Composting of Olive Mill Wastewater Sludge Using a Combination of Multiple Strategies: Assessment of Improvement in Biodegradability, GHG Emissions, and Characteristics of the End Product

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Physicochemical Analyses

2.3. OM Modeling and Thermal and Spectroscopic Analysis

2.4. GHG Measurement During Composting

2.5. Economic Value of the Product

2.6. Statistical Analyses

3. Results and Discussion

3.1. Temperature Changes and Exothermic Indexes

3.2. OM Dynamics and Thermal Analysis

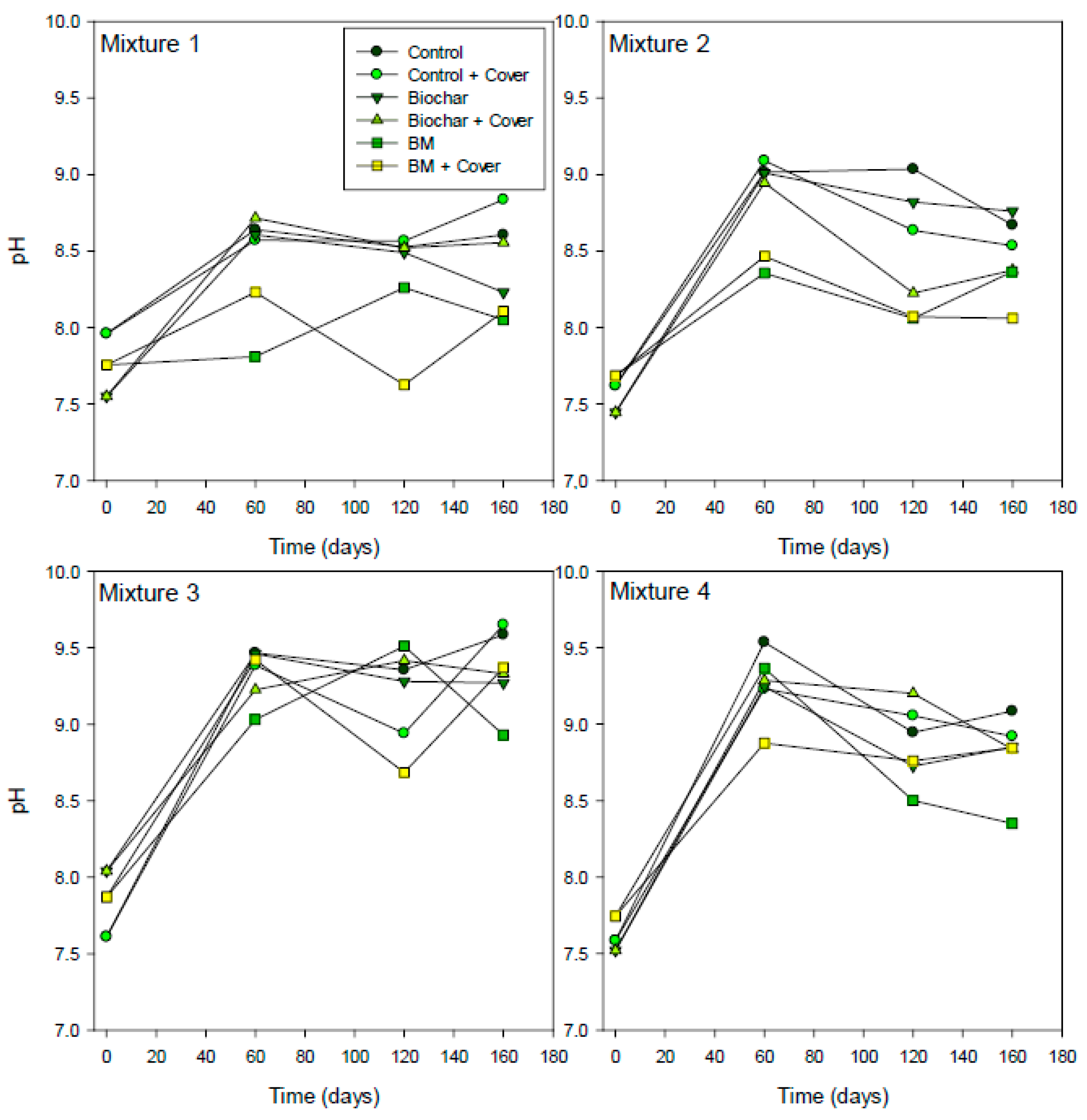

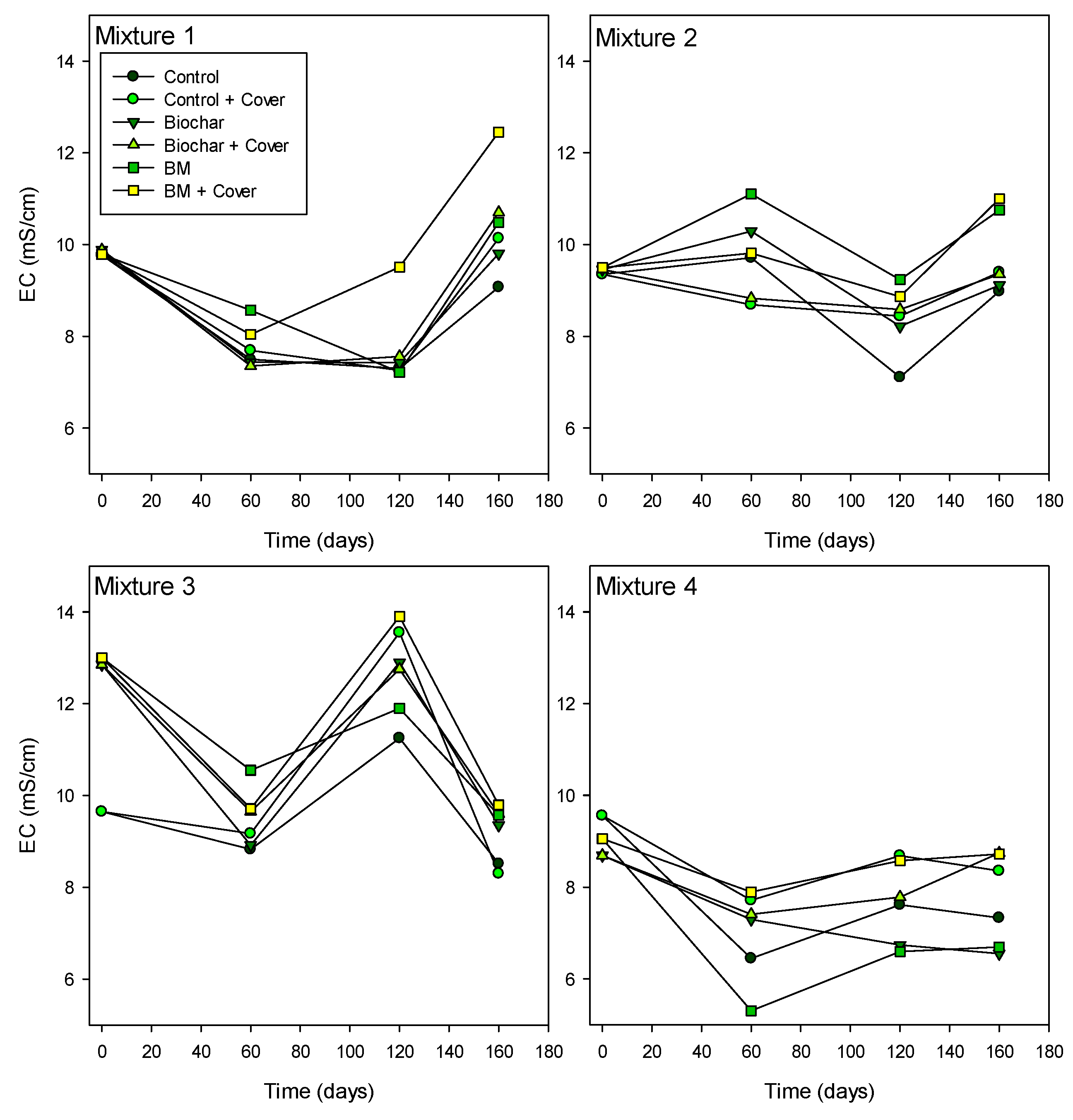

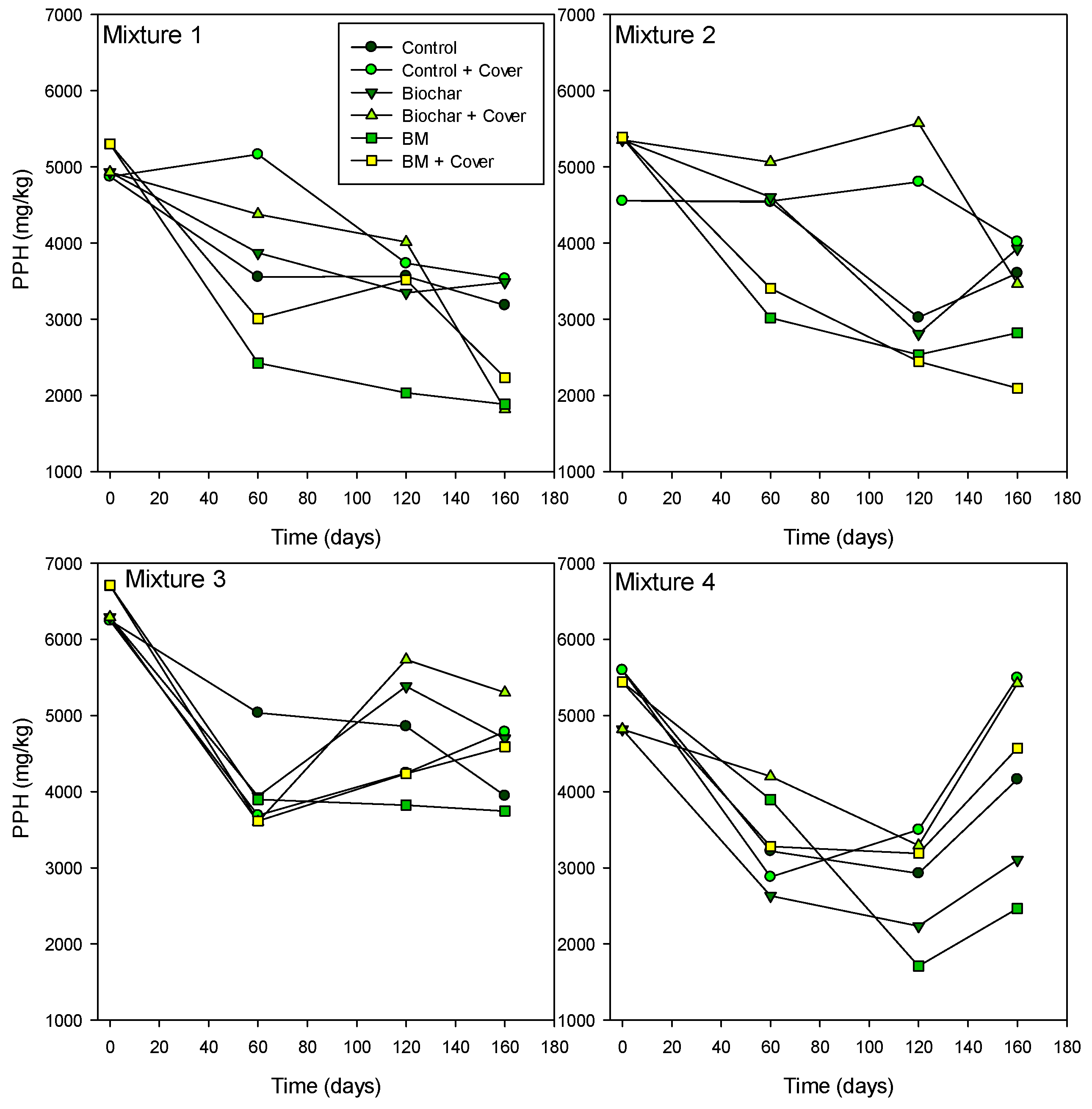

3.3. Changes in Physicochemical Parameters During the Composting Process

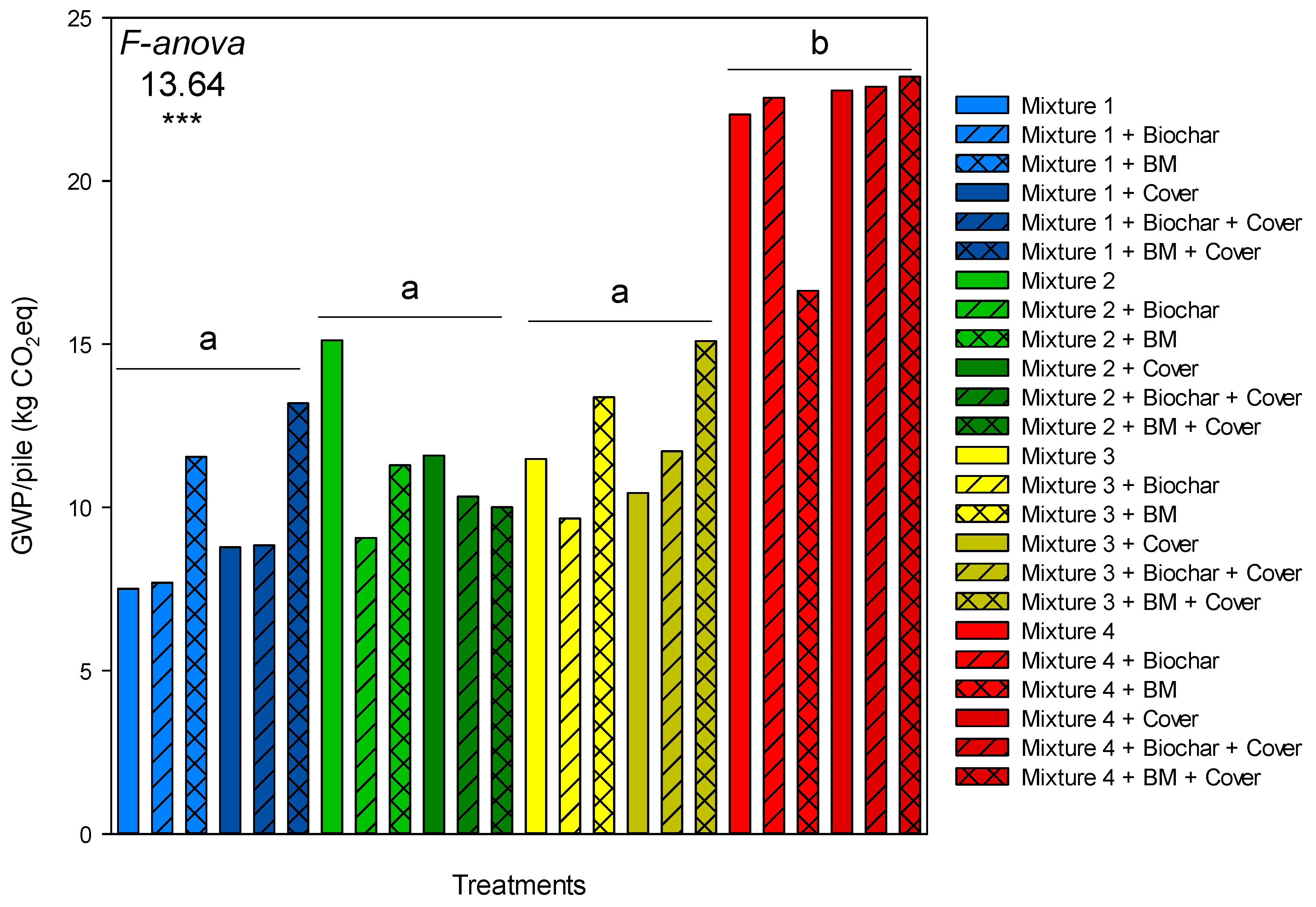

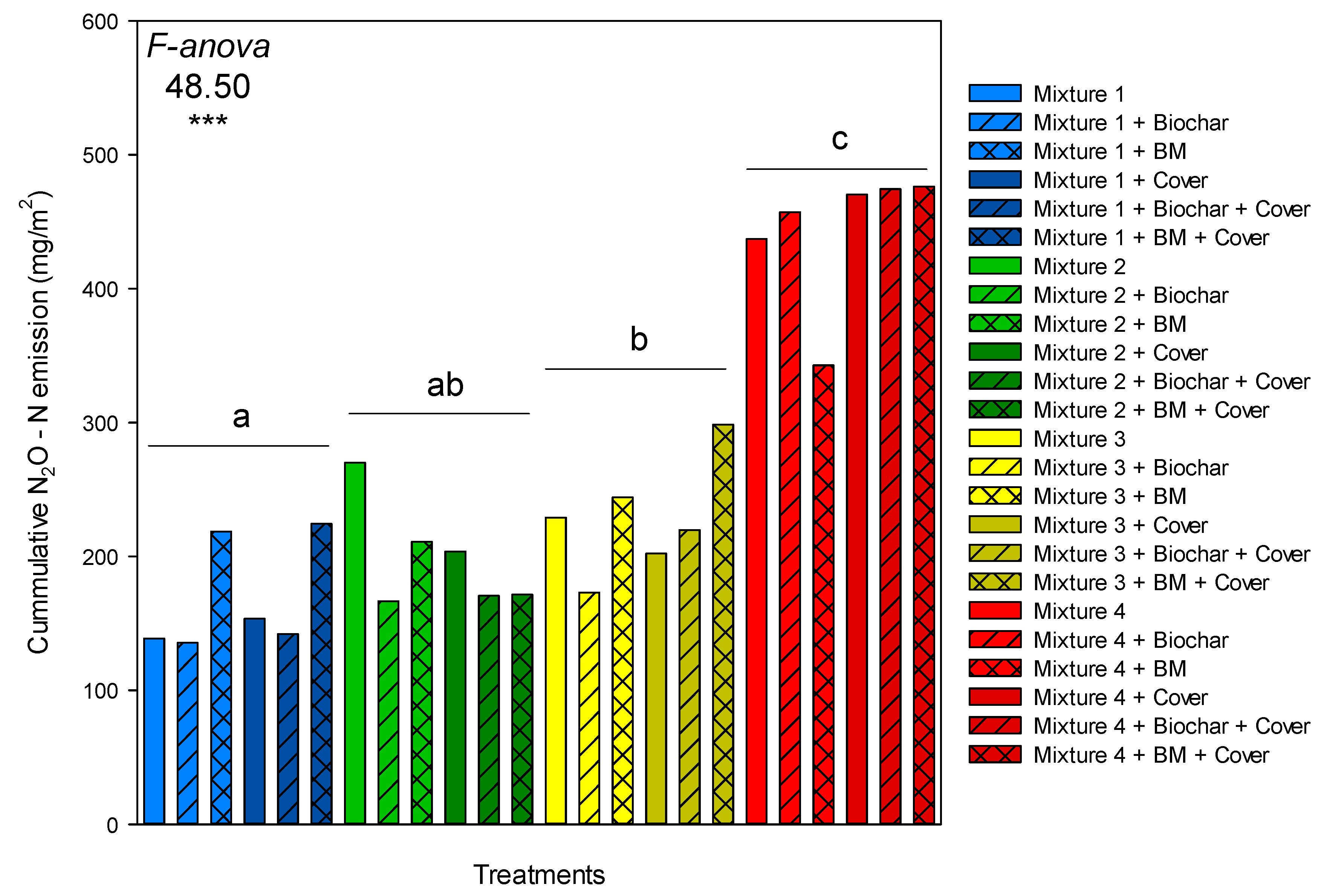

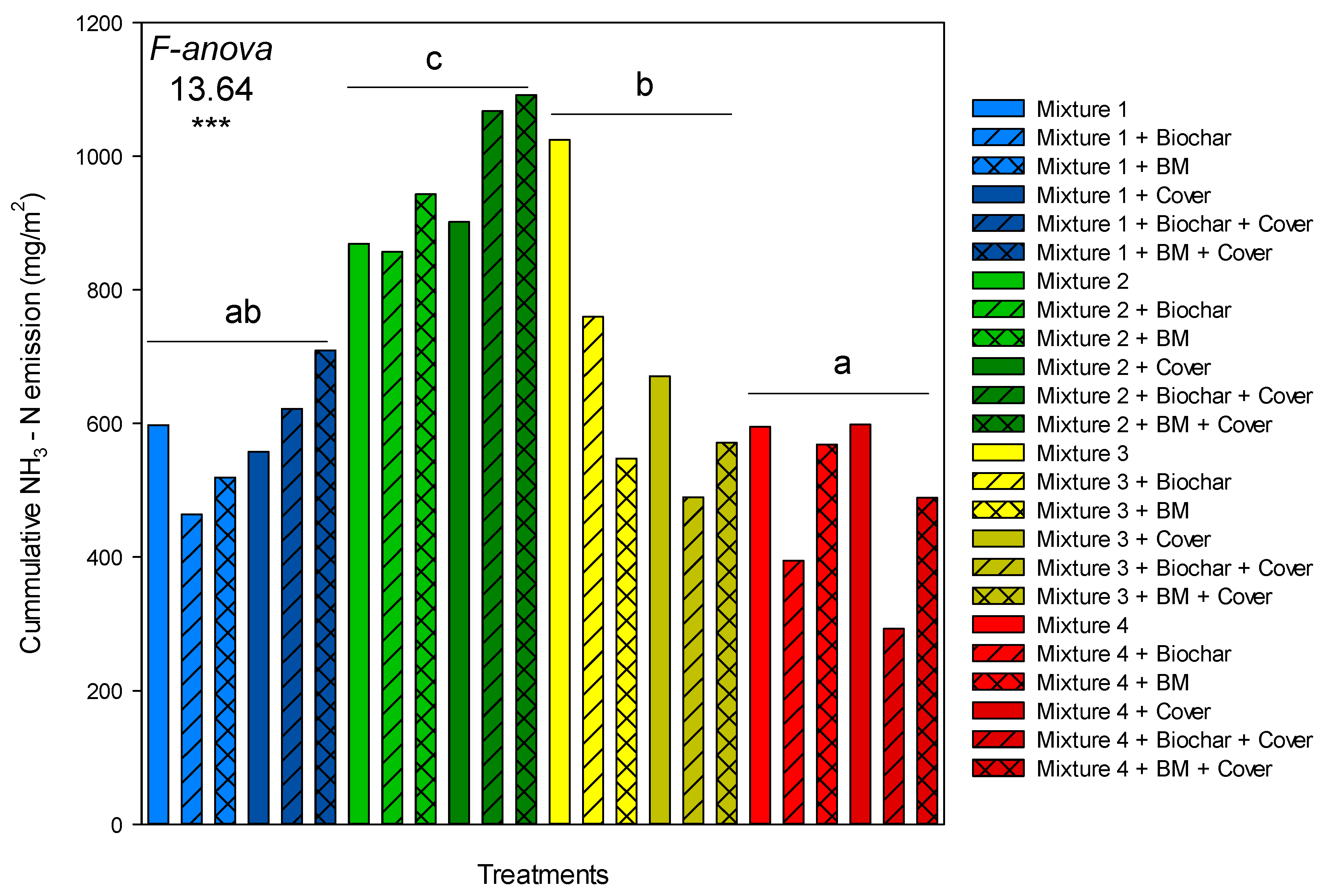

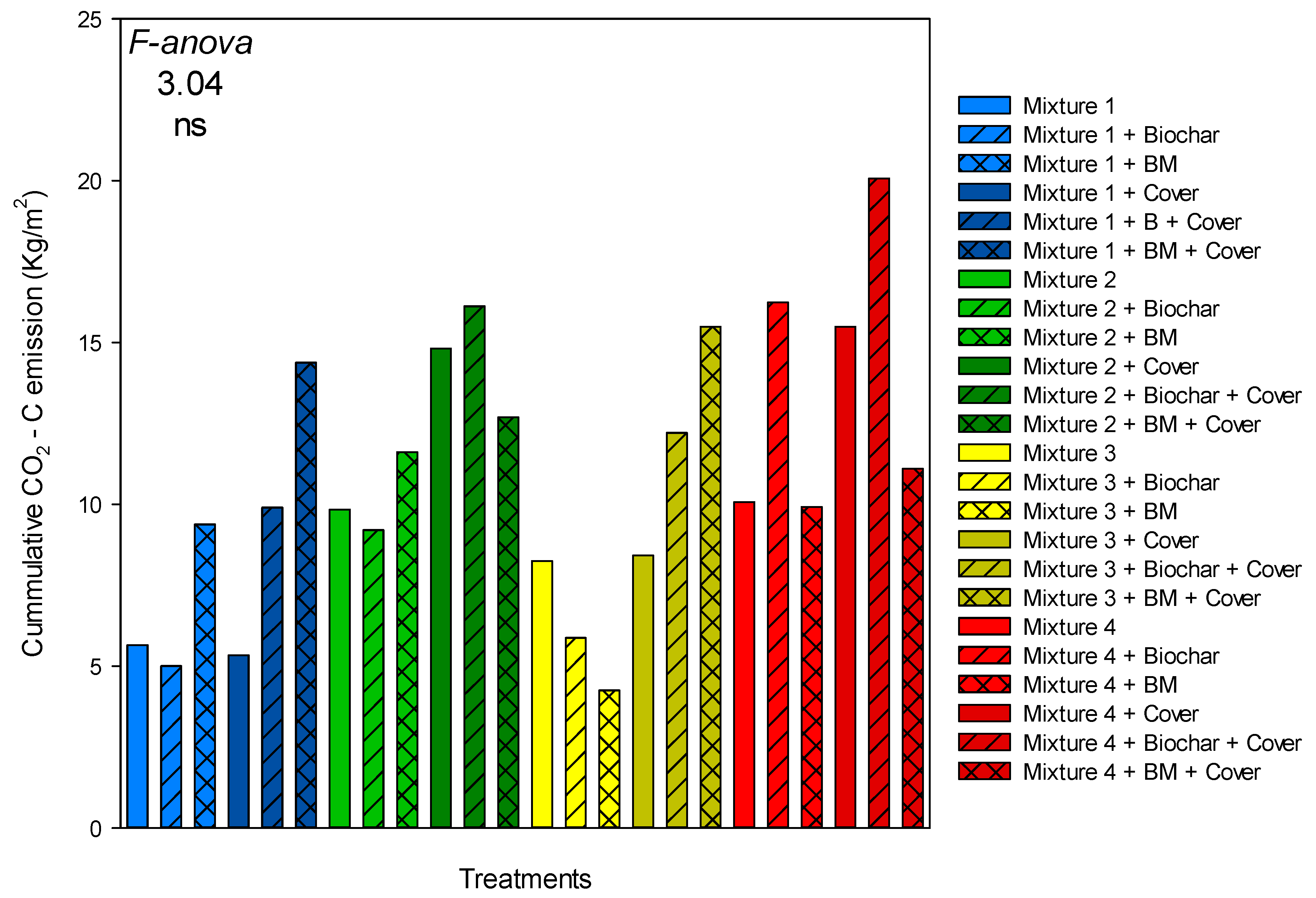

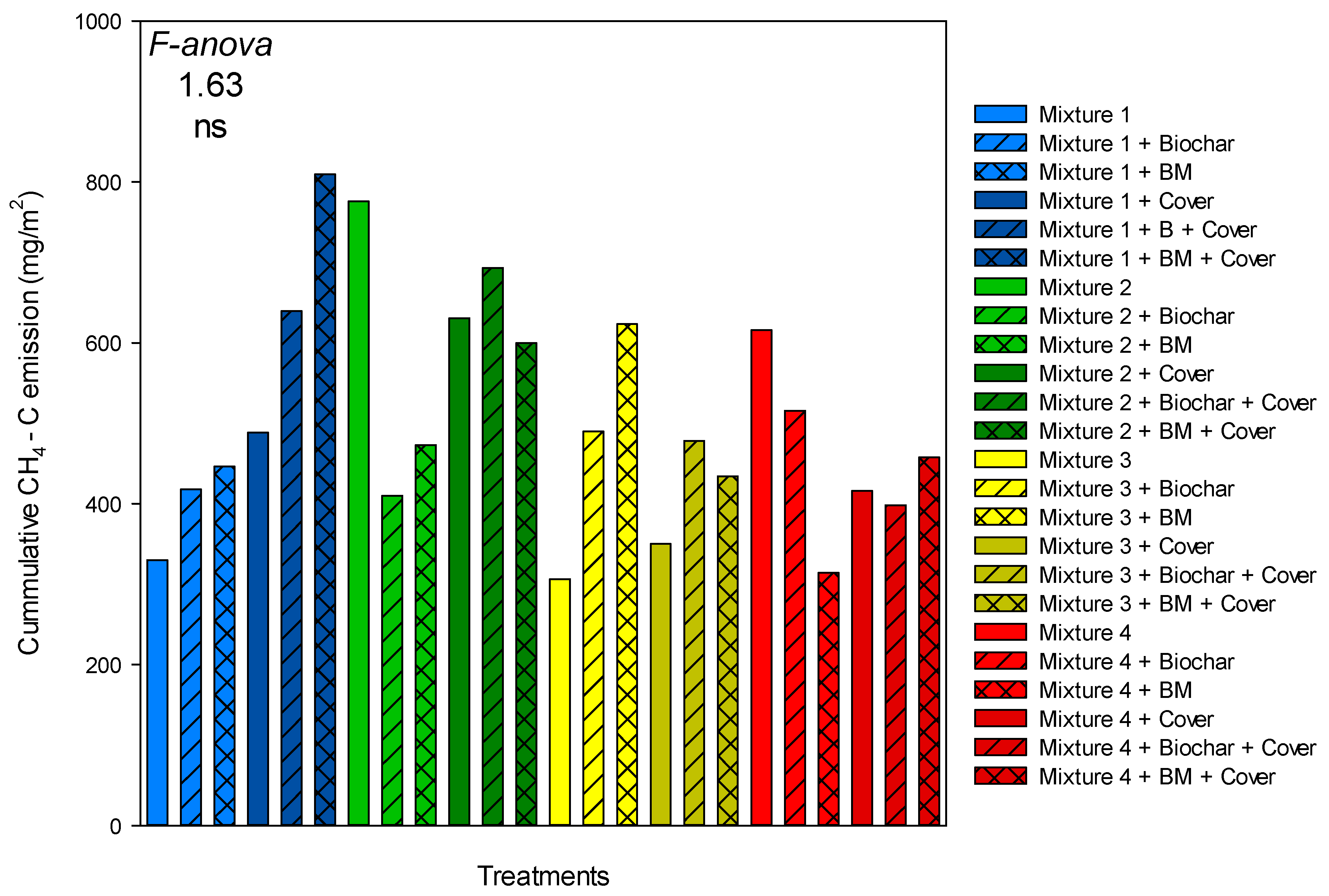

3.4. Greenhouse Gas Emissions During Composting and GWP Assessment

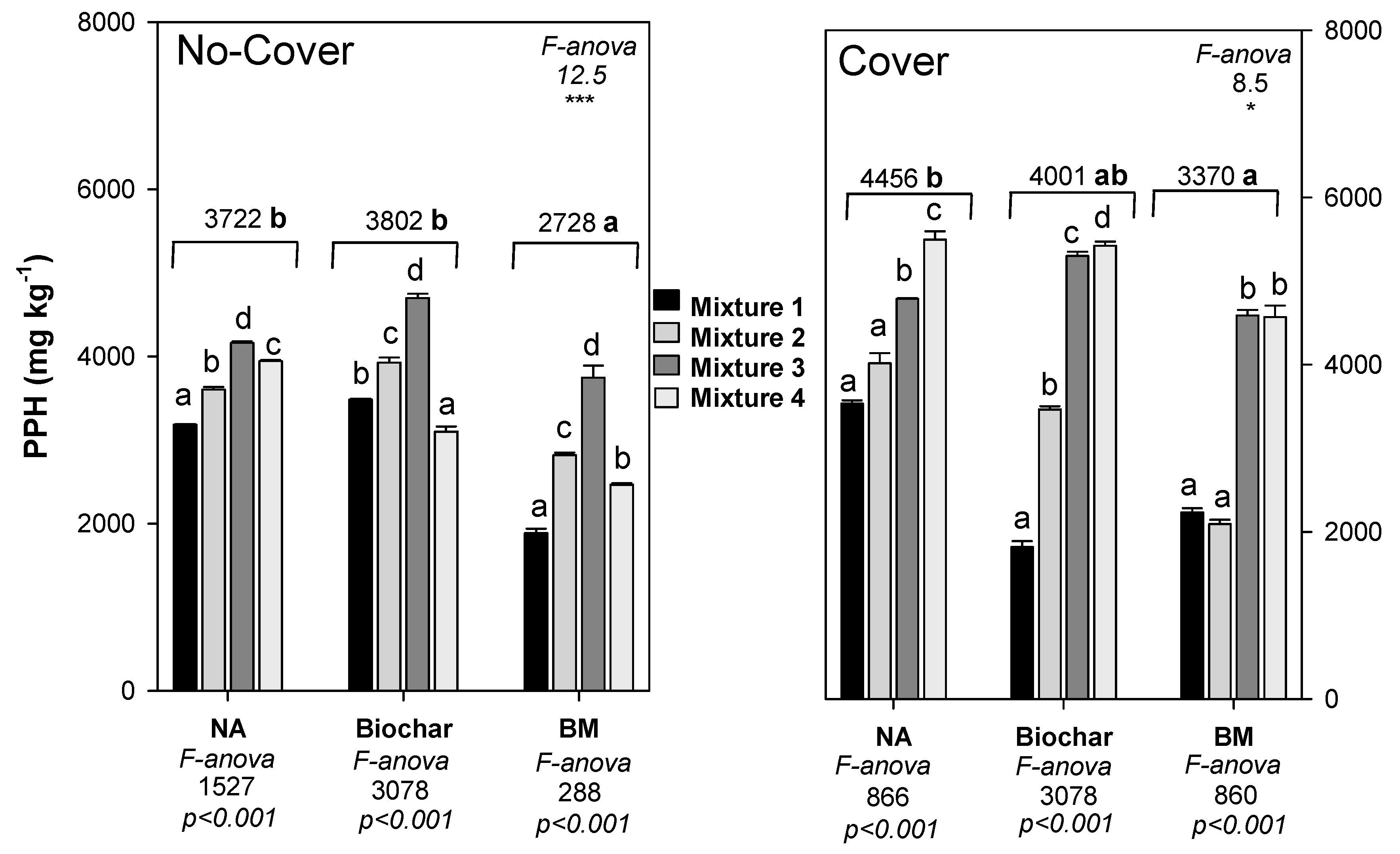

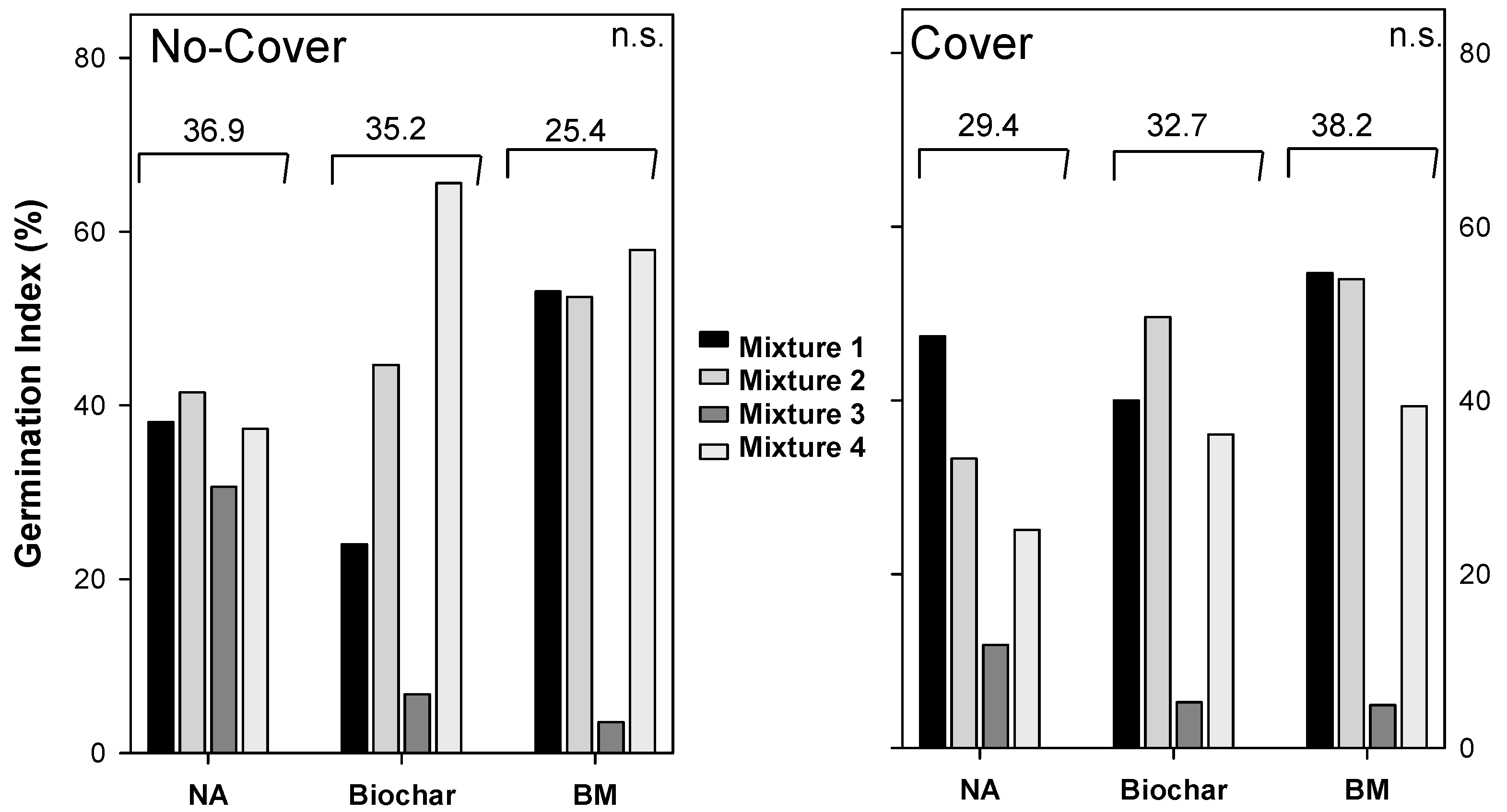

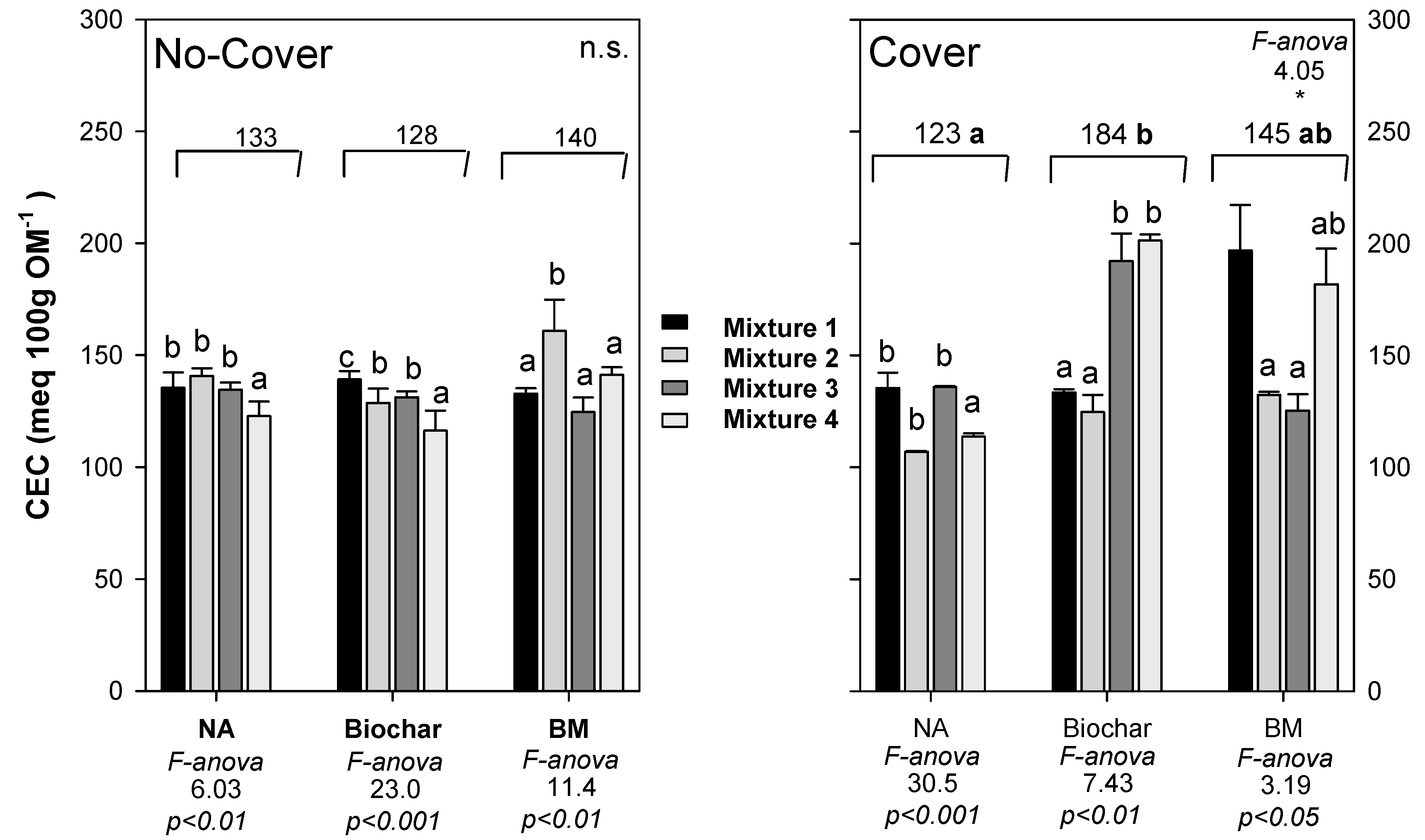

3.5. Characteristics of the Final Compost

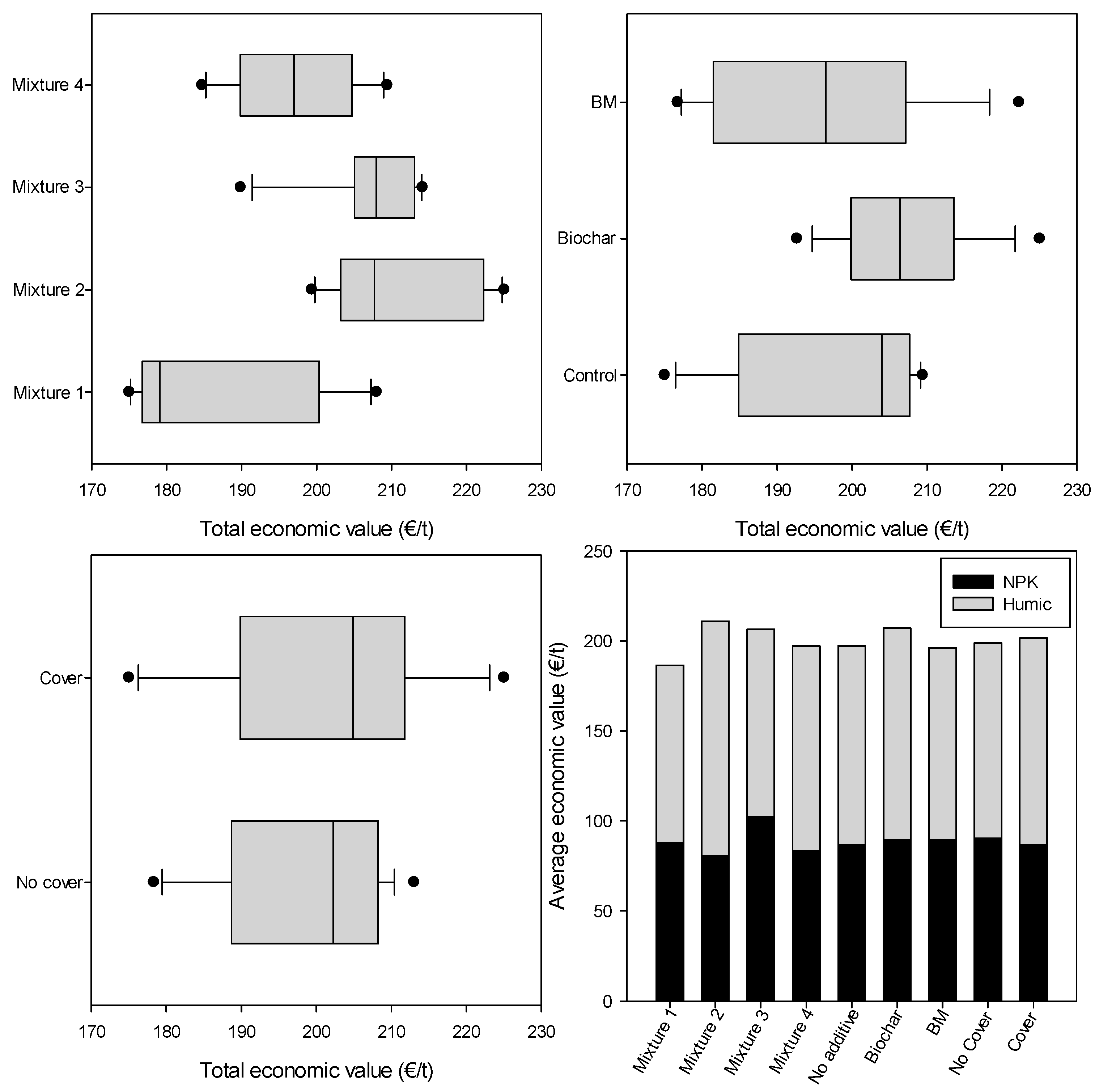

4. Nutrient Content and Economic Marketable Value

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Galliou, F.; Markakis, N.; Fountoulakis, M.S.; Nikolaidis, N.; Manios, T. Production of Organic Fertilizer from Olive Mill Wastewater by Combining Solar Greenhouse Drying and Composting. Waste Manag. 2018, 75, 305–311. [Google Scholar] [CrossRef] [PubMed]

- ESYRCE Encuesta Sobre Superficies y Rendimientos Cultivos, Encuesta de Marco de Áreas de España. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/esyrce/ (accessed on 1 February 2025).

- Babić, S.; Malev, O.; Pflieger, M.; Lebedev, A.T.; Mazur, D.M.; Kužić, A.; Čož-Rakovac, R.; Trebše, P. Toxicity Evaluation of Olive Oil Mill Wastewater and Its Polar Fraction Using Multiple Whole-Organism Bioassays. Sci. Total Environ. 2019, 686, 903–914. [Google Scholar] [CrossRef] [PubMed]

- Enaime, G.; Baçaoui, A.; Yaacoubi, A.; Belaqziz, M.; Wichern, M.; Lübken, M. Phytotoxicity Assessment of Olive Mill Wastewater Treated by Different Technologies: Effect on Seed Germination of Maize and Tomato. Environ. Sci. Pollut. Res. 2020, 27, 8034–8045. [Google Scholar] [CrossRef]

- Chadwick, D.; Sommer, S.; Thorman, R.; Fangueiro, D.; Cardenas, L.; Amon, B.; Misselbrook, T. Manure Management: Implications for Greenhouse Gas Emissions. Anim. Feed. Sci. Technol. 2011, 166–167, 514–531. [Google Scholar] [CrossRef]

- Calvin, K.; Dasgupta, D.; Krinner, G.; Mukherji, A.; Thorne, P.W.; Trisos, C.; Romero, J.; Aldunce, P.; Barrett, K.; Blanco, G.; et al. Climate Change 2023: Synthesis Report; Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Lee, H., Romero, J., Eds.; IPCC: Geneva, Switzerland, 2023. [Google Scholar]

- Chiappero, M.; Norouzi, O.; Hu, M.; Demichelis, F.; Berruti, F.; Di Maria, F.; Mašek, O.; Fiore, S. Review of Biochar Role as Additive in Anaerobic Digestion Processes. Renew. Sustain. Energy Rev. 2020, 131, 110037. [Google Scholar] [CrossRef]

- García-Prats, M.; González, D.; Sánchez, A. Characterization of Biochars of Different Origin and Application to the Anaerobic Digestion of Source-Selected Organic Fraction of Municipal Solid Waste under Batch Conditions and at Different Dosages. Front. Chem. Eng. 2024, 6, 1384495. [Google Scholar] [CrossRef]

- Sebahire, F.; Faridullah, F.; Irshad, M.; Bacha, A.U.R.; Hafeez, F.; Nduwamungu, J. Effect of Biochar on Composting of Cow Manure and Kitchen Waste. Land 2024, 13, 1545. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, C.; Tang, J.; Gu, J.; Li, H.; Duan, M.; Wang, X.; Chen, R. Bamboo Charcoal Enhances Cellulase and Urease Activities during Chicken Manure Composting: Roles of the Bacterial Community and Metabolic Functions. J. Environ. Sci. 2021, 108, 84–95. [Google Scholar] [CrossRef]

- Sun, X.; Ma, S.; Han, L.; Li, R.; Schlick, U.; Chen, P.; Huang, G. The Effect of a Semi-Permeable Membrane-Covered Composting System on Greenhouse Gas and Ammonia Emissions in the Tibetan Plateau. J. Clean. Prod. 2018, 204, 778–787. [Google Scholar] [CrossRef]

- Fang, C.; Su, Y.; He, X.; Han, L.; Qu, H.; Zhou, L.; Huang, G. Membrane-Covered Composting Significantly Decreases Methane Emissions and Microbial Pathogens: Insight into the Succession of Bacterial and Fungal Communities. Sci. Total Environ. 2022, 845, 157343. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, W.; Liu, G.; Cui, B.; Zhang, L.; Wuyun, D.; Wang, Q.; Wang, G.; Li, G.; Yuan, J. Effect of a Semi-Permeable Membrane Covered Composting on Greenhouse Gas Emissions and Bacterial Community Succession: A Comparative Study with Biomass Materials Covering. J. Clean. Prod. 2024, 434, 140146. [Google Scholar] [CrossRef]

- Varga, Z.I.; Shahzad, S.; Ramay, M.W.; Damak, M.; Gulyás, M.; Béres, A.; Gyuricza, C.; Székács, A.; Aleksza, L. Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover. Agronomy 2024, 14, 1471. [Google Scholar] [CrossRef]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of Mixing and Covering with Mature Compost on Gaseous Emissions during Composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, W.; Liu, G.; Kong, Y.; Wang, G.; Yin, Z.; Li, G.; Yuan, J. Effects of Cornstalk and Sawdust Coverings on Greenhouse Gas Emissions during Sheep Manure Storage. Waste Manag. 2023, 166, 104–114. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Ma, S.; He, X.; Han, L.; Huang, G. Nitrogen Transformation and Dynamic Changes in Related Functional Genes during Functional-Membrane Covered Aerobic Composting. Bioresour. Technol. 2021, 332, 125087. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Yong, X.; Wu, X.; Jia, H.; Wong, J.W.C.; Wu, H.; Zhou, J. Odor Emission and Microbial Community Succession during Biogas Residue Composting Covered with a Molecular Membrane. Bioresour. Technol. 2020, 297, 122518. [Google Scholar] [CrossRef]

- Ma, S.; Sun, X.; Fang, C.; He, X.; Han, L.; Huang, G. Exploring the Mechanisms of Decreased Methane during Pig Manure and Wheat Straw Aerobic Composting Covered with a Semi-Permeable Membrane. Waste Manag. 2018, 78, 393–400. [Google Scholar] [CrossRef]

- Hsieh, C.W. Geotextiles in Agriculture and Aquaculture. In Geotextiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 511–530. [Google Scholar]

- Farina, R.; Testani, E.; Campanelli, G.; Leteo, F.; Napoli, R.; Canali, S.; Tittarelli, F. Potential Carbon Sequestration in a Mediterranean Organic Vegetable Cropping System. A Model Approach for Evaluating the Effects of Compost and Agro-Ecological Service Crops (ASCs). Agric. Syst. 2018, 162, 239–248. [Google Scholar] [CrossRef]

- Dijkstra, F.A.; Keitel, C. Maximising Carbon Sequestration through Mixing Compost in Moist Soil. Soil. Biol. Biochem. 2024, 191, 109330. [Google Scholar] [CrossRef]

- Pelegrín, M.; Sáez-Tovar, J.A.; Andreu-Rodríguez, J.; Pérez-Murcia, M.D.; Martínez-Sabater, E.; Marhuenda-Egea, F.C.; Pérez-Espinosa, A.; Bustamante, M.A.; Agulló, E.; Vico, A.; et al. Composting of the Invasive Species Arundo Donax with Sewage and Agri-Food Sludge: Agronomic, Economic and Environmental Aspects. Waste Manag. 2018, 78, 730–740. [Google Scholar] [CrossRef]

- Díaz, M.J.; Ruiz-Montoya, M.; Palma, A.; de-Paz, M.-V. Thermogravimetry Applicability in Compost and Composting Research: A Review. Appl. Sci. 2021, 11, 1692. [Google Scholar] [CrossRef]

- Grube, M.; Lin, J.G.; Lee, P.H.; Kokorevicha, S. Evaluation of Sewage Sludge-Based Compost by FT-IR Spectroscopy. Geoderma 2006, 130, 324–333. [Google Scholar] [CrossRef]

- Soobhany, N.; Gunasee, S.; Rago, Y.P.; Joyram, H.; Raghoo, P.; Mohee, R.; Garg, V.K. Spectroscopic, Thermogravimetric and Structural Characterization Analyses for Comparing Municipal Solid Waste Composts and Vermicomposts Stability and Maturity. Bioresour. Technol. 2017, 236, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Bustamante, M.A.; Moral, R.; Paredes, C.; Vargas-García, M.C.; Suárez-Estrella, F.; Moreno, J. Evolution of the Pathogen Content during Co-Composting of Winery and Distillery Wastes. Bioresour. Technol. 2008, 99, 7299–7306. [Google Scholar] [CrossRef]

- Zucconi, F.; Pera, A.; Forte, M.; de Bertoldi, M. Evaluating Toxicity of Immature Compost. Biocycle 1981, 2, 54–57. [Google Scholar]

- Paredes, C.; Roig, A.; Bernal, M.P.; Sánchez-Monedero, M.A.; Cegarra, J. Evolution of Organic Matter and Nitrogen during Co-Composting of Olive Mill Wastewater with Solid Organic Wastes. Biol. Fertil. Soils 2000, 32, 222–227. [Google Scholar] [CrossRef]

- Marhuenda-Egea, F.C.; Martínez-Sabater, E.; Jordá, J.; Sánchez-Sánchez, A.; Moral, R.; Bustamante, M.A.; Paredes, C.; Pérez-Murcia, M.D. Evaluation of the Aerobic Composting Process of Winery and Distillery Residues by Thermal Methods. Thermochim. Acta 2007, 454, 135–143. [Google Scholar] [CrossRef]

- Torres-Climent, A.; Gomis, P.; Martín-Mata, J.; Bustamante, M.A.; Marhuenda-Egea, F.C.; Pérez-Murcia, M.D.; Pérez-Espinosa, A.; Paredes, C.; Moral, R. Chemical, Thermal and Spectroscopic Methods to Assess Biodegradation of Winery-Distillery Wastes during Composting. PLoS ONE 2015, 10, e0138925. [Google Scholar] [CrossRef]

- Sánchez-Navarro, V.; Shahrokh, V.; Martínez-Martínez, S.; Acosta, J.A.; Almagro, M.; Martínez-Mena, M.; Boix-Fayos, C.; Díaz-Pereira, E.; Zornoza, R. Perennial Alley Cropping Contributes to Decrease Soil CO2 and N2O Emissions and Increase Soil Carbon Sequestration in a Mediterranean Almond Orchard. Sci. Total Environ. 2022, 845, 157225. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). The Earth’s Energy Budget, Climate Feedbacks and Climate Sensitivity. In Climate Change 2021—The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2023; pp. 923–1054. [Google Scholar]

- Christensen, T.H.; Gentil, E.; Boldrin, A.; Larsen, A.W.; Weidema, B.P.; Hauschild, M. C Balance, Carbon Dioxide Emissions and Global Warming Potentials in LCA-Modelling of Waste Management Systems. Waste Manag. Res. J. A Sustain. Circ. Econ. 2009, 27, 707–715. [Google Scholar] [CrossRef]

- Jara-Samaniego, J.; Pérez-Murcia, M.D.; Bustamante, M.A.; Paredes, C.; Pérez-Espinosa, A.; Gavilanes-Terán, I.; López, M.; Marhuenda-Egea, F.C.; Brito, H.; Moral, R. Development of Organic Fertilizers from Food Market Waste and Urban Gardening by Composting in Ecuador. PLoS ONE 2017, 12, e0181621. [Google Scholar] [CrossRef] [PubMed]

- Di Rienzo, J.; Casanoves, F.; Balzarini, M.; Gonzalez, L.; Tablada, M.; Robledo, C. InfoStat Versión 2020. Centro de Transferencia InfoStat, FCA, Universidad Nacional de Córdoba, Argentina. Available online: https://www.infostat.com.ar/ (accessed on 20 March 2025).

- Nelson, M.I.; Marchant, T.R.; Wake, G.C.; Balakrishnan, E.; Chen, X.D. Self-Heating in Compost Piles Due to Biological Effects. Chem. Eng. Sci. 2007, 62, 4612–4619. [Google Scholar] [CrossRef]

- Sun, X.; Huang, G.; Huang, Y.; Fang, C.; He, X.; Zheng, Y. Large Semi-Membrane Covered Composting System Improves the Spatial Homogeneity and Efficiency of Fermentation. Int. J. Environ. Res. Public. Health 2022, 19, 15503. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Su, Y.; He, X.; Han, L.; Huang, G. Effects of Functional Membrane Coverings on Carbon and Nitrogen Evolution during Aerobic Composting: Insight into the Succession of Bacterial and Fungal Communities. Bioresour. Technol. 2023, 369, 128463. [Google Scholar] [CrossRef]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-Composting of Poultry Manure Mixtures Amended with Biochar—The Effect of Biochar on Temperature and C-CO2 Emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef]

- Nleya, Y.; Young, B.; Nooraee, E.; Baroutian, S. Anaerobic Digestion of Dairy Cow and Goat Manure: Comparative Assessment of Biodegradability and Greenhouse Gas Mitigation. Fuel 2025, 381, 133458. [Google Scholar] [CrossRef]

- Hachicha, S.; Cegarra, J.; Sellami, F.; Hachicha, R.; Drira, N.; Medhioub, K.; Ammar, E. Elimination of Polyphenols Toxicity from Olive Mill Wastewater Sludge by Its Co-Composting with Sesame Bark. J. Hazard. Mater. 2009, 161, 1131–1139. [Google Scholar] [CrossRef]

- Guo, H.; Gu, J.; Wang, X.; Song, Z.; Yu, J.; Lei, L. Microbial Mechanisms Related to the Effects of Bamboo Charcoal and Bamboo Vinegar on the Degradation of Organic Matter and Methane Emissions during Composting. Environ. Pollut. 2021, 272, 116013. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, W.; Yuan, J.; Li, G.; Luo, Y. Effects of Woody Peat and Superphosphate on Compost Maturity and Gaseous Emissions during Pig Manure Composting. Waste Manag. 2017, 68, 56–63. [Google Scholar] [CrossRef]

- Akdeniz, N. A Systematic Review of Biochar Use in Animal Waste Composting. Waste Manag. 2019, 88, 291–300. [Google Scholar] [CrossRef]

- Godlewska, P.; Schmidt, H.P.; Ok, Y.S.; Oleszczuk, P. Biochar for Composting Improvement and Contaminants Reduction. A Review. Bioresour. Technol. 2017, 246, 193–202. [Google Scholar] [CrossRef]

- Khan, N.; Clark, I.; Sánchez-Monedero, M.A.; Shea, S.; Meier, S.; Qi, F.; Kookana, R.S.; Bolan, N. Physical and Chemical Properties of Biochars Co-Composted with Biowastes and Incubated with a Chicken Litter Compost. Chemosphere 2016, 142, 14–23. [Google Scholar] [CrossRef]

- Martín-Mata, J.; Lahoz-Ramos, C.; Bustamante, M.A.; Marhuenda-Egea, F.C.; Moral, R.; Santos, A.; Sáez, J.A.; Bernal, M.P. Thermal and Spectroscopic Analysis of Organic Matter Degradation and Humification during Composting of Pig Slurry in Different Scenarios. Environ. Sci. Pollut. Res. Int. 2016, 23, 17357–17369. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Sabater, E.; Bustamante, M.A.; Marhuenda-Egea, F.C.; El-Khattabi, M.; Moral, R.; Lorenzo, E.; Paredes, C.; Gálvez, L.N.; Jordá, J.D. Study of the Evolution of Organic Matter during Composting of Winery and Distillery Residues by Classical and Chemometric Analysis. J. Agric. Food Chem. 2009, 57, 9613–9623. [Google Scholar] [CrossRef]

- Wichuk, K.M.; McCartney, D. Compost Stability and Maturity Evaluation—A Literature ReviewA Paper Submitted to the Journal of Environmental Engineering and Science. Can. J. Civ. Eng. 2010, 37, 1505–1523. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Mondini, C.; Sánchez-Monedero, M.A.; Roig, A. Chemical Properties and Hydrolytic Enzyme Activities for the Characterisation of Two-Phase Olive Mill Wastes Composting. Bioresour. Technol. 2008, 99, 4255–4262. [Google Scholar] [CrossRef] [PubMed]

- Sáez, J.A.; Pérez-Murcia, M.D.; Vico, A.; Martínez-Gallardo, M.R.; Andreu-Rodríguez, F.J.; López, M.J.; Bustamante, M.A.; Sanchez-Hernandez, J.C.; Moreno, J.; Moral, R. Olive Mill Wastewater-Evaporation Ponds Long Term Stored: Integrated Assessment of in Situ Bioremediation Strategies Based on Composting and Vermicomposting. J. Hazard. Mater. 2021, 402, 123481. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Sánchez-Monedero, M.A.; Roig, A. Two-Phase Olive Mill Waste Composting: Enhancement of the Composting Rate and Compost Quality by Grape Stalks Addition. Biodegradation 2010, 21, 465–473. [Google Scholar] [CrossRef]

- Abid, N.; Sayadi, S. Detrimental Effects of Olive Mill Wastewater on the Composting Process of Agricultural Wastes. Waste Manag. 2006, 26, 1099–1107. [Google Scholar] [CrossRef]

- Azzam, M.O.J.; Hazaimeh, S.A. Olive Mill Wastewater Treatment and Valorization by Extraction/Concentration of Hydroxytyrosol and Other Natural Phenols. Process Saf. Environ. Prot. 2021, 148, 495–523. [Google Scholar] [CrossRef]

- Kavvadias, V.; Elaiopoulos, K.; Theocharopoulos, S.; Soupios, P. Fate of Potential Contaminants Due to Disposal of Olive Mill Wastewaters in Unprotected Evaporation Ponds. Bull. Environ. Contam. Toxicol. 2017, 98, 323–330. [Google Scholar] [CrossRef] [PubMed]

- Cayuela, M.L.; Sánchez-Monedero, M.A.; Roig, A. Evaluation of Two Different Aeration Systems for Composting Two-Phase Olive Mill Wastes. Process Biochem. 2006, 41, 616–623. [Google Scholar] [CrossRef]

- Ba, S.; Qu, Q.; Zhang, K.; Groot, J.C.J. Meta-Analysis of Greenhouse Gas and Ammonia Emissions from Dairy Manure Composting. Biosyst. Eng. 2020, 193, 126–137. [Google Scholar] [CrossRef]

- Pardo, G.; Moral, R.; Aguilera, E.; del Prado, A. Gaseous Emissions from Management of Solid Waste: A Systematic Review. Glob. Change Biol. 2015, 21, 1313–1327. [Google Scholar] [CrossRef]

- Sanchez-Monedero, M.A.; Cayuela, M.L.; Roig, A.; Jindo, K.; Mondini, C.; Bolan, N. Role of Biochar as an Additive in Organic Waste Composting. Bioresour. Technol. 2018, 247, 1155–1164. [Google Scholar] [CrossRef]

- Steiner, C.; Das, K.C.; Melear, N.; Lakly, D. Reducing Nitrogen Loss during Poultry Litter Composting Using Biochar. J. Environ. Qual. 2010, 39, 1236–1242. [Google Scholar] [CrossRef] [PubMed]

- Dias, B.O.; Silva, C.A.; Higashikawa, F.S.; Roig, A.; Sánchez-Monedero, M.A. Use of Biochar as Bulking Agent for the Composting of Poultry Manure: Effect on Organic Matter Degradation and Humification. Bioresour. Technol. 2010, 101, 1239–1246. [Google Scholar] [CrossRef]

- Li, M.; Zhang, A.; Wu, H.; Liu, H.; Lv, J. Predicting Potential Release of Dissolved Organic Matter from Biochars Derived from Agricultural Residues Using Fluorescence and Ultraviolet Absorbance. J. Hazard. Mater. 2017, 334, 86–92. [Google Scholar] [CrossRef]

- Ma, S.; Xiong, J.; Cui, R.; Sun, X.; Han, L.; Xu, Y.; Kan, Z.; Gong, X.; Huang, G. Effects of Intermittent Aeration on Greenhouse Gas Emissions and Bacterial Community Succession during Large-Scale Membrane-Covered Aerobic Composting. J. Clean. Prod. 2020, 266, 121551. [Google Scholar] [CrossRef]

- Wang, S.; Shi, D.; Yang, R.; Xu, Y.; Guo, H.; Yang, X. Solvent Extraction of Phenol from Aqueous Solution with Benzyl 2-ethylhexyl Sulfoxide as a Novel Extractant. Can. J. Chem. Eng. 2015, 93, 1787–1792. [Google Scholar] [CrossRef]

- Jindo, K.; Sonoki, T.; Matsumoto, K.; Canellas, L.; Roig, A.; Sanchez-Monedero, M.A. Influence of Biochar Addition on the Humic Substances of Composting Manures. Waste Manag. 2016, 49, 545–552. [Google Scholar] [CrossRef] [PubMed]

- Agyarko-Mintah, E.; Cowie, A.; Van Zwieten, L.; Singh, B.P.; Smillie, R.; Harden, S.; Fornasier, F. Biochar Lowers Ammonia Emission and Improves Nitrogen Retention in Poultry Litter Composting. Waste Manag. 2017, 61, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, M.K.; Lin, C.; Hoang, H.G.; Sanderson, P.; Dang, B.T.; Bui, X.T.; Nguyen, N.S.H.; Vo, D.V.N.; Tran, H.T. Evaluate the Role of Biochar during the Organic Waste Composting Process: A Critical Review. Chemosphere 2022, 299, 134488. [Google Scholar] [CrossRef] [PubMed]

| Mixture | OMW | CM | GM | Alm | Vn |

|---|---|---|---|---|---|

| Mixture 1 (% f.w.) | 50 | 40 | - | 10 | - |

| Mixture 2 | 50 | 40 | - | - | 10 |

| Mixture 3 | 50 | - | 40 | 10 | - |

| Mixture 4 | 50 | - | 40 | - | 10 |

| Moisture (%) | 71.2 | 55.4 | 47.9 | 10.2 | 7.1 |

| pH | 6.06 | 8.11 | 8.79 | 6.76 | 7.65 |

| EC (dS m−1) | 1.48 | 9.46 | 9.31 | 1.11 | 1.23 |

| TOC (%) | 51.1 | 36.8 | 36.6 | 45.3 | 35.4 |

| TN (%) | 1.72 | 2.15 | 1.87 | 0.44 | 1.02 |

| TOC/TN | 29.5 | 17.1 | 19.6 | 104 | 34.7 |

| PPH (mg kg−1) | 29,804 | 1963 | 3480 | 3928 | 960 |

| Total elements | |||||

| P (g kg−1) | 2.61 | 7.16 | 7.43 | 0.41 | 1.22 |

| K (g kg−1) | 33.2 | 23.2 | 25.3 | 2.1 | 6.4 |

| Ca (g kg−1) | 0.80 | 2.63 | 3.17 | 0.50 | 4.81 |

| Cd (mg kg−1) | 0.04 | 0.20 | 0.16 | 0.01 | 0.15 |

| Cr (mg kg−1) | 4.79 | 15.1 | 12.9 | 5.43 | 30.7 |

| Cu (mg kg−1) | 43.2 | 46.9 | 43.4 | 3.02 | 35.9 |

| Ni (mg kg−1) | 4.40 | 6.86 | 5.12 | 2.08 | 6.22 |

| Pb (mg kg−1) | 3.12 | 5.01 | 2.84 | 0.92 | 8.91 |

| Zn (mg kg−1) | 53.3 | 189 | 319 | 6.76 | 42.8 |

| Tmax (°C) | Tave (°C) | Days > 50 °C | Days > 60 °C | Days > 70 °C | EXI2 (x1000) | ||

|---|---|---|---|---|---|---|---|

| Mixture 1 | 64.0 a | 36.8 a | 11.0 a | 4.0 a | 0.0 a | 38.1 a | |

| Mixture 2 | 67.4 b | 41.7 b | 27.0 bc | 9.0 a | 1.0 a | 63.9 b | |

| Mixture 3 | 62.7 a | 38.9 ab | 19.0 ab | 10 a | 0.0 a | 44.1 a | |

| Mixture 4 | 79.7 c | 46.0 c | 34.0 c | 22 b | 11 b | 86.6 c | |

| F-anova | 22.7 *** | 8.71 *** | 11.0 *** | 9.98 *** | 71.0 *** | 21.8 *** | |

| N source | CM | 65.7 | 39.1 | 18.6 | 6.0 a | 0.0 | 51.0 |

| GM | 71.2 | 42.5 | 26.5 | 16 b | 5.0 b | 65.3 | |

| F-anova | ns | ns | ns | 9.95 ** | 8.47 ** | ns | |

| C source | Alm | 63.6 a | 37.7 a | 15.0 a | 7.0 a | 0.0 a | 41.1 a |

| Vn | 73.6 b | 43.8 b | 30.0 b | 15 b | 6.0 b | 75.2 b | |

| F-anova | 17.6 *** | 16.3 *** | 21.1 *** | 7.27 * | 12.2 ** | 35.8 *** | |

| Additive | No additive | 66.4 | 38.8 | 20.0 | 7.8 | 2.5 | 53.5 |

| Biochar | 68.6 | 39.9 | 20.6 | 11 | 3.1 | 53.6 | |

| BM | 70.4 | 43.5 | 27.0 | 13 | 2.8 | 67.2 | |

| F-anova | ns | ns | ns | ns | ns | ns | |

| Cover | No cover | 67.5 | 41.8 | 23.8 | 9.5 | 2.0 | 58.9 |

| Cover | 69.4 | 39.7 | 25.9 | 12.5 | 3.0 | 57.3 | |

| F-anova | ns | ns | ns | ns | ns | ns |

| A | k | A | k | ||||

| N source | CM | 49.2 | 0.0199 | Cover | No Cover | 49.3 | 0.021 |

| GM | 48.1 | 0.0218 | Cover | 47.8 | 0.021 | ||

| F-anova | ns | ns | F-anova | ns | ns | ||

| C source | Alm | 46.2 b | 0.0176 | Additive | SN | 48.3 | 0.021 |

| Vn | 51.1 a | 0.0245 | B | 49.0 | 0.027 | ||

| BM | 49.6 | 0.014 | |||||

| F-anova | 1.25 * | ns | F-anova | ns | ns | ||

| Mixtures | A | k | R2 | RMS | F-value | ||

| Mixture 1 | 46.3 | 0.0191 | 0.99 | 0.8 | 16,467 | ||

| Mixture 2 | 52.1 | 0.0208 | 0.99 | 7.2 | 19,298 | ||

| Mixture 3 | 46.1 | 0.0162 | 0.98 | 4.1 | 3457 | ||

| Mixture 4 | 50.1 | 0.0273 | 0.99 | 5.5 | 933 | ||

| F-anova | ns | ns | |||||

| Start-Up (Day 0) | Thermophilic (Day 60) | End Bio-Oxidative (Day 120) | Matured (Day 165) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R1 | R2 | R1 | R2 | R1 | R2 | ||

| N source | CM | 0.69 | 1.77 | 1.03 a | 2.81 a | 1.15 a | 3.29 b | 1.15 | 3.20 b |

| GM | 0.70 | 1.71 | 0.98 b | 2.36 b | 1.11 b | 2.58 a | 1.11 | 2.55 a | |

| F-anova | ns | ns | 8.52 ** | 15.3 *** | 4.45 * | 25.4 *** | ns | 31.9 *** | |

| C Source | Alm | 0.71 | 1.83 | 1.00 | 2.59 | 1.13 | 3.05 | 1.15 | 3.04 |

| Vn | 0.68 | 1.64 | 1.01 | 2.57 | 1.13 | 2.82 | 1.11 | 2.71 | |

| F-anova | ns | ns | ns | ns | ns | ns | ns | ns | |

| Cover | No Cover | 0.70 | 1.74 | 0.96 a | 2.60 | 1.17 b | 3.14 | 1.16 | 3.00 |

| Cover | 0.70 | 1.74 | 1.02 b | 2.57 | 1.08 a | 2.73 | 1.10 | 2.84 | |

| F-anova | ns | ns | 4.45 * | ns | 27.9 ** | 6.86 * | 8.70 ** | ns | |

| Start-Up (Day 0) | Thermophilic (Day 60) | End Bio-Oxidative (Day 120) | Matured (Day 165) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R1 | R2 | R1 | R2 | R1 | R2 | ||

| N source | CM | 0.69 | 1.77 | 1.03 a | 2.81 a | 1.15 a | 3.29 b | 1.15 | 3.20 b |

| GM | 0.70 | 1.71 | 0.98 b | 2.36 b | 1.11 b | 2.58 a | 1.11 | 2.55 a | |

| F-anova | ns | ns | 8.52 ** | 15.3 *** | 4.45 * | 25.4 *** | ns | 31.9 *** | |

| C Source | Alm | 0.71 | 1.83 | 1.00 | 2.59 | 1.13 | 3.05 | 1.15 | 3.04 |

| Vn | 0.68 | 1.64 | 1.01 | 2.57 | 1.13 | 2.82 | 1.11 | 2.71 | |

| F-anova | ns | ns | ns | ns | ns | ns | ns | ns | |

| Cover | No Cover | 0.70 | 1.74 | 0.96 a | 2.60 | 1.17 b | 3.14 | 1.16 | 3.00 |

| Cover | 0.70 | 1.74 | 1.02 b | 2.57 | 1.08 a | 2.73 | 1.10 | 2.84 | |

| F-anova | ns | ns | 4.45 * | ns | 27.9 ** | 6.86 * | 8.70 ** | ns | |

| Mixture | g NH3/pile | g N2O/pile | g CH4/pile | kg CO2/pile | GWP (kg CO2-eq/pile) |

|---|---|---|---|---|---|

| N source | |||||

| CM | 98 b | 30 a | 79 | 397 | 10.4 a |

| GM | 75 a | 55 b | 63 | 440 | 16.8 b |

| F-anova | 4.88 * | 16.77 *** | ns | ns | 13.90 ** |

| C source | |||||

| Alm | 80 | 33 a | 68 | 333 a | 10.8 a |

| Vn | 92 | 53 b | 73 | 503 b | 16.5 b |

| F-anova | 1.09 ns | 8.84 ** | ns | 9.12 ** | 9.60 ** |

| Cover | |||||

| No Covered | 87 | 42 | 67 | 337 a | 13.2 |

| Covered | 86 | 44 | 75 | 500 b | 14.1 |

| F-anova | ns | ns | ns | 8.06 ** | ns |

| Additive | |||||

| Control | 93 | 44 | 69 | 374 | 13.7 |

| Biochar | 79 | 40 | 71 | 455 | 12.8 |

| BM | 87 | 45 | 73 | 427 | 14.3 |

| F-anova | ns | ns | ns | ns | ns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mira-Urios, M.Á.; Sáez, J.A.; Orden, L.; Marhuenda-Egea, F.C.; Andreu-Rodríguez, F.J.; Toribio, A.J.; Agulló, E.; López, M.J.; Moral, R. Composting of Olive Mill Wastewater Sludge Using a Combination of Multiple Strategies: Assessment of Improvement in Biodegradability, GHG Emissions, and Characteristics of the End Product. Agronomy 2025, 15, 808. https://doi.org/10.3390/agronomy15040808

Mira-Urios MÁ, Sáez JA, Orden L, Marhuenda-Egea FC, Andreu-Rodríguez FJ, Toribio AJ, Agulló E, López MJ, Moral R. Composting of Olive Mill Wastewater Sludge Using a Combination of Multiple Strategies: Assessment of Improvement in Biodegradability, GHG Emissions, and Characteristics of the End Product. Agronomy. 2025; 15(4):808. https://doi.org/10.3390/agronomy15040808

Chicago/Turabian StyleMira-Urios, Miguel Ángel, José A. Sáez, Luciano Orden, Frutos C. Marhuenda-Egea, Francisco Javier Andreu-Rodríguez, Ana J. Toribio, Enrique Agulló, Maria J. López, and Raúl Moral. 2025. "Composting of Olive Mill Wastewater Sludge Using a Combination of Multiple Strategies: Assessment of Improvement in Biodegradability, GHG Emissions, and Characteristics of the End Product" Agronomy 15, no. 4: 808. https://doi.org/10.3390/agronomy15040808

APA StyleMira-Urios, M. Á., Sáez, J. A., Orden, L., Marhuenda-Egea, F. C., Andreu-Rodríguez, F. J., Toribio, A. J., Agulló, E., López, M. J., & Moral, R. (2025). Composting of Olive Mill Wastewater Sludge Using a Combination of Multiple Strategies: Assessment of Improvement in Biodegradability, GHG Emissions, and Characteristics of the End Product. Agronomy, 15(4), 808. https://doi.org/10.3390/agronomy15040808