Designing of an Enterprise Resource Planning for the Optimal Management of Agricultural Plots Regarding Quality and Environmental Requirements

Abstract

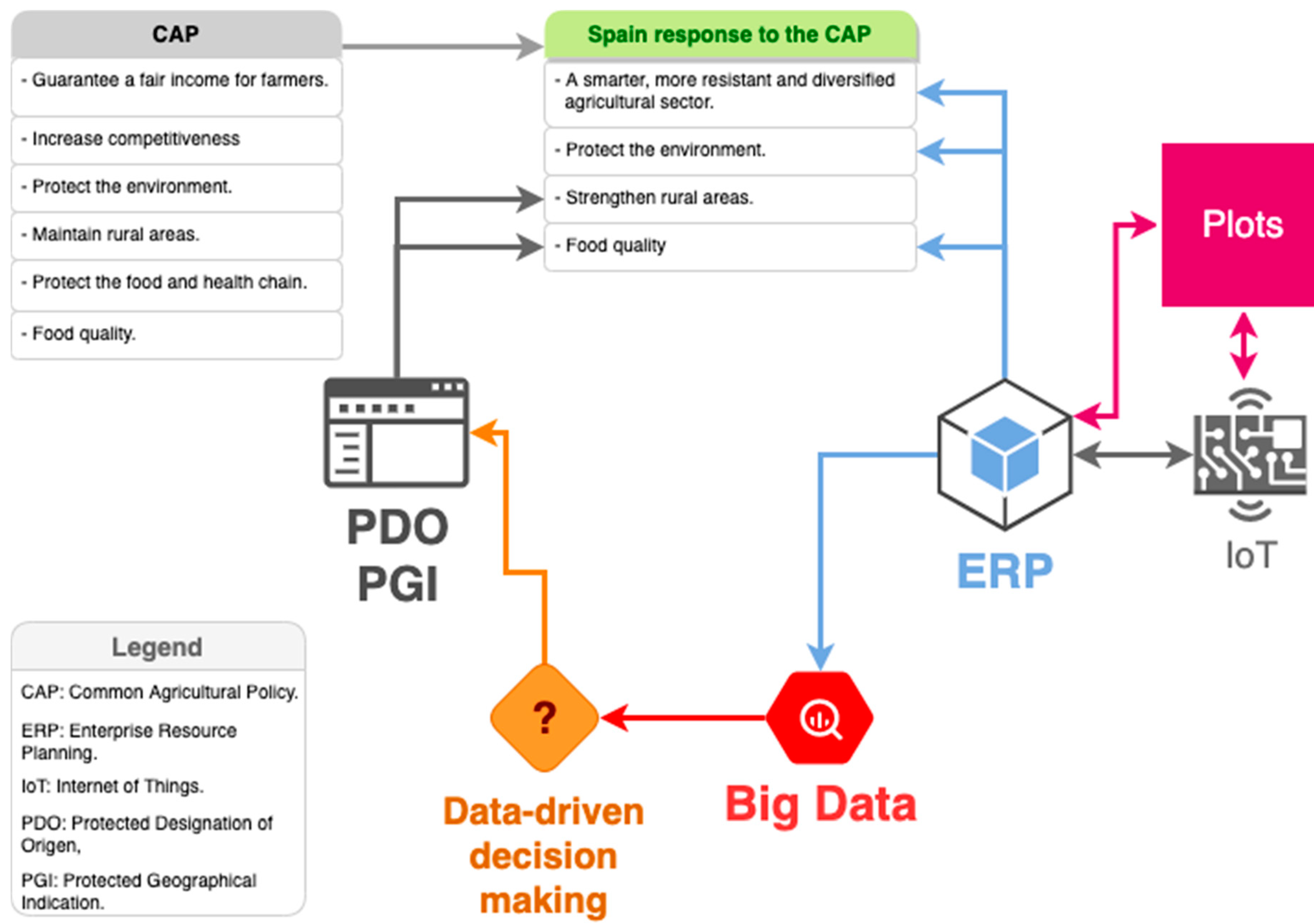

1. Introduction

- The storage infrastructure. This can reveal the limitations of the company’s technical capabilities and requires major changes at different levels of the organization [12].

- The technology to integrate the information into the system. At this point, development of an Application Programming Interface (API) is essential, allowing Internet of Things (IoT) components to communicate and exchange information with the database in a safe way [13].

- The diversity of the formats according to the source. Data collection from such different sources and their translation into useful and structured information are two of the big challenges that Big Data faces [14].

- The calibration system, source verification and data security.

- The speed of data processing. Traditional Relational Database Management Systems (RDBMS) have been the systems mainly used since 1970 [15]. They show great efficiency and integrity in data management; but they are not designed to be systems distributed or balanced depending on the load. This is where NoSQL or non-relational systems can show their full potential, offering functionalities in data analysis that are impossible for traditional RDBMS systems [16]. In this sense, one of the main solutions that companies are adopting is the use of a hybrid data storage system, where the best properties of each of the systems are exploited [17].

- Geographic Information System (GIS) which provides information separated into layers. This technological system has been used for decades for territorial and environmental management [19].

- Satellite images. For instance, Normalized Difference Vegetation Index (NDVI) images permit differentiating distinct states of vegetative growth.

- Weather stations at the plot level as climatic variability is an important aspect of uncertainty in agriculture.

- IoT. Allows the development of sensors and automation to obtain plot information in real time.

- External information sources. Access to databases, public or private, that can provide information (climatic, geographic, statistical, economic, etc.).

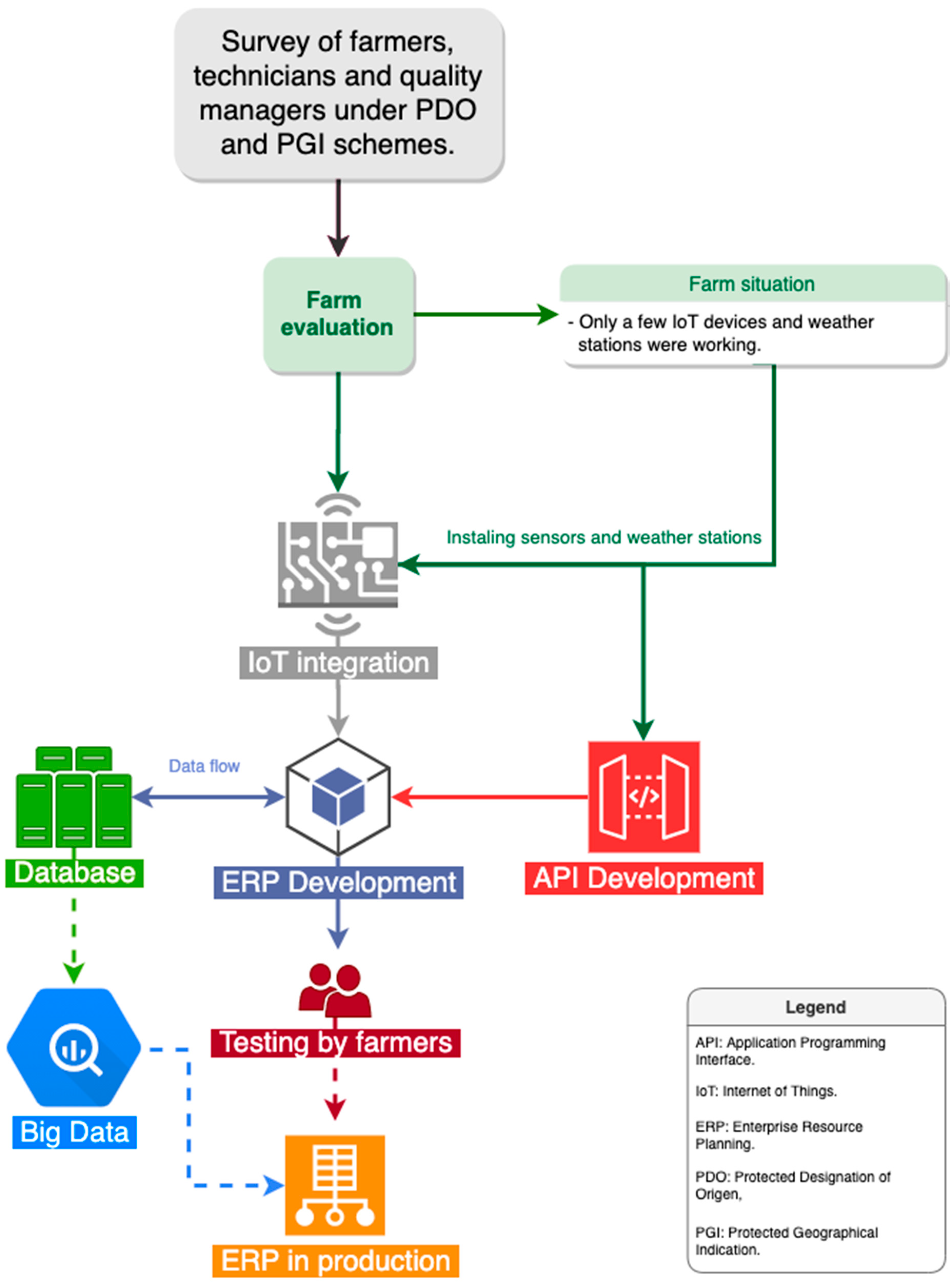

2. Materials and Methods

2.1. Survey of Farmers, Technicians, and Quality Managers under PDO and PGI Schemes

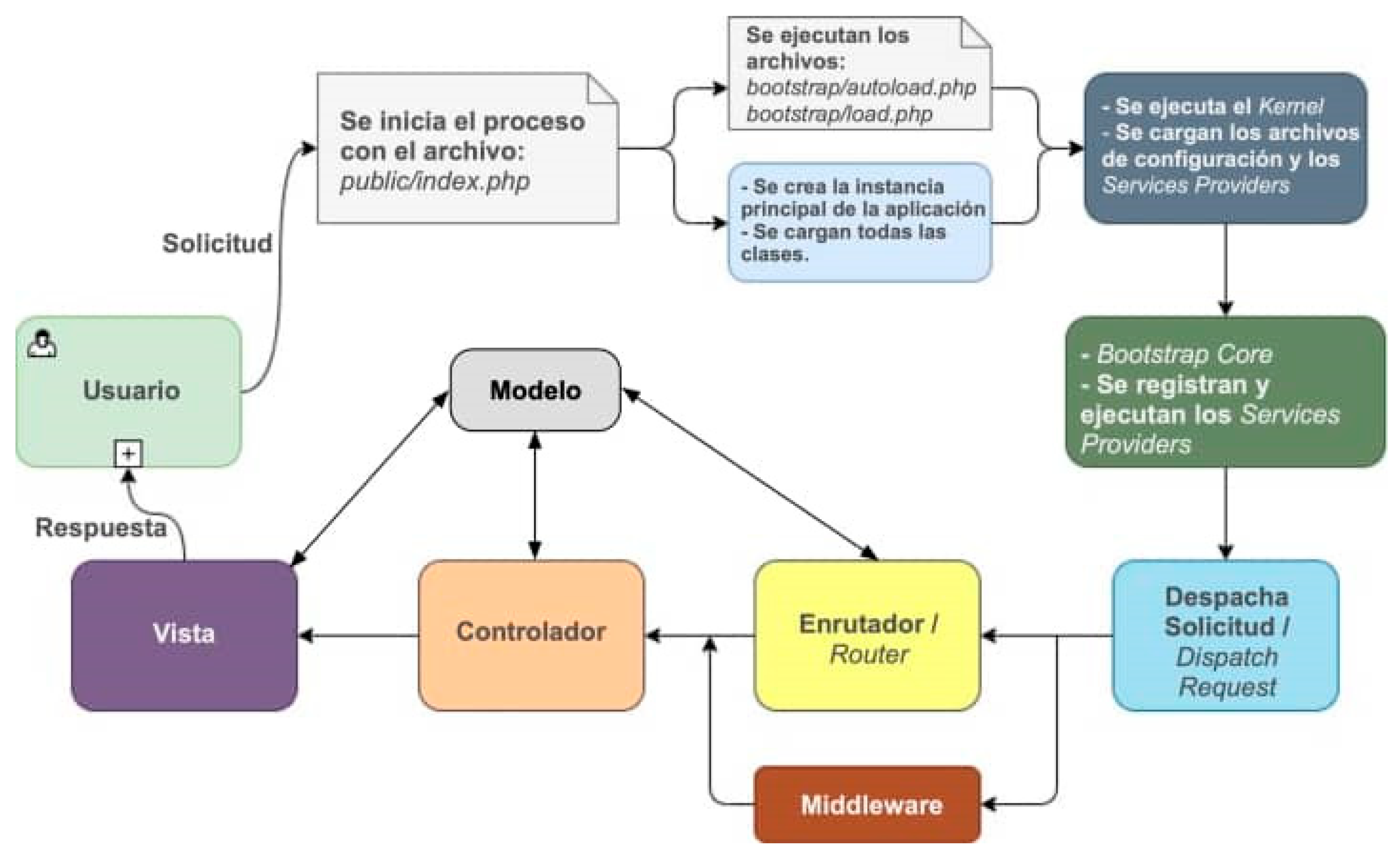

2.2. Design of an ERP Platform for an Agricultural Holding

2.2.1. System Architecture Design

- anhskohbo/no-captcha: wrapper for Google no-captcha, version 3.0 [31].

- askedio/laravel-soft-cascade: used to manage the deletion of entries in the database from related tables, version 5.6 [32].

- barryvdh/laravel-dompdf: used to generate reports in pdf format, version 0.8.2 [33].

- genealabs/laravel-model-caching: for automatic model caching, version 0.2.62 [34].

- intervention/image: powerful tool for image management, version 2.4 [35].

- grimzy/laravel-mysql-spatial: used to store geolocated data in the database, version 1.0 [36].

- maatwebsite/excel: used to import data from excel files, version 2.1.0 [37].

- spatie/laravel-cookie-consent: a configurable way to display the cookie consent, version 2.2 [38].

- spatie/laravel-html: for advanced HTML management, version 2.19 [39].

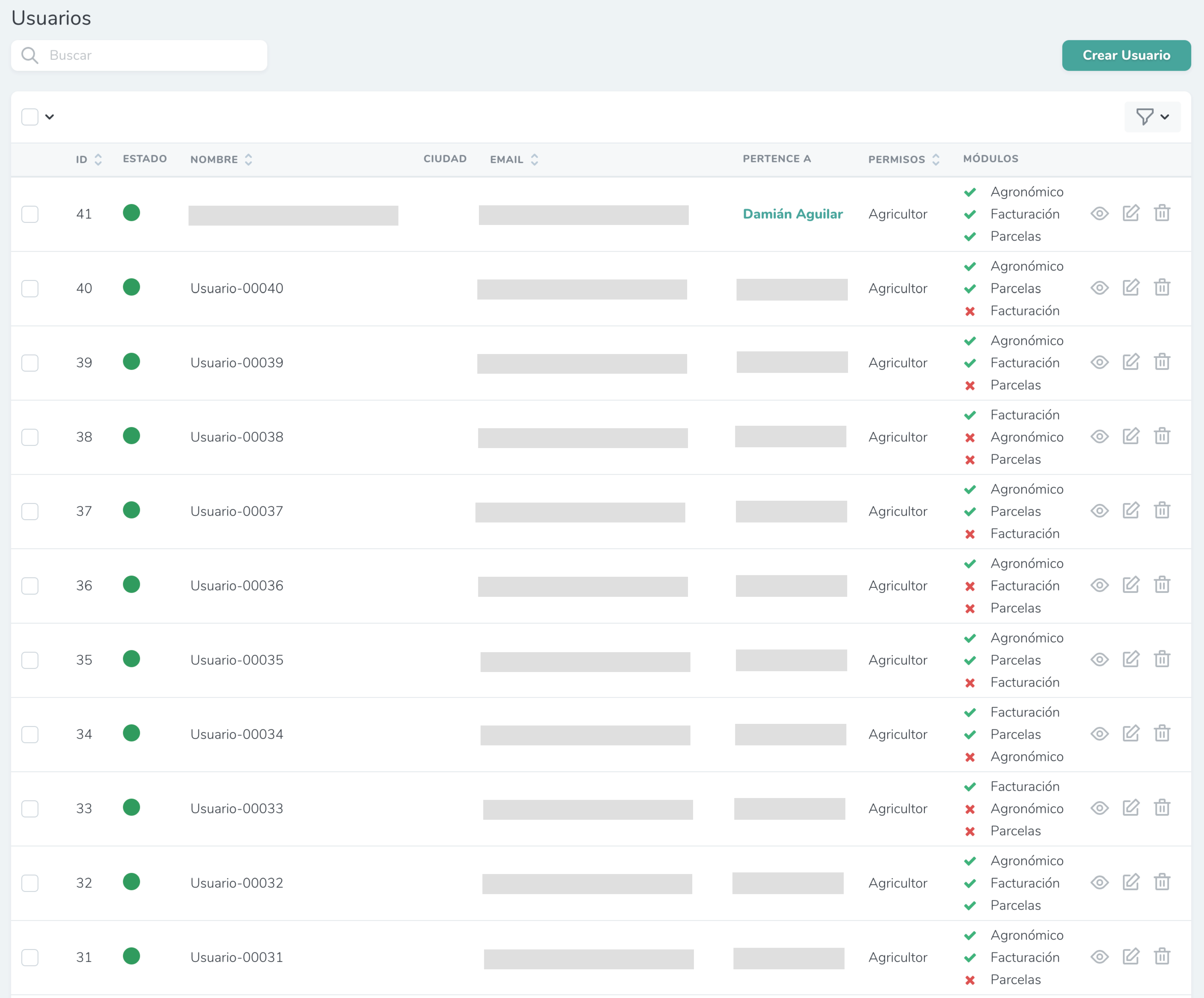

- spatie/laravel-permission: for roles and permissions, version 2.1 [40].

- The Https middleware, which forces the use of secure routes under a secure server.

- The Locale middleware, which investigates user preferences for his default language and determines this language as preselected.

- The IsAdmin middleware, to identify the system administrator.

2.2.2. Databases and Eloquent ORM

2.2.3. API Connection

2.2.4. Cloud Computing with PaaS

2.3. Statistical Analysis

3. Results and Discussion

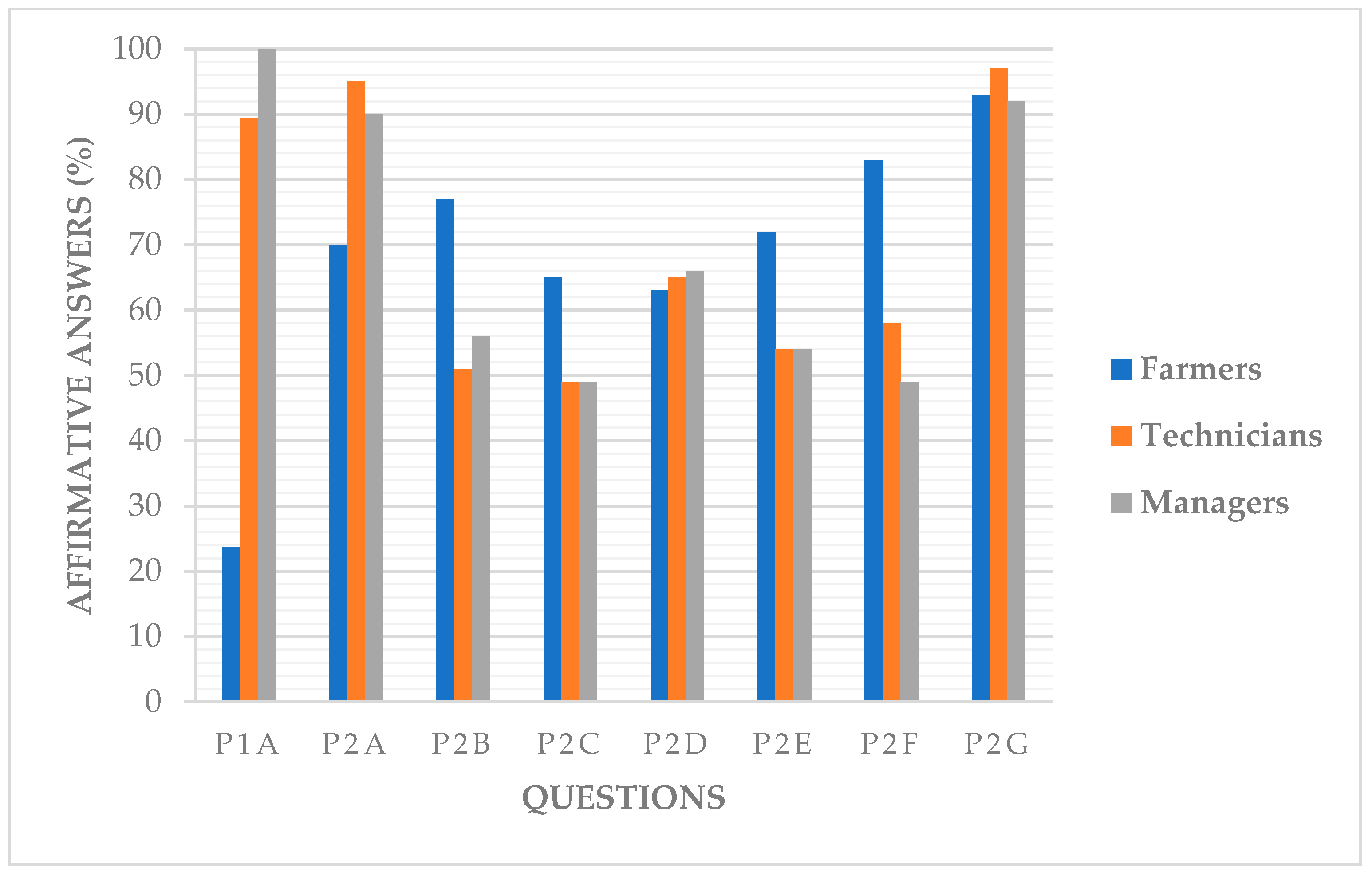

3.1. Survey Outcomes

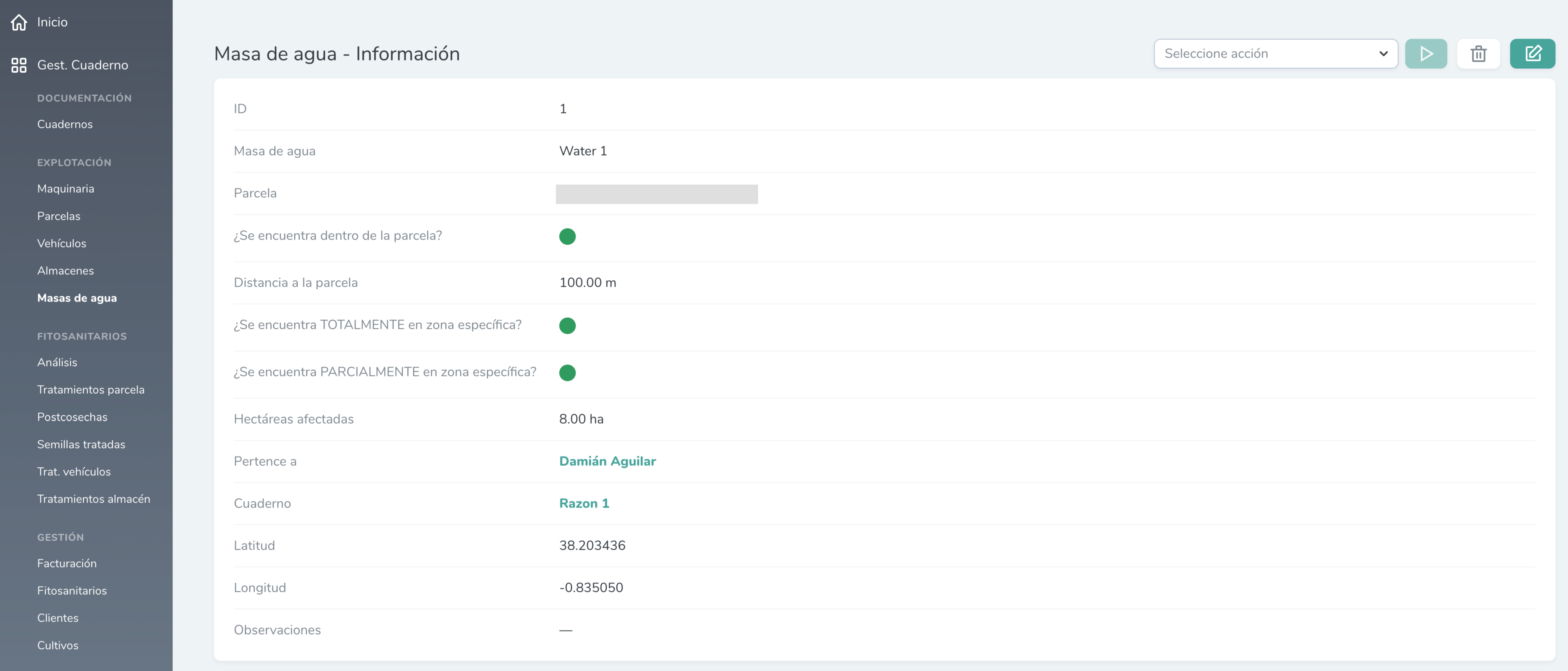

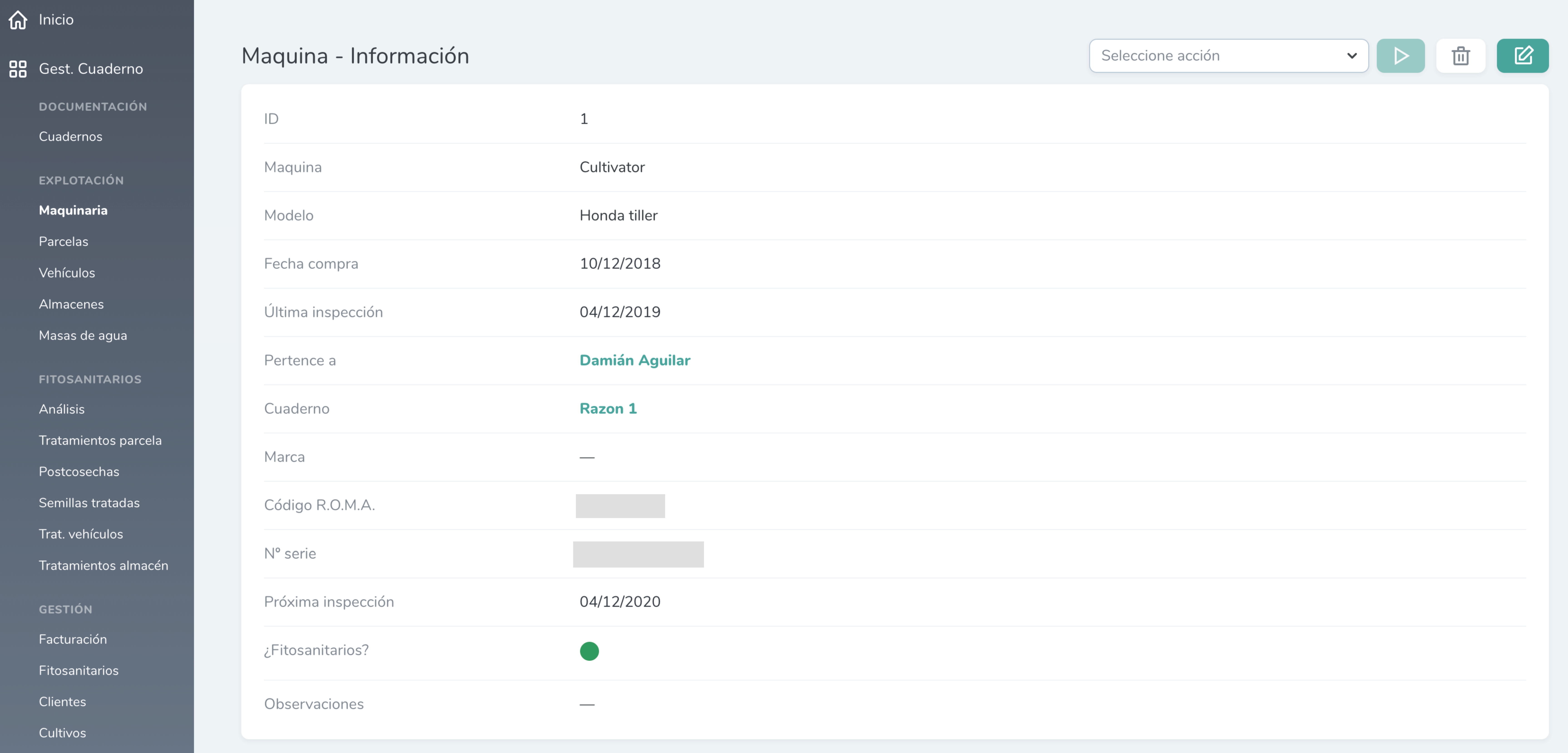

3.2. Functioning of the ERP Platform for an Agricultural Holding

3.2.1. Agronomic Management of the Plots

3.2.2. Irrigation Records

3.2.3. Reports of Climatic Data

3.2.4. Management System

3.2.5. Other Components

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Van Ittersum, K.; Candel, M.J.J.M.; Meulenberg, M.T.G. The influence of the image of a product’s region of origin on product evaluation. J. Bus. Res. 2003, 56, 215–226. [Google Scholar] [CrossRef]

- Ruiz, M.P.M.; Zarco, A.I.J. La potenciación del origen en las estrategias de marketing de productos agroalimentarios. Boletín Económico ICE 2006, 2880, 18. [Google Scholar]

- Felzensztein, C.; Hibbert, S.; Vong, G. Is the Country of Origin the Fifth Element in the Marketing Mix of Imported Wine? J. Food Prod. Mark. 2004, 10, 73–84. [Google Scholar] [CrossRef]

- Kur, A.; Cock, S. Nothing but a GI Thing: Geographical Indications under EU Law. Intellect. Prop. Media Entertain. Law J. 2007, 17, 19. [Google Scholar]

- Simon, Z. UE: Campaña en Tokaj para Acabar con las Imitaciones. Available online: http://elmundovino.elmundo.es/elmundovino/noticia.html?vi_seccion=7&vs_fecha=200406&vs_noticia=1086850889 (accessed on 4 September 2020).

- Skuras, D.; Vakrou, A. Consumers’ willingness to pay for origin labelled wine: A greek case study. Brit. Food J. 2002, 104, 898–912. [Google Scholar] [CrossRef]

- Jones, G.V.; Snead, N.; Nelson, P. Geology and Wine 8. Modeling Viticultural Landscapes: A GIS Analysis of the Terroir Potential in the Umpqua Valley of Oregon. Geosci. Can. 2004, 31, 4. [Google Scholar]

- Caesarius, L.M.; Hohenthal, J. Searching for big data: How incumbents explore a possible adoption of big data technologies. Scand. J. Manag. 2018, 34, 129–140. [Google Scholar] [CrossRef]

- Sakr, S.; Gaber, M.M. Large Scale and Big Data—Processing and Management; Auerbach Publications: Boca Raton, FL, USA, 2014. [Google Scholar]

- Cukier, K.; Mayer-Schönberger, V. Big Data: La Revolución de los Datos Masivos, 1st ed.; Turner Publicaciones S.L.: Madrid, Spain, 2013; ISBN 978-84-15427-81-0. [Google Scholar]

- Aguilar, L.J. Big Data, Análisis de Grandes Volúmenes de Datos en Organizaciones; Alfaomega Grupo Editor: Mexico City, Mexico, 2016; ISBN 978-607-707-757-2. [Google Scholar]

- Bhat, W.A. Bridging data-capacity gap in big data storage. Future Gener. Comput. Syst. 2018, 87, 538–548. [Google Scholar] [CrossRef]

- De, B. API Management: An Architect’s Guide to Developing and Managing APIs for Your Organization; Apress: New York, NY, USA, 2017; ISBN 978-1-4842-1305-6. [Google Scholar]

- Nguyen, V.-Q.; Nguyen, S.N.; Kim, K. Design of a Platform for Collecting and Analyzing Agricultural Big Data. J. Digit. Contents Soc. 2017, 18, 149–158. [Google Scholar] [CrossRef]

- Corbellini, A.; Mateos, C.; Zunino, A.; Godoy, D.; Schiaffino, S. Persisting big-data: The NoSQL landscape. Inf. Syst. 2017, 63, 1–23. [Google Scholar] [CrossRef]

- Bicevska, Z.; Oditis, I. Towards NoSQL-based Data Warehouse Solutions. Procedia Comput. Sci. 2017, 104, 104–111. [Google Scholar] [CrossRef]

- Liao, Y.-T.; Zhou, J.; Lu, C.-H.; Chen, S.-C.; Hsu, C.-H.; Chen, W.; Jiang, M.-F.; Chung, Y.-C. Data adapter for querying and transformation between SQL and NoSQL database. Future Gener. Comput. Syst. 2016, 65, 111–121. [Google Scholar] [CrossRef]

- Bongiovani, R.; Chartuni, E.; Best, S.; Roel, Á. Agricultura de Precisión: Integrando Conocimientos para una Agricultura Moderna y Sustentable; Procisur/IICA: San José, Costa Rica, 2006; ISBN 978-92-9039-741-0. [Google Scholar]

- Pucha-Cofrep, F.; Fries, A.; Cánovas-García, F.; Oñate-Valdivieso, F.; González-Jaramillo, V.; Pucha-Cofrep, D. Fundamentos de SIG: Aplicaciones con ArcGIS; Ediloja Cia. Ltda.: Loja, Ecuador, 2017; ISBN 978-9942-28-901-8. [Google Scholar]

- Carbonell, I.M. The ethics of big data in big agriculture. Internet Policy Rev. 2016, 5. [Google Scholar] [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6. [Google Scholar] [CrossRef]

- Weltzien, C. Digital agriculture—Or why agriculture 4.0 still offers only modest returns. Agric. Eng. 2016, 71, 66–68. [Google Scholar]

- Braun, A.-T.; Colangelo, E.; Steckel, T. Farming in the Era of Industrie 4.0. Procedia Cirp 2018, 72, 979–984. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Latorre, M. Historia de las Web, 1.0, 2.0, 3.0 y 4.0. Available online: http://umch.edu.pe/arch/hnomarino/74_Historia%20de%20la%20Web.pdf (accessed on 7 August 2020).

- Surjit, R.; Rathinamoorthy, R.; Vardhini, K.J.V. ERP for Textiles and Apparel Industry; CRC Press: Boca Ratón, FL, USA, 2016; ISBN 978-93-85059-59-9. [Google Scholar]

- Elragal, A.; Haddara, M. The Future of ERP Systems: Look backward before moving forward. Procedia Technol. 2012, 5, 21–30. [Google Scholar] [CrossRef]

- Stauffer, M. Laravel: Up and Running: A Framework for Building Modern PHP Apps; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2016. [Google Scholar]

- Hasan, S.S.; Isaac, R.K. An integrated approach of MAS-CommonKADS, Model–View–Controller and web application optimization strategies for web-based expert system development. Expert Syst. Appl. 2011, 38, 417–428. [Google Scholar] [CrossRef]

- Chen, X.; Ji, Z.; Fan, Y.; Zhan, Y. Restful API Architecture Based on Laravel Framework. J. Phys. Conf. Ser. 2017, 910, 012016. [Google Scholar] [CrossRef]

- Anh, N.V. Anhskohbo/no-captcha. Available online: https://github.com/anhskohbo/no-captcha (accessed on 10 August 2020).

- Askedio/laravel-soft-cascade: Cascade Delete & Restore When Using Laravel SoftDeletes. Available online: https://github.com/Askedio/laravel-soft-cascade (accessed on 10 August 2020).

- Heuvel, B. vd barryvdh/laravel-dompdf: A DOMPDF Wrapper for Laravel. Available online: https://github.com/barryvdh/laravel-dompdf (accessed on 10 August 2020).

- Bronner, M. GeneaLabs/laravel-model-caching: Eloquent Model-Caching Made Easy. Available online: https://github.com/GeneaLabs/laravel-model-caching (accessed on 10 August 2020).

- Intervention Image—Introduction. Available online: http://image.intervention.io/ (accessed on 10 August 2020).

- Estefane, J. Grimzy/laravel-mysql-spatial: MySQL Spatial Data Extension Integration with Laravel. Available online: https://github.com/grimzy/laravel-mysql-spatial (accessed on 10 August 2020).

- Brouwers, P. Maatwebsite/Laravel-Excel: Supercharged Excel Exports and Imports in Laravel. Available online: https://github.com/Maatwebsite/Laravel-Excel (accessed on 10 August 2020).

- Spatie/laravel-cookie-consent: Make Your Laravel App Comply with the Crazy EU Cookie Law. Available online: https://github.com/spatie/laravel-cookie-consent (accessed on 10 August 2020).

- Spatie/laravel-html: Painless Html Generation. Available online: https://github.com/spatie/laravel-html (accessed on 10 August 2020).

- Spatie/laravel-permission: Associate Users with Roles and Permissions. Available online: https://github.com/spatie/laravel-permission (accessed on 10 August 2020).

- Laravel Nova. Available online: https://nova.laravel.com/ (accessed on 11 August 2020).

- Forta, B. MariaDB Crash Course; Addison-Wesley Professional: Boston, MA, USA, 2011; ISBN 978-0-13-284235-8. [Google Scholar]

- Chodorow, K. MongoDB: The Definitive Guide: Powerful and Scalable Data Storage; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2013; ISBN 978-1-4493-4482-5. [Google Scholar]

- Sarig, M. MongoDB vs. MySQL: The Differences Explained. Available online: https://blog.panoply.io/mongodb-and-mysql (accessed on 10 August 2020).

- Object-Relational Mapping. Available online: https://en.wikipedia.org/w/index.php?title=Object-relational_mapping&oldid=952535425 (accessed on 10 August 2020).

- Bean, M. Laravel 5 Essentials; Packt Publishing Ltd.: Birmingham, UK, 2015; ISBN 978-1-78528-329-1. [Google Scholar]

- Xu, C.; Sun, X.; Li, B.; Lu, X.; Guo, H. MULAPI: Improving API method recommendation with API usage location. J. Syst. Softw. 2018, 142, 195–205. [Google Scholar] [CrossRef]

- Sturm, R.; Pollard, C.; Craig, J. Chapter 11—Application Programming Interfaces and Connected Systems. In Application Performance Management (APM) in the Digital Enterprise; Sturm, R., Pollard, C., Craig, J., Eds.; Morgan Kaufmann: Boston, MA, USA, 2017; pp. 137–150. [Google Scholar]

- Helmke, M. Ubuntu Unleashed 2015 Edition: Covering 14.10 and 15.04; Sams Publishing: Carmel, IN, USA, 2014. [Google Scholar]

- Sistema de Información Geográfica de Parcelas Agrícolas (SIGPAC). Available online: https://www.mapa.gob.es/es/agricultura/temas/sistema-de-informacion-geografica-de-parcelas-agricolas-sigpac-/default.aspx (accessed on 10 August 2020).

- Portal de la Dirección General del Catastro. Available online: http://www.catastro.minhap.gob.es/esp/wms.asp (accessed on 10 August 2020).

| 1st Block. Analysis of the perception of the ERP applications in agriculture. |

| P1a. Do you use electronic devices or the internet in your work on a daily basis? |

| P2a. What is your perception of the internet and computer programs in the management of your company? |

| Evaluate, from 0 to 10 in order of importance, the following characteristics of a computer application intended to help you in your management: |

| P2b. It must be simple |

| P2c. It must help to show the profitability |

| P2d. It must assist the paperwork |

| P2e. It must integrate the soil, climate, and production data in each plot |

| P2f. It is important that it serves as a field notebook |

| P2g. It must serve to make the daily tasks easier |

| 2nd Block. Analysis of the recording of data in the holdings. |

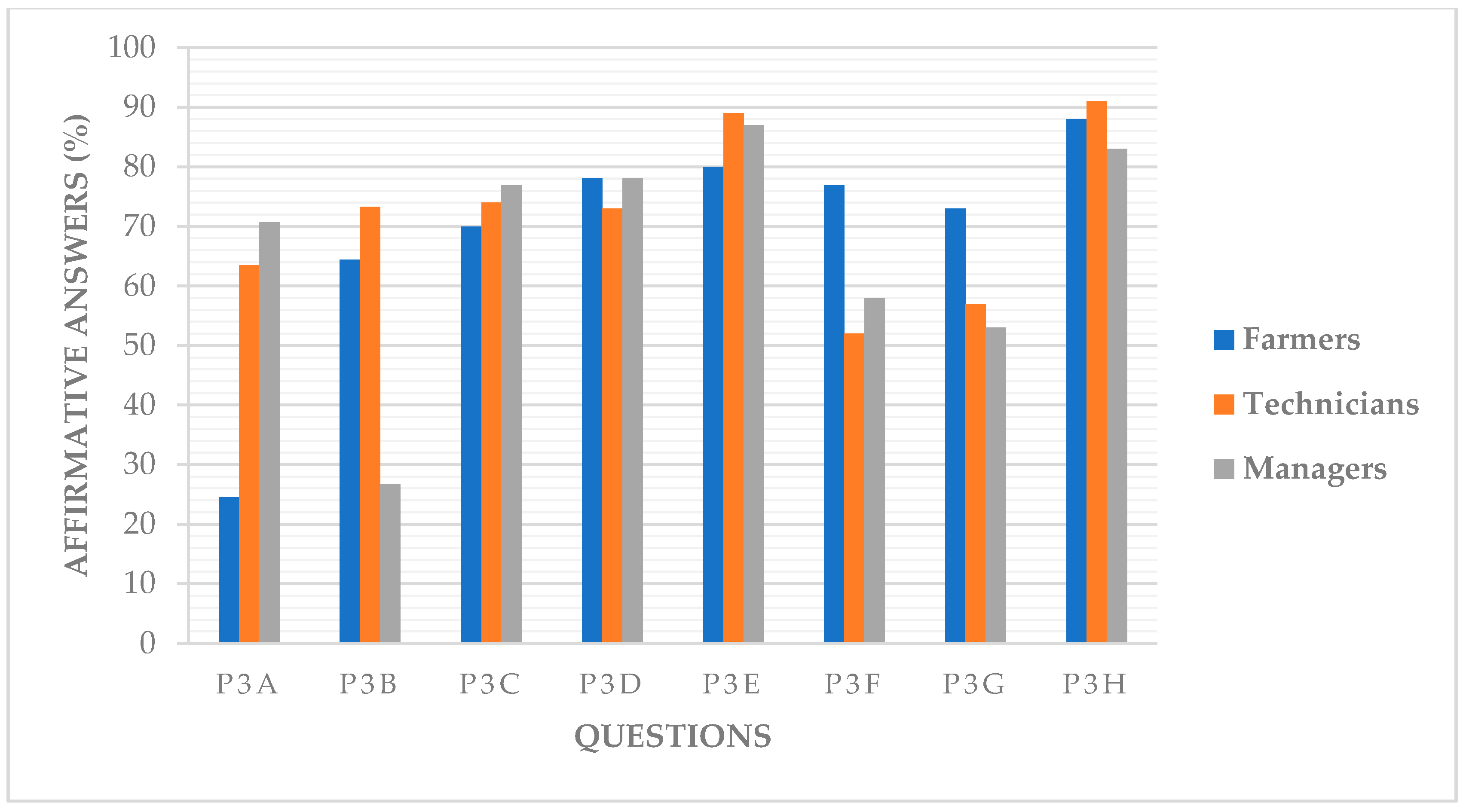

| P3a. Do you have a register of the climatic data related to the plots that you manage? |

| P3b. And a register of the yields? |

| Evaluate, from 0 to 10 in order of importance, the following modules in a possible application for the management of the plots: |

| P3c. Climatic data |

| P3d. Production data |

| P3e. Incidence of pests and diseases |

| P3f. Data for the machinery used in the holding |

| P3g. Register of the cultivation tasks performed |

| P3h. Management of documents |

| 3th Block. Management and decision-making needs. |

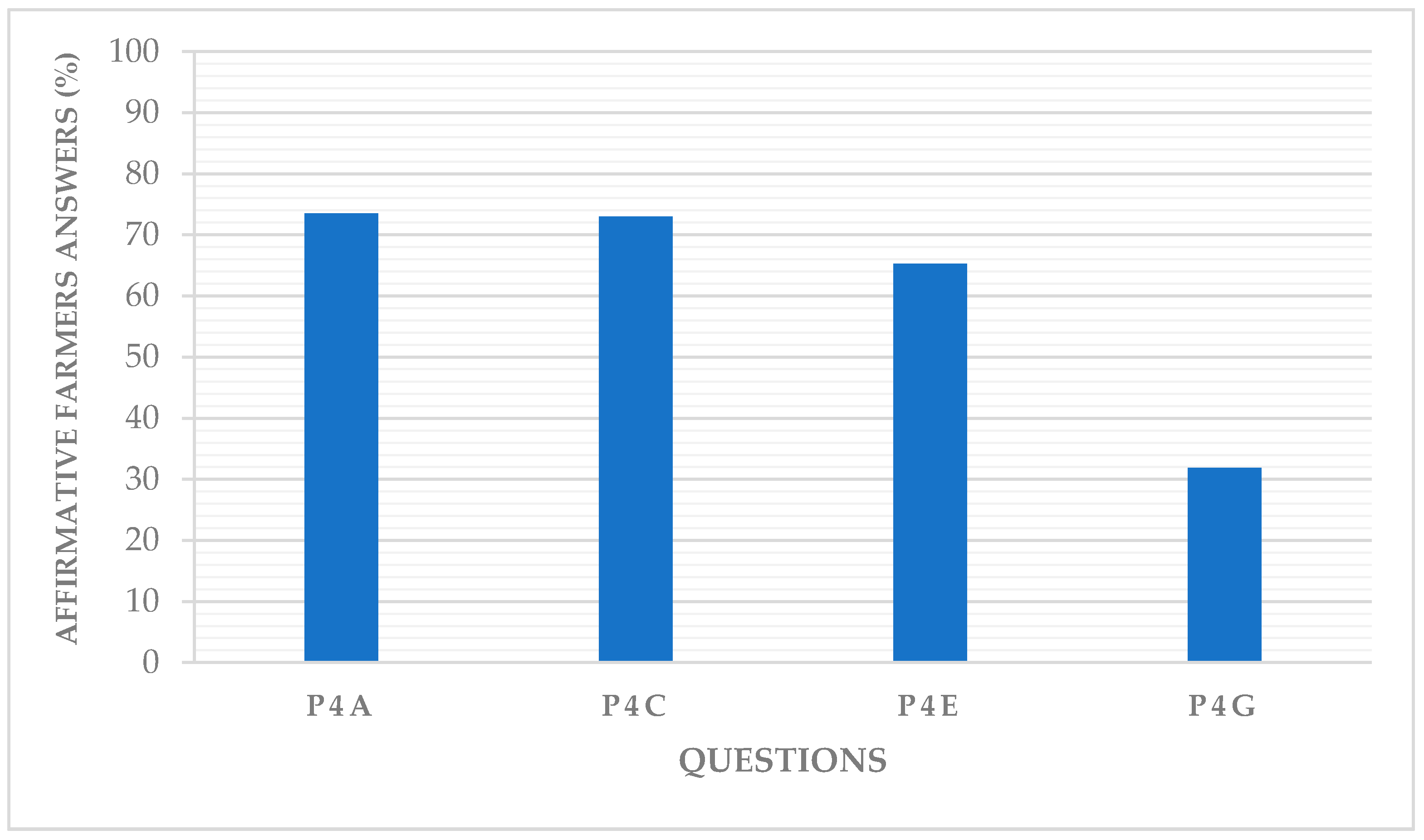

| P4a. Do you know how each of the plots that you cultivate behaves? |

| P4b. Do you have to manage data concerning the members of your organization? |

| P4c. Do you know the sizes of those plots? |

| P4d. Can you obtain up-to-date information for each of your associates in a reasonable amount of time? |

| P4e. When was the last time that someone asked you for any information about your plots? |

| P4f. Can you tell me, with real data, if edaphoclimatic differences exist among the zones that your organization looks after or manages? |

| P4g. Can you tell me, using real edaphoclimatic data, if there are differences among your distinct plots? |

| P4h. When was the last time that someone asked you for specific information about one of your associates? |

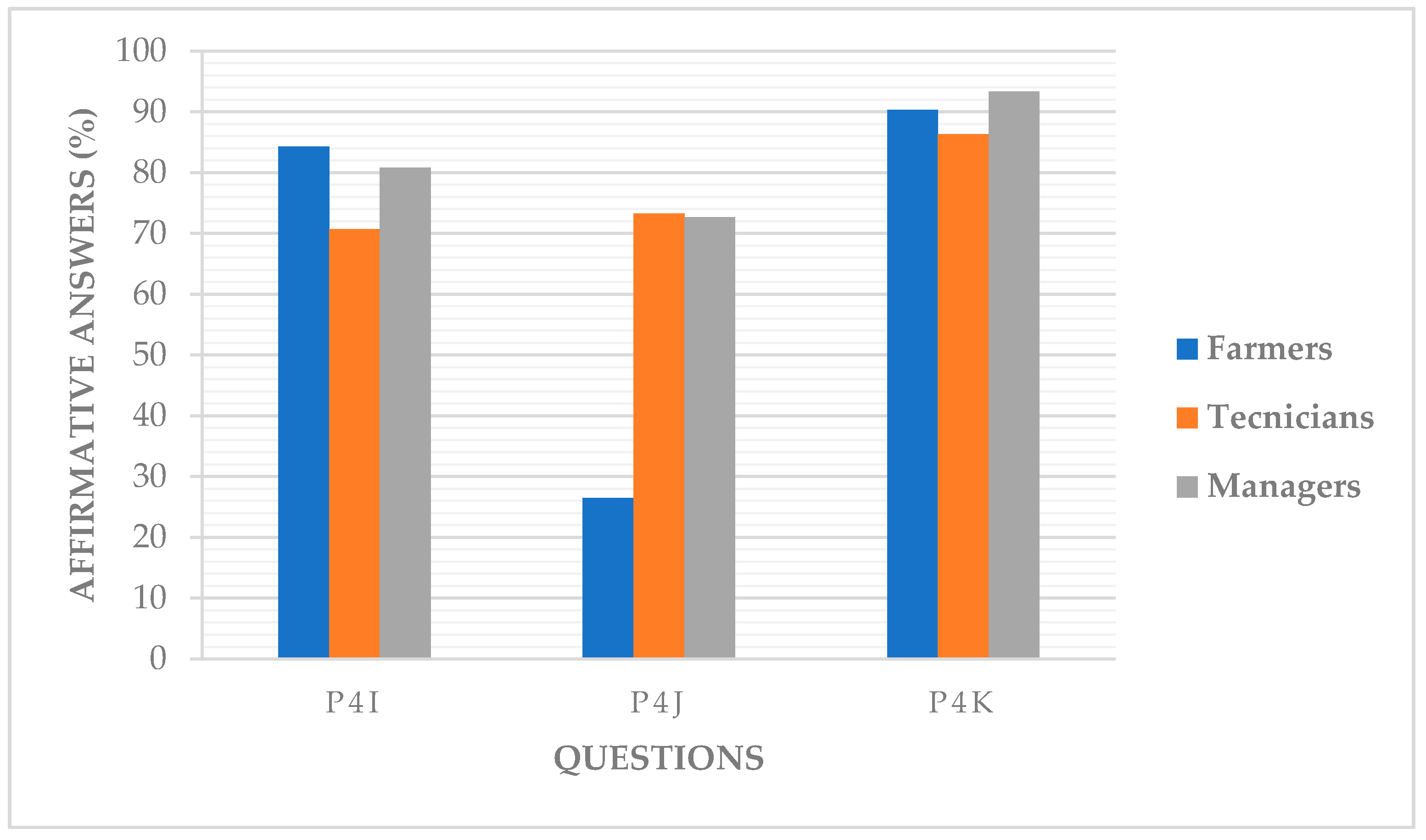

| P4i. Do you find it difficult to fill in the documentation that you are required to complete by the current legislation? |

| P4j. Do you need information grouped by zones in order to make general decisions? |

| P4k. Do you consider necessary an accounting system linked to the supply of production data? |

| 4th Block. Use of applications and solutions. |

| P5a Do you use any type of computer program to manage the information relating to your plots? |

| P5b Do you use any type of computer program to manage the information relating to your different associates? |

| P5c And to assist you to make decisions concerning production? |

| P5d And to make decisions at the territorial level? |

| Name | Summary | Value |

|---|---|---|

| HTTPS Connection | The API HTTPS gateway | https://127.0.0.1/API/ |

| Key | The API identification key. This is a unique value for any device or external user | An alphanumeric value |

| ItemID | For get, update, or deleting, specific data from the database. | A numeric value |

| KeyName | This is an optimal field, if we want to add a custom name for the device or user | An alphanumeric value |

| Date | The current date | Format: DD/MM/YYYY |

| ValueName | The item name. For example: max-temperature | An alphanumeric value |

| Value | The item value. For example: 37 | An alphanumeric value |

| ValueNameItem | When we need to send multiple values for different items. This item can be repeated as many times as we need. For example: max-temperature::37. | Format: ValueName::Value |

| Action | The action type. Not all the types are allowed; by default, the system uses PUT. | GET, PUT, DELETE, UPDATE |

| Farmers (F) | Technicians (T) | Managers (M) | Interactions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F × T × M | T × M | F × M | F × T | F × (T + M) | ||||||||||||

| X2 Pearson | ||||||||||||||||

| %Yes | %No | %Yes | %No | %Yes | %No | X2 | p | X2 | p | X2 | p | X2 | p | X2 | p | |

| P1a | 23.7 | 76.3 | 89.3 | 10.7 | 100 | 0 | 44.6 | 0.00 *2 | 0.1 | 0.74 | 26.1 | 0.00 * | 27.3 | 0.00 * | 44.4 | 0.00 * |

| P3a | 24.5 | 75.5 | 63.5 | 36.5 | 70.7 | 29.3 | 23.1 | 0.00 * | 0.0 | 0.97 | 10.9 | 0.00 * | 14.7 | 0.00 * | 23.1 | 0.00 * |

| P3b | 67.4 | 42.6 | 73.3 | 26.7 | 72.7 | 27.3 | 2.4 | 0.31 | - | - | - | - | - | - | - | - |

| P4a | 73.5 | 26.5 | - | - | - | - | - 1 | - | - | - | - | - | - | - | - | - |

| P4b | - | - | 63.6 | 36.4 | 93.3 | 6.7 | - | - | 3.6 | 0.06 | - | - | - | - | - | - |

| P4c | 73.0 | 27.0 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| P4d | - | - | 80.1 | 20.9 | 93.3 | 6.7 | - | - | 0.0 | 0.76 | - | - | - | - | - | - |

| P4e | 65.3 | 34.7 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| P4f | - | - | 93.3 | 6.7 | 81.8 | 18.2 | - | - | 0.8 | 0.36 | - | - | - | - | - | - |

| P4g | 31.9 | 68.1 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| P4h | - | - | 66.7 | 33.3 | 63.6 | 36.4 | - | - | 0.0 | 0.87 | - | - | - | - | - | - |

| P4i | 84.3 | 15.7 | 70.7 | 29.3 | 80.8 | 19.2 | 0.1 | 0.92 | - | - | - | - | - | - | - | - |

| P4j | 26.5 | 73.5 | 73.3 | 26.7 | 72.7 | 27.3 | 23.1 | 0.00 * | 0.0 | 0.97 | 10.9 | 0.00 * | 14.7 | 0.00 * | 23.1 | 0.00 * |

| P4k | 90.3 | 9.7 | 86.3 | 13.7 | 93.3 | 6.7 | 2.2 | 0.32 | - | - | - | - | - | - | - | - |

| P5a | 9.8 | 90.2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| P5b | - | - | 70.4 | 29.6 | 80.3 | 19.7 | - | - | 7.3 | 0.24 | - | - | - | - | - | - |

| P5c | 9.8 | 90.2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| P5d | - | - | 66.7 | 33.3 | 63.6 | 36.4 | - | - | 0.0 | 0.87 | - | - | - | - | - | - |

| Farmers (F) | Technicians (T) | Managers (M) | Interactions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F × T × M | T×M | F × M | F × T | F × (T + M) | ||||||||||||

| H-Kruskal Wallis | U-Mann-Whitney | U-Mann-Whitney | ||||||||||||||

| m | sd | m | sd | m | sd | X2 | p | U | p | U | p | U | p | U | p | |

| P2a# | 1.6 | 0.7 | 1.1 | 0.5 | 1.2 | 0.5 | 0.8 | 0.73 | ||||||||

| P2b | 7.7 | 2.4 | 5.1 | 2.0 | 5.6 | 2.5 | 22.3 | 0.00 * | 57.5 | 0.19 | 531.5 | 0.04 * | 551.0 | 0.00 * | 1132.5 | 0.00 * |

| P2c | 6.5 | 2.3 | 4.9 | 2.7 | 4.9 | 3.0 | 8.2 | 0.02 * | 73.0 | 0.79 | 497.5 | 0.02 * | 968.0 | 0.01 * | 1745.5 | 0.00 * |

| P2d | 6.3 | 2.7 | 6.5 | 2.2 | 6.6 | 2.3 | 0.1 | 0.89 | ||||||||

| P2e | 7.2 | 2.4 | 5.4 | 2.3 | 5.4 | 3.0 | 11.6 | 0.00 * | 79.0 | 0.96 | 724.0 | 0.03 * | 875.5 | 0.00 * | 1670.5 | 0.00 * |

| P2f | 8.3 | 2.4 | 5.8 | 2.0 | 4.9 | 2.5 | 26.2 | 0.00 * | 75.4 | 0.19 | 582.5 | 0.04 * | 564.0 | 0.00 * | 1134.5 | 0.00 * |

| P2g | 9.3 | 4.7 | 9.2 | 1.3 | 9.7 | 3.6 | 2.4 | 0.73 | ||||||||

| P3c | 7.0 | 4.4 | 7.4 | 1.1 | 7.7 | 1.9 | 1.4 | 0.50 | ||||||||

| P3d | 7.8 | 2.1 | 7.3 | 1.5 | 7.8 | 2.0 | 8.1 | 0.34 | ||||||||

| P3e | 8.0 | 2.1 | 8.9 | 1.7 | 8.7 | 1.6 | 4.2 | 0.12 | ||||||||

| P3f | 7.7 | 2.4 | 5.2 | 2.0 | 5.8 | 2.5 | 24.3 | 0.00 * | 57.5 | 0.19 | 571.5 | 0.04 * | 551.0 | 0.00 * | 1122.5 | 0.00 * |

| P3g | 7.3 | 3.2 | 5.7 | 3.2 | 5.3 | 2.3 | 9.9 | 0.01 * | 80.0 | 0.89 | 655.5 | 0.02 * | 1023.0 | 0.03 * | 1678.5 | 0.00 * |

| P3h | 8.8 | 4.2 | 9.1 | 4.6 | 8.3 | 4.2 | 0.8 | 0.66 | ||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar Morales, D.; Sánchez-Bravo, P.; Lipan, L.; Cano-Lamadrid, M.; Issa-Issa, H.; Campo-Gomis, F.J.d.; Lluch, D.B.L. Designing of an Enterprise Resource Planning for the Optimal Management of Agricultural Plots Regarding Quality and Environmental Requirements. Agronomy 2020, 10, 1352. https://doi.org/10.3390/agronomy10091352

Aguilar Morales D, Sánchez-Bravo P, Lipan L, Cano-Lamadrid M, Issa-Issa H, Campo-Gomis FJd, Lluch DBL. Designing of an Enterprise Resource Planning for the Optimal Management of Agricultural Plots Regarding Quality and Environmental Requirements. Agronomy. 2020; 10(9):1352. https://doi.org/10.3390/agronomy10091352

Chicago/Turabian StyleAguilar Morales, Damián, Paola Sánchez-Bravo, Leontina Lipan, Marina Cano-Lamadrid, Hanán Issa-Issa, Francisco J. del Campo-Gomis, and David B. López Lluch. 2020. "Designing of an Enterprise Resource Planning for the Optimal Management of Agricultural Plots Regarding Quality and Environmental Requirements" Agronomy 10, no. 9: 1352. https://doi.org/10.3390/agronomy10091352

APA StyleAguilar Morales, D., Sánchez-Bravo, P., Lipan, L., Cano-Lamadrid, M., Issa-Issa, H., Campo-Gomis, F. J. d., & Lluch, D. B. L. (2020). Designing of an Enterprise Resource Planning for the Optimal Management of Agricultural Plots Regarding Quality and Environmental Requirements. Agronomy, 10(9), 1352. https://doi.org/10.3390/agronomy10091352