stability at a reasonable cost represents a critical challenge that must be overcome for the field to advance towards higher levels of intelligence.

9.2. Future Core Development Trends

In the face of the current challenges and anticipated future demands of precision agriculture, spray boom self-balancing technology is evolving towards deep multidisciplinary integration, with clear development trends emerging.

The transition from “agronomic-driven” to “environmentally integrated decision-making” represents a significant leap forward. Current agronomic-driven strategies, such as switching modes based on preset growth stages, remain at a preliminary level. The future trend points toward dynamic decision systems that integrate real-time information from multiple sources. These systems will not only consider crop growth stages but also incorporate real-time data such as field wind speed and direction, high-precision weather forecasts, and the machine’s own status information. It must be noted that, while the conceptual framework for such a system is clear, comprehensive experimental validation under highly variable field conditions, particularly including wind, is a critical research gap that remains to be addressed. Most current experimental validations focus on achieving geometric stability against terrain-induced disturbances. However, based on this multi-dimensional data, the control system will evolve beyond basic “contour following” or “leveling” to dynamically calculate an optimal boom posture that minimizes drift and maximizes deposition uniformity under the specific conditions encountered. This shift signifies a transition from singular geometric stability to comprehensive optimization for the best possible agronomic outcomes, highlighting a vital direction for future experimental research.

The focus shifts from ‘Vision-Motion Coordination’ to ‘Swarm Intelligence and Distributed Control’. While current explorations remain confined to individual machines, boom control will enter the realm of swarm intelligence as multiple, miniaturized, autonomous spray robots begin to collaborate in fields. It is important to note that this trend is also at a conceptual stage, and there are no specific simulation or field trial results yet published that quantitatively evaluate the effects of inter-robot coordination on spray uniformity. Nevertheless, several key strategies are being conceptually considered for this integration. The most fundamental is Coordinated Interference Avoidance, where robots use real-time communication to autonomously adjust their outer boom sections or shut off nozzles to prevent spray overlaps between adjacent units. A more advanced strategy is Collaborative Task-Oriented Posture Control, where the fleet acts as one, with a planner assigning specific, complementary boom postures to different robots to achieve an optimal collective spray pattern. A third strategy, Shared Environmental Mapping for Predictive Control, would leverage the swarm’s collective sensing, allowing leading robots to map terrain or wind data and share it with trailing robots, enabling them to pre-adjust their suspensions proactively. This will elevate spray boom control from individual intelligence to a new level of swarm intelligence, optimizing overall field operation tasks.

Author Contributions

Conceptualization, S.Z. and T.L.; methodology, S.Z., T.L. and Z.W.; software, S.Z., T.L. and Z.W.; validation, S.Z., T.L. and C.C. (Chen Cai); formal analysis, S.Z. and T.L.; investigation, S.Z. and T.L., C.C. (Chen Cai) and C.C. (Chun Chang); resources, S.Z., T.L. and C.C. (Chun Chang); data curation, S.Z., T.L. and Z.W.; writing—original draft preparation, S.Z. and T.L.; writing—review and editing, S.Z., T.L. and X.X.; visualization, S.Z. and T.L., C.C. (Chen Cai), C.C. (Chun Chang) and L.C.; supervision, S.D., Z.W. and X.X.; project administration, S.Z. and T.L.; funding acquisition, X.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (grant number: 2022YFD2001603), the Key Research and Development Project of Shandong Province (grant number 2022SFGC0204-NJS), the Agricultural Science and Technology Innovation Project of the Chinese Academy of Agricultural Sciences, Crop Protection Machinery Team (grant no. CAAS-ASTIP-CPMT) and the China Agriculture Research System of MOF and MARA (grant no. CARS-12).

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhuang, T.; Yang, X.; Dong, X.; Zhang, T.; Yan, H.; Sun, X. Research Status and Development Trend of Large Self-propelled Sprayer Booms. Trans. Chin. Soc. Agric. Mach. 2018, 49, 189–198. [Google Scholar]

- Deng, F. Design of Self Balancing and Height Automatic Control System for Spray Boom. Master’s Thesis, Shihezi University, Shihezi, China, 2017. [Google Scholar]

- Wang, R.; Cao, D.; Liu, Y.; Jin, J. Design and Test of Self Balancing Precise Fertilizer and Pesticide Applying Machine. J. Agric. Mech. Res. 2018, 41, 124–129. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Womac, A.R.; Gunn, J. Sprayer Boom Dynamic Effects on Application Uniformity. Trans. ASAE 2004, 47, 647–658. [Google Scholar] [CrossRef]

- Qu, J. Design and Experiment of Boom Attitude Control System for Potato Sprayer. Master’s Thesis, Shandong University of Technology, Zibo, China, 2024. [Google Scholar] [CrossRef]

- Anthonis, J.; Ramon, H. Design of an Active Suspension to Suppress the Horizontal Vibrations of a Spray Boom. J. Sound Vib. 2003, 266, 573–583. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Deprez, K.; Anthonis, J.; Ramon, H.; Brussel, V.H. PM—Power and Machinery: Development of a Slow Active Suspension for Stabilizing the Roll of Spray Booms, Part 1: Hybrid Modelling. Biosyst. Eng. 2002, 81, 185–191. [Google Scholar] [CrossRef]

- Frost, A.R. Simulation of an Active Spray Boom Suspension. J. Agric. Eng. Res. 1984, 30, 313–325. [Google Scholar] [CrossRef]

- Bjørnsson, H.O.; Maargaard, J.; Terp, I.C.; Wiggers, L.S. Dynamic Analysis of the Intelligent Sprayer Boom. In International Conference on Vibration Problems; IDMEC: Lisbon, Portugal, 2013. [Google Scholar]

- Cui, L.; Xue, X.; Le, F.; Mao, H.; Ding, S. Design and Experiment of Electro hydraulic Active Suspension for Controlling the Rolling Motion of Spray Boom. Int. J. Agric. Biol. Eng. 2019, 12, 72–81. [Google Scholar] [CrossRef]

- Batte, M.T.; Ehsani, M.R. The Economics of Precision Guidance with Auto-Boom Control for Farmer-Owned Agricultural Sprayers. Comput. Electron. Agric. 2006, 53, 28–44. [Google Scholar] [CrossRef]

- Xu, J. Research on Boom Height Adjustment and Self-Balancing System of Sprayer. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Dou, H.; Zhai, C.; Chen, L.; Wang, S.; Wang, X. Field Variation Characteristics of Sprayer Boom Height Using a Newly Designed Boom Height Detection System. IEEE Access 2021, 9, 17148–17160. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Womac, A.R.; Wilkerson, J.B.; Hart, W.E. Sprayer Boom Instrumentation for Field Use. Trans. ASAE 2004, 47, 659–666. [Google Scholar] [CrossRef]

- Nie, Z.; Li, J.; Chen, Y. Vibration Source and Transmission Characteristics Analysis and Experiment of Boom for Wide Sprayer. J. Agric. Mech. Res. 2023, 46, 25–34. [Google Scholar] [CrossRef]

- Lardoux, Y.; Sinfort, C.; Enfält, P.; Sevila, F. Test Method for Boom Suspension Influence on Spray Distribution, Part I: Experimental Study of Pesticide Application under a Moving Boom. Biosyst. Eng. 2007, 96, 29–39. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, X. Optimization of Spray Bar Deformation Control Based on UG Animation Simulation. J. Agric. Mech. Res. 2023, 46, 198–202. [Google Scholar] [CrossRef]

- Zhuang, T.; Yang, X.; Zhang, T.; Sang, D.; Jin, W.; Sun, X.; Wei, B. Vibration Damping Test and Optimization of Spray Boom in Large-Scale High Clearance Sprayer. Agric. Eng. 2023, 13, 98–103. [Google Scholar] [CrossRef]

- Ramon, H.; Baerdemaeker, D.J. A Modelling Procedure for Linearized Motions of Tree Structured Multibodies—2: Design of an Active Spray Boom Suspension on a Spraying-Machine. Comput. Struct. 1996, 59, 361–375. [Google Scholar] [CrossRef]

- Cui, L.; Mao, H.; Xue, X. Hydraulic-Drive Roll Movement Control of a Spray Boom Using Adaptive Robust Control Strategy. Adv. Mech. Eng. 2019, 11, 1–15. [Google Scholar] [CrossRef]

- Cui, L.; Mao, H.; Xue, X.; Ding, S.; Qiao, B. Optimized Design and Test for a Pendulum Suspension of the Crop Spray Boom in Dynamic Conditions Based on a Six DOF Motion Simulator. Int. J. Agric. Biol. Eng. 2018, 11, 76–85. [Google Scholar]

- Herbst, A.; Osteroth, H.; Stendel, H. A Novel Method for Testing Automatic Systems for Controlling the Spray Boom Height. Biosyst. Eng. 2018, 174, 115–125. [Google Scholar] [CrossRef]

- Herbst, A.; Osteroth, H.; Fleer, W.; Stendel, H. A Method for Testing Automatic Spray Boom Height Control Systems. In 2015 ASABE Annual International Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2015; p. 1. [Google Scholar]

- Anthonis, J.; Audenaert, J.; Ramon, H. Design Optimisation for the Vertical Suspension of a Crop Sprayer Boom. Biosyst. Eng. 2005, 90, 153–160. [Google Scholar] [CrossRef]

- Lardoux, Y.; Sinfort, C.; Enfält, P.; Miralles, A.; Sevila, F. Test Method for Boom Suspension Influence on Spray Distribution, Part II: Validation and Use of a Spray Distribution Model. Biosyst. Eng. 2007, 96, 161–168. [Google Scholar] [CrossRef]

- Sobotka, M.S.; Lipiński, J.A. A New Structure of the Stabilization System of a Suspended Sprayer Boom. Agric. Eng. 2015, 19, 127–132. [Google Scholar]

- Deprez, K.; Anthonis, J.; Ramon, H.; Brussel, V.H. PM—Power and Machinery: Development of a Slow Active Suspension for Stabilizing the Roll of Spray Booms, Part 2: Controller Design. Biosyst. Eng. 2002, 81, 273–279. [Google Scholar] [CrossRef]

- Sun, J.; Miao, Y. Modeling and Simulation of the Agricultural Sprayer Boom Leveling System. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shangshai, China, 6–7 January 2011; IEEE: Piscataway, NJ, USA, 2011; Volume 2, pp. 613–618. [Google Scholar]

- Li, F.; Bai, X.; Su, Z.; Tang, S.; Wang, Z.; Li, F.; Yu, H. Development of a Control System for Double-Pendulum Active Spray Boom Suspension Based on PSO and Fuzzy PID. Agriculture 2023, 13, 1660. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, M.; Chen, Y.; Ming, R.; Xiang, Y.; Luo, X. Automatic Leveling Control of Rotors Hovering Spray Boom Sprayer. Trans. Chin. Soc. Agric. Mach. 2022, 53, 70–79. [Google Scholar]

- Zhang, Z.; Cao, J.; Guo, P.; Wang, M.; Yu, C. Structure design and levelling control system development for self-propelled sprayer boom. INMATEH-Agric. Eng. 2025, 75, 200–211. [Google Scholar] [CrossRef]

- Tan, H.; Dou, H.; Zhai, C.; Li, Y.; Yang, S.; Chen, L. Design and Test of Roller Nylon Brush PotatoCleaning and Classifying Machine. J. Agric. Mech. Res. 2020, 43, 156–160. [Google Scholar] [CrossRef]

- Sun, X.; Yang, X.; Dong, X.; Zhang, T.; Yan, H.; Wang, Z. Spray Boom Height Intelligent Adjustment System Based on Expert Control. Trans. Chin. Soc. Agric. Mach. 2020, 51, 275–282. [Google Scholar]

- Dou, H.; Wang, S.; Zhai, C.; Chen, L.; Wang, X.; Zhao, X. A LiDAR Sensor-Based Spray Boom Height Detection Method and the Corresponding Experimental Validation. Sensors 2021, 21, 2107. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qu, J.; Xu, Y.; Li, X.; Xiao, Z.; Wang, L. Spray Boom Height Control System of Potato Sprayer Based on Canopy Information. Trans. Chin. Soc. Agric. Mach. 2023, 54, 198–207. [Google Scholar]

- Yin, X.; An, J.; Wang, X.; Wang, Y.; Li, J.; Jin, C. Design and Test of Automatic Beam Leveling System forHigh-clearance Sprayer. Trans. Chin. Soc. Agric. Mach. 2021, 53, 98–105+115. [Google Scholar]

- Wu, J.; Yang, S.; Li, C.; Zhai, C. Design and Test of Spray Boom Height Control System for3WSH-500 Boom Sprayer. J. Agric. Mech. Res. 2024, 47, 121–129. [Google Scholar] [CrossRef]

- Cui, L.; Xue, X.; Kong, W.; Ding, S.; Gu, W.; Le, F. Design and Implementation of a Nonlinear Robust Controller Based on the Disturbance Observer for the Active Spray Boom Suspension. Int. J. Agric. Biol. Eng. 2023, 16, 153–161. [Google Scholar] [CrossRef]

- Li, M.; Li, S.; Guo, A. Adaptive Fuzzy Control for Active Pendulum Suspension System of Spray Boom. Comput. Meas. Control 2020, 28, 70–75+80. [Google Scholar] [CrossRef]

- Mona, T.; Musa, M.; Gohari, M.; Rahman, A.R. Vibration Suppression of Sprayer Boom Structure Using Active Torque Control and Iterative Learning. Part I: Modelling and Control via Simulation. J. Vib. Control 2018, 24, 4689–4699. [Google Scholar]

- Tahmasebi, M.; Gohari, M.; Mailah, M.; Rahman, A.R. Vibration Suppression of Sprayer Boom Structure Using Active Torque Control and Iterative Learning. Part II: Experimental Implementation. J. Vib. Control 2018, 24, 4740–4750. [Google Scholar] [CrossRef]

- Cui, L.; Xue, X.; Ding, S.; Le, F. Development of a DSP-Based Electronic Control System for the Active Spray Boom Suspension. Comput. Electron. Agric. 2019, 166, 105024. [Google Scholar] [CrossRef]

- Burgers, A.T.; Gaard, D.J.; Hyronimus, J.B. Comparison of Three Commercial Automatic Boom Height Systems for Agricultural Sprayers. Appl. Eng. Agric. 2021, 37, 287–298. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |