Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture?

Abstract

1. Introduction

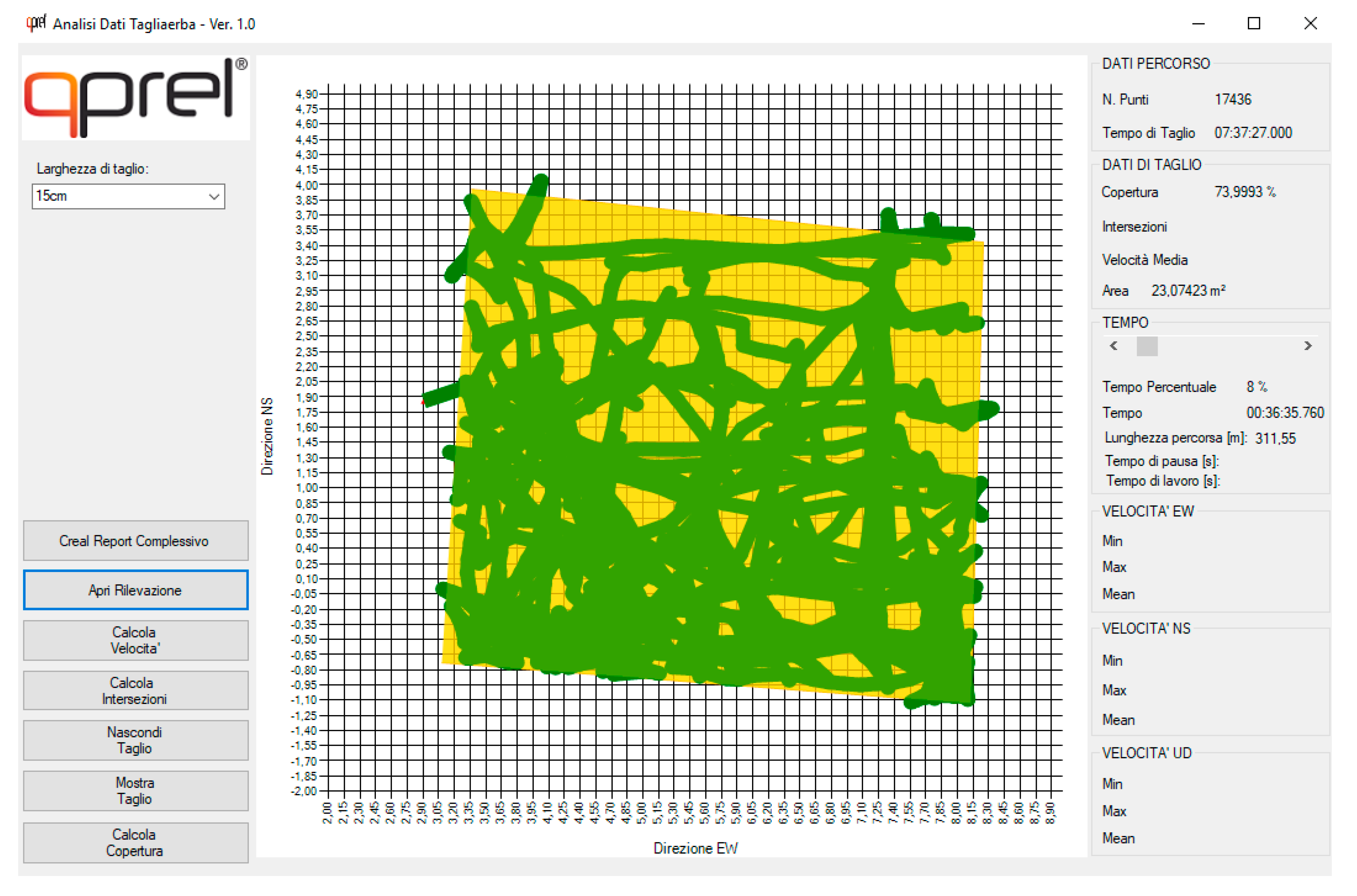

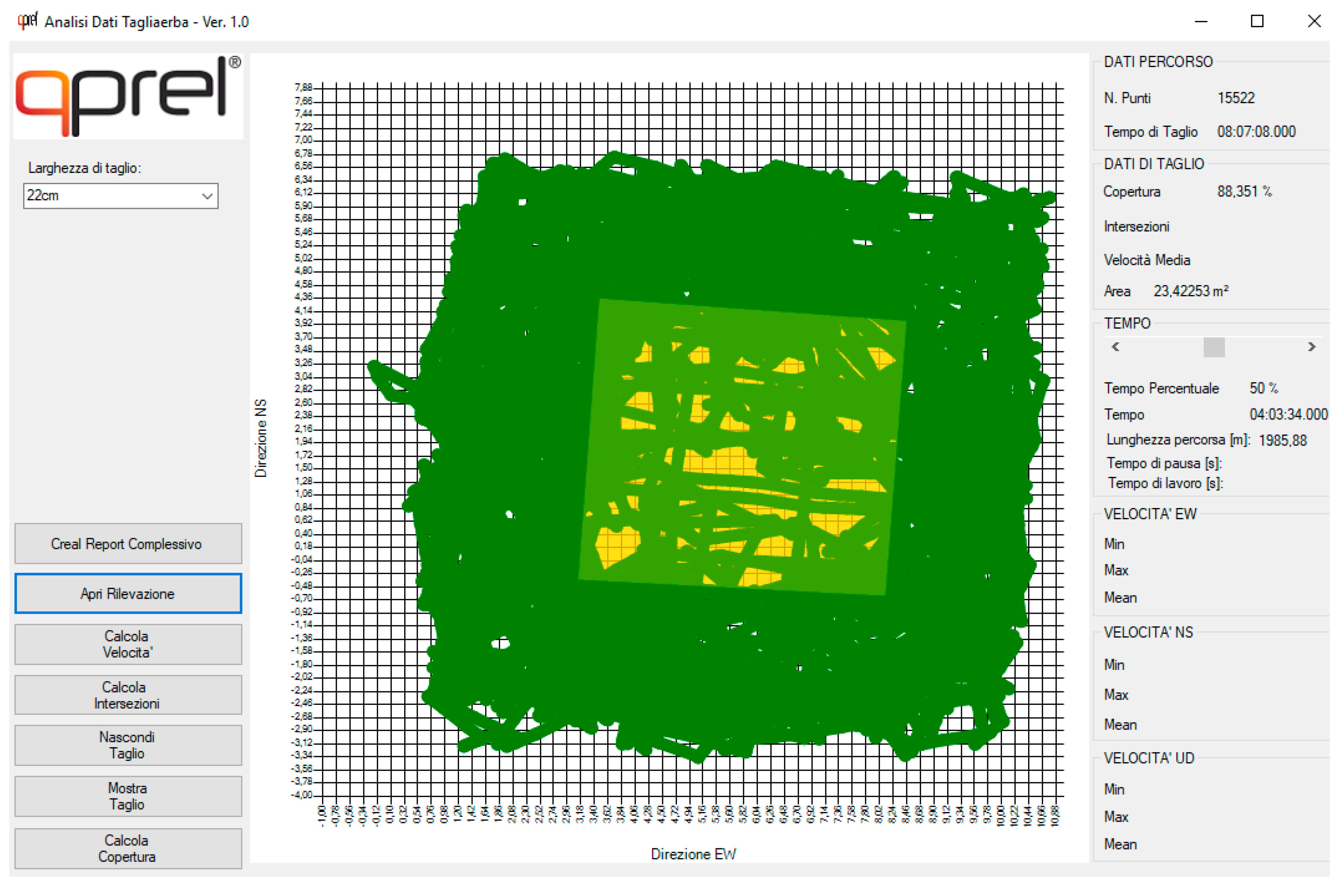

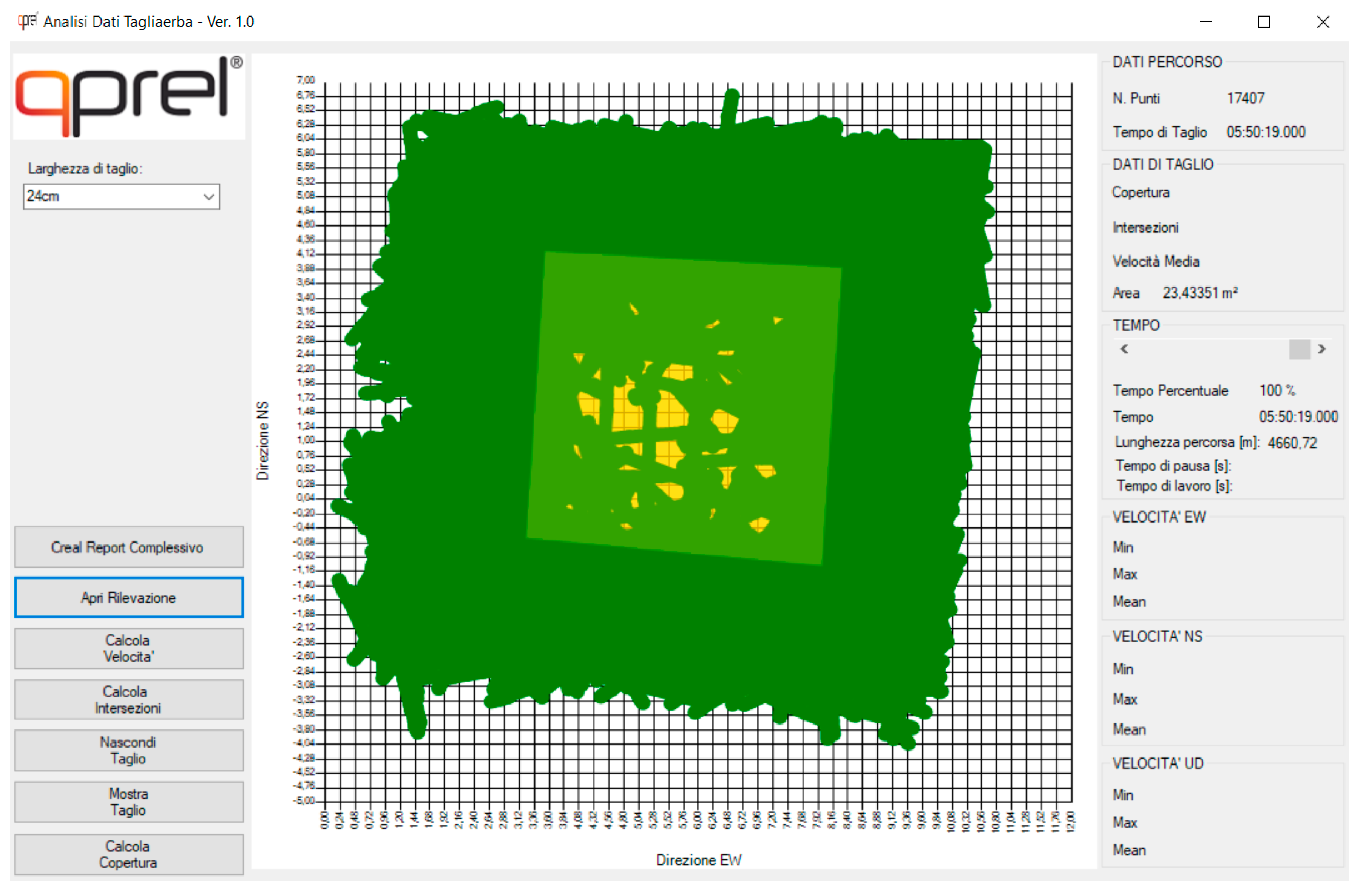

2. Materials and Methods

2.1. The Experimental Trial

2.2. Description of the Machines

2.3. Data Collection

2.4. Statistical Analysis

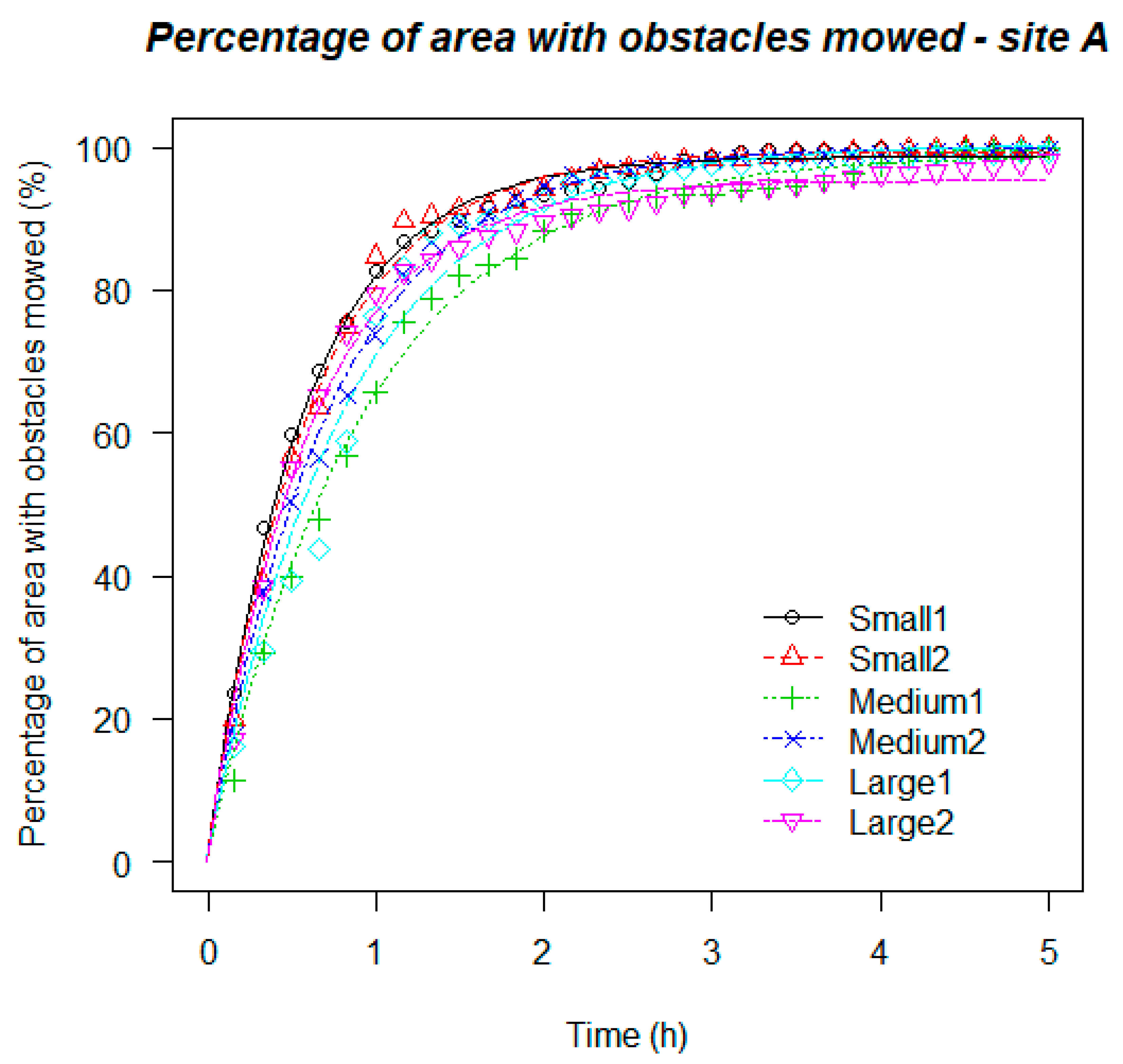

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Report Buyer. Robotic Lawn Mower Market–Global Outlook and Forecast 2018–2023. Available online: https://www.reportbuyer.com/product/5398687/robotic-lawn-mower-market-global-outlook-and-forecast-2018-2023.html (accessed on 10 February 2020).

- Pirchio, M.; Fontanelli, M.; Frasconi, C.; Martelloni, L.; Raffaelli, M.; Peruzzi, A.; Gaetani, M.; Magni, S.; Caturegli, L.; Volterrani, M.; et al. Autonomous Mower vs. Rotary Mower: Effects on Turf Quality and Weed Control in Tall Fescue Lawn. Agronomy 2018, 8, 15. [Google Scholar] [CrossRef]

- Hicks, R.W.; Hall, E.L. Survey of robot lawn mowers. In Proceedings SPIE 4197, Intelligent Robots and Computer Vision XIX: Algorithms, Techniques, and Active Vision; Society of Photo-Optical Instrumentation Engineers (SPIE): Boston, MA, USA, 2000; pp. 262–269. [Google Scholar]

- Nelson, R.G. Automated Lawn Mower. U.S. Patent No. 5,974,347, 26 October 1999. [Google Scholar]

- Ragonese, A.; Marx, J. The applications of sensor technology in the design of the autonomous robotic lawn mower, Paper No. 5094. In Proceedings of the 15th Annual Freshman Engineering Conference, Pittsburgh, PA, USA, 11 April 2015. [Google Scholar]

- Peless, E.; Even, Y.; Shai, A.; Ramat, G.; Gideon, D. Navigation Method and System for Autonomous Machines with Markers Defining the Working Area. U.S. Patent No. 6,417,641, 9 July 2002. [Google Scholar]

- Slaughter, D.C.; Giles, D.K.; Downey, D. Autonomous robotic weed control systems: A review. Comput. Electron. Agric. 2008, 61, 63–78. [Google Scholar] [CrossRef]

- Chandler, R.C. Autonomous Agent Navigation Based on Textural Analysis. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2003. [Google Scholar]

- Zucchetti. Ambrogio Robot. Available online: http://www.ambrogiorobot.com/en/ambrogiorobot (accessed on 10 February 2020).

- Husqvarna. Husqvarna Automower 105/310/315/320/330X/420/430X/450X Operator’s Manual. Available online: http://www.husqvarna.com/uk/support/manuals-downloads/ (accessed on 10 February 2020).

- Marinoudi, V.; Sørensen, C.G.; Pearson, S.; Bochtis, D. Robotics and labour in agriculture. A context consideration. Biosyst. Eng. 2019, 184, 111–121. [Google Scholar] [CrossRef]

- Auat Cheein, F.A.; Carelli, R. Agricultural robotics: Unmanned robotic service units in agricultural tasks. IEEE Ind. Electron. Mag. 2013, 7, 48–58. [Google Scholar] [CrossRef]

- Eberhardt, M.; Vollrath, D. The Effect of Agricultural Technology on the Speed of Development. World Dev. 2018, 109, 483–496. [Google Scholar] [CrossRef]

- Vasconez, J.P.; Kantor, G.A.; Auat Cheein, F.A. Human–robot interaction in agriculture: A survey and current challenges. Biosyst. Eng. 2019, 179, 35–48. [Google Scholar] [CrossRef]

- Birrell, S.; Hughes, J.; Cai, J.Y.; Iida, F. A field-tested robotic harvesting system for iceberg lettuce. J. Field Robot. 2020, 37, 225–245. [Google Scholar] [CrossRef] [PubMed]

- Raja, R.; Nguyen, T.T.; Slaughter, D.C.; Fennimore, S.A. Real-time weed-crop classification and localisation technique for robotic weed control in lettuce. Biosyst. Eng. 2020, 192, 257–274. [Google Scholar] [CrossRef]

- Grossi, N.; Fontanelli, M.; Garramone, E.; Peruzzi, A.; Raffaelli, M.; Pirchio, M.; Martelloni, L.; Frasconi, C.; Caturegli, L.; Gaetani, M.; et al. Autonomous Mower Saves Energy and Improves Quality of Tall Fescue Lawn. HortTechnology 2016, 26, 825–830. [Google Scholar] [CrossRef]

- Pirchio, M.; Fontanelli, M.; Frasconi, C.; Martelloni, L.; Raffaelli, M.; Peruzzi, A.; Caturegli, L.; Gaetani, M.; Magni, S.; Volterrani, M.; et al. Autonomous Rotary Mower versus Ordinary Reel Mower—Effects of Cutting Height and Nitrogen Rate on Manila Grass Turf Quality. HortTechnology 2018, 28, 509–515. [Google Scholar] [CrossRef]

- MacLaren, C.; Bennett, J.; Dehnen-Schmutz, K. Management practices influence the competitive potential of weed communities and their value to biodiversity in South African vineyards. Weed Res. 2019, 59, 93–106. [Google Scholar] [CrossRef]

- Vitirover. Vitirover Solutions. Available online: https://www.vitirover.fr/en-robot (accessed on 10 February 2020).

- Franklin robotics. Franklin Robotics Tertill. Available online: https://www.franklinrobotics.com (accessed on 10 February 2020).

- Keresztes, B.; Germain, C.; Da Costa, J.P.; Grenier, G.; Beaulieu, X.D. Vineyard Vigilant & INNovative Ecological Rover (VVINNER): An autonomous robot for automated scoring of vineyards. In Proceedings of the International Conference of Agricultural Engenieering, Zurich, Switzerland, 6–10 July 2014; Available online: https://pdfs.semanticscholar.org/e4e0/4bb9ba6714117783833406442bdf4561b2b2.pdf (accessed on 20 March 2020).

- Husqvarna. Husqvarna Automower 535 AWD Operator’s Manual. Available online: http://service.webec.husqvarna.net/documents/HUSO/HUSO2020_EUen/HUSO2020_EUen__1141840-26.pdf (accessed on 20 March 2020).

- Xun, Q.; Jie, G.; Hong-jia, P.; Kai-yu, Z.; Wei, S.; Xiao-juan, W.; Hua, G. Effects of living mulches on the soil nutrient contents, enzyme activities, and bacterial community diversities of apple orchard soils. Eur. J. Soil Biol. 2015, 70, 23–30. [Google Scholar]

- Hartwig, N.L.; Ammon, H.U. Cover crops and living mulches. Weed Sci. 2002, 50, 688–699. [Google Scholar] [CrossRef]

- Song, B.Z.; Zhang, J.; Hu, J.H.; Wu, H.Y.; Kong, Y.; Yao, Y.C. Temporal dynamics of the arthropod community in pear orchards intercropped with aromatic plants. Pest Manag. Sci. 2011, 67, 1107–1114. [Google Scholar]

- Antichi, D.; Sbrana, M.; Martelloni, L.; Abou Chehade, L.; Fontanelli, M.; Raffaelli, M.; Mazzoncini, M.; Peruzzi, A.; Frasconi, C. Agronomic Performances of Organic Field Vegetables Managed with Conservation Agriculture Techniques: A Study from Central Italy. Agronomy 2019, 9, 810. [Google Scholar] [CrossRef]

- Emlid. A Reach RTK docs. Specification. Available online: https://docs.emlid.com/reach/specs/ (accessed on 10 February 2020).

- Martelloni, L.; Fontanelli, M.; Pieri, S.; Frasconi, C.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; Pirchio, M.; Raffaelli, M.; et al. Assessment of the Cutting Performance of a Robot Mower Using Custom Built Software. Agronomy 2019, 9, 230. [Google Scholar] [CrossRef]

- Takasu, T. RTKLIB ver. 2.4.2 Manual. Available online: http://www.rtklib.com/prog/manual_2.4.2.pdf (accessed on 10 February 2020).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2016; Available online: https://www.R-project.org/ (accessed on 10 February 2020).

- Gerhard, D.; Ritz, C. medrc: Mixed Effect Dose-Response Curves. R package version 1.1-0. Available online: https://rdrr.io/github/DoseResponse/medrc/man/metadrm.html (accessed on 10 February 2020).

- Ritz, C. Asymptotic regression model. In Analysis of Dose-Response Curves; Ritz, C., Strebig, J.C., Eds.; 2016; pp. 7–8. Available online: https://cran.r-project.org/web/packages/drc/drc.pdf (accessed on 10 February 2020).

- Knezevic, A. Overlapping Confidence Intervals and Statistical Significance. 2008. Available online: https://www.cscu.cornell.edu/news/statnews/stnews73.pdf (accessed on 10 February 2020).

- Bechar, A.; Vigneault, C. Agricultural robots for field operations. Part 2: Operations and systems. Biosyst. Eng. 2017, 153, 110–128. [Google Scholar] [CrossRef]

- Fetouh, M. Edible Landscaping in Urban Horticulture. In Urban Horticulture; Springer: Cham, Switzerland, 2018; pp. 41–173. [Google Scholar]

- Napawan, N.C.; Townsend, S.A. The landscape of urban agriculture in California’s capital. Landsc. Res. 2016, 41, 780–794. [Google Scholar] [CrossRef]

| Parameter | Unit | Autonomous Mower | |||||

|---|---|---|---|---|---|---|---|

| Automower 450X “Open Areas” Large 1 | Automower 450X “Complex Areas” Large 2 | Automower 310 “Open Areas” Medium 1 | Automower 310 “Complex Areas” Medium 2 | Ambrogio L15 Small 1 | Automower 105 Small 2 | ||

| Working Capacity | m2 | 5000 ± 20% | 5000 ± 20% | 1000 ± 20% | 1000 ± 20% | 600 ± 20% | 600 ± 20% |

| Average Mowing Time | min | 260 | 260 | 70 | 70 | 150 | 70 |

| Average Charging Time | min | 75 | 75 | 60 | 60 | 60 | 50 |

| Blade Motor Speed | rpm | 2300 | 2300 | 2300 | 2300 | 4200 | 2900 |

| Cutting Width | cm | 24 | 24 | 22 | 22 | 15 | 17 |

| Dimension (Length × Height × Width) | cm | 72 × 31 × 56 | 72 × 31 × 56 | 63 × 25 × 51 | 63 × 25 × 51 | 42 × 25 × 22 | 55 × 25 × 39 |

| GPS Assisted Navigation | yes | yes | no | no | no | no | |

| Mowing Time (h) | Percentage of Area with Obstacles Mowed (%) | LSD | p Value | |||||

|---|---|---|---|---|---|---|---|---|

| Autonomous Mower Type | ||||||||

| Small 1 | Small 2 | Medium 1 | Medium 2 | Large 1 | Large 2 | |||

| 1 | 85.06 a | 83.05 a | 65.94 c | 73.84 bc | 79.64 ab | 76.85 ab | 1159 | ** |

| 2 | 94.13 | 94.36 | 89.12 | 94.83 | 89.75 | 93.03 | 1635 | ns |

| 3 | 98.93 a | 98.52 a | 94.21 b | 98.27 a | 94.52 b | 97.65 ab | 1084 | * |

| 4 | 99.82 a | 99.63 a | 97.98 bc | 99.20 ab | 96.85 c | 98.63 abc | 0626 | * |

| 5 | 99.95 | 99.95 | 99.85 | 99.71 | 98.71 | 99.7 | 0431 | ns |

| Mowing Time (h) | Percentage of Area with Obstacles Mowed (%) | LSD | p Value | |||||

|---|---|---|---|---|---|---|---|---|

| Autonomous Mower Type | ||||||||

| Small 1 | Small 2 | Medium 1 | Medium 2 | Large 1 | Large 2 | |||

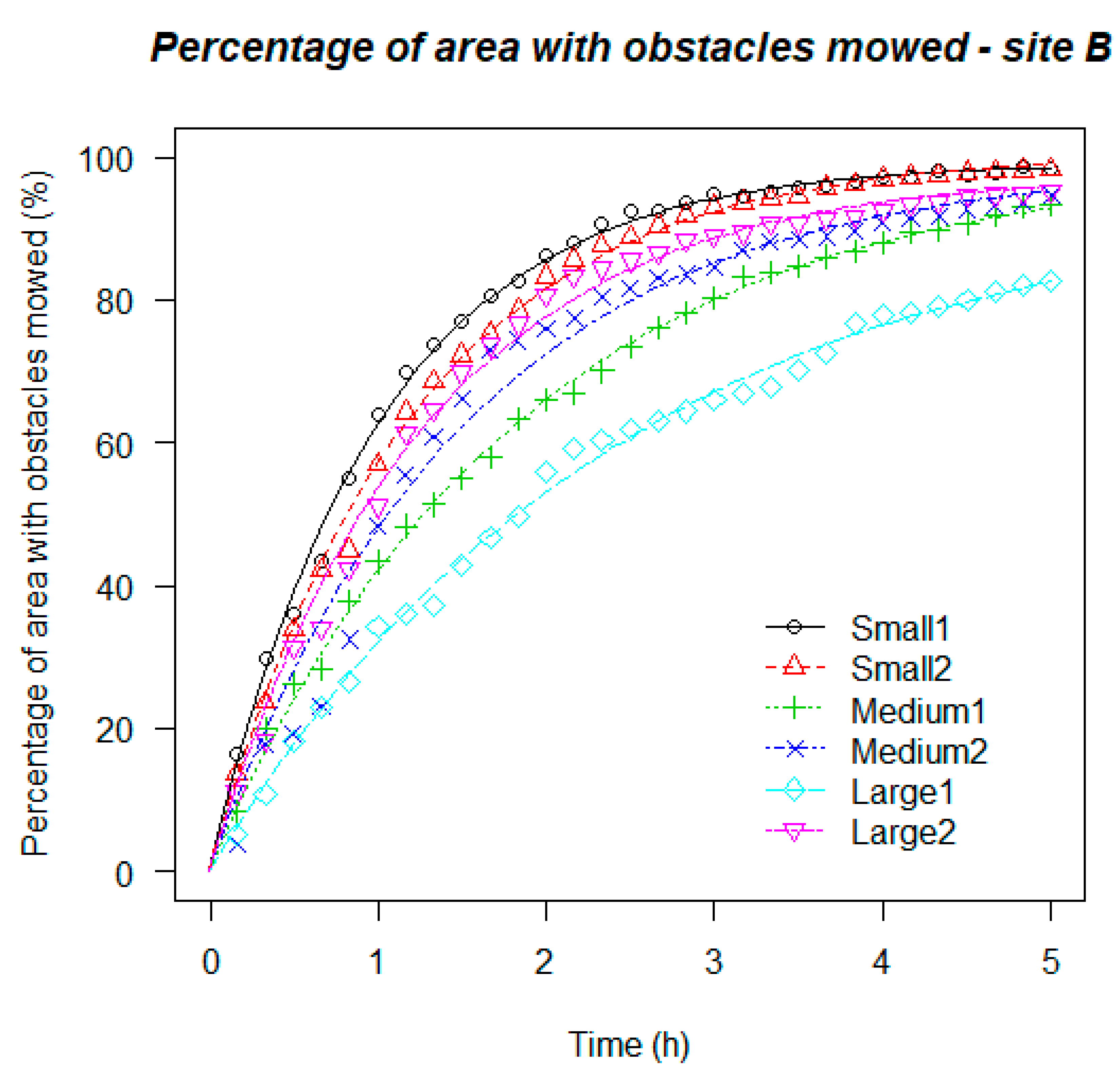

| 1 | 64.04 a | 57.00 ab | 43.21 cd | 48.16 bc | 34.26 d | 51.15 bc | 1163 | *** |

| 2 | 86.51 a | 83.43 a | 66.39 bc | 76.14 ab | 56.04 c | 80.85 a | 1982 | *** |

| 3 | 95.01 a | 93.33 ab | 80.40 d | 85.08 cd | 66.30 e | 89.19 bc | 1198 | *** |

| 4 | 97.32 a | 97.03 a | 88.43 b | 91.15 b | 78.23 c | 92.81 b | 0943 | *** |

| 5 | 98.52 a | 98.42 a | 93.59 b | 95.06 ab | 83.01 c | 95.97 ab | 1078 | *** |

| Autonomous Mower | d | e | Effective Time (h) | ||

|---|---|---|---|---|---|

| ET10 | ET50 | ET90 | |||

| Small 1 | 98.71 (0.587) | 34.07 (1.132) | 0.06 (0.002) | 0.40 (0.013) | 1.31 (0.044) |

| Small 2 | 99.48 (0.593) | 36.40 (1.129) | 0.06 (0.002) | 0.42 (0.013) | 1.40 (0.043) |

| Medium 1 | 99.06 (0.749) | 55.52 (1.673) | 0.10 (0.003) | 0.64 (0.019) | 2.13 (0.064) |

| Medium 2 | 100.09 (0.642) | 43.69 (1.297) | 0.08 (0.002) | 0.51 (0.015) | 1.68 (0.050) |

| Large 1 | 100.40 (0.678) | 49.43 (1.405) | 0.09 (0.003) | 0.57 (0.016) | 1.90 (0.054) |

| Large 2 | 95.40 (0.600) | 36.69 (1.219) | 0.06 (0.002) | 0.42 80.014) | 1.41 (0.047) |

| Autonomous Mower | d | e | Effective Time (h) | ||

|---|---|---|---|---|---|

| ET10 | ET50 | ET90 | |||

| Small 1 | 99.25 (0.968) | 60.41 (2.218) | 0.11 (0.004) | 0.70 (0.026) | 2.32 (0.085) |

| Small 2 | 100.62 (1.134) | 71.84 (2.699) | 0.13 (0.005) | 0.83 (0.031) | 2.76 (0.104) |

| Medium 1 | 99.21 (1.942) | 109.20 (5.315) | 0.19 (0.009) | 1.26 (0.061) | 4.19 (0.204) |

| Medium 2 | 98.87 (1.450) | 90.68 (3.729) | 0.16 (0.007) | 1.05 (0.043) | 3.48 (0.143) |

| Large 1 | 94.75 (3.017) | 145.92 (9.544) | 0.26 (0.017) | 1.69 (0.110) | 5.60 (0.366) |

| Large 2 | 97.87 (1.190) | 75.91 (2.943) | 0.13 (0.005) | 0.88 (0.034) | 2.91 (0.113) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sportelli, M.; Pirchio, M.; Fontanelli, M.; Volterrani, M.; Frasconi, C.; Martelloni, L.; Caturegli, L.; Gaetani, M.; Grossi, N.; Magni, S.; et al. Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture? Agronomy 2020, 10, 553. https://doi.org/10.3390/agronomy10040553

Sportelli M, Pirchio M, Fontanelli M, Volterrani M, Frasconi C, Martelloni L, Caturegli L, Gaetani M, Grossi N, Magni S, et al. Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture? Agronomy. 2020; 10(4):553. https://doi.org/10.3390/agronomy10040553

Chicago/Turabian StyleSportelli, Mino, Michel Pirchio, Marco Fontanelli, Marco Volterrani, Christian Frasconi, Luisa Martelloni, Lisa Caturegli, Monica Gaetani, Nicola Grossi, Simone Magni, and et al. 2020. "Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture?" Agronomy 10, no. 4: 553. https://doi.org/10.3390/agronomy10040553

APA StyleSportelli, M., Pirchio, M., Fontanelli, M., Volterrani, M., Frasconi, C., Martelloni, L., Caturegli, L., Gaetani, M., Grossi, N., Magni, S., Raffaelli, M., & Peruzzi, A. (2020). Autonomous Mowers Working in Narrow Spaces: A Possible Future Application in Agriculture? Agronomy, 10(4), 553. https://doi.org/10.3390/agronomy10040553