1. Introduction

Pest control in empty industrial buildings, silos, and similar structures is crucial for preventing disruptions in supply chains. Infestations pose significant threats to food safety, economic stability, and regulatory compliance. Pests can introduce pathogens to where the food is processed or stored, posing health risks [

1], while pests such as

Tribolium spp. and

Sitophilus spp., commonly addressed as flour beetles and grain weevils, can cause substantial loss to quality and quantity in stored grains, which can impact food security [

2]. These infestations undermine the safety and quality of food products, leading to significant economic impacts. For instance, insect infestations can lead to damages or destroyed products, resulting in significant financial losses to producers and retailors [

3]. Moreover, the presence of pests in food premises can lead to formal actions by food authorities, and stringent pest control measures are essential to prevent the spread of invasive species through international trade, ensuring compliance with global pest control standards [

1,

4].

Fumigation with phosphine is a traditional and widely used method to control pests in grain storage, but it comes with significant drawbacks [

5]. Insects start developing resistance to chemical pesticides, rendering them ineffective over time. Resistance to Bacillus thuringiensis (bt) toxins has been developed by the diamondback moth (

Plutella xylostella) and tobacco budworm (

Heliothis virescens) [

6]. Similarly, many stored product insect populations (

Rhyzopertha dominica and, specifically in Greece,

Oryzaephilus surinamensis) have developed resistance to phosphine throughout the world, a commonly used fumigant, complicating its effectiveness [

5,

7,

8,

9,

10,

11,

12,

13]. Extensive use of chemical pesticides leads to environmental pollution and poses a human health hazard [

14]. Furthermore, indiscriminate use of chemicals disrupts ecosystems by reducing biodiversity among natural predators, harming non-target species, and overall disrupting food webs in ecosystems [

15]. Due to chemicals’ negative health impact and environmental effects, many chemical fumigants face stringent regulatory restrictions. For example, methyl bromide has been banned in several countries, although it is still used in several quarantine applications [

14]. Methyl bromide also has a complex application process; effective fumigation requires precise application and monitoring, which is logistically challenging. For instance, constructing gas-tight enclosures and ensuring proper aeration post-fumigation are critical steps that require expertise and resources. Aeriation of the treated facility (e.g., silo, warehouse) is essential after fumigation to ensure that residual fumigants are safely vented and the site is safe for re-entry.

Heat treatments are increasingly recognized as effective and environmentally friendly alternatives to chemical pesticides for managing stored product insects in several structures, such as flour mills, rice mills, or feed mills [

16,

17]. Heat treatment is based on the application of high temperatures for a relatively short time for the control of different stored product insects without affecting product quality [

18]. There are different types of heat treatments that are effective in different applications; for instance, there is the dry heat and forced hot air, the first of which utilizes high temperatures and is effective in flour mills and grain-processing facilities [

19,

20], and the other involves circulating hot air to maintain uniform temperatures and is commonly used in post-harvest treatments for fruits and vegetables [

21,

22]. Sterilization of plant media is crucial in horticulture and greenhouse systems, as it prevents the spread of soil-borne pathogens and ensures plant health. Amongst the available techniques, steam and vapor heat are commonly used. Steam is applied to sterilize plant media to control fungal and bacterial pathogens effectively as well as plant-parasitic nematodes [

23]. Vapor heat is typically used to disinfest commodities like dates, ensuring pest control without chemical residue [

24]. While these methods are more commonly used in post-harvest fruits and horticulture contexts, the underlying principles of heat-based pest control are applicable to industrial settings. Additionally, there are hot water treatments, which are more efficient than hot air treatments and are often used in post-harvest treatments of fruits and also certain plants because of the benefit of increasing rooting, budding, or shelf life [

22]. Lastly, radio frequency (RF) heating uses electromagnetic energy to heat commodities, and it is effective for disinfesting legumes and walnuts, though uniformity remains a challenge [

25].

There are various applications of heat treatments in industrial facilities. Firstly, there are the flour mills, which use electric heaters and have shown efficacy in controlling pests like the confused flour beetle,

Tribolium confusum Jacquelin du Val (Coleoptera: Tenebrionidae), and the rice weevil,

Sitophilus oryze (L.) (Coleoptera: Curculionidae) [

26,

27]. The treatment duration is still a matter of some debate; some studies suggest that a few minutes of elevated temperature is sufficient to disinfest a building completely [

28], while others posit that a treatment duration of 24–36 h is typically necessary for complete pest control [

20]. Heat treatments are successfully used to control insect pests in stored grains in grain-processing facilities [

26,

29,

30]. Temperature distribution and the use of circulating fans are critical for effective pest control [

31]. Also, heat treatments have been successfully applied in Sicilian mills, demonstrating both technical and economic feasibility [

32,

33].

Heat treatments are valued for reducing environmental impact and leaving no chemical residues [

21,

32]. They are effective against a broad spectrum of pests, including insects [

18,

27], nematodes, and plant pathogens [

22,

23]. A key distinction between heat treatments and chemical fumigation lies in their application methods. Heat treatments are typically applied to empty storage and processing facilities, targeting residual pests in structural components and equipment. In contrast, chemical fumigants such as phosphine are generally used to treat the commodity itself, penetrating the product to eliminate internal infestations while leaving the surrounding equipment untreated [

12]. Despite their advantages, heat treatments face notable challenges, primarily the high energy demands associated with heating large buildings. Energy consumption is significantly influenced by the structure and insulation properties of the facility [

34]. Moreover, ensuring uniform temperature distribution is essential for achieving effective and consistent pest control outcomes [

22,

35].

Heat treatments can be monitored and made more efficient using sensors or IoT devices. For example, an IoT system was developed to monitor and regulate temperature in a clean room, achieving a data accuracy rate of approximately 99% [

36]. This system includes sensors for dynamic temperature and air conditioning, which can be adapted for monitoring heat treatments in warehouses or silos. The integration of advanced automation and sensor systems is crucial for optimizing thermal treatments. Sensors play a pivotal role in monitoring and regulating parameters such as temperature, pressure, relative humidity, and flow rates, enabling real-time data collection and immediate adjustments to maintain optimal conditions [

12,

37,

38,

39]. Specifically, Sakka et al., 2022 deployed temperature wireless sensors and monitored the temperature change during the treatment [

27]. In their study, electric and gas heaters were also included, as well as floor fans that were electronically controlled and automatically changed to provide hot air to attain the desired air temperature in the ambient space (>50 °C). The use of IoT (Internet of Things) and wireless sensor networks for industrial automation, including temperature control, enables remote monitoring and control of industrial devices, reducing complexity and costs [

40].

Data analysis and machine learning (ML) can play a crucial role in optimizing heat treatment parameters. Exploratory data analysis (EDA) is crucial for thoroughly exploring and analyzing datasets, which is a preliminary step before applying ML models. It helps in identifying key features and understanding complex patterns and dependencies within the data, leading to more accurate predictions [

41]. ML models such as random forest, support vector machines, decision tree, and artificial neural network have been employed to predict and optimize heat treatment parameters. These models help in understanding complex patterns and dependencies within the data, leading to more accurate predictions [

41,

42,

43].

Thermal imaging combined with ML algorithms is used for early detection and automated identification of pests and diseases [

44]. Various ML techniques, including supervised learning, unsupervised learning, and deep learning, are employed for pest and disease detection. ML techniques help in classifying diseases, detecting anomalies, and improving crop health monitoring, while some of them help in establishing the probability of pest presence and aid in decision making [

45,

46]. Studies have shown that sensors can be deployed and collect data on gas concentration, temperature, and exposure time that would provide information on treatment effectiveness and help guide the way to improve efficacy [

38,

47]. AI systems integrated with sensors optimize irrigation, fertilization, and pest management plans. These systems can trigger automatic responses based on real-time data, improving crop yields and reducing resource use [

48].

ML models like RF and SVM are used to predict the temperature of heat-carrying agents in heating systems, which are essential for optimizing energy efficiency and diagnosing non-typical processes [

42]. Also, ML methods are applied to predict these parameters in heat exchangers, surpassing the accuracy of traditional empirical correlations [

43]. While no studies have specifically applied ML to heat treatment in empty silos or empty industrial storage facilities, the principles of ML and data analysis used in other heat treatment systems can be adapted to this context. For instance, predicting the duration or temperature required for effective heat treatments in silos can benefit from similar ML techniques, enabling more precise control and optimization of the process. This study uses data derived from Agrospecom, a pest control company in Greece that collaborates with Centaur [

49] and uses IoT devices to monitor heat treatments for pest control.

The primary aim of this study is to address a gap in the literature by gathering and analyzing time series and general heat treatment data for pest control. By leveraging machine learning as a tool, we aim to develop a predictive model that can accurately estimate the duration of each treatment as a function of structural and environmental variables. This approach will not only help optimize heat treatments, reducing energy consumption, but also provide a deeper understanding of the factors influencing the effectiveness of heat treatments in industrial settings. Machine learning serves to achieve these objectives, enabling data-driven insights and more efficient pest control strategies.

2. Materials and Methods

2.1. Data Collection

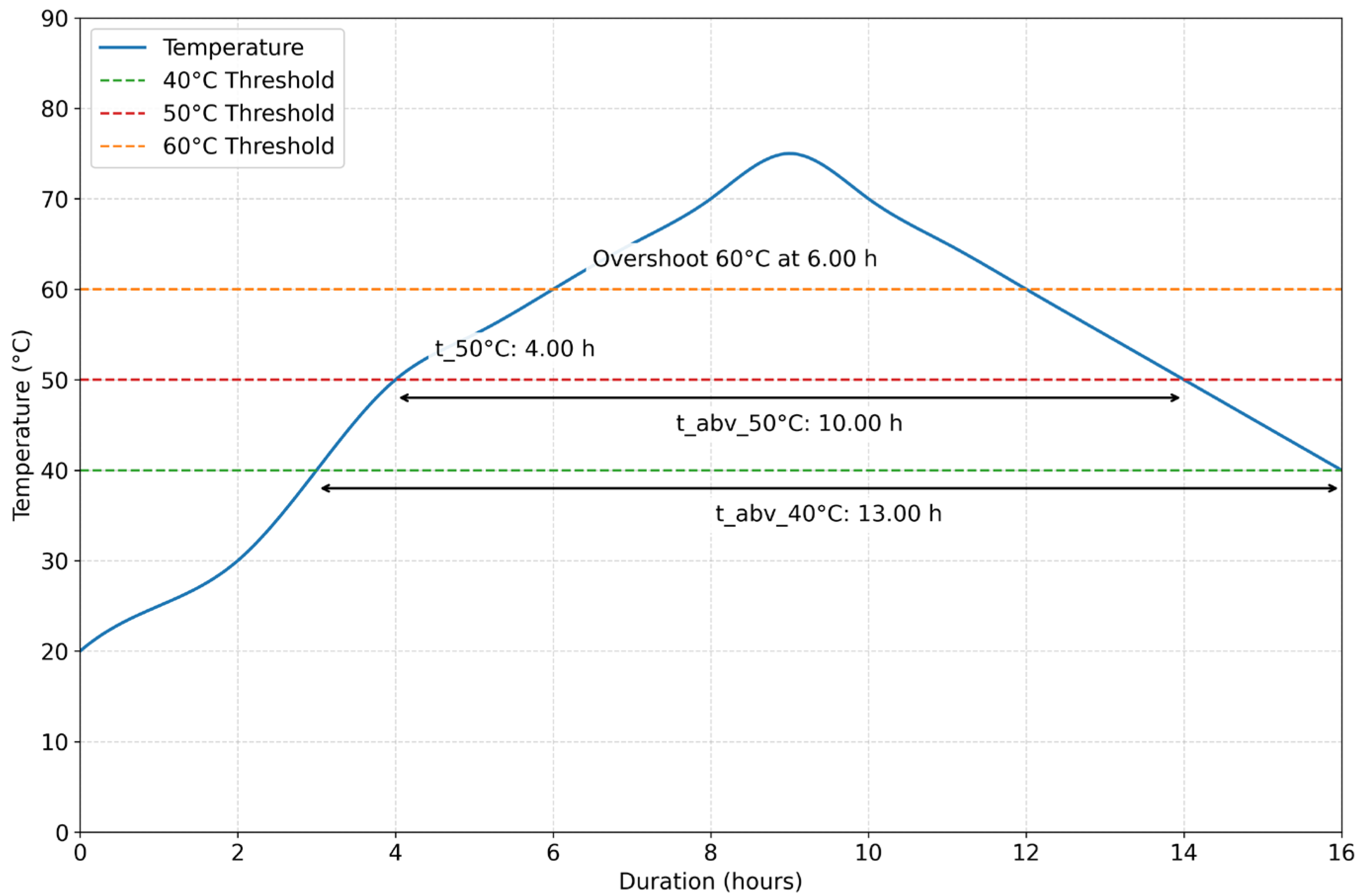

The dataset used in this study was collected from heat treatment processes conducted in empty industrial buildings and silos over a 2-year span (2022 and 2023). The data were obtained from IoT devices deployed by Agrospecom, Thessaloniki, Greece, accessible through the Internet of Crops platform developed by Centaur, Volos, Greece. The dataset comprised 1423 heat treatments, containing 6503 time series records. Each record included measurements of temperature and time. Data records also included a brief description of the process (e.g., building type), location (latitude, longitude), average temperature, and start time. Derived data, including the month and exact building type, were extracted for each heat treatment. Additionally, time series analysis was performed to determine whether each treatment reached 40 °C and 50 °C (t_40 °C, t_50 °C), the time it took to reach these temperatures, the duration above these thresholds, and whether the temperature exceeded 60 °C (overshot), as

Figure 1 explains.

The industrial facilities involved in this study varied significantly in size, structure, and material composition. These included flat storage warehouses, upright cylindrical silos, ISPM-15 compliant wooden crates, and concrete storage rooms. Such structural differences affect the thermal properties of the buildings, with materials like concrete and metal influencing the rate of heat retention and dissipation. The facilities ranged widely in scale, from small structures ranging from 33 to 66 m3 to large industrial facilities like flour mills and flat storage warehouses, with volumes reaching up to approximately 30,000 m3. Typically, heaters are positioned at floor level or near air inlets, and hot air is circulated using high-capacity fans to achieve uniform temperature distribution. Mapping airflow paths is crucial in practice, as uneven heating can lead to cold spots where pests may survive. These structural and operational factors contribute to the variation in heat treatment effectiveness and are reflected in the predictive models developed in this study.

Although the dataset used in this study does not include pre-treatment pest counts, it is important to note that in real-world applications, pest population assessments are commonly performed before heat treatment. Methods such as pitfall traps, probe traps, and visual inspections are used to detect key pests like Tribolium spp. and Sitophilus spp., providing critical information for treatment planning and success evaluation.

2.2. Data Preprocessing

The raw data were preprocessed to ensure quality and consistency before analysis. All preprocessing and analysis were conducted using Python (v. 3.12.4), a programming language widely used in scientific computing and data analysis due to its simplicity, readability, and extensive ecosystem of libraries [

50]. The data were structured into a Pandas Dataframe. Pandas is a powerful library for data manipulation and analysis, particularly suited for handling structured data [

51]. To incorporate environmental factors, the Open-Meteo API [

52] was used to fetch the average daily temperature for each treatment based on its location and date.

The preprocessing steps began with handling missing values, which were identified and removed to maintain data accuracy and realism. This step ensured that only complete and reliable records were used for analysis. Sensors with unrealistically low durations before reaching 40 °C (less than 12 min) were also removed, as they were deemed unreliable for analysis. Each treatment was categorized according to building type (industrial storage, containers, ipsm15, rooms), and unrecognized building types were classified as “Others” and excluded from further analysis. To account for the circularity of time, the start time and month were encoded to cyclical variables using sine and cosine transformations. Time-based features, such as hours of the day or months of the year, are inherently cyclical, meaning that the end of cycle (e.g., 23:59) is adjacent to the beginning (e.g., 00:00). However, many machine learning models treat features as linear, which can lead to incorrect assumptions about the relationships between adjacent time points. For example, the model might interpret 23:59 and 00:00 as being far apart, even though they are only one minute apart in reality. To address this, we transformed the start time and month into two new features, one representing the sine of the time and the other representing the cosine of the time. For start time, the hour of the day (ranging from 0 to 23) was converted into an angle (ranging from 0 to 2π) and then transformed using sine and cosine functions. The months of the year (ranging from 1 to 12) were similarly converted into an angle and transformed. Geographical clustering was performed using the DBSCAN algorithm from the scikit-learn library [

53], which grouped treatments based on latitude and longitude, allowing for the identification of regional patterns in heat treatment effectiveness. Previous studies have shown that susceptibility to heat varies across insect life stages, with eggs and pupae often being more tolerant than larvae or adults. Effective mortality typically requires several minutes of exposure above 50 °C (t_abv_50 °C), with Fields [

28] reporting that a duration above 50 °C (t_abv_50 °C) of a few minutes is required for complete pest mortality; for this purpose, the threshold of 4.8 min (0.08 h) was chosen. Finally, categorical data, such as building type, were encoded using the “get_dummies” function in pandas [

51], creating a separate dataset suitable for machine learning models that require numerical input.

2.3. Exploratory Data Analysis (EDA)

Exploratory data analysis was conducted to uncover patterns and relationships in the dataset. A geographical heatmap was created using the Folium library to visualize the distribution of heat treatments across different locations. The heatmap highlighted clusters of treatments and their density, providing insights into regional trends. Temporal analysis was performed to calculate the average duration until 50 °C by month, and the average temperature of major geographical clusters (representing mostly Greek cities) was analyzed monthly to identify seasonal trends. The Pearson correlation coefficient, calculated using the scipy library [

54], was used to assess the relationship between the average duration until 50 °C and the monthly average temperature. Statistical tests, including one-way ANOVA [

55], were performed to evaluate differences in treatment effectiveness across building categories. Post hoc analysis was conducted using Tukey’s test to identify specific group differences.

2.4. Machine Learning Model Preparation, Evaluation, and Refinement

The dataset was further modified to make it suitable for machine learning (ML) training. The parameters used as input features for the ML models included environmental temperature, which was derived from the average temperature during the heat treatment using the Open-Meteo API. To account for the cyclical nature of the time-based data, the start time and month were encoded as cyclical variables using sine and cosine transformations, resulting in features such as “time sin”, “time cos”, “month sin”, and “month cos”. Additionally, the building type (e.g., industrial storage, containers, rooms) was one-hot encoded to represent categorical data numerically, while the geographical location of each treatment was represented by clusters generated using the DBSCAN algorithm, replacing raw latitude and longitude coordinates. The target variable for the ML models was the duration until the temperature reached 50 °C (t_till_50 °C), a critical threshold for effective pest control. ML tasks were performed using the scikit-learn library [

53].

The dataset was split into training (80%) and testing (20%) sets to ensure robust model evaluation. The target variable was set as the duration until the temperature reaches 50 °C. The data were scaled to ensure compatibility with the support vector regressor (SVR) model. Scaling was not required for other models, such as random forest regressor, XGBoost regressor, and ridge regressor, which are capable of handling non-linear relationships without preprocessing. Regression models were chosen because the goal was to predict numerical values (duration) rather than probabilities or binary outcomes. The selected models included random forest regressor [

53], an ensemble method known for its robustness and ability to handle non-linear relationships, XGBoost regressor [

56], a gradient boosting algorithm renowned for its performance in regression tasks, ridge regressor [

53], a linear model with L2 regularization to prevent overfitting, and support vector regression (SVR) [

53], a kernel-based method effective for capturing complex, non-linear relationships.

Grid search with cross-validation was used to optimize hyperparameters for each model, ensuring optimal performance. Grid search is an exhaustive search technique that evaluates all possible combinations of hyperparameters within a predefined search space. For each combination, the model is trained and evaluated using k-fold cross-validation, where the dataset is split into k subsets (folds) and the model is trained on k-1 folds while being validated on the remaining fold. This process is repeated k times, with each fold serving as the validation set once. The performance metric (negative mean absolute error) is averaged across all folds to provide a robust estimate of the model’s generalization ability. The combination of hyperparameters that yields the best performance is selected as the optimal configuration. In this study, a parameter grid was defined to specify the range of hyperparameters to be explored (e.g., learning rate, number of trees, maximum depth of trees, minimum samples required at leaf node, etc.).

The grid search was implemented using the GridSearchCV class from the scikit-learn library [

53], with 5-fold cross-validation and negative mean absolute error (MAE) as the scoring metric. The negative MAE was used because scikit-learn optimizes for higher scores, and minimizing MAE is equivalent to maximizing its negative value. After fitting the grid search, the best hyperparameters and corresponding scores were identified for each model.

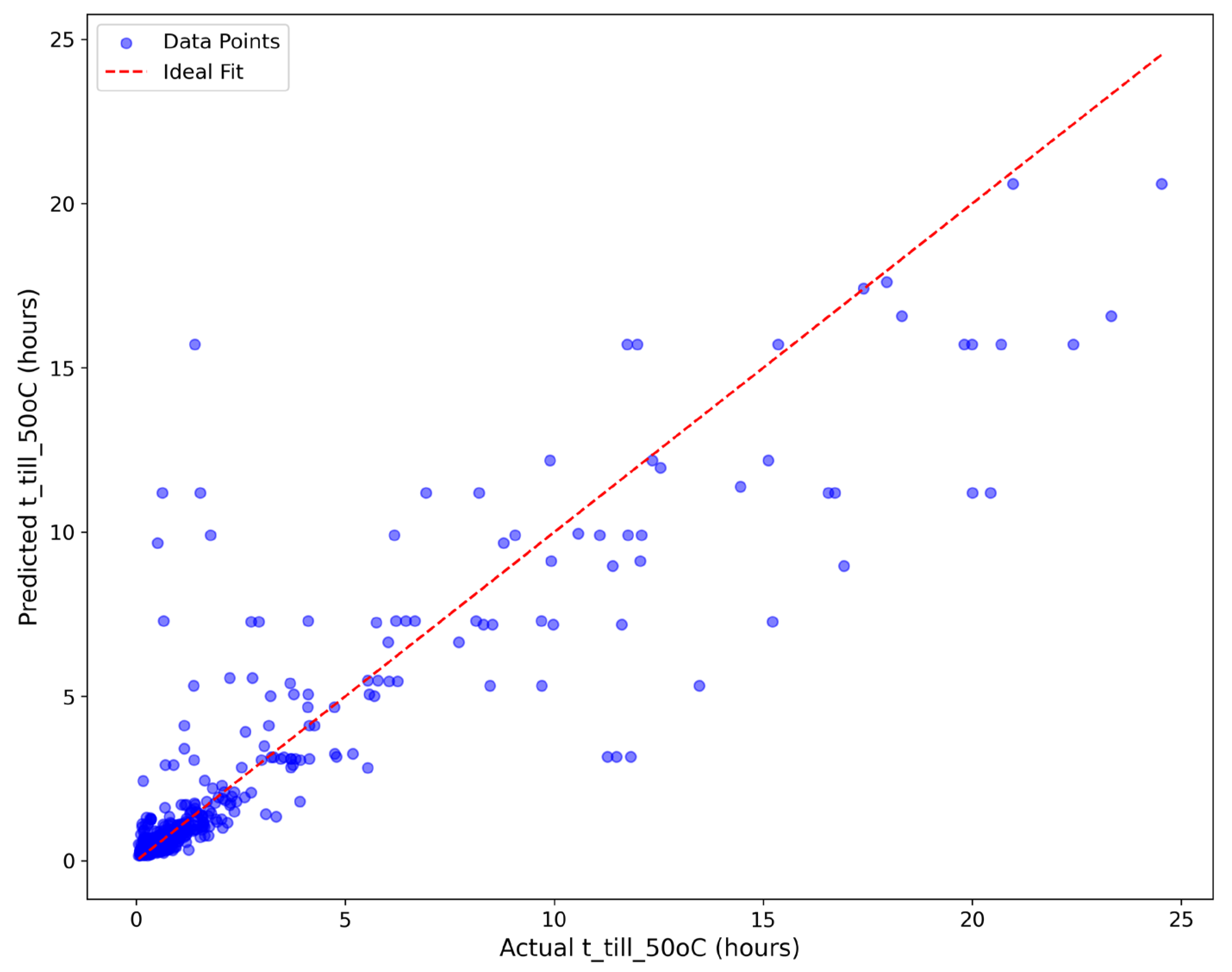

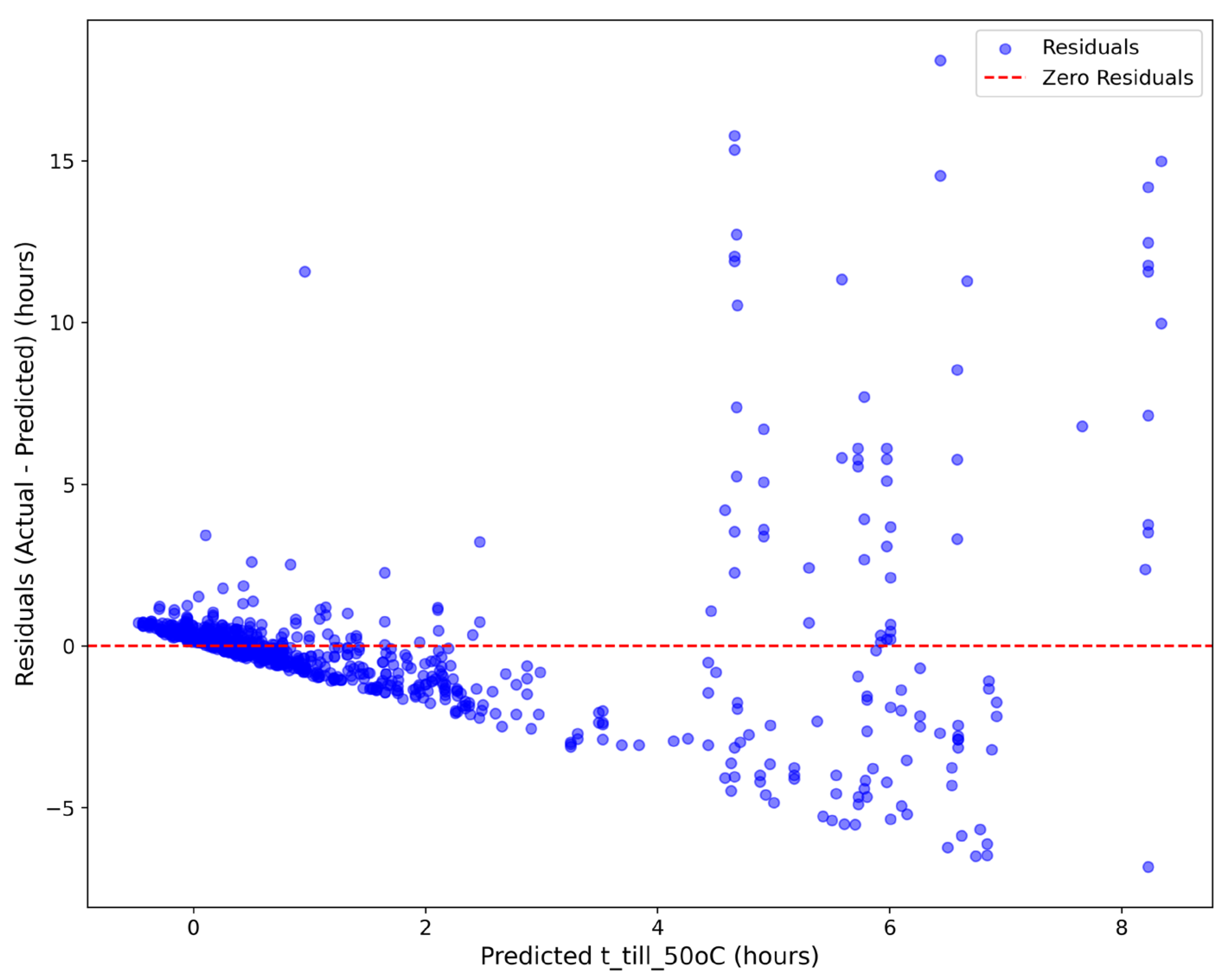

The performance of each model was evaluated using metrics such as mean absolute error (MAE), mean squared error (MSE), and R2 score. Visualizations, including actual vs. predicted values and residual plots, were generated using Matplotlib to visually assess model performance. These visualizations provided insights into the models’ ability to capture the underlying patterns in the data and identify any systematic errors.

To further refine the models, the two best-performing models (based on MAE, MSE, and R2 scores) were retrained on data subsets to specific building categories (e.g., industrial storage, containers, rooms). This approach aimed to improve model performance by capturing category-specific patterns.

4. Discussion

The findings of this study provide valuable insights into the factors influencing the effectiveness of heat treatments for pest control in industrial buildings and silos. By analyzing a large dataset of heat treatment processes, we identified significant variations in treatment effectiveness across different building types, geographical regions, and environmental conditions. These results have important implications for optimizing heat treatment protocols and improving pest management strategies in real-world conditions.

One of the key findings of this study is the significant influence of building type on the duration required to reach 50 °C, a critical threshold for effective pest control. Treatments in industrial storages required significantly longer durations compared to containers and rooms, as revealed by the one-way ANOVA and Tukey’s test. This variation can be attributed to differences in building size, insulation, and structural materials, which affect heat distribution and retention [

32,

34]. For example, Jian et al., 2012 underlined the difficulties associated with uniformly heating large-scale flour mills, emphasizing that areas with thicker walls or inadequate insulation frequently operate as “thermal sinks”, slowing down the heating process and creating refuges where pests can survive. Moreover, the complexity of the internal equipment and stored commodities in such facilities contributes to temperature stratification and impedes uniformity [

31]. Several published studies have emphasized the importance of achieving uniform heat distribution in a treated facility and identified that the internal fluctuations of the temperature profile are the major factor contributing to insect survival [

28,

29]. These findings indicate that specialized heat treatment techniques, such as strategic heater placement and real-time temperature monitoring, are required for larger structures to ensure lethal temperatures are maintained throughout the facility.

The analysis also revealed a moderate negative correlation (r = −0.65,

p-value = 0.02) between the average duration until 50 °C and the mean temperature by month. This relationship has been extensively documented in prior studies, in which higher ambient temperatures during summer months resulted in shorter heating periods and lower energy consumption [

18,

27,

31]. For instance, Mahroof et al., 2003 showed that ambient temperatures above 25 °C considerably improved the effectiveness of heat treatments in food-processing facilities, reducing the risk of treatment failure due to incomplete heating [

29]. The results of the present study are in accordance with the previous studies, where higher ambient temperatures, particularly during warmer months, facilitate faster heating and reduce the time required to achieve effective pest control. This finding emphasizes the role of environmental conditions in heat treatment performance. However, the seasonal variability of heat treatments also underscores the need for adaptive treatment protocols that account for fluctuations in ambient temperature. While ambient temperature was incorporated into the model, relative humidity was not included due to inconsistent availability across the dataset. Humidity can influence both pest mortality and heat distribution, and its integration into future models could enhance predictive performance and ecological validity. Additionally, while the model captures structural and environmental variation, it does not account for differences in thermal tolerance among pest species. Since different insects exhibit varying degrees of heat resistance, incorporating species-specific biological parameters in future studies could improve the accuracy and applicability of treatment duration prediction.

The geographical heatmap highlighted regional variations in treatment frequency, with dense clusters of treatments in urban areas and fewer treatments in rural regions. This pattern likely reflects the distribution of industrial activity, as urban areas tend to have higher concentrations of food-processing and storage facilities. Gerken and Campbell (2022) observed similar patterns, finding that the pest management treatments are common in locations with a dense network of storage-processing facilities [

3]. The clustering of treatments suggests that regional factors, such as climate and infrastructure, may influence the implementation and effectiveness of heat treatments.

The machine learning models developed in this study demonstrated strong predictive performance, particularly the random forest regressor and XGBoost regressor. These models outperformed linear methods like ridge regression, highlighting the non-linear nature of the relationships between predictors and the target variable. The success of tree-based models can be attributed to their ability to capture complex interactions between building type, geographical cluster, and environmental factors. While the models employed in this study are considered classical, their application to real-time prediction of industrial heat treatment duration represents a novel use case. These models offer the advantage of interpretability and operational readiness, making them particularly suitable for industry adoption. The results demonstrate that even with established algorithms, significant performance can be achieved when paired with structured real-world data. The integration of IoT monitoring systems, as demonstrated by Agrafioti et al., 2019 and Sakka et al., 2022, highlighted that these predictive models provide real-time data from several points within each facility [

18,

27]. The exceptional performance of category-specific models further underscores the importance of tailoring heat treatment protocols to specific building types and conditions.

The results of this study have practical implications for pest control in industrial settings. Firstly, the significant variation in treatment effectiveness across building types highlights the need for customized treatment protocols that account for structural differences. For example, industrial storages may require longer treatment durations or additional heating sources to achieve uniform temperatures. Secondly, the influence of ambient temperature suggests that treatment schedules should be adjusted seasonally to optimize efficiency. Finally, the success of machine learning models in predicting treatment duration demonstrates the potential of data-driven approaches to improve pest control strategies. By integrating IoT devices and predictive models, industrial facilities can monitor and optimize heat treatments in real time, reducing energy consumption and operational costs.

The observed impact of building type on treatment duration likely stems from underlying physical and structural differences among facility types. For example, flat warehouses with large open volumes may experience slower heating due to air stratification and poor circulation, while upright silos heat more rapidly but may lose heat through exposed metal walls. Similarly, materials such as concrete offer better thermal mass and insulation compared to steel or wood, influencing both heat retention and energy requirements. These structural and material characteristics play a critical role in determining the dynamics of heat distribution during treatment, and practitioners should consider them when designing or adjusting thermal protocols.

Despite these promising outcomes, certain limitations should be acknowledged. The dataset analyzed in that study was geographically limited to industrial facilities in Greece, which may limit the generalizability of the findings to other regions with different climate conditions and building structures. Future research should expand the geographical scope to include diverse industrial settings. Moreover, while the building type and ambient temperature were examined, some other factors, such as pest species, infestation levels, and building occupancy patterns, could be incorporated to further improve model accuracy. Furthermore, the machine learning models were trained on historical data, which may not fully capture the dynamic nature of heat treatment processes. Future studies should focus on incorporating real-time monitoring and adaptive control systems to enhance treatment effectiveness [

42,

43]. Finally, although this study uses treatment duration as an indicator of operational efficiency, a direct comparison of energy consumption between machine learning-guided protocols and conventional methods was not conducted. Future studies could address this gap by linking model predictions with energy use metrics to quantify potential cost savings and sustainability benefits.