Low Density Wood-Based Particleboards Bonded with Foamable Sour Cassava Starch: Preliminary Studies

Abstract

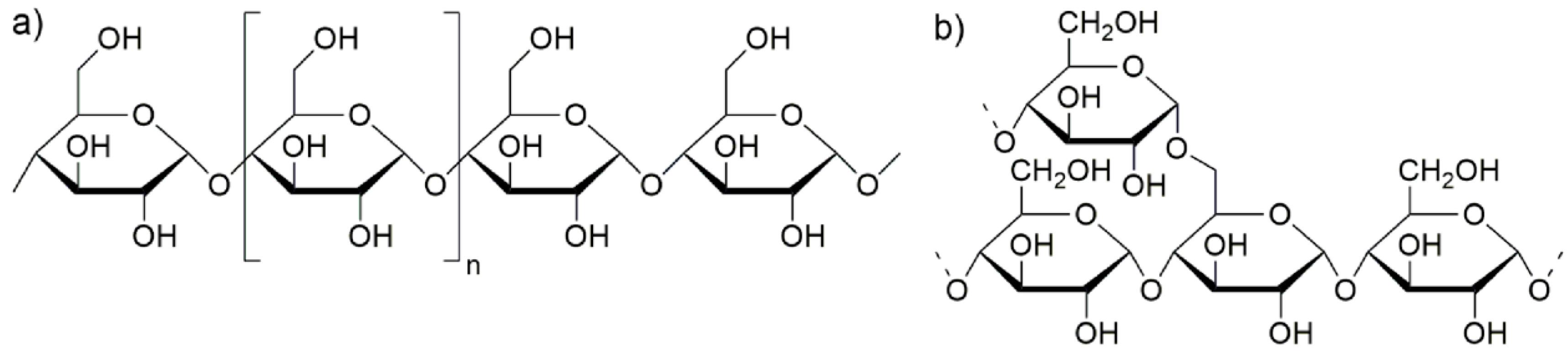

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Amylose Content

2.3. Scanning Electron Microscopy

2.4. Fourier Transform Infrared (FTIR) Spectroscopy

2.5. Preparation of Binder System

2.6. Foamability of Sour and Native Cassava Starch

2.7. Particleboard Production

2.8. Particleboard Characterization

3. Results and Discussion

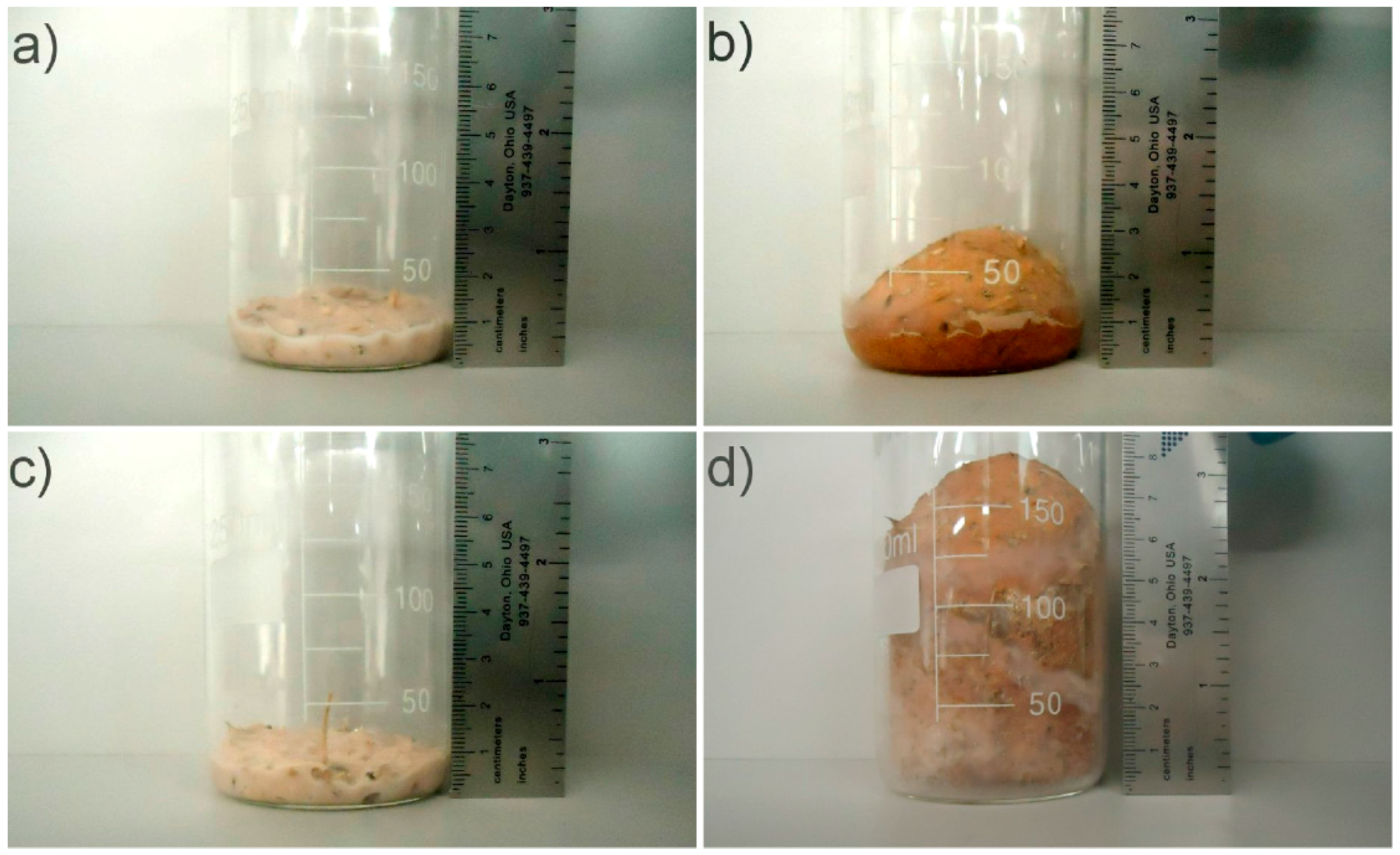

3.1. Foamability of Sour Cassava Starch

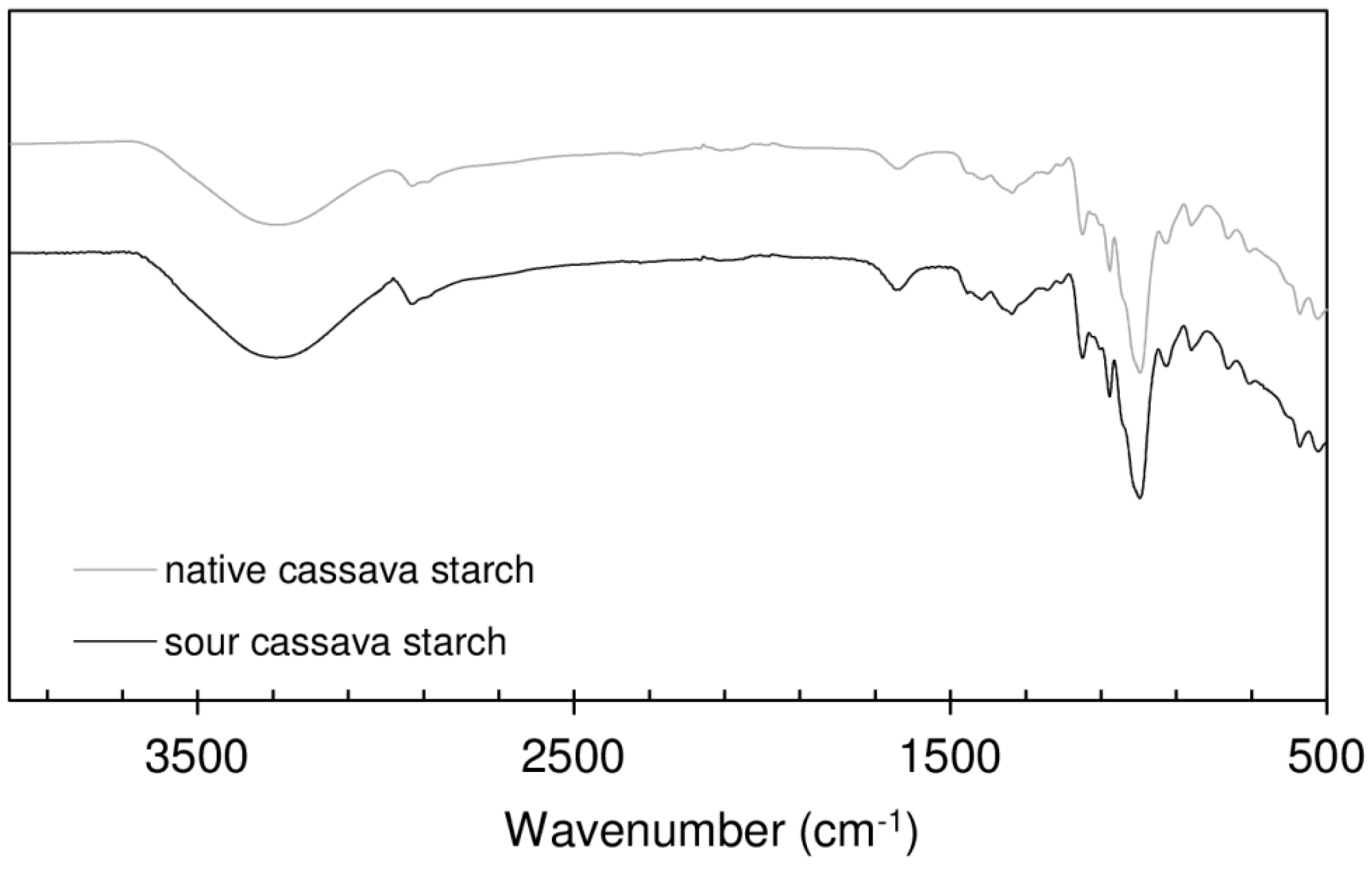

3.2. FTIR Spectroscopy Analysis

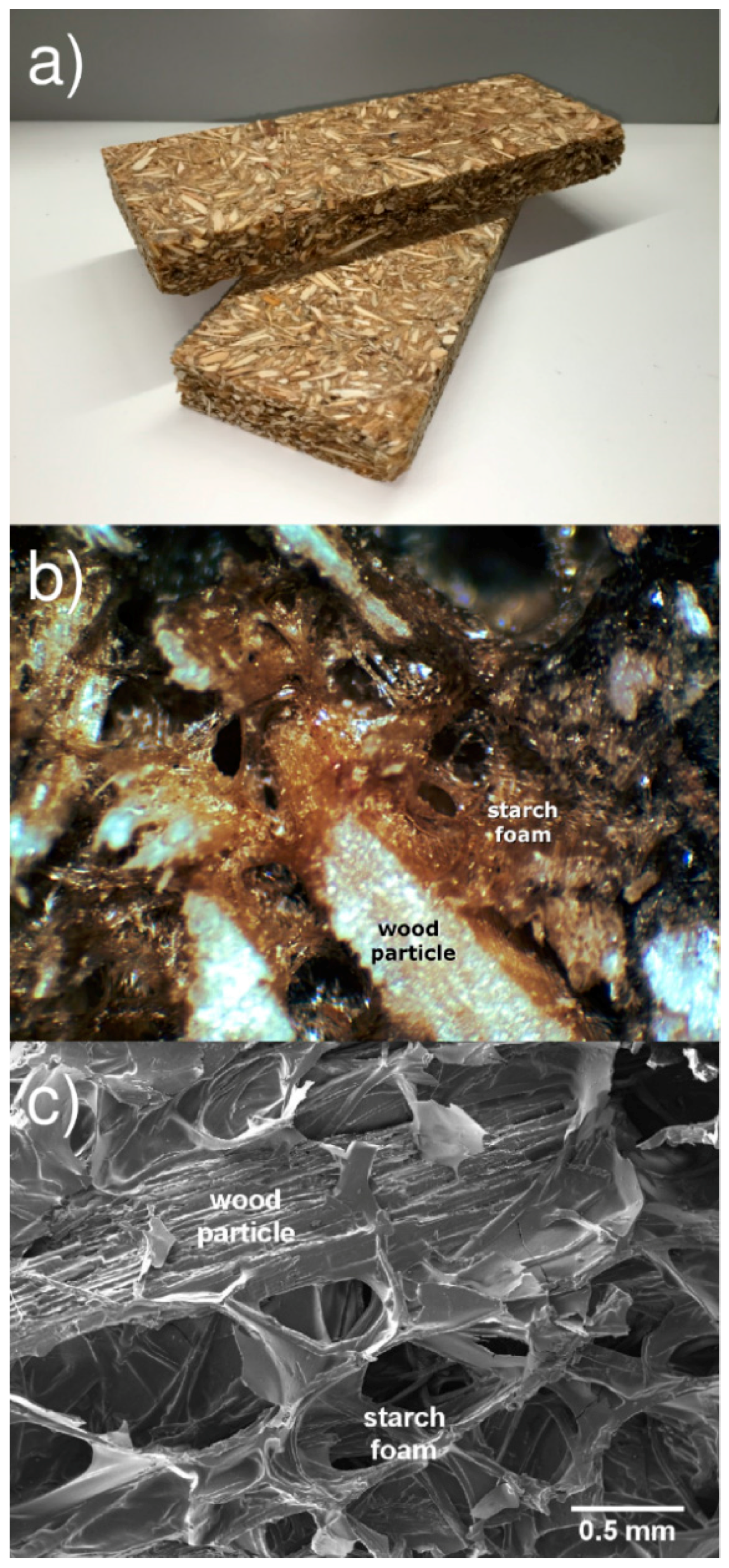

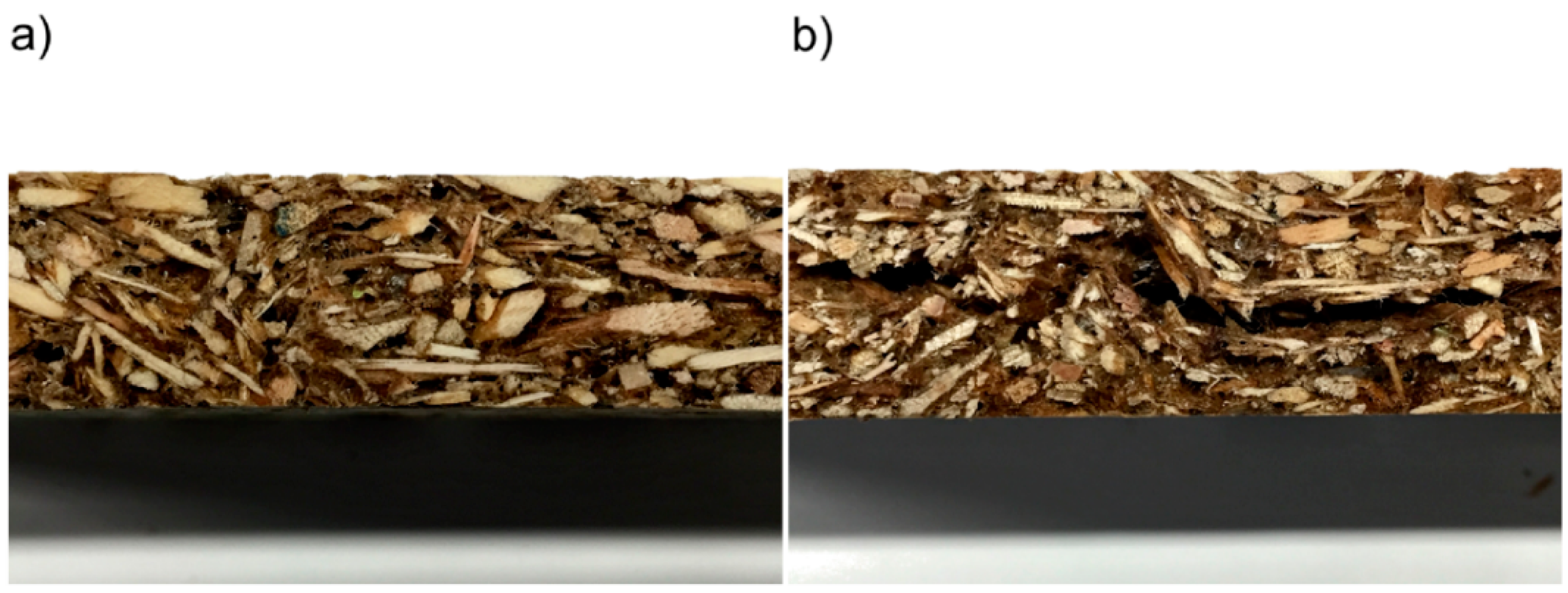

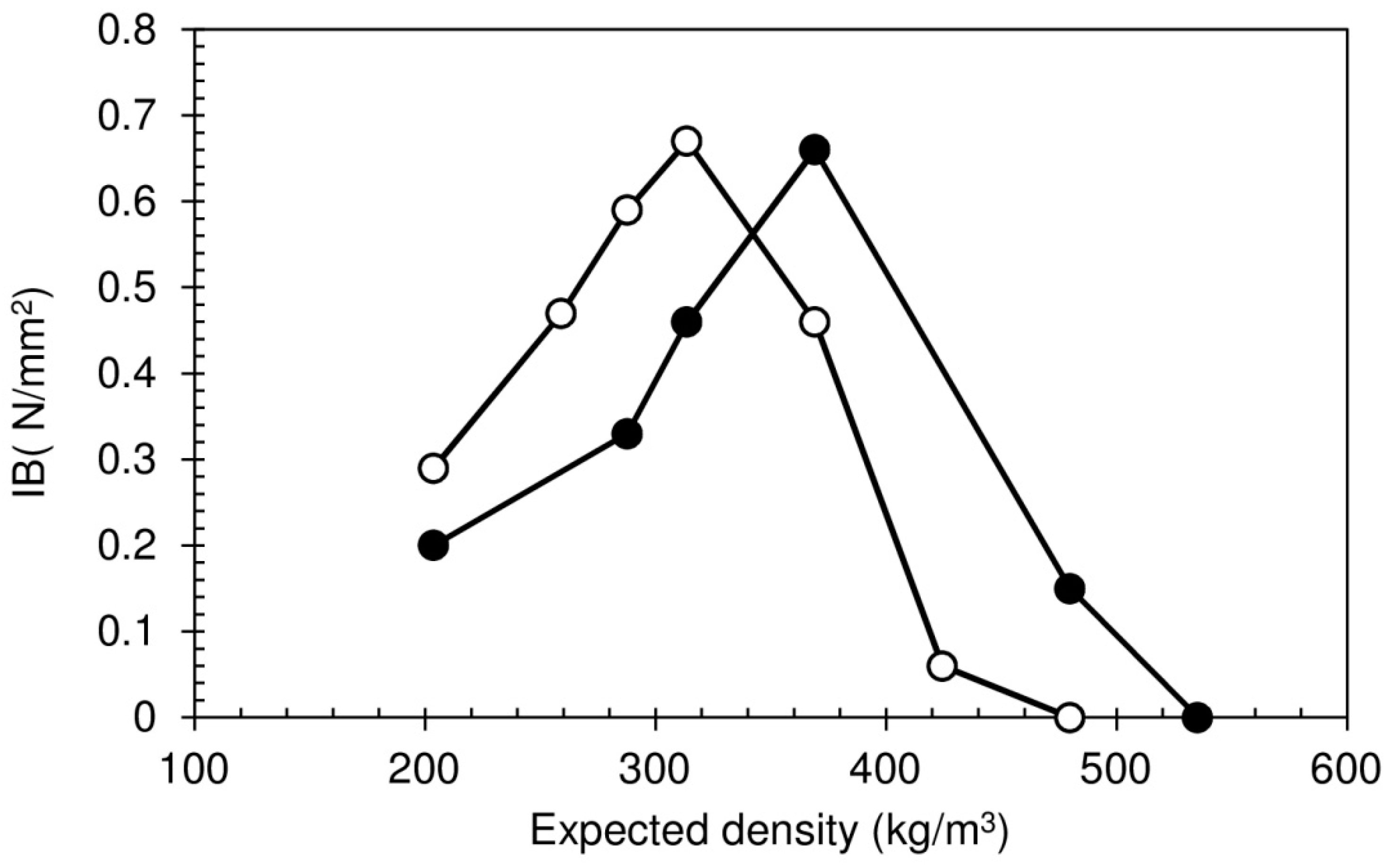

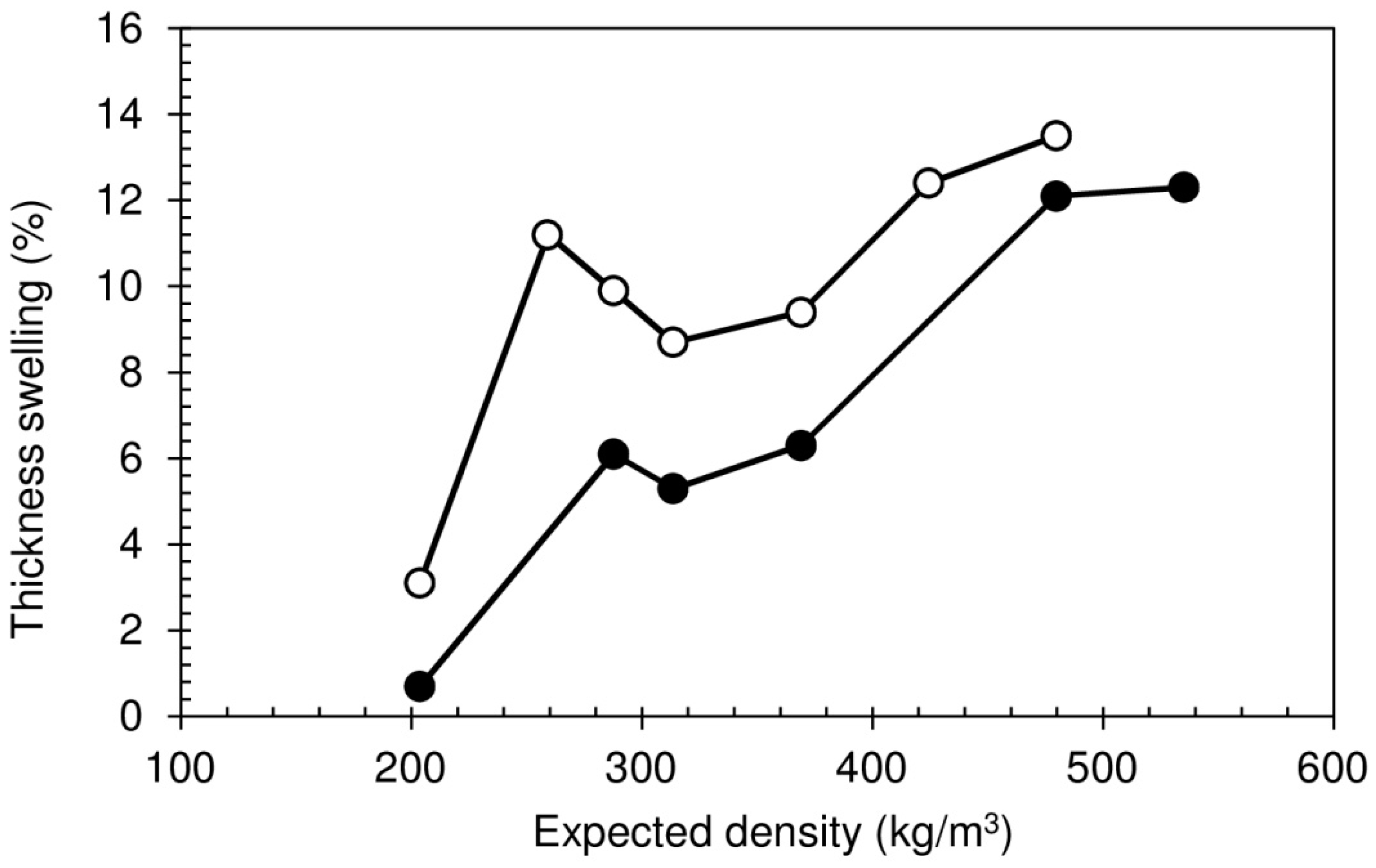

3.3. Physico-Mechanical Properties of Particleboards

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- Mohanty, A.K.; Misra, M.; Drzal, T. Sustainable Bio-Composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A Review of the Environmental Impacts of Biobased Materials. J. Ind. Ecol. 2012, 16, 169–181. [Google Scholar] [CrossRef]

- European Committee for Standardization. Particleboards—Definition and Classification. EN 309, 2005.

- European Committee for Standardization. Lightweight Particleboards—Specifications. CEN/TS 16368, 2014.

- Monteiro, S.; Dias, Â.; Martins, J.; Carvalho, L. Synthesis of Multihollow Polyester Particles in Supra- and Infra-Millimeter Size Ranges by Double Emulsion Process. Polym. Eng. Sci. 2016, 56, 590–597. [Google Scholar] [CrossRef]

- Ballerini, A.; Despres, A.; Pizzi, A. Non-Toxic, zero emission tannin-glyoxal adhesives for wood panels. Eur. J. Wood Wood Prod. 2005, 63, 477–478. [Google Scholar] [CrossRef]

- Valenzuela, J.; Leyser, E.V.; Pizzi, A.; Westermeyer, C.; Gorrini, B. Industrial production of pine tannin-bonded particleboard and MDF. Eur. J. Wood Wood Prod. 2012, 70, 735–740. [Google Scholar] [CrossRef]

- Mansouri, N.E.; Pizzi, A.; Salvado, J. Lignin-Based polycondensation resins for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Chemical modification of soy protein for wood adhesives. Macromol. Rapid Commun. 2002, 23, 739–742. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K. Development and characterization of adhesives from soy protein for bonding wood. Int. J. Adhes Adhes. 2007, 27, 59–67. [Google Scholar] [CrossRef]

- Wescott, J.M.; Frihart, C.R.; Traska, E. High-Soy-Containing water-durable adhesives. J. Adhes. Sci. Technol. 2006, 20, 859–873. [Google Scholar] [CrossRef]

- Lorenz, L.; Frihart, C.R.; Wescott, J.M. Chromatographic analysis of the reaction of soy flour with formaldehyde and phenol for wood adhesives. J. Am. Oil Chem. Soc. 2007, 84, 769–776. [Google Scholar] [CrossRef]

- Amini, M.H.M.; Hashim, R.; Hiziroglu, S.; Sulaiman, N.S.; Sulaiman, O. Properties of particleboard made from rubberwood using modified starch as binder. Compos. Part B Eng. 2013, 50, 259–264. [Google Scholar] [CrossRef]

- Belgacem, M.; Gandini, A. Monomers, Polymers and Composites from Renewable Resources, 1st ed.; Elsevier: Oxford, UK, 2008; pp. 321–342. [Google Scholar]

- Mansouri, H.R.; Navarrete, P.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Pasch, H.; Rigolet, S. Synthetic-Resin-Free wood panel adhesives from mixed low molecular mass lignin and tannin. Eur. J. Wood Wood Prod. 2011, 69, 221–229. [Google Scholar] [CrossRef]

- Imam, S.H.; Mao, L.; Chen, L.; Greene, R.V. Wood Adhesive from Crosslinked Poly(Vinyl Alcohol) and Partially Gelatinized Starch: Preparation and Properties. Starch/Stärke 1999, 51, 225–229. [Google Scholar] [CrossRef]

- Tharanathan, R.N. Starch—Value addition by modification. Crit. Rev. Food Sci. Nutr. 2005, 45, 371–384. [Google Scholar] [CrossRef] [PubMed]

- Tondi, G.; Wieland, S.; Wimmer, T.; Schnabel, T.; Petutschnigg, A. Starch-Sugar synergy in wood adhesion science: Basic studies and particleboard production. Eur. J. Wood Wood Prod. 2012, 70, 271–278. [Google Scholar] [CrossRef]

- Zhu, F. Composition, structure, physicochemical properties, and modifications of cassava starch. Carbohydr. Polym. 2015, 122, 456–480. [Google Scholar] [CrossRef] [PubMed]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Biodegradable foam tray from cassava starch blended with natural fiber and chitosan. Ind. Crop. Prod. 2012, 37, 542–546. [Google Scholar] [CrossRef]

- Salgado, P.R.; Schmidt, V.C.; Ortiz, S.E.; Mauri, A.N.; Laurindo, J.B. Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J. Food Eng. 2008, 85, 435–443. [Google Scholar] [CrossRef]

- Fueangvivat, V.; Jarusombuti, S.; Hiziroglu, S.; Bauchongkol, P. Properties of Sandwich-Type Particleboard Panels Made from Rubberwood and Eastern Redcedar. For. Prod. J. 2014, 64, 72–76. [Google Scholar] [CrossRef]

- Okudoh, V.; Trois, C.; Workneh, T.; Schmidt, S. The potential of cassava biomass and applicable technologies for sustainable biogas production in South Africa: A review. Renew. Sustain. Energy Rev. 2014, 39, 1035–1052. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.; Nigam, P.; Soccol, V.; Vandenberghe, L.; Mohan, R. Biotechnological potential of agro-industrial residues. I: Sugarcane bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Nassar, N.; Ortiz, R. Cassava improvement: Challenges and impacts. J. Agric. Sci. 2007, 145, 163. [Google Scholar] [CrossRef]

- Taiwo, K. Utilization Potentials of Cassava in Nigeria: The Domestic and Industrial Products. Food Rev. Int. 2006, 22, 29–42. [Google Scholar] [CrossRef]

- Sanginga, M. Root and Tuber Crops (Cassava, Yam, Potato and Sweet Potato). Available online: http://www.afdb.org/fileadmin/uploads/afdb/Documents/Events/DakAgri2015/Root_and_Tuber_Crops__Cassava__Yam__Potato_and_Sweet_Potato_.pdf (accessed on 30 September 2016).

- Tilman, D.; Socolow, R.; Foley, J.; Hill, J.; Larson, E.; Lynd, L.; Pacala, S.; Reilly, J.; Searchinger, T.; Somerville, C.; et al. Beneficial biofuels-the food, energy, and environment trilemma. Science 2009, 325, 270–271. [Google Scholar] [CrossRef] [PubMed]

- Banks, W.; Greenwood, C.T.; Muir, D.D. The characterization of starch and its components. Part 3: The technique of semi-micro, differentail, potentiometric, iodine titration and the factors affecting it. Starch/Stärke 1971, 21, 118–124. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Wang, X.L.; Zhao, G.M.; Wang, Y.Z. Preparation and properties of oxidized starch with high degree of oxidation. Carbohydr. Polym. 2012, 87, 2554–2562. [Google Scholar] [CrossRef]

- Klein, B.; Vanier, N.L.; Moomand, K.; Pinto, V.Z.; Colussi, R.; Zavareze, E.; Dias, A.R.G. Ozone oxidation of cassava starch in aqueous solution at different pH. Food Chem. 2014, 155, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Van Soest, J.J.G.; Tournois, H.; Wit, D.; Vliegenthart, J.F.G. Short-Range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr. Res. 1995, 279, 201–214. [Google Scholar] [CrossRef]

- Demiate, I.M.; Dupuy, N.; Huvenne, J.P.; Cereda, M.P.; Wosiacki, G. Relationship between baking behavior of modified cassava starches and starch chemical structure determined by FTIR spectroscopy. Carbohydr. Polym. 2000, 42, 149–158. [Google Scholar] [CrossRef]

- Zavareze, E.D.R.; Dias, A.R.G. Impact of heat-moisture treatment and annealing in starches: A review. Carbohydr. Polym. 2011, 83, 317–328. [Google Scholar] [CrossRef]

- Gunaratne, A.; Hoover, R. Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydr. Polym. 2002, 49, 425–437. [Google Scholar] [CrossRef]

- Nafchi, A.M.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic starches: Properties, challenges, and prospects. Starch/Stärke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- European Committee for Standardization. Particleboards—Specifications. EN 312, 2010.

| Component | Quantity (wt %) |

|---|---|

| Sour cassava starch | 30.5 |

| Distilled water | 30.5 |

| Chitosan solution | 33.4 |

| Populus fibers | 2.8 |

| Glycerol | 2.8 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monteiro, S.; Martins, J.; Magalhães, F.D.; Carvalho, L. Low Density Wood-Based Particleboards Bonded with Foamable Sour Cassava Starch: Preliminary Studies. Polymers 2016, 8, 354. https://doi.org/10.3390/polym8100354

Monteiro S, Martins J, Magalhães FD, Carvalho L. Low Density Wood-Based Particleboards Bonded with Foamable Sour Cassava Starch: Preliminary Studies. Polymers. 2016; 8(10):354. https://doi.org/10.3390/polym8100354

Chicago/Turabian StyleMonteiro, Sandra, Jorge Martins, Fernão D. Magalhães, and Luísa Carvalho. 2016. "Low Density Wood-Based Particleboards Bonded with Foamable Sour Cassava Starch: Preliminary Studies" Polymers 8, no. 10: 354. https://doi.org/10.3390/polym8100354

APA StyleMonteiro, S., Martins, J., Magalhães, F. D., & Carvalho, L. (2016). Low Density Wood-Based Particleboards Bonded with Foamable Sour Cassava Starch: Preliminary Studies. Polymers, 8(10), 354. https://doi.org/10.3390/polym8100354