1. Introduction

Returning crop straw to the soil is a cornerstone of sustainable agriculture. Incorporation of residues improves soil structure, enhances nutrient cycling, and contributes to carbon sequestration. It increases soil fertility, improves soil structure, and enhances organic matter recycling in intensive rice–wheat rotational cropping systems [

1,

2]. Straw incorporation also reduces reliance on chemical fertilizers and mitigates environmental impacts such as air pollution and greenhouse gas emissions [

3,

4].

Straw decomposition increases soil organic carbon and provides necessary nutrients like nitrogen (N), phosphorus (P), and potassium (K), vital for subsequent crop growth [

5]. However, the high carbon-to-nitrogen (C:N) ratio of straw can cause immobilization of nitrogen, thus the need of the application of decomposing agents to enhance breakdown and synchronize nutrient release [

6]. However, its high C:N ratio can cause nitrogen immobilization, necessitating decomposing agents to synchronize nutrient release [

6]. Biodegradable plastic films have been shown to regulate soil moisture and temperature, thereby supporting microbial activity and organic matter decay [

7]. Straw return enhances soil health by improving physical properties such as bulk density, porosity, and water infiltration, increasing chemical attributes like soil organic carbon and nutrient cycling efficiency, and boosting biological factors including microbial biomass, enzymatic activity, and biodiversity [

8,

9]. The spatial and temporal control of straw return is critical. Shallow incorporation (5–10 cm) enables rapid decomposition, while deeper incorporation (15–20 cm) enhances long-term organic matter accumulation [

10,

11]. Decomposers (e.g., cellulolytic fungi and N-fixing bacteria) accelerate straw degradation and reduce methane emissions [

12]. Biodegradable plastic films insulate soil, promoting gradual decomposition and moisture conservation [

7,

13].

Globally, rice and wheat generate more than 1 billion tons of straw annually, with China, India, and Ethiopia among the largest producers. In many regions, improper straw management (e.g., burning) contributes to severe air pollution and carbon emissions, reinforcing the urgency of sustainable return practices [

14,

15]. While many studies confirm the general benefits of straw return, most do not systematically address how spatial factors (depth, horizontal distribution, and burial mode) interact with temporal factors (decomposition timing, decomposers, and mulching films). This creates fragmented recommendations and a knowledge gap [

16,

17].

The research was conducted in Babaiqiao Town, Nanjing, China, a region with a long history of rice–wheat rotation and straw return practices. The study area’s soil, characterized as clay loam, provides an ideal setting for investigating the spatial and temporal patterns of straw incorporation and their correlation with soil health. This study aimed to provide a comprehensive understanding of the factors influencing straw decomposition and incorporation by analyzing soil and straw parameters, moisture content, bulk density, porosity, length, and density.

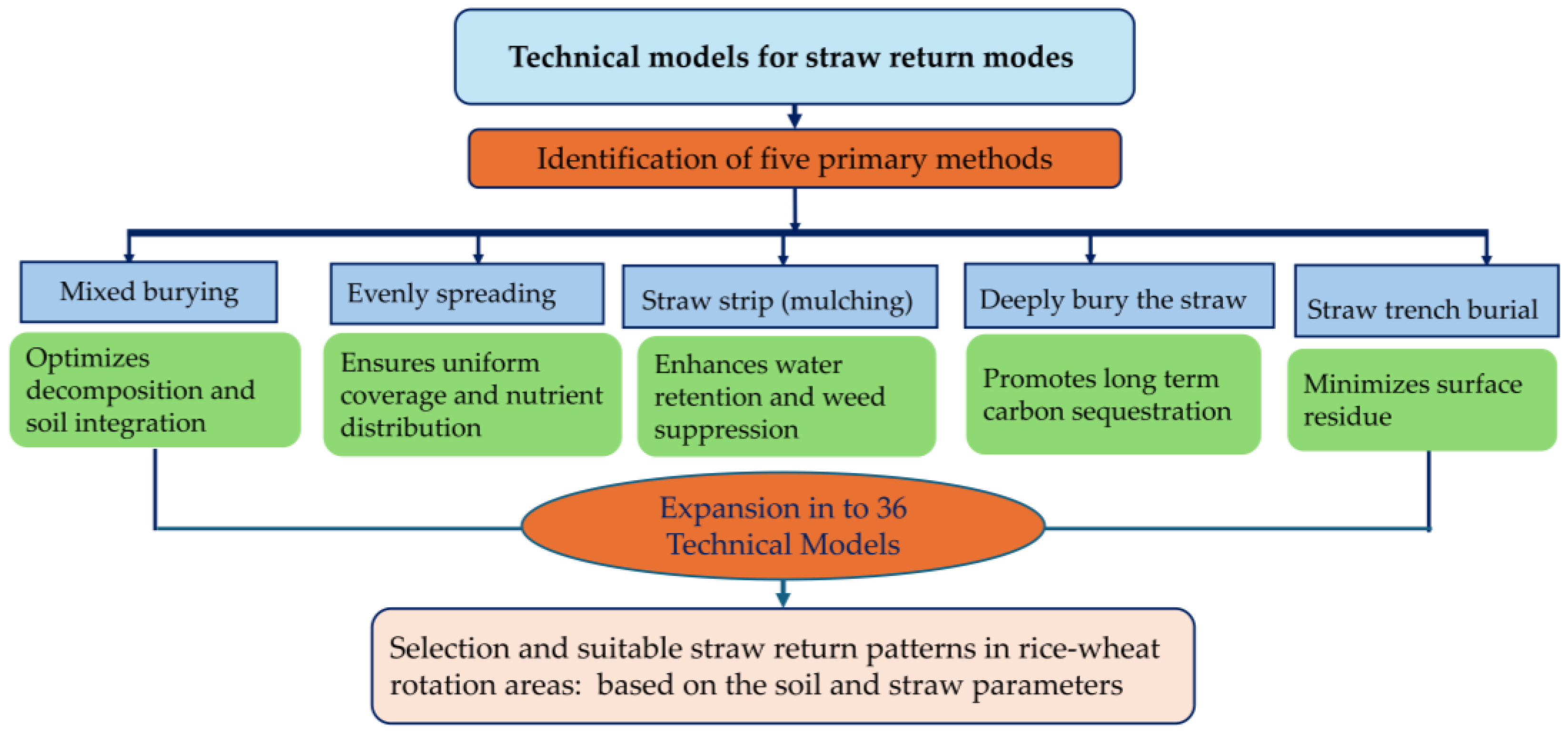

We hypothesize that integrating spatial and temporal variability into straw return strategies will enhance straw decomposition efficiency and improve soil physical and chemical properties. The practices of straw return are focused on developing and examining 36 technical models of straw return, accounting for the spatial and temporal factors in order to choose the best management practices. Specifically, the research objectives include (i) classifying straw return modalities based on their spatial and temporal characteristics and (ii) assessing the spatial and temporal distribution characteristics of different straw return methods. Thus, this study filled an important gap in the current body of literature and argues for innovative strategies that enhance the sustainability of rice–wheat rotational cropping systems.

2. Materials and Methods

2.1. Study Area

The technical models for straw return modes were developed based on a study area in Babaiqiao Town (118°59′ E, 31°98′ N), Luhe District, Nanjing, Jiangsu Province, China, within a typical tableland landscape. This region lies in the lower reaches of the Yangtze River basin, where rice–wheat rotation has been practiced for several decades. The rice is typically planted in early June, while wheat is sowed in early November each year. The study area is selected due to its relevance in rice–wheat cropping systems and the long history of straw return practices in the region. The soil at the site is clay loam in texture, composed of 21.30% sand, 39.84% silt, and 38.86% clay.

2.2. Soil and Straw Parameters

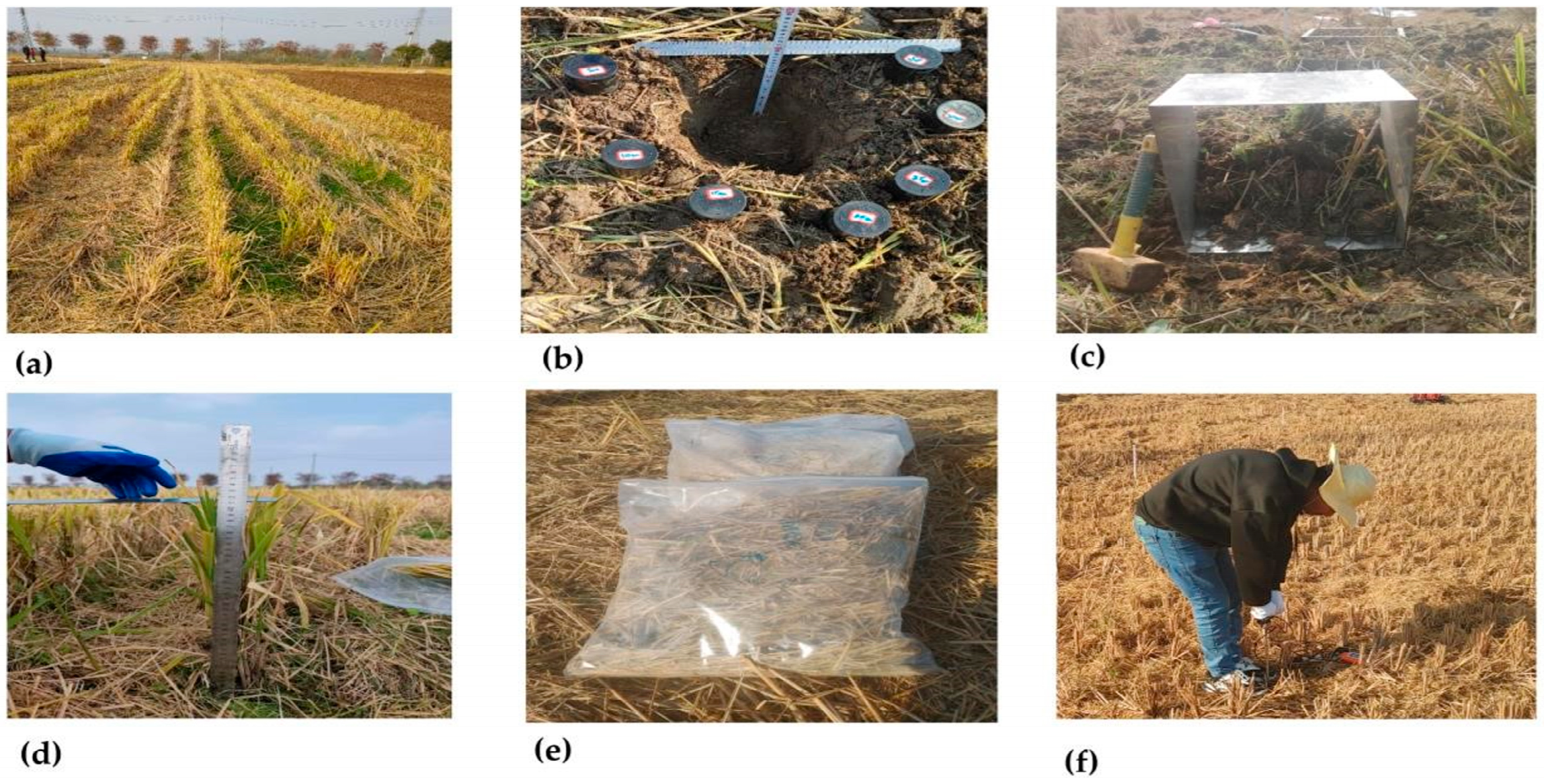

Soil and straw parameters are crucial in determining the selection and suitability of straw return strategies in agricultural systems. Samples of soil and straw were collected from the study area, shown in

Figure 1. Soil properties were water content, bulk density, and porosity that influence the decomposition of returned straw and its integration into the soil [

18]. All measurements were conducted in triplicate (n = 3 per depth interval, 0–20 cm). High water retention capacity and low bulk density facilitate better aeration and water infiltration, enhancing straw incorporation efficiency strategies. Uniformly distributed straw with appropriate density and coverage ensures better soil protection, reduced water evaporation, and enhanced soil moisture conservation [

19].

2.2.1. Soil Moisture Content

Place the soil sample in an aluminum box and weigh it on an analytical balance. After the wet weight is measured, place the soil sample in an oven at 105 °C for 24 h. Weigh the dry weight of the soil sample after 24 h [

20]. The soil moisture content was calculated using Formula (1):

where

—soil moisture content (%);

—soil wet weight (g);

—soil dry weight (g).

2.2.2. Bulk Density

Place the soil sample in an oven at 105 °C for 24 h and weigh the soil dry weight. Use Formula (2) to calculate the soil dry density [

21]. The bulk density is expressed as

where

is the bulk density (g/cm

3),

is the dry mass of soil (g), and

is the volume of the core (cm

3).

2.2.3. Porosity

The porosity (f) of the soil reflects the proportion of pore spaces available for air and water movement and storage. It was calculated from the bulk density and the particle density (

ρb), assuming a particle density of 2.65 g/cm

3 [

20,

21].

where

f is the total porosity (%),

is the bulk density (g/cm

3), and

is the particle density (g/cm

3).

2.2.4. Straw Length

Straw length is a key parameter that affects the uniformity of straw distribution, decomposition rate, and soil coverage. It was measured by taking random samples of straw from the field and measuring their lengths using a ruler [

22].

where

is the average straw length (cm),

is the length of the

straw sample (cm), and n is the total number of straw samples.

2.2.5. Straw Density

Straw density refers to the mass of straw per unit area and is essential for determining the level of coverage and its impact on soil properties. It was calculated by collecting straw from a known area and weighing it after drying [

23].

where

is the straw density (kg/m

2),

is the mass of straw collected from a specific area (kg), and A is the area sampled (m

2).

2.3. Data Collection

Data collection was a fundamental step in this study, beginning with the retrieval of relevant publications from major scientific databases, including Elsevier, ScienceDirect, Springer, MDPI, and Taylor & Francis. To ensure efficient screening, all retrieved articles were compiled into a structured database. The literature search was performed using specific keywords such as mixed burial, even spreading, strip mulching, deep burial, ditch burial, and spatial temporal variability in the title, abstract, or keywords. Additionally, peer-reviewed articles indexed in Clarivate Web of Science and Scopus were utilized to validate results and uncover relevant studies. Google Scholar was used to conduct forward citation searches to find any possibly ignored but important works. All authors looked, and the most recent update was on 12 June 2025. Titles and abstracts were used to screen. The studies were design and analysis of novel technical models for straw return based on inclusion criteria, whereby there was a focus on straw return practices, analyzing straw return, examining spatial–temporal variability interactions, and focusing on the most recent studies from the last 10 years to ensure relevance and up-to-date methodology. A summary table of site conditions (soil type, climatic factors, and crop management) and the key study focus relevant to the reviewed models is found in

Supplementary Table S1.

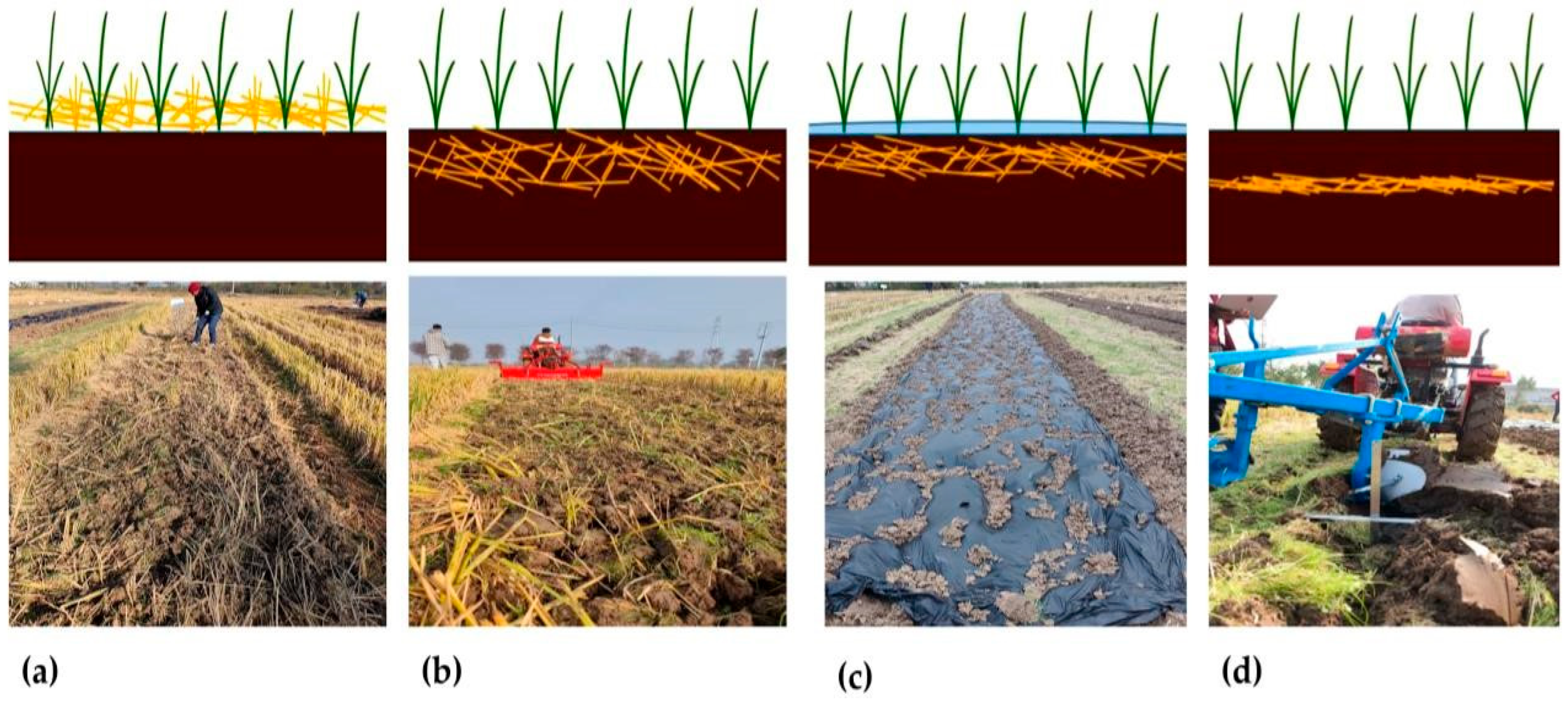

2.4. Design and Agronomic Principles

Rice–wheat rotation has been practiced for several decades; rice cultivation follows a structured planting pattern. A common row spacing of 300 mm, plant spacing between 250 mm, and a planting depth of 20–40 mm is maintained to promote optimal tillering and enhance yield potential. The region’s soil composition varies, with alluvial soil being the most favorable due to its loose structure, high fertility, and excellent water and nutrient retention capacity. The alluvial soil layer typically extends up to 200 mm in depth, while the plow subsoil layer beneath it reaches approximately 300 mm. Straw is evenly spread over the field after the rice harvest to create a 100–150 mm thick layer, therefore enhancing soil organic matter and supporting sustainable rice–wheat rotation. A soil structure split into three separate layers: the straw layer, the plow layer, and the deep plow subsoil layer depicts in (

Figure 2).

For the optimum return of straw and soil sustainability, improved straw management strategy includes soil, straw, plastic film, and decomposing agents. A returning machine for straw is used to uniformly apply decomposing agents on the surface of the straw when blending it into the soil [

24]. This approach increases decomposition of straws, thus enhancing the soil with macro-nutrients, i.e., nitrogen (N), phosphorus (P), and potassium (K). Furthermore, it increases the microbial activity, increases soil organic matter, and enhances soil structure by reducing its bulk density. Utilization of plastic film covering also helps in preserving moisture and temperature, therefore facilitating a more effective mechanism of releasing nutrients.

2.5. Design and Technical Models for Straw Return Modes

2.5.1. Topsoil Shallow Rotation

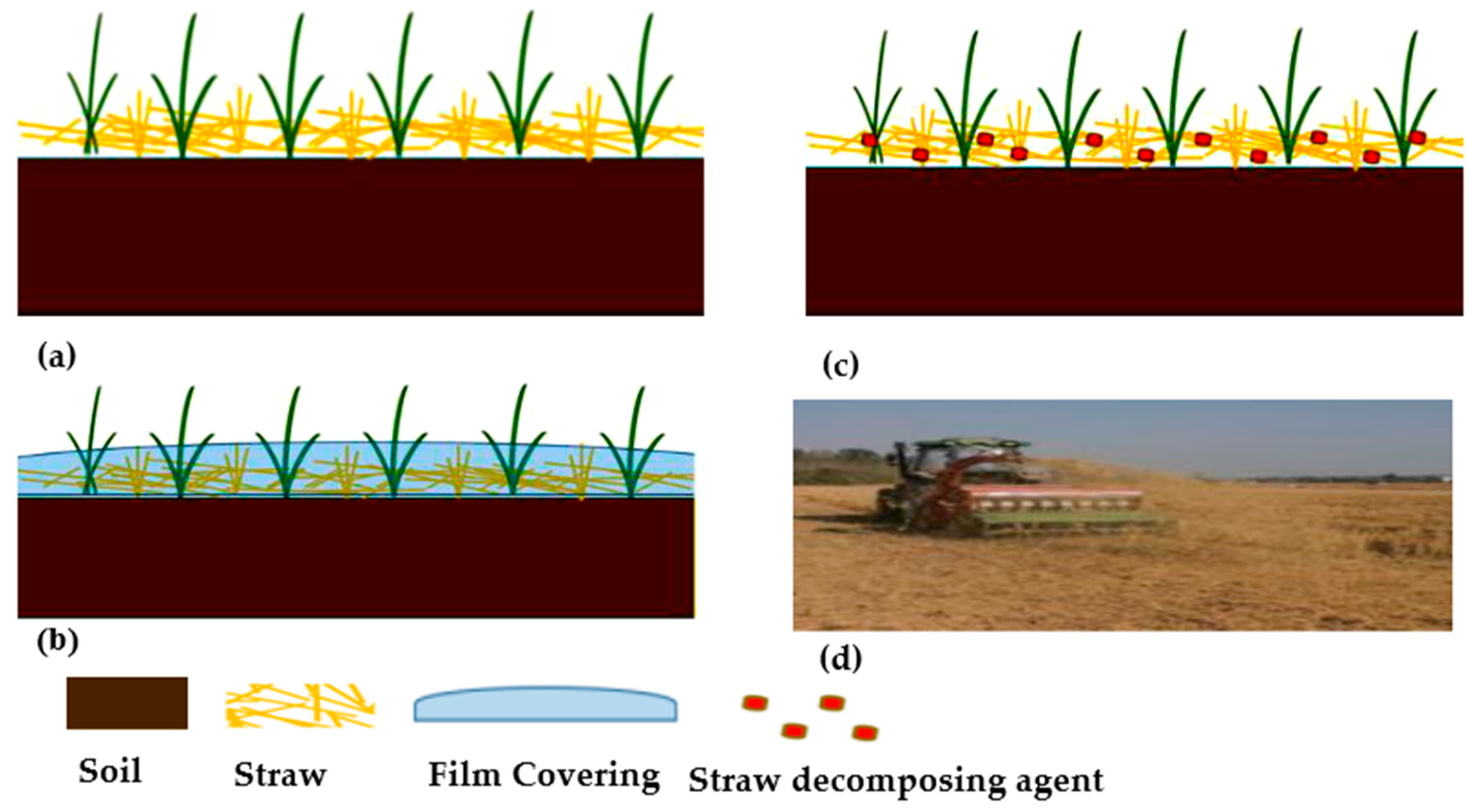

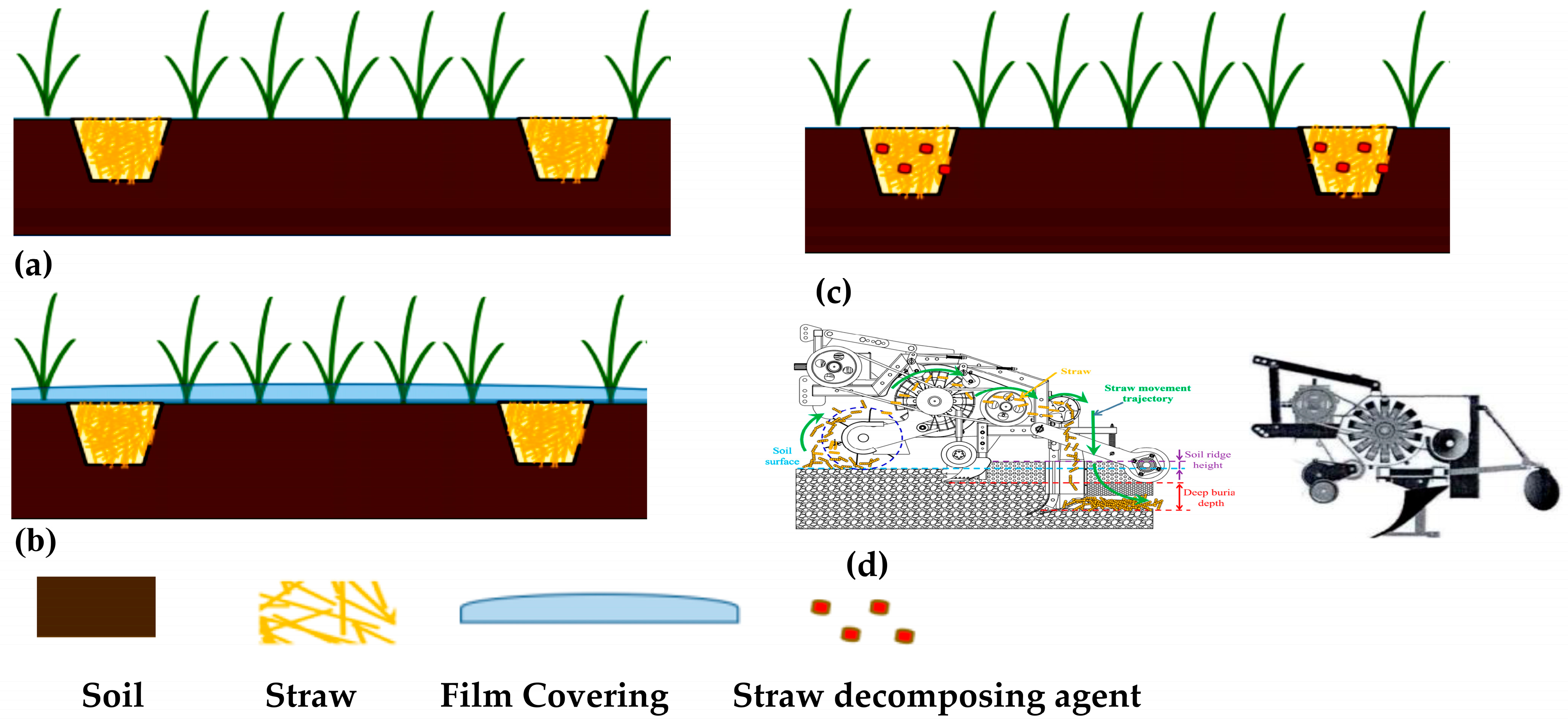

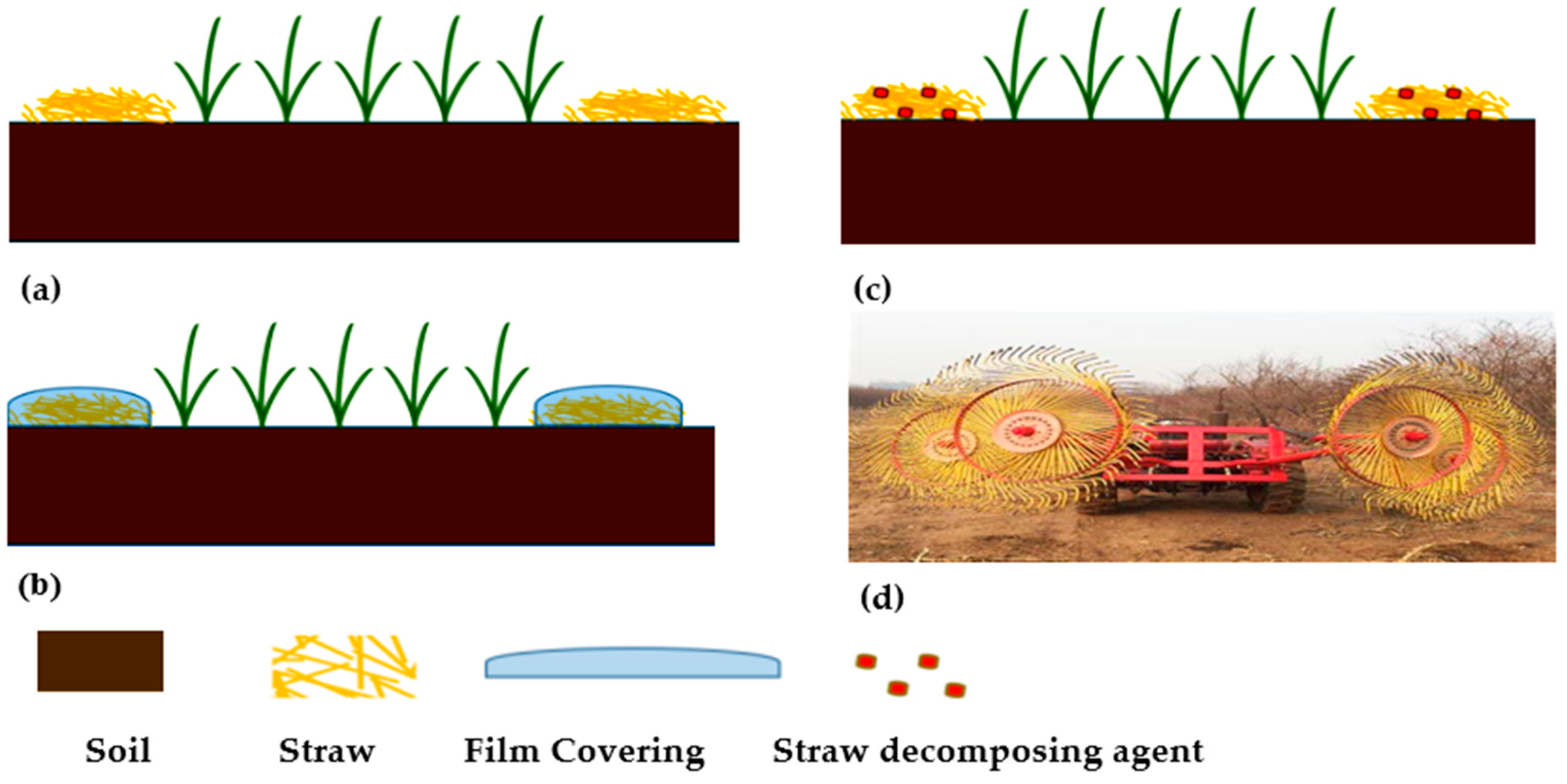

According to

Figure 3a, the shallow rotation of the topsoil assists in the conservation of soil in rice–wheat cultivation. This approach increases soil structure, nutrient cycling, and crops output. It minimizes soil disturbance, and builds organic matter from returned straw and losses in nitrogen. Important farming factors include organic carbon in the soil, activity of the microbes in the soil, and porosity of the soil. There are shallow rotary tillers with straw mulchers as tools that help in this approach. Proper till depth which should lay between 5 to 10 cm, effective straw mixing, and appropriate soil moisture preservation are a basis for a successful operation of this system [

25]. Specific objectives of shallow topsoil rotation are the preservation of soil balance, and reduction of gas emissions, as well as improvement of breathable air in the ground. The method develops outstanding soil quality and promotes sustainable agriculture systems and maintains environment in the active rice–wheat cultivation domains [

26].

Topsoil shallow rotation combined with film mulching is a fundamental way to enhance the soil health and the yield production in rice–wheat agricultural fields, as shown in

Figure 3b. The farming process involves crop debris that is brought into surface soil as well as the use of mulch to control temperature, motion of water, and microbial activity. The farming measures include organic matter of the soil, microbial carbon mass, the density of soil, and the rate of water infiltration, and the requisite tools include shallow rotary tillers and straw-cutters combined with no-till planters and soil-residual spreaders. Such technical indicators as optimal mulch coverage percentage (30–50 percent), decomposition rates, and dynamics of soil respiration define the efficiency of this practice [

25,

27]. This technique improves soil structure, increases nutrient use, and mitigates environmental challenges.

Figure 3c depicts a novel straw return system combining topsoil shallow rotation with decomposer additives to both speed up residue breakdown and maintain soil structure in rice–wheat rotational systems. Straw is incorporated shallowly into the top 5–10 cm of soil as microbial or chemical decomposer agents are used to boost microbial activity and speed up lignocellulose decomposition and increase nutrient availability [

28,

29]. The main agronomic parameters include soil microbial biomass carbon, enzymatic activity, and both soil organic carbon quantity and nitrogen mineralization rates. Various tools used as support equipment consist of shallow rotary tillers as well as precision decomposer sprayers, straw shredders, and depth-controlled rakes. The efficiency of this practice depends on technical indicators, which include straw decomposition rate as well as carbon-to-nitrogen ratio adjustment and soil respiration rates.

2.5.2. Conventional Rotary Plowing

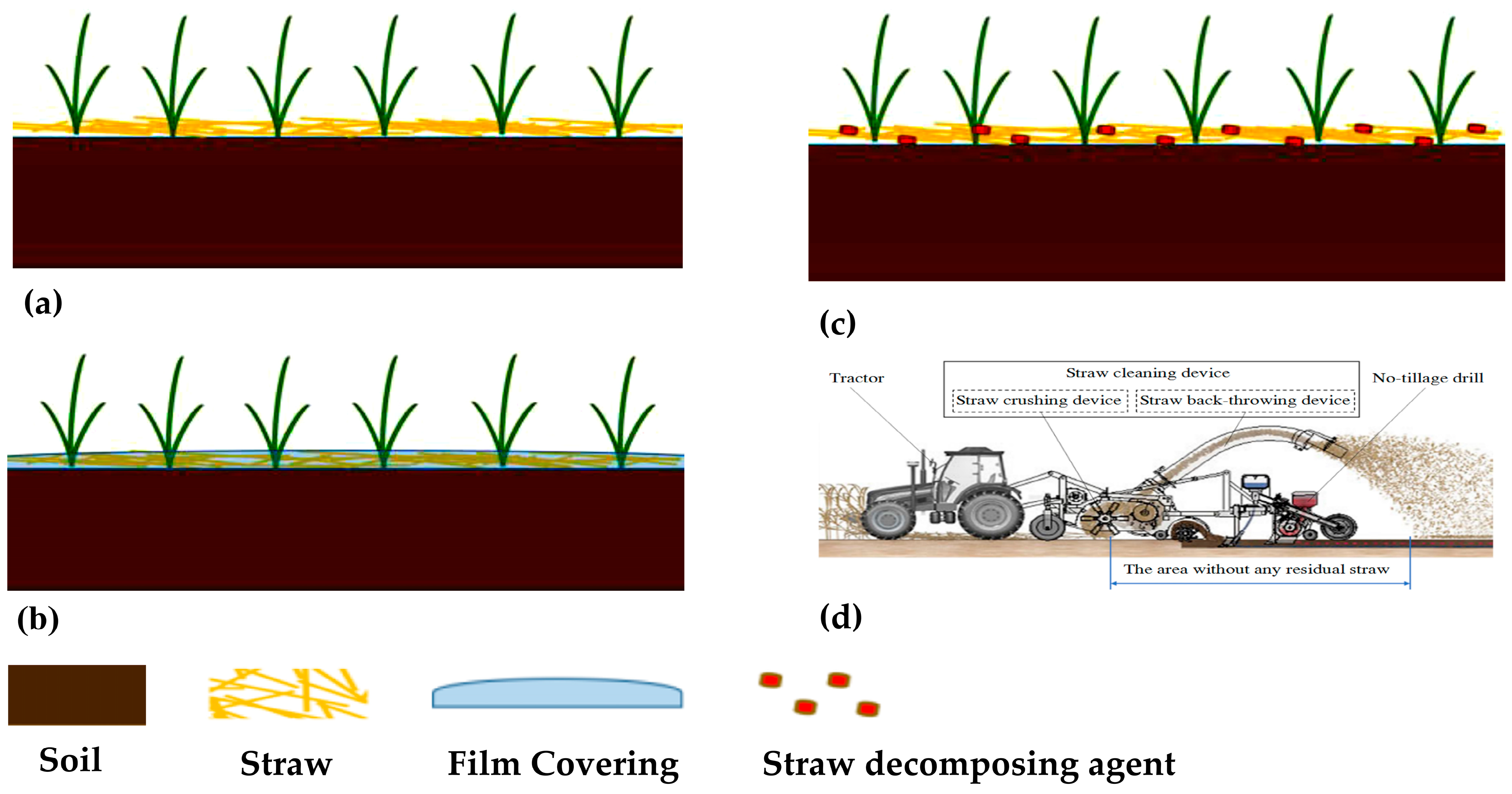

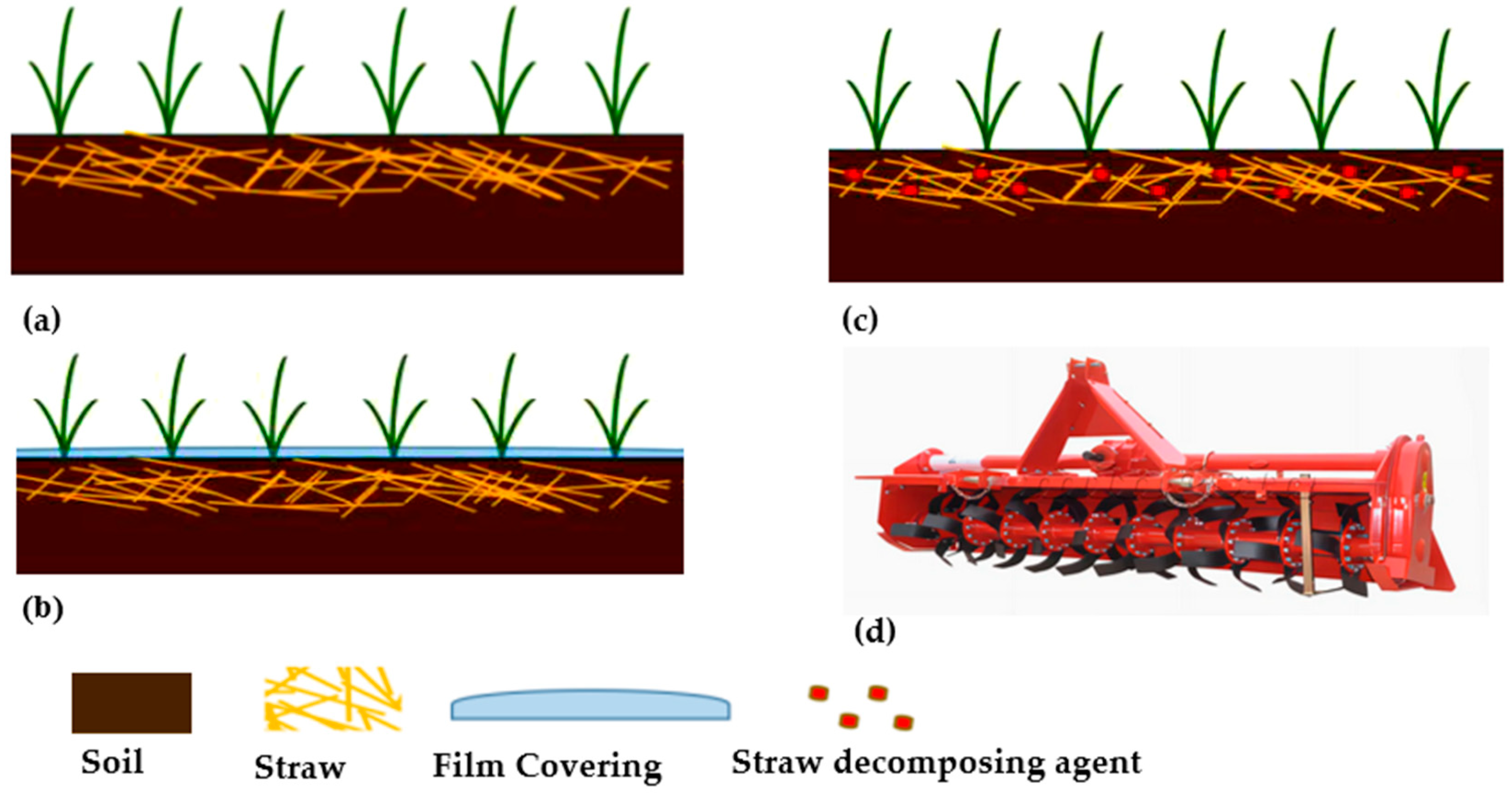

Figure 4a illustrates the conventional rotary plowing that is a widely used tillage practice in rice–wheat systems, allowing for the efficient incorporation of crop residues like straw into the soil while preparing the seedbed for subsequent crops. Key parameters influencing its effectiveness include plowing depth (10–20 cm), rotor speed (150–300 rpm), and forward speed (2–5 km/h). Supporting equipment includes tractor-mounted rotary tillers with L-shaped blades for soil cutting, pulverization, and residue mixing. Advanced models may include adjustable depth control systems and hydraulic mechanisms to optimize performance across different soil conditions. Technical indicators for evaluating rotary plowing include soil tilth quality, residue incorporation rate (>80%), and fuel consumption per unit area [

30,

31]. Agronomic parameters like soil moisture content (18–22%), organic matter distribution, and weed suppression are critical for success. Conventional rotary plowing aims to enhance soil aeration, promote microbial decomposition of incorporated straw, and minimize soil compaction, supporting sustainable crop productivity.

Figure 4b indicates that the conventional rotary tillage combined with film mulching is an innovative method in rice–wheat systems to improve soil health, conserve moisture, and boost crop productivity. The parameters governing this practice include tillage depth (10–20 cm), rotor speed (150–300 rpm), and film thickness (0.008–0.012 mm), which affect soil structure, residue incorporation, and microclimate regulation. Supporting equipment includes tractor-mounted rotary tillers with L-shaped blades for soil pulverization and residue mixing, and mechanical film-laying machines for precise mulch application. Technical indicators for evaluating this practice include soil temperature modulation (2–5 °C increase under mulch), moisture retention efficiency (aiming for 20–30% reduction in evaporation), and residue decomposition rate [

30,

32,

33]. Some of the agronomic attributes such as the content of organic carbon in the soil, weed suppression, and crop yield response measure are essential to evaluate the efficiency of this method. Film mulching makes these effects even better because soil temperature can be managed, weed development is suppressed, and the soil moisture is conserved, contributing to the sustainable intensification in rice–wheat systems.

Figure 4c indicates that the traditional rotary tillage and decomposer agents are a combination that promotes straw decompositions and soil fertility in rice–wheat systems. The parameters important for this practice are depth of tillage (10–20 cm), speed of the rotor (150–300 rpm) and decomposer application rate (2–5 kg/ha) affecting soil-residue interaction, microbial activity, and nutrition release. Associated equipment consists of tillers on tractor for pulverization of the soil and mixing of residues and sprayers or granular applicators for even application of decomposers. High-level systems could adopt precision agriculture technologies that would help optimize the dosage of decomposers depending on the residue load and the soil conditions. Technical indicators with which to assess this practice include straw rate of composting (>70% within 30–60 days), soil microbial biomass carbon, and nutrient availability [

5,

32]. Such agronomic characteristics as the level of soil organic matter content, crop yield response, and weed reduction are important for evaluating the general performance of this approach.

2.5.3. Deep Rotary Plowing

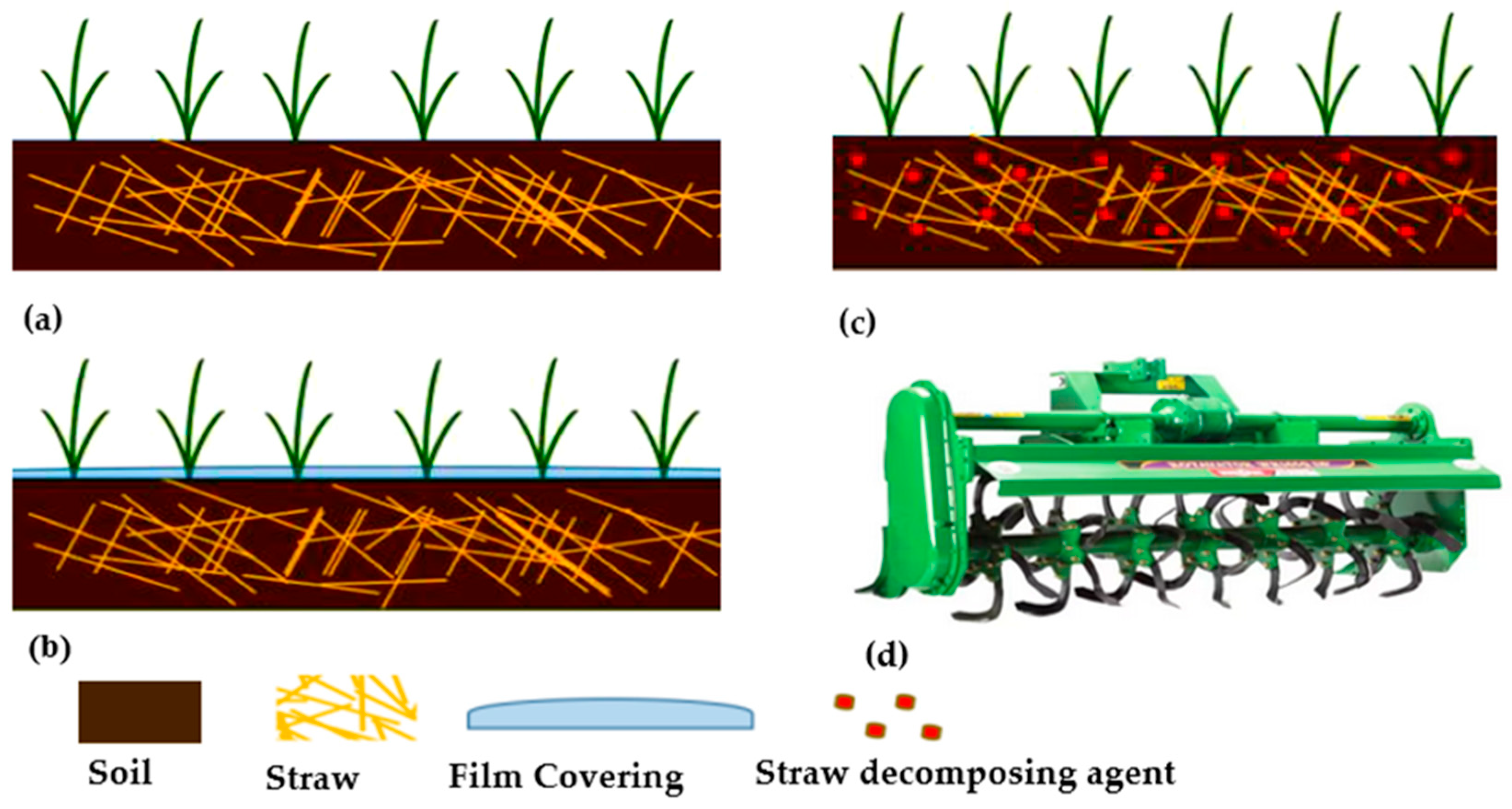

Figure 5a indicates that the deep rotary plowing is a tillage practice in rice–wheat systems that enhances the structure of the soil, incorporation of residue, and long-term health since it functions more deeply than conventional tillage. It is characterized by conventional plowing depth (15–30 cm), rotor speed (100–200 rpm), and forward speed (2–4 km/h) in influencing soil loosening, and residue burial. The equipment that provides support also consists of tractor-mounted rotary plows with deep-diving blades/tines. Technical indicators for evaluations of deep rotary plowing include reduction in bulk density of soil (10–20%), particles incorporation (>90%), and fuel consumption per unit area [

33,

34]. Some of the agronomic parameters such as soil organic carbon distribution, depth of root penetration, and levels of water infiltration play crucial roles in determining the benefits of this practice. The concepts of deep rotary plowing are breaking up snow lands, improving aeration and preservation of water, and encouraging straw decay.

Figure 5b shows that deep rotary plowing and film mulching are critical technologies of rice–wheat systems for straw return to influence soil structural development, nutrient cycling, and crop growth. Important parameters are tillage depth (15–30 cm), soil fragmentation index, and rotary speed (100–200 rpm), influencing soil aeration and rate of return straws’ decomposition. Some of the supporting tools are rotary tillers and special film-laying machines for uniform mulching cover. Technical indicators, such as soil moisture retention, temperature regulation, and the efficiency of organic matter decomposition, are the key metrics for evaluation of the effectiveness of the technique [

27,

35]. The suitability of deep rotary plowing and mulching in various contexts depends on such agronomic parameters as microbial activity, root penetration depth, and water-use efficiency.

Figure 5 depicts that the deep rotary tillage incorporation with the decomposer agents is a vital straw return technology in rice–wheat systems, as it increases the efficiency of straw decomposition and soil health. Technical parameters, such as tillage depth (15–30 cm), and rotary speed (100–200 rpm), as well as decomposer agent’s application, affect the activity of microorganisms and decomposition of organic substances. Supporting equipment includes rotary tillers and precision sprayers for effective incorporation of straw. Technical indicators such as decomposition rate, soil microbial biomass, carbon-to-nitrogen, and dynamics of nutrient release are critical in finding out the effectiveness of the system involved [

5,

36]. Phenomena such as soil organic matter levels, moisture retention capacity, and root elongation, as well as rate of nitrogen mineralization, are agronomic factors that contribute to this phenomenon. Such an approach increases the microbial decomposition of straw by enhancing optimal tillage-induced aeration and biochemical support to increase the availability of nutrients and sustainable fertility of the soil.

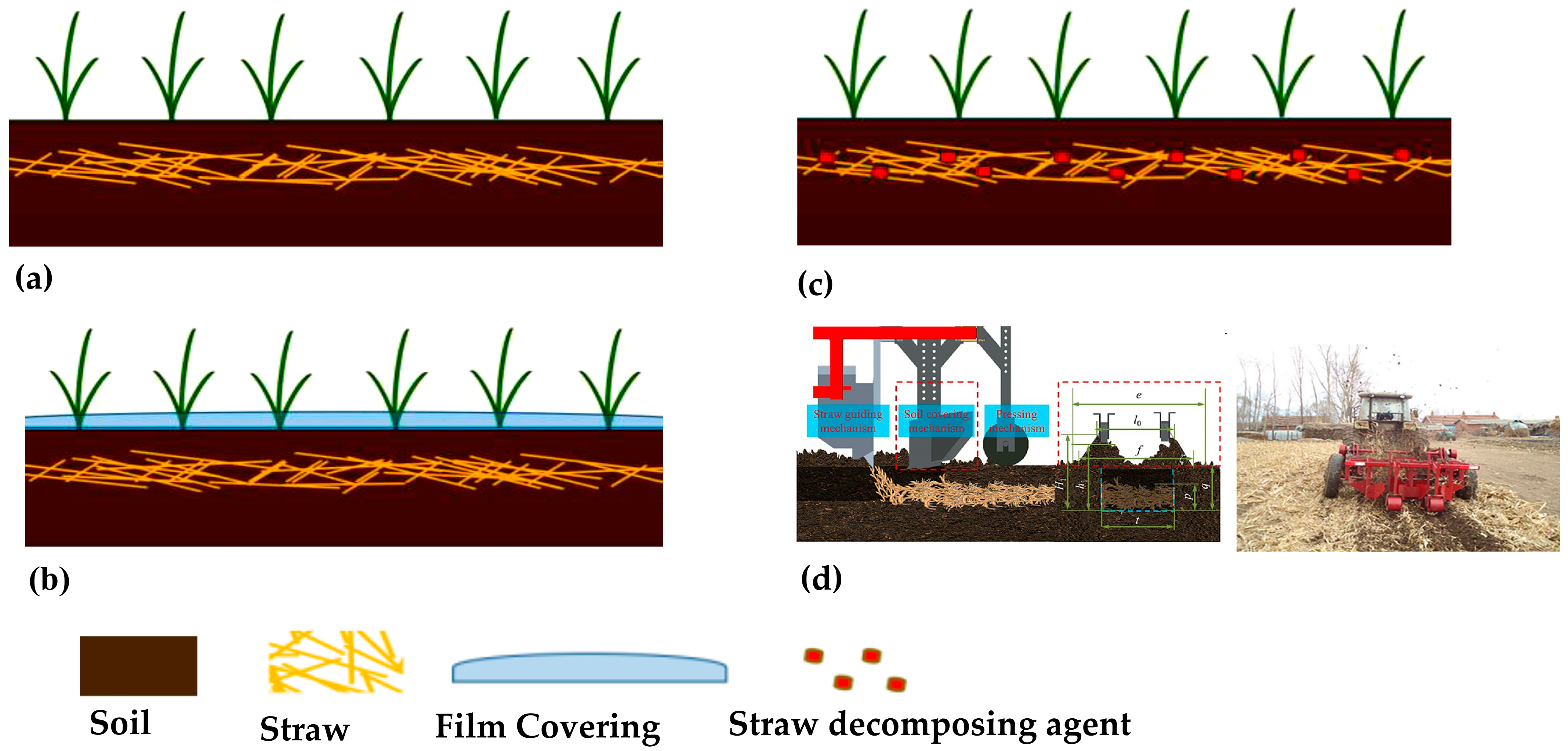

2.5.4. Even Spreading of Stubble Straw

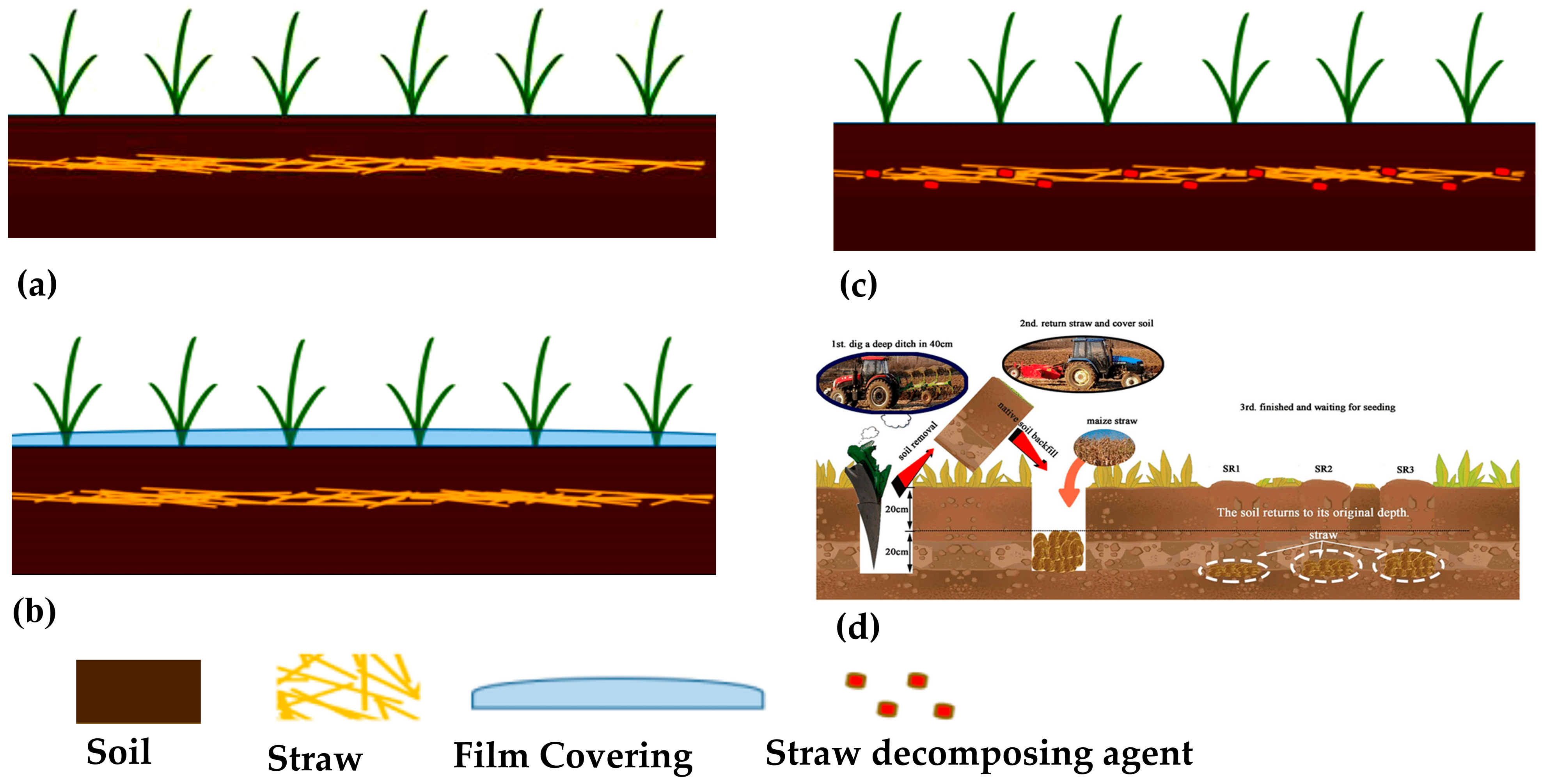

Figure 6a shows that the even spreading of stubble straw in rice–wheat systems is a very important agronomic technique through which there is the uniform breakdown and cycling of nutrients leading to the improvement of soil health. Key parameters are straw length, moisture content, and distribution density, that impact on straw incorporation. Supporting equipment such as straw spreaders, choppers, and still balers are built to accomplish equal distribution of straws, with adjustable features to regulate length of cutting, the width, and the intensity of spreading. Technical indicators such as the spreading uniformity and operating efficiency are some of the indicators used to measure the performance of equipment [

30,

37]. Agronomic parameters, such as SOC content, microbial activity, and crop yield response are monitored to determine the effects of even straw distribution in the long term. The practice helps reduce straw clumping and promote contact of straw and soil for improved microbial decomposition.

In

Figure 6b, covering, and even spreading of stubble straw in rice–wheat systems is the approach which employs advanced agronomic measures to enhance the state of soil health, moisture conservation, and nutrient cycling. Some crucial parameters are straw length, moisture content, film thickness, and coverage density, which have an impact on straw decomposition and regulation of the microclimate of soil. Supporting equipment, including straw spreaders, film-laying machines, and combined straw-film applicators, guarantee a good coverage of straw and precise film placement [

27,

38]. Technical indicators such as film coverage, straw spreading uniformity, and operational productivity are essential for the evaluation of performance. Agronomic variables such as soil temperature, moisture holding capacity, microbial activity, and response of the crop yield are scrutinized to measure the long-term advantage of this practice.

Figure 6c shows that the uniform spread of stubble straw and use of decomposer agents in rice–wheat systems is to enhance straw decomposition, nutrient cycling, and soil health. Some of the important parameters are straw length, moisture content, distribution density, and decomposer agent concentration. It is accompanied by the supporting equipment: straw spreaders, sprayers, and combined straw-decomposer applicators that guarantee the uniform spreading of the straw and the accurate application of the decomposer agents. These machines are designed to control straw cutting length, spreading width, and spray volume, ensuring compatibility with varying field conditions and straw loads. Technical indicators like spreading uniformity, decomposer application accuracy, and operational efficiency are critical for assessing system performance [

5,

39]. Agronomic parameters like soil organic carbon content, microbial biomass, enzyme activity, and crop yield response are monitored to evaluate the long-term impacts of this practice. The principles underlying even straw spreading and decomposer application emphasize creating optimal conditions for microbial activity, such as maintaining adequate moisture and temperature levels, while ensuring uniform straw–soil contact to accelerate decomposition.

Figure 6.

Extended returning mode based on straw evenly spreading: (

a) even spreading of stubble straw; (

b) film covering and even spreading of stubble straw; and (

c) even spreading of stubble straw and application of decomposers; (

d) straw picker, breaker and spreading device [

40].

Figure 6.

Extended returning mode based on straw evenly spreading: (

a) even spreading of stubble straw; (

b) film covering and even spreading of stubble straw; and (

c) even spreading of stubble straw and application of decomposers; (

d) straw picker, breaker and spreading device [

40].

2.5.5. No Stubble and Even Spreading of Straw

Figure 7a, showing the no stubble and even spreading of straw is practice in rice–wheat systems aim to optimize straw management to improve soil health, nutrient cycling, and crop productivity without retaining stubble. Key parameters include straw length, moisture content, distribution density, and incorporation depth. Supporting equipment like straw choppers, spreaders, and rotary tillers are designed to achieve uniform straw distribution and thorough incorporation into the soil. Technical indicators like spreading uniformity, incorporation efficiency, and operational productivity are critical for assessing system performance [

30,

41]. Agronomic parameters like soil organic carbon content, microbial activity, nutrient availability, and crop yield response are monitored to evaluate the long-term impacts of this practice. The principles emphasize minimizing residue interference with seedbed preparation and crop emergence while maximizing straw–soil contact to accelerate decomposition and nutrient release.

Figure 7b indicates that the even spreading of straw without stubble combined with film mulching is a straw return technique in rice–wheat systems, aiming to enhance soil fertility, and improve residue decomposition. Technical parameters such as the chopping length of straw, spreading uniformity coefficient, film thickness, permeability rate, and soil coverage ratio are concerned, and they regulate microbial activity, conservation of moisture, and weed suppression. The availability of supporting equipment, such as straw choppers, uniform distribution devices, and film-laying machines, is essential for improving operational efficiency. Technical indicators such as soil moisture retention capacity, temperature regulation efficiency, decomposition rate, and weed suppression index are of high significance for assessing this technique effectiveness [

42,

43]. Agronomic parameters such as rate of germination, root zone aeration, nutrient mineralization, and microbial biomass activity define the approach applicability to the various conditions. The purpose of the approach is to optimize straw decomposition with an exclusion of bulky stubble residues. holding soil moisture and temperature, and suppression of weed competition.

Figure 7.

Extended returning mode based on no stubble and even spreading of straw: (

a) no stubble and even spreading of straw; (

b) even spreading of straw without stubble and mulching; (

c) even spreading of straw without stubble and application of decomposing agents; and (

d) straw crushing device and the straw back-throwing device [

44].

Figure 7.

Extended returning mode based on no stubble and even spreading of straw: (

a) no stubble and even spreading of straw; (

b) even spreading of straw without stubble and mulching; (

c) even spreading of straw without stubble and application of decomposing agents; and (

d) straw crushing device and the straw back-throwing device [

44].

A technique used to improve decomposition, nutrient cycling, and soil health is the uniform application of decomposing agents and stubble-free straw in rice–wheat systems, as shown in

Figure 7c. Key parameters include straw length, moisture content, distribution density, decomposing agent concentration, and application rate. Supporting equipment, such as straw choppers, spreaders, and sprayers, ensure uniform straw distribution and application of decomposing agents. Technical indicators like spreading uniformity, decomposing agent coverage, and operational efficiency are critical for assessing system performance [

5,

45]. Agronomic parameters like soil organic carbon content, microbial biomass, enzyme activity, nutrient availability, and crop yield response are monitored to evaluate the long-term impacts of this practice. The principles emphasize creating optimal conditions for microbial activity, maintaining adequate moisture and temperature levels, and ensuring even straw–soil contact to accelerate decomposition and nutrient release.

2.5.6. Straw Inter-Row Mulching

As indicated by

Figure 8a, straw inter-row mulching is a crucial technique in rice–wheat systems, affecting soil properties, moisture retention, and crop productivity. It involves parameters like mulch thickness, decomposition rate, and spatial distribution, which impact nutrient cycling and microbial activity. Supporting equipment includes straw choppers, row mulchers, and no-till seeders with residue management functions. Technical indicators include mulch coverage percentage, decomposition efficiency, and soil temperature and moisture conservation [

46,

47]. Through agronomic factors such as nitrogen release dynamics, weed suppression, and crop emergence rate, it is vital to assess the efficacy of this technique. Principles underlying straw inter-row mulching centers on increasing the fertility of the soil, and minimizing losses through evaporation, as well as the reduction of greenhouse gas emissions through the controlled decomposition of the straws.

As depicted in

Figure 8b, one of the techniques entails using the film covering technique which involves the combination of straw inter-row mulching and is a way of optimizing soil moisture, temperature regulation, nutrient cycling in the rice–wheat systems. Its effectiveness is determined by some of the key parameters such as film thickness, light transmittance, straw mulch depth, and decomposition rate. Some of the supporting equipment is film-laying machines, straw mulchers, and precision seeders. Technical indicators are cinematic degradation rate, soil temperature fluctuations, water retention capacity, and weed suppression [

42,

48]. Such agronomic parameters as emergence rate of seedlings, root zone temperature, organic matter accumulation in soil, and dynamics of mineralization of nitrogen should also be used in assessing its effectiveness. The fundamental principles of this method are based on improving soil–water dynamics, reducing evaporation, maximizing nutrient retention, and establishing a favorable microenvironment for plants.

In

Figure 8c it is revealed that straw inter-row mulching with decomposer agents can speed up the straw decomposition rate, enhance soil fertility, and raise crop yields in rice–wheat programs. Affecting factors of this technique include mulch thickness, decomposition rate, microbial activity, and carbon-to-nitrogen (C:N) ratio adjustments. Efficiency depends on temperature, moisture content, and decomposer agent composition. Supporting equipment includes straw mulchers, precision sprayers, and no-till seeders. Technical indicators include decomposition rate, soil organic matter content, nutrient release dynamics, and microbial biomass activity [

46,

47]. Agronomic parameters like nitrogen mineralization, seed germination rate, and weed suppression capacity are crucial for evaluating the system’s impact on crop growth.

2.5.7. Straw Seedbed Collection

Figure 9a indicates that the straw seedbed harvest is an important facet in rice–wheat systems with a specific view towards the effective harvesting of crop residues for the development of seedbeds for planting. Key parameters include residue collection, moisture content of the straw, and collection timing relative to crop harvest. Mechanical balers, rakes, and straw collectors are used to collect residues with minimal soil disruptions and ensure uniform seedbed conditions. Technical indicators such as residue removal rate, soil compaction levels, and seedbed quality relating to this technology assess on performance [

49,

50]. Agronomic factors such as seedling emergence rate, root system development, and early crop vigor can all directly correlate to the quality of the ground, which is in itself maximized by good straw gathering and residual care. The principles for straw seedbed collection integrate spatial and temporal variability to suit residue removal strategies to specific field conditions.

Figure 9b shows that the straw seedbed collection in combination with the film mulching is a new approach that maximizes seedbed condition and holds moisture in the soil and increased nutrients availability in the rice–wheat system. Important parameters are straw collection efficiency, mulch covering rate, thickness of film, temperature regulation of the soil, and decomposition dynamics. By this method, seedling emergence is improved, reducing rate of evaporation and increasing microbial activity for breaking down of organic matter. Driving devices are additional equipment, such as straw collectors, balers, rotary tillers, film-laying machines, and precision seeders with residue and film management capabilities [

49,

51]. Some of the technical indicators are straw removal rate, film degradation rate, soil moisture conservation efficiency, and temperature stabilization capacity. It has a direction toward persistent soil structure, attenuation of water outflow, and fostering of sustainable decomposition practices due to the measured residues management and film technology.

As shown in

Figure 9c, the straw seedbed collection with decomposing agents is an upgraded residue management practice to optimize seedbed status, hasten decomposition of the straw, and enhance soil fertility under rice–wheat systems. Major determinants of this technique include straw collection efficiency, decomposition rate, level of microbial activity, soil organic matter transformation, and carbon-to-nitrogen (C: N) ratio adjustments. Decomposition efficiency is conditional on environmental factors such as temperature, moisture content, and microbial decomposers. Aiding equipment are straw collectors, balers, precision sprayers, and no-till seeders with residue management capacities. Technical indicators include decomposition efficiency, soil organic matter content, nitrogen mineralization rate, and soil aeration improvements [

45,

52]. Agronomic parameters like seed germination rate, root growth, nutrient release dynamics, and weed suppression capacity are critical for evaluating system performance.

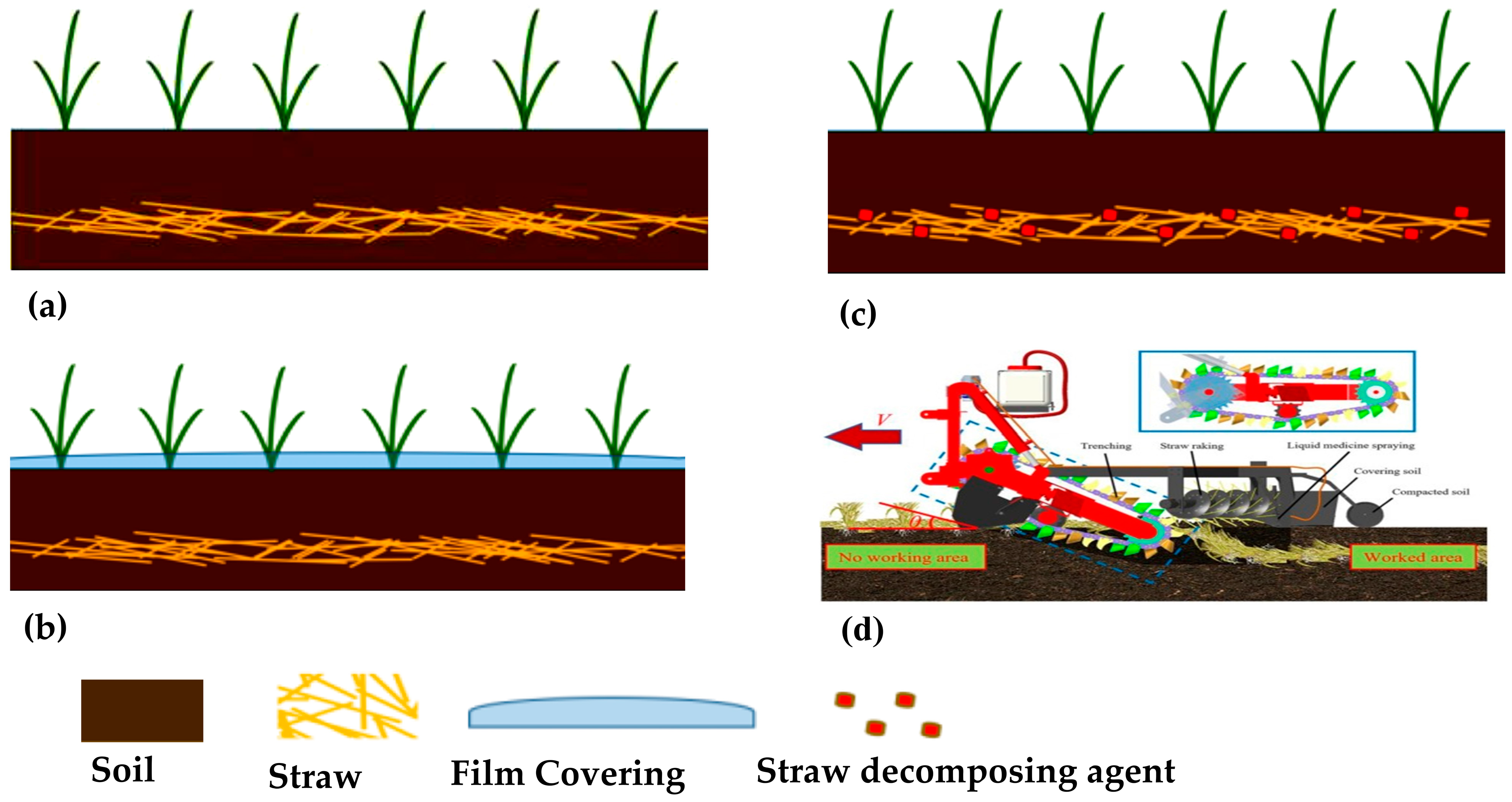

2.5.8. Straw Plowing and Burying

Figure 10a shows that the straw plowing and deep burying are crucial methods in rice–wheat systems to improve soil fertility and organic matter content while reducing straw burning. The effectiveness of this technique depends on soil depth, moisture content, and decomposition rate. Key technical indicators include the depth of incorporation, uniformity of straw distribution, and its impact on soil aeration and microbial activity. Supporting equipment includes moldboard plows, chisel plows, rotary tillers, and straw incorporation machines [

53,

54]. Agronomic parameters like soil texture, nitrogen–carbon balance, and microbial biomass also influence degradation rate and nutrient availability. The principles governing straw plowing and deep burying emphasize maintaining soil structure, enhancing microbial decomposition, and optimizing nutrient cycling.

As can all be seen in

Figure 10b, straw plowing and film mulching is a technique to enhance the soil moisture, increase the rate decomposition of straws, and increase the soil nutrient availability in rice–wheat systems. This technique is based on the use of some of the parameters such as the depth of incorporating the straw (10–20 cm), thickness of mulching, and regulation of soil temperature. Supporting equipment consists of rotary plows, precision straw incorporation machines, and film-laying devices. Indicators of technology include rate of straw decomposition, changes in soil organic matter, and water-use efficiency improvement [

55,

56]. Agronomic parameters such as soil temperature stability, microbial diversity, and N mineralization rate are also very crucial for crop growth. The principles of straw plowing and film mulching are aimed at conserving soil moisture and reducing weed competition, while simultaneously promoting nutrient cycling and plant growth.

Figure 10c shows that straw plough-burying with decomposer agents is a very important strategy for rice–wheat systems for speeding up straw decomposition and enhancing nutrient availability for succeeding crops. A number of factors such as the degree to which straw is incorporated, the moisture content of soil, and the type of decomposer agent used influence the effectiveness of the given technique. Supporting machinery includes rotary tillers, moldboard plows, and machinery for incorporating straw with systems for applications of liquid or granular decomposer. Some technical indicators for assessing this approach include decomposition rate, soil organic carbon and nitrogen content, and dynamics of microbial biomass [

57,

58]. Agronomic parameters like soil pH, carbon-to-nitrogen ratio, and enzyme activity also play a role in optimizing decomposition processes and improving soil health. The principles of this method include speed-up of organic matter mineralization, and enhancement of biodiversity of soil microbes, as well as synchronization of nutrient output with crop growth requirements.

Figure 10.

Straw plowing and burying: (

a) straw plowing and burying; (

b) straw plowing and mulching; (

c) straw plowing and burying and application of decomposers; (

d) the method and process of straw deep burying with three steps [

56].

Figure 10.

Straw plowing and burying: (

a) straw plowing and burying; (

b) straw plowing and mulching; (

c) straw plowing and burying and application of decomposers; (

d) the method and process of straw deep burying with three steps [

56].

2.5.9. Straw Spiral Conveyor Deeply Buried

Figure 11a shows that the straw spiral conveyor deep-burying technique is an advanced straw return mode in rice–wheat systems, designed to enhance deep incorporation efficiency and promote long-term soil fertility. Key parameters affecting this approach are burial depth (25–40 cm), straw distribution uniformity, aeration of soil, and functioning of microbes, which impact decomposition dynamics and nutrient availability. Supporting equipment involves spiral conveyor burying machines, deep plowing devices, and automated straw feeding systems. The principles of this method are aimed at reducing the surface residue interference, enhancement of the subsoil integration of organic matter, and the maximization of the subsoil synchronization of organics straw decomposition and nutrient uptake from the crop. Performance evaluations include decomposition rate, soil organic matter improvement, and aeration levels [

57,

59]. Agronomic factors such as moisturization capability of soil, carbon-to-nitrogen ratio, and microbial enzymatic activity govern the rate of waste disintegration and recycling of nutrients. These are factors that determine the best breakdown of buried straw by microorganisms.

The straw spiral conveyance, deep burial, and film coverage in rice–wheat systems as depicted in

Figure 11b is an ingenious method of return of straw that emphasizes on effective residue management, betterment of soil health, and micro climatic regulation. The technology relies on such keynote parameters as straw length, moisture content, soil texture, and burial depth to govern the rate of decomposition and release of nutrients, as well as soil temperature fluctuations. Sustaining apparatus consists of spiral conveyors, deep tillage implements, optimal depths (20–40 cm), and film-laying machines. Such technical indicators as straw burial efficiency and compaction levels of soil are crucial for performance analysis. The concepts of straw spiral conveying, deep burial, and film covering all point to the synergistic effects of residue incorporation and mulching that strengthens structure of soil, prevents evaporation, and inhibits weed growth, promoting nutrient cycling [

57,

60]. Long-term benefits of this integrated approach in terms of agronomic parameters are monitored through crop yield, soil organic carbon content, and microbial biomass.

Figure 11c represents the straw spiral conveying of a deep burial and that the application of decomposer agents is an improved straw return mode in rice–wheat systems that advances effective decomposition, soil fertility level, and reduction of the surface residue interference. The manner of decomposition relies on different factors such as burial depth (25–40 cm), size of the straw fragments, the soil’s moisture content, and the agents responsible for the decomposition process. Supporting equipment includes spiral conveyor straw-burying machines, deep tillage plows, and decomposer applicators. Performance evaluation includes decomposition rate, soil organic carbon and nitrogen content, microbial activity levels, and soil aeration improvements [

39,

61,

62]. Agronomic parameters like soil pH balance, carbon-to-nitrogen ratio, and enzymatic activity are crucial for optimizing decomposition processes and ensuring nutrient release in line with crop growth demands.

Figure 11.

Straw spiral conveyor deeply buried: (

a) straw spiral conveyor deeply buried; (

b) straw spiral conveying, deep burial, and film covering; (

c) straw spiral conveying, deep burial, and application of decomposers; (

d) the method and process of straw deep burying [

62].

Figure 11.

Straw spiral conveyor deeply buried: (

a) straw spiral conveyor deeply buried; (

b) straw spiral conveying, deep burial, and film covering; (

c) straw spiral conveying, deep burial, and application of decomposers; (

d) the method and process of straw deep burying [

62].

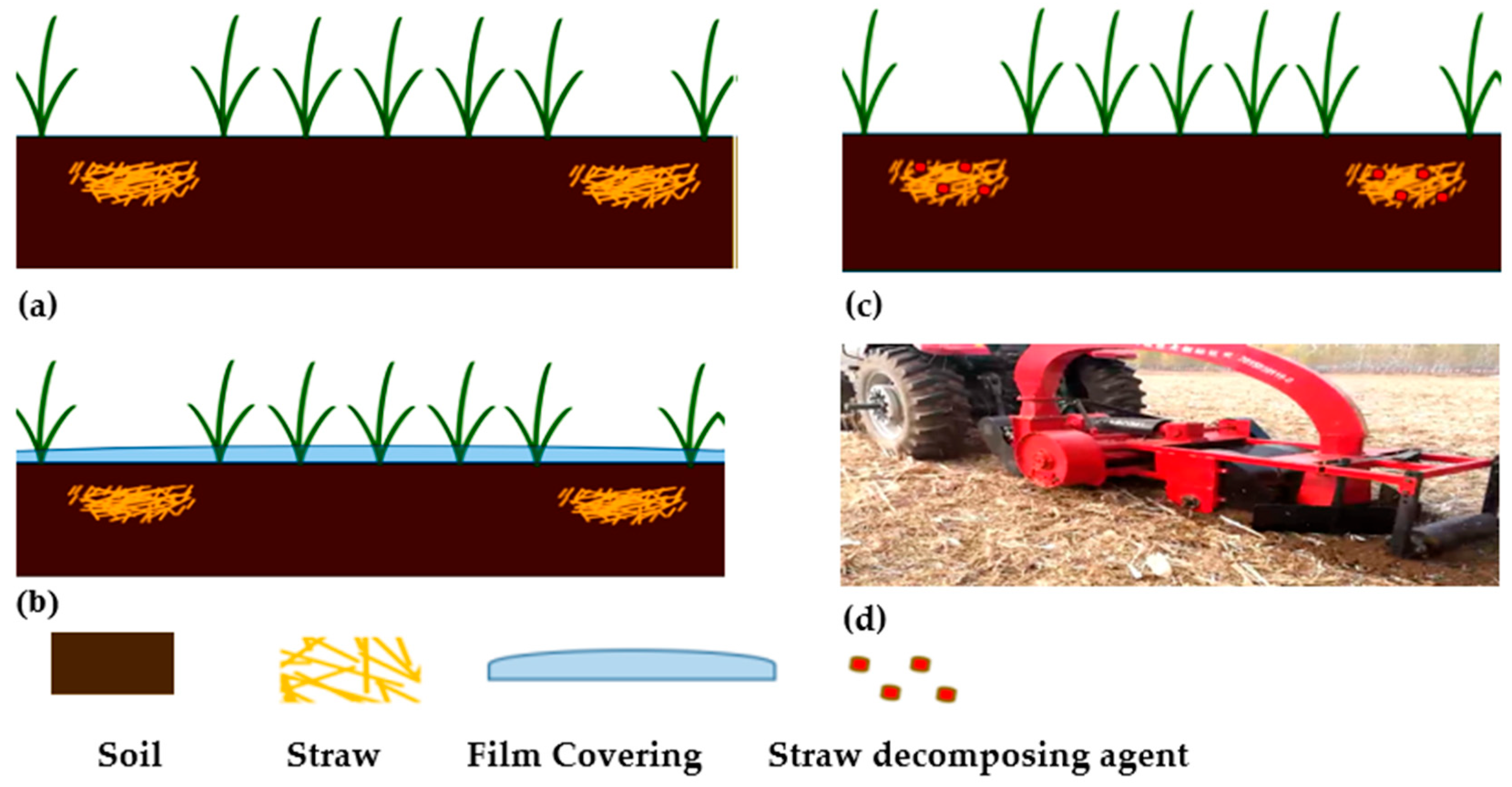

2.5.10. Under-Soil Straw Deep Burying

Figure 12a illustrates that the under-soil straw deep burying is an effective straw return mode in rice–wheat systems that enhances soil organic matter content, promotes microbial activity, and improves long-term soil structure. The technique for nutrient cycling and soil fertility relies on parameters like burial depth (25–50 cm), straw fragmentation degree, soil aeration, and decomposition rate. Supporting equipment includes deep plowing machines, subsoilers with straw attachments, and precision-controlled straw conveyors. Technical indicators assess the method’s effectiveness, while agronomic parameters like soil texture, moisture retention, and microbial diversity regulate decomposition dynamics and optimize nutrient availability for subsequent crops [

53,

57]. The principles governing this technique emphasize minimizing surface residue interference, enhancing deep soil organic matter integration, and synchronizing decomposition with crop growth stages.

Figure 12b shows that under-soil straw deep burying combined with film mulching is a straw return mode in rice–wheat systems designed to enhance soil moisture retention, improve decomposition, and optimize nutrient cycling. The effectiveness of a technique for mulching depends on factors like burial depth (25–50 cm), straw fragmentation size, film thickness, and soil moisture regulation. Supporting equipment includes deep plowing machines, precision film-laying devices, and automated straw laying systems. Technical indicators are decomposition rate, amount of organic carbon and nitrogen in the soil and activity of microbial biomass, and water-use efficiency increase [

57,

63]. Agronomic parameters such as soil temperature stability, carbon-to-nitrogen ratio, and microbial enzymatic activity maximize decomposition processes and harmonize nutrient release with the growth demand of plants.

Figure 12c shows a new straw return practice under-soil deep burying approach assisted by a decomposer agent as an innovative straw return mode in rice–wheat systems which expedites straw decomposition, increases nutrient availability in the soil, and enhances soil structure. The effectiveness of this approach depends on such variables as the depth of burial (25–50 cm), fragment size of straw, soil aeration, and decomposer agent (type and concentration). Supporting equipment is made up of deep plowing machines, precision straw placement devices, and decomposer application systems. Technical indicators that will be used to assess this approach are rates of decomposition, soil organic carbon and nitrogen levels, microbial biomass activity, and soil permeability [

5,

64]. Agronomic parameters such as balance of soil pH and C/N ratio as well as enzymatic activity also play an important role in efficient decomposition.

2.5.11. Opening Straw Ditches, Ditch Burial

As indicated by

Figure 13a, the context of the development and analysis of technical models for straw return modes in rice–wheat systems, the opening straw ditches and ditch burial are critical aspects for efficient straw incorporation and nutrient cycling. The depth, width, and spacing of the ditches significantly influence straw burial efficiency and decomposition rates. Supporting equipment includes specialized ditching machines and straw incorporation equipment for uniform straw distribution. Technical indicators for assessing straw burial effectiveness include the rate of straw decomposition, uniformity of straw distribution within the ditch, and impact on soil structure and organic matter content [

65,

66]. Agronomic parameters like timing of straw burial, soil moisture content, and soil texture must be considered to influence the interaction between straw and soil.

Figure 13b illustrates opening straw ditches, ditch burial, and film covering, and the parameters include soil texture, moisture content, straw decomposition rates, and spatial–temporal variability in soil nutrient distribution. Existing supporting equipment for this technology typically involves straw shredders, ditch openers, and film-laying machines, which are designed to optimize straw incorporation and soil coverage. Technical indicators such as straw burial depth (15–25 cm), film thickness (0.008–0.012 mm), and ditch spacing (30–50 cm) are critical for ensuring efficient straw decomposition and nutrient cycling. The principles underlying this sub-topic emphasize the integration of straw into the soil to enhance soil structure, reduce evaporation, and improve water retention, while film covering aids in temperature regulation and weed suppression [

49,

67]. Agronomic parameters, including crop yield, soil organic carbon content, and microbial activity, are monitored to assess the long-term impacts of these practices.

As seen in

Figure 13c, the rice–wheat rotation system involves the opening of straw ditches, burial of the ditch, and the application of decomposer agents. Key parameters influencing straw return modes include soil type, moisture content, straw decomposition rate, and burial depth. Supporting equipment, such as straw ditch-burying machines and rotary tillage implements, facilitate precise ditch opening and straw incorporation. Technical indicators like operational efficiency, (forward speed of 0.4 m/s), straw return rate (up to 97% decomposition with agents), and energy consumption serve as benchmarks for performance [

64,

68]. Agronomic parameters such as nutrient release rate reduction, soil bulk density reduction, and effects of crop yield are very important for synergizing these technologies with sustainable farming ambitions. The development of straw ditches entails working furrows (20–40 cm deep) to focus residues which are then followed by burial ditches for improved decomposition and sequestration of carbon.

Figure 13.

Opening straw ditches, ditch burial: (

a) opening straw ditches, ditch burial; (

b) opening straw ditches, ditch burial, and film covering; (

c) opening straw ditches, ditch burial, and application of decomposers; (

d) operating principle of the direct-injection straw deep-burying machine [

69].

Figure 13.

Opening straw ditches, ditch burial: (

a) opening straw ditches, ditch burial; (

b) opening straw ditches, ditch burial, and film covering; (

c) opening straw ditches, ditch burial, and application of decomposers; (

d) operating principle of the direct-injection straw deep-burying machine [

69].

2.5.12. Straw Trench Mixed Soil Trench Burying

Figure 14a shows straw trench mixed soil trench burying to be a key technology in the sustainability and productivity of rice–wheat systems in terms of efficient incorporation of the straw into the soil. The outstanding parameters in this approach include trench depth (25–35 cm), ratio of straw–soil mixing and soil moisture levels, which have spatial and temporal variation and effectiveness in decomposition. A number of existing supporting equipment such as trench-digging plows and mixed-soil incorporators, simplify this process with technical performance indicators such as the speed of trenching (0.3–0.5 m/s), uniformity of straw incorporation (coefficient of variation < 15%) fuel efficiency [

59,

60]. The agronomical parameters like soil organic carbon increment (5.6–12.3% within 0–30 cm depth) growth of the microbial activity, and increase in the yield of wheat indicate the possibility of the method to promote the soil fertility and increase the productivity of the crops.

Figure 14b points out that important factors are trench thickness (between 25 and 35 cm), trench width (between 30 and 40 cm), the ratio of straw to soil (1:2 to 1:3), and changes to moisture levels between seasons, as these control differences in decomposition. Mechanical instruments like tractor-mounted trenchers and soil–straw mixers aid in this practice, and their success can be measured by trenching rate (0.3–0.5 m/s), how well the mixture is mixed (<12%), and the energy they use [

60,

70]. Agronomic parameters, including soil organic matter gains in the top 30 cm of soil (by 8.2–14.1%), growth of soil microbes, and larger crop yields by 5.9–7.4% versus conventional tillage demonstrate the efficacy of the process. Straw trench mixed soil trench burying is a sustainable method for managing residue in rice–wheat systems, enhancing decomposition, nutrient release, and carbon storage through deep trenches.

Figure 14c illustrates that the key parameters encompass furrow depth (20–30 cm), straw–soil mixing ratio (1:2.5), decomposer agent concentration (0.5–1 kg/ha), and soil temperature, all of which vary spatially and temporally, influencing decomposition rates and nutrient availability. Existing supporting equipment includes furrow-forming plows, soil–straw mixing implements, and sprayers for decomposer application, with technical indicators such as furrow formation rate (0.4–0.6 m/s), straw burial consistency (variation < 10%), and decomposition acceleration (85% straw breakdown within 120 days) serving as performance benchmarks [

54,

71]. Agronomic parameters, such as increased soil nitrogen content (9.3–15.6% in the 0–20 cm layer), improved soil porosity, and wheat yield gains (7.5% over untreated controls), demonstrate the method’s agronomic benefits.

A comprehensive comparison of all 36 evaluated models is cataloged in

Supplementary Table S2, detailing each model’s name, spatial and temporal resolution, key technical indicators, and primary agronomic objectives and benefits.

3. Results

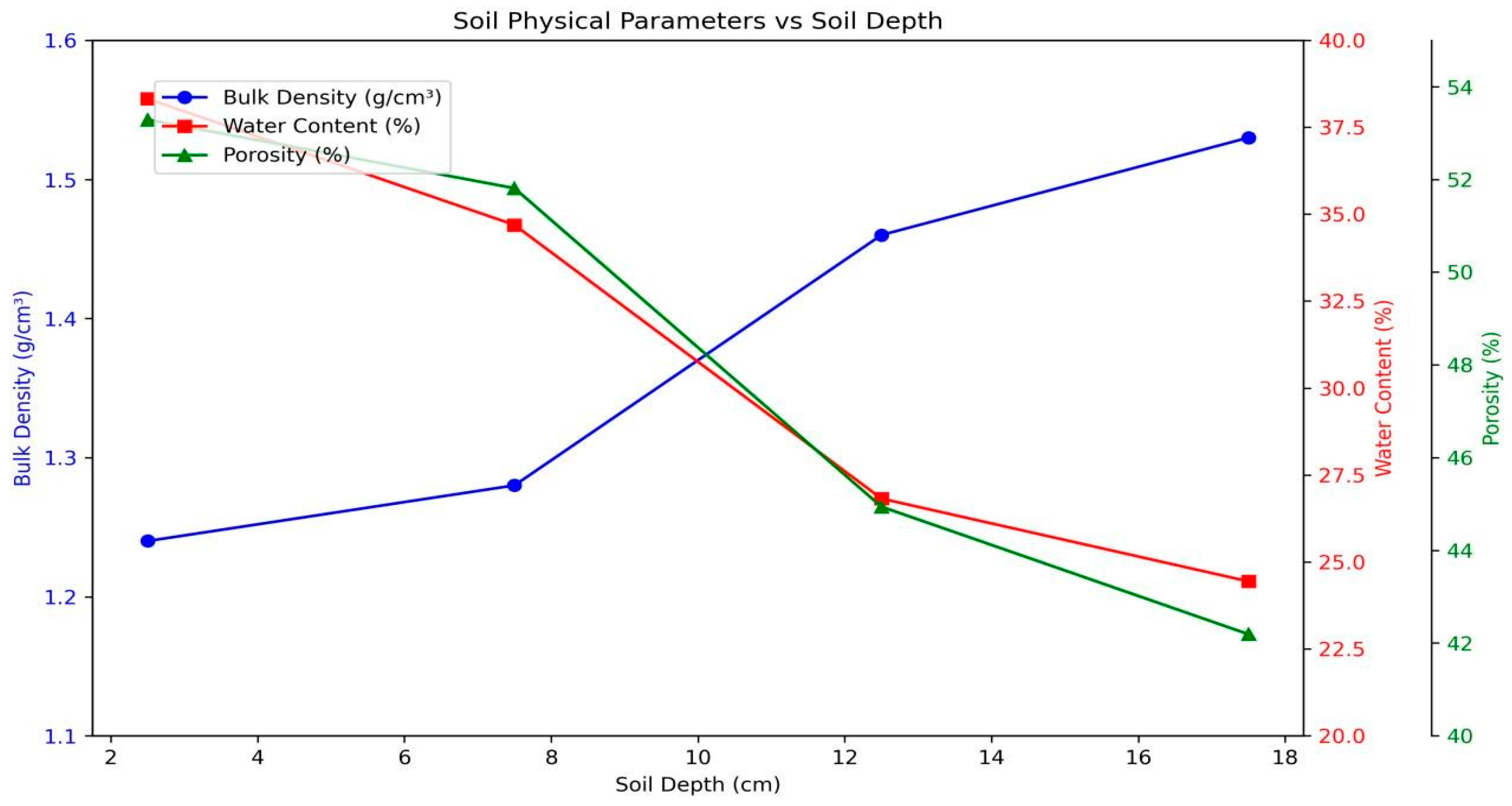

3.1. The Effects of Soil Physical Parameters on Straw Distribution

The present research, being carried out in Babaiqiao Town, Nanjing, China, investigates the effects of soil physical parameters on selection and suitable straw return in a rice–wheat rotation system. The lower Yangtze River basin landscape, having a long history of intensive rice–wheat farming and straw management practices, offers a strong background for understanding the spatial and temporal patterns of straw incorporation and its correlation with soil health. The advanced framework developed in this study, comprising 36 expanded straw return modes, was utilized to identify suitable strategies that optimize soil conditions and ensure sustainable crop productivity. The frequent rainfall during the experiment led to a high total water content in the experimental plots, and the physical properties for the depth of 0–20 cm are presented in

Table 1 below.

The research revealed that the depth of the soil is significantly related to straw return practice. When the depth is 0–5 cm, incorporating straw enhances soil structure and organic matter, and integral straw mulching or shallow incorporation is most beneficial. The increase in bulk density at 15–20 cm depths create obstructions for decomposition and straw incorporation, and partial straw return or surface mulching is the best. These reduce soil compaction to a minimal level and improve top aeration without excessive depth compaction (

Figure 15).

Straw return efficiency is governed by soil moisture content. The upper strata, 38% moisture content, are most suitable for microbial growth and straw breakdown and hence best for no-tillage straw mulching or shallow ploughing. Deeper soil layers, with a moisture content of 26%, require specialized straw return management to preserve soil moisture, Surface mulching is suitable for the conservation of moisture, especially in the dry season, and for slow release of nutrients over a prolonged duration of time.

Porosity, which declined drastically with soil depth (52% at 0–5 cm to 42% at 15–20 cm), imposed an effect on aeration and water-holding capacity that was critical for straw decomposition. In highly porous topsoil’s, straw mulching promoted aggregation and organic carbon sequestration in the soil towards long-term fertility improvement. Surface modes of straw return or minimum tillage practices were preferred for deeper layers with lower porosity, as these practices prevented further compaction and improved subsoil structure.

3.2. Expansion of Technical Models Based on Spatial Distribution

According to the idea of spatial and temporal variability, the distribution state of straw after returning to the field is the key to influence soil quality and environmental sustainability. The distribution status of straw returned to the field and different straw return methods can be summarized into five main categories: straw-mixed burial return (straw mixed with soil and buried into the field soil), straw even spread return (straw evenly spread on the field surface), straw collection strip mulching (straw gathered into strips to cover the field surface), straw deep burying return (straw buried under a certain depth of soil) and straw buried in furrows return (straw buried under a certain depth of soil).

Based on the straw’s spatial and temporal status, the five types of straw returning methods can be further expanded into 36 novel straw returning modes. This framework combines spatial dimensions (vertical and horizontal positioning of straw) with temporal dimensions (timing of decomposition and decay management), enabling a more comprehensive understanding of straw decomposition dynamics (

Figure 16).

3.3. Selection of Straw Return Modes Based on Spatial Distribution

In order to improve the sowing quality, straw should be avoided as much as possible in the 0~5 cm tillage layer. This study shows that increasing the operating depth of rotary tillage or plowing can reduce the straw content in the 0~5 cm soil layer. When the plowing depth is shallow, the subsequent rotary tillage treatment will mix the straw buried in the bottom layer with the tillage layer soil, increasing the proportion of straw in the 0~5 cm and 5~10 cm soil layers, and reducing the quality of plowing and burying operations. The studies showed that the uniform return of straw to the field makes crop residue evenly distributed in the soil, which is conducive to accelerating the decomposition and transformation of crop residue, and can improve soil structure and soil fertility [

28,

72].

Based on the soil physical parameters and spatial distribution of the study area, four typical straw return modes were used for rice–wheat rotation systems. These modes are, namely, even spreading of stubble straw, straw rotary plowing for field return, conventional rotary tillage and mulching, and straw plowing and burying.

Figure 17 illustrates the varying quality of spatial straw distribution associated with each return mode.

4. Discussion

The analysis of 36 novel technical models for straw return in rice–wheat systems give an integrative approach to the consideration of the ways in which spatial and temporal variability impacts the efficacy of the residue management strategies. This study expands upon the existing literature by incorporating multidimensional frameworks that assess straw return methods not only based on their mechanical implementation in the field, but also based on their ecological, agronomic, and biochemical impacts.

Studies show that deeper burial (25–50 cm) promotes long-term SOC accumulation and microbial activity [

73,

74], whereas shallow incorporation (0–5 cm) accelerates nutrient release. For instance, deep-burial models (under-soil burial at 25–50 cm) have dramatic effects on increasing microbial activity and organic carbon storage in subsoil layers, in line with the previous findings that the deep incorporation sustains long-term soil fertility and structural perseverance. The even spreading and topsoil shallow rotation methods of surface incorporation provide rapid decomposition with microbial decomposers that facilitate rapid release of nutrients.

Decomposers and mulching films regulate decomposition timing, improving nutrient synchronization and reducing GHG emissions [

75]. When decomposing agents and mulching films are used, herein, efficient moisture and temperature management is achieved with a view to ensuring favorable microbial action along with the reduction of greenhouse gas emissions. The integration of spatial depth management solutions and temporal decomposition control allows us to achieve extraordinary outcomes in the spiral conveyor deep-burial models that are furnished with film and decomposing agents.

Based on the soil physical parameters and straw distribution patterns study area, four typical straw return modes were identified as suitable for rice–wheat rotation systems: even spreading of stubble straw, straw rotary plowing for field return, conventional rotary tillage and mulching, and straw plowing and burying. Each of these modes offers distinct advantages in terms of soil protection, moisture conservation, and straw decomposition. The findings underscore the importance of adopting innovative straw return strategies that consider both spatial and temporal dimensions to enhance the sustainability of rice–wheat rotational cropping systems.

These findings demonstrate the need for developing straw return approaches that match edaphoclimatic conditions of different soils. The models that are demonstrating successful performances in clay loam soils of the research site would require adjustments to produce the necessary outcomes in the soils with different regimes of moisture level and diverse microbial bases. The technical models described here provide practical guidance for selecting context-appropriate straw return techniques that align with agronomic goals and environmental sustainability imperatives.

5. Conclusions

This study proposed and analyzed 36 novel technical models for straw return in rice–wheat systems by explicitly integrating spatial and temporal variability into residue management, as well as shallow incorporation with decomposers or films to enhance rapid decomposition and nutrient availability. The development of this expanded framework represents an important scientific contribution, as it provides a systematic basis for matching straw return practices with soil conditions, crop requirements, and environmental sustainability goals.

Among the models, shallow incorporation with mulching films and decomposer agents proved particularly effective in enhancing rapid decomposition and nutrient availability under moist topsoil conditions. In contrast, deep rotary plowing and trench burial models showed greater potential for long-term organic matter accumulation, improved soil structure, and enhanced carbon sequestration in clay loam soils. These results suggest that selecting suitable straw return strategies should be context-specific, guided by soil physical properties, water availability, and crop rotation dynamics.

Future research should focus on field validation of the 36 expanded straw return modes, with an emphasis on quantifying their agronomic and environmental impacts. Long-term studies are also necessary to assess the effects of these methods on soil health, crop productivity, and overall environmental sustainability. The findings of this study have significant implications for sustainable agriculture, particularly in regions heavily reliant on rice–wheat rotation systems.

Author Contributions

Conceptualization, S.B.M., R.H. and X.Y.; methodology, S.B.M.; software, A.N.; validation, Y.L., X.Y., R.H. and A.N.; formal analysis, X.Y., A.N. and Q.D.; investigation, X.Y.; resources, Q.D.; data curation, S.B.M.; writing—original draft preparation, S.B.M.; writing—review and editing, S.B.M., Q.D., X.Y. and A.N.; visualization, Y.L., X.Y. and R.H.; supervision, X.Y. and Q.D.; project administration, Q.D.; funding acquisition, Q.D. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank the National Key Research and Development Program of China (No. 2022YFD2300304), College of Engineering, Nanjing Agricultural University, Nanjing 210031, China for supporting this research.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhao, X.; Yuan, G.; Wang, H.; Lu, D.; Chen, X.; Zhou, J. Effects of full straw incorporation on soil fertility and crop yield in rice-wheat rotation for silty clay loamy cropland. Agronomy 2019, 9, 133. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W.; Zhou, Y.; Ding, Y.; Xu, L.; Jiang, Y.; Li, G. Long-term straw incorporation increases rice yield stability under high fertilization level conditions in the rice–wheat system. Crop J. 2021, 9, 1191–1197. [Google Scholar] [CrossRef]

- Sarkar, S.; Skalicky, M.; Hossain, A.; Brestic, M.; Saha, S.; Garai, S.; Ray, K.; Brahmachari, K. Management of crop residues for improving input use efficiency and agricultural sustainability. Sustainability 2020, 12, 9808. [Google Scholar] [CrossRef]

- Fu, B.; Chen, L.; Huang, H.; Qu, P.; Wei, Z. Impacts of crop residues on soil health: A review. Environ. Pollut. Bioavailab. 2021, 33, 164–173. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Geng, P.; Yang, Q.; Chen, K.; Liu, N.; Fan, Y.; Zhan, X.; Han, X. Effects of different returning method combined with decomposer on decomposition of organic components of straw and soil fertility. Sci. Rep. 2021, 11, 15495. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Xu, Y.; Wang, Z.; Li, Z.; Ling, J.; Wu, G.; Wen, Y. Subsoil SOC increased by high C:N ratio straw application with optimized nitrogen supplementation. Soil Use Manag. 2024, 40, e13020. [Google Scholar] [CrossRef]

- Qian, R.; Guo, R.; Liu, Y.; Naseer, M.A.; Hussain, S.; Liu, D.; Zhang, P.; Chen, X.; Ren, X. Biodegradable film mulching combined with straw incorporation can significantly reduce global warming potential with higher spring maize yield. Agric. Ecosyst. Environ. 2022, 340, 108181. [Google Scholar] [CrossRef]

- Liu, C.; Lu, M.; Cui, J.; Li, B.; Fang, C. Effects of straw carbon input on carbon dynamics in agricultural soils: A meta-analysis. Glob. Change Biol. 2014, 20, 1366–1381. [Google Scholar] [CrossRef]

- Lal, R. Soil organic matter and water retention. Agron. J. 2020, 112, 3265–3277. [Google Scholar] [CrossRef]

- Cui, S.; Cao, G.; Zhu, X. Effects of Straw Return Duration on Soil Carbon Fractions and Wheat Yield in Rice–Wheat Cropping System. Sustainability 2024, 16, 754. [Google Scholar] [CrossRef]

- Wang, X.; Yang, H.; Liu, J.; Wu, J.; Chen, W.; Wu, J.; Zhu, L.; Bian, X. Effects of ditch-buried straw return on soil organic carbon and rice yields in a rice-wheat rotation system. Catena 2015, 127, 56–63. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, D.L.; Schwenke, G.; Yang, B. The global warming potential of straw-return can be reduced by application of straw-decomposing microbial inoculants and biochar in rice-wheat production systems. Environ. Pollut. 2019, 252, 835–845. [Google Scholar] [CrossRef] [PubMed]

- Akhir, M.A.M.; Mustapha, M. Formulation of Biodegradable Plastic Mulch Film for Agriculture Crop Protection: A Review. Polym. Rev. 2022, 62, 890–918. [Google Scholar] [CrossRef]

- Huang, X.; Li, M.; Li, J.; Song, Y. A high-resolution emission inventory of crop burning in fields in China based on MODIS Thermal Anomalies/Fire products. Atmos. Environ. 2012, 50, 9–15. [Google Scholar] [CrossRef]

- Chen, J.; Gong, Y.; Wang, S.; Guan, B.; Balkovic, J.; Kraxner, F. To burn or retain crop residues on croplands? An integrated analysis of crop residue management in China. Sci. Total Environ. 2019, 662, 141–150. [Google Scholar] [CrossRef]

- Memon, M.S.; Guo, J.; Tagar, A.A.; Perveen, N.; Ji, C.; Memon, S.A.; Memon, N. The effects of tillage and straw incorporation on soil organic carbon status, rice crop productivity, and sustainability in the rice-wheat cropping system of Eastern China. Sustainability 2018, 10, 961. [Google Scholar] [CrossRef]

- Xu, G.; Xie, Y.; Liang, L.; Ding, Q.; Xie, H.; Wang, J. Straw-Soil-Rotary Blade Interaction: Interactive Effects of Multiple Operation Parameters on the Straw Movement. Agronomy 2022, 12, 847. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Liu, S.; Li, J.; Geng, J.; Wang, L. Key soil properties influencing infiltration capacity after long-term straw incorporation in a wheat (Triticum aestivum L.)–maize (Zea mays L.) rotation system. Agric. Ecosyst. Environ. 2023, 344, 108301. [Google Scholar] [CrossRef]

- Liu, P.; He, J.; Li, H.; Wang, Q.; Lu, C.; Zheng, K.; Liu, W.; Zhao, H.; Lou, S. Effect of Straw Retention on Crop Yield, Soil Properties, Water Use Efficiency and Greenhouse Gas Emission in China: A Meta-Analysis. Int. J. Plant Prod. 2019, 13, 347–367. [Google Scholar] [CrossRef]

- Novák, V.; Hlaváčiková, H. Soil-water content and its measurement. In Applied Soil Hydrology; Springer International Publishing: Cham, Switzerland, 2019; Volume 32. [Google Scholar] [CrossRef]

- Panagos, P.; De Rosa, D.; Liakos, L.; Labouyrie, M.; Borrelli, P.; Ballabio, C. Soil bulk density assessment in Europe. Agric. Ecosyst. Environ. 2024, 364, 108907. [Google Scholar] [CrossRef]

- Xu, G.; Xie, Y.; Alele, J.O.; Chen, X.; Matin, M.A.; Abbas, A.; He, R.; Ding, Q. A novel method for measuring and evaluating spatial distribution of straw incorporated by rotary tillage. Agron. J. 2022, 114, 853–866. [Google Scholar] [CrossRef]

- Guo, J.; Ji, C.; Fang, H.; Zhang, Q.; Hua, F.; Zhang, C. Experimental analysis of soil and straw displacement after up-cut and down-cut rotary tillage. Trans. Chin. Soc. Agric. Mach. 2016, 47, 21–26. [Google Scholar] [CrossRef]

- Yang, F.K.; He, B.; Zhang, L.; Zhang, G.; Gao, Y. An Approach to Improve Soil Quality: A Case Study of Straw Incorporation with a Decomposer Under Full Film-Mulched Ridge-Furrow Tillage on the Semiarid Loess Plateau, China. J. Soil Sci. Plant Nutr. 2020, 20, 125–138. [Google Scholar] [CrossRef]

- Guo, L.; Zheng, S.; Cao, C.; Li, C. Tillage practices and straw-returning methods affect topsoil bacterial community and organic C under a rice-wheat cropping system in central China. Sci. Rep. 2016, 6, 33155. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.P.; Li, X.; He, H.J.; Zhou, H.; Geng, D.Y.; Zhang, Y.Z. Effects of Rotational Tillage on Soil Physicochemical Properties and Crop Yield in a Rice–Wheat Double Cropping Area. Sustainability 2023, 15, 474. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Y.; Feng, H.; Liu, J.; Si, B.; Zhang, A.; Chen, J.; Cheng, G.; Sun, B.; Pi, X.; et al. Effects of straw and plastic film mulching on greenhouse gas emissions in Loess Plateau, China: A field study of 2 consecutive wheat-maize rotation cycles. Sci. Total Environ. 2017, 579, 814–824. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, N.; Yang, M.; Zhan, X.; Zhang, Z. Effects of different tillage and straw return on soil organic carbon in a rice-wheat rotation system. PLoS ONE 2014, 9, e88900. [Google Scholar] [CrossRef]

- Guo, L.; Shi, J.; Lin, W.; Liang, J.; Lu, Z.; Tang, X.; Liu, Y.; Wu, P.; Li, C. Soil Bacteria Mediate Soil Organic Carbon Sequestration under Different Tillage and Straw Management in Rice-Wheat Cropping Systems. Agriculture 2022, 12, 1552. [Google Scholar] [CrossRef]

- Xu, G.; Xie, Y.; Matin, M.A.; He, R.; Ding, Q. Effect of Straw Length, Stubble Height and Rotary Speed on Residue Incorporation by Rotary Tillage in Intensive Rice–Wheat Rotation System. Agriculture 2022, 12, 222. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, J.; Fu, G.; Zhao, Y. Rotary tillage in rotation with plowing tillage improves soil properties and crop yield in a wheat-maize cropping system. PLoS ONE 2018, 13, e0198193. [Google Scholar] [CrossRef]

- Al-Shammary, A.A.G.; Lahmod, N.R.; Fernández-Gálvez, J.; Caballero-Calvo, A. Effect of Tillage Systems Combined with Plastic Film Mulches and Fertilizers on Soil Physical Properties in a Wheat-Agricultural Site in Southern Iraq. Geogr. Res. Lett. 2023, 49, 51–63. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Dang, P.; Wei, L.; Qin, X.; Siddique, K.H.M. The effect of tillage on nitrogen use efficiency in maize (Zea mays L.) in a ridge–furrow plastic film mulch system. Soil Tillage Res. 2019, 195, 104409. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, M.; Pang, D.; Yin, Y.; Han, M.; Li, Y.; Luo, Y.; Xu, X.; Li, Y.; Wang, Z. Straw return and appropriate tillage method improve grain yield and nitrogen efficiency of winter wheat. J. Integr. Agric. 2017, 16, 1708–1719. [Google Scholar] [CrossRef]

- De Yin, J.; Zhang, X.C.; Ma, Y.F.; Yu, X.F.; Hou, H.Z.; Wang, H.L.; Fang, Y.J. Vertical rotary sub-soiling under ridge–furrow with plastic mulching system increased crops yield by efficient use of deep soil moisture and rainfall. Agric. Water Manag. 2022, 271, 107767. [Google Scholar] [CrossRef]

- Zhao, Z.; Geng, P.; Wang, X.; Li, X.; Cai, P.; Zhan, X.; Han, X. Improvement of Active Organic Carbon Distribution and Soil Quality with the Combination of Deep Tillage and No-Tillage Straw Returning Mode. Agronomy 2023, 13, 2398. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Xia, J. Combination blade roller for straw returning cultivator. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Qingdao, China, 28–30 May 2021; Volume 792. [Google Scholar] [CrossRef]

- Schillinger, W.F.; Smith, T.A.; Schafer, H.L. Chaff and straw spreader for a plot combine. Agron. J. 2008, 100, 398–399. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhou, W.; Yang, Q.; Jiang, J.; Miao, M. Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement. Agronomy 2023, 13, 2774. [Google Scholar] [CrossRef]

- Wang, B.; Gu, F.; Wu, F.; Ma, J.; Yang, H.; Hu, Z. Analysis of Influencing Factors and Operation Quality Evaluation Strategy of Straw Crushing and Scattering System. Agriculture 2022, 12, 508. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, C.; Zhang, W.; Yang, Q.; Li, D.; Liu, Z.; Xia, J. Evaluation of straw spatial distribution after straw incorporation into soil for different tillage tools. Soil Tillage Res. 2020, 196, 104440. [Google Scholar] [CrossRef]

- Gou, Z.; Yin, W.; Chai, Q. Straw and residual film management enhances crop yield and weakens CO2 emissions in wheat–maize intercropping system. Sci. Rep. 2021, 11, 14077. [Google Scholar] [CrossRef]

- Shao, X.; Gao, J.; Liu, Y.; Wang, X.; Guo, L. Effects of Plastic Mulching and Straw Incorporation on Rice Yield and Nitrogen Use Efficiency in a Cold Region. Eng. Agric. 2021, 41, 504–516. [Google Scholar] [CrossRef]

- Xu, H.; Hu, Z.; Zhang, P.; Gu, F.; Wu, F.; Song, W.; Wang, C. Optimization and experiment of straw back-throwing device of no-tillage drill using multi-objective qpso algorithm. Agriculture 2021, 11, 986. [Google Scholar] [CrossRef]

- Gong, H.; Li, J.; Ma, J.; Hou, R.; Zhang, X.; Ouyang, Z. Effects of straw incorporation combined with inorganic-organic fertilization on soil water and nitrogen changes and microbial community structure in winter wheat. Shengtai Xuebao/Acta Ecol. Sin 2019, 39, 2203–2214. [Google Scholar] [CrossRef]

- Luo, W.; Gu, F.; Wu, F.; Xu, H.; Chen, Y.; Hu, Z. Design and Experiment of Wheat Planter with Straw Crushing and Inter-furrow Collecting-mulching under Full Amount of Straw and Root Stubble Cropland. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 42–52. [Google Scholar] [CrossRef]

- Visconti, F.; Peiró, E.; Pesce, S.; Balugani, E.; Baixauli, C.; de Paz, J.M. Straw mulching increases soil health in the inter-row of citrus orchards from Mediterranean flat lands. Eur. J. Agron. 2024, 155, 127115. [Google Scholar] [CrossRef]

- Xie, Y.; Li, J.; Jin, L.; Wei, S.; Wang, S.; Jin, N.; Wang, J.; Xie, J.; Feng, Z.; Zhang, G.; et al. Combined Straw and Plastic Film Mulching Can Increase the Yield and Quality of Open Field Loose-Curd Cauliflower. Front. Nutr. 2022, 9, 888728. [Google Scholar] [CrossRef]

- Awad, M.; Fouda, O.; Fathy, W.; El Balkemy, W.; Egela, M.; El-Fakhrany, W.; Okasha, M. A combined machine for collecting and chopping rice straw. Heliyon 2022, 8, e10412. [Google Scholar] [CrossRef]

- Haytham, M.E.; Hassaanein, M.K.; Zahoor, A.; Kotamy, T.E. Rice Straw-Seedbed for Producing Rice Seedling Mat. Int. J. Sustain. Agric. 2010, 2, 26–33. [Google Scholar]

- Hu, Y.; Ma, P.; Duan, C.; Wu, S.; Feng, H.; Zou, Y. Black plastic film combined with straw mulching delays senescence and increases summer maize yield in northwest China. Agric. Water Manag. 2020, 231, 106031. [Google Scholar] [CrossRef]

- Lü, W.; Huang, G.; Shao, Z.; Zeng, Y.; Shi, Q.; Pan, X.; Wei, S. Straw substrate with decomposition agent improving seedling quality and yield of machine-transplanted rice. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2017, 33, 195–202. [Google Scholar] [CrossRef]

- Tang, H.; Wang, D.; Zhao, J.; Xu, C.; Wang, J. Mode and experiments of a straw ditch-burying returning and maturing in cold region of Northeast China. Eur. J. Agron. 2023, 151, 127006. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Dou, S.; Guan, S.; Yang, C.; Wang, Z. Deep Straw Burial Accelerates Straw Decomposition and Improves Soil Water Repellency. Agronomy 2023, 13, 1927. [Google Scholar] [CrossRef]

- Huo, L.; Pang, H.; Zhao, Y.; Wang, J.; Lu, C.; Li, Y. Buried straw layer plus plastic mulching improves soil organic carbon fractions in an arid saline soil from Northwest China. Soil Tillage Res. 2017, 165, 286–293. [Google Scholar] [CrossRef]

- Li, J.; Ye, X.; An, J.; Jin, X.; Fan, Q.; Zou, H.; Zhang, Y. The more straw we deep-bury, the more soil TOC will be accumulated: When soil bacteria abundance keeps growing. J. Soils Sediments 2022, 22, 162–171. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Xu, W.; Xu, Y.; Xiang, Y.; Wang, J. Method of straw ditch-buried returning, development of supporting machine and analysis of influencing factors. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef]

- Zhu, F.; Lin, X.; Guan, S.; Dou, S. Deep incorporation of corn straw benefits soil organic carbon and microbial community composition in a black soil of Northeast China. Soil Use Manag. 2022, 38, 1266–1279. [Google Scholar] [CrossRef]

- Tian, Y.; Lin, J.; Li, B. Design and Test of Conveying Device of Pneumatic Straw Deep Burying and Returning Machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49. [Google Scholar] [CrossRef]

- Tian, Y.; Lin, J.; Li, B.; Zhang, T.; Qi, L.; Wang, J. Design and test of pneumatic 1JH-2 style straw deep burying and returning machine. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2018, 34, 10. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Q.; Tang, H.; Zhou, W.; Duo, T.; Zhao, Y. Design and experiment of rice straw deep buried and whole straw returning device. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2015, 46, 112–117. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Wang, C.; Xiang, Y.; Tang, H. Design and simulation of a trenching device for rice straw burial and trenching based on MBD-DEM. Comput. Electron. Agric. 2023, 207, 107722. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Dang, P.; Wei, L.; Qin, X.; Siddique, K.H.M. Combined ditch buried straw return technology in a ridge–furrow plastic film mulch system: Implications for crop yield and soil organic matter dynamics. Soil Tillage Res. 2020, 199, 104596. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Zhang, Y.; Zhang, J.; Xia, S.; Qin, H.; Feng, C.; Bie, S. Influence of decomposition agent application and schedule in wheat straw return practice on soil quality and crop yield. Chem. Biol. Technol. Agric. 2023, 10, 8. [Google Scholar] [CrossRef]

- Zheng, Z.; He, J.; Wang, Q.; Li, H.; Li, W.; Chen, W. Design and Experiment on Straw Pickup-chopping and Ditch-burying Integrated Machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 87–96. [Google Scholar] [CrossRef]

- Wu, G.; Ling, J.; Zhao, D.Q.; Xu, Y.P.; Liu, Z.X.; Wen, Y.; Zhou, S.L. Deep-injected straw incorporation improves subsoil fertility and crop productivity in a wheat-maize rotation system in the North China Plain. Field Crops Res. 2022, 286, 108612. [Google Scholar] [CrossRef]