Research on the Application Effect and Parameter Optimization of 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment in Fruit Tree Canopy

Abstract

1. Introduction

2. Materials and Methods

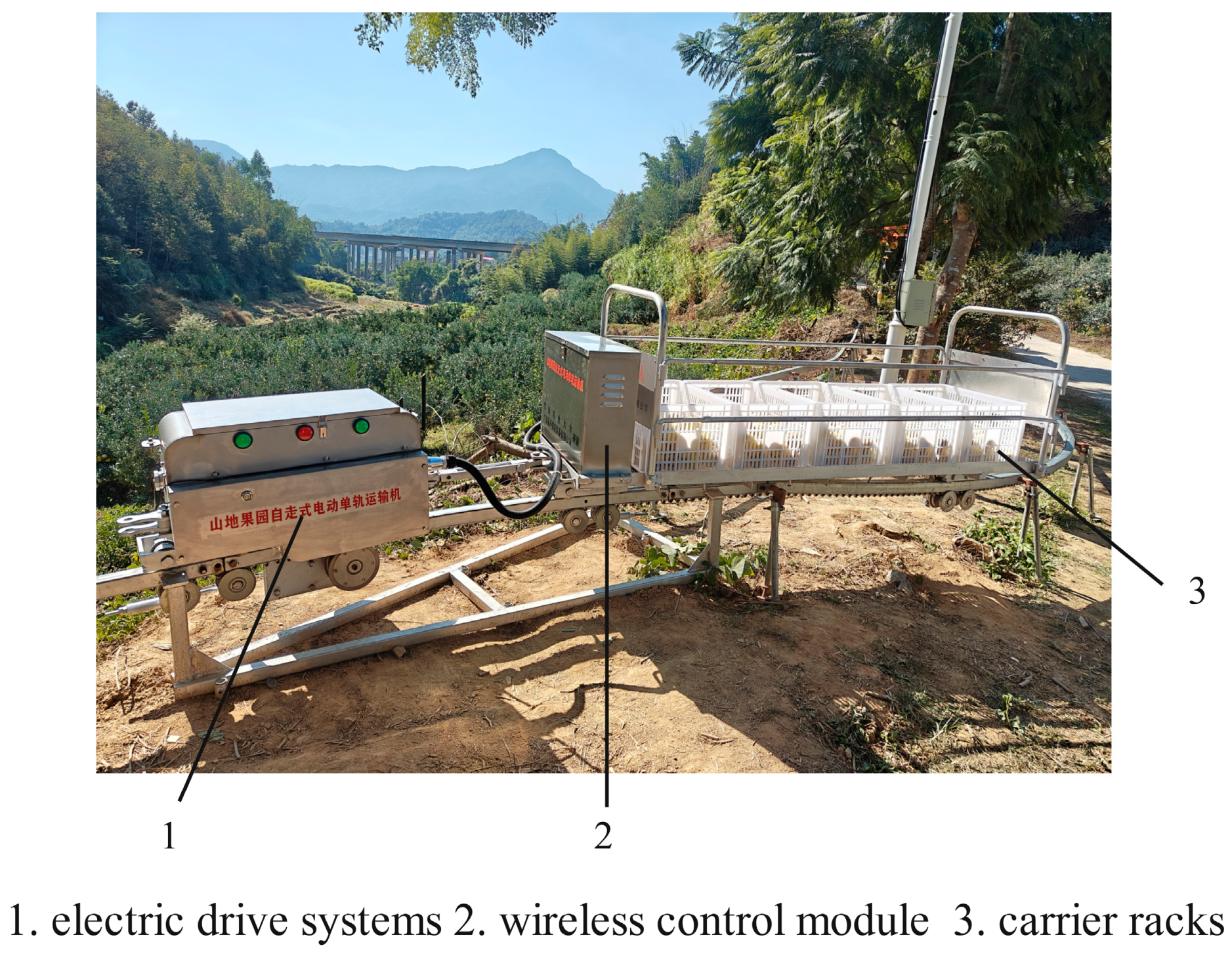

2.1. System Architecture of the 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment

2.1.1. Technical Specifications of the 3HW36 Wind-Driven Plant Protection Unit

- Reinforced chassis (structural foundation);

- Rotary support system (±90° horizontal rotation);

- Axial fan mechanism (airflow generation);

- Pitching system (−10°–30° blower pitch angle adjustment);

- Hydraulic spraying system (droplet atomization);

- Integrated electric control system (centralized command).

2.1.2. Technical Specifications of the Self-Propelled Electric Monorail Transport Platform

- Motor rated power: 3 kW (continuous operation under 300 kg load).

- Maximum gradability: 35° slope angle, representing the steepest incline the platform can ascend/descend while maintaining traction and stability.

- Positioning accuracy: 2.3 mm radial error under full load (validated via laser theodolite measurements).

- Wireless control range: 3000 m line-of-sight (obstruction-free environments).

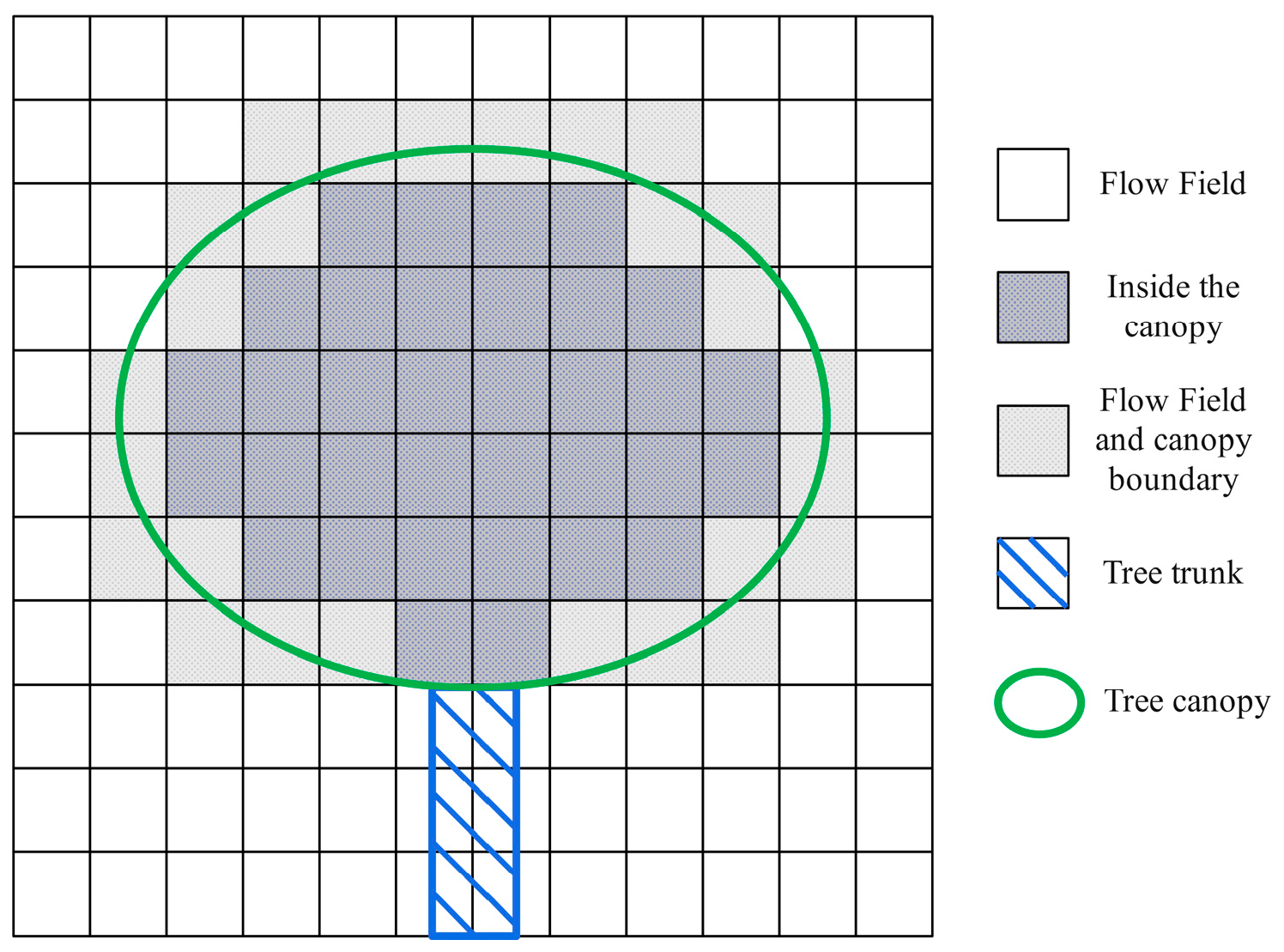

2.2. Development of CFD Simulation Model

2.2.1. Governing Equations and Models

2.2.2. Porous Media Model

2.2.3. Computational Domain and Boundary Conditions

2.2.4. CFD Simulation Limitations

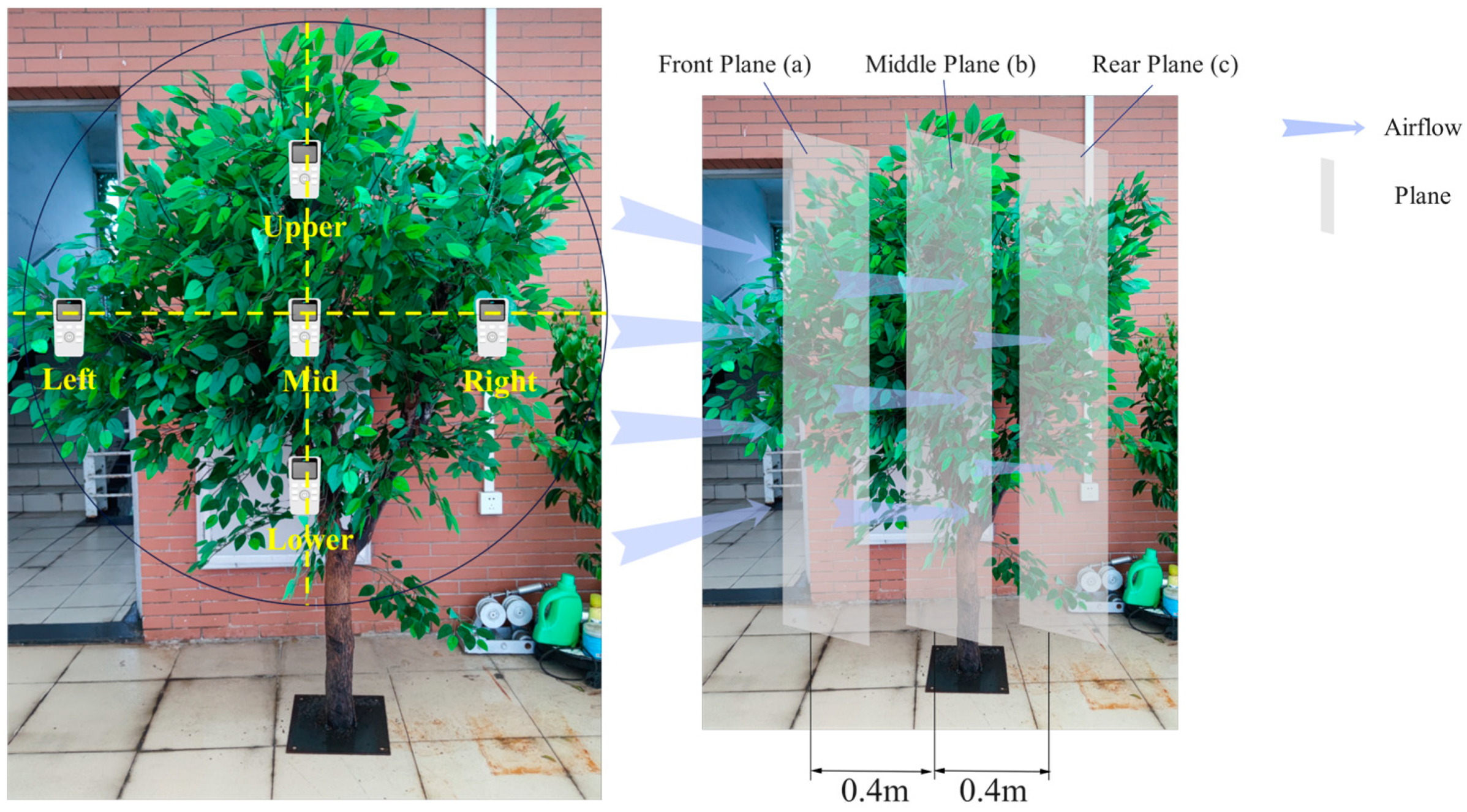

2.3. The Wind Field Distribution Validation Test

2.4. Single-FactorField Test

Test Methods

3. Results

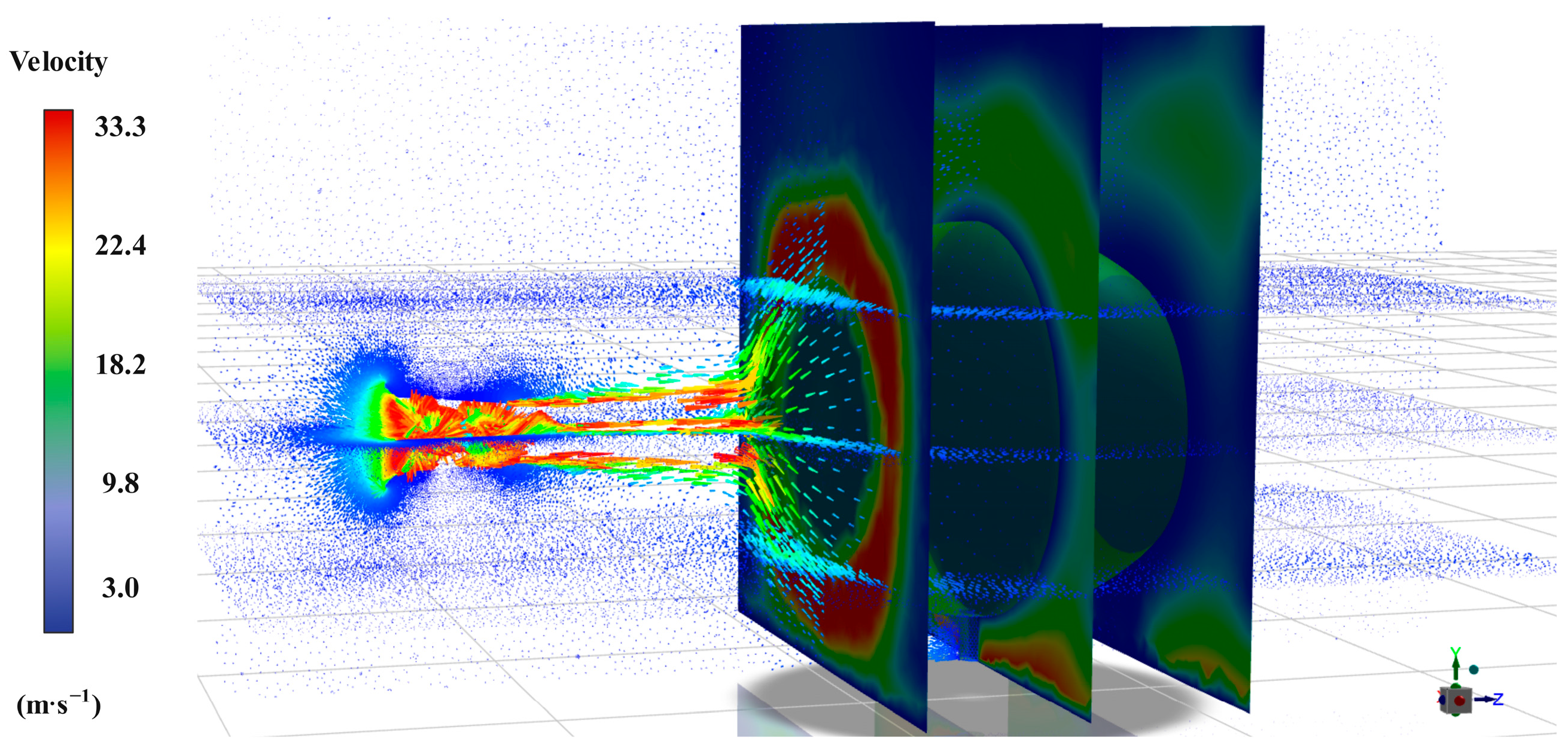

3.1. Analysis of Simulation Results

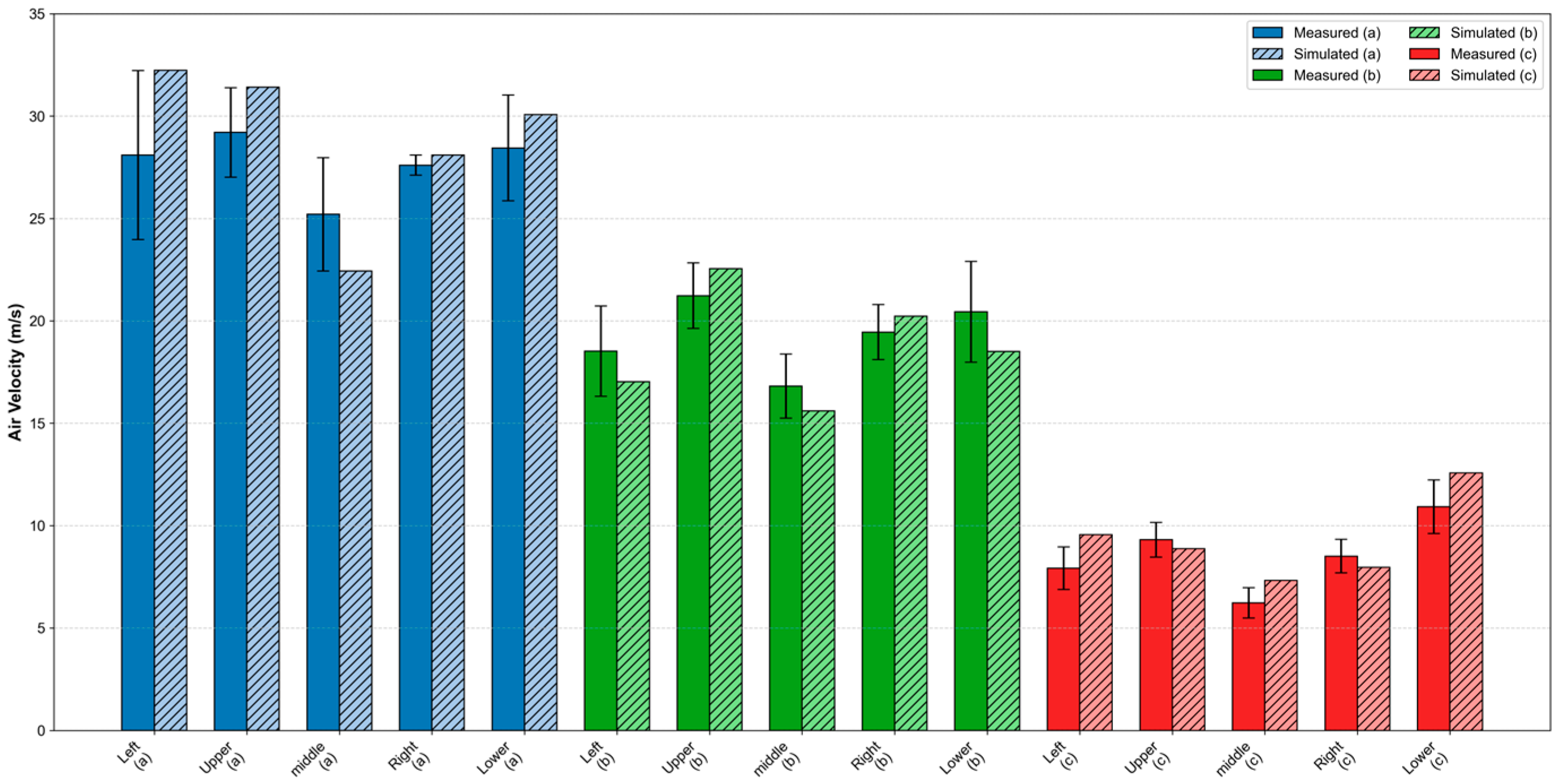

3.2. Wind Field Distribution Validation Test Results

3.3. Single-Factor Field Test Results

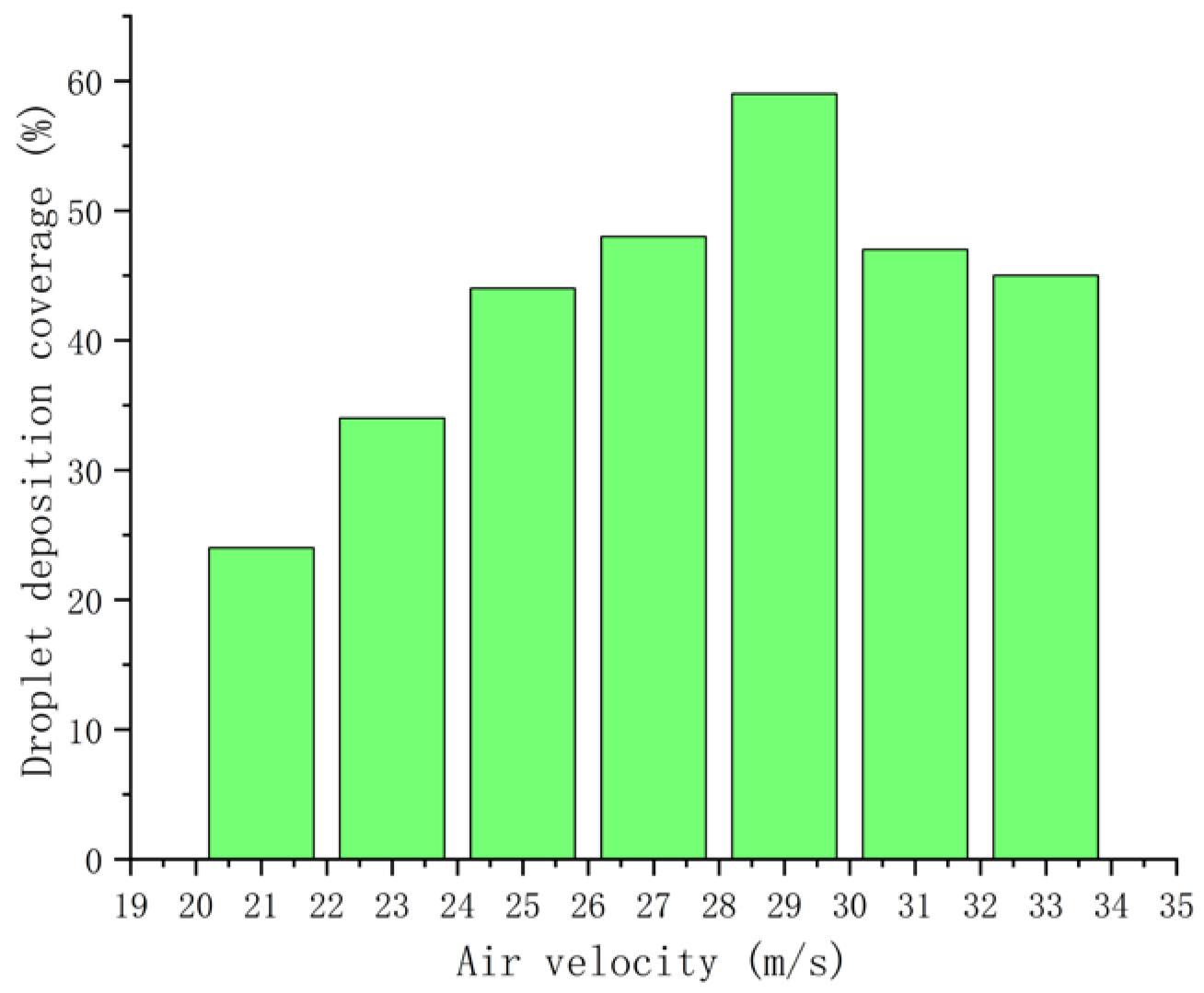

3.3.1. Spraying Air Velocity Effects

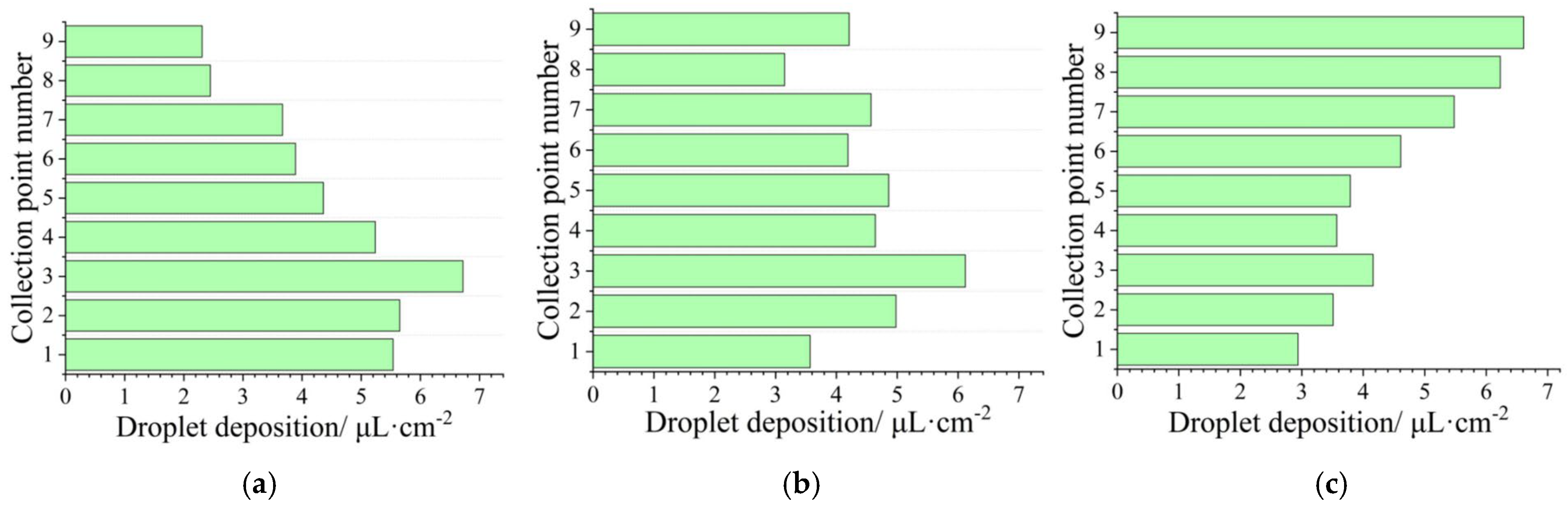

3.3.2. Sprayer Blower Pitch Angle Effects

3.3.3. The Self-Propelled Electric Monorail Transport Platform Movement Speed Effects

3.4. Field Multifactorial Test Results

3.4.1. Mathematical Modeling and Analysis of Variance

3.4.2. Response Surface Analysis (RSA)

4. Discussion

4.1. Aerodynamic Mechanisms and Model Validation

4.2. Model Performance and Limitations

4.3. Single-Factor Field Test and Analysis

4.3.1. Airflow–Droplet Dynamics

4.3.2. Blower Pitch Angle Optimization Mechanisms

4.3.3. Railcar Speed Dynamics

4.4. Multifactorial Synergy and Terrain-Adaptive Optimization in Mountainous Orchard Spraying

4.4.1. Model Interpretation and Practical Significance

4.4.2. Response Surface Analysis

5. Conclusions

- ▪ Airflow velocity × railcar speed (p = 0.0496);

- ▪ Blower angle × railcar speed (p = 0.0719).

- ▪ Reduced calibration complexity: Pre-validated parameter combinations minimized trial-and-error adjustments.

- ▪ Enhanced canopy penetration: Sustained post-canopy velocities (>6.4 m/s) ensured pesticide delivery to the interior foliage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kleinman, P.J.A.; Harmel, R.D. Grappling with the success and trade-offs of global nutrient redistribution. Environ. Dev. Sustain. 2024, 26, 29793–29811. [Google Scholar] [CrossRef]

- Díaz-Siefer, P.; Olmos-Moya, N.; Fontúrbel, F.E.; Lavandero, B.; Pozo, R.A.; Celis-Diez, J.L. Bird-mediated effects of pest control services on crop productivity: A global synthesis. J. Pest. Sci. 2022, 95, 567–576. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, B.; Lyu, H.; Kang, F.; Jiang, S. Research progress of orchard plant protection mechanization technology and equipment in China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 110–124. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Yu, S.; Wang, P.; Liu, H.; Yang, X. Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review. Agronomy 2023, 13, 2679. [Google Scholar] [CrossRef]

- Xu, T.; Lv, X.; Qi, Y.; Zeng, J.; Lei, X.; Yuan, Q. China’s orchard wind spray equipment and technology research progress. J. Chin. Agric. Mech. 2023, 44, 69–77. [Google Scholar]

- Zhang, J. Integrated management technology of apple orchard pests and diseases. World Trop. Agric. Inf. 2022, 6, 626–657. [Google Scholar]

- Ding, S.; Fu, X.; Xue, X.; Zhou, L.; Lv, X. Design and experiment of self-propelled air-assisted sprayer in orchard with dwarf culture. Trans. Chin. Soc. Agric. Eng. 2013, 29, 18–25. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, Z.; Fan, G.; Cao, L. Crawler self-propelled directional wind sprayer for orchards. J. Agric. Mach. 2014, 45, 117–122. [Google Scholar]

- Qu, F.; Sheng, X.; Li, X.; Zhang, J.; Li, W.; Liu, J. 3WZF-400A type orchard wind sprayer improvement design. J. Agric. Mach. 2017, 48, 15–21. [Google Scholar]

- Li, S.; Zhang, K.; Wang, J.; Li, J.; Liu, S. Optimisation of wind turbine parameters for airborne spraying device based on CFD. China Agric. Sci. Technol. Herald. 2023, 25, 93–102. [Google Scholar]

- Endalew, A.M.; Debaer, C.; Rutten, N.; Vercammen, J.; Delele, M.A.; Ramon, H.; Nicolaï, B.M.; Verboven, P. A new integrated CFD modelling approach towards air-assisted orchard spraying. Part I. Model development and effect of wind speed and direction on sprayer airflow. Comput. Electron. Agr. 2010, 71, 128–136. [Google Scholar] [CrossRef]

- Mercer, G.N. Modelling to determine the optimal porosity of shelterbelts for the capture of agricultural spray drift. Environ. Modell. Softw. 2009, 24, 1349–1352. [Google Scholar] [CrossRef]

- Shan, C.; Wang, G.; Wang, H.; Xie, Y.; Wang, H.; Wang, S.; Chen, S.; Lan, Y. Effects of droplet size and spray volume parameters on droplet deposition of wheat herbicide application by using UAV. Int. J. Agr. Biol. Eng. 2021, 14, 74–81. [Google Scholar] [CrossRef]

- Xu, S.; Feng, Y.; Han, L.; Ran, X.; Zhong, Y.; Jin, Y.; Song, J. Evaluation of the Wind Field and Deposition Effect of a Novel Air-Assisted Strawberry Sprayer. Agriculture 2023, 13, 230. [Google Scholar] [CrossRef]

- Shan, C.; Xue, C.; Zhang, L.; Song, C.; Kaousar, R.; Wang, G.; Lan, Y. Effects of different spray parameters of plant protection UAV on the deposition characteristics of droplets in apple trees. Crop Prot. 2024, 184, 106835. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Zhang, C.; Zhou, H.; Jiang, X.; Yang, F.; Wang, Y. CFD analysis and RBFNN-based optimization of spraying system for a six-rotor unmanned aerial vehicle (UAV) sprayer. Crop Prot. 2023, 174, 106433. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Zhou, H.; Zhang, C.; Jiang, X.; Lv, X. CFD analysis and RSM-based design optimization of axial air-assisted sprayer deflectors for orchards. Crop Prot. 2024, 184, 106794. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, L.; Wan, J.; Musiu, E.; Zhou, J.; Lu, Z.; Wang, P. Numerical simulation of downwash airflow distribution inside tree canopies of an apple orchard from a multirotor unmanned aerial vehicle (UAV) sprayer. Comput. Electron. Agr. 2022, 195, 106817. [Google Scholar] [CrossRef]

- Zeng, Y.; Wang, H.; Sun, M.; Wang, C.; Liu, X. A review of SST turbulence modelling improvement studies. J. Aeronaut. 2023, 44, 103–134. [Google Scholar]

- Li, T.; Qin, D.; Zhang, J. Effect of RANS Turbulence Model on Aerodynamic Behavior of Trains in Crosswind. J. Mech. Eng. 2019, 32, 85. [Google Scholar] [CrossRef]

- Hong, S.; Zhao, L.; Zhu, H. CFD simulation of airflow inside tree canopies discharged from air-assisted sprayers. Comput. Electron. Agr. 2018, 149, 121–132. [Google Scholar] [CrossRef]

- Sun, H.; Zheng, H.; Yu, H.; Qiu, W.; Cao, Y.; Lv, X.; Zhang, Z. CFD Simulation of Circulating-Airflow Distribution Inside Canopy From Novel Air-Assisted Sprayer in Orchard. J. Asabe 2023, 66, 533–547. [Google Scholar] [CrossRef]

- Yang, Y.; Tse, T.K.T.; Jin, X.; Yang, L.; Gu, M. A numerical tree canopy model and its application in computational wind engineering simulation. In Proceedings of the 7th International Colloquium on Bluff Body Aerodynamics and Applications (BBAA7), Shanghai, China, 2–6 September 2012. [Google Scholar]

- Gu, J.; Zhu, H.; Ding, W.; Wang, X. Characterization of Air Profiles Impeded by Plant Canopies for a Variable-Rate Air-Assisted Sprayer. T Asabe 2014, 57, 1307–1315. [Google Scholar]

- Wilson, J.D. Numerical studies of flow through a windbreak. J. Wind. Eng. Ind. Aerod 1985, 21, 119–154. [Google Scholar] [CrossRef]

- Mayhead, G.J. Some drag coefficients for british forest trees derived from wind tunnel studies. Agric. Meteorol. 1973, 12, 123–130. [Google Scholar] [CrossRef]

- Kane, B.; Smiley, E. Drag coefficients and crown area estimation of red maple. Can. J. Forest Res. 2006, 36, 1951–1958. [Google Scholar] [CrossRef]

- Chakir, S.; Bekraoui, A.; Majdoubi, H.; Senhaji, A.; Mouqallid, M. Numerical Simulation and Measurement of Air Temperature and Relative Humidity in an Olive Cuttings Tunnel Greenhouse. Open J. Model. Simul. 2021, 10, 32–47. [Google Scholar] [CrossRef]

- Nezhad, M.; Lange, C.; Fleck, B. Performance Evaluation of the RANS Models in Predicting the Pollutant Concentration Field within a Compact Urban Setting: Effects of the Source Location and Turbulent Schmidt Number. Atmosphere 2022, 13, 1013. [Google Scholar] [CrossRef]

- Wunder, S.; Lehmann, B.; Nestmann, F. Determination of the drag coefficients of emergent and just submerged willows. Int. J. River Basin Manag. 2011, 9, 231–236. [Google Scholar] [CrossRef]

- Grant, E.R.; Ross, A.N.; Gardiner, B.A.; Mobbs, S.D. Field Observations of Canopy Flows over Complex Terrain. Bound-Lay. Meteorol. 2015, 156, 231–251. [Google Scholar] [CrossRef]

- ISO/TC 23/SC 6; Equipment for Crop Protection—General Test Methods. Association Française de Normalization: Saint-Denis, France, 2014.

- Li, X.; Wang, P.; Li, J.; Yang, X.; Bian, Y. Simulation analysis and test of the air supply mechanism of multi-channel air sprayer for orchard. J. Hebei Agric. Univ. 2021, 44, 122–127. [Google Scholar]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of Droplet Size Parameters on Droplet Deposition and Drift of Aerial Spraying by Using Plant Protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Li, L.; He, X.; Song, J.; Zhong, C. Spray characteristics on pulse-width modulation variable application based on high frequency electromagnetic valve. Trans. Chin. Soc. Agric. Eng. 2016, 32, 97–103. [Google Scholar] [CrossRef]

- Zhai, C.; Zhao, C.; Ning, W.; John, L.; Wang, X.; Paul, W.; Zhang, H. Research progress on precision control methods of air-assisted spraying in orchards. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–15. [Google Scholar] [CrossRef]

- Delele, M.A. Engineering Design of Spraying Systems for Horticultural Applications Using Computational Fluid Dynamics. Ph.D. Thesis, KU Leuven University, Leuven, Belgium, 2009. [Google Scholar]

| Parameter | Value |

|---|---|

| Rated operating voltage | DC48 V |

| Pump operating pressure | 0.7 MPa |

| Hydraulic pump rated power | 90 W |

| Liquid pump rated flow | 5 L·min−1 |

| Fan rated power | 2000 W |

| Speed reducer rated power | 70 W |

| Electric push rod rated power | 36 W |

| Effective spraying distance | ≥27.5 m |

| Horizontal rotation angle | ±90° |

| Pitch angle range | −10°–30° |

| Parameter | Value |

|---|---|

| Motor rated power | 3 kW |

| Battery capacity | 220 Ah |

| Bearing wheel and double round wheel track | 108 mm |

| Running speed | 0~1 m/s |

| Maximum gradability | 35° |

| Climbing biggest loading quality | 300 kg |

| Transport equipment positioning error | 2.3 mm |

| Wireless communication distance | 3000 m |

| Sampling Point Location | Air Velocity/(m·s−1) | Simulated/(m·s−1) | Relative Error Value/% |

|---|---|---|---|

| Left of plane a | 28.1 | 32.23 | 14.68 |

| Upper of plane a | 29.2 | 31.41 | 7.47 |

| Middle of plane a | 25.2 | 22.43 | −11 |

| Right of plane a | 27.6 | 28.09 | 1.79 |

| Lower plane a | 28.44 | 30.07 | 9.08 |

| Left of plane b | 18.52 | 17.03 | −11.94 |

| Upper plane b | 21.23 | 22.54 | 7.52 |

| Middle of plane b | 16.81 | 15.61 | −9.29 |

| Right of plane b | 19.45 | 20.23 | 6.92 |

| Lower plane b | 20.44 | 18.50 | −12.02 |

| Left of plane c | 7.92 | 9.56 | 13.14 |

| Upper plane c | 9.31 | 8.88 | −9.04 |

| Middle of plane c | 6.23 | 7.32 | 11.93 |

| Right of plane c | 8.51 | 7.97 | 9.64 |

| Lower plane c | 10.92 | 12.58 | 12.02 |

| Sprayer Blower Pitch Angle /(°) | Droplet Deposition/μL·cm−2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Collection Point 1 | Collection Point 2 | Collection Point 3 | Collection Point 4 | Collection Point 5 | Collection Point 6 | Collection Point 7 | Collection Point 8 | Collection Point 9 | |

| 0 | 5.54 | 5.65 | 6.72 | 5.24 | 4.36 | 3.89 | 3.67 | 2.45 | 2.31 |

| 15 | 3.57 | 4.98 | 6.12 | 4.64 | 4.86 | 4.19 | 4.57 | 3.15 | 4.21 |

| 30 | 2.94 | 3.51 | 4.16 | 3.57 | 3.79 | 4.61 | 5.48 | 6.23 | 6.61 |

| Encodings | Air Velocity (m·s−1) | Sprayer Blower Pitch Angle | Monorail Machine Movement Speed |

|---|---|---|---|

| −1 | 25 | 0 | 0 |

| 0 | 29 | 15 | 0.5 |

| 1 | 33 | 30 | 1 |

| No. | A | B | C | Droplet Deposition (μL·cm−2) |

|---|---|---|---|---|

| 1 | 1 | −1 | 0 | 3.88 |

| 2 | 0 | 0 | 0 | 4.14 |

| 3 | 1 | 0 | 1 | 3.39 |

| 4 | 0 | 0 | 0 | 4.24 |

| 5 | 0 | −1 | 1 | 3.87 |

| 6 | 1 | 0 | −1 | 4.02 |

| 7 | 0 | 0 | 0 | 3.92 |

| 8 | −1 | 0 | 0 | 3.88 |

| 9 | −1 | 1 | 0 | 3.72 |

| 10 | 0 | 0 | 0 | 4.31 |

| 11 | −1 | −1 | 0 | 3.13 |

| 12 | 0 | 0 | 0 | 3.11 |

| 13 | −1 | 0 | 1 | 3.13 |

| 14 | 0 | 1 | 1 | 3.81 |

| 15 | 1 | 1 | 0 | 3.58 |

| 16 | 0 | −1 | −1 | 3.24 |

| 17 | 0 | 1 | −1 | 4.44 |

| Variation Source | Sum of Square | Degree of Freedom | Mean Square | F Value | p Value |

|---|---|---|---|---|---|

| Model | 1.70 | 9 | 0.1886 | 9.73 | 0.0033 ** |

| A | 0.5565 | 1 | 0.5565 | 28.71 | 0.0011 ** |

| B | 0.0136 | 1 | 0.0136 | 0.7023 | 0.4297 |

| C | 0.396 | 1 | 0.396 | 20.43 | 0.0027 * |

| AB | 0.009 | 1 | 0.009 | 0.4656 | 0.5169 |

| AC | 0.0196 | 1 | 0.0196 | 1.01 | 0.3481 |

| BC | 0.1089 | 1 | 0.1089 | 5.62 | 0.0496 * |

| A2 | 0.462 | 1 | 0.462 | 23.84 | 0.0018 ** |

| B2 | 0.009 | 1 | 0.009 | 0.4647 | 0.5174 |

| C2 | 0.087 | 1 | 0.087 | 4.49 | 0.0719 ** |

| Residual | 0.1357 | 7 | 0.0194 | ||

| Lack of fit | 0.0619 | 3 | 0.0206 | 1.12 | 0.4407 |

| Pure error | 0.0738 | 4 | 0.0184 | ||

| Total value | 1.83 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Bu, M.; Li, Z.; Li, Y.; Liu, Y.; Ye, W.; Huang, C.; Lyu, S. Research on the Application Effect and Parameter Optimization of 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment in Fruit Tree Canopy. Agronomy 2025, 15, 781. https://doi.org/10.3390/agronomy15040781

Xue X, Bu M, Li Z, Li Y, Liu Y, Ye W, Huang C, Lyu S. Research on the Application Effect and Parameter Optimization of 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment in Fruit Tree Canopy. Agronomy. 2025; 15(4):781. https://doi.org/10.3390/agronomy15040781

Chicago/Turabian StyleXue, Xiuyun, Maofeng Bu, Zhen Li, Yichi Li, Yifu Liu, Wenqi Ye, Chengle Huang, and Shilei Lyu. 2025. "Research on the Application Effect and Parameter Optimization of 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment in Fruit Tree Canopy" Agronomy 15, no. 4: 781. https://doi.org/10.3390/agronomy15040781

APA StyleXue, X., Bu, M., Li, Z., Li, Y., Liu, Y., Ye, W., Huang, C., & Lyu, S. (2025). Research on the Application Effect and Parameter Optimization of 3HW36 Mountain Orchard Rail-Mounted Wind-Driven Plant Protection Equipment in Fruit Tree Canopy. Agronomy, 15(4), 781. https://doi.org/10.3390/agronomy15040781