Abstract

Plants have long been exploited as a sustainable source of food, flavors, agrochemicals, colors, therapeutic proteins, bioactive compounds, and stem cell production. However, plant habitats are being briskly lost due to scores of environmental factors and human disturbances. This necessitates finding a viable alternative technology for the continuous production of compounds that are utilized in food and healthcare. The high-value natural products and bioactive compounds are often challenging to synthesize chemically since they accumulate in meager quantities. The isolation and purification of bioactive compounds from plants is time-consuming, labor-intensive, and involves cumbersome extraction procedures. This demands alternative options, and the plant cell culture system offers easy downstream procedures. Retention of the metabolic cues of natural plants, scale-up facility, use as stem cells in the cosmetics industry, and metabolic engineering (especially the rebuilding of the pathways in microbes) are some of the advantages for the synthesis and accumulation of the targeted metabolites and creation of high yielding cell factories. In this article, we discuss plant cell suspension cultures for the in vitro manipulation and production of plant bioactive compounds. Further, we discuss the new advances in the application of plant cells in the cosmetics and food industry and bioprinting.

1. Introduction

Plants are a potent and inexhaustible source of phytoconstituents. Out of 50,000 plant species spread the world over, only one percent of them produce bioactive compounds, leading to their overexploitation, destruction of natural habitat, and extinction [1]. Nearly 25% of modern medicines are derived from natural resources such as algae, fungi, and higher plants [2,3]. Plant-based drugs have been in use since time immemorial, and the market has been growing steadily and may reach USD 50 billion during the next five years or so [1]. While some plants are endemic, others are endangered. Many plants produce nano quantities of secondary plant products and are often dependent on seasonal variations. Conventional methods of obtaining bioactive compounds are confronted with a number of inherent drawbacks and are affected by several internal and external factors. Plant tissue cultures are an excellent source for the extraction of many targeted metabolites. Therefore, plant tissue, organ, and cell suspension cultures are being exploited for the accumulation and analysis of numerous phytochemicals and for the biotransformation of physiologically not-so-active compounds into pharmacologically active compounds [4,5,6,7,8,9]. Further, morphogenic cell suspensions are a good source and an exceptional platform for the examination of metabolomic and proteomic changes that take place during the production of various bioactive compounds [10,11]. Such an approach may ultimately lead to the discovery of biosynthetic pathways of the bioactive compounds. The homogeneity of cell suspensions, scalability, reasonably good cell doubling time, less space requirement, and ease of handling the cultures are the key features that offer attractive options for the production of many secondary plant products. Further, in vitro cultures are free from seasonal variations and microbial contamination and, hence, are ideal for the large-scale generation of bioactive molecules. Biochemical and physiological pathways associated with secondary plant products have been elucidated by integrating the data generated through multi-omic techniques in many plant systems, including the model plant A. thaliana [12]. Elicitation, immobilization, and permeabilization coupled with in situ adsorption of secondary plant products using resins such as XAD7 are possible using suspensions [12,13]. Elicitation is one well-known yield enhancement strategy, usually implemented to induce or enhance secondary metabolite synthesis by the plant cells. In addition to enhancing secondary metabolite production, elicitation involves the manipulation of various parameters that can induce stress in biochemical and metabolic pathways and, thus, can be applied to understanding the role of several stress factors on plants by using plant cells or tissue culture as model systems [14]. This provides an opportunity for intensive research in the field of biosciences for the exploitation of plant cells to produce high-value secondary metabolites. Chodisetti et al. [15] reported the elicitation of gymnemic acid in the cell suspension cultures of Gymnema sylvestre R. Br. using phytohormones such as salicylic acid and methyl jasmonate as elicitors. In addition, Chodisetti et al. [16] improved gymnemic acid production in the suspension cultures using biotic elicitors such as Agrobacterium rhizogenes, Saccharomyces cerevisiae, Aspergillus niger, Bacillus subtilis, and Escherichia coli. Veerashree et al. [17] reported the elicitation of gymnemic acid through cell suspension cultures using biotic elicitors such as methyl jasmonate, yeast extract, pectin, and chitin. Several reports emphasized the importance of yeast extract in eliciting secondary metabolite production for in vitro cultures, including rosmarinic acid and lithospermic acid B [18], plumbagin [12], and camptothecin [19]. There are several reports on the use of pectin as an elicitor, for example, the elicitation of triterpene acids from Uncaria tomentosa cell suspension cultures [20] and menthol from Mentha piperita cell culture [21]. The production of high-value compounds from plant cell cultures using biotic and abiotic elicitors has instigated a novel research area that has commercial benefits for the pharmaceutical industry. Hence, numerous factors, such as the type and concentration of elicitor, age of culture, cell viability, cell line selected, period of elicitor exposure, nutrient composition, and growth regulation that affect the process of elicitation, should be taken into consideration while performing elicitation studies [22]. Methods that can be applied to determine the ideal time include biomass evaluation, carbohydrate utilization, and analyzing extracellular products formed. The appropriate quantity of elicitor that effectively enhances the production of secondary metabolite varies widely for each cell material and must be determined.

Such novel techniques facilitate the exploitation of cell cultures for large-scale production of secondary metabolites, pigments, aromas, flavors, dietary supplements, fragrances, cosmetics, and bio-stimulants [23,24,25,26]. In situ adsorption of the compounds aid in the extraction of the compounds directly and avoids the purification steps in the downstream process [12]. Therefore, hairy root cultures and suspensions are good alternative sources, especially in the wake of competition for land use in view of intensive agriculture, climate change, and dwindling natural resources. Elicitation-enhanced synthesis of secondary products such as chicoric acid, rosmarinic acid, rutin, isoquercetin, linalool, and estragole have been reported in Ocimum basilicum [26]. In saffron, cell suspension cultures were used to establish a system for salicylic acid-elicited production of specialized metabolites such as crocin and carotenoid [27].

High-value compounds obtained from plant cell suspension cultures that have entered the pharmaceutical industry include carotenoids, rosmarinic acid, polysaccharides, berberine, podophyllotoxin, docetaxel, paclitaxel, scopolamine, and shikonin [1]. Commercialization of such compounds has further encouraged researchers to exploit cell culture techniques for the accumulation of other high-value and low-volume products on a large scale. Because of their high homogeneity and growth rate in liquid cultures, suspensions are also regarded as model systems for deciphering complex biochemical processes [28,29]. Specific tobacco cell lines Bright Yellow 2 (BY-2) have been utilized as model systems to investigate molecular mechanisms associated with cell divisions, phytohormone signaling, intracellular trafficking, and the production of secondary products [30,31]. Bioreactors are now developed for industrial-scale production of cell suspensions having value-added compounds [1,32]. Numerous types of bioreactors using plant cells, such as stirred tanks, bubble beds, rotary bioreactors, membrane bioreactors, and reactors for hairy root cultures, have been designed [33]. The effects of two-stage culture, initially for proliferation and then for the production of secondary metabolites, have been studied. Bioreactors for immobilized plant cells are also described. Immobilized cells in the bioreactors are protected from fluid dynamic stresses and are metabolically stable, but mass transfer limitations and other factors such as oxygen, substrate, and product transports could be problematic and challenging. Approaches for enhancing the productivity of plant cultures in bioreactors are coupled with the design of well-organized systems, and an acceptable method is often linked to using a combination of different techniques and treatments. A number of studies and patents related to bioreactor designs and fabrications are revolutionizing the entire process of plant cell culture technology [1,33].

We used the following keywords and web pages to obtain the crucial information furnished here. While the important keywords include bioactive compounds, cosmetics, foods and food ingredients, hairy roots, industrial production, phytochemicals, plant cell cultures, and suspension cultures, the following web pages have also been explored: (a) https://www.abres.it/echinacoside.php (accessed on 20 January 2022); (b) https://www.abres.it/teupolioside.php (accessed on 25 February 2022); (c) https://www.abres.it/verbascoside-acteoside.php (accessed on 6 April 2022); (d) https://mibellebiochemistry.com/phytocelltectm-nunatakr (accessed on 10 March 2022); (e) https://mibellebiochemistry.com/phytocelltectm-symphytum (accessed on 15 May 2022). PhytoCellTec™ by Mibelle Biochemistry used bioreactors for the culture of stem cells in large-scale bioreactors, and other examples include cell suspension bioreactor cultures, including Rosa damascena, Haberlea rhodopensis, and Calendula officinalis. Many cosmetic and pharmaceutical companies are now using bioreactors for modern pharmaceutical and cosmetic products with exceptional properties [34]. In addition, an anti-aging or antioxidant composition including compounds derived from a ginseng cambium-derived plant stem cell line as an active ingredient has been patented by Unhwa Corp. (Patent number: US9095532B2). The product is designed to minimize the side effects associated with existing anti-aging agents and antioxidants, making it safe for the skin. It also has antioxidant properties, inhibiting reactive oxygen species caused by exposure to UV radiation, which is the main cause of skin aging. Another example is TEUPOL 10P or 50P, which is an extract from Ajuga repta.

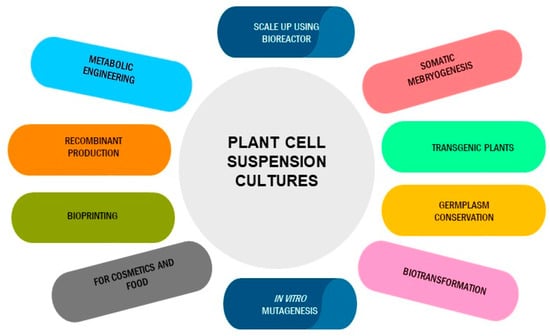

Plant cell suspensions, being sustainable, free from pesticide residues, and independent of climate changes, have advantages over field-grown intact plants, which display developmental stages of growth, age of the plant, and organ-specific variations [5,35]. Plant cell cultures have the potential to release biologically active chemicals through the cell membrane and cell walls into the intercellular spaces or into the spent medium; hence, the process of their extraction and purification is meaningfully simplified [36]. The secreted substances, after downstream processing from the cells, have a high degree of purity with minimal losses. Several biochemical and genetic factors play significant roles in product synthesis in the cell cultures. Genetic background, feedback regulation, channeling, cell selection and screening, and degradation and adsorption of metabolites determine the metabolite synthesis and accumulation in the cell cultures [7,36]. Plant cell suspension cultures are now being employed for recombinant protein expression, scaled-up using bioreactors, transgenic plant development, in vitro germplasm preservation, generation of novel mutants, bioprinting, cosmetics, and biotransformation (Figure 1). Suspensions have certain limitations since some of the compounds cannot be produced in suspensions, unlike that of organ cultures like hairy roots (exploited for root-derived chemicals) or shooty teratomas (produced for the synthesis of secondary produced noticed in aerial parts of plants) [37,38]. Cell suspensions established from the meristematic cells have certain unique features and are generally genetically stable and, hence, are widely exploited for higher metabolite synthesis [39,40]. Extensive work has been carried out using meristem-derived cell suspensions for the production of specialized biomolecules [41,42].

Figure 1.

Potential applications of plant cell cultures. Rare and endangered plants can be conserved in vitro in the form of cell suspensions (in vitro germplasm preservation), and also the cells can be treated with physical and chemical mutagens for generating variations in the secondary metabolite content. The rest of the applications are explained in the text.

2. Production of Therapeutic Recombinant Proteins from Cell Cultures

The biopharmaceutical market has been growing fast; several products are commercialized, and many more are in the pipeline [23,43]. Therapeutic recombinant proteins have become an effective arsenal against several diseases (Table 1). Currently, bacteria, yeasts, and insect and mammalian host cells grown in fermenters are the preferred platforms for producing recombinant proteins. Similar to mammalian cells and microbial cultures, tobacco BY-2 suspensions have been found to be highly encouraging for the synthesis of therapeutic recombinant proteins. While a microbial system is a simple and economically feasible system, it cannot synthesize complex proteins and perform post-translational modifications. Contrarily, mammalian cells perform precise folding of proteins and other essential modifications, but economic feasibility is a question. Additionally, both platforms are prone and susceptible to unwanted contamination, posing problems for downstream processing and obtaining the purified proteins [23].

In this regard, plant cells undergo post-translational modifications and can synthesize many therapeutic proteins with proper folding. Plant cell suspensions or organ cultures have been used for the production of recombinant proteins, antibodies, and vaccines [44] (Table 1). The added benefits are a scale-up possibility under a sterile environment, low growth costs, production of complex proteins, low risk of contamination with human pathogens, and the possibility of optimized growth procedures [45].

Table 1.

Compendium on therapeutic proteins produced using plant cell cultures/hairy roots.

Table 1.

Compendium on therapeutic proteins produced using plant cell cultures/hairy roots.

| Name of the Therapeutic Protein | Plant Cells Used as Hosts | Yield of Therapeutic Protein | Reference |

|---|---|---|---|

| Hyaluronic acid (recombinant human hyaluronic acid synthase2, rhHAS2) (A polysaccharide used in pharmaceutical, biomedical, and cosmetic fields) | Nicotiana tabacum hairy root cultures | 65.72 ng/kg fresh weight | [46] |

| Miraculin protein in transgenic carrot callus suspensions using air-lift bioreactors | Daucus carota suspension cultures using air-lift bioreactors | 0.024 µg/µL (0.98% of TSP) at 6 days | [47] |

| L-Asparaginase II | Solanum tuberosum hairy root cultures | 301.27 international units of activity/mg of protein | [48] |

| Human α1-antitrypsin | Nicotiana tabacum BY-2 cell cultures | 34.7 mg/L medium | [49] |

| Anti-CD20scFv-Fc (tumor-targeting antibody) (enhancing the secretion of a glycoengineered anti-CD20 scFv-Fc antibody) | Nicotiana benthamiana hairy root cultures | 334 mg/L medium | [50] |

| Human epidermal growth factor (hEGF) | Arachis hypogaea hairy root cultures | 10.7 µg/g weight | [51] |

| Human alpha-L-iduronidase (IDUA) | Brassica rapa hairy roots | Not known | [52] |

| Human gastric lipase (hGL) (therapeutic enzyme used for pancreatic enzyme deficiency, it contributes to fatty acid release from ingested triglycerides) | Brassica rapa subspecies rapa hairy root cultures | 528 units of hGL/g dry weight of tissue | [53] |

| Virus-like particle harboring recombinant protein shells of Johnson grass chlorotic stripe mosaic virus (JgCSMV) and their use as drug carriers | Nicotiana tabacum hairy roots | Not known | [54] |

| Recombinant human erythropoietin (rhEPO) (glycoprotein hormone that influences the production of erythrocytes through erythropoiesis. EPO is used for the treatment of anemia) | Nicotiana tabacum hairy root cultures | 66.75 ng/g of total soluble protein | [55] |

| Bevacizumab monoclonal antibody | Oryza sativa callus cultures | 160.7–242.8 mg/kg of transgenic rice callus | [56] |

| Tumor-targeting antibody with a human-compatible glycosylation profile | Nicotiana benthamiana hairy root cultures | 2–3 mg/L medium | [57] |

| MAP30 protein of Momordica charantia (valuable type I ribosome-inactivating protein (RIP) with anti-tumor and anti-HIV activities) | Nicotiana tabacum hairy root cultures | Not known | [58] |

| Human pro-insulin | Fragaria x ananassa Duch. hairy root cultures | 160 ng in 100 mg of tissue (0.14% of the total soluble protein) | [59] |

| Human serum albumin | Oryza sativa cell suspension cultures | 45 mg/L in a bioreactor | [60] |

| Monoclonal antibody M12 for cancer treatment | Nicotiana tabacum hairy root cultures | 5.9 mg/L medium | [61] |

| Thaumatin sweetener (intensely sweet protein) | Nicotiana tabacum hairy root cultures | 2.63 mg/L medium | [62] |

| Bovine trypsins | Oryza sativa cv. Dongjin cell suspension cultures | 15 mg/L at 5 days of incubation | [63] |

| Human growth hormone | Nicotiana tabacum BY-2 cell cultures | 5.2% total soluble proteins | [64] |

| Cytotoxic T cells surface antigen (hCTLA4Ig) | Fed-batch cultivation of Oryza sativa cells | 76.5 mg/L medium | [65] |

| Human epidermal growth factor (hEGF) | Hairy root cultures of Nicotiana tabacum | 2 µg/g fresh weight | [66] |

| Human interleukin-12 (hIL-12), a heterodimeric cytokine) | Oryza sativa cell suspensions | 31 mg/L | [67] |

| Human acetylcholinesterase (a bio-scavenger of organophosphate toxins used as pesticides and chemical warfare nerve agents) | Nicotiana benthamiana hairy root cultures | 3.3% total soluble proteins | [68] |

| Human growth hormone | Oryza sativa cv. Donjin 57 cell suspensions | 57 mg/L | [69] |

| Human collagen α1 chain industrially important protein | Hordeum vulgare cell cultures | 2–9 mg/L medium | [70] |

| Human interferon α-2b | Nicotiana tabacum cv. BY-2 cells as arabinogalactan-protein fusions | 28 mg/L | [71] |

| Human CTLA4ig (cytotoxic T-lymphocyte antigen 4 immunoglobulin (hCTLA4I g) fusion protein, a novel immunosuppressive agent) | Oryza sativa cell suspensions | 31.4 mg/L suspension cultures | [72] |

| Human secreted alkaline phosphatase | Nicotiana tabacum cv. NT-1 cell suspensions | 27 mg/L | [73] |

| Human antibody 14D9 | Nicotiana tabacum hairy root cultures | 64.03 µg/mL of medium | [74] |

| Human α-1-antitrypsin | Oryza sativa cell cultures |

100–247 mg/L (4–10% of the total extracellular protein) | [75] |

| Human serum albumin | Oryza sativa cell cultures | 76.4 mg/L in 4-day-old cultures | [76] |

| Human interferon gamma | Oryza sativa cell suspension cultures | 17.4 ng/mL media and 131.6 ng/g cell in culture medium and intracellularly | [77] |

| Human granulocyte-macrophage colony-stimulating factor | Oryza sativa cell suspension cultures | 129 mg/L at day 13 | [78] |

| Antimicrobial human lysozyme | Oryza sativa cv. Taipie grains | 0.6% of the brown rice weight or 45% of total soluble proteins | [79] |

| Human α-1 antitrypsin | Oryza sativa cultured cells | 200 mg/L | [80] |

| Human 1-antitrypsin | Oryza sativa callus and suspension cultures | 4.6–5.7 mg/g dry cell weight | [81] |

| Human erythropoietin | Nicotiana tabacum cv. BY-2 | 1 picogram on dry weight basis | [82] |

| Human serum albumin | Nicotiana tabacum and Solanum tuberosum suspension cultures | Not known | [83] |

Upscaling cell cultures in bioreactors enhances the production of recombinant proteins similar to bacterial or mammalian systems [45,84]. A comparative account has been made for the production of the anticancer compound viscumin (a lectin) both in microbes and plant cell packs [85]. The authors observed that cost savings were more than 80% when produced in tobacco in comparison with E. coli. Further, the yield was 50% higher in plant cell packs compared to microbes [85], inferring that plant cells have the potential to produce complex therapeutic proteins which are otherwise toxic to mammalian cells. For the production of therapeutic pharmaceuticals, antibodies, and vaccine proteins, cells of Daucus carota, Oryza sativa, and Nicotiana tabacum BY-2 cells are being exploited [86]. Edible tubers, fruits, and seeds of many plants act as bioreactors and are good candidates for the production of edible vaccines. Traditionally, vaccines are stored at low temperatures, but the need for the cold chain for storing the vaccine can be avoided, especially in rural areas, if edible vaccines are promoted. If vaccines are produced in edible plant parts, the advantage is that one can leave out the product purification step and, thus, reduce the cost of production and avoid storage concerns [87].

Human cytotoxic T-lymphocyte antigen 4-immunoglobulin (hCTLA4I g), alpha1-antitrypsin besides human growth hormone and interferon-gamma (INF-γ) production has been demonstrated in transgenic rice suspensions [88]. Likewise, immunoglobulins such as IgA, IgG4, and IgG, surface hepatitis virus antigen B, and rabies virus surface human immunodeficiency virus (HIV) have been produced in N. tabacum cv. BY-2 suspensions. Some examples of vaccines produced in plant cell cultures include lysozyme, DNAase I hemagglutinin-neuraminidases, hemagglutinin, and thermolabile toxin in E. coli [86]. Yao et al. [89] produced the human monoclonal antibody M12 in a bioreactor. Kumar et al. [90] reported the secretion of hepatitis B surface antigens in transformed tobacco cell suspension cultures. Sadoch et al. [91] optimized the induction medium for the production of recombinant proteins in BY-2 tobacco cells and, thus, paved the way for large-scale production. Lico et al. [92] churned out protein antigens as vaccine candidates and also antibodies as therapeutic proteins on a large scale, demonstrating the power of molecular plant farming as a potential strategy against COVID-19. Imamura et al. [93] produced ORF8 protein from SARS-CoV2 in suspension cultures of BY-2 tobacco cells using a virus-mediated expression system. Recombinant proteins fused to a glycomodule tag, such as that of hydroxyproline (Hyp)-O-glycosylated peptides (designer HypGP tag composed of an ‘Ala-Pro’ motif of 20 units), have been found to secrete proteins in large quantities in cultured plant cells. Zhang et al. [94] engineered (AP)20 proteins and increased the secretion of human protease inhibitor α1-antitrypsin protein (34.7 mg/L) in cultured BY-2 cells with a better glycosylation module (Table 1). Another interesting example is plant cell-secreted stem cell factor that stimulated the differentiation of key erythropoietic growth factor hematopoietic stem cells using a designer hydroxyproline (Hyp)-O-glycosylated peptide (HypGP) containing 20 tandem repeats of the “Ser-Pro” motif or (SP)20 in BY-2 cells. Additionally, the stem cell factor displayed proliferation of the TF-1 cell line [95]. The US FDA approved the production of taliglucerase-α enzyme (ElelysoR), the first therapeutic recombinant protein produced from plant cell cultures [96]. Genome editing technologies such as CRISPR/Cas9 are being utilized to create plant cells with desired characteristics that can aid in the production of recombinant therapeutic proteins.

3. Specialty Molecules

Several chemotherapy agents appear to be plant-based [97]. Plants are a rich source of bioactive molecules such as paclitaxel (used as a source for antineoplastic drugs and approved by the US FDA), ginseng, artemisinin, and veregen, in addition to neutraceuticals, herbal medicines, and botanical drugs [98,99]. Paclitaxel, an anticancer chemotherapy drug, was initially produced from cultured cells of Taxus species [100]. Adventitious roots of Panax ginseng have been cultivated on a large scale in vitro and sold on a commercial scale [101,102]. Ginseng has been used in China for thousands of years as a dietary supplement or as an ingredient in many drinks, including tea [99]. Ginseng has also been approved as a drug for treating certain diseases in Korea [103]. Cell cultures are being used for the production of colorants, especially anthocyanins, betacyanins, and shikonin, in addition to health food ingredients [103,104,105]. Colorants can now be produced up to kilograms in 600 Litre bioreactors. Shikonin is being produced at up to 5 kg per bioreactor run by Mitsui Petrochemicals Industries Ltd., using plant cell and tissue culture [105]. It may be noted that the productivity of shikonin in cultured plant cells is 800 times higher compared to the traditional methods. Likewise, echinacoside was scaled up to a bioreactor level by Diversa Gesellschaft fur Bio-und Verfahrenstechnik in Germany [106]. The same company (also known as Phyton Biotech) has also been producing paclitaxel on a commercial scale [107]. Protalix Biotherapeutics targeted the development of a proprietary bioreactor technology for the mass production of recombinant human therapeutic proteins using plant cell suspensions [108].

Other examples include the production of pharmaceuticals using plant cell cultures and transformed cells [89,108,109]. Plant-made antibodies have been commercialized by Planet Biotechnology, Inc. (Hayward, CA, USA) (https://www.planetbiotechnology.com/index.html (accessed on 21 June 2022)) [89]. Transformed tobacco plants produced DPP4-Fc, an immune adhesin for the treatment of MERS-CoV coronavirus infection, and CMG2- Fc (PBI-220), an immunoadhesin for the treatment of inhalational anthrax. Transgenic carrot cell suspensions have also been used to produce ElelysoR by Protalix BioTherapeutics, Inc. (Carmiel, Israel), for controlling type 1 Gaucher’s disease [89]. Plant cell suspension cultures have also been used in the production of berberine from Coptis japonica and Thalictrum minus by Mitsui Chemicals, Inc. (Tokyo, Japan) for their anticancer, antibiotic, and anti-inflammatory properties, Echinacea polysaccharides from Echinacea purpurea, Echinacea angustifolia by Diversa (Ahrensburg, Germany) as an immunostimulant, anti-inflammatory activities, and podophyllotoxin from Podophyllum species by Nippon Oil (Tokyo, Japan) for anticancer treatment [6]. These examples amply demonstrate that it is possible to produce specialty chemicals on a commercial scale using plant cell and tissue cultures. However, challenges such as optimal product titer and regulatory issues have to be resolved before such products are released into the market.

4. Metabolic Engineering for Enhanced Production

Secondary metabolites extracted from plant sources and efforts to improve them as cost-effective molecules have largely been impaired by the lack of knowledge of their metabolic pathways, intermediates, and the enzymes involved. The development and integration of next-generation sequencing technologies, high-throughput proteomics and metabolomic analyses, and bioinformatics coupled with systems biology have become handy in unraveling the metabolic pathways. Such an integrated approach helps us elucidate the pathways and genes associated with the pathways, allowing us to perform metabolic engineering and subsequently enhance the bioactive compounds [110,111]. Manipulating plant metabolism begins with the elucidation of the biosynthetic pathways that lead to a preferred product as well as the precise regulation of discrete enzymes. It is necessary to redeem the metabolic engineering of plants, including regulatory factors and precursors that influence the metabolic and physiological networks, to enhance the bioactive molecules [112]. Metabolic engineering enhances the prospects of boosting the compounds that are synthesized in low quantities in cells or specific tissues and compounds that are not originally produced in plants. Plant cell suspension cultures have been successfully used for the production of shikonin, ginsenosides, and vinblastine [113] and are considered efficient platforms for integrating the genomic, metabolomics, proteomic, and for metabolic engineering of key pathways associated with the production of high-value compounds of economic importance. Jamil et al. [114] reported metabolic profiles of callus and cell suspensions of mangosteen (Garcinia mangostana). Metabolic engineering comprises overexpression or downregulation of a specific metabolic pathway by adding precursors, enzymes, and regulatory proteins in conjunction with recombinant DNA technology and genome editing. While unraveling the biosynthetic pathways associated with secondary plant products is of primary importance, advances in technologies have enabled us to engineer microbial systems to reconstitute the metabolism, which is becoming a dominant option in synthetic biology [115,116].

Expression of plant genes or gene clusters associated with biosynthetic capabilities in microbial systems for the production of bioactive compounds has gained importance over time to incorporate polyculture and co-culture consortiums [112]. For the expression of complex biosynthetic pathway genes and for the production of secondary metabolites, hosts such as E. coli, Saccharomyces cerevisiae, Crynebacterium glutamicum, and Yarrowia lipolytica are being exploited [117,118]. In E. coli, the isoprenoid pathway has been optimized for taxol precursor overproduction [119]. Metabolic engineering of glucosinolates has been carried out in Raphanus sativa based on comparative genomics [115]. Notably, betalain color has been achieved in Saccharomyces cerevisiae using metabolic engineering [120]. Resveratrol production in E. coli [121], malonyl-CoA metabolism using synthetic antisense RNAs for the production of natural products in E. coli [122], remarkable production of stilbenoid antioxidants [123], and production of a plant-derived cancer chemopreventive precursor glucoraphanin in E. coli [124] have also been accomplished. More astoundingly, Lv et al. [125] unleashed a modular method to construct the flavonoid pathways (antioxidant and anti-aging agents) in the yeast Yarrowia lipolytica to produce flavonoids and hydroxylated flavonoids. The authors identified the optimal gene copy number for chalcone synthase (CHS) and cytochrome P450 reductases (CPR) as 5 and 2, respectively. In shake flask cultures, the yeast strain was able to produce 252.4 mg/L naringenin, 134.2 mg/L eriodictol (a bitter-masking flavanone), and 110.5 mg/L taxifolin (also known as dihydroquercetin, belonging to the subclass flavanonols in the flavonoids) from glucose. These findings infer that yeast can serve as a workhorse for the large-scale production of natural products that are otherwise proprietary of plant systems. However, yeast grows slowly, and there is a need to enhance the biomass in liquid cultures by manipulating the carbon, nitrogen, and other nutrients that can improve the biomass dramatically and yet be able to produce bioactive compounds economically and sustainably.

Mora–Vasquez et al. [126] recently reviewed the metabolic engineering for increasing the content of alkaloids in medicinal plants. It was suggested that co-overexpression of genes in two or more rate-limiting steps is an effective protocol for genetic manipulation. By overexpressing the endogenous pathway gene encoding secologanin synthase, Rather et al. [127] were able to increase camptothecin (an anticancer indole alkaloid) biosynthesis in Nothapodytes nimmoniana. Likewise, overexpression of the hyoscyamine 6β-hydroxylase (H6H) gene in Datura innoxia resulted in enhanced hyoscyamine content [35]. On the other hand, heterologous overexpression of the strictosidine synthase gene isolated from Nothapodytes foetida increased the camptothecin in Ophiorrhiza rugosa [128]. In addition to the biosynthetic pathway genes, transcription factors such as CrERF5 (an APETALA2/Ethylene Response Factor 5 from Catharanthus roseus) and also OpWRKY2 (isolated from Ophiorrhiza pumila WRKY2) have been introduced into C. roseus and O. pumila, and the transgenic plants showed enhanced bisindole alkaloids and indole alkaloid camptothecin [129,130]. Further, silencing of the quinolinic acidphosphoribosyl transferase (QPT) gene improved the accumulation of scopolamine in hairy root cultures of Duboisia leichhardtii [131]. Interestingly, an engineered combinational module of transcription factors has also enhanced the production of indole alkaloids in Catharanthus roseus [132]. Furthermore, overexpression of tryptophan decarboxylase and strictosidine synthase has boosted the accumulation of vinblastine alkaloids in Catharanthus roseus [133]. Thus, overexpression of the biosynthetic pathway genes encoding endogenous enzymes, heterologous expressions, transcription factor overexpression, gene silencing, and co-overexpressions have yielded positive results in boosting the bioactive compounds. However, concerns such as identifying the pathway genes for alkaloids, flavonoids, chalcones, and terpenes, need to be addressed for the large-scale production of many bioactive compounds to make them commercially viable.

5. Biotransformation and Production of Physiologically Active Compounds

Suspension-cultured cells can be used in biotransformation processes to produce new chemicals or known chemicals more economically, investigate the metabolic fate of xenobiotics, and elucidate the metabolic pathways [134]. Several advantages of plant cell cultures as a source for biotransformation and other purposes are listed in Figure 2. The mechanisms of biotransformation have been used for the commercialization of bioactive molecules. The conversion of physiologically not-so-active compounds into pharmacologically active compounds is vital for the pharmaceutical industry.

Figure 2.

Advantages of plant cell cultures for metabolic engineering.

The biotransformation of hyoscyamine into scopolamine was achieved in transgenic tobacco cell cultures [135], and cell suspension cultures of Digitalis lanata synthesized three new compounds [136]. Moreover, a specific cell death-inducing cardenolide compound was produced in D. lanata cell cultures [137,138]. New compounds such as eudesmane (a major sesquiterpene hydrocarbon of calamondin orange) and guaiane (a sesquiterpene that inhibits the growth of human renal cancer cell lines) were synthesized from the biotransformation of (-)α-santonin (a drug used as anthelminthic) in cell cultures of Catharanthus roseus. Moreover, biotransformation of progesterone to 17α-hydroxyprogesterone has been reported using the plant cell suspension culture of C. roseus [139]. The biotransformation of bioactive principles such as dydrogesterone (used as a drug against recurrent miscarriage in humans) was incubated with Azadirachta indica cells for the production of 20R-hydroxy-9β,10α-pregna-4,6-diene-3-one [140].

6. Plant Stem Cells for the Production of Cosmetics

Plant stem cells help to stimulate and regenerate plants after an injury, similar to human stem cells. There is a growing interest in the extraction of cell culture-based cosmetics and food products/neutraceuticals [99,141,142,143]. The plant stem cell culture technology is environmentally friendly, and its application permits the generation of prized compounds, even from rare or hard-to-access plants, without causing any disturbance to their natural ecosystem. Cosmetic and food formulations of plant cell extracts are available at reasonable prices [144]. Extracts of cultured apple stem cells that are liposome-encapsulated have been used in anti-aging products (Table 2).

Table 2.

Plant stem cells/callus/suspensions/hairy roots being used for cosmetic purposes by different companies.

Likewise, cells of Catheranthus roseus are being used now in cosmetics [145]. Interestingly, Rubus cell cultures for anti-inflammatory activity, tobacco for collagen synthesis, and Coffea cells for epidermal hydration and collagen synthesis in the skin cells are some of the highly rewarding commercial products seen in today’s market from plant cell cultures. Plant stem cells from apple, grape, jasmine, pine, lilac, and other plants have been widely and successfully used in cosmetic preparations used the world over. Tomato cultured stem cells have demonstrated potential in protecting skin from heavy metal toxicity since tomato is rich in antioxidant molecules such as lycopene, ascorbic acid, vitamin E, flavonoids, and phenolic acids [145]. Moreover, tomato stem cell extract contained metal-chelating compounds such as phytochelatins [146]. Phytochelatins are potent metal-binding proteins, and new products prepared from tomato neutralize the damage caused by heavy metals on the degradation of collagen by inhibiting collagenase. It has also been found that Coffea bengalensis culture-derived stem cells [22] stimulate the regeneration of skin cells by invigorating fibroblasts to synthesize collagen [149]. These studies indicate that plant stem cells preserve exceptional anti-aging properties and stimulate fibroblasts to synthesize collagen, stimulate skin regeneration, and repair DNA damage. Plant cells contain kinetin, which perhaps helps to protect skin cells from various stresses, including oxidative stress [150].

7. Plant Stem Cells for the Production of Food Ingredients

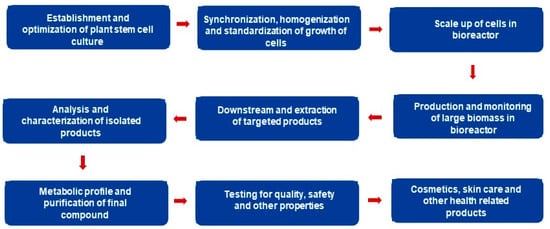

The increasing world population and fluctuating climate changes have been creating strenuous demands on the food supply. This necessitates the exploration of alternate agriculture options, including plant cell cultures, since they can be grown under a controlled, closed environment and have a sustainable process of manufacturing important food ingredients. The use of plant cell cultures instead of whole plants facilitates the preparation of products for the cosmetics and food industries with less energy, minimal possible impacts on the environment, and, importantly, independent of location and season. Plant stem cells are undifferentiated cells present in the meristematic tissues of plants. Both apical and lateral meristems are vital sources of stem cells. The stem cells are self-renewed, do not undergo aging, and supply precursor cells that differentiate into diverse tissues or organs based on their location. In vitro callus is first initiated, suspension cultures are derived from callus and scaled up, and then cells are analyzed through different analytical techniques for secondary product synthesis. For details, see the review by Aggarwal et al. [151]. There are different factors that determine the success of plant stem cell cultivation, for example, optimized cell suspensions, their synchronization, scale-up for bioreactor, monitoring of the biomass during large-scale production, quality aspects, and metabolic profile (Figure 3).

Figure 3.

Flow chart of plant stem cell cultivation and product synthesis.

A list of commercial firms that use plant callus, suspension cultures, and hairy roots for the production/extraction of stem cells is shown in Table 2. Accordingly, plant cell cultures have been expanded for food use and are now considered a favorable source with high nutritional values [28,151]. Cambium meristematic cell-derived suspensions have high potential and represent true stem cells. Stem cell isolation has been reported for Ginko biloba [152], Taxus cuspidata [39], and Tripterygium wilfordii [40]. A patent on the technique for the isolation of stem cells has been granted to Unhwa Corporation [103]. Examples of plant cell cultures for extracting colorants, aromas, and food ingredients have been amply demonstrated [103]. Nutritional facts and sensory properties of cultured cells of cloudberry, lingo berry, and stone berry have been investigated [153]. Enhanced production of vanillin flavor, a prime food constituent metabolite, has been achieved by precursor feeding into cell suspensions [154]. Theobroma cacao suspensions prepared in a wave-mixed bioreactor have been demonstrated to be of immense use as an important component in chocolate products. While the sensory profile of cell culture chocolate displayed a fruity and sour aroma, chemical analysis exhibited volatile and non-volatile flavor compounds (6.69 g/g of polyphenol content). However, the cultures grown in a stirred tank bioreactor have been found to differ in their aroma, with enhanced bitterness [155]. However, there is a need to improve the biomass without compromising the aroma quality, which should be comparable to that of intact plants. Additionally, the nutritional qualities (carbohydrates, proteins, lipids, dietary fiber, etc.) of suspensions of Rubus chamaemorus (cloudberry), Rubus saxatilis, and Vaccinium vitisidaea (lingonberry or mountain cranberry) cultivated on an industrial scale have been investigated alongside the sensory properties [153,156,157]. Daucus carota cells grown in shake flasks and bioreactors have been found to have food applications as a colorant (higher anthocyanins than natural red carrot) and for skin care, nutraceutical, and food applications [144].

8. Regulatory Issues Related to Food Ingredients or Foods Prepared through Plant Suspension Cultures

Regulations are meant to ensure the safety of food and food ingredients to the consumers, though they may differ from country to country. Foods derived from plant suspension cultures are considered and come under the novel food category as per the definition of the European Union Regulation 2015/2283 [158]. The regulatory landscape, with a complex framework of plant suspension or hairy root culture-derived novel food and health-related products, is undeniably a limiting factor for the early commercialization of the products. Any delays in approval will escalate the production costs. However, food colorants and flavorings do not fall within the scope of European Union Regulation 2015/2283 [158]. In India, the Food Safety and Standards Act (FSS) 2006 is the law that regulates all food ingredients. Generally, the Food Safety Standards Act of India (FSSAI) looks after and enforces the safety standards within India. On the other hand, in the USA, the addition of any substance to food is considered a food additive and needs approval from the Food and Drug Administration (FDA). However, if the substance is proven as safe through scientific data generated under the supervision of qualified scientists or has a traditional history of safe use for a long period of time, or if it meets the procedures laid down by the Federal Food, Drug, and Cosmetic Act, then approvals may not be necessary before such products are marketed. In the case of traditional foods, a long history of safe usage is taken into consideration, but not in plant tissue culture-derived foods and food ingredients since these are labeled as “novel”. Novel foods derived from plant suspensions and hairy root cultures may vary in their constituent profile in comparison with traditional foods. Therefore, such novel foods need a safety assessment performed by the European Food Safety Authority (EFSA) as per the guidelines laid down with all the evidence of the scientific data [159]. Extracts derived from the suspensions of plants such as Ajuga reptans and Echinaceae angustifolia are considered novel food supplements under EU Regulation 2015/2283. However, food colorants such as anthocyanins and betalains have not been granted any authorizations by the EFSA for use in food, although they are common food ingredients in grapes, beetroot, and others [158,160]. Lastly, it is vital to take the sensory perception of consumers into account since this aspect is also crucial.

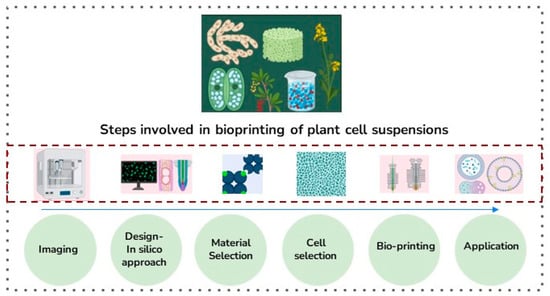

9. Bioprinting

Bioprinting is a novel technique for creating tissues, organs, and biological materials [161,162]. The technology is based on bio-ink to generate the bio-structures of relevance in life science, medicine, and bioengineering [163]. For bio-inks, non-hazardous, natural, or synthetic biomaterials are used, which mimic the properties of cells [163]. This technique envisages the establishment of a biocompatible and non-toxic scaffold to be integrated with biological systems for supporting cellular growth [162]. High-throughput structural and functional 3D bioprinting strategies used in plant cellular modeling consist of bioprinting materials with multiple functional, structural, and mechanical properties [162]. Research in bioprinting of plant cells has been used to develop 3D plant cells to study growth-related functions such as viability, cell division, and cell identity in Arabidopsis and soybean [163]. The 3D bioprinting could also confer advantages to design and control cellular dynamic structures in a physiologically accurate manner toward tissue regeneration akin to natural conditions [164]. Different components of the bioprinting workflow using plant cell suspensions and applications are presented in Figure 4. This technique opens up avenues for understanding the cellular and physiological processes involved in mechanical and molecular interactions between cells and their cellular environment. Growing cells are surrounded by cellular structures governed by complex biochemical networks and many inherent cellular factors, and hence, the conventional plant cell culture techniques cannot reproduce such a complex cellular setting to diverse external factors. The embedded cells in the 3D scaffold adjust their shapes to fit the adjacent spaces and grow, which can be monitored more easily than the native plant tissues. A recent study on Arabidopsis root cells and embryonic soybean cells showed that more than half of the 3D bioprinted cells were viable and divided over time to form microcalli, or small colonies of cells [163]. The 3D bioprinting has applications in plant sciences, agriculture, and identification of appropriate compatibility of 3D bioprinting materials with different components of plant cells [165]. Some of the materials used in bioprinting include alginate nanocellulose, carrageenan, agarose, pectin, starch, and fucoidan [162,164]. Being in a 3D environment, plant cellular behavior and physiology might offer vital clues that help to better understand plant cell dynamics, suggesting that 3D bioprinting has considerable potential in plant science research and the bioprinted materials could find applications in wound dressings, implantable medical devices, and drug delivery systems [162].

Figure 4.

Different components of bioprinting using plant cell suspensions and its applications.

10. Conclusions and Future Outlook

Plants are prime sources for assorted biopharmaceuticals and have been extensively and widely exploited as medicines and therapeutic products. Stem cells are now being isolated from cultured plant cells in the gigantic cosmetic industry. The advantages, problems, and challenges need to be gauged, and new scientific contributions need to be weighed carefully for further exploitation. Although many plants contain precious metabolites, their content is generally low. This has necessitated enhancing their synthesis by employing elicitors and precursors for a substantial extraction of the products, and plant cell suspension cultures/bioreactors would be an ideal platform for the production of high-value metabolites [166,167]. The emerging science of omics and the range of hosts available in synthetic biology has given new insights for understanding the basic mechanisms of synthesis and rebuilding plant bioactive metabolites in microbes and yeasts on a commercial scale. Examples of metabolically engineered microbes producing plant natural products have been very well established. Culturing cambial meristematic cells from plants has also been exploited for the preparations of several cosmetics, primarily skin care products. Now, this technology has been stretched to isolate useful metabolites using stem cell suspensions/hairy roots. Genes associated with biosynthetic pathways must be unraveled. For the technology to be sustained, they must be cloned and expressed for the large-scale production of plant metabolites in microorganisms. In this context, synthetic biology is advancing with the deployment of new tools for constructing, controlling, and optimizing complex metabolic pathways of plants in unicellular organisms. Generally, experimental procedures unleash the feasibilities, demonstrating the potentialities of cell cultures for industrial applications. In the foreseeable future, plant cells, together with the development of high-yielding, stable cell lines, need to be separated out, which can be a base for industrial-scale production. However, both biomass and secondary plant products must be refined to enable suspensions, hairy root cultures, or stem cell cultures for the scale-up and subsequent exploitation by the pharmaceutical industry. Further, the design and development of home bioreactors and their availability to the household must be cheaper and should produce in kilogram quantities per day. Plant suspension culture-derived or stem cell-derived products must undergo rigorous regulatory procedures before they are released into the market.

Author Contributions

Conceptualization—V.A.B.; writing, original draft preparation—V.A.B., S.P. and P.B.K.K.; review and editing—V.A.B., S.P., P.B.K.K., N.J. and S.M.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

VAB thanks INSA, New Delhi, India, for the Honorary scientist fellowship.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Motolinia-Alcantara, E.A.; Castillo-Araiza, C.O.; RodríguezMonroy, M.; Román-Guerrero, A.; Cruz-Sosa, F. Engineering considerations to produce bioactive compounds from plant cell suspension culture in bioreactors. Plants 2021, 10, 2762. [Google Scholar] [CrossRef]

- Zafar, T.; Shrivastava, V.K.; Shaik, B. Pharmaceutical Biotechnology in Herbal Neuroprotection; Springer: Singapore, 2018; pp. 221–228. [Google Scholar]

- Elkordy, A.A.; Haj-Ahmad, R.R.; Awaad, A.S.; Zaki, R.M. An overview on natural product drug formulations from conventional medicines to nanomedicines: Past, present and future. J. Drug Deliv. Sci. Technol. 2021, 63, 102459. [Google Scholar] [CrossRef]

- Shriram, V.; Vinay Kumar Kavi Kishor, P.B.; Suryawanshi, S.B.; Upadhyay, A.K.; Bhat, M.K. Cytotoxic activity of 9,10-dihydro-2,5-dimethoxyphenanthrene-1,7-diol from Eulophia nuda against human cancer cells. J. Ethnopharmacol. 2010, 128, 251–253.5. [Google Scholar] [CrossRef] [PubMed]

- Madhavi, D.; Abhayankar, G.; Reddy, V.D.; Kavi Kishor, P.B. Carbohydrate and elicitor enhanced withanolide (withaferin A and withanolide A) accumulation in hairy root cultures of Withania somnifera (L.). Indian J. Exp. Biol. 2012, 50, 484–490. [Google Scholar]

- Ochoa-Villarreal, O.V.M.; Howat, S.; Hong, S.M.; Jang, M.O.; Jin, Y.W.; Lee, E.K.; Loake, G.J. Plant cell culture strategies for the production of natural products. BMB Rep. 2016, 49, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Jawahar, G.; Punita, D.L.; Rajasheker, G.; Manoharachary, C.; Venkatachalam, P.; Kavi Kishor, P.B. Feeding elicitors and precursors enhance colchicine accumulation in morphogenic cultures of Gloriosa superba L. Plant Cell Tiss. Organ Cult. 2018, 135, 235–245. [Google Scholar] [CrossRef]

- Espinosa-Leal, C.A.; Puente-Garza, C.A.; García-Lara, S. In vitro plant tissue culture: Means for production of biological active compounds. Planta 2018, 248, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Arya, S.S.; Rookes, J.E.; Cahill, D.M.; Lenka, S.K. Next-generation metabolic engineering approaches towards development of plant cell suspension cultures as specialized metabolite producing biofactories. Biotechnol. Adv. 2020, 45, 107635. [Google Scholar] [CrossRef]

- Moscatiello, R.; Baldan, B.; Navazio, L. Plant Cell Suspension Cultures. In Plant Mineral Nutrients. Methods in Molecular Biology (Methods and Protocols); Maathuis, F., Ed.; Humana Press: Totowa, NJ, USA, 2013; p. 953. [Google Scholar] [CrossRef]

- Gandra, J.; Patel, H.K.; Kumar, S.A.; Doma, M.; Deepthi, Y.; Bhalothia, P.; Jalaja, N.; Chimakurthy, J.; Polavarapu, R.; Katam, R.; et al. Metabolomic and proteomic signature of Gloriosa superba leaves treated with mercuric chloride and phenylalanine, a precursor of colchicine alkaloid. Ind. Crops Prod. 2022, 178, 114557. [Google Scholar] [CrossRef]

- Komaraiah, P.; Ramakrishna, S.V.; Reddanna, P.; Kavi Kishor, P.B. Enhanced production of plumbagin in immobilized cells of Plumbago rosea by elicitation and in situ adsorption. J. Biotechnol. 2003, 101, 181–187. [Google Scholar] [CrossRef]

- Cortese, E.; Carraretto, L.; Baldan, B.; Navazio, L. Arabidopsis photosynthetic and heterotrophic cell suspension cultures. Methods Mol. Biol. 2021, 2200, 167–185. [Google Scholar] [PubMed]

- Narayani, M.; Shrivastava, S. Elicitation: A stimulation of stress in in vitro plant cell/tissue cultures for enhancement of secondary metabolite production. Phytochemical. Rev. 2017, 16, 1227–1252. [Google Scholar] [CrossRef]

- Chodisetti, B.; Rao, K.; Gandi, S.; Giri, A. Gymnemic acid enhancement in the suspension cultures of Gymnema sylvestre by using the signaling molecules—Methyl jasmonate and salicylic acid. Vitr. Cell. Dev. Biol.-Plant 2015, 51, 88–92. [Google Scholar] [CrossRef]

- Chodisetti, B.; Rao, K.; Suryakala, G.; Archana, G. Improved Gymnemic acid production in the suspension cultures of Gymnema sylvestre through biotic elicitation. Plant Biotechnol. Rep. 2013, 7, 519–525. [Google Scholar] [CrossRef]

- Veerashree, V.; Anuradha, C.M.; Vadlapudi, K. Elicitor-enhanced production of gymnemic acid in cell suspension cultures of Gymnema sylvestre R. Br. Plant Cell Tiss Organ Cult. 2012, 108, 27–35. [Google Scholar] [CrossRef]

- Chen, H.; Chena, F.; Chiu, F.C.; Lo, C.M. The effect of yeast elicitor on the growth and secondary metabolism of hairy root cultures of Salvia miltiorrhiza . Enzym. Microb. Technol. 2001, 28, 100–105. [Google Scholar] [CrossRef]

- Deepthi, S.; Satheeshkumar, K. Enhanced camptothecin production induced by elicitors in the cell suspension cultures of Ophiorrhiza mungos Linn. Plant Cell Tissue Organ Cult. 2016, 124, 483–493. [Google Scholar] [CrossRef]

- Flores-Sanchez, I.J.; Ortega-Lopez, J.; del Carmen Montes-Horcasitas, M.; Ramos-Valdivia, A.C. Biosynthesis of sterols and triterpenes in cell suspension cultures of Uncaria tomentosa . Plant Cell Physiol. 2002, 43, 1502–1509. [Google Scholar] [CrossRef]

- Chakraborty, A.; Chattopadhyay, S. Stimulation of Menthol Production in Mentha piperita Cell Culture. Vitr. Cell. Dev. Biol. Plant. 2008, 4, 518–524. [Google Scholar] [CrossRef]

- Wilson, S.A.; Roberts, S.C. Recent advances towards development and commercialization of plant cell culture processes for the synthesis of biomolecules. Plant Biotechnol. J. 2012, 10, 249–268. [Google Scholar] [CrossRef]

- Santos Rita, B.; Rita, A.; Rainer, F.; Markus, S.; Holland, T.H. Putting the spotlight back on plant suspension cultures. Front. Plant Sci. 2016, 7, 297. [Google Scholar] [CrossRef] [PubMed]

- Eibl, R.; Meier, P.; Stutz, I.; Schildberger, D.; Hühn, T.; Eibl, D. Plant cell culture technology in the cosmetics and food industries: Current state and future trends. Appl. Microbiol. Biotechnol. 2018, 102, 8661–8675. [Google Scholar] [CrossRef] [PubMed]

- Krasteva, G.; Georgiev, V.; Pavlov, A. Recent applications of plant cell culture technology in cosmetics and foods. Eng. Life Sci. 2021, 21, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Kerbler, S.M.; Fernie, A.R.; Zhang, Y. Plant cell cultures as heterologous bio-factories for secondary metabolite production. Plant Commun. 2021, 2, 100235. [Google Scholar] [CrossRef] [PubMed]

- Acikgoz, M.A. Establishment of cell suspension cultures of Ocimum basilicum L. and enhanced production of pharmaceutical active ingredients. Ind. Crops Prod. 2020, 148, 112278. [Google Scholar] [CrossRef]

- Garcia-Perez, P.; Miras-Moreno, B.; Lucini, L.; Gallego, P.P. The metabolomics reveals intraspecies variability of bioactive compounds in elicited suspension cell cultures of three Bryophyllum species. Ind. Crops Prod. 2021, 163, 113322. [Google Scholar] [CrossRef]

- Kreis, W. Exploiting plant cell culture for natural product formation. J. Appl. Bot. Food Qual. 2019, 92, 216–225. [Google Scholar] [CrossRef]

- Hakkinen, S.T.; Oksman-Caldentey, K.M. Progress and prospects of hairy root research. In Hairy Roots: An Effective Tool of Plant Biotechnology; Srivastava, V., Mehrotra, S., Mishra, S., Eds.; Springer: Singapore, 2018; pp. 3–19. [Google Scholar] [CrossRef]

- Nielsen, E.; Temporiti, M.E.E.; Cella, R. Improvement of phytochemical production by plant cells and organ culture and by genetic engineering. Plant Cell Rep. 2019, 38, 1199–1215. [Google Scholar] [CrossRef]

- Nourani, A.; Popova, E.; Titova, M. Biotechnology based on cell cultures of higher plants. E3S Web Conf. 2021, 265, 04012. [Google Scholar] [CrossRef]

- Furusaki, S.; Takeda, T. Bioreactors for Plant Cell Culture, Reference Module in Life Sciences; Elsevier: Dordrecht, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Werner, S.; Maschke, R.W.; Eibl, D.; Eibl, R. Bioreactor technology for sustainable production of plant cell-derived products. In Bioprocessing of Plant In Vitro Systems. Reference Series in Phytochemistry; Pavlov, A., Bley, T., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Kowalczyk, T.; Merecz-Sadowska, A.; Picot, L.; Brčić Karačonji, I.; Wieczfinska, J.; Śliwiński, T.; Sitarek, P. Genetic manipulation and bioreactor culture of plants as a tool for industry and its applications. Molecules 2022, 27, 795. [Google Scholar] [CrossRef]

- Li, Y.; Kong, D.; Fu, Y.; Sussman, M.R.; Wu, H. The effect of developmental and environmental factors on secondary metabolites in medicinal plants. Plant Physiol. Biochem. 2020, 148, 80–89. [Google Scholar] [CrossRef] [PubMed]

- Zagorskayaa, A.A.; Deinekoa, E.V. Suspension-cultured plant cells as a platform for obtaining recombinant proteins. Russ. J. Plant Physiol. 2017, 64, 795–807. [Google Scholar] [CrossRef]

- Subroto, M.A.; Hamill, J.; Doran, P. Development of shooty teratomas from several solanaceous plants: Growth kinetics, stoichiometry and alkaloid production. J. Biotechnol. 1996, 45, 45–57. [Google Scholar] [CrossRef]

- Fazili, M.A.; Bashir, I.; Ahmad, M.; Yaqoob, U.; Geelani, S.N. In vitro strategies for the enhancement of secondary metabolite production in plants: A review. Bull. Natl. Res. Cent. 2022, 46, 35. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.K.; Jin, Y.W.; Park, J.H.; Yoo, Y.M. Cultured cambial meristematic cells as a source of plant natural products. Nat. Biotechnol. 2010, 28, 1213–1217. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Chen, S.; Wang, X.; Zhang, R. A novel strategy to enhance terpenoids production using cambial meristematic cells of Tripterygium wilfordii Hook. f. Plant Methods 2019, 15, 129. [Google Scholar] [CrossRef]

- Marchev, A.S.; Yordanova, Z.P.; Georgiev, M.I. Green (cell) factories for advanced production of plant secondary metabolites. Crit. Rev. Biotechnol. 2020, 40, 443–458. [Google Scholar] [CrossRef]

- Moon, S.H.; Pandurangan, M.; Kim, D.H.; Venkatesh, J.; Patel, R.V.; Mistry, B.M. A rich source of potential bioactive compounds with anticancer activities by Catharanthus roseus cambium meristematic stem cell cultures. J. Ethnopharmacol. 2018, 217, 107–117. [Google Scholar] [CrossRef]

- Kesik-Brodacka, M. Progress in biopharmaceutical development. Biotechnol. Appl. Biochem. 2018, 65, 306–322. [Google Scholar] [CrossRef]

- Tak, H.; Negi, S.; Ganapathi, T.R.; Bapat, V.A. Molecular farming: Prospects and limitation. In Banana: Genomics and Transgenic Approaches for Genetic Improvement; Mohandas, K.V., Ravishankar, G.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Burnett, J.B.M.; Burnett, A.C. Therapeutic recombinant protein production in plants: Challenges and opportunities. Plants People Planet. 2020, 2, 121–132. [Google Scholar] [CrossRef]

- Nazeri, A.; Niazi, A.; Afsharifar, A.; Taghavi, S.V.; Moghadam, A.; Aram, F. Heterologous production of hyaluronic acid in Nicotiana tabacum hairy roots expressing a human hyaluronan synthase 2. Sci. Rep. 2021, 11, 17966. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.J.; Han, J.E.; Lee, H.; Jung, Y.J.; Murthy, H.N.; Park, S.Y. Large-scale production of recombinant miraculin protein in transgenic carrot callus suspension cultures using air-lift bioreactors. AMB Expr. 2020, 10, 140. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Niazi, A.; Aram, F.; Hassani, F.; Ghasemi, Y. Transformation of the L-asparaginase II gene to potato hairy roots for production of recombinant protein. J. Crop. Sci. Biotechnol. 2020, 23, 81–88. [Google Scholar] [CrossRef]

- Zhang, N.; Wright, T.; Caraway, P.; Xu, J. Enhanced secretion of human α1-antitrypsin expressed with a novel glycosylation module in tobacco BY-2 cell culture. Bioengineered 2019, 10, 87–97. [Google Scholar] [CrossRef]

- Lonoce, C.; Salem, R.; Marusic, C.; Jutras, P.V.; Scaloni, A.; Salzano, A.M.; Lucretti, S.; Steinkellner, H.; Benvenuto, E.; Donini, M. Production of a tumour-targeting antibody with a human-compatible glycosylation profile in N. benthamiana hairy root cultures. Biotechnol. J. 2016, 11, 1209–1220. [Google Scholar] [CrossRef]

- Yao, Q.; Yu, Z.; Liu, P.; Zheng, H.; Xu, Y.; Sai, S.; Wu, Y.; Zheng, C. High efficient expression and purification of human epidermal growth factor in Arachis hypogaea L. Int. J. Mol. Sci. 2019, 20, 2045. [Google Scholar] [CrossRef]

- Cardon, F.; Pallisse, R.; Bardor, M.; Caron, A.; Vanier, J.; Ele Ekouna, J.P.; Lerouge, P.; Boitel-Conti, M.; Guillet, M. Brassica rapa hairy root based expression system leads to the production of highly homogenous and reproducible profiles of recombinant human alpha-L-iduronidase. Plant. Biotechnol. J. 2019, 17, 505–516. [Google Scholar] [CrossRef]

- Ekouna, J.P.E.; Boitel-Conti, M.; Lerouge, P.; Bardor, M.; Guerineau, F. Enhanced production of recombinant human gastric lipase in turnip hairy roots. Plant Cell Tissue Organ Cult. 2017, 131, 601–610. [Google Scholar] [CrossRef]

- Alemzadeh, E.; Izadpanah, K.; Ahmadi, F. Generation of recombinant protein shells of Johnson grass chlorotic stripe mosaic virus in tobacco plants and their use as drug carrier. J. Virol. Methods 2017, 248, 148–153. [Google Scholar] [CrossRef]

- Gurusamy, P.D.; Schäfer, H.; Ramamoorthy, S.; Wink, M. Biologically active recombinant human erythropoietin expressed in hairy root cultures and regenerated plantlets of Nicotiana tabacum L. PLoS ONE 2017, 12, e0182367. [Google Scholar] [CrossRef]

- Chen, L.; Yang, X.; Luo, D.; Yu, W. Efficient production of a bioactive bevacizumab monoclonal antibody using the 2a self-cleavage peptide in transgenic rice callus. Front. Plant Sci. 2016, 7, 1156. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Yang, D.; Qiang, Z.; Meng, Y.; Li, R.; Fan, X.; Zhao, W.; Meng, Y. Ribosome-inactivating protein MAP30 isolated from Momordica charantia L. induces apoptosis in hepatocellular carcinoma cells. Recent Pat. Anticancer Drug Discov. 2022. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, A.; Niazi, A.; Afsharifar, A.; Taghavi, S.M. Expression of a recombinant anti-HIV and anti-tumor protein, MAP30, in Nicotiana tabacum hairy roots: A pH-stable and thermophilic antimicrobial protein. PLoS ONE 2016, 11, e0159653. [Google Scholar] [CrossRef]

- Tavizi, A.; Javaran, M.J.; Moieni, A.; Mohammadi-Dehcheshmeh, M.; Mohebodini, M.; Ebrahimie, E. Root and shoot parts of strawberry: Factories for production of functional human pro-insulin. Mol. Biol. Rep. 2015, 42, 1013–1023. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.K.; Li, Y.T.; Lu, C.F.; Huang, L.F. Enhancement of recombinant human serum albumin in transgenic rice cell culture system by cultivation strategy. New Biotechnol. 2015, 32, 328–334. [Google Scholar] [CrossRef]

- Häkkinen, S.; Raven, N.; Henquet, M.; Laukkanen, M.-L.; Anderlei, T.; Pitkänen, J.-P.; Twyman, R.M.; Bosch, D.; Oksman-Caldentey, K.-M.; Schillberg, S.; et al. Molecular farming in tobacco hairy roots by triggering the secretion of a pharmaceutical antibody. Biotechnol. Bioeng. 2014, 111, 336–346. [Google Scholar] [CrossRef]

- Pham, N.B.; Schäfer, H.; Wink, M. Production and secretion of recombinant thaumatin in tobacco hairy root cultures. Biotechnol. J. 2012, 7, 537–545. [Google Scholar] [CrossRef]

- Kim, N.S.; Yu, H.Y.; Chung, N.D.; Shin, Y.J.; Kwon, T.H.; Yang, M.S. Production of functional recombinant bovine trypsin in transgenic rice cell suspension cultures. Protein Expr. Purif. 2011, 76, 121–126. [Google Scholar] [CrossRef]

- Xu, J.; Okada, S.; Tan, L.; Goodrum, K.J.; Kopchick, J.J.; Kieliszewski, M.J. Human growth hormone expressed in tobacco cells as an arabinogalactan-protein fusion glycoprotein has a prolonged serum life. Transgenic Res. 2010, 19, 849–867. [Google Scholar] [CrossRef]

- Park, C.I.; Lee, S.J.; Kang, S.H.; Jung, H.S.; Kim, D.I.; Lim, S.M. Fed-batch cultivation of transgenic rice cells for the production of hCTLA4Ig using concentrated amino acids. Process. Biochem. 2010, 45, 67–74. [Google Scholar] [CrossRef]

- Parsons, J.; Wirth, S.; Dominguez, M.; Bravo-Almonacid, F.; Giulietti, A.; Talou, J.R. Production of human epidermal growth factor (hEGF) by In vitro cultures of Nicotiana tabacum: Effect of tissue differentiation and sodium nitroprusside addition. Int. J. Biotechnol. Biochem. 2010, 6, 131–138. [Google Scholar]

- Shin, Y.J.; Lee, N.J.; Kim, J.; An, X.H.; Yang, M.S.; Kwon, T.H. High-level production of bioactive heterodimeric protein human interleukin-12 in rice. Enzym. Microb. Technol. 2010, 46, 347–351. [Google Scholar] [CrossRef]

- Woods, R.R.; Geyer, B.C.; Mor, T.S. Hairy-root organ cultures for the production of human acetylcholinesterase. BMC Biotechnol. 2008, 8, 95. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.G.; Baek, M.Y.; Lee, E.K.; Kwon, T.H.; Yang, M.S. Expression of human growth hormone in transgenic rice cell suspension culture. Plant Cell Rep. 2008, 27, 885–891. [Google Scholar] [CrossRef] [PubMed]

- Anneli, R.; Wahlström, E.H.; Holkeri, H.; Anders, H.; Katri, E.; Baez, J.; Kristiina, M.; Anna, N. Production of a recombinant industrial protein using barley cell cultures. Protein Expr. Purif. 2008, 59, 274–281. [Google Scholar] [CrossRef]

- Xu, J.; Tan, L.; Goodrum, K.J.; Kieliszewski, M.J. High-yields and extended serum half-life of human interferon α2b expressed in tobacco cells as arabinogalactan-protein fusions. Biotechnol. Bioeng. 2007, 97, 997–1008. [Google Scholar] [CrossRef]

- Lee, S.J.; Park, C.I.; Park, M.Y.; Jung, H.S.; Ryu, W.S.; Lim, S.M.; Tan, H.K.; Kwon, T.H.; Yang, M.S.; Kim, D.I. Production and characterization of human CTLA4Ig expressed in transgenic rice cell suspension cultures. Protein Expr. Purif. 2007, 51, 293–302. [Google Scholar] [CrossRef]

- Becerra-Arteaga, A.; Mason, H.S.; Shuler, M.L. Production, secretion, stability and n-glycosylation of human secreted alkaline phosphatase in tobacco NT1 cell suspension cultures. Biotechnol. Prog. 2006, 22, 1643–1649. [Google Scholar] [CrossRef]

- Martinez, C.; Petruccelli, S.; Giulietti, A.M.; Alvarez, M.A. Expression of the antibody 14D9 in Nicotiana tabacum hairy root roots. Electron. J. Biotechnol. 2005, 8, 170–176. [Google Scholar] [CrossRef]

- McDonald, K.A.; Hong, L.M.; Trombly, D.M.; Xie, Q.; Jackman, A.P. Production of human α-1-antitrypsin from transgenic rice cell culture in a membrane bioreactor. Biotechnol. Prog. 2005, 21, 728–734. [Google Scholar] [CrossRef]

- Huang, L.F.; Liu, Y.K.; Lu, C.A.; Hsieh, S.L.; Yu, S.M. Production of human serum albumin by sugar starvation induced promoter and rice cell culture. Transgenic Res. 2005, 14, 569–581. [Google Scholar] [CrossRef]

- Chen, T.L.; Lin, Y.L.; Lee, Y.L.; Yang, N.S.; Chan, M.T. Expression of bioactive human interferon gamma in transgenic rice cell suspension cultures. Transgenic Res. 2004, 13, 499–510. [Google Scholar] [CrossRef] [PubMed]

- Shin, Y.J.; Hong, S.Y.; Kwon, T.H.; Jang, Y.S.; Yang, M.S. High level of expression of recombinant human granulocyte-macrophage colony stimulating factor in transgenic rice cell suspension culture. Biotechnol. Bioeng. 2003, 82, 778–783. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Nandi, S.; Wu, L.; Yalda, D.; Bartley, G.; Rodriguez, R.; Lonnerda, L.B.; Huang, N. Expression of natural antimicrobial human lysozyme in rice grains. Mol. Breeding 2002, 10, 83–94. [Google Scholar] [CrossRef]

- Huang, J.; Sutliff, T.D.; Wu, L.; Nandi, S.; Benge, K.; Terashima, M.; Ralston, A.H.; Drohan, W.; Huang, N.; Rodriguez, R.L. Expression and purification of functional human α-1-antitrypsin from cultured plant cells. Biotechnol. Progr. 2001, 17, 126–133. [Google Scholar] [CrossRef]

- Terashima, M.; Murai, Y.; Kawamura, M.; Nakanishi, S.; Stoltz, T.; Chen, L.; Drohan, W.; Rodriguez, R.L.; Katoh, S. Production of functional human 1 -antitrypsin by plant cell culture. Appl. Microbiol. Biotechnol. 1999, 52, 516–523. [Google Scholar] [CrossRef]

- Matsumoto, S.; Ikura, K.; Ueda, M.; Sasaki, R. Characterization of a human glycoprotein (erythropoietin) produced in cultured tobacco cells. Plant Mol. Biol. 1995, 27, 1163–1172. [Google Scholar] [CrossRef]

- Sijmons, P.C.; Dekker, B.M.M.; Schrammeijer, B.; Verwoerd, T.C.; van den Elzen, P.J.M.; Hoekema, A. Production of correctly processed human serum albumin in transgenic plants. Nat. Biotechnol. 1990, 8, 217–221. [Google Scholar] [CrossRef]

- Huang, T.K.; McDonald, K.A. Bioreactor systems for In vitro production of foreign proteins using plant cell cultures. Biotechnol. Adv. 2012, 30, 398–409. [Google Scholar] [CrossRef]

- Gengenbach, B.B.; Keil, L.L.; Opdensteinen, P.; Muschen, C.R.; Melmer, G.; Lentzen, H.; Buhrmann, J.; Buyel, J.F. Comparison of microbial and transient expression (tobacco plants and plant cell packs) for the production and purification of the anticancer mistletoe lectin viscumin. Biotechnol. Bioeng. 2019, 116, 2236–2249. [Google Scholar] [CrossRef]

- Rosales-Mendoza, S.; Tello-Olea, M.A. Carrot cells: A pioneering platform for biopharmaceuticals production. Mol. Biotechnol. 2015, 57, 219–232. [Google Scholar] [CrossRef] [PubMed]

- Gerszberg, A.; Hnatuszko-Konka, K. Compendium on food crop plants as a platform for pharmaceutical protein production. Int. J. Mol. Sci. 2022, 23, 3236. [Google Scholar] [CrossRef]

- Ghag, S.B.; Adki, V.S.; Ganapathi, T.R.; Bapat, V.A. Plant platforms for efficient heterologous protein production. Biotechnol. Bioprocess Eng. 2021, 26, 546–567. [Google Scholar] [CrossRef]

- Yao, J.; Weng, Y.; Dickey, A.; Wang, K.Y. Plants as factories for human pharmaceuticals: Applications and challenges. Int. J. Mol. Sci. 2015, 16, 28549–28565. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.B.S.; Ganapathi, T.R.; Srinivas, L.; Revathi, C.J.; Bapat, V.A. Secretion of hepatitis B surface antigen in transformed tobacco cell suspension cultures. Biotechnol. Lett. 2005, 27, 927–932. [Google Scholar] [CrossRef] [PubMed]

- Sadoch, J.; Pyc, M.; Urbanowicz, A.; Iglewski, A.; Pilarski, R. High throughput evolutionary optimization of the induction medium towards recombinant protein production in BY-2 tobacco. Biotechnol. Bioeng. 2021, 118, 676–689. [Google Scholar] [CrossRef] [PubMed]

- Lico, C.; Santi, L.; Baschieri, S.; Noris, E.; Marusic, C.; Donini, M.; Pedrazzini, E.; Maga, G.; Franconi, R.; Di Bonito, P.; et al. Plant molecular farming as a strategy against COVID19-the Italian perspective. Front. Plant Sci. 2020, 11, 609910. [Google Scholar] [CrossRef]

- Imamura, T.; Isozumi, N.; Higashimura, Y.; Ohki, S.; Mori, M. Production of ORF8 protein from SARS-CoV-2 using an inducible virus-mediated expression system in suspension-cultured tobacco BY-2 cells. Plant Cell Rep. 2021, 40, 433–436. [Google Scholar] [CrossRef]

- Musiychuk, K.; Sivalenka, R.; Jaje, J.; Bi, H.; Flores, R.; Shaw, B.; Jones, R.M.; Golovina, T.; Schnipper, J.; Khandker, L.; et al. Plant-produced human recombinant erythropoietic growth factors support erythroid differentiation in vitro . Stem Cells Dev. 2013, 22, 2326–2340. [Google Scholar] [CrossRef]

- Wang, X.; Karki, U.; Abeygunaratne, H.; Unnold Cofre, C.; Xu, J. Plant cell-secreted stem cell factor stimulates expansion and differentiation of hematopoietic stem cells. Process. Biochem. 2021, 100, 39–48. [Google Scholar] [CrossRef]

- Dehelean, C.A.; Marcovici, I.; Soica, C.; Mioc, M.; Coricovac, D.; Iurciuc, S.; Cretu, O.M.; Pinzaru, I. Plant-derived anticancer compounds as new perspectives in drug discovery and alternative therapy. Molecules 2021, 26, 1109. [Google Scholar] [CrossRef] [PubMed]

- Newman, D.J.; Gordon, M.C. Natural products as sources of new drugs over the nearly four decades from 01/1981 to 09/2019. J. Nat. Prod. 2020, 83, 770–803. [Google Scholar] [CrossRef] [PubMed]

- Farrar, M.C.; Jacobs, T.F. Paclitaxel; StatPearls Publishing: Treasure Island, FL, USA, 2020. [Google Scholar]

- Dou, J.; Weathers, P. Specialty molecules from plants and In vitro cultures as new drugs: Regulatory considerations from flask to patient. Plant Cell Tiss. Org. Cult. 2022, 149, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Fett-Neto, A.G.; DiCosmo, F.; Reynolds, W.; Sakata, K. Cell culture of Taxus as a source of the antineoplastic drug taxol and related taxanes. Nat. Biotechnol. 1992, 10, 1572–1575. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.E.; Jeong, J.H.; Shin, C.K. Hormone-independent embryogenic callus production from ginseng cotyledons using high concentrations of NH4NO3 and progress towards bioreactor production. Plant Cell Tiss. Org. Cult. 2003, 72, 229–235. [Google Scholar] [CrossRef]

- Gantait, S.; Mitra, M.; Chen, J.T. Biotechnological interventions for ginsenosides production. Biomolecules 2020, 10, 538. [Google Scholar] [CrossRef]

- Lyu, X.; Lyu, Y.; Yu, H.W.; Chen, W.N.; Ye, L.; Yang, R. Biotechnological advances for improving natural pigment production: A state-of-the-art review. Bioresour. Bioprocess. 2022, 9, 8. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Akita, M.; Sakamoto, K.; Liu, H.; Shigeoka, T.; Koyano, T.; Kawamura, M.; Furuya, T. Large-scale production of anthocyanin by Aralia cordata cell suspension cultures. Appl. Microbiol. Biotechnol. 1993, 40, 215–218. [Google Scholar] [CrossRef]

- Yazaki, K. Lithospermum erythrorhizon cell cultures: Present and future aspects. Plant Biotechnol. J. 2017, 34, 131–142. [Google Scholar] [CrossRef]

- Aitken-Christie, J.; Kozai, T.; Smith, M.A.L. (Eds.) Automation and Environmental Control in Plant Tissue Culture; Springer: Dordrecht, Germany, 1995. [Google Scholar]

- Georgiev, M.I.; Weber, J.; Maciuk, A. Bioprocessing of plant cell cultures for mass production of targeted compounds. Appl. Microbiol. Biotechnol. 2009, 83, 809–823. [Google Scholar] [CrossRef]

- Tekoah, Y.; Shulman, A.; Kizhner, T.; Ruderfer, I.; Fux, L.; Nataf, Y.; Bartfeld, D.; Ariel, T.; Gingis-Velitski, S.; Hanania, U.; et al. Large-scale production of pharmaceutical proteins in plant cell culture-the protalix experience. Plant Biotech. J. 2015, 13, 1199–1208. [Google Scholar] [CrossRef]

- Satish, L.; Rency, A.S.; Muthubharathi, B.C.; Shamili, S.; Rameshkumar, R.; Swamy, M.K.; Ramesh, M. Transgenic plant cell cultures: A promising approach for secondary metabolite production. In Natural Bio-Active Compounds: Volume 3: Biotechnology, Bioengineering, and Molecular Approaches; Akhtar, M.S., Swamy, M.K., Eds.; Springer: Singapore, 2019; pp. 79–122. [Google Scholar]

- Wawrosch, C.; Zotchev, S.B. Production of bioactive plant secondary metabolites through in vitro technologies—status and outlook. Appl. Microbiol. Biotechnol. 2021, 105, 6649–6668. [Google Scholar] [CrossRef] [PubMed]

- Nett, R.S.; Lau, W.; Sattely, E.S. Discovery and engineering of colchicine alkaloid biosynthesis. Nature 2020, 584, 148–153. [Google Scholar] [CrossRef] [PubMed]

- Birchfield, A.S.; McIntosh, C.A. Metabolic engineering and synthetic biology of plant natural products-A mini review. Curr. Plant Biol. 2020, 24, 100163. [Google Scholar] [CrossRef]

- Chandran, H.; Meena, M.; Barupal, T.; Sharma, K. Plant tissue culture as a perpetual source for production of industrially important bioactive compounds. Biotechnol. Rep. 2020, 26, e00450. [Google Scholar] [CrossRef] [PubMed]

- Jamil, S.; Rohani, E.R.; Baharum, S.N.; Noor, N.M. Metabolite profiles of callus and cell suspension cultures of mangosteen. 3 Biotech 2018, 8, 322. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, Y.; Wang, X.; Yue, Z.; Yang, X.; Chen, X.; Zhang, X.; Shen, D.; Wang, H.; Song, J.; et al. Insights into the species-specific metabolic engineering of glucosinolates in radish (Raphanus sativus L.) based on comparative genomic analysis. Sci. Rep. 2017, 7, 16040. [Google Scholar] [CrossRef]

- Pyne, M.E.; Narcross, L.; Martin, V.J.J. Engineering plant secondary metabolism in microbial systems. Plant Physiol. 2019, 179, 844–861. [Google Scholar] [CrossRef]

- Pandey, R.P.; Parajuli, P.; Koffas, M.A.G.; Sohng, J.K. Microbial production of natural and non-natural flavonoids: Pathway engineering, directed evolution and systems/synthetic biology. Biotechnol. Adv. 2016, 34, 634–662. [Google Scholar] [CrossRef]

- Turanlı-Yıldız, B.; Hacısalihoğlu, B.; Çakar, Z.P. Advances in metabolic engineering of Saccharomyces cerevisiae for the production of industrially and clinically important chemicals. In Old Yeasts-New Quest; Lucas, C., Pais, C., Eds.; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef]

- Ajikumar, P.K.; Xiao, W.H.; Tyo, K.E.J.; Wang, Y.; Simeon, F.; Leonard, E.; Mucha, O.; Phon, T.H.; Pfeifer, B.; Stephanopoulos, G. Isoprenoid pathway optimization for taxol precursor overproduction in Escherichia coli . Science 2010, 330, 70–74. [Google Scholar] [CrossRef]