RETRACTED: A Bio Polymeric Adhesive Produced by Photo Cross-Linkable Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Preparation of Samples

2.3. Ultra Violet Irradiation for Cross-Linked Systems Formation

2.4. Capacity of H2O-Sorption

2.5. Estimation of Adhesive Capacity: Effect of Substrate

2.6. Morphology of Samples: SEM-Examination

2.7. Dynamic Mechanical Thermal Analysis

2.8. Plasma Degeneration

2.9. Surface Properties

3. Results and Discussions

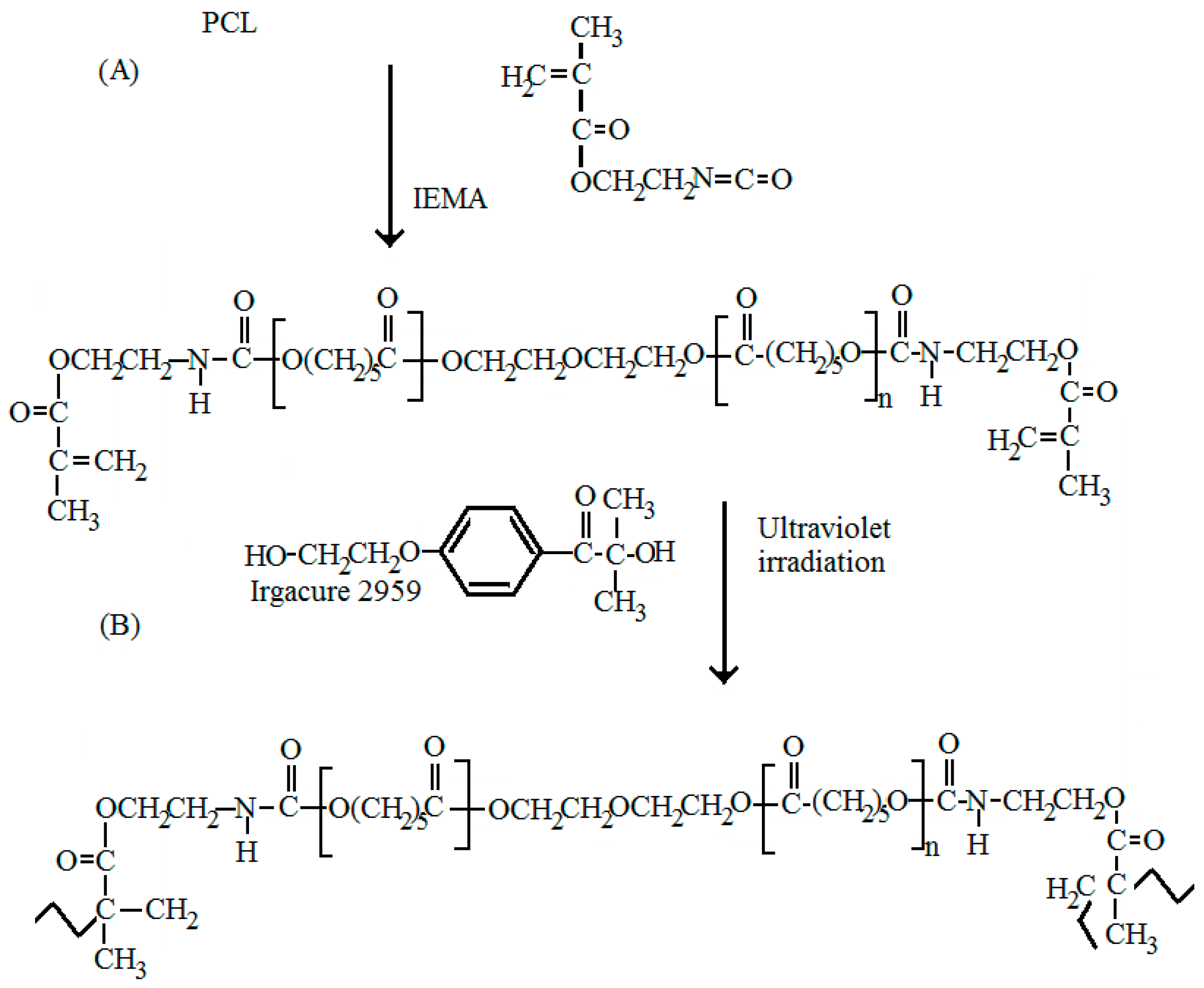

3.1. Preparation of Samples

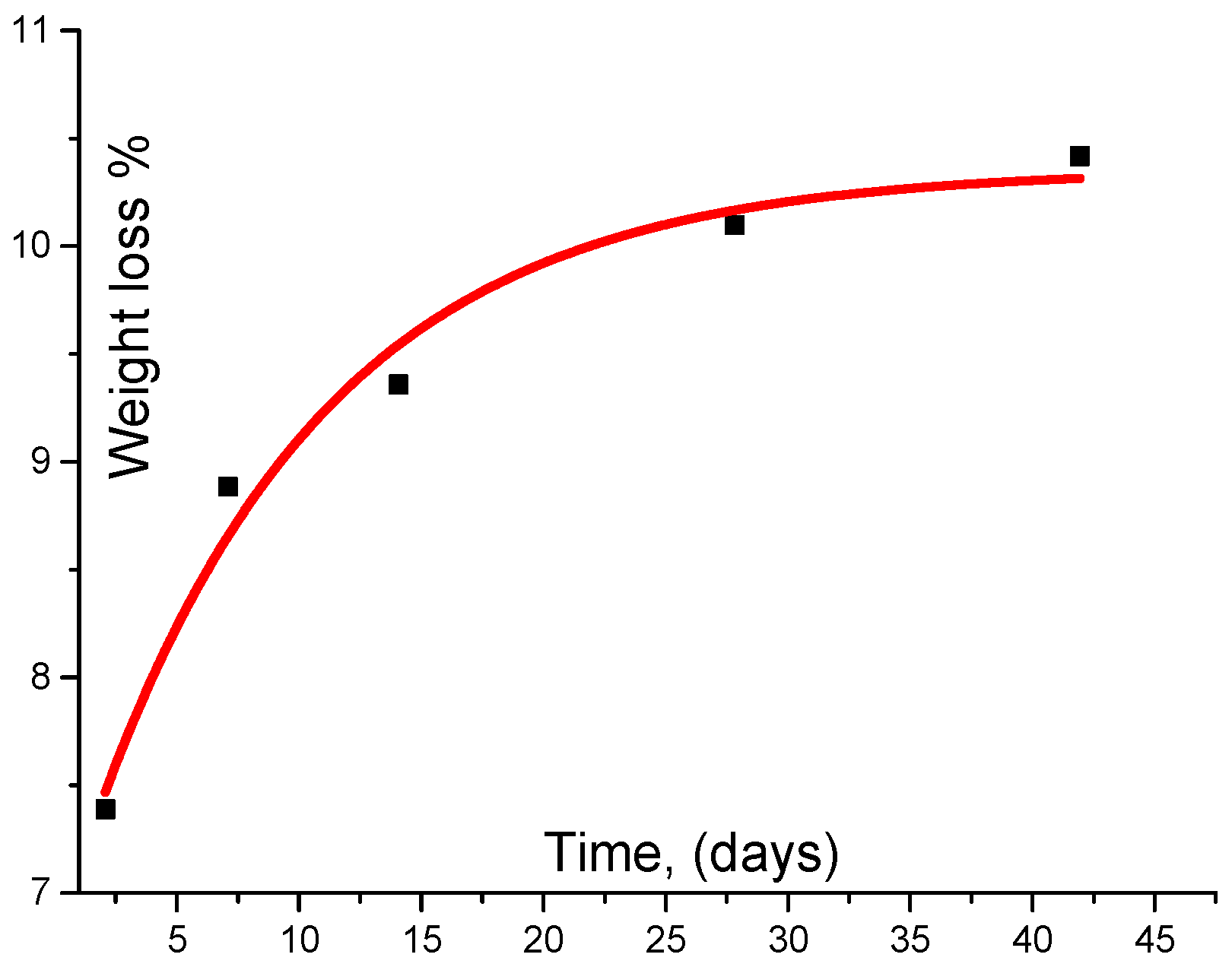

3.2. Capacity of H2O-Sorption

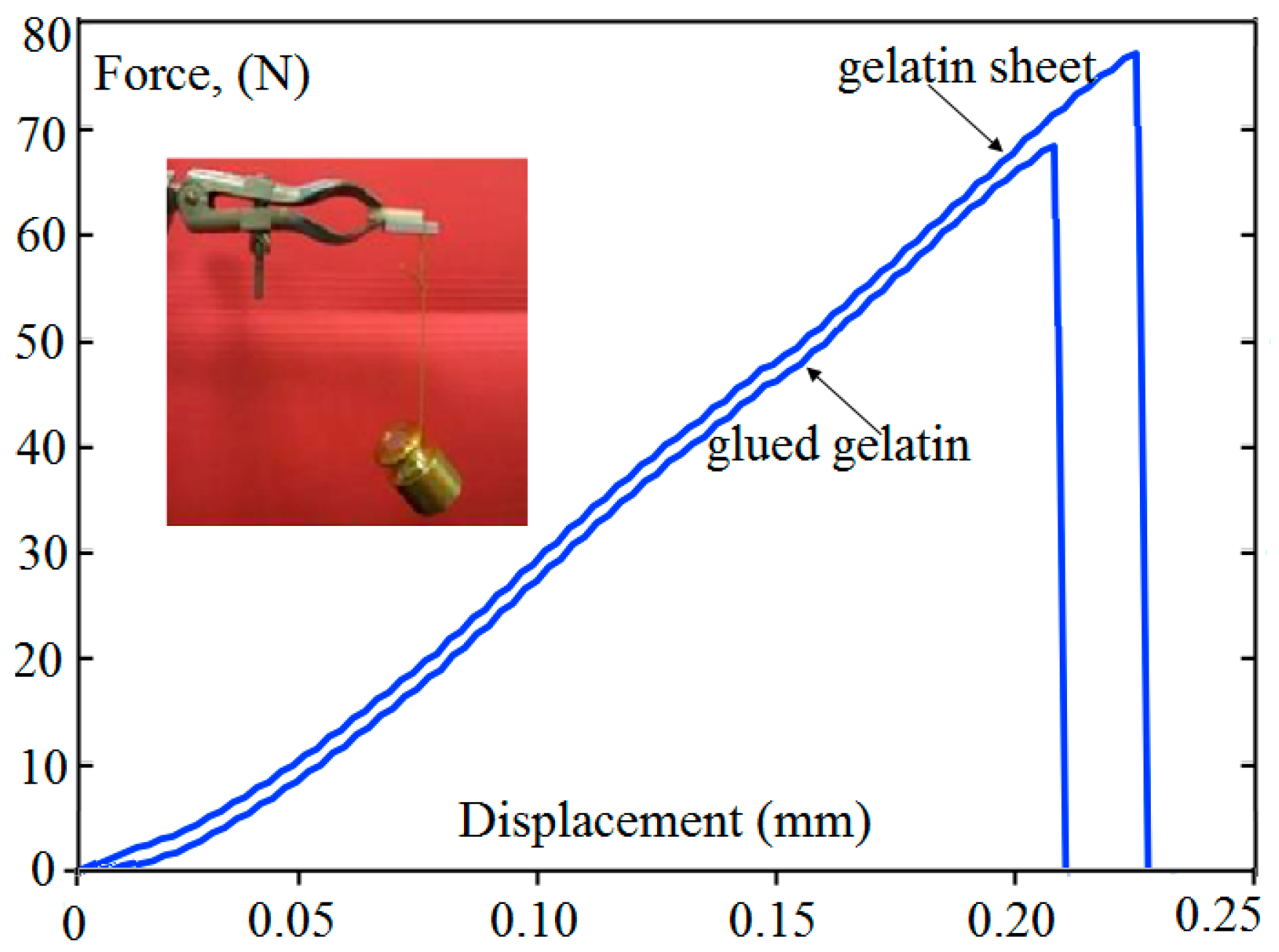

3.3. Estimation of Adhesive Capacity: Effect of Substrate

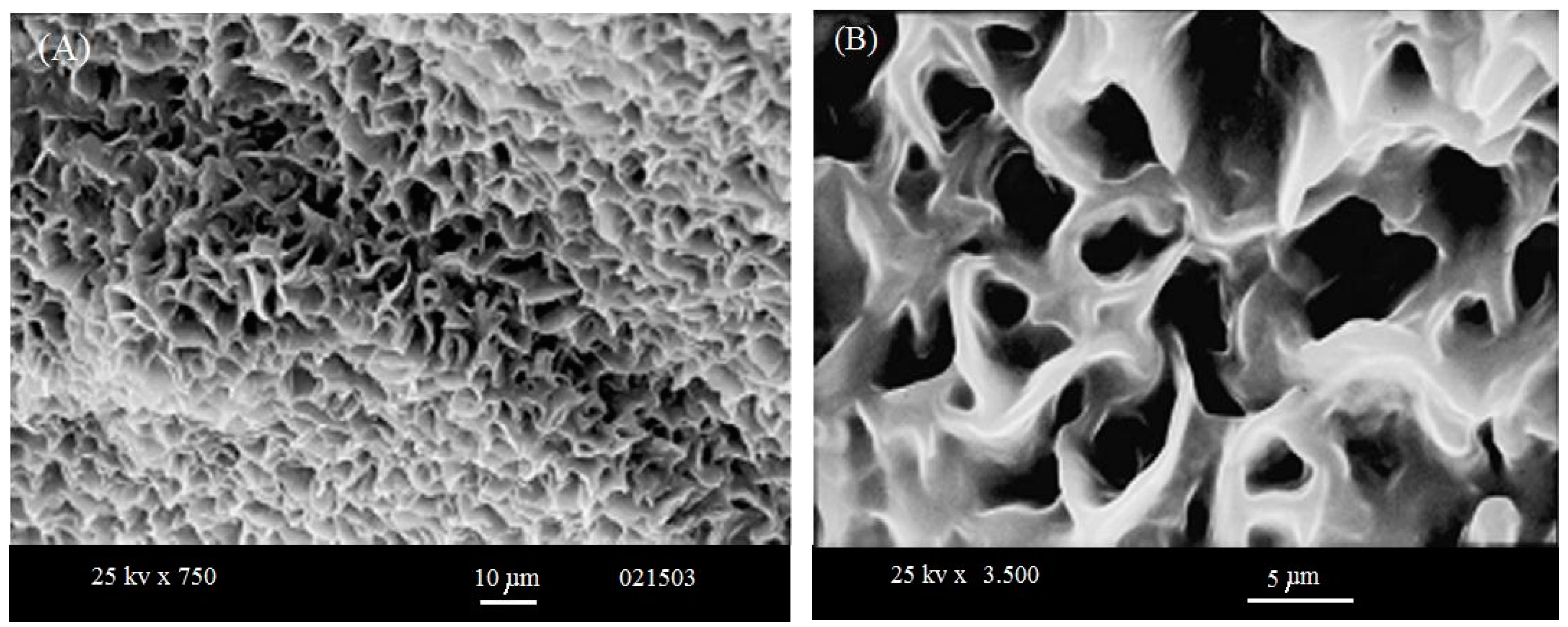

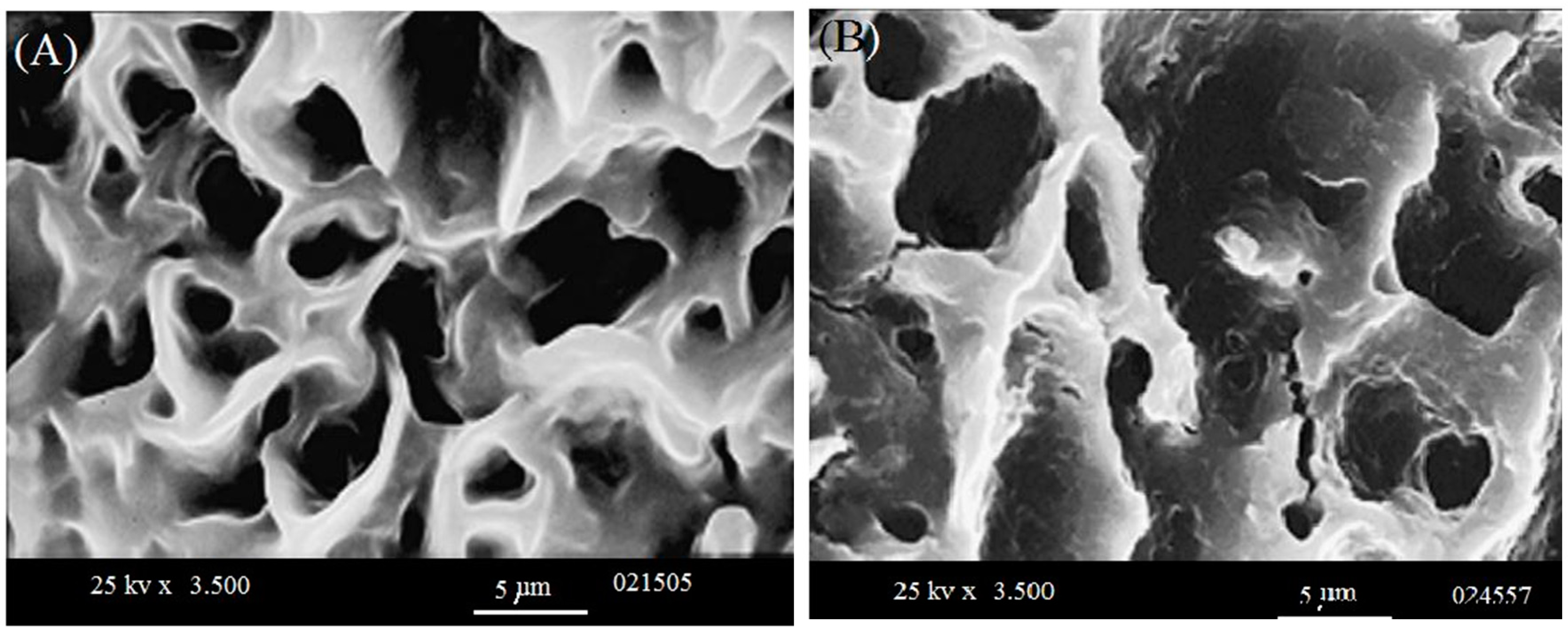

3.4. Morphology of Samples: SEM-Examination

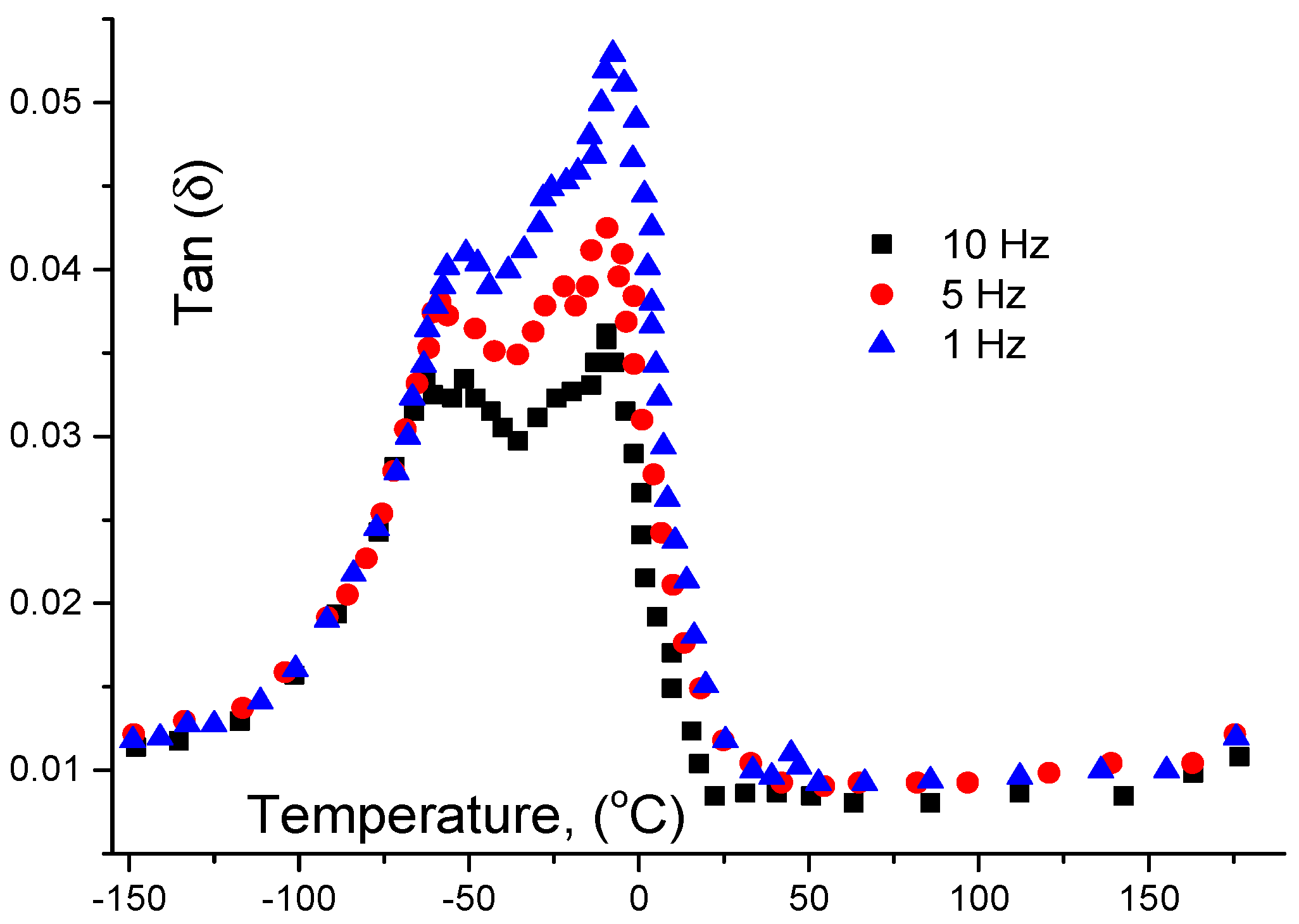

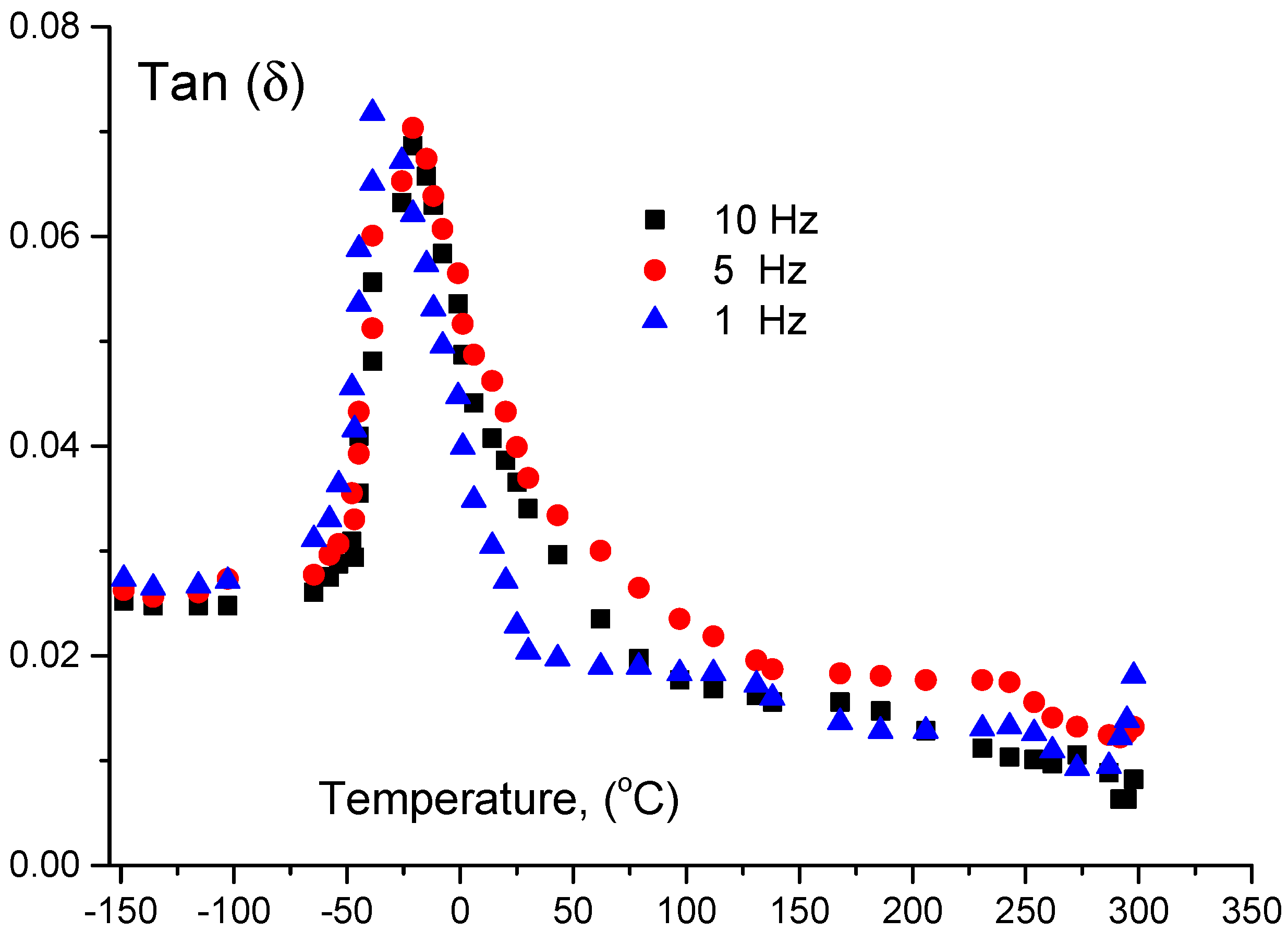

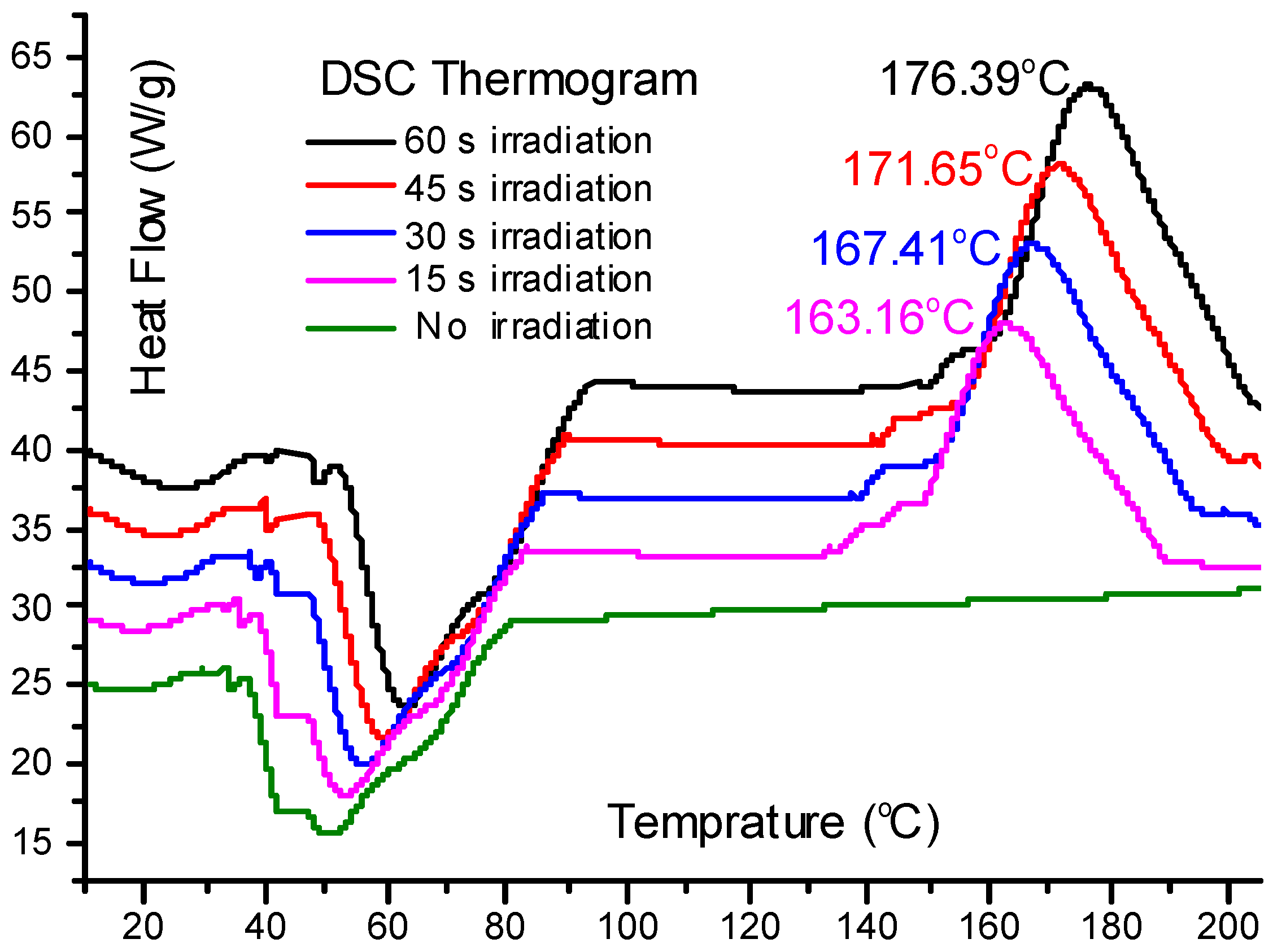

3.5. Dynamic Mechanical Thermal Analysis

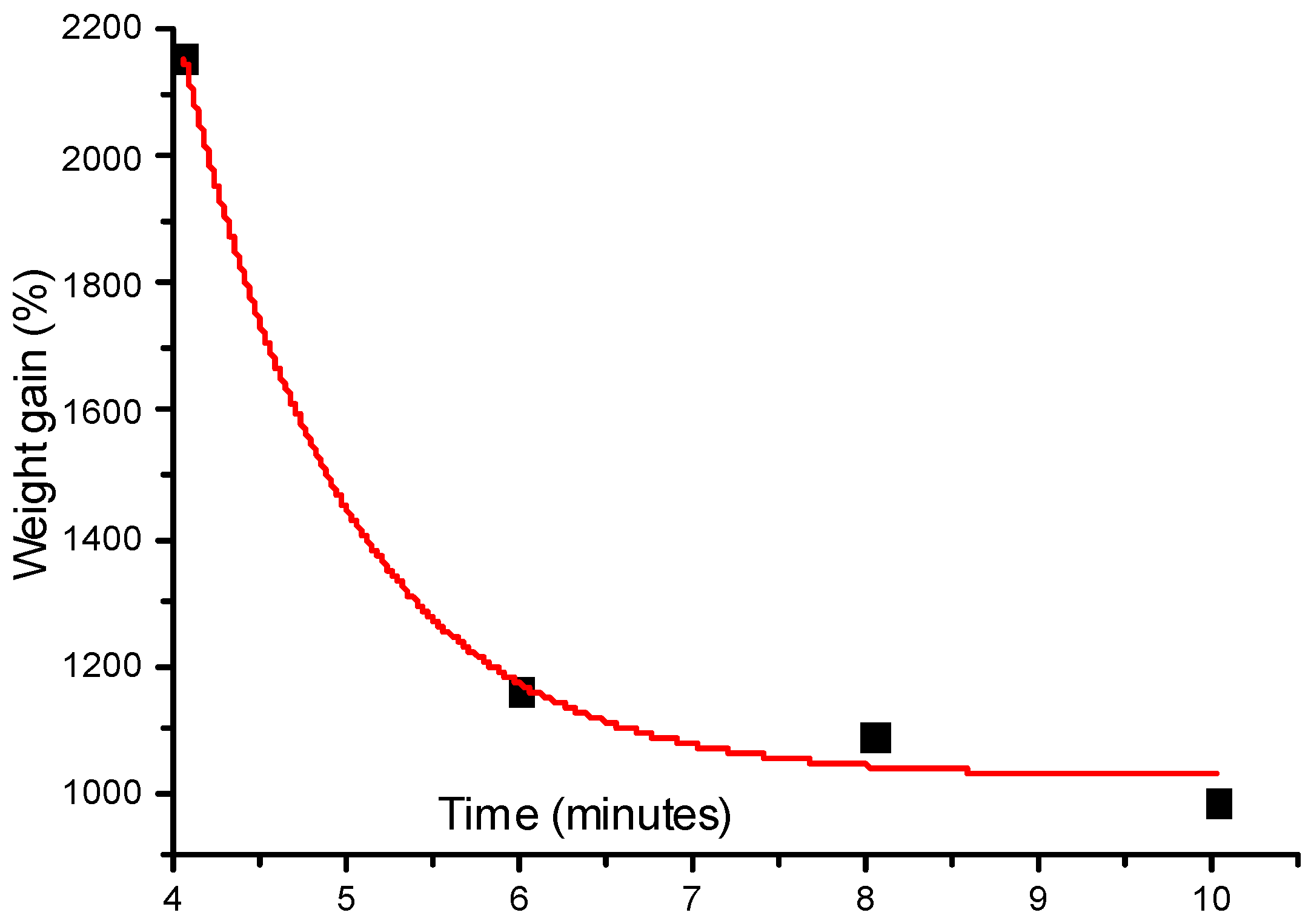

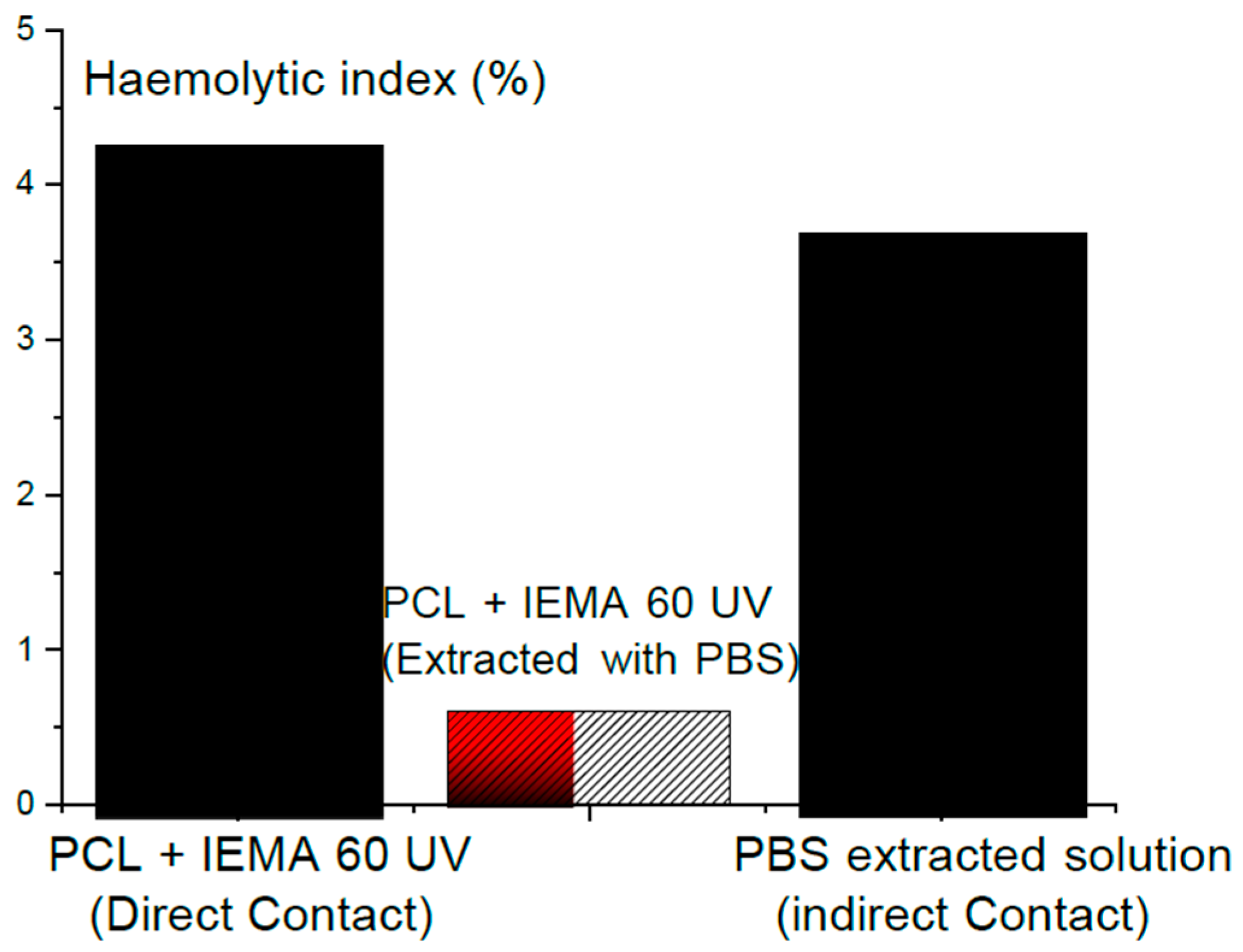

3.6. Plasma Self-Elimination

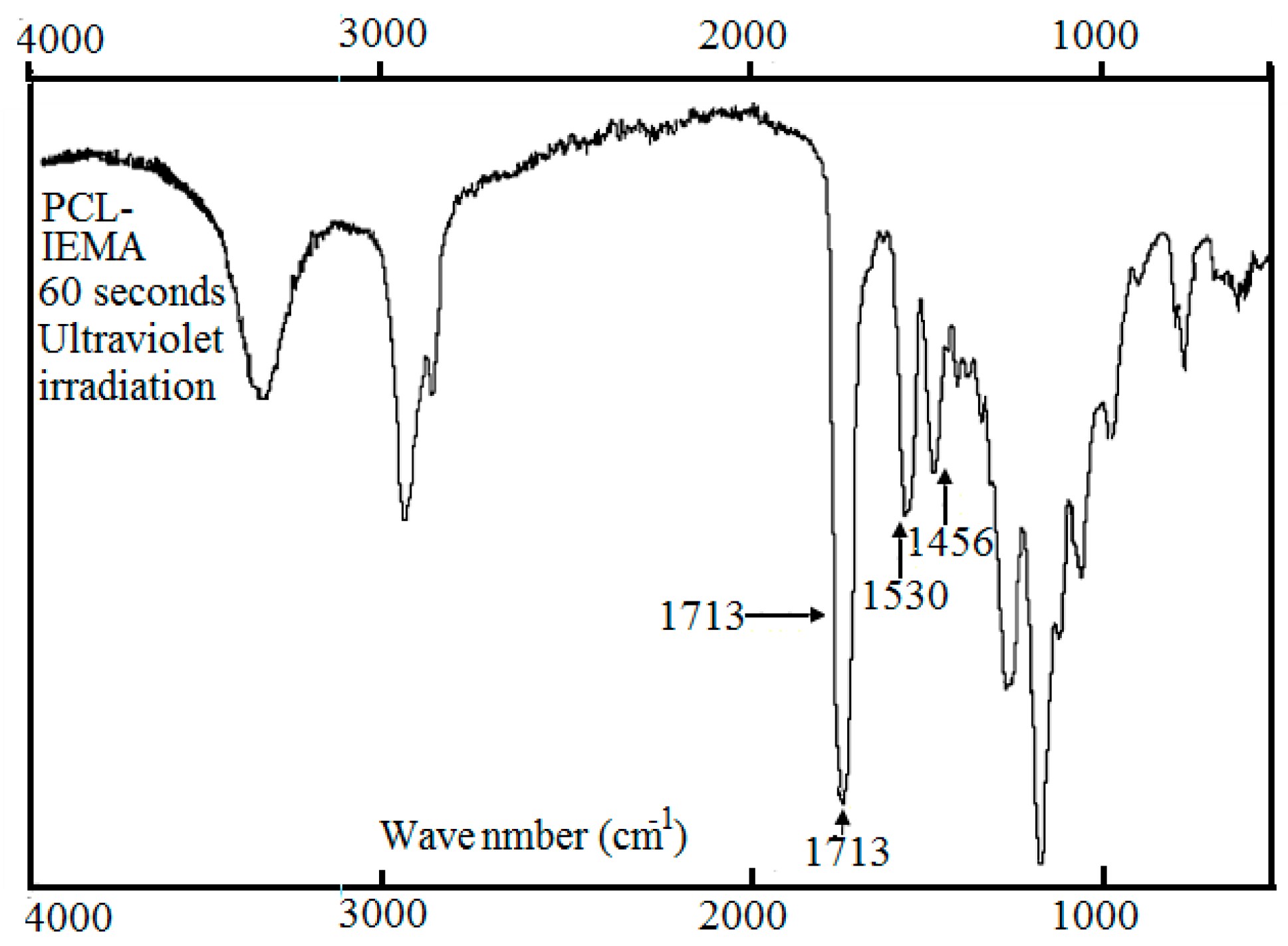

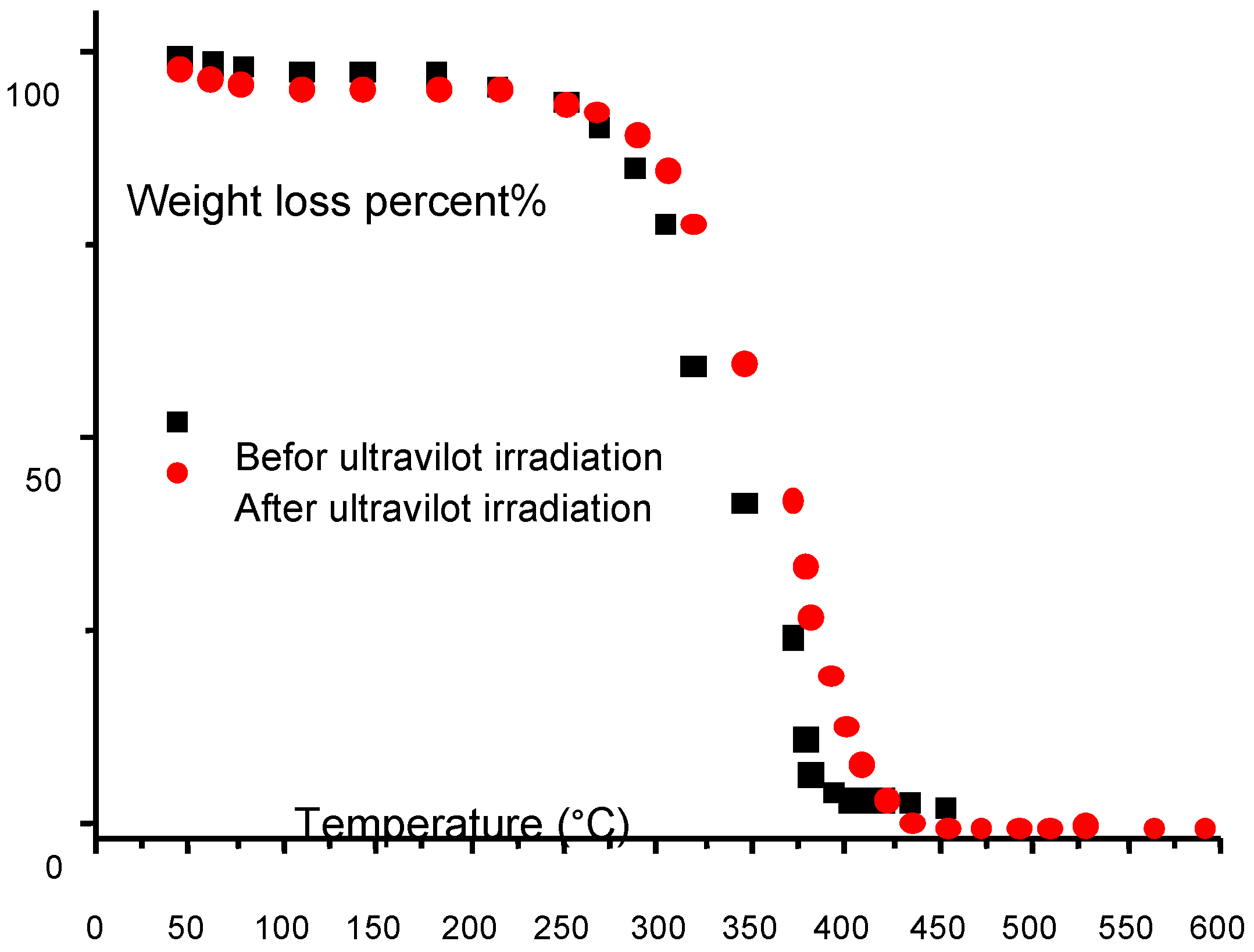

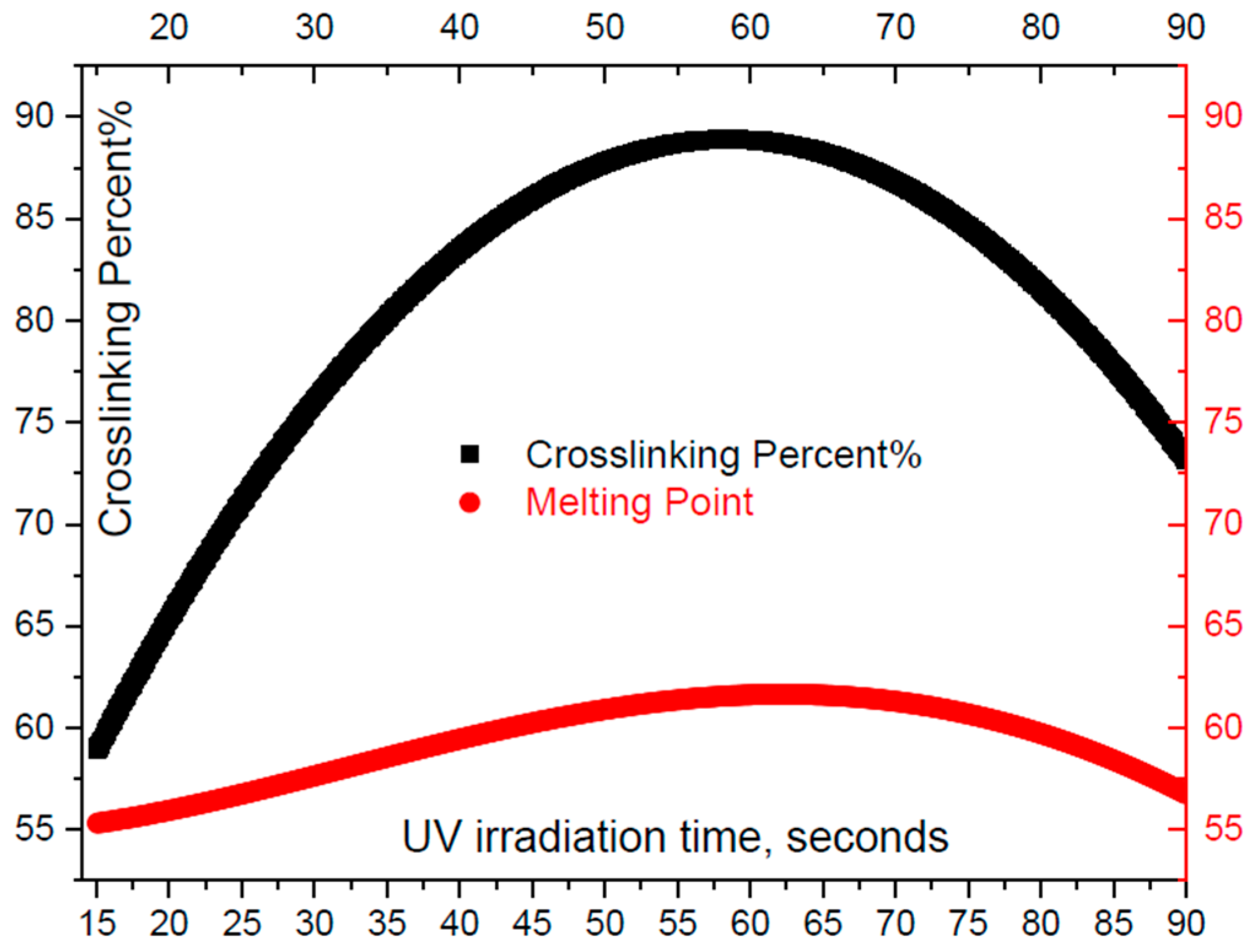

3.7. Cross Linking Estimation

3.8. Surface Properties

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Chen, F.; Yu, S.; Liu, B.; Ni, Y.; Yu, C.; Su, Y.; Zhu, X.; Yu, X.; Zhou, Y.; Yan, D. An injectable enzymatically crosslinked carboxymethylated pullulan/chondroitin sulfate hydrogel for cartilage tissue engineering. Sci. Rep. 2016, 6, 20014. [Google Scholar] [CrossRef] [PubMed]

- Salzig, D.; Leber, J.; Merkewitz, K.; Lange, M.C.; Köster, N.; Czermak, P. Attachment, growth, and detachment of human mesenchymal stem cells in a chemically defined medium. Stem Cells Int. 2016, 2016, 5246584. [Google Scholar] [CrossRef] [PubMed]

- Opperman, T.; Leber, J.; Elseberg, C.; Salzig, D.; Czermak, P. hMSC production in disposable bioreactors in compliance with cGMP guidelines and PAT. Am. Pharm. Rev. 2014, 17, 42–47. [Google Scholar]

- Benedict, C.V.; Picciano, P.T. Bioadhesives for Cell and Tissue Adhesion. U.S. Patent 5108923, 28 April 1992. [Google Scholar]

- Ferreira, P.; Coelho, J.F.J.; Almeida, J.F.; Gil, M.H. Photocrosslinkable polymers for biomedical applications. In Biomedical Engineering—Frontiers and Challenges; Fazel-Rezai, R., Ed.; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- Scognamiglio, F.; Travan, A.; Rustighi, I.; Tarchi, P.; Palmisano, S.; Marsich, E.; Borgogna, M.; Donati, I.; de Manzini, N.; Paoletti, S. Adhesive and sealant interfaces for general surgery applications. J. Biomed. Mater. Res. Part B 2016, 104, 626–639. [Google Scholar] [CrossRef] [PubMed]

- Lally, T.J. Multi-Purpose Bio-Material Composition. U.S. Patent 20120141596 A1, 25 September 2011. [Google Scholar]

- Mehdizadeh, M.; Yang, J. Design strategies and applications of tissue bioadhesives. Macromol. Biosci. 2013, 13, 271–288. [Google Scholar] [CrossRef] [PubMed]

- Ebner, F.M.; Paul, A.; Peters, J.; Hartmann, M. Venous air embolism and intracardiac thrombus after pressurized fibrin glue during liver surgery. Br. J. Anaesth. 2011, 106, 180–182. [Google Scholar] [CrossRef] [PubMed]

- Petrie, E.M. Cyanoacrylate Adhesives in Surgical Applications. Rev. Adhes. Adhes. 2014, 3, 253–310. [Google Scholar] [CrossRef]

- Agarwal, A.; Jacob, S.; Kumar, D.A.; Narasimhan, S. Handshake technique for glued intrascleral haptic fixation of a posterior chamber intraocular lens. J. Cataract Refract. Surg. 2013, 39, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Vangala, M.R.L.; Rudraraju, A.; Subramanyam, R.V. Mounting ground sections of teeth: Cyanoacrylate adhesive versus Canada balsam. J. Oral Maxillofac. Pathol. 2016, 20, 20–24. [Google Scholar] [PubMed]

- Dunn, C.J.; Goa, K.L. Fibrin sealant: A review of its use in surgery and endoscopy. Drugs 1999, 58, 863–886. [Google Scholar] [CrossRef] [PubMed]

- Quan, Y.; Hasegawa, J.; Kamiyama, F. Urethane-Based Pressure Sensitive Adhesive. Patent WO/2016/043300, 24 March 2016. [Google Scholar]

- Cencer, M.; Liu, Y.; Winter, A.; Murley, M.; Meng, H.; Lee, B.P. Effect of pH on the rate of curing and bioadhesive properties of dopamine functionalized poly(ethylene glycol) hydrogels. Biomacromolecules 2014, 15, 2861–2869. [Google Scholar] [CrossRef] [PubMed]

- Karikari, A.S.; Edwards, W.F.; Mecham, J.B.; Long, T.E. Influence of peripheral hydrogen bonding on the mechanical properties of photo-cross-linked star-shaped poly (d,l-lactide) networks. Biomacromolecules 2005, 6, 2866–2874. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhan, H.; Skelton, S.; Lee, B.P. Marine adhesive containing nanocomposite hydrogel with enhanced materials and bioadhesive properties. MRS Proc. 2013. [Google Scholar] [CrossRef]

- Anderson, J.; Lin, M.-H.; Privette, C.; Flowers, M.; Murley, M.; Lee, B.P.; Ong, K.G. Wireless magnetoelastic sensors for tracking degradation profiles of nitrodopamine-modified poly(ethylene glycol). Scijet 2015, 4, 1–14. [Google Scholar] [PubMed]

- Cencer, M.; Murley, M.; Liu, Y.; Lee, B.P. Effect of nitro-functionalization on the cross-linking and bioadhesion of biomimetic adhesive moiety. Biomacromolecules 2015, 16, 404–410. [Google Scholar] [CrossRef] [PubMed]

- Chavda, H.; Modhia, I.; Mehta, A.; Patel, R.; Patel, C. Development of bioadhesive chitosan superporous hydrogel composite particles based intestinal drug delivery system. BioMed Res. Int. 2013, 2013. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, P.; Coelho, J.F.; Gil, M.H. Development of a new photocrosslinkable biodegradable bioadhesive. Int. J. Pharm. 2008, 352, 172–181. [Google Scholar] [CrossRef] [PubMed]

- Bochyńska, A.I.; Hannink, G.; Grijpma, D.W.; Buma, P. Tissue adhesives for meniscus tear repair: An overview of current advances and prospects for future clinical solutions. J. Mater. Sci. 2016, 27, 85. [Google Scholar] [CrossRef] [PubMed]

- Annabi, N.; Yue, K.; Tamayol, A.; Khademhosseini, A. Elastic sealants for surgical applications. Eur. J. Pharm. Biopharm. 2015, 95, 27–39. [Google Scholar] [CrossRef] [PubMed]

- Shirai, M. Photocrosslinkable polymers with degradable properties. Polym. J. 2014, 46, 859–865. [Google Scholar] [CrossRef] [PubMed]

- Marques, D.S.; Santos, J.M.C.; Ferreira, P.; Correia, T.R.; Correia, I.J.; Gil, M.H.; Baptista, C.M.S.G. Photocurable bioadhesive based on lactic acid. Mater. Sci. Eng. 2016, 58, 601–609. [Google Scholar] [CrossRef] [PubMed]

- Correia, T.R.; Ferreira, P.; Vaz, R.; Alves, P.; Figueiredo, M.M.; Correia, I.J.; Coimbra, P. Development of UV cross-linked gelatin coated electrospun poly(caprolactone) fibrous scaffolds for tissue engineering. Int. J. Biol. Macromol. 2016. [Google Scholar] [CrossRef] [PubMed]

- Van Oss, C.J.; Chaudhury, M.K.; Good, R.J. Interfacial Lifshitz-van der Waals and Polar Interactions in Macroscopic Systems. Chem. Rev. 1988, 88, 927–941. [Google Scholar] [CrossRef]

- Owens, D.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Singh, B.; Sharma, A.; Dhiman, A.; Kumar, S. Mechanical, mucoadhesive and biocompatibility behavior of hydrogel films: A slow anticancer drug delivery system. Am. J. Polym. Sci. Technol. 2015, 1, 1–8. [Google Scholar]

- Ferreira, P.; Pereira, R.; Coelho, J.F.; Silva, A.F.; Gil, M.H. Modification of the biopolymer castor oil with free isocyanate groups to be applied as bioadhesive. Int. J. Biol. Macromol. 2007, 40, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, P.; Coelho, J.F.J.; Pereira, R.; Gil, M.H. Synthesis and characterization of a poly(ethylene glycol) prepolymer to be applied as a bioadhesive. J. Appl. Polym. Sci. 2007, 105, 593–601. [Google Scholar] [CrossRef]

- International Journal of Engineering Research and Applications (IJERA). Available online: www.ijera.com (accessed on 27 July 2016).

- Parthasarathy, M.; Sethuraman, S. Hierarchical characterization of biomedical polymers. In Natural and Synthetic Biomedical Polymers; Kumbar, S.G., Laurencin, C.T., Deng, M., Eds.; Elsevier: Burlington, MA, USA, 2014; pp. 33–42. [Google Scholar]

- Coelho, J.F.J.; Silva, A.M.F.P.; Popov, A.V.; Percec, V.; Abreu, M.V.; Gonçalves, P.M.O.F.; Gil, M.H. Single electron transfer-degenerative chain transfer living radical polymerization of N-butyl acrylate catalyzed by Na2S2O4 in water media. J. Polym. Sci. A 2006, 44, 2809–2825. [Google Scholar] [CrossRef]

- Dos Santos, K.S.C.R.; Coelho, J.F.J.; Ferreira, P.; Pinto, I.; Lorenzetti, S.G.; Ferreira, E.I.; Higa, O.Z.; Gil, M.H. Synthesis and characterization of membranes obtained by graft copolymerization of 2-hydroxyethylmethacrylate and acrylic acid onto chitosan. Int. J. Pharm. 2006, 310, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Yari, A.; Teimourian, S.; Amidi, F.; Bakhtiyari, M.; Heidari, F.; Sajedi, N.; Veijouye, S.J.; Dodel, M.; Nobakht, M. The role of biodegradable engineered random polycaprolactone nanofiber scaffolds seeded with nestin-positive hair follicle stem cells for tissue engineering. Adv. Biomed. Res. 2016, 5, 22. [Google Scholar] [PubMed]

- Dehdilani, N.; Shamsasenjan, K.; Movassaghpour, A.; Akbarzadehlaleh, P.; Amoughli Tabrizi, B.; Parsa, H.; Sabagi, F. Improved survival and hematopoietic differentiation of murine embryonic stem cells on electrospun polycaprolactone nanofiber. Cell J. 2016, 17, 629–638. [Google Scholar] [PubMed]

- Barbarini, A.L.; Reyna, D.L.; Martino, D.M. The effect of light intensity, film thickness, and monomer composition in styrene-based bio inspired polymers. Green Chem. Lett. Rev. 2010, 3, 231–237. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J., Jr. Statistical theory of chain configuration and physical properties of high polymers. Ann. N. Y. Acad. Sci. 1943, 44, 419–429. [Google Scholar] [CrossRef]

- Schmid, M.; Varga, P. The Chemical Physics of Solid Surfaces, Volume 10: Alloy Surfaces and Surface Alloys; Woodruff, D.P., Ed.; Elsevier: Amsterdam, the Netherlands, 2002; pp. 118–151. [Google Scholar]

- Guo, J.; Wang, W.; Hu, J.; Xie, D.; Gerhard, E.; Nisic, M.; Shan, D.; Qian, G.; Zheng, S.; Yang, J. Synthesis and characterization of anti-bacterial and anti-fungal citrate-based mussel-inspired bio-adhesives. Biomaterials 2016, 85, 204–217. [Google Scholar] [CrossRef] [PubMed]

- Dehne, T.; Zehbe, R.; Krüger, J.P.; Petrova, A.; Valbuena, R.; Sittinger, M.; Schubert, H.; Ringe, A. Method to screen and evaluate tissue adhesives for joint repair applications. J. BMC Musculoskelet. Disord. 2012, 13, 175–184. [Google Scholar] [CrossRef] [PubMed]

- Repka, M.A.; McGinity, J.W. Physical–mechanical, moisture absorption and bioadhesive properties of hydroxypropylcellulose hot-melt extruded films. Biomaterials 2000, 21, 1509–1517. [Google Scholar] [CrossRef]

- Hrnčíř, E.; Rosina, J. Surface tension of blood. Physiol. Res. 1997, 46, 319–321. [Google Scholar] [PubMed]

- Wei, F.; Zhenling, L.; Bei, F.; Renjie, H.; Xiaomin, H.; Hao, W.; Meng, Y.; Huimin, H.; Haibo, Z.; Wei, W. Electrospun gelatin/PCL and collagen/PLCL scaffolds for vascular tissue engineering. Int. J. Nanomed. 2014, 13, 2335–2344. [Google Scholar]

- Han, M.-E.; Kim, S.-H.; Kim, H.D.; Yim, H.-G.; Bencherif, S.A.; Kim, T.-I.; Hwang, N.S. Extracellular matrix-based cryogels for cartilage tissue engineering. Int. J. Biol. Macromol. 2016. [Google Scholar] [CrossRef] [PubMed]

- Renné, T.; Pozgajová, M.; Grüner, S.; Schuh, K.; Pauer, H.-U.; Burfeind, P.; Gailani, D.; Nieswandt, B. Defective thrombus formation in mice lacking coagulation factor XII. J. Exp. Med. 2005, 202, 271–281. [Google Scholar] [CrossRef] [PubMed]

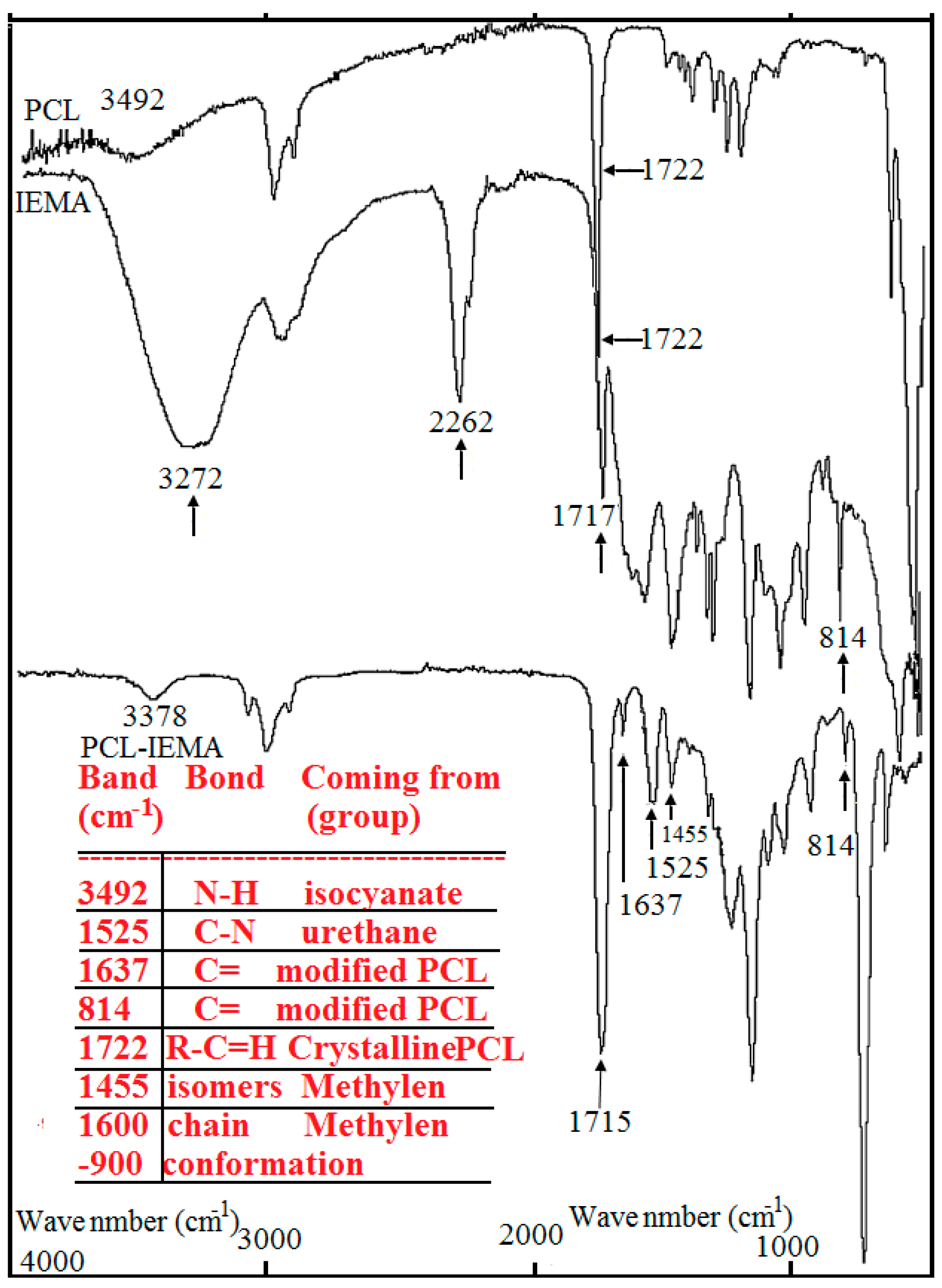

| Band, cm−1 | Bond | Coming from |

|---|---|---|

| 3,378 cm−1 | N–H hydrogen bond stretching | Isocyanates group |

| 1,525 cm−1 | C–N stretching and N–H bending | Urethane group |

| 3,492 cm−1 | NCO groups | Isocyanates group |

| 1,637 cm−1 | carbon double bonds | modified PCL |

| 814 cm−1 | carbon double bonds | modified PCL |

| 1,722 cm−1 | carbonyl absorption in | crystalline PCL |

| 1,455 cm−1 | associated with the gauche isomer | The methylene groups in the amorphous regions |

| 1,600–900cm-1 | chain conformation | vibration of the methylene and ester groups |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdalla, S.; Al-Aama, N.; Al-Ghamdi, M.A. RETRACTED: A Bio Polymeric Adhesive Produced by Photo Cross-Linkable Technique. Polymers 2016, 8, 292. https://doi.org/10.3390/polym8080292

Abdalla S, Al-Aama N, Al-Ghamdi MA. RETRACTED: A Bio Polymeric Adhesive Produced by Photo Cross-Linkable Technique. Polymers. 2016; 8(8):292. https://doi.org/10.3390/polym8080292

Chicago/Turabian StyleAbdalla, Soliman, Nabil Al-Aama, and Maryam A. Al-Ghamdi. 2016. "RETRACTED: A Bio Polymeric Adhesive Produced by Photo Cross-Linkable Technique" Polymers 8, no. 8: 292. https://doi.org/10.3390/polym8080292

APA StyleAbdalla, S., Al-Aama, N., & Al-Ghamdi, M. A. (2016). RETRACTED: A Bio Polymeric Adhesive Produced by Photo Cross-Linkable Technique. Polymers, 8(8), 292. https://doi.org/10.3390/polym8080292