A Novel Large-Particle Slow-Release Fertilizer Improves Nutrient Use Efficiency and Yield of Cassava by Boundary Layer Limitation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Slow-Release Fertilizer

2.3. Determination of Nutrient Content, Microstructure, and FTIR Characteristic

2.4. Analysis of Slow-Release Performance and Mechanism of the Studied Fertilizers

2.5. Fertilizer Efficiency Experiment for Cassava Growth

2.6. Statistical Analysis

3. Results

3.1. Optimization of Fertilizer Production Process

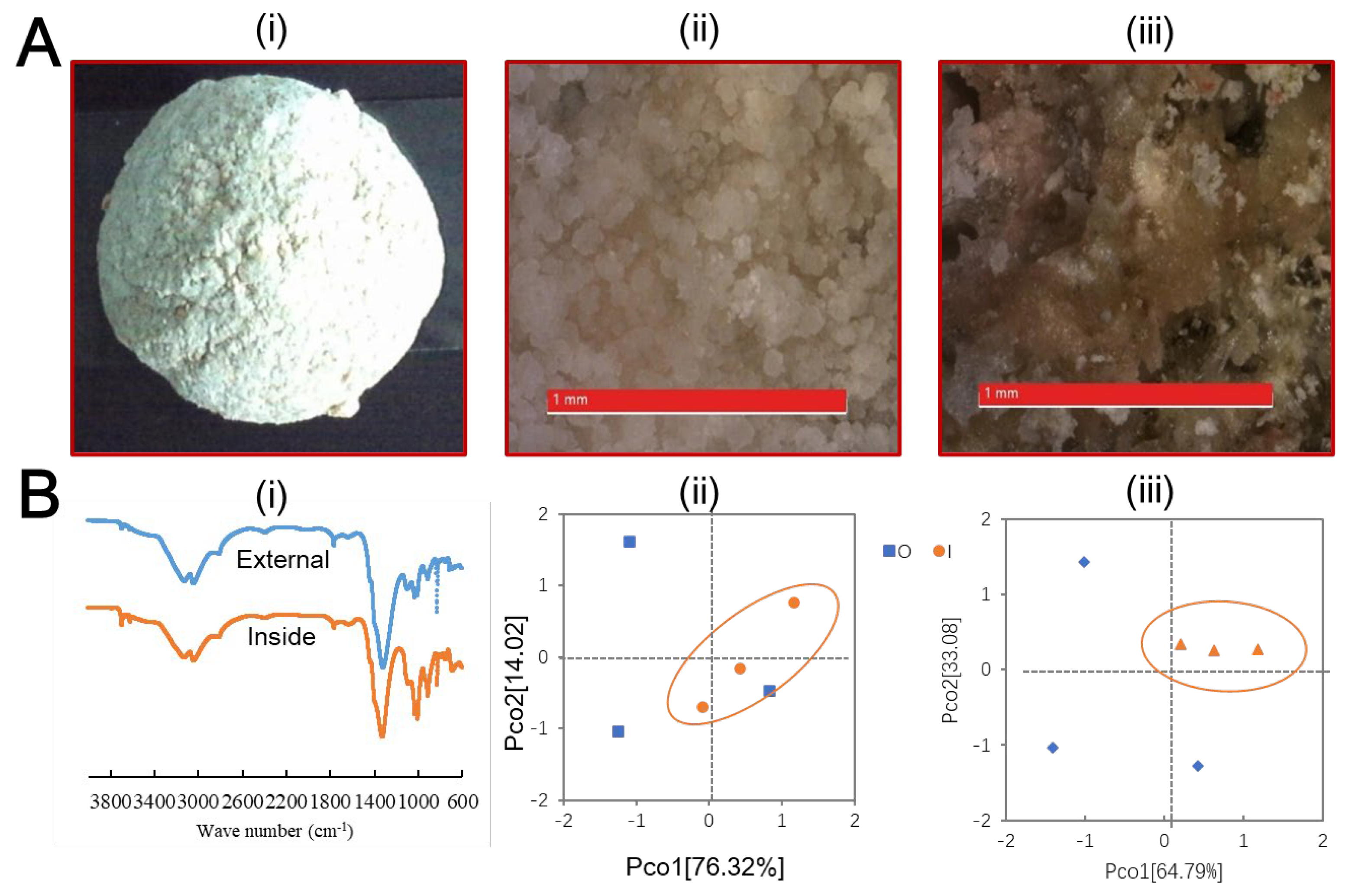

3.2. Characterization of Morphology and Composition of Large-Particle Slow-Release Fertilizer

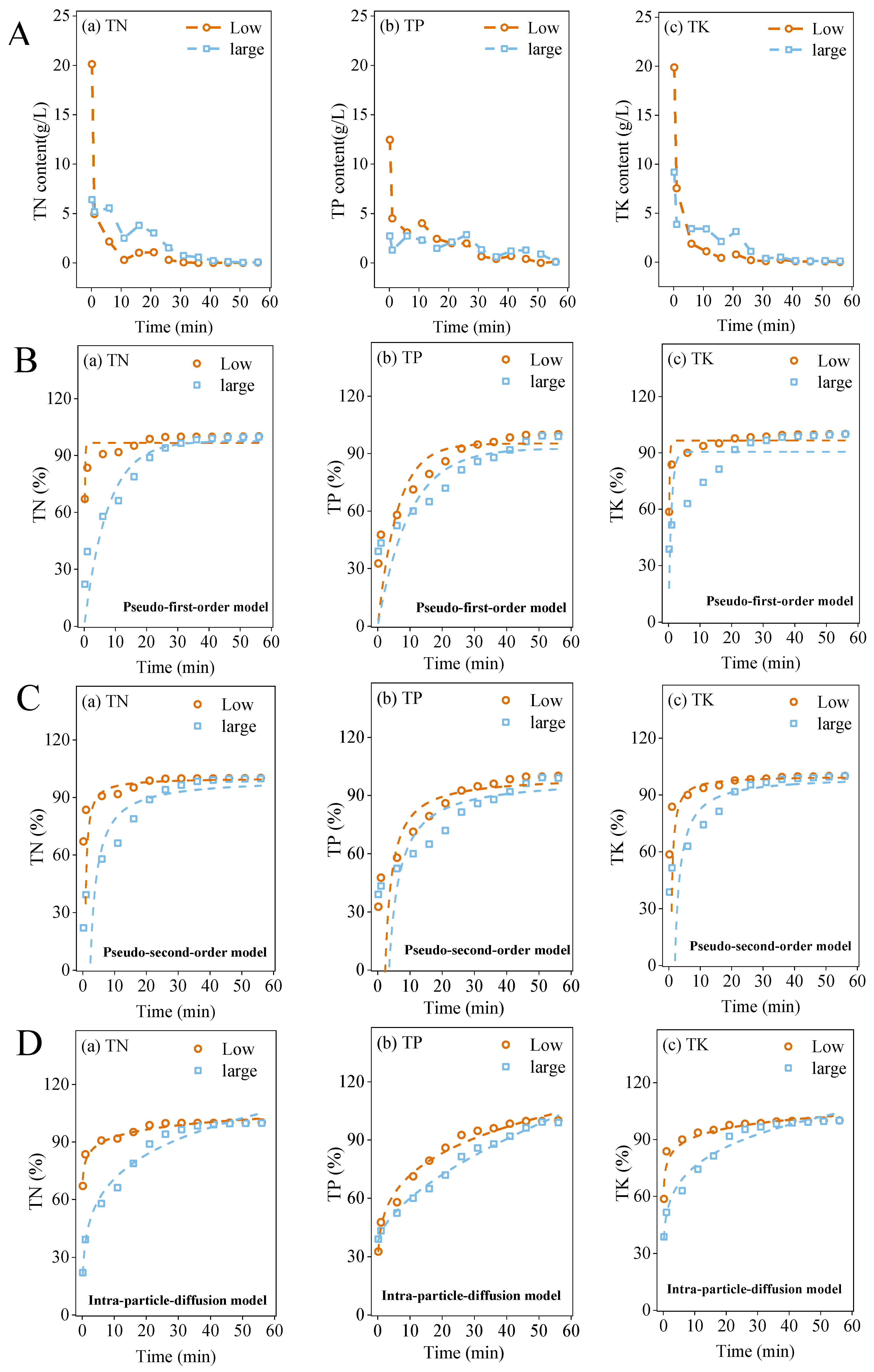

3.3. Comparison of Slow-Release Performance Between Large-Particle and Conventional Small-Particle Slow-Release Fertilizers

3.4. Field-Scale Evaluation of Slow-Release Fertilizer Application in Cassava Systems

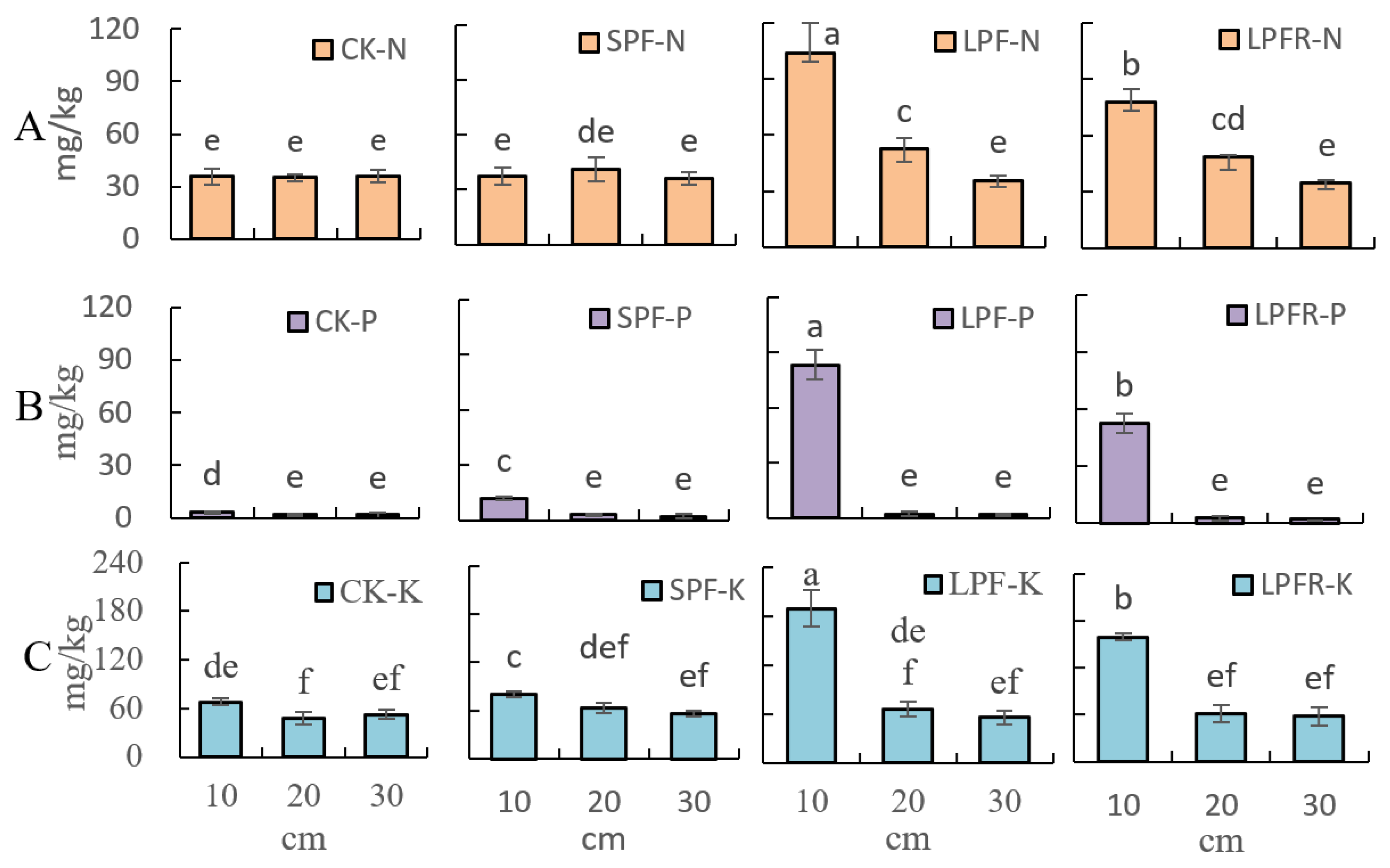

3.4.1. Horizontal Soil Nutrient Transport in Response to Slow-Release Fertilizer Application

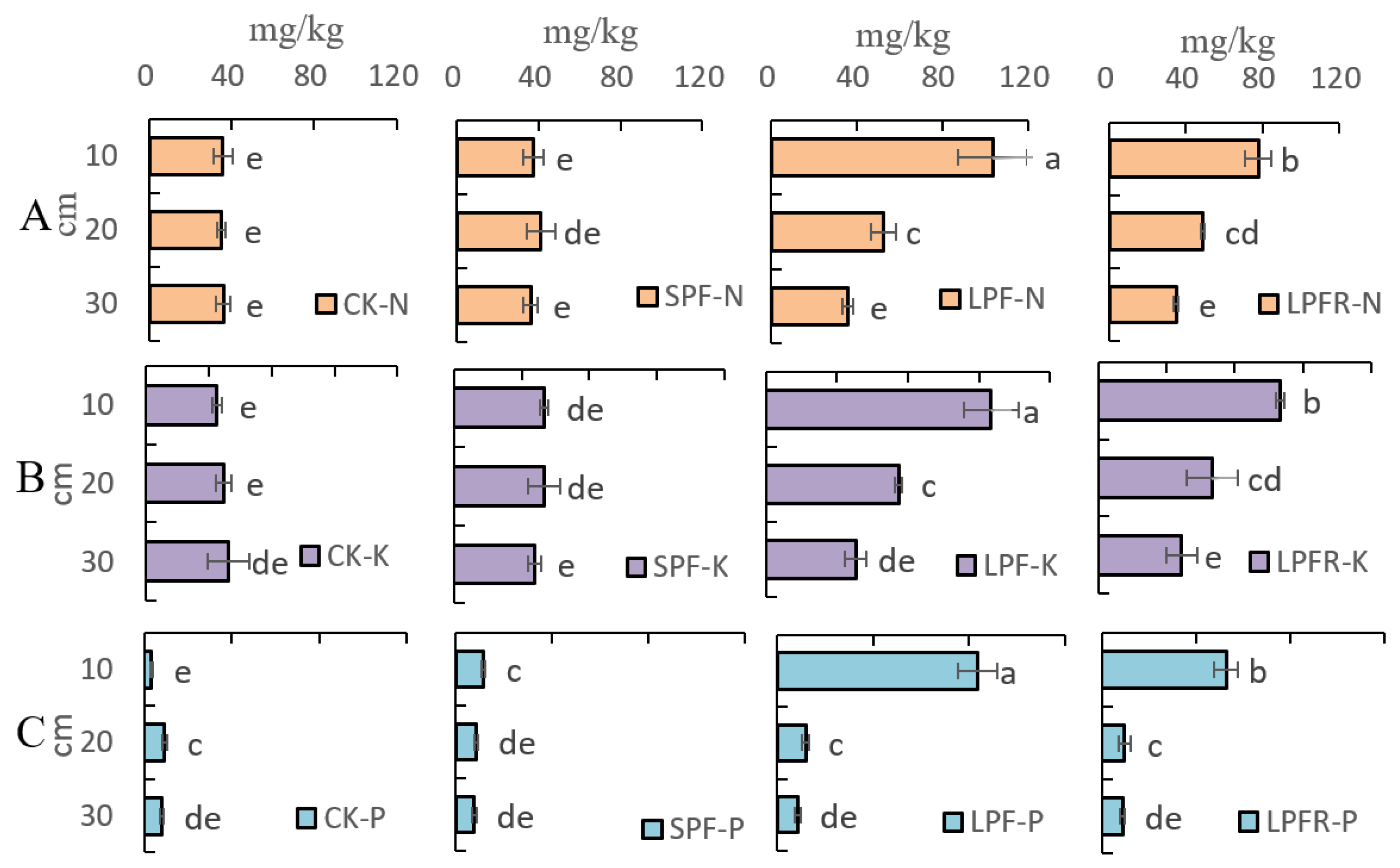

3.4.2. Vertical Distribution of Soil Nutrients in Response to Slow-Release Fertilizer Application

3.4.3. Effect of Large-Particle Slow-Release Fertilizer on Cassava Yield

4. Discussion

4.1. Advantages of Large-Particle Slow-Release Fertilizer Synthesis

4.2. Nutrient Release Performance of Large-Particle Slow-Release Fertilizer

4.3. Influence of Large-Particle Slow-Release Fertilizer on Cassava Growth

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ruiz, G.A.P.; Medina, R.D.; José Ramón, T.; Angela, M.B. Selectivity of Pre-Emergent Herbicides in Cassava (Manihot Esculenta Crantz) and Its Relationship with the Stem Cutting Planting System. Crop Prot. 2025, 187, 106985. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Statistical Database; FAO: Rome, Italy, 2023. [Google Scholar]

- Chirinda, N.; Trujillo, C.; Loaiza, S.; Salazar, S.; Luna, J.; Encinas, L.A.T.; Lavalle, L.A.B.L.; Tran, T. Nitrous Oxide Emissions from Cassava Fields Amended with Organic and Inorganic Fertilizers. Soil Use Manag. 2021, 37, 257–263. [Google Scholar] [CrossRef]

- Nwokoro, C.C. Improvements to Cassava-Maize Intercropping Systems in Southern Nigeria. Diss; ETH: Zurich, Switzerland, 2021. [Google Scholar]

- Byju, G.; Suja, G. Mineral Nutrition of Cassava. Adv. Agron. 2020, 159, 169–235. [Google Scholar]

- NB/T 34031-2015; Technical Regulations for Energy Cassava Production. China National Energy Administration: Beijing, China, 2015.

- Acheampong, P.P.; Addison, M.; Wongnaa, C.A.; Baafi, E.; Opoku, M. Assessment of Impacts of Adoption of Improved Sweetpotato Varieties in Ghana: Accounting for Differences in Male and Female Farmers. Gend. Technol. Dev. 2024, 28, 181–204. [Google Scholar] [CrossRef]

- Kwiatkowski, C.A.; Harasim, E.; Pawłowski, L.; Pawlowski, A.; Pawlowska, M.; Kolodziej, B. Organic Versus Conventional Farming: Nutritional Value and Health Safety of Food Products; Routledge Press: New York, NY, USA, 2023; pp. 57–69. [Google Scholar]

- Wang, W.; Yang, S.; Zhang, A.; Yang, Z. Synthesis of A Slow-Release Fertilizer Composite Derived from Waste Straw That Improves Water Retention and Agricultural Yield. Sci. Total Environ. 2021, 768, 144978. [Google Scholar] [CrossRef]

- Balasuriya, B.T.G.; Ghose, A.; Gheewala, S.H.; Prapaspongsa, T. Assessment of Eutrophication Potential from Fertiliser Application in Agricultural Systems in Thailand. Sci. Total Environ. 2022, 833, 154993. [Google Scholar] [CrossRef]

- Zhang, T.; Xie, X.; Huang, Z. The Policy Recommendations on Cassava Ethanol in China: Analyzed from The Perspective of Life Cycle “2E&W”. Resour. Conserv. Recycl. 2017, 126, 12–24. [Google Scholar]

- Lu, J.; Li, Y.; Cai, Y.; Jiang, P.; Yu, B. Co-incorporation of hydrotalcite and starch into biochar-based fertilizers for the synthesis of slow-release fertilizers with improved water retention. Biochar 2023, 5, 44–57. [Google Scholar] [CrossRef]

- An, X.; Wu, Z.; Yu, J.; Cravotto, G.; Liu, X.; Li, Q.; Yu, B. Copyrolysis of Biomass, Bentonite, And Nutrients as A New Strategy for the Synthesis of Improved Biochar-Based Slow-Release Fertilizers. ACS Sustain. Chem. Eng. 2020, 8, 3181–3190. [Google Scholar] [CrossRef]

- Fu, J.; Wang, C.; Chen, X.; Huang, Z.; Miu, J.; Shi, L.; Wang, S. Preparation and Characterization of Attapulgite-Fly Ash–Based Binuclear Slow-Release Fertilizer Encapsulated by Eudragit. Agron. J. 2019, 111, 2411–2421. [Google Scholar] [CrossRef]

- Lyu, Y.; Yang, X.; Pan, H.; Zhang, X.; Cao, H.; Ulgiati, S.; Wu, J.; Zhang, Y.; Wang, G.; Xiao, Y. Impact of Fertilization Schemes With Different Ratios Of Urea To Controlled Release Nitrogen Fertilizer On Environmental Sustainability, Nitrogen Use Efficiency And Economic Benefit Of Rice Production: A Study Case From Southwest China. J. Clean. Prod. 2021, 293, 126198. [Google Scholar] [CrossRef]

- Li, G.-H.; Cheng, G.-G.; Lu, W.-P.; Lu, D.-L. Differences of Yield and Nitrogen Use Efficiency under Different Applications of Slow-Release Fertilizer in Spring Maize. J. Integr. Agric. 2021, 20, 554–564. [Google Scholar] [CrossRef]

- Guan, Y.; Song, C.; Gan, Y.; Li, F.-M. Increased maize yield using slow-release attapulgite-coated fertilizers. Agron. Sustain. Dev. 2014, 34, 657–665. [Google Scholar] [CrossRef]

- Poku, E.A. Improving Phosphorus Uptake by Cassava (Manihot Esculanata Crantz) Using Arbuscular Mycorrhizal Fungi (AMF). Diss; University of KwaZulu-Natal: Pietermaritzburg, South Africa, 2014. [Google Scholar]

- Laxminarayana, K.; Mishra, S.; Soumya, S. Good Agricultural Practices in Tropical Root and Tuber Crops. In Tropical Roots and Tubers: Production, Processing and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 183–224. [Google Scholar]

- Wang, W.; Yang, S.; Zhang, A.; Yang, Z. Preparation and Properties of Novel Corn Straw Cellulose–Based Superabsorbent 2ith Water-Retaining and Slow-Release Functions. J. Appl. Polym. Sci. 2020, 137, 2–9. [Google Scholar]

- Lin, Y.; Gao, X.; Yue, J.; Fang, Y.; Shi, J.; Meng, L.; Clayton, C.; Zhang, X.-X.; Shi, F.; Deng, J.; et al. A soil-inspired dynamically responsive chemical system for microbial modulation. Nat. Chem. 2023, 15, 119–128. [Google Scholar] [CrossRef]

- Yu, Y.; Pi, S.; Ke, T.; Zhou, B.; Chao, W.; Yang, Y.; Li, Z.; Li, G.; Ren, N.; Gao, X.; et al. Artificial Soil-Like Material Enhances CO2 Bio-Valorization into Chemicals in Gas Fermentation. ACS Appl. Mater. Interfaces 2023, 15, 53488–53497. [Google Scholar] [CrossRef]

- Kenawy, E.; Seggiani, M.; Cinelli, P.; Elnaby, H.M.H.; Azaam, M.M. Swelling Capacity of Sugarcane Bagasse-G-Poly (Acrylamide)/Attapulgite Superabsorbent Composites and Their Application as Slow Release Fertilizer. Eur. Polym. J. 2020, 133, 109769. [Google Scholar] [CrossRef]

- Xie, L.; Liu, M.; Ni, B.; Zhang, X.; Wang, Y. Slow-Release Nitrogen and Boron Fertilizer from A Functional Superabsorbent Formulation Based on Wheat Straw and Attapulgite. Chem. Eng. J. 2011, 167, 342–348. [Google Scholar] [CrossRef]

- Ren, C.; Li, G.; Wu, D.; Zou, Y.; Li, Q.; Tian, Y.; Wang, J. Stand Development Reduces Soil Carbon Mineralization in Rubber Plantations Through Regulating Microbial Metabolic Strategy and Substrate Availability. Ind. Crop. Prod. 2024, 218, 118955. [Google Scholar] [CrossRef]

- Wu, D.; Ren, C.; Ren, D.; Tian, Y.; Li, Y.; Wu, C.; Li, Q. New Insights into Carbon Mineralization in Tropical Paddy Soil Under Land Use Conversion: Coupled Roles of Soil Microbial Community, Metabolism, And Dissolved Organic Matter Chemodiversity. Geoderma 2023, 432, 116393. [Google Scholar] [CrossRef]

- Meuser, H.; Meuser, H. Rehabilitation of Soils in Mining and Raw Material Extraction Areas. In Soil Remediation and Rehabilitation; Springer: Berlin/Heidelberg, Germany, 2013; pp. 37–126. [Google Scholar]

- Pinto, J.; Colónia, J.; Abdolvaseei, A.; Vale, C.; Henriques, B.; Pereira, E. Algal Sorbents and Prospects for Their Application in The Sustainable Recovery of Rare Earth Elements from E-Waste. Environ. Sci. Pollut. Res. 2023, 30, 74521–74543. [Google Scholar] [CrossRef] [PubMed]

- Akay, G. Hydrogen, Ammonia And Symbiotic/Smart Fertilizer Production Using Renewable Feedstock and Co2 Utilization Through Catalytic Processes and Nonthermal Plasma with Novel Catalysts and in Situ Reactive Separation: A Roadmap for Sustainable and Innovation-Based Technology. Catalysts 2023, 13, 1287. [Google Scholar] [CrossRef]

- Yu, X.; Li, B. Release Mechanism of a Novel Slow-Release Nitrogen Fertilizer. Particuology 2019, 45, 124–130. [Google Scholar] [CrossRef]

- Alikhani, M.; Mirbolook, A.; Sadeghi, J.; Lakzian, A. Effect of a New Slow-Release Zinc Fertilizer Based on Carbon Dots on The Zinc Concentration, Growth Indices, And Yield in Wheat (Triticum aestivum). Plant Physiol. Biochem. 2023, 200, 107783. [Google Scholar] [CrossRef]

- Shannon, E.; Abu-Ghannam, N. Enzymatic Extraction of Fucoxanthin from Brown Seaweeds. Int. J. Food Sci. Technol. 2018, 53, 2195–2204. [Google Scholar] [CrossRef]

- Wu, D.; Yun, Y.; Jiang, L.; Wu, C. Influence of Dissolved Organic Matter on Sorption and Desorption of MCPA in Ferralsol. Sci. Total Environ. 2018, 616, 1449–1456. [Google Scholar] [CrossRef]

- Yang, G.; Wang, Y.; Wang, S.; Zhao, X. Drilling of Super Large Granular Slow-Release Humic Acid Compound Fertilizer Improves Simultaneously Environmental and Economic Benefits in Peach Orchard. Agric. Ecosyst. Environ. 2023, 348, 108437. [Google Scholar] [CrossRef]

- Vejan, P.; Khadiran, T.; Abdullah, R.; Li, H.K. Controlled Release Fertilizer: A Review on Developments, Applications and Potential in Agriculture. J. Control. Release 2021, 339, 321–334. [Google Scholar] [CrossRef]

- Kalita, A.; Elayarajan, M.; Janaki, P.; Suganya, S.; Sankari, A.; Parameswari, E. Organo-Monomers Coated Slow-Release Fertilizers: Current Understanding and Future Prospects. Int. J. Biol. Macromol. 2024, 274, 133320. [Google Scholar] [CrossRef]

- Salimi, M.; Channab, B.-E.; El Idrissi, A.; Zahouily, M.; Motamedi, E. A Comprehensive Review on Starch: Structure, Modification, And Applications in Slow/Controlled-Release Fertilizers in Agriculture. Carbohydr. Polym. 2023, 13, 121326. [Google Scholar] [CrossRef]

- Mirbolook, A.; Rasouli-Sadaghiani, M.; Keshavarz, P. Development and Characterization of a Slow-Release Dual-Purpose N And Zn Fertilizer Based on Diatomite and Nano-Diatomite. Clay. Clay. Miner. 2024, 72, 6–18. [Google Scholar]

- Lu, J.; Liu, C.; Sui, B.; Wang, H.; Liu, S.; Hu, N.; Zhang, Y.; Zhao, L. Study on The Nitrogen Release Rate and Fertility Effect of Large Round Granular Fertilizer. J. Maize Sci. 2019, 27, 148–154. [Google Scholar]

- Tang, Y.; Wang, X.Y.; Yang, Y.C.; Gao, B.; Wan, Y.S.; Li, Y.C.; Cheng, D.C. Activated Lignite-Based Super Large Granular Slow-Release Fertilizers Improve Apple Tree Growth: Synthesis, Characterizations, and Laboratory and Field Evaluations. J. Agric. Food Chem. 2017, 265, 5879–5889. [Google Scholar] [CrossRef]

- Tang, Y.F. Development of Large-Grained Activated Humic Acid Slow-Release Fertilizer and Its Application on Apple; Shandong Agricultural University: Taian, China, 2021. [Google Scholar]

- Xing, X.; Ma, X.; Chen, L.T.; Li, H.; Wen, Z.; Zeng, G. Experimental Study on Physical Characteristics of Granular Fertilizer. J. Agric. Mech. Res. 2020, 42, 125–130. [Google Scholar]

- Zhang, W.; Wu, Q.; Gu, S.; Zhang, J. Slow-Release Characteristic Analysis of Nugget Slow-Release Tree Fertilizer. Chem. Ind. Eng. Prog. 2011, 30, 53–55. [Google Scholar]

- Vakal, S.; Vakal, V.; Artyukhov, A.; Shkola, V.; Yanovska, A. Granulated Organo-Mineral Fertilizers: The Process of Formation and Investigation of Porous Phosphate-Diatomite Shell. Appl. Nanosci. 2023, 13, 5157–5516. [Google Scholar] [CrossRef]

- Smailov, B.M.; Beisenbayev, O.K.; Anarbayev, A.A.; Zakirov, B.S.; Aravind, U.K. Influence of Granule Structure Mineral Fertilizers for Their Physical and Chemical Properties. Kompleks. Ispolz. Miner. Syra 2025, 335, 26–33. [Google Scholar] [CrossRef]

- Thanaporn, S.; Seree, W.; Jetsada, P.; Kanda, R.S.; Arthit, P.; Poramate, B.; Mahisorn, L. Design, Development, And Testing of a Cassava Storage Root-Cutting Robot Utilizing A Stewart Platform And Mask R-CNN For Precision Agriculture. Smart Agric. Technol. 2024, 9, 100687. [Google Scholar]

- Enesi, R.O.; Hauser, S.; Pypers, P.; Kreye, C.; Tariku, M.; Six, J. Understanding Changes in Cassava Root Dry Matter Yield by Different Planting Dates, Crop Ages at Harvest, Fertilizer Application and Varieties. Eur. J. Agron. 2022, 133, 126448. [Google Scholar] [CrossRef]

- Luo, L.Y.; Xue, X.X.; Wei, Y.X.; Huang, J.; Zhang, Y.F.; Zhao, C.M.; Luo, X.H.; Wang, W.B. Yield and Nutrient Absorption and Utilization Characteristics of Cassva Under Reduced Fertilizer Application. Chin. J. Trop. Crop. 2021, 42, 3173–3179. [Google Scholar]

- Tan, Y.W.; Cong, X.; Hua, S. Analysis of Cassava Production and Trade Development in China. World Agric. 2018, 10, 163–168. [Google Scholar]

- Van Laere, J.; Munyahali, W.; De Bauw, P.; Dercon, G.; Kintche, K.; Merckx, R. Early Planting of Cassava Enhanced the Response of Improved Cultivars to Potassium Fertilization in South Kivu, Democratic Republic of Congo. Field Crops Res. 2023, 296, 108903. [Google Scholar]

- Munyahali, W.; Birindwa, D.; Pypers, P.; Swennen, R.; Vanlauwe, B.; Merckx, R. Increased Cassava Growth and Yields Through Improved Variety Use and Fertilizer Application in The Highlands of South Kivu, Democratic Republic of Congo. Field Crops Res. 2023, 302, 109056. [Google Scholar] [CrossRef]

| Serial Number | A (cm) | B (C) | C (t) | D (Bar) | E (%) | F (%) | Release Time of 80% Nutrient (min) |

|---|---|---|---|---|---|---|---|

| 1 | 3 | 90 | 120 | 0.4 | 40 | 15 | 26 |

| 2 | 1 | 90 | 80 | 0 | 40 | 15 | 16 |

| 3 | 1 | 70 | 120 | 0 | 30 | 5 | 17 |

| 4 | 2 | 80 | 40 | 0 | 30 | 15 | 14.7 |

| 5 | 2 | 80 | 80 | 0.4 | 40 | 5 | 16.5 |

| 6 | 2 | 90 | 80 | 0.8 | 30 | 10 | 15 |

| 7 | 3 | 70 | 40 | 0 | 40 | 10 | 22 |

| 8 | 3 | 70 | 80 | 0.4 | 30 | 10 | 22 |

| 9 | 1 | 80 | 120 | 0.4 | 50 | 10 | 18 |

| 10 | 3 | 90 | 40 | 0.8 | 50 | 5 | 23 |

| 11 | 2 | 70 | 40 | 0.4 | 50 | 15 | 17 |

| 12 | 2 | 90 | 120 | 0 | 50 | 10 | 18 |

| 13 | 1 | 80 | 40 | 0.8 | 40 | 10 | 15 |

| 14 | 2 | 70 | 120 | 0.8 | 40 | 5 | 18 |

| 15 | 3 | 80 | 80 | 0 | 50 | 5 | 25 |

| 16 | 1 | 90 | 40 | 0.4 | 30 | 5 | 15 |

| 17 | 3 | 80 | 120 | 0.8 | 30 | 15 | 28 |

| 18 | 1 | 70 | 80 | 0.8 | 50 | 15 | 15 |

| Nutrients | Treatments | Pseudo-First-Order Model | Intra-Particle Diffusion Model | |||

|---|---|---|---|---|---|---|

| K1 | 1-R2 | Kp | Cp | P-R2 | ||

| N | small | 5.809 | 0.702 | 5.077 | 5.074 | 0.948 |

| large | 0.133 | 0.826 | 69.045 | 31.078 | 0.973 | |

| P | small | 0.164 | 0.627 | 5.938 | 7.259 | 0.977 |

| large | 0.101 | 0.391 | 27.477 | 36.349 | 0.989 | |

| K | small | 4.460 | 0.825 | 1.426 | 1.925 | 0.902 |

| large | 1.123 | 0.565 | 44.120 | 17.171 | 0.967 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, C.; Wang, H.; Li, G.; Huang, J.; Wang, D.; Qin, X.; Zhang, W.; Wu, D.; Jiu, Y.; Zhao, M.; et al. A Novel Large-Particle Slow-Release Fertilizer Improves Nutrient Use Efficiency and Yield of Cassava by Boundary Layer Limitation. Agronomy 2025, 15, 261. https://doi.org/10.3390/agronomy15020261

He C, Wang H, Li G, Huang J, Wang D, Qin X, Zhang W, Wu D, Jiu Y, Zhao M, et al. A Novel Large-Particle Slow-Release Fertilizer Improves Nutrient Use Efficiency and Yield of Cassava by Boundary Layer Limitation. Agronomy. 2025; 15(2):261. https://doi.org/10.3390/agronomy15020261

Chicago/Turabian StyleHe, Cuicui, Hua Wang, Guichun Li, Jie Huang, Dengfeng Wang, Xindao Qin, Wen Zhang, Dongming Wu, Yuanda Jiu, Min Zhao, and et al. 2025. "A Novel Large-Particle Slow-Release Fertilizer Improves Nutrient Use Efficiency and Yield of Cassava by Boundary Layer Limitation" Agronomy 15, no. 2: 261. https://doi.org/10.3390/agronomy15020261

APA StyleHe, C., Wang, H., Li, G., Huang, J., Wang, D., Qin, X., Zhang, W., Wu, D., Jiu, Y., Zhao, M., Xie, Y., Chen, Q., Zhou, R., & Xu, M. (2025). A Novel Large-Particle Slow-Release Fertilizer Improves Nutrient Use Efficiency and Yield of Cassava by Boundary Layer Limitation. Agronomy, 15(2), 261. https://doi.org/10.3390/agronomy15020261