Abstract

Mechanical under-row weed control in the vineyard emerges as a sustainable choice compared to chemical control, with tillage-based approaches proving especially efficient. A rollhacke, finger weeder, and blade weeder are valid alternatives to commonly used implements that cause excessive soil disruption and display suboptimal efficiency. The trial aimed to compare different under-row weed control strategies in terms of weed control efficacy and operational performance. Among these, in ST1, a tool-holder equipped with both a rollhacke and finger weeder was used at the first and second intervention; in ST2, a rollhacke was used at the first intervention and blade weeder at the second one; in ST3, firstly the tool-holder equipped with a rollhacke and finger weeder was used, then the blade weeder; in ST4, a rollhacke was used first and then the tool-holder equipped with a rollhacke and finger weeder. Weed height, weed cover, and weed biomass were evaluated before the first and after the second intervention. Total field time, fuel consumption, and CO2 emissions of each strategy were assessed. ST1 proved to be the best compromise in terms of weed control effectiveness and operational performance compared to the other strategies. Indeed, ST1 tendentially achieved a lower weed height (20.42 cm) and weed biomass around vine trunks (105.33 g d.m. m−2) compared to the other strategies. In terms of total field time, fuel consumption and CO2 emissions, ST1 recorded intermediate values equal to 3.85 h ha−1, 15.29 kg ha−1, and 48.72 kg ha−1, respectively. Further studies are needed to evaluate these strategies in different vineyard conditions, considering their effect on weed flora composition. Furthermore, exploring automation technology for real-time implement adjustments based on weed infestation levels could further improve the intervention effectiveness and efficiency.

1. Introduction

Up to the present time, agriculture has encountered a multitude of challenges, including the impacts of climate change, environmental deterioration, and resource depletion [1]. In the pursuit of global sustainability, both policymakers and consumers are keenly interested in researching and implementing sustainable agricultural practices [2]. In the Mediterranean area, vine cultivation is widespread, representing an important economic activity. Italy recorded 718,198 ha dedicated to vineyards in 2022, which resulted in being one of the world’s leading wine producers with 49,843 hL [3]. Among the various agricultural practices required in the vineyard, weed management plays a crucial role to ensure satisfactory grape yields [4]. Usually, weed management in vineyards involves preserving the resident vegetation in the inter-row area through mowing or sowing cover crops which can then be managed as a green manure. Instead, weeds in the under-row area are generally completely removed [5]. Their presence is a major cause of production losses [6], as they compete with crops, attract pests, increase canopy humidity (promoting fungal diseases) [7], and hinder harvesting [8]. Their management is challenging due to the difficulty of reaching the area under the vines with the risk of damaging vines and roots [6].

The application of pre-emergence and post-emergence chemical herbicides is one of the most commonly adopted methods for this purpose, being economical and timely [9,10,11]. Nevertheless, due to growing concern about the development of herbicide-resistant weeds, the negative impacts on the environment and human health, and following the stringent restrictions for some active substances, the fate of chemicals is uncertain [12]. Thermal methods are a sustainable alternative to chemicals, offering residue-free, broad-spectrum weed control, without resistance issues. However, high energy consumption, costs, and the production of greenhouse gases limit broader adoption [13].

Mechanical methods are commonly adopted as an alternative to chemicals for under-row weed control, and are also more cost effective than thermal ones [14]. Among the mechanical methods, there are those based on mowing and those based on soil tillage. Implements equipped with a vine-skipping mechanism are usually used. These machines are equipped with a feeler that enables the implement to operate under the row and re-enter when it detects trunks or poles, preventing damage to vine plants. [15]. Mowing can be performed with implements like brush weeders or horizontal discs with blades. However, although brush weeders perform effective weed control between and around vines, they can cause wounds on vine trunks, favoring the spread of diseases [16]. Instead, horizontal discs with blades showed lower weed control efficacy compared to tillage [17,18]. Tillage, when performed in a timely manner, enables efficient weed control [19]. However, choosing the right technique should consider not only its effectiveness but also the vineyard’s morphology, the soil’s pedological characteristics, and its environmental impact [20]. Vineyards exhibit one of the highest average soil loss rates among various land use categories, with approximately 9.5 Mg ha−1 year−1 compared to the average of 2.5 Mg ha−1 year−1 for all land use types [21,22,23,24,25]. Intensive tillage practices may promote further degradation. Therefore, care must be taken to avoid negative effects. For example, to prevent soil compaction, under-row weed control operations in spring should be carried out when the soil is adequately dry to support the equipment [7]. The different tools available present different levels of soil disturbance and efficiency, resulting in differences in intervention timeliness [20,26]. Among these, there are rotary hoes and harrows, motorized disks, plowshares, blade weeders, rollhacke and finger weeders. Rotary hoes and harrows, plowshares, and motorized disks, despite ensuring effective weed control, tend to cause excessive soil disturbance by destroying soil structure, reducing organic matter, and fostering soil erosion [14,27]. Blade weeders are a frequently used tool for under-row weed management. The implement consists of a horizontal blade designed to slightly penetrate the soil surface and cut off weeds. Blade weeders typically enable a greater working capacity compared to rotary hoes and harrows, plowshares, and motorized disks, operating at speeds ranging from 3 to 7 km h−1 [26,28]. A rollhacke consists of a star-shaped, ground-driven tiller designed to break up the soil close to vine plants [29]. Simultaneously, it deposits a layer of soil underneath the vines, suffocating weeds. The machine presents a higher working capacity than most other tools used for the same purpose, with a working speed of around 6–8 km h−1 [26]. A rollhacke can be used simultaneously in combination with a finger weeder, a horizontal disk with ground-driven flexible fingers, for enhanced weed control around vine trunks [30]. During the vine growing season, different strategies can be adopted which involve using these tools in different sequences, maintaining soil stability and optimizing weed control intervention efficacy. A standard strategy adopted by vine growers consists of performing an initial intervention with a rollhacke, followed by an intervention with a blade weeder. Using the two tools in sequence is advantageous as the amount of soil brought under the row by a rollhacke facilitates the blade insertion, allowing it to remove weeds that have developed above more easily [19].

The aim of this field trial is to compare different strategies for under-row weed control in vineyards. These involved the use in different sequences of a rollhacke, blade weeder, and rollhacke employed simultaneously with finger weeder. The strategies tested were evaluated in terms of weed control effect, field time, fuel consumption, and CO2 emissions.

2. Materials and Methods

2.1. Site Characteristics

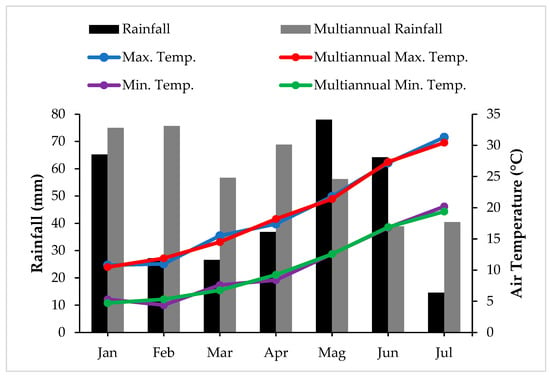

This trial was conducted in 2023 at Tenuta Montefoscoli owned by Castellani, Palaia (Pisa, Italy) (43°33′54′′ N, 10°44′23′′ E). The vineyard (Vitis vinifera L., cv: Vermentino), was established in 2019, and trained to Guyot (unilateral). The vines are spaced 2.30 m between rows, and 0.8 m within rows, with canes tied to a supporting wire at about 1 m above the ground. The soil texture is of medium mixture tending to sandy. The vineyard was managed in accordance with organic farming criteria (Reg. CE 834/2007). The area exhibited a characteristic Mediterranean climate, featuring seasonal rainfall spikes in spring and fall. Figure 1 illustrates the monthly cumulative precipitation (in millimeters) as well as the average minimum and maximum air temperatures at the experimental site for the period when the trial took place, alongside the 10-year average values.

Figure 1.

The monthly accumulation of rainfall (mm) and the average minimum and maximum air temperatures (°C) at the experimental site presented during the period in which the experimental trial was carried out, in addition to the 10-year average values.

2.2. Experimental Layout and Implements Employed

In this trial, different under-row weed control strategies were compared in two consecutive weed control interventions performed during the growing season to evaluate their weed control effect and operative performance. These strategies involved the use of implements such as rollhacke, finger weeder, and blade weeder in different combinations and sequences. The first under-row weed control intervention was carried out on 16 March 2023, while the second one on 8 June 2023. Among the tested strategies, one involved performing under-row weed control using a tool-holder equipped with rollhacke and finger weeder in both the first and second interventions (ST1); another strategy, that represents a standard under-row weed control itinerary in vineyards, in which the first intervention was performed with rollhacke and the second one with blade weeder (ST2); a third strategy, in which the tool-holder equipped with rollhacke and finger weeder was used in the first intervention, and blade weeder in the second one (ST3); a fourth strategy, in which rollhacke was used for the first treatment and the tool-holder equipped with rollhacke and finger weeder was used for the second one (ST4). Table 1 shows the implements used in each strategy. Comparison of strategies was performed according to a randomized complete block design with three replications. Four adjacent rows were chosen, and each was divided into three blocks of 45 m each. Before the start of the trial, all the rows of the vineyard involved in the test had been managed with rollhacke on 10 February 2023.

Table 1.

Implements employed on each strategy for under-row weed control.

The Implements

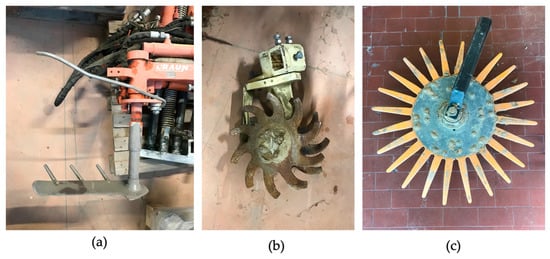

The blade weeder LUV Perfekt (Braun, Landau in der Pfalz, Germany) consists of a horizontal blade which is inserted slightly below the soil surface to cut weed shoots from their roots (Figure 2a). The implement is equipped with a horizontal feeler which enables the vine-skipping mechanism. The blade weeder was equipped with three fins which allow the soil to be separated from weed roots to favor their desiccation. During the test, the implement was mounted in the intermediate axel area on a vertical hydraulic lifter on the right side of the tractor. The vertical lifter (Braun, Landau in der Pfalz, Germany) consists of two ground round steels, two strong-walled steel tubes with integrated plain bearings and dirt wipers, and return spring. The lifter allows the hydraulic adjustment of the working depth and side inclination of the tool. The height of the vertical lifter corresponds to 0.70 m, the width to 0.30 m, and the depth to 0.38 m. This was set to obtain a blade weeder working depth equal to 5 cm.

Figure 2.

Implements used during the trial. Blade weeder (a); rollhacke (b); finger weeder (c).

Rollhacke (Braun, Landau in der Pfalz, Germany) consists of a rotary star tiller with two disks (Figure 2b). The implement loosens the soil, removing weeds near the area under the row, and throws a quantity of soil under the row, suffocating weeds present in this area. Rollhacke works by dragging, and, therefore, without the aid of the hydraulic system. During the trial, rollhacke was mounted on a tool-holder positioned in the front area of the tractor. The tool-holder consists of UKR-basic frame with single tube (Braun, Landau in der Pfalz, Germany), hydraulic width adjustment, pair of sliding parts with side inclination adjustment, and rigid support wheels. The tool-holder has a minimum width of 1.30 m, depth of 0.70 m, and height of 0.75 m. During the test, the width of the tool-holder was set to 1.60 m. The level of rollhacke tillage intensity can be controlled by adjusting the angle of the disk system on the bracket.

The finger weeder consists of ground-driven flexible fingers which fit around the vine and uproot weeds under the row (Figure 2c). The shallow operating depth of this implement reduces vine root damage, and its flexible fingers cause minimal damage to vines. In the present experiment, the finger weeder was always used in combination with rollhacke. The above-mentioned tool-holder was used, positioned in the front area of the tractor, carrying both implements (Figure 3). In relation to the tractor’s forward orientation, the rollhacke was situated ahead of the finger weeder on the tool-holder. Each implement used for under-row weed control was mounted on only one side of the tractor. During the trial, a New Holland T4. 90 F powered by a 63 kW diesel engine was used.

Figure 3.

View of the tool-holder positioned in the tractor front area, and disposition of rollhacke and finger weeder.

2.3. Data Collection

Weed cover, weed height, and weed biomass were assessed before the first treatment and four days after the second treatment. Measurements before the first under-row weed control intervention took place on 16 March 2023, immediately before the treatment. Measurements after the second intervention were conducted on 12 June 2023. Weed cover, representing the visual soil weed coverage, was determined by capturing images within a square frame measuring 30 × 25 cm using a Nikon Coolpix 7600 camera (Nikon Corporation, Tokyo, Japan). These images were then analyzed using the Canopeo app [31], which calculates the weed cover percentage by assessing the proportion of green pixels in the image. The average height of the weed population was assessed within the same square frame using a folding ruler. Weed cover assessments were conducted between vine trunks, whereas weed height evaluations were performed both between and around vine trunks. Two measurements were taken for each replicate, both for weed cover and weed height, before the initial intervention and after the second one. Measurements to determine weed biomass were performed by cutting and collecting the live above-ground weed biomass present within the 30 × 25 cm square frame. The total fresh biomass was subsequently subjected to oven-drying at 100 °C for 3–4 days, continuing until a constant mass was achieved. Dry biomass was then determined. One measurement for each replicate of weed biomass was carried out both between and around vine trunks, before the initial intervention and after the second one. The parameters of weed height, cover, and biomass were also collected on an untreated control adjacent to the rows where the strategies were tested. The control was chosen before the start of the trial and was characterized by a uniform level of weed infestation compared to rows in which the strategies were tested. Before the start of the trial, the weed flora in terms of ground coverage consisted of 70% annual species and 30% perennial species. Among the annual species, major weeds present were Bromus sterilis L., Avena fatua L., Hordeum murinum L., Veronica persica Poir., and Erodium cicutarium L.. Among the perennial species, the most frequent were Lolium perenne L. Pers., Poa trivialis L., Cynodon dactylon L. Pers., Verbascum sinuatum L., and Sonchus oleraceus L.

Operational parameters such as working speed and turning time were collected. For the calculation of the machines’ working speed during the intervention, travel times for the entire length of the plot area were timed. Theoretical field times, which correspond to the time the machines effectively operate at an optimum working speed and work over their full width of action, were measured. The field time of each implement for each intervention was measured considering the theoretical field time and the turning time. Subsequently, the total field time of each strategy was calculated by adding the field times of the implements employed. Fuel consumption was estimated by applying the hourly consumption formula:

where Ch represents the tractor hourly fuel consumption (kg fuel hour−1), W is the power of the tractor (kW), d represents the effort percentage of the tractor’s engine (which varies based on the implement used, with 1 indicating maximum power required), and Cs stands for the tractor energetic efficiency (kg fuel kWh−1). For this study, the energetic efficiency of the tractor Cs was considered to be 0.25 kg fuel kWh−1. CO2 emissions were estimated considering a CO2 emission value per kg of diesel (for a four-stroke engine) equal to 3.19 kg per kg of diesel [32,33].

2.4. Statistical Analysis

A two-way ANOVA was conducted to examine the effect of strategy, position, and their interactions on both weed biomass and weed height. To assess the significance of the strategy used on weed cover, a one-way ANOVA test was employed. To evaluate normality distribution, the Shapiro–Wilk test was employed. Bartlett test was used to assess homoscedasticity. When necessary to meet the normality assumption, data underwent arcsine or square root transformations. For both trials, LSD post hoc test was carried out at a significance level of 0.05. Data underwent analysis utilizing the statistical software R (version 4.3.1; R Foundation for Statistical Computing: Vienna, Austria) [34]. LSD post hoc test was conducted using the “agricolae” package. Graphs were generated using the “ggplot2” extension package [35].

3. Results

3.1. Comparison of the Weed Control Effects of the Strategies

Regarding the analysis of the parameters relating to the level of weed infestation before the first treatment, the two-way ANOVA revealed that strategy, position, and the interaction among factors did not affect weed height. Weed biomass was neither affected by the strategy used, nor by the interaction between strategy and position, while position had a significant effect on the parameter (p < 0.001). The one-way ANOVA revealed that strategy did not affect weed cover. The results of the one-way and two-way ANOVA regarding the level of weed infestation before the first weed control intervention are shown on Table 2.

Table 2.

Results of the ANOVA analysis testing the effect of strategy, position, and interaction among factors on weed height and biomass, and the effect of strategy on weed cover before the first under-row weed control intervention.

Weed biomass was higher in the area around vine trunks (340.58 g d.m. m−2) than between vine trunks (107.83 g d.m. m−2), with a percentage increase of 215.9%. Therefore, it is possible to state that before the first treatment, the level of weed infestation in the plots in which the different strategies were tested was homogeneous, both in terms of weed height and weed cover. Weed biomass was also homogeneous in the plots in which the strategies were tested, even though varying levels of infestation were observed in the two positions under investigation, i.e., between vine trunks and around them.

Regarding the evaluation conducted four days after the last treatment, the two-way ANOVA showed that both strategy (p < 0.05) and position (p < 0.05) had a significant effect on weed height, while the interaction among factors did not affect the parameter. Weed biomass was affected by position (p < 0.001) and the interaction among strategy and position (p < 0.05), while strategy did not affect the parameter. The one-way ANOVA highlighted no significant differences between the strategies tested in terms of weed cover. The F-value and p-value of the two-way and one-way ANOVAs conducted regarding the level of weed infestation after the last treatment are reported in Table 3.

Table 3.

Results of the ANOVA analysis testing the effect of strategy, position, and interaction among factors on weed height and biomass, and the effect of strategy on weed cover four days after the last intervention of under-row weed control.

In the untreated control, four days after the last treatment, average weed cover values of 74% were recorded. Moreover, average weed height and biomass values equal to 68.36 cm and 401.64 g d.m. m−2, and 69.05 cm and 584.20 g d.m. m−2, were recorded between and around vine trunks, respectively.

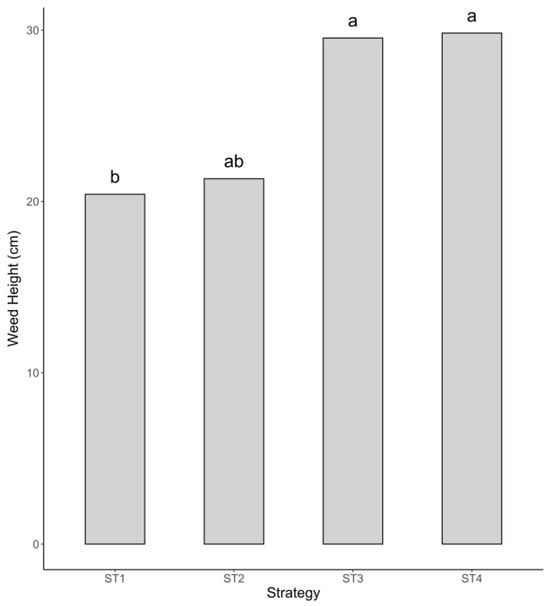

In the plots managed with ST1, lower values of weed height were observed compared to ST3 and ST4 (with values of 20.42, 29.54, and 29.83 cm, respectively) (p < 0.05), while there were no significant differences between ST1 and ST2 (21.33 cm). No significant differences emerged even in the comparison between ST2, ST3, and ST4 (Figure 4). Weed height was higher in the area around vine trunks (31.58 cm) compared to between vine trunks (18.98 cm), with a percentage increase of 66.9%.

Figure 4.

Effect of the strategy employed on weed height four days after the last under-row weed control intervention. Means denoted by different letters are significantly different at p < 0.05 (LSD test). ST1—Strategy 1, in which both the first and the second intervention of under-row weed control were performed with the tool-holder equipped with rollhacke and finger weeder; ST2—Strategy 2, in which the first intervention was carried out with rollhacke, and the second one with blade weeder; ST3—Strategy 3, in which the first intervention was realized with tool-holder equipped with rollhacke and finger weeder, and the second one with blade weeder; ST4—Strategy 4, in which rollhacke was used during the first treatment, and the tool-holder equipped with rollhacke and finger weeder was used during the second one.

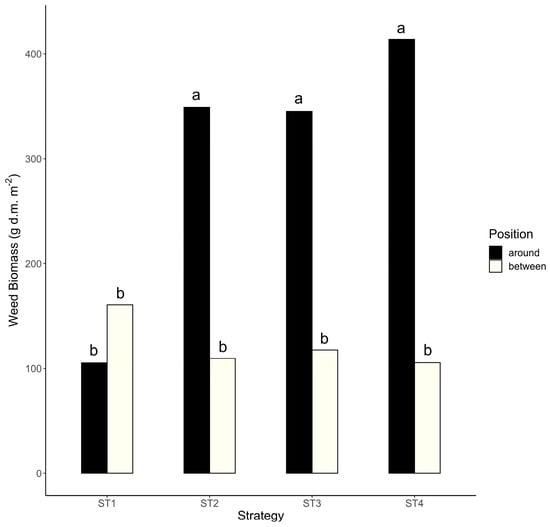

No differences emerged among the tested strategies in terms of weed biomass between vine trunks. Instead, lower values of weed biomass around vine trunks were obtained in plots managed with ST1 (105.33 g d.m. m−2) compared to ST2 (349.09 g d.m. m−2), ST3 (345.09 g d.m. m−2), and ST4 (413.82 g d.m. m−2) with an average decrease of 71.5% (p < 0.05) (Figure 5). Weed biomass was higher around vine trunks (303.33 g d.m. m−2), compared to between vine trunks (123.38 g d.m. m−2).

Figure 5.

Effect of the interaction among strategy and position on weed biomass four days after the last under-row weed control intervention. Means denoted by different letters are significantly different at p < 0.05 (LSD test). ST1—Strategy 1, in which both the first and the second intervention of under-row weed control were performed with the tool-holder equipped with rollhacke and finger weeder; ST2—Strategy 2, in which the first intervention was carried out with rollhacke, and the second one with blade weeder; ST3—Strategy 3, in which the first intervention was realized with tool-holder equipped with rollhacke and finger weeder, and the second one with blade weeder; ST4—Strategy 4, in which rollhacke was used during the first treatment, and the tool-holder equipped with rollhacke and finger weeder was used during the second one. Around—around vine trunks; Between—between vine trunks.

3.2. Strategies’ Operative Performances

The operative performances of each under-row weed control strategy tested, including implement working speed, turning time, field time, fuel consumption, and CO2 emissions, are reported in Table 4.

Table 4.

Operative parameters of each under-row weed control strategy tested. These include tractor working speed and turning time for each implement employed, total field time, fuel consumption, and CO2 emission of each strategy tested.

The absence of relevant differences in terms of field time between the rollhacke used alone or used with finger weeder is evident. The field time of the tool-holder equipped with a rollhacke and finger weeder during the second intervention was greater than that of the first intervention. The blade weeder presents the highest field time. Thus, the strategies in which the blade weeder was used (ST2 and ST3) showed a greater field time compared to the others, with an average increase of 15.2%. The use of the blade weeder also resulted in a greater fuel consumption compared to the use of the tool-holder with rollhacke and finger weeder, and compared to the rollhacke alone, which presents the lowest consumption. Indeed, the blade weeder led to an increase in fuel consumption equal to 177.9% compared to the rollhacke, and, on average, of 78.9% compared to the tool-holder with rollhacke and finger weeder. Overall, ST2 and ST3 showed a higher fuel consumption compared to ST1 with an average increase of 23.6%, and with an average increase of 38% with respect to ST4, the strategy resulting in the lowest consumption. The strategy in which the tool-holder with rollhacke and finger weeder was used at the first intervention and blade weeder at the second one (ST3), showed the highest fuel consumption. Since CO2 is closely linked to fuel consumption, emissions results showed the same fuel consumption trend, with ST2 and ST3 presenting higher emissions compared to ST1 and ST4.

4. Discussion

Concerning the level of weed infestation before the first under-row weed control intervention, weed biomass was higher around vine trunks rather than between them. This phenomenon can be attributed to the efficacy constraint observed for the majority of implements that perform under-row weed control with tillage in this area [36]. In this case, before the start of the field trial, all the rows involved were managed with a rollhacke.

After the last weed control intervention, weed height was higher around vine trunks compared to between them with a percentage increase of 66.9%, regardless of the strategy tested. Nevertheless, in plots managed with ST1, i.e., with the use of the tool-holder equipped with rollhacke and finger weeder, weed height was lower compared to those managed with ST3 and ST4 (with values of 20.42, 29.54, and 29.83 cm, respectively). No differences emerged between ST1 and ST2 (21.33 cm) (the standard strategy commonly adopted by vine growers, consisting in carrying out the first treatment with a rollhacke and the second with blade weeder). The results achieved by ST1 and ST2 for this parameter appear to be encouraging as the values obtained are slightly higher than those obtained by Sportelli et al. [37] with post-emergence herbicide applications (12.61 cm). It is crucial to keep weeds at a low height to minimize competition with vine plants [38,39] and promote adequate grape cluster aeration to prevent fungal diseases [7].

No significant differences emerged among the strategies in terms of weed biomass between vine trunks, with values in the range from 105.57 to 160.66 g d.m. m−2. On the other hand, the strategy in which the tool-holder equipped with rollhacke and finger weeder was used during both interventions (ST1) obtained the best results around vine trunks. Indeed, ST1 allowed an average decrease in weed biomass around vine trunks equal to 71.5% compared to the other strategies. This corroborates what Castaldi [26] stated, according to which the finger weeder, operating in close proximity to vine trunks, enhances the functionality of other implements that may exhibit restricted efficacy around trunks. Instead, strategies involving the use of the tool-holder with rollhacke and finger weeder only during the second intervention (ST4), or those utilizing blade weeders during the second intervention (ST2 and ST3), achieved higher values, and similar to each other. The blade weeder’s ability to cut weeds in this area is hampered by the presence of the trunk itself which induces the re-entry of the tool by means of the vine-skipping mechanism. Pergher et al. [19] also observed a greater effectiveness of the blade weeder between vine trunks rather than around them. Another aspect to consider about the blade weeder is the implement mode of action, which consists of cutting weeds from underneath without necessarily turning them over. This could lead to weeds’ reestablishment if their roots remain in contact with the soil and there is enough moisture available. [14]. Nonetheless, the results of weed biomass between vine trunks obtained by ST2 and ST3 where this implement was employed were in line with the other strategies tested. Furthermore, compared to other implements such as plowshares, the action on the soil performed by the blade weeder is less intense and therefore less impactful on soil stability [14].

Regarding operational performance, using a rollhacke alone or tool-holder equipped with rollhacke and finger weeder resulted in the same field time. This is because the finger weeder can be used at the same working speeds as the rollhacke, which tend to be higher than most implements employed for the same purpose [26]. The field time of the tool-holder with rollhacke and finger weeder during the second intervention was higher compared to the first intervention. This is due to the tractor’s lower working speed during the second intervention for a greater weed infestation compared to the first one. Overall, the total field times of ST2 and ST3 were higher than ST1 and ST4, with an average percentage increase of 15.2%. The higher values of ST2 and ST3 are mainly attributable to the use of the blade weeder, whose working speed (3.20 km h−1) was lower than with the rollhacke (6.50 km h−1), and rollhacke used with finger weeder (5.25 km h−1, on average). The field time of each implement determines the timeliness of intervention. The timeliness of the weed control intervention is crucial for its effectiveness, and because the vine grower may have limited time windows to perform the operation due to adverse climatic events such as rainfall [40]. Furthermore, it is important to carry out tillage when the soil is in the most suitable condition to avoid compaction damage which would enhance its degradation [7]. Using the tool-holder equipped with both implements involved greater fuel consumption than using the rollhacke alone. However, the greatest consumption was recorded for the blade weeder, with an increase of 177.9% compared to the rollhacke, and an average of 78.9% compared to the tool-holder with rollhacke and finger weeder. Consequently, ST4 recorded the lowest fuel consumption value (13.69 kg ha−1), ST1 achieved an intermediate value (15.29 kg ha−1), while ST2 and ST3 presented higher values (18.10 and 19.69 kg ha−1, respectively). No relevant differences emerged between strategies in which the rollhacke alone (ST2) or the tool-holder equipped with finger weeder and rollhacke (ST3) were used before the blade weeder. The CO2 emissions results followed the same trend as the fuel consumption. Therefore, also in this case, ST2 and ST3 recorded higher values, with average increases of 23.6 and 38% compared to ST1 and ST4, respectively. Nevertheless, with the same power of the tractor used, the resulting values of each tested strategy were lower than those found by Manzone et al. [20] for a rotary hoe used for the same purpose.

Overall, it is possible to state that ST1 proved to be the best compromise in terms of weed control effectiveness, fuel consumption, and CO2 emissions among the strategies tested. The results obtained are encouraging and generally not too far from those obtained with chemical control by other authors. This shows that mechanical under-row weed control with tillage can be a reliable alternative to chemical control. Nonetheless, it is necessary to consider that the results obtained in this trial must be contextualized in relation to the characteristics of the vineyard in which it was conducted and based on the level of previous weed infestation. For example, in cases of vineyards located on steep slopes, it is advisable to use implements that allow maintaining a permanent sod to limit the risk of soil erosion [19]. Therefore, it is essential to select suitable implements for under-row weed management by considering the vineyard’s morphological and pedoclimatic features, while ensuring both effective weed control and preservation of soil stability.

5. Conclusions

In the present study, the strategies tested for under-row weed control in the vineyard achieved encouraging results, demonstrating that tillage can be a sustainable and reliable alternative solution to chemical control. Moreover, the implements employed in these strategies confer environmental benefits. Indeed, they exert a lesser impact on soil stability and result in reduced CO2 emissions compared to other implements commonly used for soil tillage, such as rotary hoes or harrows. Overall, ST1 proved to be the best compromise in terms of weed control effectiveness, total field time, fuel consumption, and CO2 emissions among the strategies tested. This strategy tendentially obtained a lower weed height (20.42 cm) compared to the other strategies tested. Furthermore, ST1, thanks to the use of the tool-holder with rollhacke and finger weeder in both interventions, resulted in the best weed biomass outcomes around vine trunks (105.33 g d.m. m−2), addressing common under-row management limitations. In terms of field time, fuel consumption and emissions, ST1 obtained intermediate results compared to the other strategies, with values of 3.85 h ha−1, 15.29 kg of fuel ha−1, and 48.72 kg of CO2 ha−1. Further studies are needed to evaluate these strategies in vineyards with different morphological and pedoclimatic characteristics, also taking into consideration the effects on the weed flora composition. Additionally, it would be useful to assess the implementation of automation technologies, enabling real-time implement adjustments to perform interventions based on the actual infestation levels, thereby also achieving greater precision around vine trunks.

Author Contributions

Conceptualization, M.R., L.G. and M.F.; methodology, M.R., L.G. and S.M.L.; software, L.G. and S.M.L.; validation, M.F. and C.F.; formal analysis, S.M.L.; investigation, L.G. and S.M.L.; resources, M.R.; data curation, M.F., C.F. and S.M.L.; writing—original draft preparation, L.G. and S.M.L.; writing—review and editing, S.M.L., M.R. and M.F.; visualization, A.P.; supervision, M.R. and A.P.; project administration, M.R. and C.F.; funding acquisition, M.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to acknowledge Alessandro Moretto of Tenuta Montefoscoli owned by Castellani for hosting the trial and for the technical support provided; Eloisa Coppedè of Azienda Agricola La Frustaia for the essential technical support provided for the execution of the trial.

Conflicts of Interest

The authors declare no conflict of interest.

References

- El Bilali, H.; Strassner, C.; Ben Hassen, T. Sustainable Agri-Food Systems: Environment, Economy, Society, and Policy. Sustainability 2021, 13, 6260. [Google Scholar] [CrossRef]

- Qasemi, M.; Allahyari, M.S.; Ben Hassen, T.; Askari, M.I.; El Bilali, H. Cultivating Change: Perceptions and Attitudes of Agricultural Experts towards the Sustainable Development Goals. Land 2023, 12, 1604. [Google Scholar] [CrossRef]

- OIV (Organizzazione Internazionale Della Vigna e Del Vino) Nota Di Congiuntura Del Settore Vitivinicolo Mondiale Nel 2022. Available online: https://www.oiv.int/sites/default/files/documents/OIV_Nota_di_congiuntura_del_settore_vitivinicolo_mondiale_nel_2022_0.pdf (accessed on 15 September 2023).

- Pala, F. The Effect of Different Weed Management on Weeds and Grape Yield in Vineyards. Fresenius Environ. Bull. 2020, 29, 766–772. [Google Scholar]

- Magni, S.; Sportelli, M.; Grossi, N.; Volterrani, M.; Minelli, A.; Pirchio, M.; Fontanelli, M.; Frasconi, C.; Gaetani, M.; Martelloni, L.; et al. Autonomous Mowing and Turf-Type Bermudagrass as Innovations for An Environment-Friendly Floor Management of a Vineyard in Coastal Tuscany. Agriculture 2020, 10, 189. [Google Scholar] [CrossRef]

- Balsari, P.; Demeneghi, M.; Manzone, M.; Marucco, P. Comparison between Different Techniques for Weed Control in Vineyards. Asp. Appl. Biol. 2018, 137, 109–115. [Google Scholar]

- Hanson, B.D.; Roncoroni, J.; Hembree, K.J.; Molinar, R.; Elmore, C.L. Weed Control in Orchards and Vineyards. In Encyclopedia of Applied Plant Sciences; Academic Press: New York, NY, USA, 2016; pp. 479–484. [Google Scholar]

- Alcorta, M.; Fidelibus, M.W.; Steenwerth, K.L.; Shrestha, A. Competitive Effects of Glyphosate-Resistant and Glyphosate-Susceptible Horseweed (Conyza canadensis) on Young Grapevines (Vitis vinifera). Weed Sci. 2011, 59, 489–494. [Google Scholar] [CrossRef]

- Grella, M.; Marucco, P.; Balafoutis, A.T.; Balsari, P. Spray Drift Generated in Vineyard during Under-Row Weed Control and Suckering: Evaluation of Direct and Indirect Drift-Reducing Techniques. Sustainability 2020, 12, 5068. [Google Scholar] [CrossRef]

- Guler, H.; Zhu, H.; Ozkan, H.E.; Derksen, R.C.; Yu, Y.; Krause, C.R. Krause Spray Characteristics and Drift Reduction Potential with Air Induction and Conventional Flat-Fan Nozzles. Trans. ASABE 2007, 50, 745–754. [Google Scholar] [CrossRef]

- Foster, H.C.; Sperry, B.P.; Reynolds, D.B.; Kruger, G.R.; Claussen, S. Reducing Herbicide Particle Drift: Effect of Hooded Sprayer and Spray Quality. Weed Technol. 2018, 32, 714–721. [Google Scholar] [CrossRef]

- Centner, T.J.; Russell, L.; Mays, M. Viewing Evidence of Harm Accompanying Uses of Glyphosate-Based Herbicides under US Legal Requirements. Sci. Total Environ. 2019, 648, 609–617. [Google Scholar] [CrossRef]

- Facchinetti, D.; Bacenetti, J.; Eleonora Galli, L.; Luis Ruiz, G.; Pessina, D. Operative and Environmental Performance of a Hot-Foam Machine for the Herbicide-Free Weeding of the Vineyard. Riv. Studi Sulla Sostenibilita’ 2020, 2, 363–374. [Google Scholar] [CrossRef]

- Shrestha, A.; Kurtural, S.K.; Fidelibus, M.W.; Dervishian, G.; Konduru, S. Efficacy and Cost of Cultivators, Steam, or an Organic Herbicide for Weed Control in Organic Vineyards in the San Joaquin Valley of California. HortTechnology 2013, 23, 99–108. [Google Scholar] [CrossRef]

- Yezekyan, T.; Olt, J. Vineyard Floor Management with Novel Free-Active Inter-Row Tiller. In Proceedings of the 15th Internal Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2016. [Google Scholar]

- Moretti, M. Mechanical Weed Control under the Vine. Available online: https://smallgrains.wsu.edu/weeders-of-the-west/2021/07/14/mechanical-weed-control-under-the-vine/ (accessed on 16 September 2023).

- Mainardis, M.; Boscutti, F.; Rubio Cebolla, M.D.M.; Pergher, G. Comparison between Flaming, Mowing and Tillage Weed Control in the Vineyard: Effects on Plant Community, Diversity and Abundance. PLoS ONE 2020, 15, e0238396. [Google Scholar] [CrossRef] [PubMed]

- Cabrera-Pérez, C.; Llorens, J.; Escolà, A.; Royo-Esnal, A.; Recasens, J. Organic Mulches as an Alternative for Under-Vine Weed Management in Mediterranean Irrigated Vineyards: Impact on Agronomic Performance. Eur. J. Agron. 2023, 145, 126798. [Google Scholar] [CrossRef]

- Pergher, G.; Gubiani, R.; Mainardis, M. Mainardis Field Testing of a Biomass-Fueled Flamer for In-Row Weed Control in the Vineyard. Agriculture 2019, 9, 210. [Google Scholar] [CrossRef]

- Manzone, M.; Demeneghi, M.; Marucco, P.; Grella, M.; Balsari, P. Technical Solutions for Under-Row Weed Control in Vineyards: Efficacy, Costs and Environmental Aspects Analysis. J. Agric. Eng. 2020, 51, 36–42. [Google Scholar] [CrossRef]

- Panagos, P.; Borrelli, P.; Poesen, J.; Ballabio, C.; Lugato, E.; Meusburger, K.; Montanarella, L.; Alewell, C. The New Assessment of Soil Loss by Water Erosion in Europe. Environ. Sci. Policy 2015, 54, 438–447. [Google Scholar] [CrossRef]

- Champart, L.P.d.C.; Guilpart, N.; Mérot, A.; Capillon, A.; Gary, C. Determinants of the Degradation of Soil Structure in Vineyards with a View to Conversion to Organic Farming. Soil Use Manag. 2013, 29, 557–566. [Google Scholar] [CrossRef]

- García-Díaz, A.; Marqués, M.J.; Sastre, B.; Bienes, R. Labile and Stable Soil Organic Carbon and Physical Improvements Using Groundcovers in Vineyards from Central Spain. Sci. Total Environ. 2018, 621, 387–397. [Google Scholar] [CrossRef]

- Fiera, C.; Ulrich, W.; Popescu, D.; Buchholz, J.; Querner, P.; Bunea, C.-I.; Strauss, P.; Bauer, T.; Kratschmer, S.; Winter, S.; et al. Tillage Intensity and Herbicide Application Influence Surface-Active Springtail (Collembola) Communities in Romanian Vineyards. Agric. Ecosyst. Environ. 2020, 300, 107006. [Google Scholar] [CrossRef]

- Rodrigo-Comino, J.; Keesstra, S.; Cerdà, A. Soil Erosion as an Environmental Concern in Vineyards. The Case Study of Celler Del Roure, Eastern Spain, by Means of Rainfall Simulation Experiments. Beverages 2018, 4, 31. [Google Scholar] [CrossRef]

- Castaldi, R. Lavorazione Del Terreno Nel Sottofila. In Vite. Meccanizzazione del Vigneto. Guida Alla Scelta e All’utilizzo di Macchine e Attrezzature; Edizioni L’Informatore Agrario: Verona, Italy, 2018; pp. 67–78. [Google Scholar]

- Lisek, J. Possibilities and Limitations of Weed Management in Fruit Crops of the Temperate Climate Zone. J. Plant Prot. Res. 2014, 54, 318–326. [Google Scholar] [CrossRef]

- Australian Wine Research Institute. Non-Chemical Weed Management. Available online: https://www.awri.com.au/industry_support/viticulture/weed-management/non-chemical-weed-management/ (accessed on 19 September 2023).

- Sozzi, M.; Pasquetti, E.; De Ros, A.; Ferro, F. Performance Evaluation of Automated Implement for Vineyard Mechanical Weed Control. In Proceedings of the International Scientific Conference, Riga, Latvia, 26–28 May 2021. [Google Scholar]

- Australian Wine Research Institute. Finger Weeder. Available online: https://www.awri.com.au/industry_support/viticulture/weed-management/non-chemical-weed-management/finger-weeder/ (accessed on 11 April 2023).

- Patrignani, A.; Ochsner, T.E. Canopeo: A Powerful New Tool for Measuring Fractional Green Canopy Cover. Agron. J. 2015, 107, 2312–2320. [Google Scholar] [CrossRef]

- European Commission Commission Delegated Regulation (EU). 2023/1185 of 10 February 2023. Supplementing Directive (EU) 2018/2001 of the European Parliament and of the Council by Establishing a Minimum Threshold for Greenhouse Gas Emissions Savings of Recycled Carbon Fuels and by Specifying a Methodology for Assessing Greenhouse Gas Emissions Savings from Renewable Liquid and Gaseous Transport Fuels of Non-Biological Origin and from Recycled Carbon Fuels. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023R1185 (accessed on 21 September 2023).

- Ministero della Giustizia Italiano. Supplemento Ordinario n. 42/L alla Gazzetta Ufficiale del 30 Novembre 2021, Serie Generale—n. 285. Allegato V—Contenuto Energetico dei Combustibili. Available online: https://www.gazzettaufficiale.it/atto/serie_generale/caricaArticolo?art.versione=1&art.idGruppo=18&art.flagTipoArticolo=5&art.codiceRedazionale=21G00214&art.idArticolo=1&art.idSottoArticolo=1&art.idSottoArticolo1=10&art.dataPubblicazioneGazzetta=2021-11-30&art.progressivo=0 (accessed on 21 September 2023).

- R Core Team R. A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2023. [Google Scholar]

- De Mandiburu, F. Agricolae: Statistical Procedures for Agricultural Research; R Package Version 1.3-6; R Foundation for Statistical Computing: Vienna, Austria, 2023. [Google Scholar]

- Lanini, W.T.; McGourty, G.T.; Thrupp, L.A. Weed Management for Organic Vineyards. In Organic Winegrowing Manual; University of California, Agriculture and Natural Resources: Los Angeles, CA, USA, 2011; pp. 69–82. [Google Scholar]

- Sportelli, M.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Raffaelli, M.; Magni, S.; Caturegli, L.; Volterrani, M.; Mainardi, M.; Peruzzi, A. Autonomous Mowing and Complete Floor Cover for Weed Control in Vineyards. Agronomy 2021, 11, 538. [Google Scholar] [CrossRef]

- MacLaren, C.; Bennett, J.; Dehnen-Schmutz, K. Management Practices Influence the Competitive Potential of Weed Communities and Their Value to Biodiversity in South African Vineyards. Weed Res. 2019, 59, 93–106. [Google Scholar] [CrossRef]

- Garnier, E.; Navas, M.-L. A Trait-Based Approach to Comparative Functional Plant Ecology: Concepts, Methods and Applications for Agroecology: A Review. Agron. Sustain. Dev. 2012, 32, 365–399. [Google Scholar] [CrossRef]

- Gianessi, L.P.; Reigner, N.P. The Value of Herbicides in U.S. Crop Production. Weed Technol. 2007, 21, 559–566. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).