Development of an Integrated IoT-Based Greenhouse Control Three-Device Robotic System

Abstract

:1. Introduction

2. Related Work

3. System Description

- i.

- A solar-powered cablebot equipped with a spectroscopic camera and an array of other sensors (Figure 1) that will collect data much like a drone in an open-air crop [8,9]. The device is hung from an overhead cable, hence the name cablebot or it can be attached to a slider overhanging from the greenhouse roof.

- ii.

- A flow control valve through which the system will autonomously control the greenhouse irrigation network.

- iii.

- A four-legged ground robot (agbot), a ground-based sensor carrier that can roam the greenhouse and collect data (Figure 2).

4. Operational Methodology

4.1. Cablebot

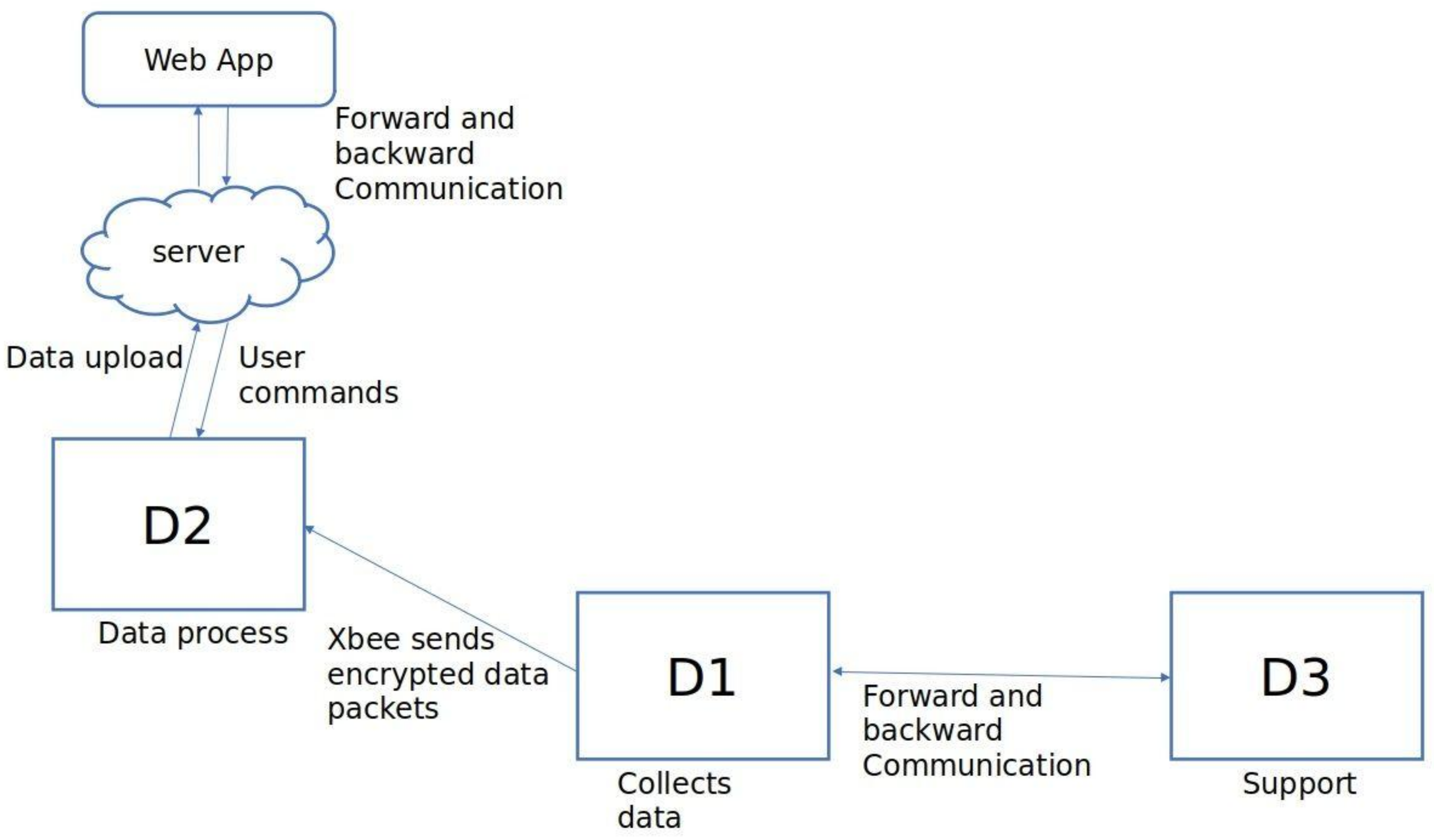

4.2. Coordinator

4.3. Sensors

4.4. Web Application

5. Data Collection and Transmission

- Meteorological station with embedded specialized instruments and sensors for monitoring and controlling greenhouse micro and macroclimate. Indicatively reported: Datalogger (CR1000X) with two relay analog multiplexer units

- Sensors, including a silicon type pyranometer (model SPLITE), a Thermopile-type pyranometer (model CMP3), a Photo-synthetically active radiometer (model PAR-LITE), a Pyrgeometer (model CGR3), a temperature and relative humidity probe (model MP101A), a Temperature and relative humidity probe (model S3CO3), a rain gauge (model 52203), an anemometer (model A100K) with threshold sensitivity 0.15 m s

- Analyzer Datalogger Software

- Photovoltaic panel and accumulators of electricity

- Temperature sensor (Ta_glass in C)

- Relative humidity sensor (RH_glass in %)

- Radiation sensor (Sol_glass in Watt/m)

- PAR sensor (Par_glass mol)

- Multispectral camera [16]

6. Conclusions

7. Future Work

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Dwivedi, A.; Naresh, R.K.; Kumar, R.; Yadar, R.S.; Kumar, R. PRECISION AGRICULTURE. 2017. [Google Scholar]

- Gonzalez, F.; McFadyen, A.; Puig, E. New Technologies in Precision Agriculture. Advances in Unmanned Aerial Systems and Payload Technologies for Precision Agriculture; Routledge: London, UK; Taylor & Francis Group: London, UK, 2019. [Google Scholar]

- Vasudevan, A.; Kumar, D.A.; Bhuvaneswari, N.S. Precision farming using unmanned aerial and ground vehicles. In Proceedings of the 2016 IEEE Technological Innovations in ICT for Agriculture and Rural Development (TIAR), Chennai, India, 15–16 July 2016; pp. 146–150. [Google Scholar]

- El-Naggar, A.G.; Hedley, C.B.; Horne, D.; Roudier, P.; Clothier, B.E. Soil Sensing Technology improves application of irrigation water. Agric. Water Manag. 2019, 228. [Google Scholar] [CrossRef]

- Smith, R.J.; Baillie, J.N.; McCarthy, A.C.; Raine, S.R.; Baillie, C.P. Review of Precision Irrigation Technologies and Their Application. National Centre for Engineering in Agriculture Publication; USQ: Toowoomba, Australia, 2010; p. 1003017/1. ISBN 1 921025 29 8. [Google Scholar]

- Jackson, R.D.; Idso, S.B.; Reginato, R.J.; Pinter, P.J., Jr. Canopy Temperature as a Crop Water Stress Indicator. Water Resour. Res. 1981, 17, 1133–1138. Available online: https://ui.adsabs.harvard.edu/link_gateway/1981WRR (accessed on 10 December 2020). [CrossRef]

- Akkaş, M.A.; Sokullu, R. An IoT-based greenhouse monitoring system with Micaz motes. Procedia Comput. Sci. 2017, 113, 603–608. [Google Scholar] [CrossRef]

- Bitas, D.; Papastavros, K.N.; Tsipianitis, D. A Smart Cablebot for Spectral Imaging and Micro-climate measurements inside Greenhouses. In Proceedings of the 11th International Conference on Information Intelligence, Systems and Applications, Piraeus, Bangkok, Thailand, 1–3 July 2020. [Google Scholar]

- Kavga, A.; Bitas, D.; Papastavros, K.N.; Prapopoulos, M.; Kotsiris, G. Development of an integrated IoT-based greenhouse control cablebot system. In Proceedings of the Information and Communication Technologies in Agriculture, Food and Environment (HAICTA 2020), Thessaloniki, Greece, 24–27 September 2020. [Google Scholar]

- Comba, L.; Gay, P.; Piccarolo, P.; RicaudaAimonino, D. Robotics and Automation for Crop Management: Trends and Perspective. In Proceedings of the International Conference Ragusa (SHWA), Ragusa Ibla Campus, Italy, 16–18 September 2010. [Google Scholar]

- Donovan, K. Anytime, anywhere: Mobile Devices and Services and Their Impact on Agriculture and Rural Development. In ICT, in Agriculture (Updated Edition). Connecting Smallholders to Knowledge, Networks and Institutions; 2017; pp. 49–70. [Google Scholar] [CrossRef]

- Rojo, F.; Kizer, E.; Upadhyaya, S.; Ozmen, S.; Ko-Madden, C.; Zhang, Q. A leaf monitoring system for continuous measurement of plant water status to assist in precision irrigation in grape and almond crops. Int. Federation Autom. Control 2016, 49, 209–215. [Google Scholar] [CrossRef]

- Dhillon, R.S.; Upadhyaya, S.K.; Rojo, F.; Roach, J.; Coates, R.W.; Delwiche, M.J. Development of a continuous leaf monitoring system to predict plant water status. Trans. ASABE 2017, 60, 1445–1455. [Google Scholar] [CrossRef]

- Yu, H.; Liu, D.; Chen, G.; Wan, B.; Wang, S.; Yang, B. InScience Direct. A neural network ensemble method for precision fertilization modeling. Math. Comput. Model. 2010, 51, 1375–1382. [Google Scholar] [CrossRef]

- Sollazzo, A.; Colliaux, D.; Garivani, S.; Minchin, J.; Garlanda, L.; Hanappe, P. Automated vegetable growth analysis from outdoor images acquired with a cablebot.

- Mahajan, U.; Bundel, B.R. Drones for Normalized Difference Vegetation Index (NDVI), to Estimate Crop Health for Precision Agriculture: A Cheaper Alternative for Spatial Satellite Sensors. In Proceedings of the International Conference on Innovative Research in Agriculture, Food Science, Forestry, Horticulture, Aquaculture, Animal Sciences, Biodiversity, Ecological Sciences and Climate Change (AFHABEC-2016), Siliguri, India, 17–18 March 2016. [Google Scholar]

- Adamides, G.; Kalatzis, N.; Stylianou, A.; Marianos, N.; Chatzipapadopoulos, F.; Giannakopoulou, M.; Papadavid, G.; Vassiliou, V.; Neocleous, D. Smart Farming Techniques for Climate Change Adaptation in Cyprus. Atmosphere 2020, 11, 557. [Google Scholar] [CrossRef]

| KYTION Aeir | Drone | Fixed Sensor | |

|---|---|---|---|

| Soil sensing | ✗ | ✗ | ✓ |

| Sunlight sensing | ✓ | ✗ | ✓ |

| Rain sensing | ✓ | ✗ | ✓ |

| Humidity sensing | ✓ | ✗ | ✓ |

| Temperature sensing | ✓ | ✗ | ✓ |

| RGB camera/sensor | ✓ | ✓ | ✗ |

| Spectral camera/sensor | ✓ | ✓ | ✗ |

| Measurement frequency | User defined | Needs operator | User defined |

| Spraying/Weeding | ✗ | ✓ | ✗ |

| Fertilizer application | Flow valve | ✓ | ✗ |

| Irrigation | Flow valve | ✗ | ✗ |

| Max area coverage | 4 hectares | large | small |

| Device | Functionalities |

|---|---|

| Device 1 (D1), Cablebot | (i) Development of functional 3D design software for D1 Cablebot printing |

| (ii) Design of its functional circuits with all the necessary hardware | |

| (iii) Software programming of all the individual components of the system (Xbee for communication, Raspberry and/or Arduino for control) | |

| (iv) Overall check of the proper operation of the device and its components | |

| Device 2 (D2), Flow valve | (i) Development of a functional 3D design software for the solenoid printing |

| (ii) Design of its functional circuit with all the necessary hardware | |

| (iii) Software programming the individual components of the system (Xbee for communication, Linux SBC for data checking received from the cablebot and uploading them to our server) | |

| (iv) Overall check of the proper operation of the device and its components | |

| Device 3 (D3), Quadruped Agbot | (i) Development of a functional 3D design software for the quadruped printing |

| (ii) Design of its functional circuits with all the necessary hardware | |

| (iii) Programming of all the individual components that make up the system and solving kinematics algorithms for its precise motion | |

| (iv) Overall check of the proper operation of the system and its communication protocols with D1 and D2 | |

| Support/Control App | (i) Development of a prototype user interface app that feeds the end-user with digested information and data from the coordinator. |

| (ii) Check and double-check for user-friendliness (easy to follow and understand) | |

| (iii) Improved graphical design | |

| (iv) Add-on functions such as manual override etc. |

| KYTION Aeir | KYTION Gaia | KYTION Flow | |

|---|---|---|---|

| (Cablebot) | (Agbot) | (Flow Control Valve) | |

| Soil sensing | n/a | ✓ | ✓ |

| Sunlight sensing | ✓ | ✓ | n/a |

| Rain sensing | ✓ | ✓ | n/a |

| Humidity sensing | ✓ | ✓ | n/a |

| Temperature sensing | ✓ | ✓ | n/a |

| RGB images | ✓ | ✓ | n/a |

| Spectral sensing/images | ✓ | ✗ | n/a |

| Measurement frequency | Every hour | User defined | n/a |

| Spraying | ✗ | to be determined | ✗ |

| Fertilizer application | ✗ | ✗ | ✓ |

| Irrigation | n/a | n/a | ✓ |

| Autonomy | Solar-powered | 1 hour | Solar-powered |

| Guidance | cable | GPS | n/a |

| Obstacle recognition | ✗ | ✓ | n/a |

| Ingress protection | IP67 | IP67 | IP67 |

| Battery | LiPo 2400 mAh | to be determined | |

| communication protocol | Xbee | Xbee | Xbee |

| Max area coverage | 4 hectares | 10 hectares | 10 hectares |

| Management Zones | n/a | n/a | 8 or 16 |

| Date/Time | Ta_Glass_S | RH_Glass_S | Ta_Glass_N | RH_Glass_N | Sol_Glass_S | Par_Glass_S | Sol_Glass_N | Par_Glass_N |

|---|---|---|---|---|---|---|---|---|

| 5 March 2020 | 34.08 | 49.3 | 32.30 | 51.27 | 284.94 | 530.54 | 230.99 | 446.76 |

| 6 March 2020 | 26 | 63.34 | 24.98 | 58.91 | 208.17 | 395.84 | 171.18 | 319.48 |

| 7 March 2020 | 28.15 | 70.69 | 26.45 | 68.26 | 207.27 | 391.22 | 173.17 | 326.04 |

| 8 March 2020 | 24.3 | 76.58 | 22.57 | 77.94 | 166.24 | 298.19 | 166.5 | 293.56 |

| 9 March 2020 | 20.89 | 69.65 | 20.38 | 68.54 | 129.25 | 238.71 | 131.87 | 228.97 |

| 10 March 2020 | 22.6 | 82.85 | 22.48 | 86.56 | 144.66 | 272.47 | 125.91 | 245.64 |

| 11 March 2020 | 19.21 | 92.51 | 19.02 | 93.59 | 91.92 | 153.44 | 96.3 | 154.79 |

| 12 March 2020 | 31.16 | 48.86 | 29.81 | 52.35 | 335.82 | 629.85 | 247.24 | 468.26 |

| 13 March 2020 | 28.38 | 47.87 | 28.07 | 49.39 | 276.83 | 511.42 | 219.84 | 401.37 |

| 14 March 2020 | 29.66 | 37.01 | 28.37 | 38.95 | 328 | 613.46 | 243.23 | 460.84 |

| 15 March 2020 | 28.18 | 41.14 | 27.47 | 40.38 | 277.35 | 520.93 | 215.79 | 391.58 |

| 16 March 2020 | 28.7 | 44.46 | 28.2 | 42.35 | 279.45 | 514.62 | 210.4 | 418.34 |

| 17 March 2020 | 30 | 39.16 | 28.9 | 39.68 | 345.32 | 635.6 | 278.56 | 529.15 |

| 18 March 2020 | 28.19 | 51.02 | 27.02 | 48.19 | 326.32 | 604.69 | 268.5 | 492.75 |

| 19 March 2020 | 28.78 | 57.32 | 26.84 | 55.91 | 299.2 | 566.95 | 252.03 | 475.54 |

| 20 March 2020 | 31.97 | 51.76 | 30.17 | 49.26 | 337.58 | 630.09 | 270.83 | 527.22 |

| 21 March 2020 | 29.19 | 58.88 | 27.84 | 55.32 | 288.39 | 541.08 | 252.26 | 489.47 |

| 22 March 2020 | 28.81 | 60.22 | 26.94 | 60.97 | 275.01 | 522.12 | 212.22 | 436.47 |

| 23 March 2020 | 32.63 | 50.36 | 31.32 | 47.56 | 358.99 | 665.77 | 276.46 | 540.23 |

| 24 March 2020 | 37.27 | 64.98 | 35.42 | 68.83 | 367.51 | 682.22 | 289.22 | 550.03 |

| 25 March 2020 | 30.18 | 54.77 | 29.12 | 52.5 | 363.36 | 686.81 | 283.95 | 549.46 |

| 26 March 2020 | 27.67 | 72.48 | 26.15 | 73.55 | 256.14 | 480.68 | 216.86 | 422.63 |

| 27 March 2020 | 27.63 | 52.84 | 28.05 | 52.2 | 325.96 | 621.44 | 266.63 | 519.54 |

| 28 March 2020 | 28.99 | 44.89 | 27.51 | 43.98 | 342.19 | 659.81 | 278.95 | 536.74 |

| 29 March 2020 | 25.9 | 43.3 | 24.94 | 40.42 | 323.83 | 634.71 | 274.22 | 536.77 |

| 30 March 2020 | 22.88 | 52.26 | 23.89 | 49.49 | 223.7 | 429.19 | 182.75 | 349.46 |

| 31 March 2020 | 32.09 | 33.30 | 31.83 | 31.6 | 353.34 | 668.74 | 265.65 | 531.74 |

| 1 April 2020 | 31.76 | 39.59 | 32.08 | 36.1 | 373.87 | 696.76 | 273.87 | 519.57 |

| 2 April 2020 | 27.59 | 56.45 | 27.85 | 51.86 | 310.05 | 576.84 | 249.91 | 485.72 |

| 3 April 2020 | 21.52 | 80.71 | 21.1 | 79.47 | 95.36 | 138.9 | 79.5 | 130.88 |

| 4 April 2020 | 30.44 | 49.79 | 29.74 | 48.53 | 387.86 | 743.83 | 274.85 | 548.14 |

| 5 April 2020 | 25.87 | 61.52 | 25.31 | 60.43 | 254.55 | 474.1 | 185.62 | 365.99 |

| 6 April 2020 | 27.45 | 59.39 | 27.16 | 59.7 | 277.65 | 511.92 | 205.4 | 409.82 |

| 7 April 2020 | 28.42 | 59.79 | 28.36 | 57.5 | 306.97 | 574.02 | 230.17 | 432.73 |

| 8 April 2020 | 29.53 | 46.62 | 29.23 | 44.84 | 403.57 | 757.42 | 281.44 | 541.9 |

| 9 April 2020 | 30.99 | 42.96 | 30.11 | 38.80 | 380.19 | 706.58 | 287.66 | 555.56 |

| 10 April 2020 | 29.56 | 46.96 | 28.72 | 41.59 | 319.07 | 596.21 | 260.68 | 493.43 |

| 11 April 2020 | 29.79 | 47.44 | 28.44 | 46.3 | 367.1 | 688.83 | 263.6 | 499.27 |

| 12 April 2020 | 31.53 | 51.66 | 30.06 | 49.91 | 395.53 | 734.23 | 275.42 | 539.44 |

| 13 April 2020 | 31.63 | 48.83 | 30.4 | 47.24 | 395.95 | 734.44 | 278.25 | 543.06 |

| 14 April 2020 | 31.74 | 51.6 | 29.99 | 50.43 | 396.89 | 749.66 | 280.10 | 548.55 |

| 15 April 2020 | 30.64 | 55.81 | 29.13 | 54.11 | 390.45 | 750.83 | 278.33 | 549.57 |

| 16 April 2020 | 26.29 | 56.91 | 24.53 | 57.42 | 348.78 | 675.2 | 274.42 | 513.91 |

| 17 April 2020 | 25.98 | 78.45 | 24.63 | 78.99 | 249.56 | 469.63 | 192.74 | 375.78 |

| 18 April 2020 | 28.28 | 59.6 | 26.4 | 60.55 | 380.6 | 725.82 | 293.97 | 594.08 |

| 19 April 2020 | 23.77 | 63.3 | 22.34 | 64.36 | 322.17 | 615.24 | 261.14 | 494.47 |

| 20 April 2020 | 23.45 | 48.66 | 22.45 | 48.31 | 329.52 | 629.69 | 276.42 | 528.42 |

| 21 April 2020 | 23.89 | 56.11 | 22.52 | 55.31 | 342.04 | 641.4 | 264.46 | 496.45 |

| 22 April 2020 | 21.75 | 65.32 | 20.33 | 65.37 | 258.96 | 460.58 | 203.52 | 358.35 |

| 23 April 2020 | 27.47 | 56.69 | 25.03 | 59.71 | 381.52 | 707.02 | 282.82 | 526.26 |

| 24 April 2020 | 25.45 | 52.13 | 23.26 | 52.91 | 408.54 | 791.58 | 299.65 | 567.63 |

| 25 April 2020 | 27.86 | 62.05 | 25.65 | 66.11 | 398.53 | 759.72 | 288.75 | 554.5 |

| 26 April 2020 | 28 | 48.78 | 24.81 | 48.59 | 403.87 | 761.03 | 296.06 | 556.87 |

| 27 April 2020 | 29.42 | 51.87 | 26.53 | 52.54 | 400.02 | 759.33 | 310.48 | 594.01 |

| 28 April 2020 | 28.66 | 47.14 | 26.15 | 49.32 | 388.17 | 733.43 | 300.15 | 563.17 |

| 29 April 2020 | 26.38 | 45.96 | 23.95 | 47.37 | 272.38 | 504.41 | 227.09 | 428.95 |

| 30 April 2020 | 28.34 | 61.2 | 26.12 | 66.21 | 340.09 | 650.87 | 269.33 | 510.95 |

| 1 May 2020 | 29.64 | 64.3 | 27.61 | 67.29 | 373.34 | 710.38 | 289.33 | 550.5 |

| 2 May 2020 | 29.92 | 64.48 | 27.68 | 69.35 | 366.97 | 698.91 | 282.51 | 534.17 |

| 3 May 2020 | 28.5 | 59.71 | 25.98 | 63.27 | 375.5 | 731.28 | 286.65 | 506.65 |

| 4 May 2020 | 28.43 | 57.11 | 25.82 | 59.18 | 355.33 | 680.46 | 269.17 | 520.95 |

| 5 May 2020 | 27.17 | 58.59 | 24.48 | 61.74 | 356.05 | 710.45 | 296.98 | 579.83 |

| 6 May 2020 | 28.28 | 56.19 | 25.81 | 60.49 | 330.97 | 659.75 | 281.51 | 551.08 |

| 7 May 2020 | 25.57 | 56.27 | 23.64 | 56.93 | 322.2 | 627.54 | 276.78 | 531.5 |

| 8 May 2020 | 27.07 | 57.35 | 24.63 | 59.09 | 363.79 | 707.84 | 324.07 | 616.34 |

| 9 May 2020 | 26.85 | 57.6 | 24.09 | 56.67 | 349.96 | 686.09 | 310.61 | 599.69 |

| 10 May 2020 | 27.09 | 57.55 | 27.17 | 51.12 | 373.83 | 736.34 | 322.79 | 619.63 |

| 11 May 2020 | 26.25 | 52.87 | 25.48 | 50.08 | 300.98 | 596.185 | 279.56 | 538.35 |

| 12 May 2020 | 27.68 | 41.89 | 26.45 | 40.49 | 261.85 | 508.76 | 234.48 | 436.69 |

| 13 May 2020 | 29.08 | 45.79 | 28.27 | 43.59 | 234.97 | 461.19 | 212.01 | 410.27 |

| 14 May 2020 | 28.81 | 49.86 | 28.45 | 48.36 | 276.09 | 536.35 | 265.42 | 492.15 |

| 15 May 2020 | 28.62 | 53.85 | 28.21 | 50.68 | 317.51 | 620.54 | 272.07 | 451.68 |

| 16 May 2020 | 21.29 | 89.2 | 21.07 | 82.14 | 99.4 | 189.56 | 84.42 | 112.38 |

| 17 May 2020 | 20.92 | 76.66 | 20.89 | 72.15 | 108.5 | 203.24 | 102.44 | 166.55 |

| DAY AVERAGE | 27.81 | 56.28 | 26.54 | 55.82 | 310.32 | 587.64 | 246.46 | 468.77 |

| Date/Time | Ta_Glass_S | RH_Glass_S | Ta_Glass_N | RH_Glass_N | Sol_Glass_S | Par_Glass_S | Sol_Glass_N | Par_Glass_N |

|---|---|---|---|---|---|---|---|---|

| 5 March 2020 | 16.95 | 75.26 | 15.51 | 83.51 | 0 | 0 | 0 | 0 |

| 6 March 2020 | 17.03 | 100 | 17.01 | 98.36 | 0 | 0 | 0 | 0 |

| 7 March 2020 | 17.13 | 97.33 | 17.06 | 94.78 | 0 | 0 | 0 | 0 |

| 8 March 2020 | 16.87 | 88.63 | 16.95 | 89.09 | 0 | 0 | 0 | 0 |

| 9 March 2020 | 16.44 | 91.75 | 16.73 | 89.95 | 0 | 0 | 0 | 0 |

| 10 March 2020 | 17.02 | 99.42 | 17.16 | 99.18 | 0 | 0 | 0 | 0 |

| 11 March 2020 | 17.08 | 96.63 | 17.25 | 97.3 | 0 | 0 | 0 | 0 |

| 12 March 2020 | 16.56 | 85.46 | 16.81 | 91.09 | 0 | 0 | 0 | 0 |

| 13 March 2020 | 16.95 | 87.11 | 17.08 | 92.03 | 0 | 0 | 0 | 0 |

| 14 March 2020 | 15.21 | 79.14 | 15.44 | 86.13 | 0 | 0 | 0 | 0 |

| 15 March 2020 | 16.02 | 76.48 | 16.16 | 81.19 | 0 | 0 | 0 | 0 |

| 16 March 2020 | 15.99 | 78.5 | 16.13 | 82.09 | 0 | 0 | 0 | 0 |

| 17 March 2020 | 15.89 | 84.44 | 15.97 | 93.01 | 0 | 0 | 0 | 0 |

| 18 March 2020 | 16.48 | 99.51 | 16.76 | 88.49 | 0 | 0 | 0 | 0 |

| 19 March 2020 | 17.07 | 99.95 | 17.19 | 93.27 | 0 | 0 | 0 | 0 |

| 20 March 2020 | 17.03 | 100 | 17.18 | 96.44 | 0 | 0 | 0 | 0 |

| 21 March 2020 | 17.12 | 100 | 17.05 | 99.89 | 0 | 0 | 0 | 0 |

| 22 March 2020 | 16.98 | 99.99 | 16.93 | 99.99 | 0 | 0 | 0 | 0 |

| 23 March 2020 | 17.03 | 100 | 17.19 | 99.54 | 0 | 0 | 0 | 0 |

| 24 March 2020 | 17.19 | 100 | 17.29 | 96.35 | 0 | 0 | 0 | 0 |

| 25 March 2020 | 17.28 | 100 | 17.36 | 100 | 0 | 0 | 0 | 0 |

| 26 March 2020 | 17.21 | 100 | 17.19 | 100 | 0 | 0 | 0 | 0 |

| 27 March 2020 | 16.92 | 100.2 | 17 | 100 | 0 | 0 | 0 | 0 |

| 28 March 2020 | 17.08 | 100 | 17.13 | 99.53 | 0 | 0 | 0 | 0 |

| 29 March 2020 | 16.76 | 99.97 | 16.82 | 94.75 | 0 | 0 | 0 | 0 |

| 30 March 2020 | 16.94 | 100 | 17.02 | 98.28 | 0 | 0 | 0 | 0 |

| 31 March 2020 | 16.98 | 99.08 | 17.08 | 88.49 | 0 | 0 | 0 | 0 |

| 1 April 2020 | 17.03 | 98.38 | 17.24 | 88.35 | 0 | 0 | 0 | 0 |

| 2 April 2020 | 17.12 | 99.45 | 17.26 | 87.77 | 0 | 0 | 0 | 0 |

| 3 April 2020 | 16.88 | 100 | 16.79 | 100 | 0 | 0 | 0 | 0 |

| 4 April 2020 | 16.99 | 100 | 17.18 | 95.94 | 0 | 0 | 0 | 0 |

| 5 April 2020 | 17.02 | 100 | 16.93 | 99.99 | 0 | 0 | 0 | 0 |

| 6 April 2020 | 16.83 | 100 | 17.07 | 99.66 | 0 | 0 | 0 | 0 |

| 7 April 2020 | 16.88 | 100 | 17.04 | 98.93 | 0 | 0 | 0 | 0 |

| 8 April 2020 | 16.90 | 100 | 17 | 95.83 | 0 | 0 | 0 | 0 |

| 9 April 2020 | 15.95 | 83.11 | 16.15 | 65.32 | 0 | 0 | 0 | 0 |

| 10 April 2020 | 16.87 | 89.77 | 16.96 | 69.26 | 0 | 0 | 0 | 0 |

| 11 April 2020 | 16.48 | 92.36 | 16.76 | 75.44 | 0 | 0 | 0 | 0 |

| 12 April 2020 | 16.88 | 96.65 | 16.98 | 80.84 | 0 | 0 | 0 | 0 |

| 13 April 2020 | 16.98 | 99.74 | 17.16 | 89 | 0 | 0 | 0 | 0 |

| 14 April 2020 | 17.01 | 99.12 | 17.13 | 84.42 | 0 | 0 | 0 | 0 |

| 15 April 2020 | 16.98 | 95.14 | 17.28 | 79.47 | 0 | 0 | 0 | 0 |

| 16 April 2020 | 16.92 | 99.94 | 17.03 | 90.42 | 0 | 0 | 0 | 0 |

| 17 April 2020 | 16.92 | 99.7 | 16.89 | 93.42 | 0 | 0 | 0 | 0 |

| 18 April 2020 | 17.03 | 100 | 17.19 | 97.72 | 0 | 0 | 0 | 0 |

| 19 April 2020 | 16.8 | 98.29 | 16.85 | 88.71 | 0 | 0 | 0 | 0 |

| 20 April 2020 | 16.84 | 99.59 | 16.76 | 96.58 | 0 | 0 | 0 | 0 |

| 21 April 2020 | 16.98 | 96.07 | 17.12 | 85.19 | 0 | 0 | 0 | 0 |

| 22 April 2020 | 15.02 | 83.83 | 15.35 | 66.61 | 0 | 0 | 0 | 0 |

| 23 April 2020 | 14.2 | 98.21 | 14.42 | 77.64 | 0 | 0 | 0 | 0 |

| 24 April 2020 | 15.31 | 92.02 | 15.47 | 76.26 | 0 | 0 | 0 | 0 |

| 25 April 2020 | 16.96 | 100 | 17.19 | 96.48 | 0 | 0 | 0 | 0 |

| 26 April 2020 | 14.98 | 99.88 | 15.38 | 81.05 | 0 | 0 | 0 | 0 |

| 27 April 2020 | 16.88 | 100 | 17.08 | 100 | 0 | 0 | 0 | 0 |

| 28 April 2020 | 15.81 | 96.11 | 15.8 | 77.79 | 0 | 0 | 0 | 0 |

| 29 April 2020 | 16.02 | 72.88 | 16.2 | 68.22 | 0 | 0 | 0 | 0 |

| 30 April 2020 | 18.32 | 72.02 | 18.32 | 67.28 | 0 | 0 | 0 | 0 |

| 1 May 2020 | 17.46 | 100 | 17.66 | 96.65 | 0 | 0 | 0 | 0 |

| 2 May 2020 | 17.41 | 99.98 | 17.52 | 98.22 | 0 | 0 | 0 | 0 |

| 3 May 2020 | 17.42 | 99.78 | 17.66 | 93.63 | 0 | 0 | 0 | 0 |

| 4 May 2020 | 17.12 | 97.77 | 17.25 | 82.66 | 0 | 0 | 0 | 0 |

| 5 May 2020 | 17.08 | 99.08 | 17.44 | 91.03 | 0 | 0 | 0 | 0 |

| 6 May 2020 | 17.11 | 99.25 | 17.39 | 88.58 | 0 | 0 | 0 | 0 |

| 7 May 2020 | 17.47 | 75 | 17.72 | 69.01 | 0 | 0 | 0 | 0 |

| 8 May 2020 | 17.11 | 98.23 | 17.08 | 94.88 | 0 | 0 | 0 | 0 |

| 9 May 2020 | 16.90 | 97.24 | 17.01 | 83.4 | 0 | 0 | 0 | 0 |

| 10 May 2020 | 16.83 | 97.22 | 16.72 | 81.08 | 0 | 0 | 0 | 0 |

| 11 May 2020 | 17.14 | 92.09 | 17.21 | 75.56 | 0 | 0 | 0 | 0 |

| 12 May 2020 | 17.92 | 77.59 | 18.17 | 70.59 | 0 | 0 | 0 | 0 |

| 13 May 2020 | 24.06 | 35.54 | 24.32 | 30.56 | 0 | 0 | 0 | 0 |

| 14 May 2020 | 18.18 | 98.27 | 18.63 | 91.24 | 0 | 0 | 0 | 0 |

| 15 May 2020 | 17.94 | 81.58 | 18.08 | 73.63 | 0 | 0 | 0 | 0 |

| 16 May 2020 | 17.92 | 99.78 | 18.17 | 95.15 | 0 | 0 | 0 | 0 |

| 17 May 2020 | 17.06 | 100 | 17.12 | 99.95 | 0 | 0 | 0 | 0 |

| NIGHT AVERAGE | 16.93 | 93.91 | 17.05 | 88.14 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomopoulos, V.; Bitas, D.; Papastavros, K.-N.; Tsipianitis, D.; Kavga, A. Development of an Integrated IoT-Based Greenhouse Control Three-Device Robotic System. Agronomy 2021, 11, 405. https://doi.org/10.3390/agronomy11020405

Thomopoulos V, Bitas D, Papastavros K-N, Tsipianitis D, Kavga A. Development of an Integrated IoT-Based Greenhouse Control Three-Device Robotic System. Agronomy. 2021; 11(2):405. https://doi.org/10.3390/agronomy11020405

Chicago/Turabian StyleThomopoulos, Vasileios, Dionysios Bitas, Kyriakos-Nikos Papastavros, Dimitris Tsipianitis, and Angeliki Kavga. 2021. "Development of an Integrated IoT-Based Greenhouse Control Three-Device Robotic System" Agronomy 11, no. 2: 405. https://doi.org/10.3390/agronomy11020405

APA StyleThomopoulos, V., Bitas, D., Papastavros, K.-N., Tsipianitis, D., & Kavga, A. (2021). Development of an Integrated IoT-Based Greenhouse Control Three-Device Robotic System. Agronomy, 11(2), 405. https://doi.org/10.3390/agronomy11020405