Abstract

The fate and risk identification of cyantraniliprole (CYA) and lufenuron (LUF) in pak choi were systematically analyzed through an investigation comprising field trials, dissipation kinetics, and dietary risk assessment. Initially, field experiments across ten Chinese provinces revealed half-lives of 3.04–5.41 d for CYA and 2.02–5.13 d for LUF, with dissipation following single first-order (SFO) kinetics or double first-order in parallel (DFOP) kinetics. Terminal residues (<limit of quantification (LOQ) to 0.29 mg/kg) were below maximum residue limits. Dissipation rates were significantly influenced by temperature, climate, and crop growth stage. Additionally, the multidimensional dietary assessment using deterministic and probabilistic models revealed acceptable long-term risk levels for CYA and LUF among consumer groups (risk quotients < 28.4%). Overall, this first comprehensive study from cultivation to consumption provides crucial insights for rational pesticide use in pak choi.

1. Introduction

Pak choi (Brassica rapa L. subsp. chinensis) is extensively cultivated as a nutrient-dense vegetable crop throughout Asia, with China dominating global production [1]. In 2023, pak choi had a harvested area of 1.01 million hectares and achieved a total production yield of 36.17 million tonnes, according to FAO data. However, pak choi is frequently attacked by various pests. In particular, the diamondback moth (Plutella xylostella L.) is regarded as one of the most destructive pests worldwide, with global economic losses currently estimated at US $4–5 billion annually [2]. Consequently, to prevent or minimize crop losses, 162 commercial pesticides have been registered for pak choi cultivation in China. Although detection methods have been established for multiple pesticides in pak choi and their fate has been investigated during cultivation [3,4], risk assessments have been conducted for only three pesticides (fenpropathrin, bitertanol, and chlorothalonil) [5,6,7]. Notably, chlorothalonil has been shown to pose unacceptable health risks through long-term dietary exposure seven days post-application. Considering the extensive consumption of pak choi and the indispensable role of pesticides in crop protection, urgent comprehensive risk evaluations for other registered pesticides are essential to safeguard food security and public health.

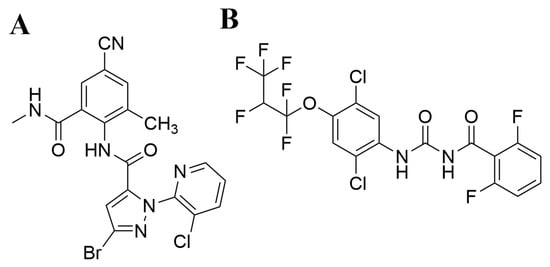

CYA and LUF (Figure 1) have been registered to control the diamondback moth on pak choi. CYA, an anthranilic diamide insecticide, exerts its effect through ryanodine receptor activation, resulting in rapid calcium ion release [8]. LUF, a benzoylurea insect growth regulator, inhibits chitin synthesis in target insects [9]. However, these pesticides pose significant human and ecological safety risks, as confirmed by existing studies. For instance, adverse sub-chronic exposure effects were observed in earthworms and zebrafish exposed to CYA [10,11]. In mammalian studies, CYA can harm the female reproductive system of pubertal and adult offspring [12]. LUF causes severe toxic effects in free-living terrestrial fauna [13]. Additionally, while LUF is used to treat animal parasites and infections in veterinary medicine, recent studies indicate it causes genetic and reproductive harm in pregnant rats [14]. Notably, these compounds have been detected in environmental matrices, vegetables, fruits, and tea, raising significant safety concerns [15,16,17,18,19,20]. The safety of these pesticides has been investigated in tomatoes [21], chili peppers [22], rice [23], and other crops. Nevertheless, comprehensive studies on pak choi remain limited. Moreover, in-depth investigations into dissipation mechanisms and probabilistic risk assessment models are lacking.

Figure 1.

The structures of CYA (A) and LUF (B).

As an important vegetable crop, pak choi suffers from the diamondback moth. While CYA and LUF are registered to control this pest, concerns exist about their occurrence and health risks. Despite extensive research on these pesticides in other crops, comprehensive studies on their fate and risk in pak choi remain lacking. Therefore, to address this critical knowledge gap, a multifaceted investigation was conducted encompassing method development, field cultivation, dissipation kinetics analysis, and risk assessment. First, an accurate and reliable ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) method was developed to detect and quantify CYA and LUF in pak choi. Subsequently, through large-scale field experiments, the occurrence, half-lives, and final levels of CYA and LUF in pak choi were systematically investigated, considering multiple factors including growth period, climatic zones, temperature, and rainfall. Finally, multidimensional dietary risks for populations were assessed using both deterministic and probabilistic modeling approaches, with exposed populations being categorized by age, region, and gender. Consequently, this study represents the first comprehensive investigation revealing the fate and risk of these pesticides from cultivation to consumption, thereby providing a theoretical foundation for rational pesticide application in pak choi production systems.

2. Materials and Methods

2.1. Chemicals and Reagents

CYA standard (C19H14BrClN6O2, CAS No. 736994–63-1, 95.2% purity) and LUF standard (C17H8Cl2F8N2O3, CAS No. 103055–07-8, 99.5% purity) were provided by Beijing Manhage Biotechnology Company (Beijing, China). All reference standards were dissolved in acetonitrile and stored at −20 °C until analysis. 20% CYA and LUF (1:1) suspension concentrate was procured from local retail outlets. High-performance liquid chromatography (HPLC) grade acetonitrile and formic acid were sourced from Fisher Scientific (Geel, Belgium) and Sigma-Aldrich Chemical Co., Ltd. (Darmstadt, Germany), respectively. Analytical grade sodium chloride (NaCl) and anhydrous magnesium sulfate were obtained from Sinopharm Chemical Reagent (Shanghai, China). Primary secondary amine (PSA), and nylon filters (0.22 μm) were acquired from Agilent Technologies (Beijing, China).

2.2. Field Trials and Sample Collection

In accordance with OECD Guidelines for the Testing of Chemicals No. 509 [24], field experiments were conducted across major pak choi-producing regions spanning ten provinces (Table 1) throughout China. One treatment plot and one control plot were established at each area, with each 50 m2 plot separated by 2 m buffer zones to prevent cross-contamination. 20% CYA and LUF suspension concentrate (1:1) was applied via foliar spray at the recommended dosage of 30 g a.i./ha to diamondback moth-infested pak choi, following good agricultural practice (GAP) recommendations. For terminal residue determination, samples were collected at 7- and 10-day pre-harvest intervals (PHI) in ten planting provinces (Trials #1–#10). Trials #1–#5 were under greenhouse conditions, and the growing conditions for Trials #6–#10 were under open-field conditions. For dissipation kinetics assessment, pak choi samples were collected at 0, 5, 7, 10, and 14 days after application in four selected provinces (#4, #6, #7, and #10). Representative, disease-free pak choi plants were randomly selected from each plot (ex-cluding edge areas) using a multi-point sampling method. Three samples were collected per plot; each sample consisted of at least 12 plants, ensuring a total weight of no less than 1 kg per sample. All collected samples were chopped into pieces, reduced to subsamples through the quartering method, and subsequently stored at –20 °C under dark conditions. Detailed information regarding growth stage and climatic conditions for each trial site is presented in Table 1.

Table 1.

Pakchoi cultivars, climate characteristics of trial sites across China.

2.3. Analytical Procedures

Prior to analysis, pak choi samples were homogenized using a commercial food processor to ensure uniform distribution. Sample pretreatment was performed using a modified QuEChERS method, which referenced established methods for CYA in chilli fruits [22] and LUF in cabbage [25]. For analytical preparation, pak choi samples were accurately weighed (10.0 ± 0.01 g) and placed into individual 50 mL capped centrifuge tubes. Each sample was treated with 25 mL of acetonitrile (MeCN). The samples were vigorously oscillated for 10 min. Following homogenization, 1 g of NaCl and 4 g of MgSO4 were added to each tube. The mixture was subsequently vortexed for 5 min and then centrifuged at 4000 rpm for 5 min. Then, 1.5 mL aliquots of the clarified supernatant were transferred to 2 mL tubes containing PSA (50 mg) and MgSO4 (150 mg). The tubes were vortex-mixed for 1 min, followed by centrifugation at 9000 rpm for 5 min. The final extracts were filtered through 0.22-μm nylon membrane syringe filters directly into autosampler vials for subsequent ultra-high-performance liquid chromatography-tandem mass spectrometry (UHPLC-MS/MS) analysis. Each sample was analyzed in triplicate.

Sample analysis was conducted using an ACQUITY UHPLC system coupled with an XEVO TQD quadrupole mass spectrometer equipped with an electrospray ionization source (ESI) (Waters, Milford, MA, USA). Chromatographic separation of CYA and LUF was achieved using a BEH C18 column (2.1 mm × 50 mm, 1.7 μm particle size, Waters Corporation, Milford, MA, USA). The mobile phases comprised acetonitrile (phase A) and water with 5 mmol/L ammonium acetate (phase B). Gradient elution was conducted as follows (0.3 mL/min): 0–0.5 min, 30% A; 0.5–2.5 min, 90% A; 2.5–3.0 min, 30% A; 3.0–5.0 min, 30% A. The chromatographic conditions were optimized with a column temperature of 40 °C and injection volume of 5 μL.

Mass spectrometric detection of CYA and LUF was optimized in positive/negative ionization modes with the following parameters: capillary voltage of 2.5 kV, source temperature of 150 °C, and desolvation temperature of 350 °C. Cone and desolvation gas flows (N2) were maintained at 50 and 650 L/h, respectively. Multiple reaction monitoring (MRM) transitions were established for CYA at m/z 473.2 → 204.2 and m/z 473.2 → 201.9 under negative ionization mode for qualitative and quantitative analysis, respectively, with both collision energies at 12 V. For LUF determination, MRM transitions of m/z 385.33 → 197.66 and m/z 385.33 → 146.4 were selected under positive ionization mode for quantitative and qualitative analysis, respectively, with collision energies optimized at 24 and 32 V. Chromatographic retention times were 2.19 min for CYA and 2.87 min for LUF. Dwell times for both target analytes were maintained at 71 ms.

2.4. Dietary Risk Assessment

The dietary risk assessments of the pesticides across different age groups encompassed chronic and acute exposure assessments, following recommendations from the Joint FAO/WHO Meeting on Pesticide Residues (JMPR). The short-term intake of residues of CYA and LUF, when used according to the evaluation process by JMPR, is unlikely to present a public health concern [26,27]. Therefore, an acute dietary risk assessment for CYA and LUF was not conducted because ARfD values were not deemed necessary.

The deterministic method constitutes a commonly utilized technique for dietary risk assessment, being extensively applied due to its ease of implementation, calculation efficiency, and requirement for limited datasets. According to Formulas (1) and (2): NEDI denotes the national estimated exposure intake (mg/kg bw), while STMRi refers to the upervised trial median residue concentration of CYA and LUF in pak choi (mg/kg). Based on the principle of risk maximization, the Maximum Residue Limits (MRLs) established for registered crops (except for pak choi) were used as the STMR values for CYA and LUF. Fi indicates the average daily intake of a specific food item in China. Both bw and Fi datasets were obtained from Chinese National Nutrition and Health Survey. RQ represents the risk quotient of chronic dietary risk (% ADI). The acceptable daily intake (ADI) values established by JMPR were 0.03 mg/kg bw for CYA and 0.02 mg/kg bw for LUF. Risk quotients are considered acceptable when RQ < 100%, while values exceeding 100% suggest potential long-term health risks [28].

Monte Carlo simulations were employed to evaluate the posterior distribution of CYA and LUF concentrations, thereby minimizing uncertainty in intake assessments. A total of 1,000,000 simulations were performed by setting the iteration number (n) to 10,000 and conducting 100 simulation procedures to ensure the reliability of results [29]. A probabilistic approach represents an established methodology for determining the occurrence, variability, and uncertainty associated with dietary risks through Formulas (3) and (4). In these equations, yij denotes the compound intake by Group i on Day j, while p represents the total count of examined food items. The parameter xijk indicates pak choi consumption by Group i on Day j, and cijk signifies the CYA and LUF concentration in pak choi ingested by Group i on Day j. bwi represents the body weight of Group i. Data sampling and model fitting were performed using @Risk software version 7.6 [28].

2.5. Data Analysis

The matrix effect (ME) refers to the impact of co-eluting substances from pak choi on the detector response and was computed according to the formula below:

where ME is the matrix effect, k1 indicates the slope of the matrix-based standard curve, and k2 represents the slope of the solvent-based standard curve. Values of ME% ≥ 10% signify pronounced matrix signal enhancement, whereas ME% ≤ −10% indicates marked matrix signal suppression. The matrix influence becomes insignificant within the range of −10% < ME% < 10% [30].

Due to inconsistent dissipation rates observed at various time intervals, different formulas (SFO model (Formulas (6) and (7)), DFOP model (Formula (8))) were utilized to determine the corresponding half-life values.

where C0 and C correspond to the initial concentration and the concentration at time t post-application, respectively. The half-life was defined as the time required for the disappearance of 50% of the pesticide after application [31].

In Formula (8), g denotes the proportion of C0 present in the solution phase, whereas k1 and k2 correspond to the kinetic constants for the rapid and gradual sub-reactions, respectively [31].

Data analyses were performed using Origin 2022 and IBM SPSS Statistics 26. Data were analyzed by the analysis of variance (ANOVA) method followed by the least signifi-cant difference (LSD) test to evaluate statistical significance of factors such as trial location, cultivation condition, and pre-harvest interval (PHI) on the residue concentrations and half-lives, as well as % RQ values between different population groups. Statistical significance was defined as p < 0.05. The optimal kinetic models were determined by evaluating the chi-square error (χ2%) and the correlation coefficient (R2).

3. Results and Discussion

3.1. Quality Assurance/Quality Control

The method was validated in terms of linearity, ME, limit of quantitation (LOQ), accuracy and precision in accordance with European guideline document SANTE/11312/2021 (v2) [32]. The absence of detectable interference at the retention times of CYA (2.21 min) and LUF (2.88 min) was confirmed by blank pak choi matrix analysis (Figure S1). Linearity was verified using solvent- and matrix-matched standard calibration curves across concentrations of 0.01–1 mg/L. As shown in Table 2, excellent linearity was achieved for all analytes, with correlation coefficients (R2) ranging from 0.9906 to 0.9988. A slight matrix enhancement effect was observed for CYA (ME% = 8.5%) and LUF (ME% = 2.2%) in pak choi. The LOQ was defined as the minimum validated spiked concentration in pak choi, established as 0.04 mg/kg for both CYA and LUF. Spiking levels were set based on the respective Maximum Residue Limits (MRLs): CYA in pak choi (MRL = 7 mg/kg) and LUF in cabbage (MRL = 1 mg/kg). Accuracy and precision were evaluated using the mean recoveries and relative standard deviations (RSDs) with five replicates at three concentrations for each analyte: 0.04, 0.1, and 7 mg/kg for CYA and 0.04, 0.1, and 1 mg/kg for LUF. Mean recoveries for CYA in pak choi ranged from 80% to 100% with RSDs of 1.7–4.7%, while recoveries for LUF ranged from 86% to 97% with RSDs of 3.8–4.5%. The stability of CYA and LUF in working and matrix-matched solutions was evaluated weekly throughout the study, with no significant degradation observed. All validation criteria—specificity, linearity, ME, LOD, LOQ, repeatability, reproducibility, and stability—met the satisfactory requirements outlined in SANTE/11312/2021 (v2).

Table 2.

Linearity, matrix effects (MEs), average recoveries (%) and relative standard deviations (RSDs,%) for CYA and LUF in pak choi.

3.2. Dissipation Characteristics of CYA and LUF in Pak Choi

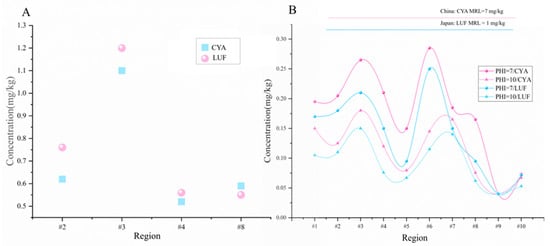

The initial deposition of CYA and LUF ranged from 0.55 to 1.2 mg/kg in pak choi across Trials #4, #6, #7, and #10 (Figure 2A), with greenhouse conditions (#4) showing the highest levels, confirming that elevated pesticide deposition typically occurs in enclosed environments [33]. The concentrations of both pesticides peaked at 2 h after application and subsequently degraded steadily over time. Notably, rapid dissipation exceeding 50% (54.5–90.0%) was observed after 7 d, with concentrations reaching minimum levels at 14 d and achieving dissipation rates of 82.7–95.2%, demonstrating distinct rapid and slow dissipation phases. Therefore, both SFO and DFOP equations were employed to fit the dissipation of the two pesticides in pak choi samples, with the most suitable equation selected based on the highest R2 values and smallest chi-square (χ2) values [34]. The DFOP model was superior to the SFO model for biphasic dissipation patterns, involving rapid initial processes (e.g., photolysis, surface hydrolysis) followed by slower ones (e.g., metabolism, bound residue release) [35]. DFOP provides a better statistical fit when SFO fails to describe these complexities, as demonstrated in prior studies on dimethachlon and difenoconazole degradation in tomatoes [34,36]. For LUF in Trial #10 (Table 3), the DFOP model demonstrated superior fitting (R2 = 0.9999; χ2 error = 1.09%) compared to the SFO model (R2 = 0.9961; χ2 error = 1.7%). Similarly, CYA dissipation in Trial #4 was better fitted by the DFOP (R2 = 0.9997; χ2 error = 1.85%) than the SFO model (R2 = 0.9992; χ2 error = 2.49%). In the other three regions, both CYA and LUF exhibited satisfactory correlation coefficients and lower errors when fitted with the SFO model. The half-lives of CYA and LUF in pak choi were 3.04–5.41 d and 2.02–5.13 d, respectively. Considering climatic factors and pak choi growth stage, significant variations in dissipation rates were observed among trials despite similar original deposition levels in Trials #6, #7, and #10. Trial #10 exhibited higher temperatures compared to the other two regions, resulting in shorter dissipation half-lives (2.02 d for LUF, and 3.26 d for CYA) due to enhanced evaporation, co-distillation, and thermal dissipation of both compounds under high temperatures [37]. Meanwhile, different biological growth stages also contributed to variations in the dissipation rates. In Trial #6 (BBCH, 33), the half-lives of LUF (5.13 d) and CYA (5.14 d) were 2.4 and 1.62 times (p < 0.05) longer than those in Trial #10 (BBCH, 45), respectively. This difference stems from the phenomenon whereby as the main root development increased along with greater plant spread, these morphological characteristics tended to accelerate the dissipation of CYA and LUF in pak choi [28]. When comparing across different crops, varying dissipation half-lives were observed for both pesticides. For CYA, comparable half-lives were observed in peppers (2.8–3.26 d) [22], watermelon (2.7 d) [38], peaches (2.5 d) [39], and tomatoes (2.6 d) [40] compared to pak choi, while significantly longer half-lives occurred in grains and straw (11.3 and 9.4 d, respectively) [41]. Similarly, LUF showed comparable half-lives in cabbage (1.7–5.0 d) [42] to our experimental results, but exhibited slower dissipation in kumquat (9.12–12.6 d) [43]. In conclusion, the dissipation of pesticides resulted from the combined influence of various environmental and agricultural parameters, including crop varieties, deposition concentration, environmental conditions, and growth period.

Figure 2.

The initial deposition of CYA and LUF in pak choi (A), and terminal levels of eCYA and LUF in pak choi with PHI of 7 d and 10 d (B).

Table 3.

Dissipation rates (%) and half-lives of CYA and LUF in pak choi. based on SFO and DFOP models.

3.3. Terminal Levels of CYA and LUF in Pak Choi

Terminal residue concentrations of CYA and LUF in pak choi ranged from <LOQ to 0.285 mg/kg (Figure 2B), as demonstrated by one-year field experiments conducted across 10 locations. The concentrations of both CYA and LUF decreased significantly with extended preharvest intervals (PHIs) in nine field trials (p = 3.4 × 10−9 for CYA, p = 2.9 × 10−8 for LUF). Notably, both compounds were undetectable in Trial #9, characterized by an alpine climate, likely due to enhanced photodegradation resulting from intense solar radiation at high altitudes [44]. In addition to altitude effects, regional climatic variations significantly influenced residue dissipation at 10-day PHI. Terminal residue levels were lowest in subtropical monsoon climate regions (CYA: 0.067 mg/kg; LUF: 0.054 mg/kg), suggesting that elevated temperature and humidity accelerate compound dissipation [33,34,37]. Furthermore, the final levels of CYA and LUF in pak choi from greenhouse cultivation (0.062–0.18 mg/kg) were higher than those from open-field cultivation (0.053–0.17 mg/kg) (p < 0.05). This result is consistent with findings for tolfenpyrad in cabbage [28], which may be attributed to both higher initial deposition in enclosed environments and the closed environment favoring compound retention in brassica vegetables [45]. This is strongly supported by the compound-specific degradation mechanisms reported by JMPR. CYA can undergo various biochemical pathways in crops and the environment through hydrolysis, oxidation, and other processes, generating up to 20 metabolites. The primary metabolite IN-J9Z38 is produced through environmental factors and plant degradation processes, with photolysis and hydrolysis being the main factors [26]. In contrast, LUF exhibits high stability in plant tissues, with its dissipation mainly relying on abiotic pathways such as photolysis on plant surfaces. This finding is consistent with our observed results regarding environmental influences on terminal residue levels [27]. Considering economic factors and terminal levels, a 7-day PHI is recommended for practical application. The highest residues (HR) were 0.29 mg/kg for CYA and 0.25 mg/kg for LUF at 7-day PHI (Table 4), which are both well below established maximum residue limit (MRL) values. The MRL for CYA in pak choi is 7 mg/kg in China, which is less stringent than the standards of the Codex Alimentarius Commission (CAC, 2 mg/kg) and Japan (3 mg/kg), but more stringent than the limit in the United States (30 mg/kg). In contrast, LUF in pak choi currently lacks established MRLs in China and other countries or regions, with only Japan having set an MRL of 1 mg/kg. Given that China is positioned as a major exporter of Brassica vegetables, strict monitoring of pesticide concentration changes in agricultural products is essential to prevent trade barriers caused by excessive pesticide residues. However, the current absence of internationally harmonized MRL standards, particularly for LUF in pak choi (where only Japan has a standard), poses potential export challenges. Therefore, accelerating the development of MRL standards for LUF in pak choi is essential to mitigate exposure risks and ensure international trade. This research provides an important theoretical foundation and scientific reference for MRL formulation, ultimately recommending 1 mg/kg as the residue limit for LUF in pak choi.

Table 4.

The STMR and HR of CYA and LUF.

3.4. Dietary Risk Assessment of Pesticides in Pak Choi

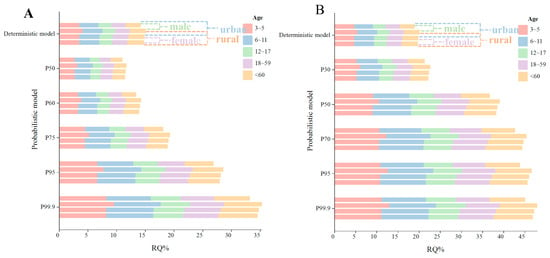

Dietary exposure assessment for pesticides has evolved from deterministic assessments based on single-point estimates (such as STMR values) to comprehensive probabilistic assessments based on Monte Carlo simulations. Probabilistic models have been widely adopted as the primary tool for pesticide exposure assessment, as they effectively address the incidence, variability, and uncertainty of dietary risks. The probabilistic model utilizes lognormal distribution and Monte Carlo resampling methods to assign more precise values to pesticide data, thereby improving risk-fitting precision and compensating for the limitations of deterministic approaches [29]. The STMR values for CYA and LUF in pak choi were determined as 0.18 mg/kg and 0.16 mg/kg (Table 4), respectively, through large-scale field trials conducted across China. According to the 2015–2017 Chinese National Nutrition and Health Survey, dietary consumption varies by gender, age, and region. Regarding CYA, the deterministic model estimated % RQ values ranging from 2.2% to 4.1%. The probabilistic model yielded results of 1.7–3.2%, 2.1–3.9%, 2.8–4.5%, 4.3–6.7%, and 5.2–9.6% at the 50th, 60th, 75th, 95th, and 99.9th percentiles, respectively (Table S1). The 60th percentile values showed the closest correspondence to deterministic results (Figure 3A). Regarding LUF, the deterministic model estimated % ADI values ranging from 2.9% to 4.7%. Probabilistic results were 3.3–6.1%, 5.7–10.6%, 6.7–10.6%, 6.9–10.9%, and 7.0–13.0% at the 30th, 50th, 70th, 95th, and 99.9th percentiles, respectively (Table S2). The 30th percentile values demonstrated the best agreement with deterministic results (Figure 3B). These comparisons demonstrate that the deterministic model overestimated or underestimated risk quotients through point value assessment, despite its operational simplicity [46]. Even when the 99.9th percentile exposure value was selected for long-term exposure assessment endpoints, all % RQ remained below 100%, indicating that prolonged exposure to CYA and LUF through pak choi consumption would not pose public health concerns. Therefore, probabilistic models are recommended to provide a comprehensive and precise risk assessment across multiple probability levels while minimizing variability and uncertainty in the evaluation process.

Figure 3.

Long-term dietary risk of CYA (A) and LUF (B) in pak choi by deterministic and probabilistic models for people of different ages, genders, and regions.

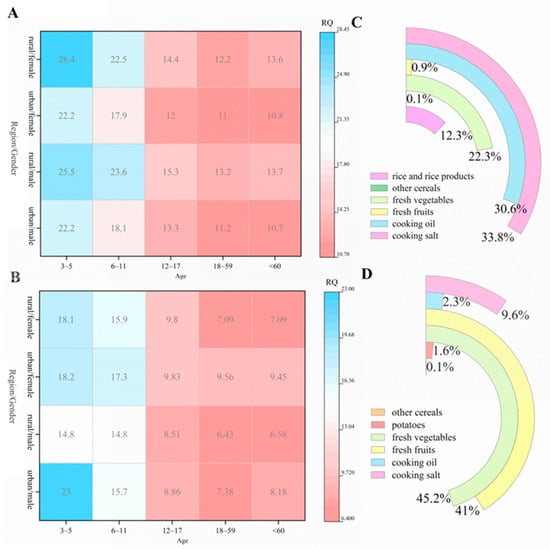

Furthermore, the health risks associated with consumption of multiple foods were much greater than those associated with single dietary crops. Therefore, the total chronic dietary risk of CYA and LUF in all registered crops in China was assessed. Following the risk maximization principle, the Maximum Residue Limit (MRL) value of registered crops was selected for assessment. The dietary classification and MRL summary of registered crops are summarized in Table 5. The deterministic assessment method was employed for evaluation. The total % RQs of all registered crops ranged from 10.7% to 28.4% for CYA (Figure 4A) and from 6.43% to 23.0% for LUF (Figure 4B). A clear decreasing trend in risk was observed from children to adults (p < 0.05). The 3–5 years age group exhibited the highest risk for CYA and LUF, with risk quotients of 22.2–28.4% and 18.1–23.0%, respectively. This elevated risk was primarily attributed to higher per-unit body weight intake and greater sensitivity to contaminants in children. Indeed, the same phenomenon has been observed in many studies: procymidone in Chinese leek, cowpea and celery poses the greatest risk to children aged 2–6 years [47], and 15 common pesticides in chrysanthemum pose the highest dietary risk to children aged 2–3 years [48]. Regarding CYA, dietary risks in rural areas were generally higher than those in urban areas. Cooking salt and cooking oil contributed 64.4% of the total NEDI (Figure 4C), with higher consumption of salt and oil observed in rural areas compared to urban areas. In contrast, urban areas demonstrated elevated LUF risks relative to rural areas due to higher fruit and vegetable consumption, which accounted for 86.2% of the total NEDI (Figure 4D). The risk levels are closely related to the dietary habits of these populations [49]. Collectively, CYA and LUF exhibited acceptable exposure risks in their registered crops.

Table 5.

Dietary risk assessment crop classification for registered crops and MRLs designated by different countries.

Figure 4.

Long-term dietary risk of CYA (A) and LUF (B) in registered crops by deterministic estimation across different ages, genders, and regions, and contributions of different crop categories to dietary exposure of CYA (C) and LUF (D) for the general consumer population.

4. Conclusions

Pak choi is extensively cultivated in China, and CYA and LUF play critical roles in pest control. However, comprehensive studies on the behavior and risks of these pesticides in pak choi systems remain limited. Therefore, this study conducted a systematic investigation from cultivation to consumption through the establishment of analytical methods, large-scale field trials across ten provinces, dissipation kinetics analysis, and dietary risk assessment. Results demonstrated half-lives of 3.04–5.41 d for CYA and 2.02–5.13 d for LUF, with dissipation rates significantly influenced by environmental factors and growth stage. Terminal residue concentrations ranged from <LOQ to 0.29 mg/kg, which were below MRLs. The dietary risk assessment demonstrated that exposure levels for all population groups remained within acceptable safety limits (<100% ADI), though children aged 3–5 years showed the highest % RQ (22.2–28.4% for CYA and 18.1–23.0% for LUF). Although % RQ values are considered safe, the elevated risk in children necessitates continued monitoring, particularly given their higher per-unit body weight intake and greater sensitivity to contaminants. This study fills a critical knowledge gap for CYA and LUF in pak choi systems; however, several limitations remain. Focusing on two pesticides alone may not reflect the cumulative risk from multiple pesticide exposures. Additionally, the impact of culinary practices on residue levels was not investigated, which could alter actual consumer exposure. Future studies should explore multi-residue interactions and the effects of food processing on pesticide dissipation. In summary, this work offers valuable insights into rational pesticide use, ensuring both food safety and international trade compliance in pak choi production.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/agronomy15102289/s1, Figure S1: Typical HPLC-MS/MS MRM chromatograms of CYA (A) and LUF (B) standards (0.01 mg/kg); Table S1: Long-term dietary risks of CYA in pakchoi for consumer groups using deterministic and probabilistic models; Table S2: Long-term dietary risks of LUF in pakchoi for consumer groups using deterministic and probabilistic models.

Author Contributions

Methodology, Y.Z.; Validation, R.L. (Rumei Li) and R.L. (Ruijuan Li); Investigation, T.L.; Writing—original draft, Y.Z.; Writing—review & editing, Y.Z. and H.L.; Project administration, Y.Z.; Funding acquisition, Y.Z., H.L. and F.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Agricultural scientific and technological innovation project of Shandong Academy of Agricultural Sciences (CXGC2025F05).

Data Availability Statement

The data presented in the study are available from the authors upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| ADI | Acceptable Daily Intake |

| ANOVA | Analysis of Variance |

| BBCH | Biologische Bundesanstalt, Bundessortenamt und CHemische Industrie |

| CAC | Codex Alimentarius Commission |

| CYA | Cyantraniliprole |

| DFOP | Double First-Order in Parallel |

| ESI | Electrospray Ionization |

| FAO | Food and Agriculture Organization |

| GAP | Good Agricultural Practice |

| HPLC | High-Performance Liquid Chromatography |

| HR | Highest Residue |

| JMPR | Joint FAO/WHO Meeting on Pesticide Residues |

| LOQ | Limit of Quantitation |

| LSD | Least Significant Difference |

| LUF | Lufenuron |

| ME | Matrix Effect |

| MeCN | Acetonitrile |

| MRL | Maximum Residue Limit |

| MRM | Multiple Reaction Monitoring |

| MS/MS | Tandem Mass Spectrometry |

| NEDI | National Estimated Daily Intake |

| OECD | Organisation for Economic Co-operation and Development |

| PHI | Pre-Harvest Interval |

| PSA | Primary Secondary Amine |

| RQ | Risk Quotient |

| RSD | Relative Standard Deviation |

| SFO | Single First-Order |

| STMR | Supervised Trial Median Residue |

| UHPLC | Ultra-High Performance Liquid Chromatography |

| WHO | World Health Organization |

References

- Liu, Z.; Qin, M.; Li, R.; Peijnenburg, W.J.G.M.; Yang, L.; Liu, P.; Shi, Q. Transport Dynamics and Physiological Responses of Polystyrene Nanoplastics in Pakchoi: Implications for Food Safety and Environmental Health. J. Agric. Food Chem. 2025, 73, 10923–10933. [Google Scholar] [CrossRef] [PubMed]

- You, M.; Ke, F.; You, S.; Wu, Z.; Liu, Q.; He, W.; Baxter, S.W.; Yuchi, Z.; Vasseur, L.; Gurr, G.M.; et al. Variation among 532 genomes unveils the origin and evolutionary history of a global insect herbivore. Nat. Commun. 2020, 11, 2321. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.; Shao, X.; Lin, H.; Hu, J. Dissipation, residues and risk assessment of metaldehyde and niclosamide ethanolamine in pakchoi after field application. Food Chem. 2017, 229, 604–609. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Qi, P.; Wang, X.; Wang, Z.; Sun, Y.; Wang, L.; Xu, X.; Xu, H.; Wang, Q.; Wang, X.; et al. Stereoselective Analysis and Degradation of Pyrisoxazole in Cabbage, Pakchoi, and Pepper by Liquid Chromatography Tandem Mass Spectrometry. J. Agric. Food Chem. 2017, 65, 8295–8301. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, X.; Si, Z.; Zhao, X.; Yan, H.; Xu, B.; Chen, Y.; Cui, L. Deposition, dissipation, metabolism, and dietary risk assessment of chlorothalonil on pakchoi. J. Food Compos. Anal. 2024, 134, 106521. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Liu, H.; Wang, Z.; Qi, P.; Zhao, H.; Liu, Z.; Gu, C.; Di, S. Study on the Enantioselective Separation, Dissipation, and Residue of Chiral Fenpropathrin in Vegetables by Supercritical Fluid Chromatography-Tandem Mass Spectrometry (SFC-MS/MS). J. Agric. Food Chem. 2024, 72, 27106–27114. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Zhao, H.; Liu, Z.; Qi, P.; Wang, Z.; Gu, C.; Di, S. SFC-MS/MS enantioseparation, stereoselective behavior and risk assessment of the chiral pesticide bitertanol in four vegetables and soil. Food Chem. 2025, 481, 143943. [Google Scholar] [CrossRef]

- Resende, M.T.C.S.d.; Souza, D.d.S.; Carneiro, L.S.; Motta, J.V.d.O.; Silva, L.L.d.; Serrão, J.E. Pathogen-pesticide-host interaction: Apoptosis modulation by Nosema ceranae increases honeybee susceptibility to the insecticide cyantraniliprole. J. Hazard. Mater. 2025, 495, 139064. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, S.; Li, M.; Wang, Y.; Shi, X.; Liang, P.; Yin, M.; Shen, J.; Gao, X. Nanodelivery System Alters an Insect Growth Regulator’s Action Mode: From Oral Feeding to Topical Application. ACS Appl. Mater. Interfaces 2022, 14, 35105–35113. [Google Scholar] [CrossRef]

- Qiao, Z.; Zhang, F.; Yao, X.; Yu, H.; Sun, S.; Li, X.; Zhang, J.; Jiang, X. Growth, DNA damage and biochemical toxicity of cyantraniliprole in earthworms (Eisenia fetida). Chemosphere 2019, 236, 124328. [Google Scholar] [CrossRef]

- Meng, Z.; Cui, J.; Liu, L.; Yang, C.; Bao, X.; Wang, J.; Chen, X. Toxicity effects of chlorantraniliprole in zebrafish (Danio rerio) involving in liver function and metabolic phenotype. Pestic. Biochem. Physiol. 2022, 187, 105194. [Google Scholar] [CrossRef]

- Ferreira de Menezes, A.C.; Luiz, K.G.; Velho, J.B.; Quadreli, D.H.; Regina da Costa, I.; Bomfim, L.P.; Stacy dos Santos Silva, M.; Ferreira, S.F.; Goulart de Andrade, F.; Ceccatto Gerardin, D.C.; et al. Oral administration of cyantraniliprole to wistar rats during pregnancy and lactation alters maternal behavior and harms the female reproductive system of pubertal and adult offspring. Food Chem. Toxicol. 2025, 197, 115272. [Google Scholar] [CrossRef]

- Saeed, S.; Afzal, G.; Ali, H.M.; Hussain, R.; Jabeen, R.; Kiran, S.; Iqbal, R.; Alam, S.; Jalal, A.; Nisa, Z.u.; et al. Patho-physiological effects of environmental relevant concentrations of lufenuron in male Japanese quails. Environ. Res. 2025, 274, 121203. [Google Scholar] [CrossRef]

- Basal, W.T.; Ahmed, A.R.T.; Mahmoud, A.A.; Omar, A.R. Lufenuron induces reproductive toxicity and genotoxic effects in pregnant albino rats and their fetuses. Sci. Rep. 2020, 10, 19544. [Google Scholar] [CrossRef]

- Jankowska, M.; Kaczyński, P.; Hrynko, I.; Rutkowska, E.; Iwaniuk, P.; Ilyasova, G.; Łozowicka, B. Dietary risk assessment of children and adults consuming fruit and vegetables with multiple pesticide residues. Chemosphere 2024, 369, 143858. [Google Scholar] [CrossRef]

- Su, Y.; Lu, J.; Liu, J.; Li, F.; Wang, N.; Lei, H.; Shen, X. Optimization of a QuEChERS–LC–MS/MS method for 51 pesticide residues followed by determination of the residue levels and dietary intake risk assessment in foodstuffs. Food Chem. 2024, 434, 137467. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Ren, X.; Zheng, L.; Wang, X.; Liu, T. A systematic analysis of residue and risk of cyantraniliprole in the water-sediment system: Does metabolism reduce its environmental risk? Environ. Int. 2023, 179, 108185. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Fang, N.; Li, Y.; Wang, X.; He, H.; Jiang, J.; Tang, T.; Xu, Z.; Zhao, X.; Li, Y. Uptake, translocation and distribution of cyantraniliprole in rice planting system. J. Hazard. Mater. 2022, 436, 129125. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, W.; Zhang, T.; Liang, G.; Hu, B.; Han, P.; Gong, W. Assessing transfer of pesticide residues from chrysanthemum flowers into tea solution and associated health risks. Ecotoxicol. Environ. Saf. 2020, 187, 109859. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, L.; Zhang, C.; Zhang, H.; Lian, K. Determination of 12 insect growth regulator residues in foods of different matrixes by modified QuEChERS and UPLC-MS/MS. RSC Adv. 2021, 11, 12162–12171. [Google Scholar] [CrossRef] [PubMed]

- Malhat, F.; Almaz, M.; Arief, M.; El-Din, K.; Fathy, M. Residue and Dissipation Dynamics of Lufenuron in Tomato Fruit Using QuEChERS Methodology. Bull. Environ. Contam. Toxicol. 2012, 89, 1037–1039. [Google Scholar] [CrossRef] [PubMed]

- Poornima, G.; Harischandra Naik, R.; Pallavi, M.S.; Saraswati, M.; Ratnamma, P.; Shwetha, A.; Paramasivam, M.; Bheemanna, M.; Udaykunar Nidoni, R. Determination of cyantraniliprole in green and red chilli fruits and Indian soil using LC-MS/MS and its dietary risk assessment. J. Food Compos. Anal. 2025, 141, 107294. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, X.; Zhao, H.; Wu, M.; He, H.; Zhang, C.; Tang, T.; Ping, L.; Li, Z. Residues of cyantraniliprole and its metabolite J9Z38 in rice field ecosystem. Chemosphere 2013, 93, 190–195. [Google Scholar] [CrossRef]

- OECD. Test No. 509: Crop Field Trial. 2021. Available online: https://www.oecd-ilibrary.org/environment/test-no-509-crop-field-trial_9789264076457-en (accessed on 16 September 2025).

- Fan, Z.; Liu, F.; Ren, X.; Cheng, Y.; Wu, M.; Zhang, H.; Zhao, L.; Chen, Z. Large-scale fate tendency of lufenuron during cabbage cultivation: New insights into dietary risk and models comparison. Ecotoxicol. Environ. Saf. 2025, 303, 118824. [Google Scholar] [CrossRef] [PubMed]

- JMPR. CYANTRANILIPROLE. 2015. Available online: https://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/Evaluation13/Cyantraniliprole.pdf (accessed on 16 September 2025).

- JMPR. LUFENURON. 2015. Available online: https://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/Evaluation2015/LUFENURON__286_.pdf (accessed on 16 September 2025).

- Tong, L.; Li, L.; Suzhen, L.; Xin, R.; Manni, W.; Fengjiao, L.; Youpu, C.; Zenglong, C. Integrating processing factors and large-scale cabbage cultivation to understand the fate tendency and health risks of tolfenpyrad using deterministic and probabilistic models. J. Hazard. Mater. 2025, 486, 137131. [Google Scholar] [CrossRef]

- Wei, D.; Wu, X.; Ji, M.; Xu, J.; Dong, F.; Liu, X.; Zheng, Y. Carboxin and its major metabolites residues in peanuts: Levels, dietary intake and chronic intake risk assessment. Food Chem. 2019, 275, 169–175. [Google Scholar] [CrossRef]

- Cui, K.; Fang, L.; Ding, R.; Ni, R.; Liang, J.; Li, T.; Wang, J.; Liu, J.; Guan, S.; Dong, Z.; et al. Dissipation and metabolism of fluxapyroxad, oxathiapiprolin and penthiopyrad in grapes: A comprehensive risk assessment from field to raisins. Food Chem. 2025, 485, 144510. [Google Scholar] [CrossRef]

- Zhu, Y.; Zheng, Y.; Dong, F.; Wu, X.; Pan, X.; Xu, J. Insight into abiotic and biotic transformations of fenaminstrobin in water and soil: Kinetics, transformation mechanism and ecotoxicity. J. Hazard. Mater. 2025, 493, 138324. [Google Scholar] [CrossRef]

- EURL. Analytical Quality Control and Method Validation Procedures for Pesticide Residues Analysis in Food and Feed. 2024. Available online: https://eurl-pesticides.eu/docs/public/tmplt_article.asp?CntID=727 (accessed on 16 September 2025).

- Wang, X.; Chen, L.; Ren, X.; Kang, S.; Zhao, L.; Zhang, H.; Li, X.; Chen, Z. Fate characteristics and risk quantification of cyflumetofen from tomato cultivation to processing based on large–scale applications. J. Hazard. Mater. 2024, 465, 133496. [Google Scholar] [CrossRef]

- Maldonado-Reina, A.J.; López-Ruiz, R.; Marín Sáez, J.; Romero-González, R.; Garrido Frenich, A. Tracing the dissipation of difenoconazole, its metabolites and co-formulants in tomato: A comprehensive analysis by chromatography coupled to high resolution mass spectrometry in laboratory and greenhouse trials. Environ. Pollut. 2024, 349, 123924. [Google Scholar] [CrossRef]

- Tang, T.; Ji, C.; Xu, Z.; Zhang, C.; Zhao, M.; Zhao, X.; Wang, Q. Degradation Kinetics and Transformation Products of Levonorgestrel and Quinestrol in Soils. J. Agric. Food Chem. 2019, 67, 4160–4169. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Liu, L.; Liu, J.; Luo, Y.; Fu, S.; Lu, P.; Hu, D.; Zhang, Y. A comprehensive assessment of the dimethachlon and its metabolites: Field degradation, processing factors and toxicity. J. Food Compos. Anal. 2025, 146, 107969. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Ren, X.; Li, W.; Chen, L.; Zhao, L. Fate and occurrence of indoxacarb during radish cultivation for multi-risk assessment. Ecotoxicol. Environ. Saf. 2023, 259, 115065. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, C.; Zhu, Y.; Wu, M.; Cai, X.; Ping, L.; Li, Z. Determination of Residues of Cyantraniliprole and Its Metabolite J9Z38 in Watermelon and Soil Using Ultra-Performance Liquid Chromatography/Mass Spectrometry. J. AOAC Int. 2013, 96, 1448–1452. [Google Scholar] [CrossRef]

- Žunić, A.; Vuković, S.; Lazić, S.; Šunjka, D.; Bošković, D. The efficacy of novel diamide insecticides in Grapholita molesta suppression and their residues in peach fruits. Plant Prot. Sci. 2020, 56, 46–51. [Google Scholar] [CrossRef]

- Malhat, F.; Kasiotis, K.M.; Shalaby, S. Magnitude of cyantraniliprole residues in tomato following open field application: Pre-harvest interval determination and risk assessment. Environ. Monit. Assess. 2018, 190, 116. [Google Scholar] [CrossRef]

- Lee, J.; Jung, M.W.; Lee, J.; Lee, J.; Shin, Y.; Kim, J.-H. Dissipation of the Insecticide Cyantraniliprole and Its Metabolite IN-J9Z38 in Proso Millet during Cultivation. Sci. Rep. 2019, 9, 11648. [Google Scholar] [CrossRef]

- Dong, B.; Zhao, Q.; Hu, J. Dissipation kinetics of emamectin benzoate and lufenuron residues in cabbage grown under field conditions. Environ. Monit. Assess. 2015, 187, 765. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Chen, W.; Deng, P.; Luo, X.; Xiong, Z.; Li, Z.; Ning, Y.; Liu, Y.; Chen, A. Dissipation, residues and risk assessment of lufenuron during kumquat growing and processing. J. Food Compos. Anal. 2022, 112, 104643. [Google Scholar] [CrossRef]

- Fang, Y.-f.; Huang, Y.-p.; Liu, D.-f.; Huang, Y.; Guo, W.; David, J. Photocatalytic degradation of the dye sulforhodamine-B: A comparative study of different light sources. J. Environ. Sci. 2007, 19, 97–102. [Google Scholar] [CrossRef]

- Lan, T.; Yang, G.; Li, J.; Chi, D.; Zhang, K. Residue, dissipation and dietary intake risk assessment of tolfenpyrad in four leafy green vegetables under greenhouse conditions. Food Chem. X 2022, 13, 100241. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Li, L.; Ren, X.; Zhang, M.; Li, W.; Chen, Z. Occurrence and fate characteristics of isoproturon from garlic cultivation to household processing: Implication for human exposure. J. Hazard. Mater. 2023, 448, 130936. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Li, S.; Zhang, W.; Cheng, Y.; Liu, Z.; Zhang, N.; Xu, J.; Wu, X.; Dong, F.; Zheng, Y.; et al. Sensitive and portable intelligent detection platform construction and dietary risk assessment of procymidone in Chinese leek, cowpea and celery. Food Chem. 2025, 465, 142081. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Fan, W.; Zha, C.; Wang, Z.; Yu, J.; Wu, L.; Zhang, X.; Luo, F.; Chen, Z.; Zhou, L. Occurrence, fate and dietary risk assessment of pesticides in chrysanthemum from garden to cup. J. Hazard. Mater. 2025, 493, 138363. [Google Scholar] [CrossRef]

- Wei, L.; Wang, K.; Liang, X.; Shi, Y.; Pan, X.; Wu, X.; Xu, J.; Dong, F.; Zheng, Y. Occurrence and risk assessment of mycotoxins and their modified forms in maize from typical planting regions of China. Food Chem. 2025, 483, 144253. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).