Abstract

Although different modifications of ridge tillage (RT) systems exist in different regions around the world, the positive impacts of RT on crop yields and weed management are quite similar. This review gives a comprehensive summary of different forms of RT and highlights the benefits of RT for crop growth, mainly due to better access to soil moisture, nutrients and light. In temperate areas, RT can accelerate crop emergence because soil temperature is usually higher on the ridge. These stimulating effects increase crop competitiveness against weeds especially in the early period of crop development until canopy closure. RT with crops placed on the top of ridges can also be used for automatically guiding inter-row hoes and intra-row band sprayers. The ridges can replace automatic vision control systems for hoeing and band spraying, which are needed for precise weeding in conventional flat seedbeds. Therefore, RT can be considered a possible platform for smart/robotic weeding. This paper introduces a new RT system using real-time kinematic (RTK) global satellite navigation systems (GNSS) for the ridging and seeding of maize and soybean on top of recompacted ridges. Straight ridges with precise positioning data were used to guide mechanical weeding elements precisely along the crop rows. Simultaneously, weeds in the valleys were suppressed by living mulches. Field experiments with this new technology in maize showed 85.5% weed dry biomass suppression compared to an untreated control and a slightly higher weed control efficacy than mechanical weeding in flat seedbeds.

1. Introduction

Ridge tillage (RT) creates raised dams or seedbeds for crops. It is often considered a form of conservation agriculture which provides a favorable environment for crop development and protects the soils from erosion and nutrient leaching [1,2]. There are different forms of RT. In intensive farming systems, for example, in potato production, dams are rebuilt every year. Less intensive forms of farming use permanent ridges [3,4]. In RT systems, mechanical weeding can be applied more efficiently and precisely than in flat seedbeds by combining hoeing or harrowing and re-building of ridges [1,3].

RT has been adopted for the cultivation of cereals (maize, winter wheat), root crops (yam, cassava, potatoes, etc.), legumes (soybean, cowpea) and some vegetables all around the world. It is often reported that RT favors crop growth and development, especially in the early growth stages [1,2]. Crops benefit from favorable soil moisture and temperature conditions [5], which enhance crop competitiveness against weeds and increase crop tolerance to mechanical weeding operations.

RT provides several benefits for weed management in organic and conventional food production systems. In conventional RT systems, band spraying on the top of dams could be combined with mechanical and biological weed control along the slope of the dams and the ridges instead of spraying herbicides on the entire field area [3,6]. In organic farming systems, mechanical weeding could substitute or complement hand-weeding to reduce production costs [3,4,7]. RT can enhance early crop development and therefore increase the competitiveness of crops against weeds. According to Jurik [8], early seedling vigor in soybean promoted by RT resulted in lower weed densities. Post-emergence mechanical weeding is often more effective in RT systems than in conventional flat seedbed systems. During mechanical weeding in RT, surface soil containing weed seeds and seedlings is moved away from crop rows, down into the valleys between ridges, with less burial of crop plants [9]. It also involves partial or complete truncation of previously cultivated ridges and re-building of ridges [10]. Ridge tillage (RT) offers the potential, also, for other integrated weed management (IWM) systems, such as cover cropping or the implementation of living mulches in the valleys between ridges [10].

RT can contribute to EU initiatives to reduce dependence on pesticide use, which would also reduce the risk of residues of herbicides in food, leaching and drift of herbicides into the environment and the evolution of herbicide-resistant weed populations [11]. Several studies have confirmed that RT can enhance yield with little or no herbicide intervention [8,11]. In fact, the use of herbicides could be drastically reduced with frequent soil disturbance, such as ridge care, harrowing and hoeing, in inter- and intra-row areas. This would be an important step towards the fulfillment of goals postulated in the Farm-to-Fork strategy (European Commission 2020) [12]. Important goals of the Green Deal include a 50% reduction in synthetic pesticide use, an increase in biodiversity, including weed species diversity, in agriculture fields and an extension of organic farming until 2030. RT contributes to all three Green Deal targets.

The aims of this review are to (i) summarize the state of the art in RT cultures in relation to yield benefits, weed population dynamics and weed management, and (ii) to further propose an innovative weed management technology for RT systems using precision farming technologies.

2. Benefits of Ridge Tillage Systems for Crops

RT increases soil microbial activity, which, in turn, drives mineralization and the steady release of soil nutrients. The positive and direct benefits of RT on soil physical and chemical properties [2] and soil structure and microbial activities are well substantiated in the literature [13,14,15,16,17,18,19]. RT could also increase the uptake of soil nutrients by crops. However, such nutrient benefit attributed to RT cultures may also result in higher weed pressure [20] and significant yield losses if weeds are not effectively controlled.

Ridge tillage has been integrated in several cropping practices in different parts of the world. The merits and demerits of RT compared to conventional flat seedbed systems have been summarized by several authors [1,2,4,21,22]. In water limited and high temperature environments, RT in combination with mulching decreased water losses due to evapotranspiration and increased crop water use efficiency by up to 37% compared with conventional tillage [5,23,24,25,26]. Nitrogen mineralization was confirmed to be higher in the ridges than in the flat seedbeds and the valleys of RT systems [1,2,27,28]. This results in higher nutrient uptake, net photosynthetic rate, stomatal conductance, transpiration rate, and chlorophyll relative content in several crops, including maize, yam and rice [16,25,29]. Furthermore, studies from Germany [28] and Northeast China [21] under temperate conditions confirmed lower CO2 emissions from RT systems than from moldboard ploughed soils, while experiments in the USA showed higher CO2 emissions than chisel tillage in three different soil topographies [30].

In addition, RT soils are often characterized by a lower bulk density [2,28] and lower penetration resistance compared to soils of conventional and no-till systems [2,31]. These properties favour root growth within the ridges [32]. Under tropical conditions on Alfisol in Southwestern Nigeria, a higher yield of yam tubers with RT was associated with lower soil bulk density compared to flat tillage with high root penetration resistance [18]. Moreover, RT increased the number of functional nodal roots in maize compared to conventional and no-till systems [33]. In temperate regions, crops benefit from higher soil temperatures in the ridges; such temperature gains induce faster germination and emergence of crop seeds [5,23,31,32,34]. If crops emerge earlier in relation to weeds, their competitive ability is increased and yield losses due to weed competition are lower [35]. Interestingly, the configuration and azimuth of ridges are critical in determining soil temperature in an RT system [7]. More precisely, it is well established that an east–west ridge configuration enhances rapid soil warming and early crop emergence [36]. However, the later configuration may be irrelevant in elevated land terrains where ridges are arranged perpendicular to slopes to reduce erosion. In addition, [37] found that ridge height affects soil temperature and moisture trends, i.e., soil within ridges that are taller than 20 cm warms to a greater depth due to a larger temperature gradient.

Soil moisture content also varied significantly between tillage systems [2,23,31]. Soil moisture is usually higher in the valleys than along the ridges [2,32]. Furthermore, seasonal fluctuations in moisture and temperature are proven to enhance soil mineralization and N fixation as well as the degradation of herbicides in RT cultivation compared with conventional tillage systems [7]. However, the relationship between weather fluctuations, soil temperature, moisture and root development remains unclarified.

In India, the re-shaping of permanently raised ridges significantly increased maize and wheat yields compared with flat tillage [5]. In double cropping systems of winter wheat and maize in China, RT combined with living mulches obtained a 4–15% higher wheat grain yield and a 10% higher maize yield compared with conventional tillage [23,24]. For tuber crops such as yam and cassava, RT is a common practice with yield gains of 21–35% compared with conventional tillage systems [6,16]. In conclusion, RT can promote crop growth and increase yields. These benefits compensate for the additional costs of ridging and the interference with machine harvesting.

3. Ridge Tillage and Weed Infestations

RT systems vary in terms of periodicity of soil disturbance, shape and size of ridges, cropping systems and weed management practices. All these factors and interactions play a significant role in weed population dynamics. On silty soils in the American Midwest, with high infestations of summer annual dicotyledonous weed species, periodic ridge truncation and re-building over seasons reduced weed density and increased the yields of maize and soybean [8,11]. On the contrary, weed seed bank density was observed to be 12 times higher in permanent RT systems for vegetable production (often practiced in permaculture farming systems) compared with an RT system with regular rebuilding of ridges [3]. This was also reflected in the aboveground weed densities in the study. Soil seed banks of weed species, such as Lamium purpureum L., Stellaria media Vill., Digitaria sanguinalis L. and Amaranthus spp., were much higher in an undisturbed RT system compared to an RT system with frequent mechanical flattening and re-building of ridges, probably because they were able to escape weed control and set seeds. Vanasse and Leroux [38] further observed higher densities of perennial weed species in RT systems with permanently undisturbed ridges. Under such poor ridge disturbance, characterized by high weed pressure, the amount of labor required for hand-hoeing was double that required for tillage systems where the weed seed banks were low [3]. This simply implies additional costs for operations, which may be economically unrealistic for farmers.

In a study in the USA, 8 years of continuous maize cropping with an RT system resulted in 66% higher weed seed densities than in conventionally tilled maize [11,20], which was associated with less effective pre- and post-emergence herbicide applications. Weed competition is therefore considered to be a problem in many ridge tillage systems. Hence, developing a sustainable weed management strategy is necessary to obtain benefit from RT systems. Interestingly, continuous soil disturbance, such as truncation and re-building of ridges at intervals, in combination with maize/soybean rotation reduces weed seeds significantly (200–700 seeds m−2) compared to continuous maize cropping in similar RT (1500–3000 seeds m−2) [10,11,20]. Another study also confirmed that the weed seed bank was significantly reduced (1000 seeds m−2) in RT systems as opposed to conventional tillage (chisel and moldboard plough) systems (1800–2800 seeds m−2) under a similar level of soil disturbance [39].

4. Weed Management in Ridge Tillage Systems

Despite several innovative approaches to selective weeding in RT systems, weeds sometimes re-grow or are left untreated due to proximity to crop plants. This has always necessitated the deployment of manual weeding to prevent yield loss and post-harvest seed rain, especially in organic farming systems [4]. Such additional weeding costs may be unaffordable where and if labor becomes scarce [3], hence the need to develop a novel weed management practice for RT systems.

RT gives crops on the top of the ridges better access to light, soil water and nutrients. Soil temperature in the ridges was found to be higher than in flat seedbeds in temperate areas [31]. These positive effects might even be enhanced if the ridges are re-compacted with heavy discs after ridging (Figure 1). Therefore, we expect that crops will grow even faster relative to weeds and make them more tolerant of weed competition in the critical period of weed control, which is in the early growth stages. Increasing crop competitiveness reduces crop yield losses and results in higher economic weed thresholds [35].

Figure 1.

(A) Ridger and re-compacting discs. (B) Soil structure after ridging and re-compacting. Photo: R. Gerhards.

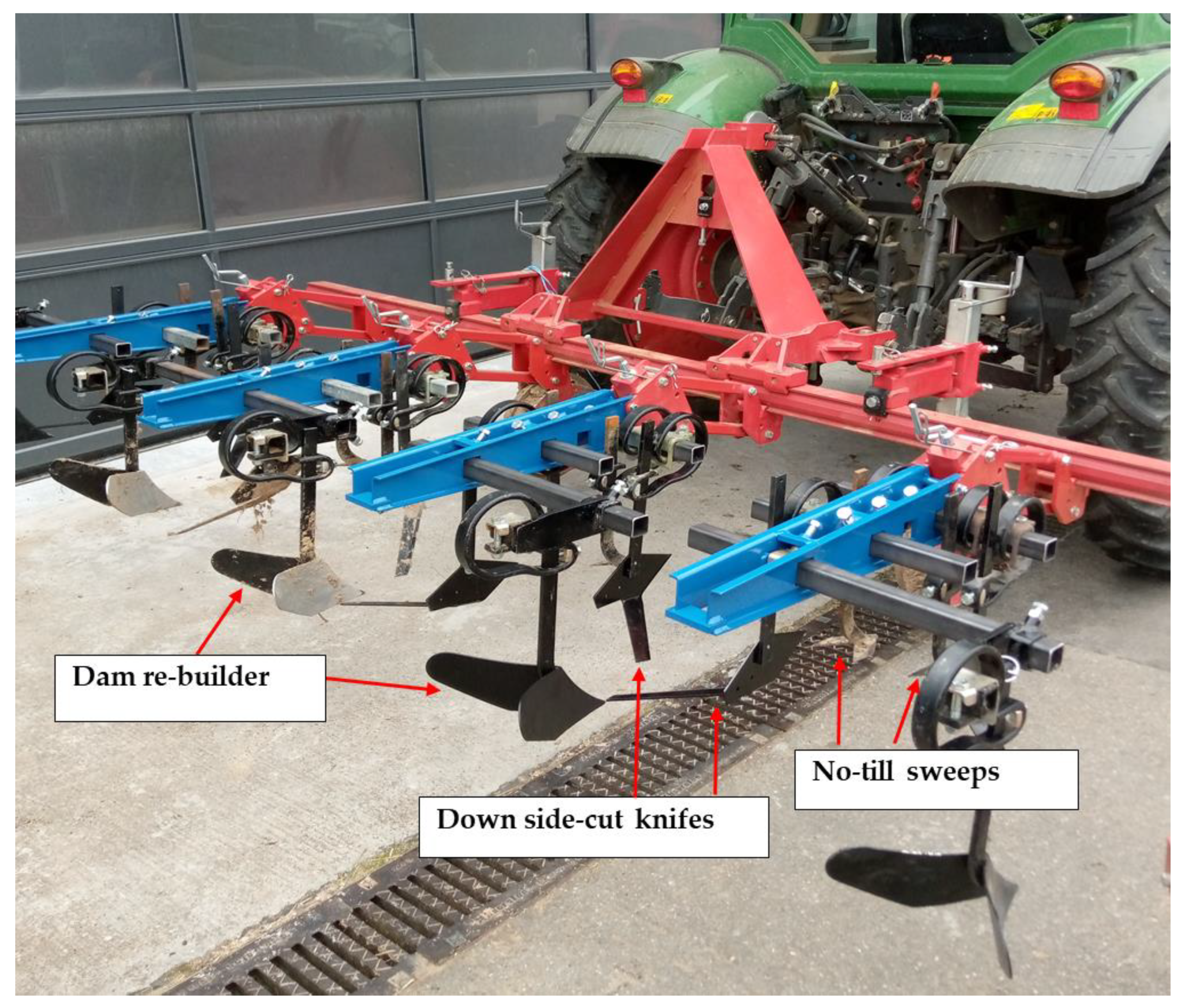

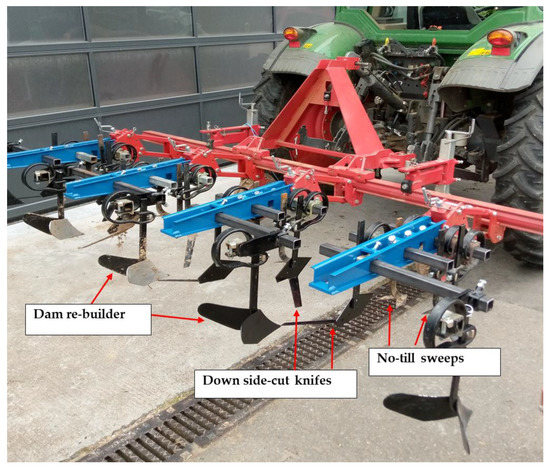

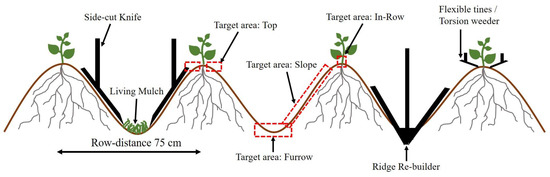

RT offers the possibility of adopting a greater variety of weed management practices and therefore allows for the adoption of IWM. With the precise placement of crops on the top of the ridge, spatial separation of weeds and crops is achieved. This may result in higher selectivity for mechanical weeding, which means a higher weed control efficacy with less crop damage due to uprooting and crop soil coverage [40]. If crop soil cover exceeds a critical threshold, the plants cannot compensate for burial and this will damage the crops, especially very sensitive crops, such as small-seeded vegetables and herbs (e.g., carrots and dill). In RT systems, the soil is moved downwards into the valleys by hoeing implements; therefore, crop soil cover is expected to be lower after hoeing compared with flat seedbed systems. This procedure also moves viable weed seeds away from the crop row where weed competition is highest. In addition to uprooting weed seedlings with flexible tines, no-till sweeps and side-cut knives along the tops and slopes of ridges, uprooted weed seedlings will be buried by the dam-rebuilder placed directly behind the hoeing elements. This combination of uprooting by the hoeing elements and burial with the dam-rebuilder increased weed control efficacy compared to sole hoeing operations in conventional flat seedbeds (Table 1, Figure 2).

Table 1.

Options for improving weed control in ridge tillage (RT) systems using precision farming technologies based on experiments with a new RT system, including re-compaction of the dams (Alagbo et al., 2022).

Figure 2.

RTK–GPS-controlled hoe for mechanical weeding in a ridge tillage system. No-till sweeps cut weeds next to the crop row on the top of the ridge, down side-cut knives remove weeds in the slopes of the ridge and ridge-re-builders are used before sowing living mulch in the furrows. Photo: O. Alagbo.

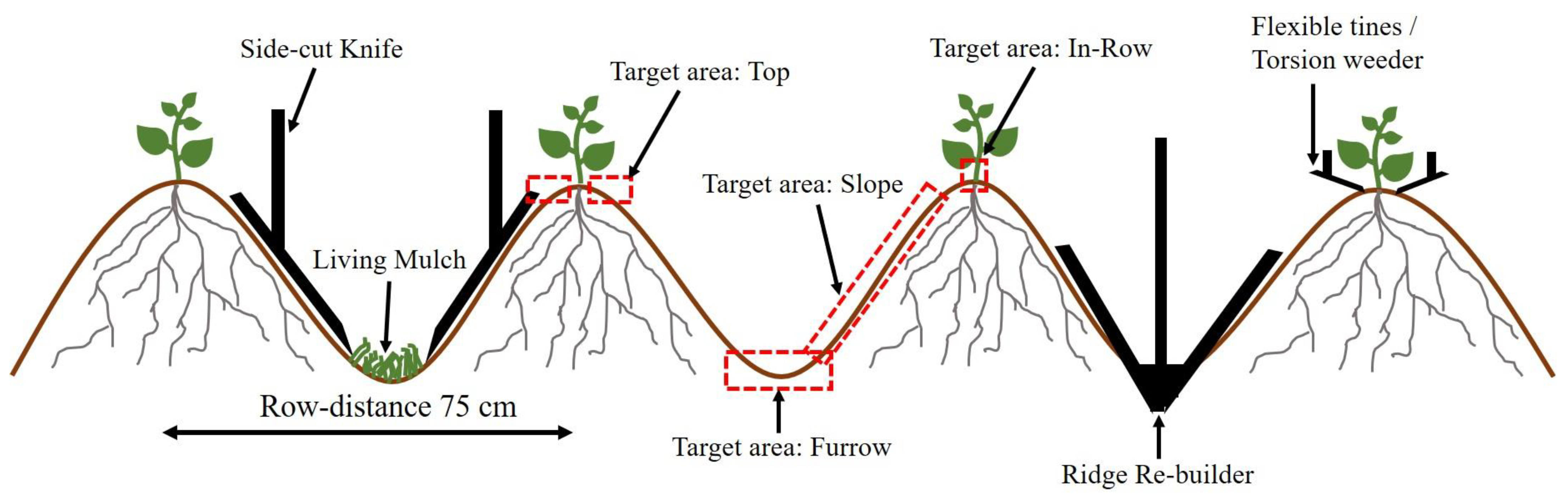

Alternatively, living mulch can be easily integrated in RT to suppress weeds (Figure 3). Living mulch is well reported to protect soil from erosion, promote the recycling of nutrients and the suppression of new emerging weeds [3,4,41] and reduce evaporation [7,39]. Short-growing cultivars of Trifolium repens (L.), Festuca rubra (L.) and Lolium perenne (L.) find suitable conditions for establishment with little or no competition with crops [42]. Hence, sowing living mulch into the valleys after the first pass of hoeing and ridge re-building may be an eco-sustainable component of IWM for RT systems. In the new RT system, living mulches are established in the ridges every year after the first pass of hoeing and dam-rebuilding. This guarantees a weed-free seedbed for the living mulches. With living mulches placed down in the ridges and the crops growing along the top of the dams, the competitive effect of living mulches on crops is expected to be lower than in flat seedbeds with living mulches in the inter-row areas.

Figure 3.

Schematic description of ridge tillage with crops placed on top of the re-compacted ridges and mechanical weeding with flexible tines close to crop rows, down side-cut knives in the slopes and living mulch in the furrows.

An additional advantage of ridge cultivation in comparison to flat seedbeds is that the ridge can be used to accurately guide physical and chemical weed control tools along the crop rows and therefore facilitate precise weeding operations, such as band spraying, inter-row hoeing and flaming, without sensor-guided row detection [43,44]. Camera-based row detection systems for mechanical hoes and automatic side-shift control provide several benefits for weed management in arable crops. The weed control efficacy of mechanical weeding was increased by almost 20% [43]. Labor efficiency was improved because of significantly higher driving speeds with camera-guided hoes compared to conventional tractor-mounted hoes [44]. Sensor-guided hoeing also reduced crop damage due to precise guidance of hoeing elements along the inter-row center [44]. This new technology has proved to be robust and effective in organic and conventional farms [44]. However, the investments required for camera technology are high. In RT systems, automatic side-shift control systems to guide hoeing elements along the center between crop rows could be used without cameras for crop row detection because ridges represent the center between the crop rows if RTK–GNSS technology is used for dam cultivation and seeding [44]. Mechanical intra-row weed control is still problematic. So far, machine intra-row hoeing is only possible for transplanted crops such as cabbage [44]. Therefore, conventional farms often combine inter-row hoeing with band spraying over the top of crop rows. Band spraying can also be integrated in RT systems. Herbicide use in RT systems was reduced by up to 70% in maize [8,40] and soybean [8] accompanied by a lower risk of herbicide leaching when compared with broadcast-spraying across the whole field. Guiding accuracy can be further increased if RTK–GNSS is used during ridge building (Figure 3). The steering wheels of weeding implements can easily be adjusted to the valleys, exactly in the center between two crop rows. Therefore, highly precise guidance and side-shift control of inter-row hoeing implements can be applied without any additional optical sensor system. Unlike conventional flat seedbeds, cameras are mounted on the hoe for crop row detection and guidance [44].

Mechanical weed control would be a good option for both conventional and organic RT systems. Specifically, it could help reduce high labor costs and workloads by complementing hand-weeding and other management strategies at any opportune time [4]. Some forms of mechanical weeding have been adopted previously in RT systems. For example, RT soybean fields in Iowa State, USA, showed higher yields and weed suppression compared to herbicide treatments when rotary weeding was carried out at four intervals [8]. This suggests that, depending on cropping systems, mechanical weeders are beneficial with periodic applications in the critical period for weed competition. Such periods would further depend on dry soil conditions, which are required for optimizing mechanical weeding efficiency [8,45,46]. Nevertheless, the adoption of mechanical weeders for RT can be difficult due to the different forms of RT systems and the need to acquire specific weeding tools modified for each system. For instance, ridges may change in shape and form due to wind and water erosion. This makes it difficult to find a suitable weeding tool, also. Furthermore, the efficiency of rotary hoe weeders can be limited by high amounts of crop residues in RT fields [9].

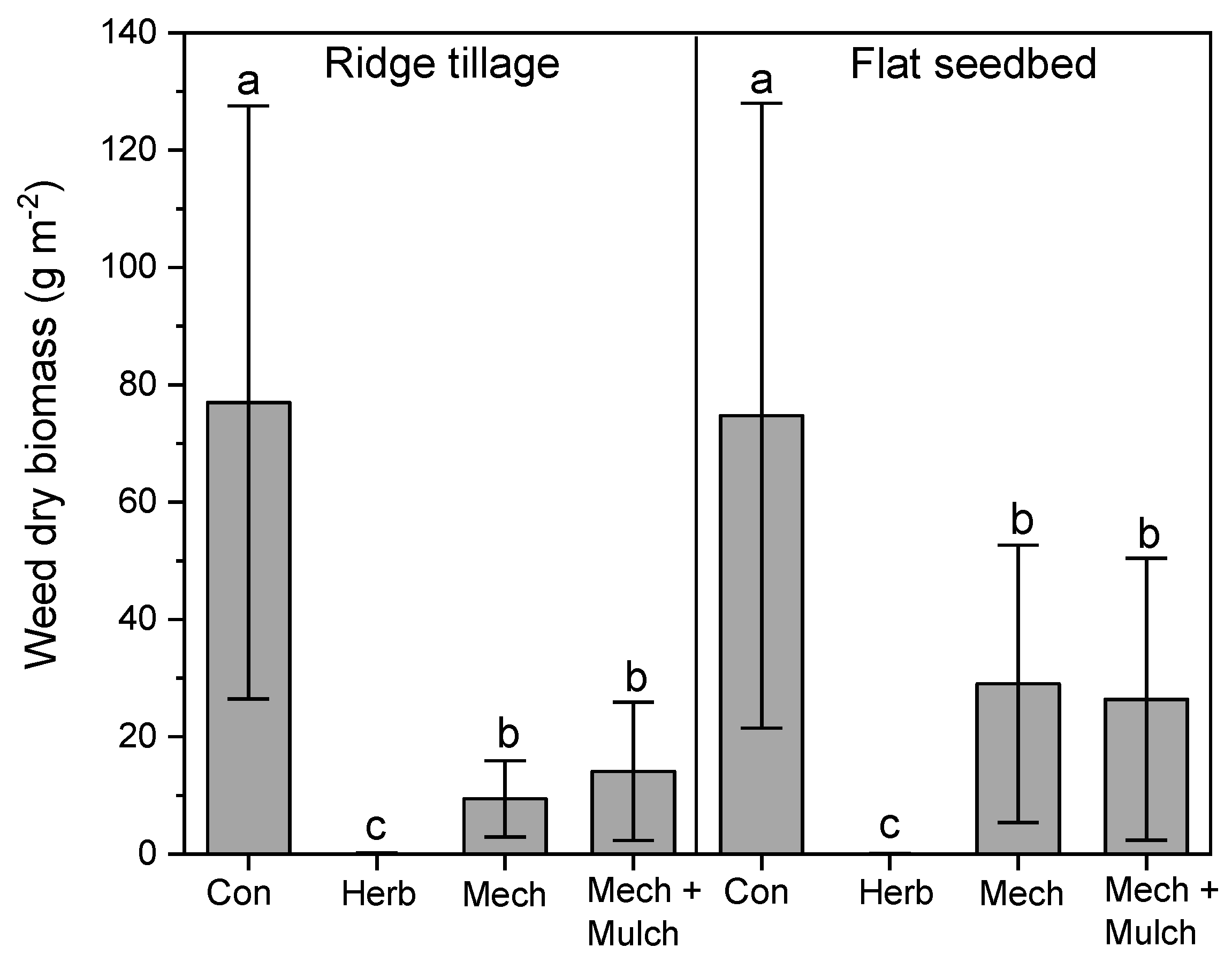

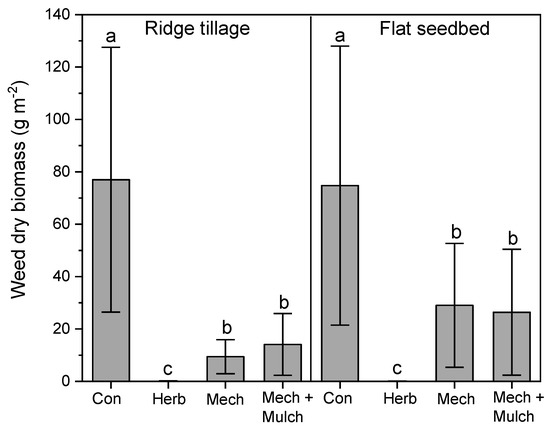

Field experiments with this new RT technology in maize fields with heavy infestations of Chenopodium album L., Stellaria media (L.) Vill., Lamium purpureum L. and Matricaria chamomilla L. as the most dominant weed species showed 85.5% weed dry biomass suppression after two passes of mechanical weeding along the top and slopes of the dam and with living mulches in the ridges compared to an untreated control [47] (Figure 4). Weed suppression was slightly higher in the RT system than in the flat seedbed.

Figure 4.

Average aboveground dry weed biomass after ridge tillage and conventional flat seedbed preparation and four weed control treatments (Con = untreated control; Herb = broadcast herbicide application with foramsulfuron + thiencarbazone methyl + iodosulfuron + cyprosulfamide (Safener); Mech = two rounds of hoeing and harrowing; Mech + Mulch = one round of hoeing and harrowing followed by sowing of living mulches in ridges pooled over two experiments 81 days after seeding maize at the University of Hohenheim Research Station, Germany, in 2021. Bars represent standard deviations. Means with the same letter are not significantly different according to Tukey’s HSD test at p ≤ 0.05.

5. Conclusions and Outlook

RT has been well considered a miniature precision agriculture [7,24]. Compared with other tillage systems, we may further argue that RT properly fits the definition of precision agriculture. The furrow tracks of RT systems can easily be used for autonomous or manual vehicle row guidance. Any form of smart field operation, such as precise fertilization, weeding and harvesting, is then possible, especially when RTK–GNSS-controlled steering systems are used to form the ridges. In that case, inter-row weed-hoeing and band spraying can be applied without any vision system for crop row detection. The latter has been commercialized in conventional flat seedbed systems [43,44].

Ridge tillage offers great potential for sustainable crop production and managing weeds with less dependency on herbicides, either by band spraying, precise mechanical inter-row weed control and applying living mulches in the ridges. Natural resources can be used more efficiently in RT systems compared to conventional flat seedbed cultivation. We expect that the new RT system with re-compacted dams would increase the weed-control efficacy of mechanical weeding and further enhance precision agriculture in ridge tillage cultivation. However, further research and development is needed to optimize weed management in RT systems. Weeds growing in inter-row areas can be controlled mechanically and by living mulches. Several automatic guidance systems are already on the market for autonomous side-shift control of inter-row hoes (e.g., K.U.L.T. Vision Control®, Garford-Robocrop®, Horsch Transformer VF®, Steketee IC®, OEM Claas Row Guard®, Einböck, Hatzenbichler, Schmotzer). These technologies can also be adopted for RT and might be operable even without camera guidance because ridges already provide precise guidance for the inter-row weeding tools. However, intra-row weed competition still causes problems in organic crop production systems. For conventional farming, the combination of autonomous inter-row hoeing with band spraying would provide high weed control efficacy and enable significant savings on herbicides, as herbicide application could be limited to a narrow band of approximately 10 cm over crop rows. For organic farming, selective mechanical weeding tools, such as torsion weeders, finger weeders or rotary harrows, can be used to treat the intra-row areas, but also more advanced machine vision systems based on artificial intelligence in combination with selective in-row weeding are available. A few tractor-mounted camera-guided in-row hoeing systems, such as Remo weed® by Ferrari Costruzioni in Italy, iSelect® by K.U.L.T in Germany, Garford Robocrop In-Row Weeder® by Zürn in Germany and Steketee IC® by Steketee in The Netherlands, and some completely autonomous robots, such as Farmdroid FD20® in Denmark, Farming Revolution in Germany, Odd Bot B.V. in The Netherlands, Agrointelli Robotti in Denmark and Naïo Technologies Dino and Oz in France, already exist. They all use vision control systems to identify weeds in crop rows. If weeds grow out of the close-to-crop area, which is approximately 5 cm around each crop plant, they can be controlled selectively with mechanical tools. So far, most systems are still limited to transplanted crops and their driving speed is rather low. They therefore need to be developed and adjusted to RT systems.

Author Contributions

Conceptualization, R.G., M.S. (Matthias Schumacher), M.S. (Marcus Saile) and O.A.; methodology, R.G., M.S. (Michael Spaeth), M.S. (Marcus Saile) and O.A.; validation, O.A. and R.G.; formal analysis R.G. and O.A.; investigation, O.A.; resources, R.G.; data curation, O.A.; writing—original draft preparation, O.A.; writing—review and editing, R.G., M.S. (Matthias Schumacher), M.S. (Marcus Saile) and M.S. (Michael Spaeth); visualization, R.G.; supervision, R.G.; project administration, R.G.; funding acquisition, R.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was part of the project Agriculture 4.0 without Chemical-Synthetic Plant Protection (NOcsPS) funded by the German Federal Ministry of Education and Research (BMBF/PtJ).

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Not applicable. The study did not involve humans.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the valuable input, ideas and suggestions of Hartmut Böhner in the setup and outline of this study and the technical support of Sebastian Hajek, Sebastian Klaasen, Wilhelm Kilpper, Carsten Götz and Stefan Wanke in developing and adopting the ridge tillage and hoeing technology and conducting the field experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, S.; Zhang, X.; Liang, A.; Zhang, J.; Müller, C.; Cai, Z. Ridge tillage is likely better than no tillage for 14-year field experiment in black soils: Insights from a 15N-tracing study. Soil Tillage Res. 2018, 179, 38–46. [Google Scholar] [CrossRef]

- Shi, X.H.; Yang, X.M.; Drury, C.F.; Reynolds, W.D.; McLaughlin, N.B.; Zhang, X.P. Impact of ridge tillage on soil organic carbon and selected physical properties of a clay loam in southwestern Ontario. Soil Tillage Res. 2012, 120, 1–7. [Google Scholar] [CrossRef]

- Jernigan, A.B.; Caldwell, B.A.; Cordeau, S.; DiTommaso, A.; Drinkwater, L.E.; Mohler, C.L.; Ryan, M.R. Weed Abundance and Community Composition following a Long-Term Organic Vegetable Cropping Systems Experiment. Weed Sci. 2017, 65, 639–649. [Google Scholar] [CrossRef]

- Mohler, C.L.; Caldwell, B.A.; Marschner, C.A.; Cordeau, S.; Maqsood, Q.; Ryan, M.R.; DiTommaso, A. Weed Seedbank and Weed Biomass Dynamics in a Long-Term Organic Vegetable Cropping Systems Experiment. Weed Sci. 2018, 66, 611–626. [Google Scholar] [CrossRef]

- Ram, H.; Singh, Y.; Saini, K.S.; Kler, D.S.; Timsina, J.; Humphreys, E.J. Agronomic and economic evaluation of permanent raised beds, no tillage and straw mulching for an irrigated maize-wheat system in northwest India. Exp. Agric. 2012, 48, 21–38. [Google Scholar] [CrossRef]

- Onasanya, O.O.; Hauser, S.; Necpalova, M.; Salako, F.K.; Kreye, C.; Tariku, M.; Six, J.; Pypers, P. On-farm assessment of cassava root yield response to tillage, plant density, weed control and fertilizer application in southwestern Nigeria. Field Crops Res. 2021, 262, 108038. [Google Scholar] [CrossRef]

- Hatfield, J. Ridge tillage for corn and soybean production: Environmental quality impacts. Soil Tillage Res. 1998, 48, 145–154. [Google Scholar] [CrossRef]

- Jurik, P. Weed population dynamics in ridge-tilled soybeans with and without herbicides. Leopold Cent. Prog. Rep. 1993, 89, 19. [Google Scholar]

- Klein, R.N.; Wicks, G.A.; Wilson, R.G. Ridge-Till, an Integrated Weed Management System. Weed Sci. 1996, 44, 417–422. [Google Scholar] [CrossRef]

- Buhler, D.D. Influence of Tillage Systems on Weed Population Dynamics and Management in Corn and Soybean in the Central USA. Crop Sci. 1995, 35, 1247–1258. [Google Scholar] [CrossRef]

- Forcella, F.; Lindstrom, M.J. Weed Seed Populations in Ridge and Conventional Tillage. Weed Sci. 1988, 36, 500–503. [Google Scholar] [CrossRef]

- European Commission. Communication from the commision to the european parlament, the council, the european economic and social committee and the committee of the regions EU. In Biodiversity Strategy for 2030 Bringing Nature back into Our Lives; European Commission: Maastricht, The Netherlands, 2020. [Google Scholar]

- Hu, X.; Liang, A.; Yao, Q.; Liu, Z.; Yu, Z.; Wang, G.; Liu, J. Ridge Tillage Improves Soil Properties, Sustains Diazotrophic Communities, and Enhances Extensively Cooperative Interactions Among Diazotrophs in a Clay Loam Soil. Front. Microbiol. 2020, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Wright, A.L.; Wang, J.; Li, Z. Long-term tillage effects on the distribution patterns of microbial biomass and activities within soil aggregates. Catena 2011, 87, 276–280. [Google Scholar] [CrossRef]

- Mloza-Banda, H.R.; Makwiza, C.N.; Mloza-Banda, M.L. Soil properties after conversion to conservation agriculture from ridge tillage in Southern Malawi. J. Arid. Environ. 2016, 127, 7–16. [Google Scholar] [CrossRef]

- Agbede, T.M. Effect of tillage on soil properties and yam yield on an Alfisol in southwestern Nigeria. Soil Tillage Res. 2006, 86, 1–8. [Google Scholar] [CrossRef]

- Adekiya, A.; Agbede, T.; Ojomo, A. Effects of Tillage Methods on Soil Properties, Nutrient Content, Growth and Yield ofTomato on an Alfisol of Southwestern Nigeria. Am.-Eurasian J. Sustain. Agric. 2009, 3, 348–353. [Google Scholar]

- Zhang, S.; Li, P.; Yang, X.; Wang, Z.; Chen, X. Effects of tillage and plastic mulch on soil water, growth and yield of spring-sown maize. Soil Tillage Res. 2011, 112, 92–97. [Google Scholar] [CrossRef]

- Li, B.; Chen, X.; Shi, X.; Liu, J.; Wei, Y.; Xiong, F. Effects of Ridge Tillage and Straw Mulching on Cultivation the Fresh Faba Beans. Agronomy 2021, 11, 1054. [Google Scholar] [CrossRef]

- Forcella, F.; Lindstrom, M.J. Movement and Germination of Weed Seeds in Ridge-Till Crop Production Systems. Weed Sci. 1988, 36, 56–59. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, X.; Chen, X.; McLaughlin, N.B.; Zhang, S.; Wei, S.; Sun, B.; Liang, A. Long-term conservation tillage influences the soil microbial community and its contribution to soil CO2 emissions in a Mollisol in Northeast China. J. Soils Sediments 2016, 16, 1–12. [Google Scholar] [CrossRef]

- László, P.; Gyuricza, C. Effect of the ridge tillage system on some selected soil physical properties in a maize monoculture. Acta Agron. Hung. 2004, 52, 211–220. [Google Scholar] [CrossRef]

- He, J.; Li, H.; Kuhn, N.J.; Wang, Q.; Zhang, X. Effect of ridge tillage, no-tillage, and conventional tillage on soil temperature, water use, and crop performance in cold and semi-arid areas in Northeast China. Soil Res. 2010, 48, 737. [Google Scholar] [CrossRef]

- Li, N.; Zhou, C.; Sun, X.; Jing, J.; Tian, X.; Wang, L. Effects of ridge tillage and mulching on water availability, grain yield, and water use efficiency in rain-fed winter wheat under different rainfall and nitrogen conditions. Soil Tillage Res. 2018, 179, 86–95. [Google Scholar] [CrossRef]

- Tao, Z.Q.; Peng, S.U.I.; Chen, Y.Q.; Chao, L.I.; Nie, Z.J.; Yuan, S.F.; Jiangtao, S.H.I.; Gao, W.S. Subsoiling and Ridge Tillage Alleviate the High Temperature Stress in Spring Maize in the North China Plain. J. Integr. Agric. 2013, 12, 2179–2188. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H.; He, J.; Li, H.; Sarker, K.K. Effect of ridge culture and no-tillage on soil moisture and maize yield. Trans. Chin. Soc. Agric. Eng. 2012, 28, 146–150. [Google Scholar]

- Clay, D.E.; Schumacher, T.E.; Brix-Davis, K.A. Carbon and nitrogen mineralization in row and interrow areas of chisel and ridge tillage systems. Soil Tillage Res. 1995, 35, 167–174. [Google Scholar] [CrossRef]

- Müller, E.; Wildhagen, H.; Quintern, M.; Heß, J.; Wichern, F.; Joergensen, R.G. Spatial patterns of soil biological and physical properties in a ridge tilled and a ploughed Luvisol. Soil Tillage Res. 2009, 105, 88–95. [Google Scholar] [CrossRef]

- Yuan-zhi, Y. Effects of ridge tillage on photosynthesis and root characters of rice. Chil. J. Agric. Res. 2015, 75, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Negassa, W.; Price, R.F.; Basir, A.; Snapp, S.S.; Kravchenko, A. Cover crop and tillage systems effect on soil CO2 and N2O fluxes in contrasting topographic positions. Soil Tillage Res. 2015, 154, 64–74. [Google Scholar] [CrossRef] [Green Version]

- Gürsoy, S.; Sessiz, A.; Kiliç, H.; Bayram, N. Tillage system and cotton residue management effects on soil physical and chemical properties of an Anatolian clay loam sown within a wheat-cotton sequence. Arch. Agron. Soil Sci. 2011, 57, 391–400. [Google Scholar] [CrossRef]

- Kovar, J.L.; Barber, S.A.; Kladivko, E.J.; Griffith, D.R. Characterization of soil temperature, water content, and maize root distribution in two tillage systems. Soil Tillage Res. 1992, 24, 11–27. [Google Scholar] [CrossRef]

- Thomas, A.L.; Kaspar, T.C. Maize Nodal Root Response to Soil Ridging and Three Tillage Systems. Agron. J. 1995, 87, 853–858. [Google Scholar] [CrossRef]

- Mert, M.; Aslan, E.; Akişcan, Y.; Çalişkan, M.E. Response of cotton (Gossypium hirsutum L.) to different tillage ystems and intra-row spacing. Soil Tillage Res. 2006, 85, 221–228. [Google Scholar] [CrossRef]

- Kropff, M.J.; Spitters, C.J.T. A simple model of crop loss by weed competition from early observations on relative leaf area of the weeds. Weed Res. 1991, 31, 97–105. [Google Scholar] [CrossRef]

- Burrows, W.C.; Larson, W.E. Effect of Amount of Mulch on Soil Temperature and Early Growth of Corn 1. Agron. J. 1962, 54, 19–23. [Google Scholar] [CrossRef]

- Benjamin, J.G.; Blaylock, A.D.; Brown, H.J.; Cruse, R.M. Ridge tillage effects on simulated water and heat transport. Soil Tillage Res. 1990, 18, 167–180. [Google Scholar] [CrossRef]

- Vanasse, A.; Leroux, G.D. Floristic diversity, size, and vertical distribution of the weed seedbank in ridge and conventional tillage systems. Weed Sci. 2000, 48, 454–460. [Google Scholar] [CrossRef]

- Clements, D.R.; Benoit, D.L.; Murphy, S.D.; Swanton, C.J. Tillage Effects on Weed Seed Return and Seedbank Composition. Weed Sci. 1996, 44, 314–322. [Google Scholar] [CrossRef]

- Rasmussen, J.; Bibby, B.M.; Schou, A.P. Investigating the selectivity of weed harrowing with new methods. Weed Res. 2008, 48, 523–532. [Google Scholar] [CrossRef] [Green Version]

- Beck, D.L.; Clay, D.E.; Reitsma, K.D. Best Management Practices for Corn Production in South Dakota: Tillage, Crop Rotations, and Cover Crops; South Dakota State University, College of Agriculture and Biological Sciences, AgBio Communications Unit, Box 2218A: Brookings, South Dakota, 2009. [Google Scholar]

- Gerhards, R. Weed suppression ability and yield impact of living mulch in cereal crops. Agriculture 2018, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Gerhards, R.; Kollenda, B.; Machleb, J.; Möller, K.; Butz, A.; Reiser, D.; Griegentrog, H.-W. Camera-guided Weed Hoeing in Winter Cereals with Narrow Row Distance. Gesunde Pflanz. 2020, 72, 403–411. [Google Scholar] [CrossRef]

- Gerhards, R.; Weber, J.F.; Kunz, C. Evaluation of weed control efficacy and yield response of inter-row and intra-row hoeing technologies in maize, sugar beet and soybean. Landtechnik 2020, 75, 247–260. [Google Scholar] [CrossRef]

- Home, M.C.W.; Tillett, N.D.; Hague, T.; Godwin, R.J. (Eds.) An Experimental Study of Lateral Positional Accuracy Achieved during Inter-Row Cultivation. In Proceedings of the 5th EWRS Workshop on Physical and Cultural Weed Control, Scuola Superiore Sant’Anna di Studi Universitari e di Perfezionamento, Pisa, Italy, 11–13 March 2002. [Google Scholar]

- Kurstjens, D.A.G.; Kropff, M.J. The impact of uprooting and soil-covering on the effectiveness of weed harrowing. Weed Res. 2001, 41, 211–228. [Google Scholar] [CrossRef]

- Alagbo, O.; Gerhards, R. Development and testing of a new mechanical weeding hoe for re-compacted ridge tillage culture in maize. In Proceedings of the 19th Symposium of the European Weed Research Society (EWRS), Athens, Greece, 20–23 June 2022. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).