A Whole-Slurry Fermentation Approach to High-Solid Loading for Bioethanol Production from Corn Stover

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Its Chemical Analysis

2.2. Autohydrolysis of Corn Stover

2.3. Enzymatic Susceptibility of the Solid Fractions

2.4. Yeast Cultivation and Inoculum Preparation

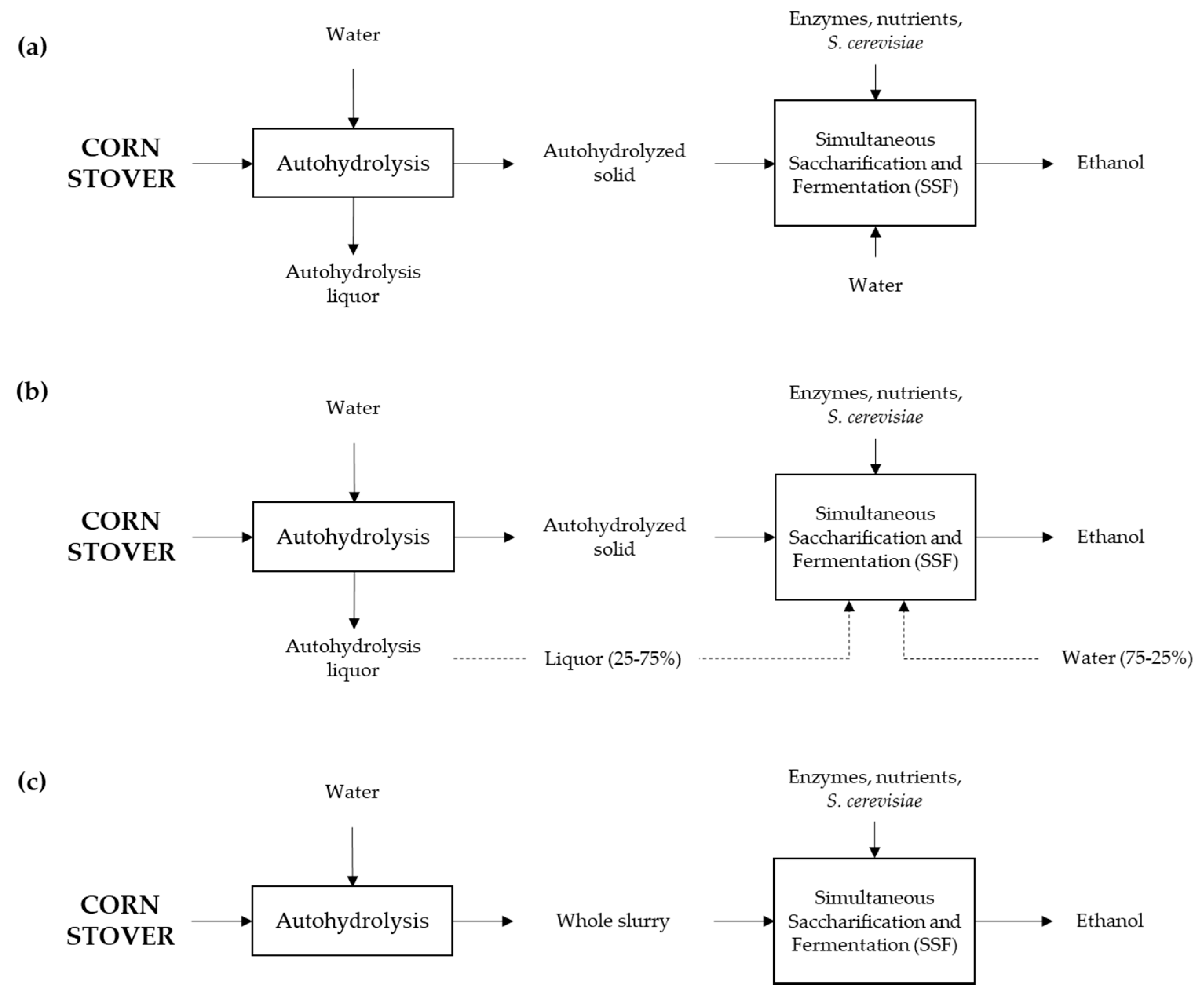

2.5. Simultaneous Saccharification and Fermentation of the Whole Slurries after Autohydrolysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Raw Material and Autohydrolysis Treatment: Chemical Analysis Composition

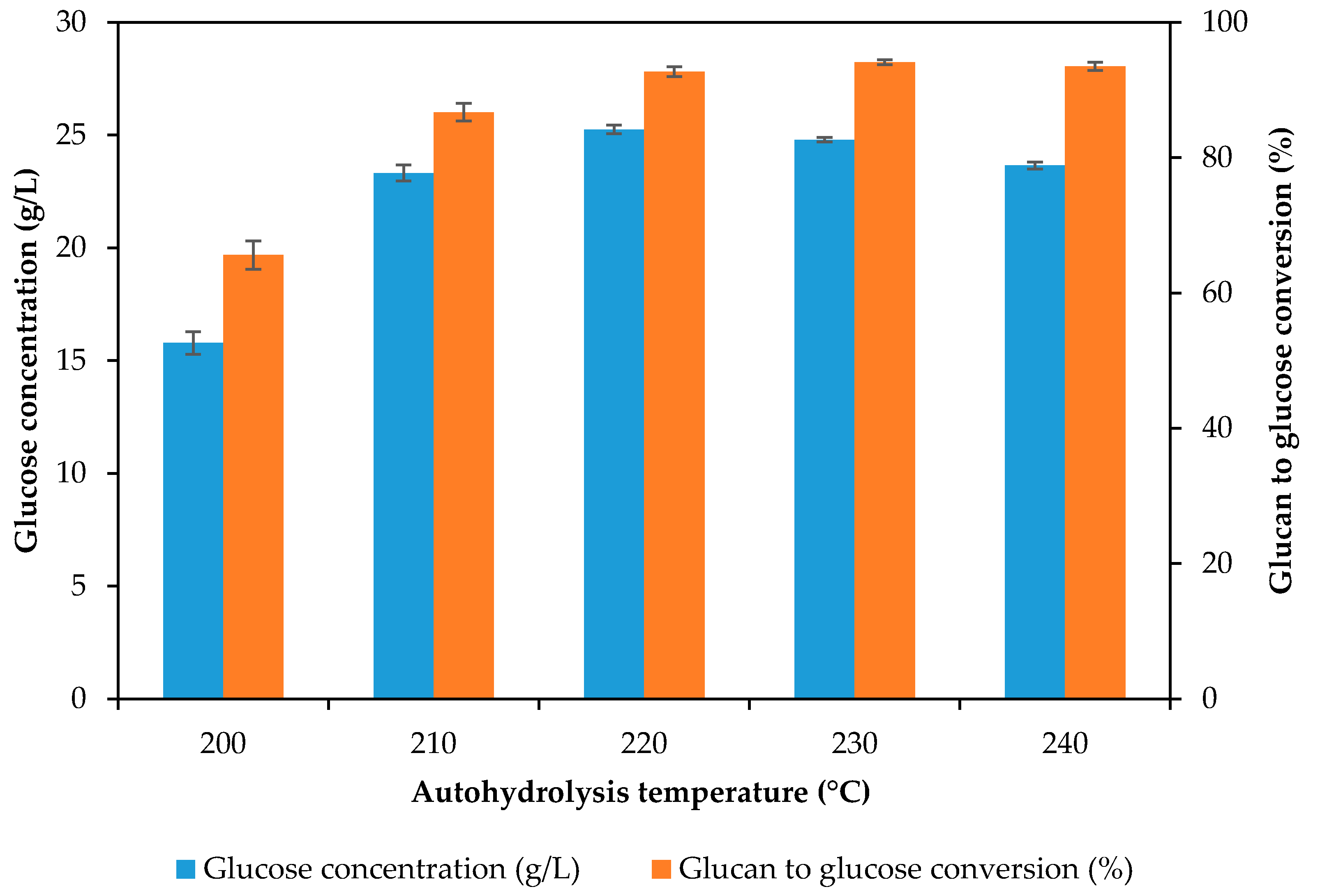

3.2. Effect of the Autohydrolysis Severity on the Enzymatic Susceptibility of the Solid Fractions

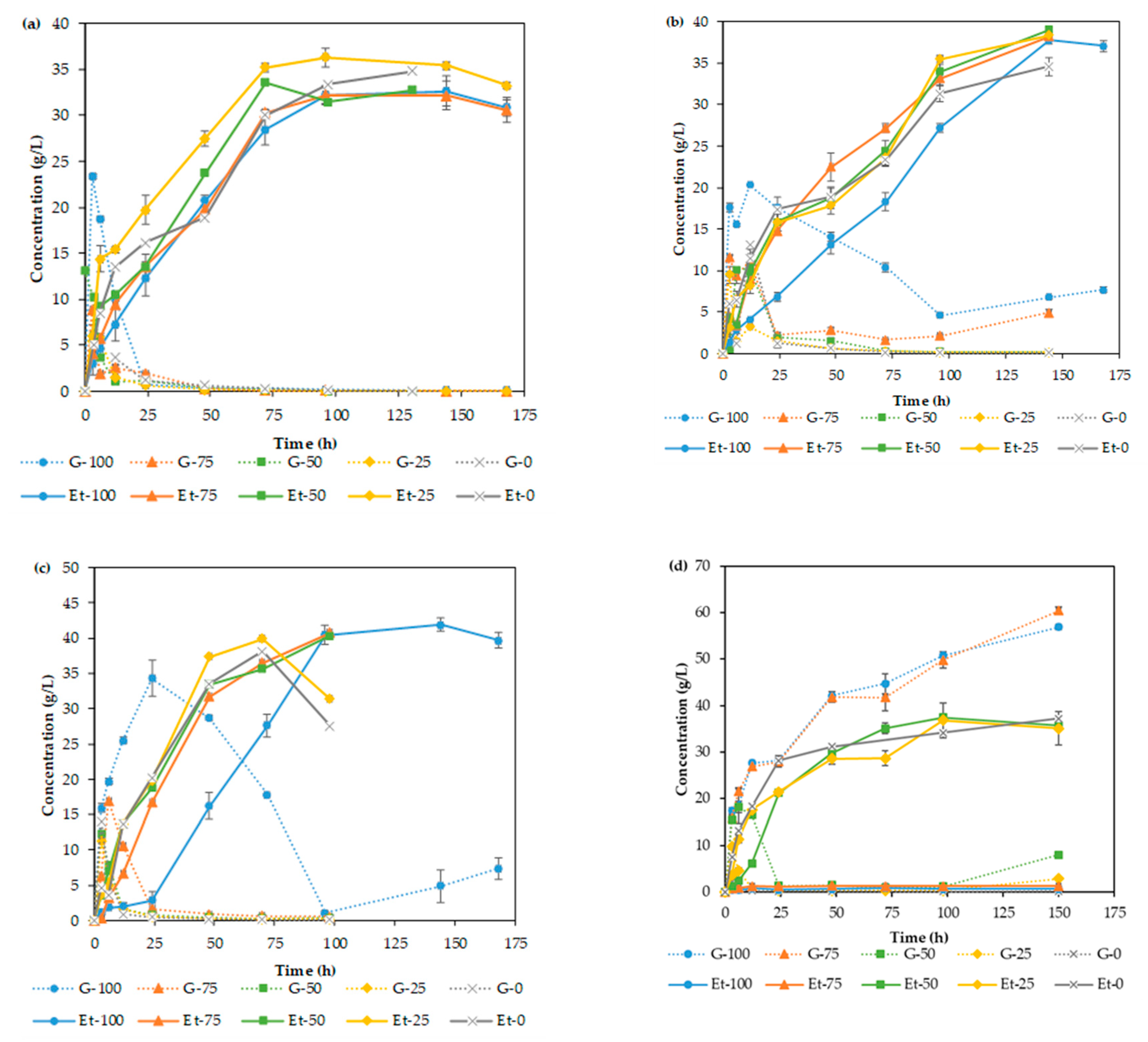

3.3. Simultaneous Saccharification and Fermentation (SSF) of the Whole Slurries after Autohydrolysis

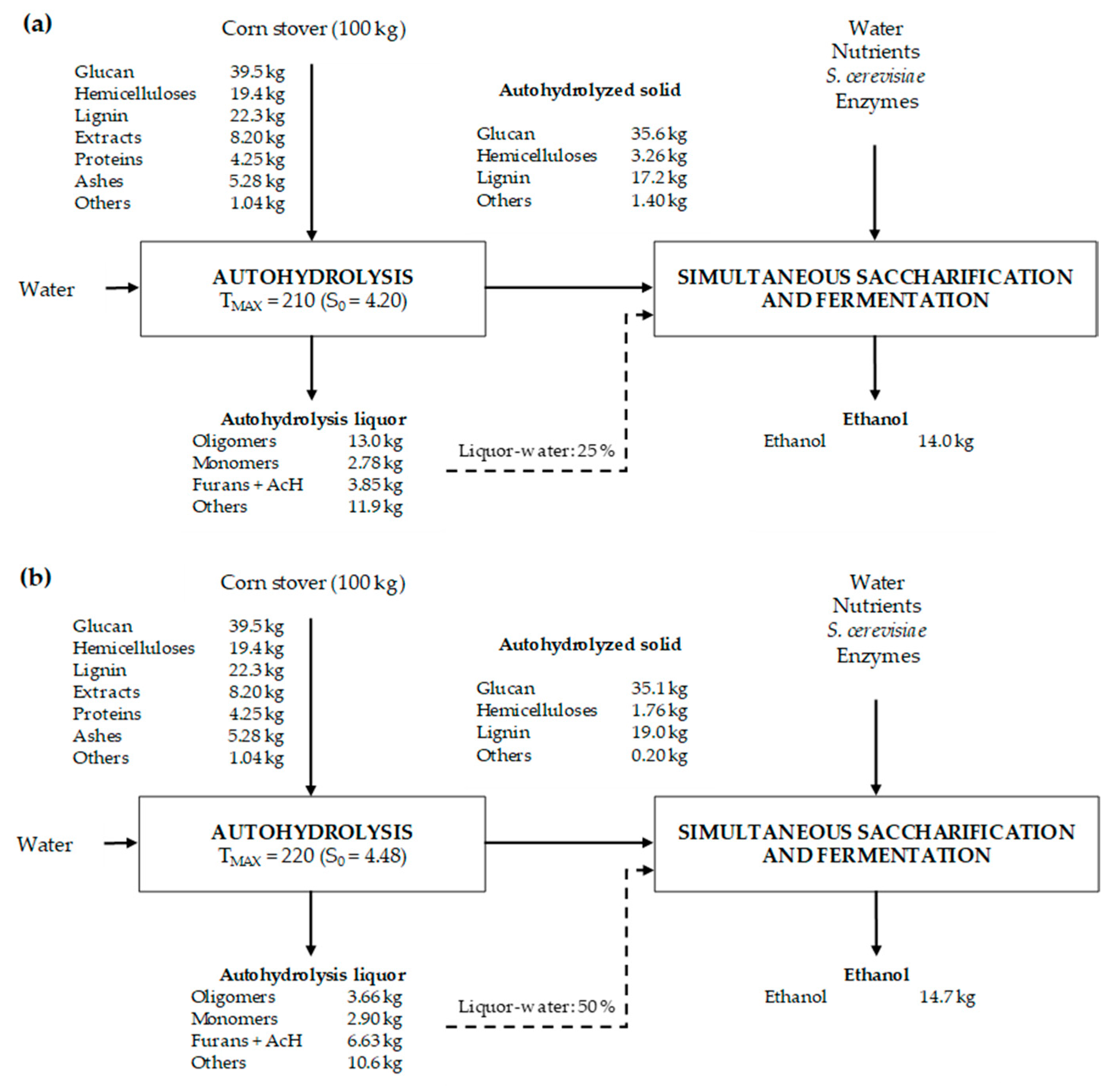

3.4. Overall Mass Balance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Del Río, P.G.; Gomes-Dias, J.S.; Rocha, C.M.R.; Romaní, A.; Garrote, G.; Domingues, L. Recent trends on seaweed fractionation for liquid biofuels production. Bioresour. Technol. 2020, 299, 122613. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, E.; del Río, P.G.; Romaní, A.; Garrote, G.; Gullón, P.; de Vega, A. Formosolv pretreatment to fractionate paulownia wood following a biorefinery approach: Isolation and characterization of the lignin fraction. Agronomy 2020, 10, 1205. [Google Scholar] [CrossRef]

- Sánchez-Gutiérrez, M.; Espinosa, E.; Bascón-Villegas, I.; Pérez-Rodríguez, F.; Carrasco, E.; Rodríguez, A. Production of cellulose nanofibers from olive tree harvest - A residue with wide applications. Agronomy 2020, 10, 696. [Google Scholar] [CrossRef]

- Von Cossel, M.; Wagner, M.; Lask, J.; Magenau, E.; Bauerle, A.; Von Cossel, V.; Warrach-Sagi, K.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; et al. Prospects of bioenergy cropping systems for a more social-ecologically sound bioeconomy. Agronomy 2019, 9, 605. [Google Scholar] [CrossRef]

- Razola-Díaz, M.; del, C.; Verardo, V.; Martín-García, B.; Díaz-De-Cerio, E.; García-Villanova, B.; Guerra-Hernández, E.J. Establishment of acid hydrolysis by box-behnken methodology as pretreatment to obtain reducing sugars from tiger nut byproducts. Agronomy 2020, 10, 477. [Google Scholar] [CrossRef]

- Krafft, M.J.; Bendler, M.; Schreiber, A.; Saake, B. Steam refining with subsequent alkaline lignin extraction as an alternative pretreatment method to enhance the enzymatic digestibility of corn stover. Agronomy 2020, 10, 811. [Google Scholar] [CrossRef]

- Mafa, M.S.; Malgas, S.; Bhattacharya, A.; Rashamuse, K. The effects of alkaline pretreatment on agricultural biomasses (corn cob and sweet sorghum bagasse) and their hydrolysis by a termite-derived enzyme cocktail. Agronomy 2020, 10, 1211. [Google Scholar] [CrossRef]

- Mkabayi, L.; Malgas, S.; Wilhelmi, B.S.; Pletscheke, B.I. Evaluating feruloyl esterase—Xylanase synergism for hydroxycinnamic zcid and xylo-oligosaccharide production from untreated, hydrothermally pre-treated and dilute-acid pre-treated corn cobs. Agronomy 2020, 10, 688. [Google Scholar] [CrossRef]

- Tandzi, L.N.; Mutengwa, C.S. Estimation of maize (Zea mays L.) yield per harvest area: Appropriate methods. Agronomy 2020, 10, 29. [Google Scholar] [CrossRef]

- López-Malvar, A.; Djemel, A.; Santiago, R.; Revilla, P. Assessment of Algerian maize populations for saccharification and nutritive value. Agronomy 2020, 10, 646. [Google Scholar] [CrossRef]

- Momayez, F.; Karimi, K.; Taherzadeh, M.J. Energy recovery from industrial crop wastes by dry anaerobic digestion: A review. Ind. Crop. Prod. 2019, 129, 673–687. [Google Scholar] [CrossRef]

- Zhao, Y.; Damgaard, A.; Christensen, T.H. Bioethanol from corn stover—A review and technical assessment of alternative biotechnologies. Prog. Energy Combust. Sci. 2018, 67, 275–291. [Google Scholar] [CrossRef]

- Akter, S.; Zabed, H.M.; Sahu, J.N.; Chowdhury, F.I.; Faruq, G.; Boyce, A.N.; Qi, X. Bioethanol production from water-soluble and structural carbohydrates of normal and high sugary corn stovers harvested at three growth stages. Energy Convers. Manag. 2020, 221, 113104. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Zong, Q.J.; Li, W.C.; Chai, M.Z.; Xu, T.; Liu, H.; Fan, H.; Li, B.Z.; Yuan, Y.J. Temperature profiled simultaneous saccharification and co-fermentation of corn stover increases ethanol production at high solid loading. Energy Convers. Manag. 2020, 205, 112344. [Google Scholar] [CrossRef]

- Jenkins, B.M. Global Agriculture: Industrial Feedstocks for Energy and Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 3. [Google Scholar] [CrossRef]

- Kont, R.; Kurašin, M.; Teugjas, H.; Väljamäe, P. Strong cellulase inhibitors from the hydrothermal pretreatment of wheat straw. Biotechnol. Biofuels 2013, 6, 1–14. [Google Scholar] [CrossRef]

- Pontes, R.; Romaní, A.; Michelin, M.; Domingues, L.; Teixeira, J.; Nunes, J. Comparative autohydrolysis study of two mixtures of forest and marginal land resources for co-production of biofuels and value-added compounds. Renew. Energy 2018, 128, 20–29. [Google Scholar] [CrossRef]

- Mondylaksita, K.; Ferreira, J.A.; Millati, R.; Budhijanto, W.; Niklasson, C.; Taherzadeh, M.J. Recovery of high purity lignin and digestible cellulose from oil palm empty fruit bunch using low acid-catalyzed organosolv pretreatment. Agronomy 2020, 10, 674. [Google Scholar] [CrossRef]

- Gullón, B.; Eibes, G.; Dávila, I.; Vila, C.; Labidi, J.; Gullón, P. Valorization of vine shoots based on the autohydrolysis fractionation optimized by a kinetic approach. Ind. Eng. Chem. Res. 2017, 56, 14164–14171. [Google Scholar] [CrossRef]

- Del Río, P.G.; Domínguez, V.D.; Domínguez, E.; Gullón, P.; Gullón, B.; Garrote, G.; Romaní, A. Comparative study of biorefinery processes for the valorization of fast-growing Paulownia wood. Bioresour. Technol. 2020, 314, 123722. [Google Scholar] [CrossRef]

- Rico, X.; Gullón, B.; Alonso, J.L.; Parajó, J.C.; Yáñez, R. Valorization of peanut shells: Manufacture of bioactive oligosaccharides. Carbohydr. Polym. 2018, 183, 21–28. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Conrad, M.; Sun, S.N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef] [PubMed]

- Rivas, S.; Moure, A.; Parajó, J.C. Pretreatment of hazelnut shells as a key strategy for the solubilization and valorization of hemicelluloses into bioactive compounds. Agronomy 2020, 10, 760. [Google Scholar] [CrossRef]

- Del Río, P.G.; Domínguez, E.; Domínguez, V.D.; Romaní, A.; Domingues, L.; Garrote, G. Third generation bioethanol from invasive macroalgae Sargassum muticum using autohydrolysis pretreatment as first step of a biorefinery. Renew. Energy 2019, 141, 728–735. [Google Scholar] [CrossRef]

- Romaní, A.; Ruiz, H.A.; Pereira, F.B.; Teixeira, J.A.; Domingues, L. Integrated approach for effective bioethanol production using whole slurry from autohydrolyzed Eucalyptus globulus wood at high-solid loadings. Fuel 2014, 135, 482–491. [Google Scholar] [CrossRef]

- Jung, Y.H.; Park, H.M.; Kim, I.J.; Park, Y.C.; Seo, J.H.; Kim, K.H. One-pot pretreatment, saccharification and ethanol fermentation of lignocellulose based on acid-base mixture pretreatment. Rsc Adv. 2014, 4, 55318–55327. [Google Scholar] [CrossRef]

- Huang, Z.J.; Feng, G.J.; Lin, K.P.; Pu, F.L.; Tan, Y.M.; Tu, W.C.; Han, Y.L.; Hou, X.D.; Zhang, H.M.; Zhang, Y. Significant boost in xylose yield and enhanced economic value with one-pot process using deep eutectic solvent for the pretreatment and saccharification of rice straw. Ind. Crop. Prod. 2020, 152, 112515. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Z. One-pot conversion of carbohydrates into furan derivatives via furfural and 5-hydroxylmethylfurfural as intermediates. ChemSusChem 2016, 9, 2015–2036. [Google Scholar] [CrossRef]

- Li, H.; Bhadury, P.S.; Riisager, A.; Yang, S. One-pot transformation of polysaccharides via multi-catalytic processes. Catal. Sci. Technol. 2014, 4, 4138–4168. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure (LAP). Natl. Renew. Energy Lab. 2008, 1617, 1–16. [Google Scholar]

- Sluiter, A.; Hames, B.; Hyman, D.; Payne, C.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Wolfe, J. Determination of total solids in biomass and total dissolved solids in liquid process samples. Laboratory Analytical Procedure (LAP). Natl. Renew. Energy Lab. 2008, 9, 1–6. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of ash in biomass. Laboratory Analytical Procedure (LAP). Natl. Renew. Energy Lab. 2008, 1–5. [Google Scholar]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass. Laboratory Analytical Procedure (LAP). Natl. Renew. Energy Lab. 2008, 1–9. [Google Scholar] [CrossRef]

- Lavoie, J.M.; Capek-Menard, E.; Gauvin, H.; Chornet, E. Production of pulp from Salix viminalis energy crops using the FIRSST process. Bioresour. Technol. 2010, 101, 4940–4946. [Google Scholar] [CrossRef] [PubMed]

- Buruiana, C.T.; Vizireanu, C.; Garrote, G.; Parajó, J.C. Optimization of corn stover biorefinery for coproduction of oligomers and second generation bioethanol using non-isothermal autohydrolysis. Ind. Crop. Prod. 2014, 54, 32–39. [Google Scholar] [CrossRef]

- Barros-Ríos, J.; Romaní, A.; Peleteiro, S.; Garrote, G.; Ordas, B. Second-generation bioethanol of hydrothermally pretreated stover biomass from maize genotypes. Biomass Bioenergy 2016, 90, 42–49. [Google Scholar] [CrossRef]

- Ghose, T.K. Measurement fo cellulase activities. Pure Appl. Chem. 1987, 59, 695–702. [Google Scholar] [CrossRef]

- Paquot, P.M.; Thonart, P. Hydrolyse enzymatique de la ceilulose régénérée. Holzforschung 1982, 36, 177–181. [Google Scholar] [CrossRef]

- Romaní, A.; Garrote, G.; Alonso, J.L.; Parajó, J.C. Bioethanol production from hydrothermally pretreated Eucalyptus globulus wood. Bioresour. Technol. 2010, 101, 8706–8712. [Google Scholar] [CrossRef]

- Romaní, A.; Garrote, G.; Parajó, J.C. Bioethanol production from autohydrolyzed Eucalyptus globulus by Simultaneous Saccharification and Fermentation operating at high solids loading. Fuel 2012, 94, 305–312. [Google Scholar] [CrossRef]

- Dávila, I.; Gordobil, O.; Labidi, J.; Gullón, P. Assessment of suitability of vine shoots for hemicellulosic oligosaccharides production through aqueous processing. Bioresour. Technol. 2016, 211, 636–644. [Google Scholar] [CrossRef]

- Sievers, C.; Marzialetti, T.; Hoskins, T.J.C.; Valenzuela Olarte, M.B.; Agrawal, P.K.; Jones, C.W. Quantitative solid state NMR analysis of residues from acid hydrolysis of loblolly pine wood. Bioresour. Technol. 2009, 100, 4758–4765. [Google Scholar] [CrossRef] [PubMed]

- Shinde, S.D.; Meng, X.; Kumar, R.; Ragauskas, A.J. Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem. 2018, 20, 2192–2205. [Google Scholar] [CrossRef]

- Gullón, B.; Eibes, G.; Dávila, I.; Moreira, M.T.; Labidi, J.; Gullón, P. Hydrothermal treatment of chestnut shells (Castanea sativa) to produce oligosaccharides and antioxidant compounds. Carbohydr. Polym. 2018, 192, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Chandra, R.; Takada, M.; Del Rio, P.; Kim, K.H.; Kim, C.S.; Liu, L.Y.; Renneckar, S.; Saddler, J. Alkaline sulfonation and thermomechanical pulping pretreatment of softwood chips and pellets to enhance enzymatic hydrolysis. Bioresour. Technol. 2020, 315, 123789. [Google Scholar] [CrossRef]

- Dávila, I.; Gullón, B.; Labidi, J.; Gullón, P. Multiproduct biorefinery from vine shoots: Bio-ethanol and lignin production. Renew. Energy 2019, 142, 612–623. [Google Scholar] [CrossRef]

- Aïssa, K.; Novy, V.; Nielsen, F.; Saddler, J. Use of carbohydrate binding modules to elucidate the relationship between fibrillation, hydrolyzability, and accessibility of cellulosic substrates. Acs Sustain. Chem. Eng. 2019, 7, 1113–1119. [Google Scholar] [CrossRef]

- Du, C.; Li, Y.; Zong, H.; Yuan, T.; Yuan, W.; Jiang, Y. Production of bioethanol and xylitol from non-detoxified corn cob via a two-stage fermentation strategy. Bioresour. Technol. 2020, 310, 123427. [Google Scholar] [CrossRef]

- Iwaki, A.; Kawai, T.; Yamamoto, Y.; Izawa, S. Biomass conversion inhibitors furfural and 5-hydroxymethylfurfural induce formation of messenger RNP granules and attenuate translation activity in Saccharomyces cerevisiae. Appl. Env. Microbiol. 2013, 79, 1661–1667. [Google Scholar] [CrossRef]

- Álvarez, C.; González, A.; Alonso, J.L.; Sáez, F.; Negro, M.J.; Gullón, B. Xylooligosaccharides from steam-exploded barley straw: Structural features and assessment of bifidogenic properties. Food Bioprod. Process. 2020, 124, 131–142. [Google Scholar] [CrossRef]

- González-García, S.; Gullón, B.; Feijoo, G.; Moreira, M.T. Environmental concerns on the production of value-added bioproducts from residual renewable sources. Adv. Feed. Convers. Technol. Altern. Fuels Bioprod. New Technol. Chall. Oppor. 2019, 339–353. [Google Scholar] [CrossRef]

- Hafid, H.S.; Nor ‘Aini, A.R.; Mokhtar, M.N.; Talib, A.T.; Baharuddin, A.S.; Umi Kalsom, M.S. Over production of fermentable sugar for bioethanol production from carbohydrate-rich Malaysian food waste via sequential acid-enzymatic hydrolysis pretreatment. Waste Manag. 2017, 67, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Pereira, F.B.; Romaní, A.; Ruiz, H.A.; Teixeira, J.A.; Domingues, L. Industrial robust yeast isolates with great potential for fermentation of lignocellulosic biomass. Bioresour. Technol. 2014, 161, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Kandhola, G.; Rajan, K.; Djioleu, A.; Carrier, D.J.; Hood, K.R.; Hood, E.E. Effects of oligosaccharides isolated from pinewood hot water pre-hydrolyzates on recombinant cellulases. Front. Bioeng. Biotechnol. 2018, 6, 1–11. [Google Scholar] [CrossRef]

- Feifičová, D.; Šnajdr, J.; Siglová, M.; Čejková, A.; Masák, J.; Jirků, V. Influence of humic acids on the growth of the microorganisms utilizing toxic compounds (comparison between yeast and bacteria). Chim. (Aarau) 2005, 59, 749–752. [Google Scholar] [CrossRef]

- Ko, J.K.; Um, Y.; Woo, H.M.; Kim, K.H.; Lee, S.M. Ethanol production from lignocellulosic hydrolysates using engineered Saccharomyces cerevisiae harboring xylose isomerase-based pathway. Bioresour. Technol. 2016, 209, 290–296. [Google Scholar] [CrossRef] [PubMed]

| Component | g/100 g Oven-Dried Corn Stover ± Standard Deviation |

|---|---|

| Glucan | 39.5 ± 0.4 |

| Xylan | 15.2 ± 0.2 |

| Arabinan | 2.07 ± 0.05 |

| Acetyl groups | 2.16 ± 0.01 |

| Klason lignin | 22.3 ± 0.0 |

| Ashes | 5.28 ± 0.06 |

| Extractives | 8.20 ± 0.18 |

| Proteins | 4.25 ± 0.06 |

| Temperature (°C) | 200 | 210 | 220 | 230 | 240 |

| S0 (dimensionless) | 3.93 | 4.20 | 4.48 | 4.75 | 5.03 |

| SY (g of autohydrolyzed corn stover/100 g of raw material) | 64.5 | 57.5 | 56.1 | 55.7 | 55.5 |

| NVC (g of nonvolatile compounds in liquid fraction/100 g of raw material) | 32.3 | 31.5 | 23.8 | 20.8 | 18.8 |

| VC (g of volatile compounds in liquid fraction/100 g of raw material) | 3.14 | 11.0 | 20.0 | 23.5 | 25.7 |

| Solid fraction composition (g/100 g of autohydrolyzed corn stover, oven-dried basis (o.d.b.)) | |||||

| Glucan | 55.4 ± 0.3 | 61.9 ± 0.4 | 62.6 ± 0.5 | 60.5 ± 0.3 | 58.0 ± 0.5 |

| Xylan | 8.82 ± 0.15 | 5.19 ± 0.14 | 2.98 ± 0.06 | 1.87 ± 0.09 | 0.00 ± 0.00 |

| Arabinan | 0.52 ± 0.06 | 0.06 ± 0.02 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Acetyl groups | 0.80 ± 0.05 | 0.42 ± 0.08 | 0.15 ± 0.07 | 0.06 ± 0.02 | 0.03 ± 0.01 |

| Klason lignin | 28.5 ± 0.2 | 30.0 ± 0.3 | 33.9 ± 0.1 | 36.2 ± 0.7 | 39.7 ± 0.2 |

| Others (by difference) | 5.96 | 2.43 | 0.36 | 1.38 | 2.22 |

| Liquid fraction composition (g/L) | |||||

| Glucose | 0.69 | 0.57 | 0.84 | 0.73 | 0.53 |

| Xylose | 0.56 | 1.89 | 2.05 | 0.86 | 0.28 |

| Arabinose | 0.28 | 0.56 | 0.25 | 0.00 | 0.00 |

| Acetic Acid | 2.58 | 3.44 | 4.70 | 5.03 | 5.18 |

| Hydroxymethylfurfural | 0.05 | 0.11 | 0.23 | 0.55 | 0.65 |

| Furfural | 0.29 | 0.80 | 1.97 | 1.96 | 1.63 |

| Glucooligosaccharides | 2.57 ± 0.06 | 3.15 ± 0.01 | 2.13 ± 0.02 | 1.03 ± 0.05 | 0.39 ± 0.04 |

| Xylooligosaccharides | 11.6 ± 0.2 | 10.5 ± 0.0 | 1.82 ± 0.01 | 0.00 ± 0.00 | 0.12 ± 0.01 |

| Arabinooligosaccharides | 0.93 ± 0.06 | 0.54 ± 0.01 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Acetyl groups linked to oligosaccharides | 0.59 ± 0.02 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Autohydrolysis Temperature (°C) | Liquor (%) | [Ethanol]MAX (g/L) | ECMAX (%) | [Ethanol]72 h (g/L) | QP 72h (g/(L·h)) |

|---|---|---|---|---|---|

| 210 | 100 | 32.6 ± 1.0 a | 59 ± 2.9 | 28.5 ± 1.7 a | 0.395 ± 0.023 |

| 75 | 32.2 ± 1.0 a | 59 ± 1.8 | 30.3 ± 0.3 ab | 0.421 ± 0.004 | |

| 50 | 33.6 ± 0.2 a | 62 ± 0.3 | 33.6 ± 0.2 bc | 0.467 ± 0.002 | |

| 25 | 36.3 ± 0.5 a | 68 ± 0.9 | 35.2 ± 0.5 c | 0.489 ± 0.007 | |

| 0 | 34.8 ± 1.4 a | 66 ± 2.6 | 30.0 ± 0.4 ab | 0.417 ± 0.006 | |

| 220 | 100 | 37.7 ± 0.5 ab | 68 ± 0.8 | 18.3 ± 1.1 a | 0.254 ± 0.015 |

| 75 | 38.2 ± 0.4 b | 69 ± 0.8 | 27.2 ± 1.7 b | 0.377 ± 0.008 | |

| 50 | 39.1 ± 0.3 b | 71 ± 0.5 | 24.5 ± 1.3 b | 0.340 ± 0.016 | |

| 25 | 38.3 ± 0.2 b | 71 ± 0.3 | 23.6 ± 1.1 ab | 0.328 ± 0.014 | |

| 0 | 34.6 ± 1.1 a | 64 ± 2.0 | 23.3 ± 1.1 ab | 0.324 ± 0.011 | |

| 230 | 100 | 41.9 ± 1.4 a | 79 ± 2.6 | 27.6 ± 1.6 a | 0.383 ± 0.022 |

| 75 | 40.7 ± 1.1 a | 77 ± 2.0 | 36.5 ± 2.0 b | 0.522 ± 0.028 | |

| 50 | 40.3 ± 1.7 a | 76 ± 3.3 | 35.6 ± 1.5 ab | 0.509 ± 0.022 | |

| 25 | 40.0 ± 0.8 a | 76 ± 1.5 | 40.0 ± 0.8 b | 0.571 ± 0.011 | |

| 0 | 38.1 ± 1.5 a | 73 ± 2.8 | 38.1 ± 1.5 b | 0.544 ± 0.021 | |

| 240 | 100 | 0.85 ± 0.3 a | 1.7 ± 0.6 | 0.85 ± 0.3 a | 0.012 ± 0.002 |

| 75 | 1.29 ± 0.1 a | 2.5 ± 0.3 | 1.26 ± 0.1 a | 0.017 ± 0.001 | |

| 50 | 37.5 ± 0.7 b | 74 ± 1.4 | 35.1 ± 1.2 c | 0.488 ± 0.000 | |

| 25 | 36.8 ± 1.7 b | 73 ± 3.4 | 28.6 ± 1.6 b | 0.398 ± 0.023 | |

| 0 | 37.2 ± 2.0 b | 74 ± 4.0 | 32.7 ± 2.0 bc | 0.454 ± 0.016 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

G. del Río, P.; Gullón, P.; Rebelo, F.R.; Romaní, A.; Garrote, G.; Gullón, B. A Whole-Slurry Fermentation Approach to High-Solid Loading for Bioethanol Production from Corn Stover. Agronomy 2020, 10, 1790. https://doi.org/10.3390/agronomy10111790

G. del Río P, Gullón P, Rebelo FR, Romaní A, Garrote G, Gullón B. A Whole-Slurry Fermentation Approach to High-Solid Loading for Bioethanol Production from Corn Stover. Agronomy. 2020; 10(11):1790. https://doi.org/10.3390/agronomy10111790

Chicago/Turabian StyleG. del Río, Pablo, Patricia Gullón, F.R. Rebelo, Aloia Romaní, Gil Garrote, and Beatriz Gullón. 2020. "A Whole-Slurry Fermentation Approach to High-Solid Loading for Bioethanol Production from Corn Stover" Agronomy 10, no. 11: 1790. https://doi.org/10.3390/agronomy10111790

APA StyleG. del Río, P., Gullón, P., Rebelo, F. R., Romaní, A., Garrote, G., & Gullón, B. (2020). A Whole-Slurry Fermentation Approach to High-Solid Loading for Bioethanol Production from Corn Stover. Agronomy, 10(11), 1790. https://doi.org/10.3390/agronomy10111790