1. Introduction

Soil compaction presents a persistent challenge in perennial orchard systems, primarily stemming from long-term management practices and repeated machinery traffic. In mature fruit orchards, routine operations such as tillage, spraying, and harvesting contribute to the formation of dense subsurface layers, commonly referred to as hardpans [

1]. Recent surveys in East Asian apple orchards illustrate the problem: bulk density in the 20–30 cm layer is 18% higher than in the surface horizon, and penetration resistance in 20-year-old blocks is almost one-third higher than in young plantings [

2,

3].

Compacted soils impose well-documented constraints on root growth and overall tree health. High bulk density and low porosity restrict the movement of water and oxygen while physically impeding root penetration [

4]. Root elongation is severely restricted at penetration resistances exceeding 2 MPa, thereby limiting access to deeper water and nutrient reserves [

5]. However, this threshold varies depending on crop species, soil texture, and moisture status. Under compacted conditions, roots tend to remain shallow, exacerbating susceptibility to drought and nutrient deficiencies. Such physiological stress translates into reduced canopy development, lower fruit yields, and impaired fruit quality. For example, poor soil aeration has been linked to diminished growth and fruit yield in citrus [

6].

The most common mechanical remedy is subsoiling—drawing a rigid shank 30–50 cm below the surface to shatter the pan. While effective in open fields [

7,

8], conventional ripping is not suitable to established orchards: it damages fine roots, disturbs the weed-suppressive orchard floor, and exposes aggregate-protected organic matter to oxidation [

9,

10,

11]. These drawbacks have stimulated interest in low-disturbance approaches that loosen the profile while preserving soil structure and carbon stocks.

Pneumatic subsoiling meets that brief. Instead of a steel tine, a lance delivers a pulse of compressed air at 800,000–1,000,000 Pa (≈8–10 bar) through a small pilot hole, propagating cracks up to 60 cm from the injection point without cutting roots or turning the soil [

12,

13,

14,

15]. Used for decades in arboriculture to treat urban trees, the method has recently been adapted for fruit crops using self-propelled rigs or hand-held units that can be operated within narrow alleys [

16,

17]. Field results, however, are mixed and appear to depend on soil texture, initial compaction severity, and crop rooting habits.

In subtropical Taiwan, Asian pear (

Pyrus pyrifolia Nakai) is a major fruit crop grown on 4856 hectares, producing 84,481 tons in 2024 [

18]. With high farm-gate prices at NTD 67–93/kg (USD 2.07 to 2.90 US based on the yearly average currency exchange rate in 2024), Asian pear is of significant economic value. However, intensive orchard management, including frequent machinery use for mowing, spraying, and harvest, exacerbates subsoil compaction. Compaction in the root zone in Asian pear orchards can limit water and nutrient acquisition, impair gas exchange, and increase vulnerability to abiotic stress, ultimately reducing yield and fruit quality [

19]. Gas explosion and air knife systems have been proposed as alternatives to ripping [

20], yet no empirical data are available on their agronomic effectiveness in commercial Asian pear orchards.

This study aims to fill a critical knowledge gap regarding the potential of pneumatic subsoiling as a sustainable management tool in Asian pear orchards, where empirical evaluations remain lacking despite similar research in other fruit crops. Based on previous research indicating that alleviating soil compaction can enhance root growth and resource uptake, we hypothesized that pneumatic deep subsoiling would reduce subsurface compaction, thereby improving vegetative growth, fruit yield, and fruit quality in Asian pear under an intensive top-working system. By linking soil physics with tree performance, we aim to clarify whether pneumatic subsoiling deserves a place in sustainable floor-management programs for high-value Asian pear orchards.

2. Materials and Methods

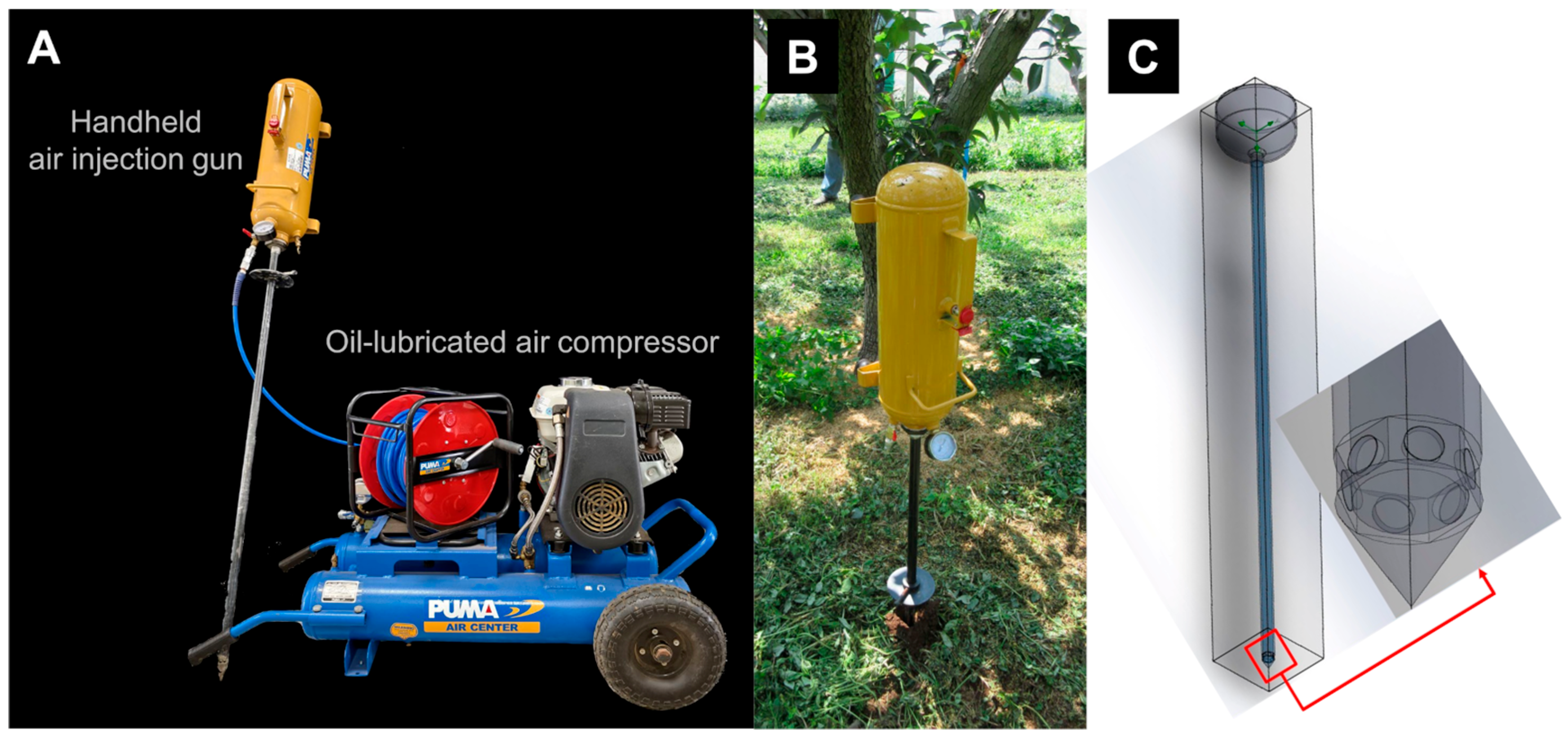

2.1. System Description for Pneumatic Subsoiling

A commercial pneumatic subsoiling system used in this study was developed by PUMA Industrial Co., Ltd. (Tianzhong Township, Changhua County, Taiwan), model STJ-006K (

Figure 1). While this equipment is used in Taiwan for soil loosening operations, its agronomic and soil physical effects in Asian pear orchard systems have not been systematically evaluated.

This handheld unit is equipped with an air injection gun designed to deliver compressed air directly into subsurface soil layers. The gun measures 1000 mm in length and is fitted with an air inlet (outer diameter: 21.8 mm; inner diameter: 16.8 mm). The nozzle, 6 mm in outer diameter and 4 mm in inner diameter, is engineered to concentrate the airflow into a high-velocity jet, enabling targeted soil fracture. Compressed air was supplied using a 32 L and 5.5 HP oil-lubricated air compressor (model FG332GW) from the same manufacturer, delivering an airflow of 340 L/min at a maximum pressure of 784,532 Pa (8 kg/cm2).

During field operation, the system was set to maintain an effective pressure of 800,000–900,000 Pa (8–9 bar). A pressure regulator and gauge ensure constant working pressure, and the compressor is mounted on a wheeled cart for easy movement between orchard rows. The gun contains a small pressure reservoir that is charged while docked to the compressor, then detached for in-row use. When the trigger is engaged, instant high-velocity air fractures the compacted subsoil, producing a brief soil heave (visible cracking at the surface) that alleviates root-zone compaction without disturbing the canopy or irrigation lines.

2.2. Experimental Site and Plant Materials

The field experiment was conducted in a commercial Asian pear orchard at Wu’s Farm, located in Zhuolan Township, Miaoli County, Taiwan (24°18′ N, 120°51′ E). The site is characterized by clay soil classified under the Tung Lo Chun Series; A recent soil surveys indicate that the particle size distribution across depths is as follows: at 0–10 cm, 35.4% sand, 24.3% silt, and 40.3% clay; at 10–30 cm, 33.0% sand, 23.7% silt, and 43.3% clay; and at 30–50 cm, 27.1% sand, 26.3% silt, and 46.6% clay [

21,

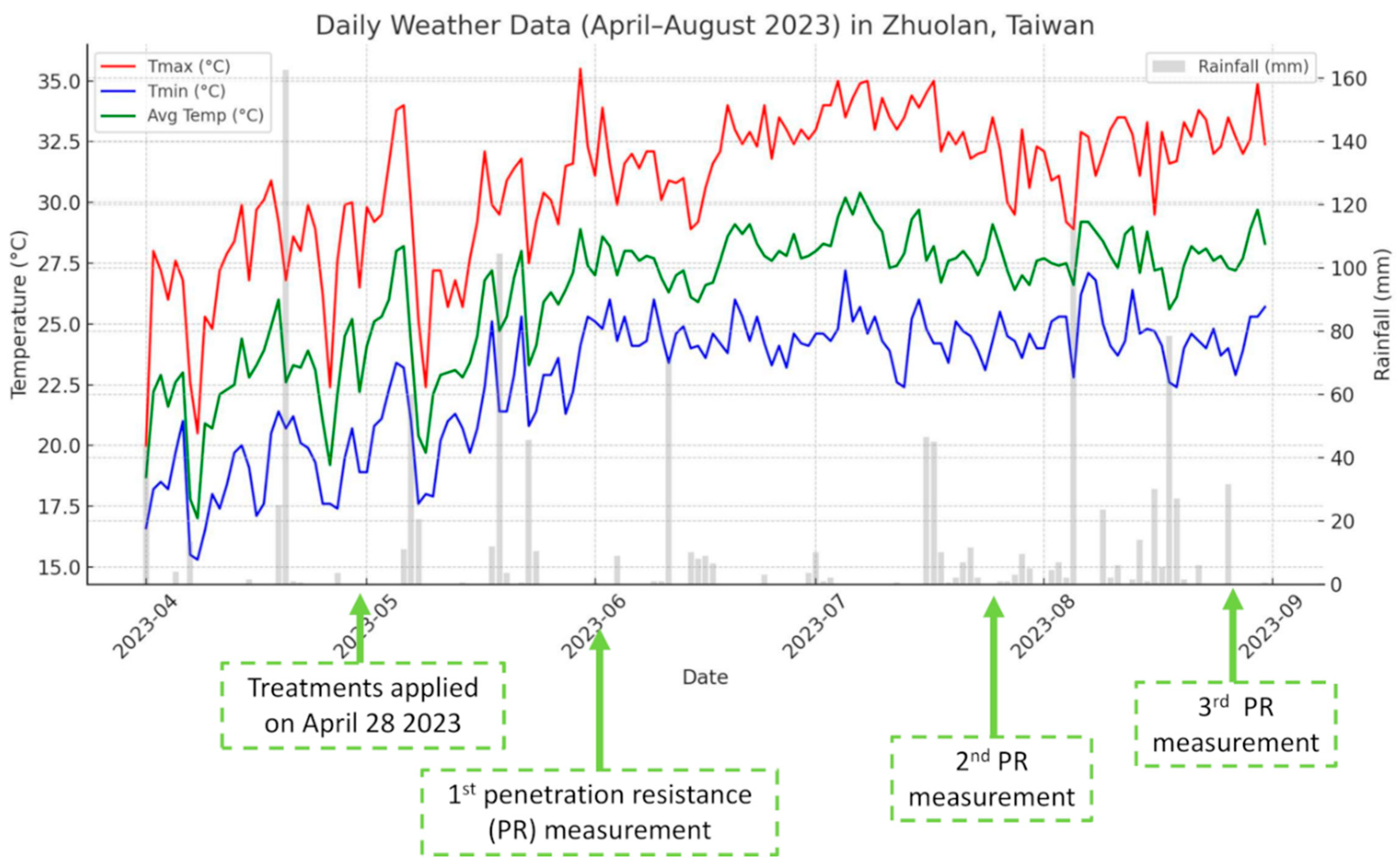

22]. The region has a subtropical monsoon climate with distinct wet and dry seasons. Weather data for the experimental period (

Figure A1) were obtained from the Zhuolan Weather Station (station C0E791; 24.3126° N, 120.8244° E), located approximately 5 km from the orchard, via the Climate Observation Data Inquiry Service of the Central Weather Administration (

https://codis.cwa.gov.tw/StationData, accessed on 6 July 2025).

It should be noted that a formal assessment of pre-treatment spatial variability in soil compaction and moisture conditions was not conducted due to orchard management constraints and the need to minimize disturbance to the commercial production system. Additionally, soil moisture at the time of treatment application was not measured, representing a limitation in interpreting penetration resistance data, although daily rainfall patterns during the study period were recorded and presented (

Figure A1).

Twenty-year-old ‘HengShan’ rootstock trees were used, spaced at 4.5 m × 6.0 m, and trained using an overhead horizontal trellis system, with canopy panels maintained at 1.8 m above the ground. The orchard employs an annual top-working technique, in which dormant budwoods of high-chill cultivars are grafted onto the low-chill rootstock trees [

23]. Although this practice is labor-intensive, it enables the commercial production of temperate pear cultivars in Taiwan’s lowland subtropical regions.

In January 2023, budwoods of two Asian pear cultivars, ‘Shinkou’ (a traditional Japanese cultivar) and ‘BaoDaoGanLu’ (a locally developed Taiwanese cultivar), were grafted onto each tree, with approximately 150 to 200 grafted units per tree. Budbreak occurred in late January, full bloom by mid-February, and manual fruit thinning was performed in early March, retaining four fruits per grafted unit.

2.3. Treatments

The experimental factor was defined as the location of pneumatic subsoiling relative to the tree trunk, and included four treatment levels:

Control (CK): No treatment applied;

R120: Four holes drilled to a depth of 80 cm, located 120 cm from the trunk, without high-pressured air injection;

R120+A: Four holes drilled to a depth of 80 cm, located 120 cm from the trunk, followed by pneumatic subsoiling (i.e., high-pressured air injection);

R180+A: Four holes drilled to a depth of 80 cm, located 180 cm from the trunk, followed by pneumatic subsoiling (i.e., high-pressured air injection).

All holes (except in the CK treatment) were drilled using a gas-powered auger (GX50, Honda Motor Co., Ltd., Tokyo, Japan) equipped with a 90 cm-long bit and a diameter of 3.5 cm. All drilled holes were not sealed after drilling. They remained open to the orchard environment throughout the study period. In the R120+A and R180+A treatments, a single and instant high-pressured air injection was administered per hole at a depth of 80 cm using a pressure of approximately 800,000–900,000 Pa (8–9 bar). The treatments were performed on 28 April 2023.

The treatments were designed to evaluate the effect of pneumatic subsoiling at two radial distances from the trunk (120 cm and 180 cm) compared to drilled-only and untreated controls. The 120 cm distance reflects the typical zone of feeder root concentration under the canopy edge in mature pear trees, while 180 cm tests potential effects in peripheral soil beyond the root concentration zone. The drilled-only treatment (R120) served to distinguish the effect of pneumatic air injection from mechanical drilling alone.

In addition, root measurements were not collected in this study. Although assessing root biomass and architecture would have provided critical insights into tree responses, root coring and destructive sampling were precluded due to orchard owner restrictions and the commercial production status of the site.

2.4. Soil Penetration Resistance

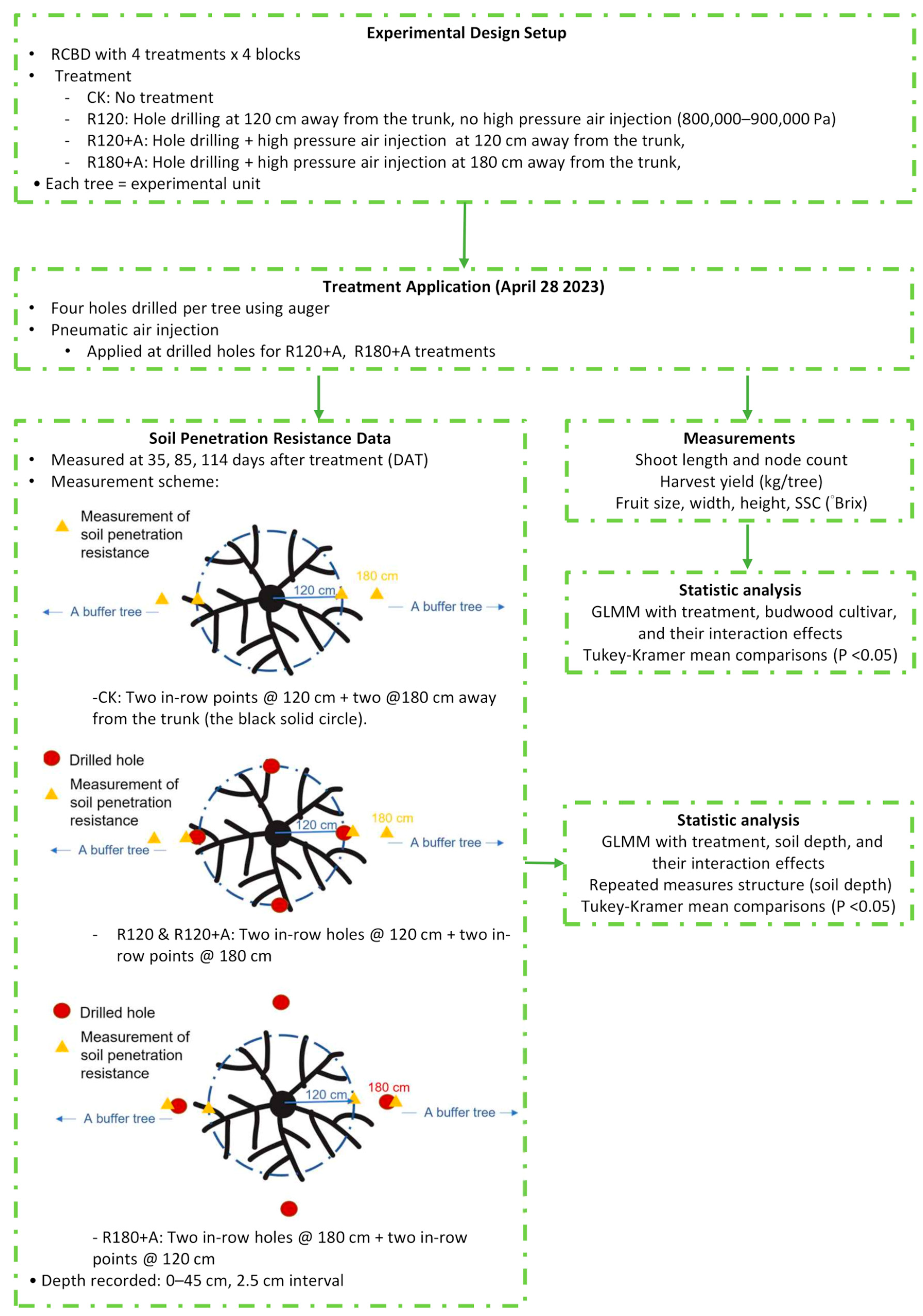

Soil penetration resistance measurements were conducted at 35, 87, and 114 days after pneumatic subsoiling treatment application (DAT). Soil penetration resistance was assessed using an electronic penetrometer (FieldScout SC 900 Soil Compaction Meter; Spectrum Technologies, Aurora, IL, USA), which has a maximum effective insertion depth of approximately 45 cm and equipped with a cone with a base diameter of 1.27 cm (0.5 inch). Measurements were taken at a constant insertion speed of approximately 3 cm/s.

For the CK treatment, measurements were taken at two in-row locations 120 cm away from the trunk, corresponding approximately to the canopy projection area, as well as at two in-row locations 180 cm away from the trunk (

Figure A2). For the R120 and R120+A treatments, although four holes were drilled 120 cm way from the trunk, penetration resistance measurements were conducted only at the two in-row holes per tree due to logistical constraints, with additional measurements taken at two in-row locations 180 cm away from the trunk. For the R180+A treatment, while four holes were drilled 180 cm away from the trunk, penetration resistance measurements were similarly collected at the two in-row holes 180 cm away from the trunk and at two in-row locations 120 cm away from the trunk. This measurement scheme ensured consistency across treatments while accommodating operational limitations inherent to the orchard setting.

2.5. Vegetative Growth

Vegetative growth was assessed by the growth of shoots. Ten newly emerging shoots were tagged in each tree, and their initial lengths and node counts were recorded before treatment.

2.6. Fruit Yield and Quality

Fruit yield per tree, fruit size, and individual fruit weight were recorded. Additionally, the soluble solids concentration (SSC) of the fruits was measured using a refractometer (PAL-1, ATAGO, Tokyo, Japan).

2.7. Experimental Design and Statistical Analysis

The experiment was conducted using a randomized complete block design (RCBD) with four treatments and four blocks (replicates). Each experimental unit comprised a single mature ‘HengShan’ rootstock tree, resulting in a total of 16 experimental trees (4 treatments × 4 blocks = 16 trees). Treatments were randomly assigned within each block. To minimize potential interference between neighboring treatments, one buffer tree was placed between adjacent experimental units, resulting in approximately 12 m spacing between experimental trees. All blocks were located in the same orchard row along a consistent contour line, with 30 m spacing between adjacent blocks to account for field heterogeneity. A schematic description of the experimental workflow and data collection process is provided as a flowchart in

Appendix B.

All statistical analyses were performed using SAS software (version 9.4; SAS Institute Inc., Cary, NC, USA), employing the generalized linear mixed model (GLIMMIX) procedure. For single-timepoint variables such as fruit yield and fruit quality parameters, treatment, budwood cultivar, and their interaction were included as fixed effects. Block was included as a random effect to account for spatial variation across the orchard. As both ‘Shinkou’ and ‘BaoDaoGanLu’ cultivars were grafted onto each ‘HengShan’ rootstock tree, budwood cultivar was treated as a subsampling factor within tree, with budwood cultivar comparisons nested within each experimental unit.

For repeated measures data, such as soil penetration resistance, the model included treatment, soil depth, and their interactions as fixed effects. A repeated measures covariance structure (type = CS) was specified to account for correlations among soil depths within each experimental unit. Similarly, for temporal growth traits (e.g., shoot length and node count), the model incorporated treatment, DAT, and their interaction as fixed effects, with a repeated measures structure applied across timepoints.

For all data, mean separations were performed using the Tukey–Kramer test, and statistical significance was determined at p < 0.05.

3. Results

3.1. Soil Penetration Resistance

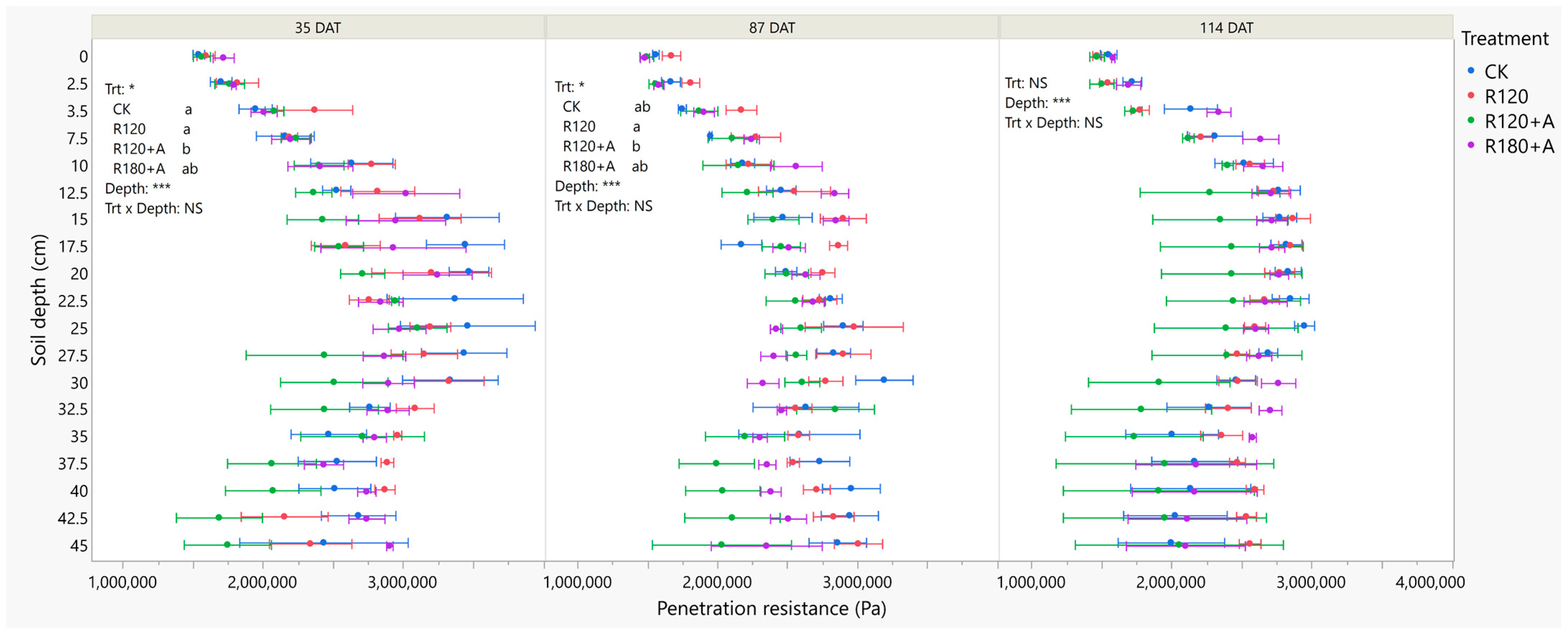

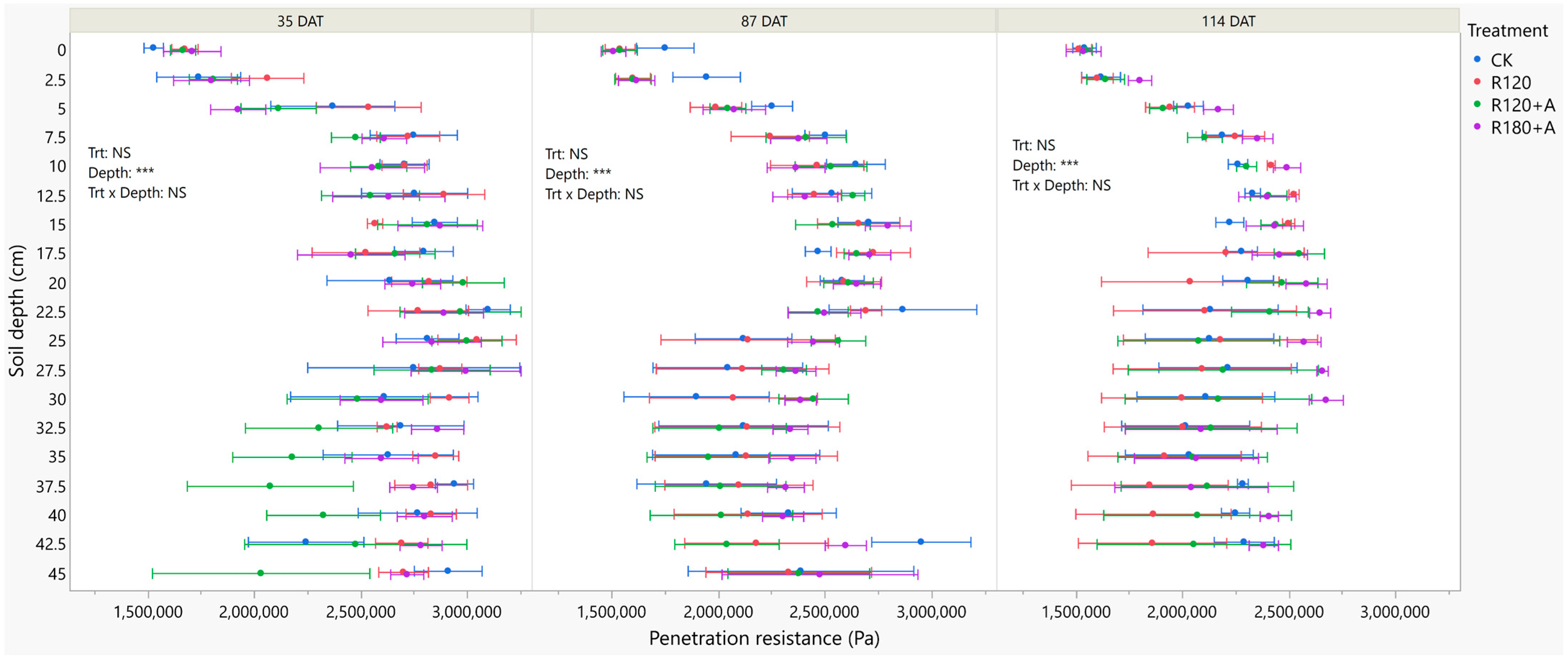

At 34 DAT, analysis indicated that treatment had a significant effect on soil penetration resistance 120 cm away from the trunk (

Figure 2). Among treatments, the pneumatic subsoiling 120 cm with air injection (R120+A) exhibited the lowest penetration resistance (2,302,888 Pa), followed by R180+A (2,647,941 Pa), R120 (2,692,599 Pa), and the highest value observed in the CK (2,724,423 Pa). However, only the R120+A treatment significantly reduced the penetration resistance (a 15.4% reduction), compared to the CK. Depth also had a significant effect, with resistance generally increasing with depth up to approximately 35 cm before stabilizing. At 87 DAT, treatment effects remained significant. The R120+A treatment maintained the lowest resistance (2,220,713 Pa), whereas the R120 treatment showed the highest penetration resistance (2,568,184 Pa), suggesting that pneumatic subsoiling effectively reduced compaction relative to drilling alone. Although the R120+A treatment showed a 10.4% reduction in penetration resistance, it was not statistically different from the control. Depth continued to significantly affect resistance values, showing a similar vertical trend as at 34 DAT. At 114 DAT, no significant treatment effect on soil penetration resistance was detected. Depth was a significant factor influencing penetration resistance. Across treatments, penetration resistance values appeared to converge over time, suggesting a gradual recovery of soil mechanical strength in treated plots to levels comparable with the control by the end of the observation period.

For soil penetration resistance 180 cm away from the trunk, the treatments did not significantly affect penetration resistance at 35, 87, and 114 DAT (

Figure 3). Depth remained a significant factor influencing resistance. Across treatments and depths, penetration resistance showed a similar trend to that measured 120 cm away from the trunk.

3.2. Vegetative Growth

Vegetative growth, as assessed by shoot length and node number, was not significantly affected by the pneumatic subsoiling treatments (

Table 1). In contrast, DAT had a significant effect on both parameters. No significant interaction was observed between treatment and DAT, indicating that the growth patterns were consistent across treatments during the measurement period.

Shoot length increased steadily from 26.2 cm at 34 days before treatment (−34 DAT) to a maximum of 143.7 cm at 87 DAT. A slight decline was observed at 114 DAT (137.7 cm). Similarly, node number rose from 11.0 at −34 DAT to peak values between 24.5 and 27.8 by 21–114 DAT.

3.3. Fruit Yield and Quality

Table 2 presents the effects of pneumatic subsoiling treatments on fruit yield and quality parameters in the fruits of the two budwood cultivars, ‘Shinkou’ and ‘BaoDaoGanLu’. For fruit yield, no significant treatment effect was observed.

For fruit size, no significant treatment effect was detected. However, cultivar differences were significant, with ‘BaoDaoGanLu’ fruits averaging 63.5% heavier than ‘Shinkou’ (1011.0 g/fruit vs. 618.2 g/fruit). Similarly, for fruit width, no treatment effect was observed. The cultivar effect was significant, with ‘BaoDaoGanLu’ fruits being approximately 2.4 cm wider than those of ‘Shinkou’. For fruit height, neither treatment nor cultivar effects were significant.

Regarding SSC, no significant treatment effect was observed, nor were there significant differences between cultivars. SSC values ranged narrowly across treatments and cultivars, with R180+A showing a slight numerical increase in SSC in both cultivars, though not statistically significant.

4. Discussion

Soil compaction is widely recognized as a limiting factor in perennial fruit crop production, often impeding root penetration, reducing aeration and water infiltration, and suppressing tree growth and yield. However, it is important to note that the specific pre-treatment compaction levels and the sensitivity of Asian pear to subsurface compaction were not directly assessed in this study. Therefore, while our findings demonstrate that pneumatic subsoiling reduced soil penetration resistance compared to untreated controls, its direct agronomic benefits should be interpreted cautiously in the absence of baseline compaction and crop response data. Nonetheless, this study contributes to evaluating pneumatic subsoiling as a potential low-disturbance soil management strategy in established orchards.

4.1. Effects of Pneumatic Subsoiling on Soil Penetration Resistance

Our results confirmed that pneumatic subsoiling reduced soil penetration resistance, especially when applied at 120 cm from the trunk (R120+A). The vertical profile of soil resistance, consistent with general soil physical behavior, showed increasing compaction with depth, peaking between 22.5 and 30 cm. Although this pattern is typical across soils regardless of treatment, it is notable because this depth range is critical for fine root proliferation in perennial fruit crops and represents the main target zone for subsoil management interventions. This pattern of compaction is consistent with previous studies conducted in similarly compacted soils. For example, Rolf (1992) reported that Terralift

® pneumatic subsoil loosening significantly decreased soil penetration resistance in sandy loam soils between 30 and 50 cm depth [

24].

Our findings align with previous engineering studies in East Asia that demonstrated the efficacy of high-pressure air injection in disrupting subsurface compaction without extensive surface disturbance. For example, Peng (1983) observed substantial reductions in soil penetration resistance in silty loam soils following a treatment of pneumatic subsoiling [

15], while Shen et al. (2019) and Zuo et al. (2023) reported effective loosening depths of 60 cm and notable improvements in porosity using air-assisted subsoiling in compacted orchard soils [

16,

17]. These results support the potential of pneumatic systems as a conservation-oriented alternative to mechanical ripping, especially when carbon preservation and minimal root disruption are priorities

However, the degree of compaction relief observed in our study may vary depending on soil type and baseline compaction levels. Rolf (1992) reported negligible improvement in heavier-textured soils, where bulk density actually increased following pneumatic subsoiling treatment, highlighting that soil responsiveness is texture-dependent [

24]. Our study site, with a clay soil, was conducive to pneumatic loosening. Additionally, initial compaction levels appear to influence treatment efficacy. Fite et al. (2011) noted that significant improvements in soil strength following pneumatic or mechanical tillage were most evident when pre-treatment bulk density approached critical thresholds for root restriction [

25]. However, such critical limits are generalized and can vary considerably depending on crop species, soil type, and climatic conditions. Although root measurements were not conducted in this study, and no specific compaction threshold for Asian pear was available for this site, the moderate compaction observed in our control plots suggests that soil strength may not have been the primary severe limitation to tree performance—potentially explaining the moderate but statistically significant reductions observed following treatment.

In addition, this study has important limitations. First, we did not collect direct soil moisture measurements during the penetration resistance assessments. Soil moisture substantially influences penetration resistance readings, as drier soils generally exhibit higher resistance due to increased soil strength. Although volumetric water content was not measured at the timepoints, daily rainfall records from a nearby weather station (

Figure A1) indicate intermittent rainfall throughout the experimental period, suggesting that extreme drying or waterlogging was unlikely during sampling. Nevertheless, future studies should incorporate concurrent soil moisture data to enable correction or interpretation of penetration resistance variability.

Second, pre-treatment soil penetration resistance measurements at each treatment site were not collected due to operational constraints and the logistical demands of conducting treatments within a commercial orchard schedule. The absence of baseline data limits our ability to quantify absolute changes attributable to the pneumatic subsoiling treatments. We recognize that penetration resistance is an indirect indicator affected by multiple factors, including texture, structure, and moisture. In this study, it served primarily as a comparative index between treatments applied within the same soil type, management regime, and seasonal timeframe. However, future research should include pre-treatment assessments and complementary soil physical properties such as bulk density and porosity to strengthen conclusions regarding compaction alleviation.

4.2. Vegetative Growth Response

Despite effective subsoil loosening in the R120+A treatment, neither shoot elongation nor node production showed significant differences across treatments. The shoot length and node count changes over DAT represent normal seasonal plant growth patterns. This outcome contrasts with our stated hypothesis that reducing subsoil compaction would enhance root resource acquisition and thereby stimulate canopy development and shoot growth.

This apparent disconnect has been documented in prior work. Smiley (1990) found that air tillage did not enhance trunk growth in trees, even though soil structure improved [

12]. Similarly, Braun et al. (2010) observed no vegetative growth response in apple trees following pre-plant subsoil ripping unless it was combined with fumigation or organic amendments, suggesting that biological or chemical soil constraints can override physical improvements [

26].

In our study, the absence of a growth response may be attributed to one or more of the following factors. First, compaction in the CK may not have been severe enough to significantly restrict root activity or tree vigor. As Fite et al. (2011) noted, trees growing in soil below critical bulk density thresholds often exhibit minimal growth response to decompaction [

25]. Second, it is possible that the time required for trees to biologically respond to improved subsoil conditions varies with context. While some studies report immediate vegetative growth improvements following subsoiling, others suggest that physiological responses such as canopy expansion or shoot elongation may manifest gradually over multiple seasons, as root system adjustments and resource allocation processes integrate the alleviated soil conditions. Therefore, longer-term monitoring is necessary to fully evaluate treatment effects.

Importantly, this study did not assess root traits directly, nor did it measure pre-treatment soil moisture, root distribution, or nutrient status, which limits interpretation of belowground and aboveground dynamics. Additionally, spatial variability, unmeasured soil physical properties, and orchard management factors could have influenced the outcomes, potentially masking treatment effects. Therefore, while the lack of observed aboveground growth response suggests that compaction relief alone may not drive vegetative gains, these findings should be interpreted cautiously. Future studies incorporating comprehensive baseline measurements and controlled experimental conditions are needed to confirm the role of pneumatic subsoiling within integrated orchard management strategies.

4.3. Fruit Yield and Quality

Budwood cultivar differences were evident in fruit size and SSC; however, treatment effects were not significant within budwood cultivars, and no treatment × budwood cultivar interaction was detected. Pneumatic subsoiling did not lead to statistically significant improvements in fruit yield or quality parameters, as fruit size and SSC remained comparable between treated and control trees. This outcome may suggest that subsoil compaction was not sufficiently severe to limit crop performance under the conditions of this study. Alternatively, it is possible that environmental factors such as adequate rainfall and orchard irrigation mitigated the potential negative effects of compaction. These findings align with prior observations in humid orchard systems, where compaction relief alone did not translate into immediate yield benefits. For example, Ben-Noah et al. (2021) found that injecting air into root zones in citrus orchards had little effect on yield or fruit quality, even though it improved oxygen availability [

6]. Similarly, Braun et al. (2010) and Percival et al. (2023) documented that soil loosening alone—without concurrent changes in nutrient availability or disease suppression—often failed to elicit changes in yield or fruit quality [

26,

27].

One likely explanation for the absence of significant treatment effects is that uniform irrigation and fertilization throughout the orchard mitigated any physiological advantages conferred by pneumatic subsoiling. Adequate soil moisture and nutrient availability, even in compacted zones, may have masked potential benefits of compaction relief. Importantly, the lack of direct soil moisture measurements during the experimental period limits our ability to fully interpret these findings. Soil moisture is a major factor influencing both penetration resistance readings and plant responses to subsoiling. This limitation underscores the need for future experiments to incorporate soil moisture monitoring to better contextualize soil compaction data and to ensure robust evaluation of treatment effects. Additionally, tree productivity is influenced by cumulative factors—bud differentiation in the prior season, weather conditions, and fruit load management—all of which were standardized across treatments.

Therefore, while pneumatic subsoiling effectively altered the physical soil environment, its benefits to fruit yield and quality may only become evident under conditions of more severe subsoil compaction or resource limitation. Importantly, these considerations should inform experimental design from the outset, including treatment selection, replication structure, measurement variables, and study duration, to ensure practical applicability of findings. Future studies should integrate thorough pre-assessment of soil compaction severity, crop sensitivity thresholds, and environmental conditions to optimize experimental designs that can generate actionable recommendations for growers.

4.4. Broader Ecosystem and Environmental Benefits

Besides tree growth and yield considerations, pneumatic subsoiling can restore aspects of soil structure by recreating macropores in the hardpan. This leads to improved water infiltration and percolation capacity [

28,

29]. In a subtropical climate (with intense seasonal rainfall), enhanced infiltration is particularly beneficial: more rainwater can soak into the soil rather than running off. By reducing runoff, the practice helps minimize soil erosion and loss of topsoil. Importantly, runoff from orchard lands often carries sediment, nutrients, and agrochemicals into waterways [

29]. A well-aerated, uncompacted soil can absorb water efficiently, thereby reducing the transport of sediments and farm chemicals off-site, which is a positive outcome for water quality in the surrounding environment.

Improved soil aeration is another environmental benefit. Compacted, waterlogged soils can become anaerobic, harming root health and soil biota. By fracturing the soil, pneumatic subsoiling increases gas exchange in the root zone. In the present study, we expect that relieving compaction will mitigate oxygen stress around roots (as noted in prior studies of air injection in orchards [

6]) even if the direct increase in soil O

2 is temporary. Additionally, breaking up compacted soil can encourage deeper root penetration, as roots encounter less physical resistance [

28]. Deeper and more extensive root systems improve trees’ access to water and nutrients, potentially increasing their resilience to drought periods common in subtropical regions.

4.5. Practical Implications

Pneumatic subsoiling proved to be operationally feasible in an orchard setting. The equipment used, a portable air compressor and injection probe, is maneuverable between tree rows and can target specific compacted zones near the trees’ root zone. Unlike conventional tractor-drawn subsoilers that cannot be used close to trunks (due to risk of root damage), the air injection gun can be inserted directly around established trees effectively “lifting” the soil with minimal surface disturbance [

30]. Each injection is quick; in our experiment, one tree (drilled + air injection for four holes) was treated in approximately 2 min. This translates to roughly 30 trees per hour per operator, indicating that hundreds of trees could be treated in a single day by one or two workers. Such efficiency makes targeted subsoiling (e.g., along tree rows or in high-traffic spots) practical during routine orchard management. We suggest this technique being deployed selectively in areas of an orchard where compaction is most severe (for example, along tractor lanes or at row ends), rather than uniformly over the entire field.

Frequency of application will depend on how quickly the soil re-compacts. In softer or well-drained soils, the benefits of a single subsoiling event might persist for several years. However, in heavier clayey soils or orchards that experience annual heavy machinery traffic, compaction can recur relatively soon. Therefore, periodic re-treatment (perhaps every few years, or as indicated by soil penetrometer readings) may be necessary to maintain improved soil conditions.

The cost of the pneumatic equipment used in the present study is moderate–on the order of NTD 100,000 approximately (USD 3400). This price point is comparable to other arboricultural soil aeration tools and is a one-time capital investment. Operating costs are also relatively low. The process uses only compressed air, so the main ongoing expenses are fuel for the compressor and labor. Labor requirements are modest given the speed of treatment. At a minimum wage rate in Taiwan in 2025 (~NTD 200 per hour (~USD 6–7/hour), an operator can treat ~30 trees in that time, which works out to only about NTD 6–8 per tree in labor cost. Even scaling up, the per-hectare cost remains reasonable. In comparison to alternative soil remediation methods, pneumatic subsoiling appears cost-effective. Traditional deep ripping with a tractor, aside from being impractical near trees, would incur fuel and equipment rental costs that can be higher, whereas our method leverages a relatively inexpensive device and human labor.

5. Conclusions

This study evaluated the effects of a handheld pneumatic subsoiling system on soil compaction and tree performance in an intensively managed Asian pear orchard. Pneumatic subsoiling effectively reduced soil penetration resistance, particularly in the subsoil layers critical for root proliferation. However, no significant improvements in vegetative growth, fruit yield, or quality were observed within the first growing season. Although these findings suggest that while pneumatic subsoiling alters the physical soil environment with minimal surface disturbance, its agronomic benefits may require longer-term observation and integration with other management practices. Moreover, the lack of baseline compaction and soil moisture data, as well as the absence of direct root measurements, limit definitive conclusions regarding treatment efficacy. Future research should incorporate multi-season assessments, detailed root system analyses, and cost–benefit evaluations across diverse orchard soils and management regimes to determine the operational feasibility and role of pneumatic subsoiling as part of integrated, climate-resilient orchard floor management strategies.