The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites

Abstract

:1. Introduction

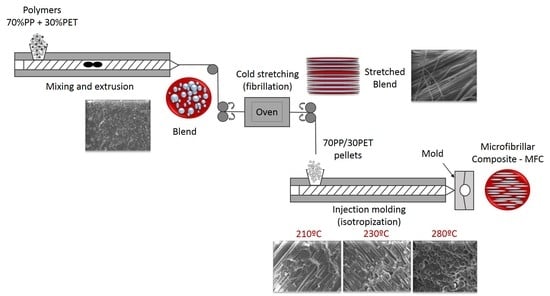

- Extrusion–melt blending of the two immiscible polymers which have different melting temperatures Tm (mixing);

- Hot or cold stretching of the extrudate with a molecular orientation of the two polymers (fibrillation);

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP/PET (Polypropylene/Polyethylene Terephthalate), IMBs (Injection Molding Blends) and MFCs (Microfibrillar Composites)

2.3. Characterization of PP/PET IMBs and MFCs

3. Results

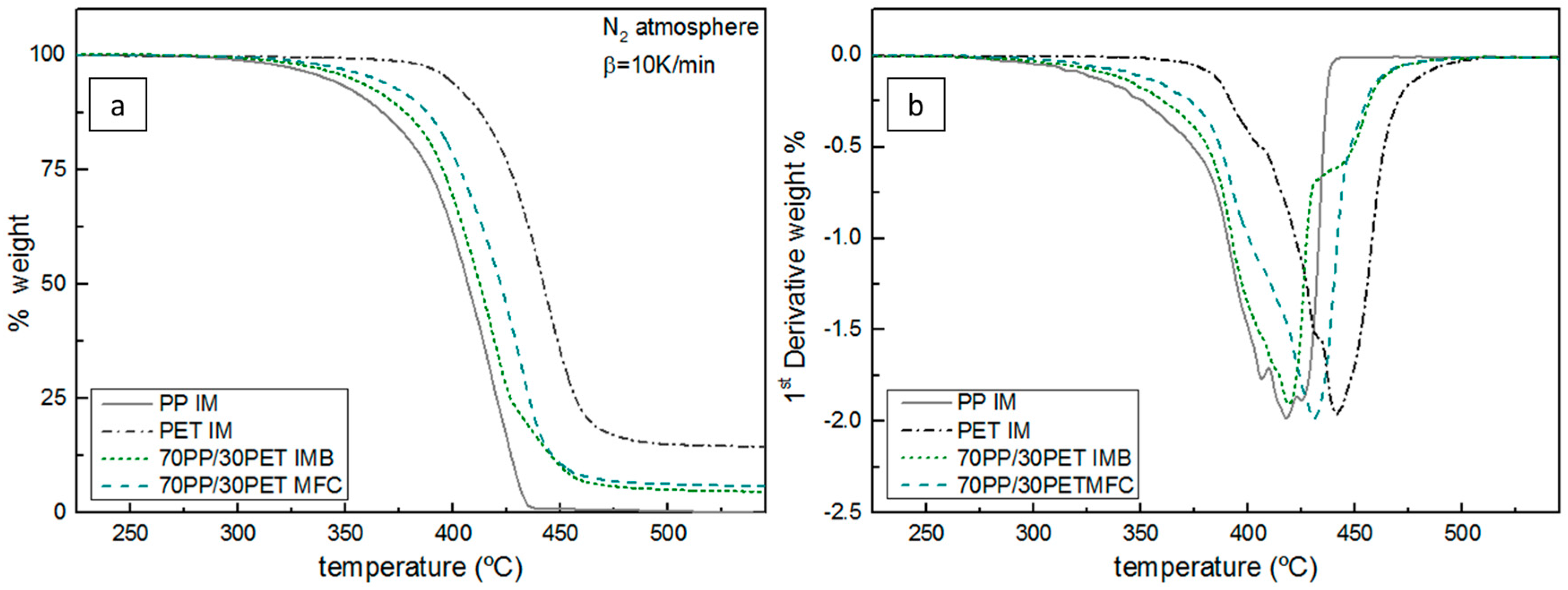

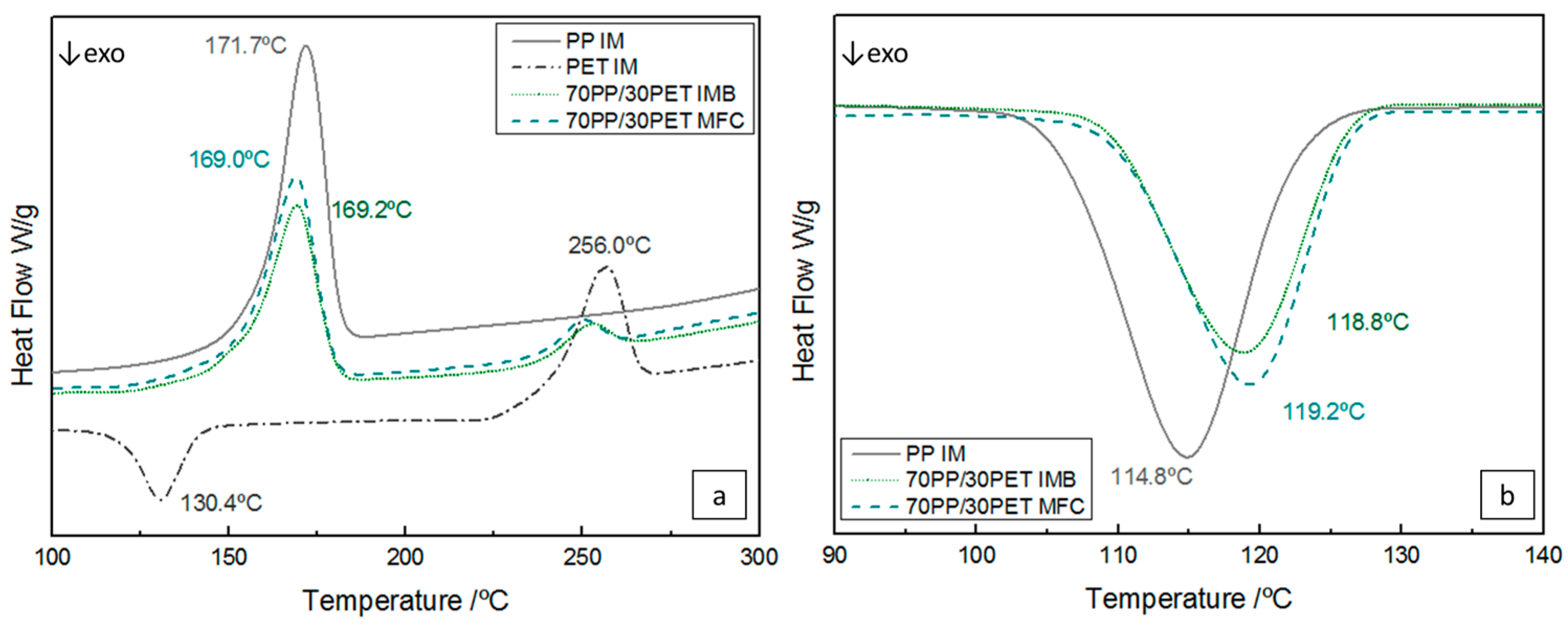

3.1. Thermal Properties of IMBs and MFCs

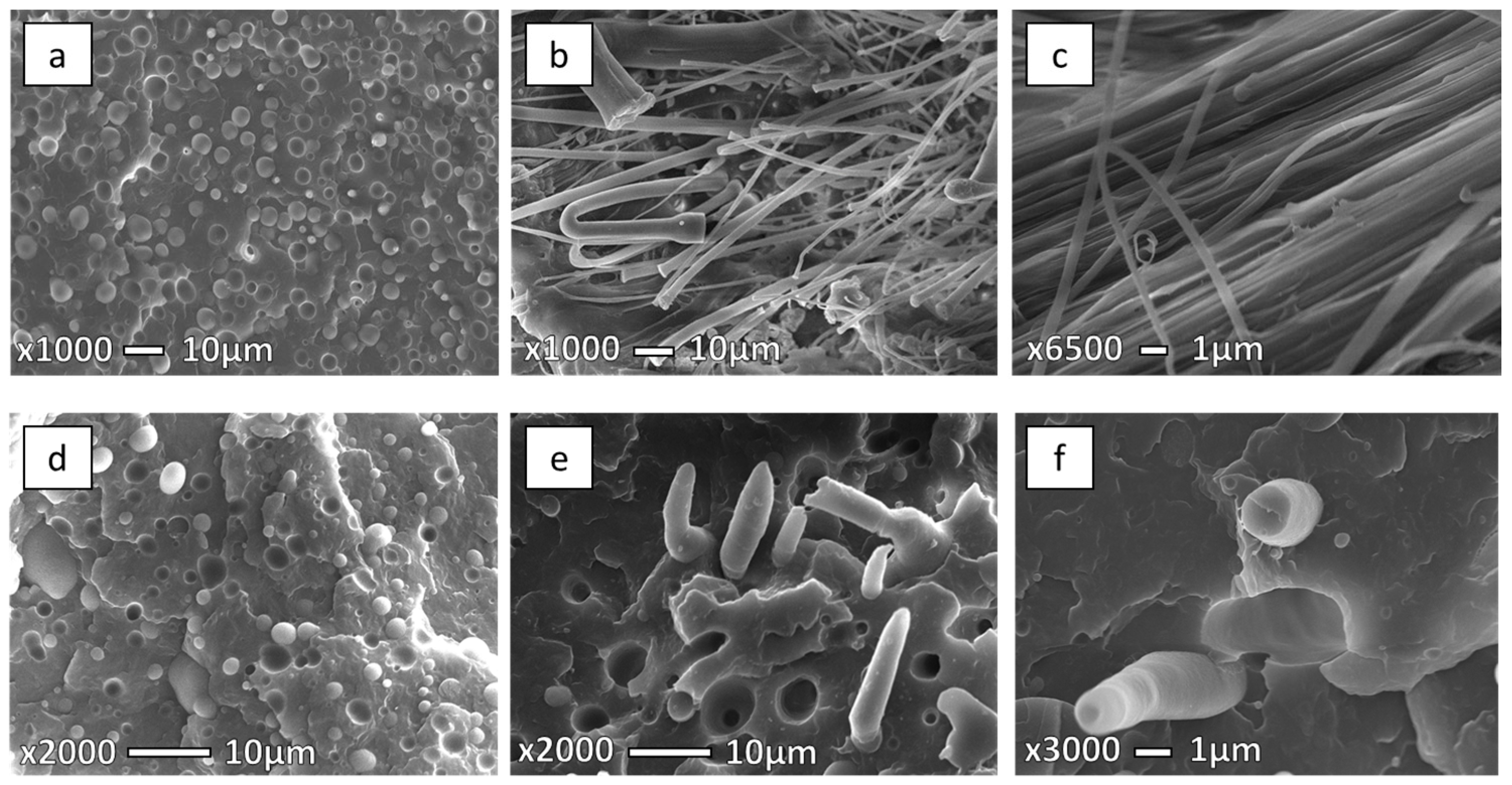

3.2. Morphology of the IMBs and MFCs

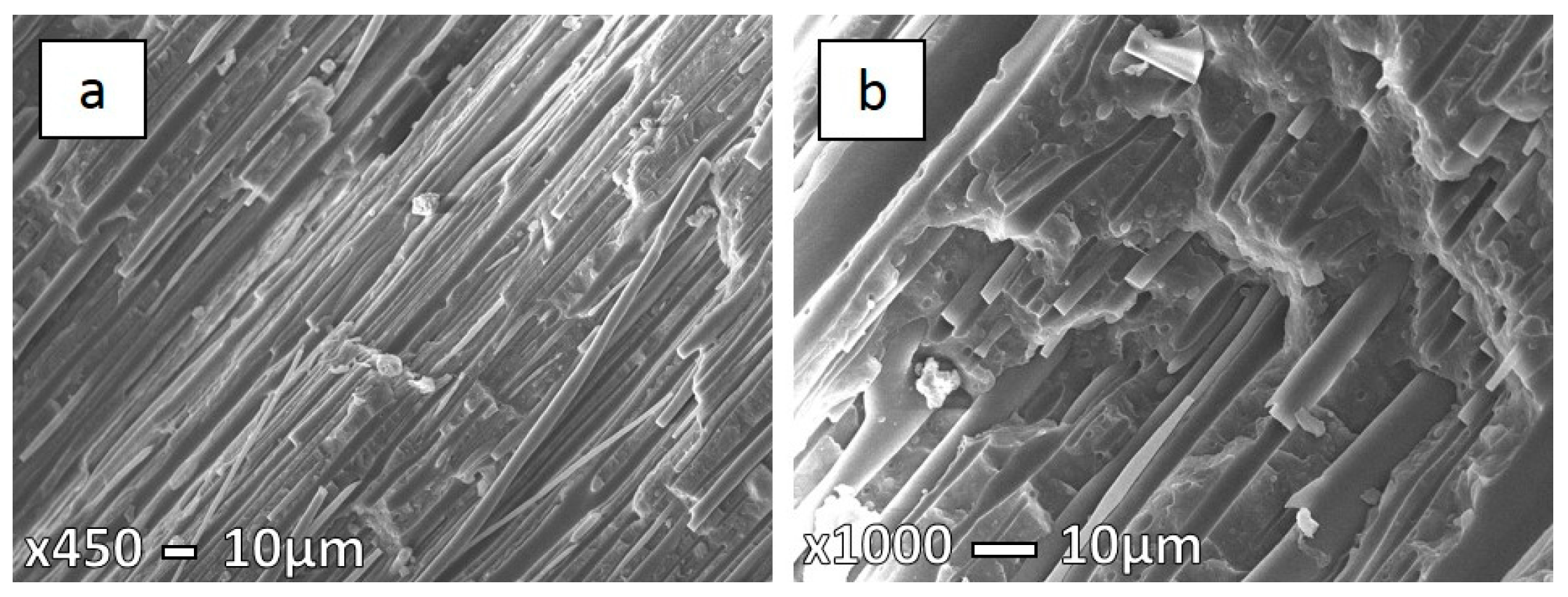

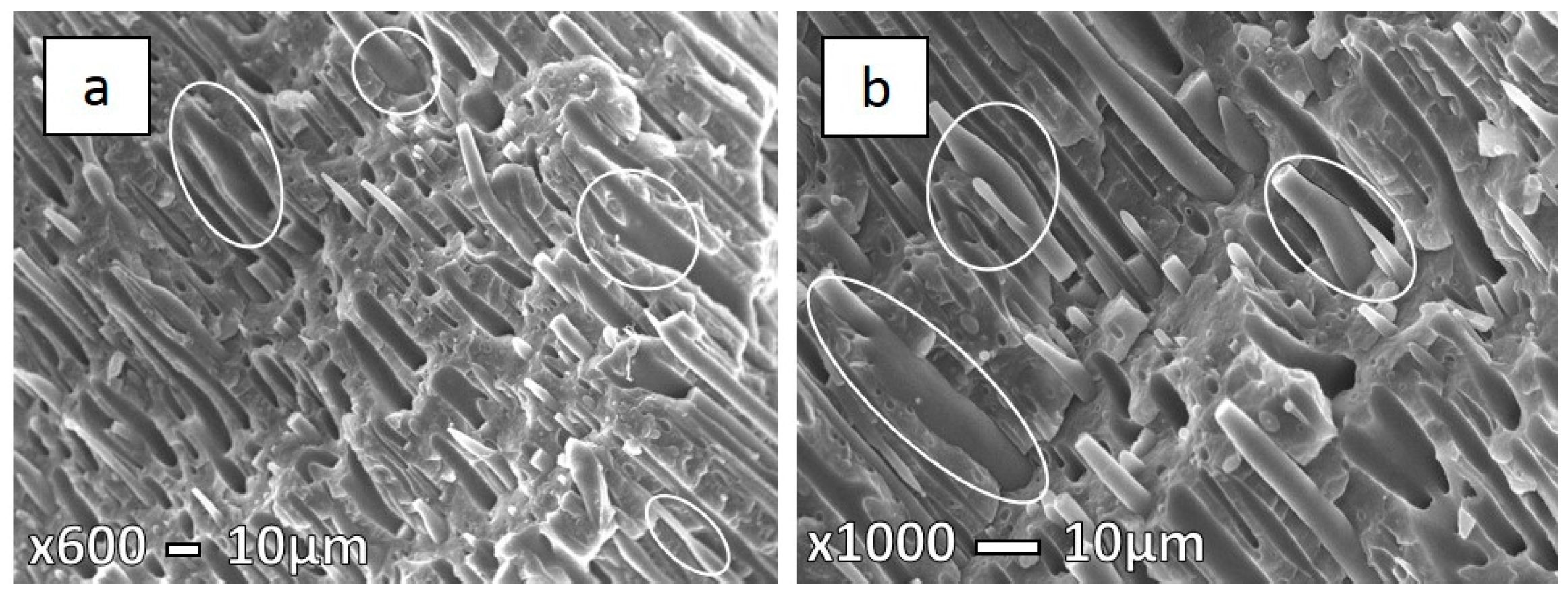

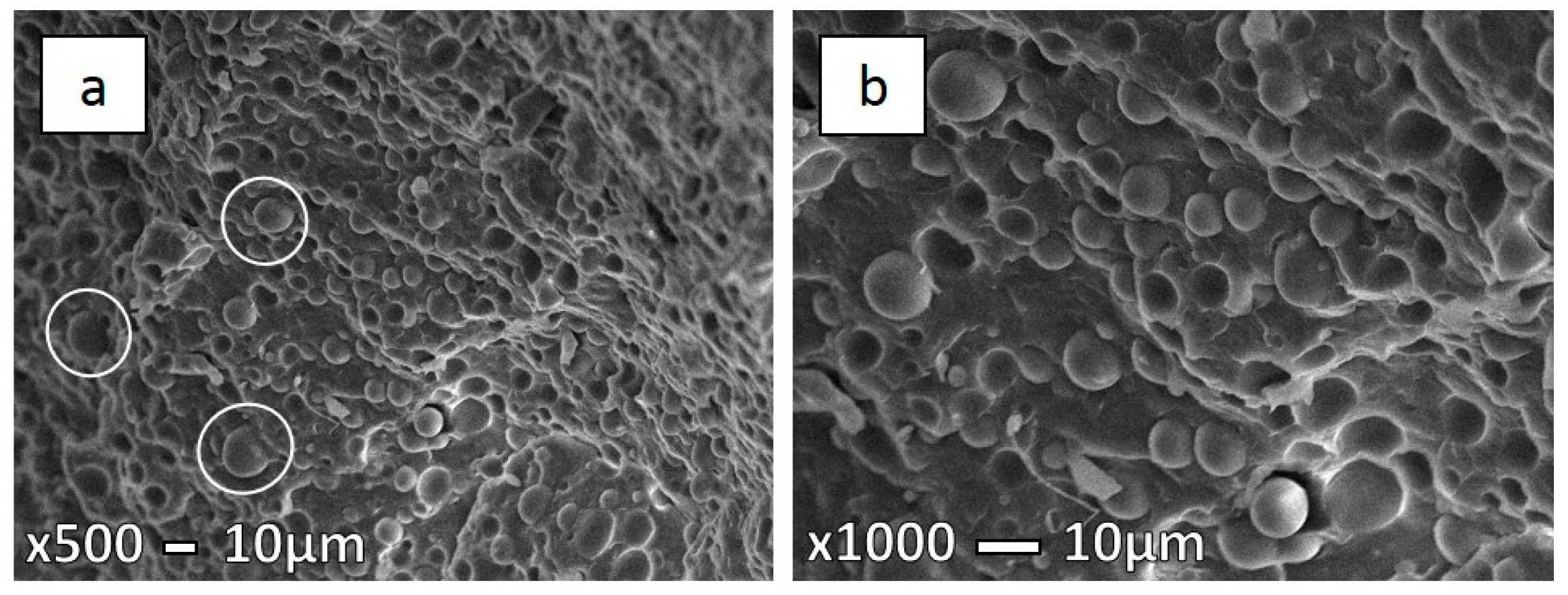

3.2.1. Morphology Development

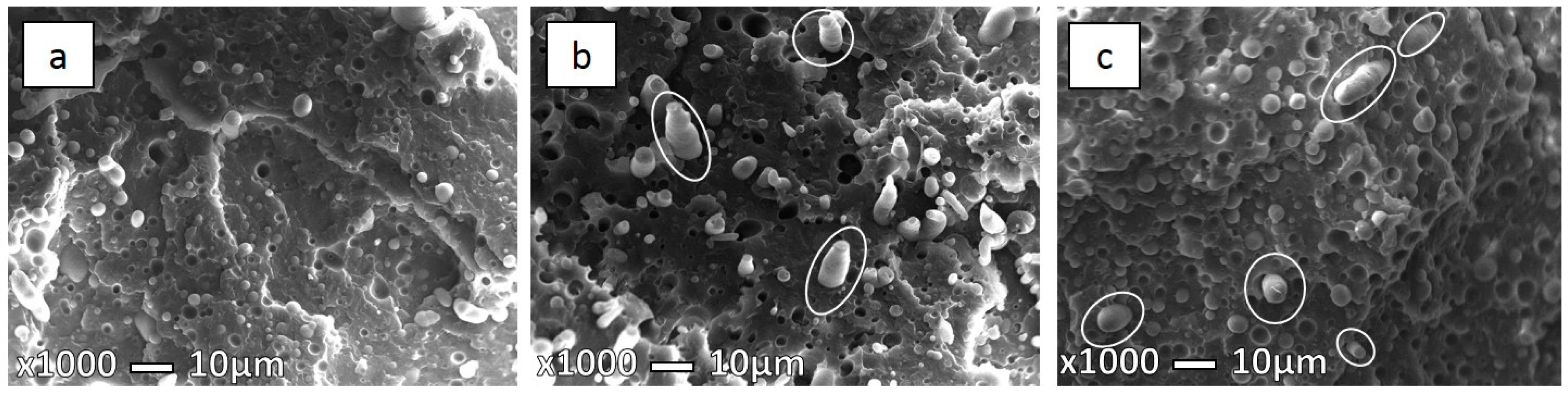

3.2.2. Influence of Tim on Morphology

3.3. Mechanical Properties

3.3.1. Development of Mechanical Properties

3.3.2. Influence of Tim on Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, J.; Yu, X.; Guo, S. Development of morphology and properties of injection-molded bars of HDPE/PA6 blends. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 184–195. [Google Scholar] [CrossRef]

- Li, Z.M.; Yang, W.; Xie, B.H.; Shen, K.Z.; Huang, R.; Yang, M.B. Morphology and tensile strength prediction of in situ microfibrillar poly(ethylene terephthalate)/polyethylene blends fabricated via slit-die extrusion-hot stretching-quenching. Macromol. Mater. Eng. 2004, 289, 349–354. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatieva, O.; Ishiic, M.; Harrassa, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Xu, L.; Zhong, G.J.; Ji, X.; Li, Z.M. Crystallization behaviour and morphology of one-step reaction compatibilized microfibrillar reinforced isotactic polypropylene/poly(ethylene therephthalate) (iPP/PET) blends. Chin. J. Polym. Sci. 2001, 29, 540–551. [Google Scholar] [CrossRef]

- Shields, R.J.; Bhattacharyya, D.; Fakirov, S. Oxygen permeability analysis of microfibril reinforced composites from PE/PET blends. Compos. Part A Appl. Sci. Manuf. 2008, 39, 940–949. [Google Scholar] [CrossRef]

- Mirjalili, F.; Moradian, S.; Ameri, F. Enhancing the dyeability of polypropylene fibers by melt blending with polyethylene terephthalate. Sci. World J. 2013, 2013, 468542. [Google Scholar] [CrossRef] [PubMed]

- Canetti, M.; Bertini, F. Supermolecular structure and thermal properties of poly(ethylene terephthalate)/lignin composites. Compos. Sci. Technol. 2007, 67, 3151–3157. [Google Scholar] [CrossRef]

- Ujhelyiová, A.; Bolhová, E.; Marcinčin, A.; Tiňo, R. Blended polypropylene/polyethylene terephthalate fibres: Crystallisation behaviour of polypropylene and mechanical properties. Fibres Text. East. Eur. 2007, 4, 26–29. [Google Scholar]

- Inuwa, I.M.; Hassan, A.; Samsudin, S.A.; Mohamad Haafiz, M.K.; Jawaid, M. Interface modification of compatibilized polyethylene terephthalate/polypropylene blends: Effect of compatibilization on thermomechanical properties and thermal stability. J. Vinyl Addit. Technol. 2015. [Google Scholar] [CrossRef]

- Shields, R.J.; Bhattacharyya, D.; Fakirov, S. Fibrillar polymer–polymer composites: Morphology, properties and applications. J. Mater. Sci. 2008, 43, 6758–6770. [Google Scholar] [CrossRef]

- Perez, L.A.; Rodriguez, D.N.; Rodriguez, F.J.; Hsiao, B.; Avila-Orta, C.A.; Sics, I. Molecular weight and crystallization temperature effects on poly(ethylene terephthalate) (pet) homopolymers, an isothermal crystallization Analysis. Polymers 2014, 6, 583–600. [Google Scholar] [CrossRef]

- Kayaisang, S.; Saikrasun, S.; Amornsakchai, T. Potential use of recycled pet in comparison with liquid crystalline polyester as a dual functional additive for enhancing heat stability and reinforcement for high density polyethylene composite fibers. J. Polym. Environ. 2013, 21, 191–206. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Thomas, S.; Joseph, K. In situ microfibrillar blends and composites of polypropylene and poly (ethylene terephthalate): Morphology and thermal properties. J. Polym. Res. 2011, 18, 1–11. [Google Scholar] [CrossRef]

- Li, Z.M.; Yang, M.B.; Feng, J.M.; Yang, W.; Huang, R. Morphology of in situ poly(ethylene terephthalate)/polyethylene microfiber reinforced composite formed via slit-die extrusion and hot-stretching. Mater. Res. Bull. 2002, 37, 2185–2197. [Google Scholar] [CrossRef]

- Chiu, H.T.; Hsiao, Y.K. Compatibilization of Poly(ethylene terephthalate)/Polypropylene Blends with Maleic Anhydride Grafted Polyethylene-Octene Elastomer. J. Polym. Res. 2006, 13, 153–160. [Google Scholar] [CrossRef]

- Li, Z.M.; Li, L.; Shen, K.Z.; Yang, M.B.; Huang, R. In situ poly(ethylene terephthalate) microfibers- and shear-induced non-isothermal crystallization of isotactic polypropylene by on-line small angle X-ray scattering. Polymer 2005, 46, 5358–5367. [Google Scholar] [CrossRef]

- Asgari, M.; Masoomi, M. Thermal and impact study of PP/PET fibre composites compatibilized with Glycidyl Methacrylate and Maleic Anhydride. Compos. Part B Eng. 2012, 43, 1164–1170. [Google Scholar] [CrossRef]

- Laukaitiné, A.; Jankauskaité, V.; Žukiené, K.; Norvydas, V.; Munassipov, S.; Janakhmetov, U. Investigation of polyvinyl chloride and thermoplastic polyurethane waste blend miscibility. Mater. Sci. 2013, 19, 397–402. [Google Scholar] [CrossRef]

- Higgins, J.S.; Lipson, J.E.G.; White, R.P. A simple approach to polymer mixture miscibility. Philos. Trans. R. Soc. A 2010, 368, 1009–1025. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Du, M.; Gu, Q.; Jiang, J.; Huth, H.; Zhou, D.; Xue, G.; Schick, C. Calorimetric study of blend miscibility of polymers confined in ultra-thin films. Eur. Phys. J. Spec. Top. 2010, 189, 187–195. [Google Scholar] [CrossRef]

- Champagne, M.F.; Huneault, M.A.; Roux, C.; Peyrel, W. Reactive compatibilization of polypropylene/polyethylene terephthalate blends. Polym. Eng. Sci. 1999, 39, 976–984. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Shields, R.J. Nanofibril reinforced composites from polymer blends. Colloids Surf. A 2008, 313, 2–8. [Google Scholar] [CrossRef]

- Fuchs, C.; Bhattacharyya, D.; Fakirov, S. Microfibril reinforced polymer–polymer composites: Application of Tsai-Hill equation to PP/PET composites. Compos. Sci. Technol. 2006, 66, 3161–3171. [Google Scholar] [CrossRef]

- Körmendy, E.; Marcinčin, A.; Hricová, M.; Kovačic, V. Phase Morphology of Polypropylene-Polyethylene Terephthalate Blend Fibres. Fibres Text. East. Eur. 2005, 13, 49. [Google Scholar]

- Fakirov, S.; Bhattacharyya, D.; Lin, R.J.T.; Fuchs, C.; Friedrich, K. Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J. Macromol. Sci. Phys. 2007, 46, 183–194. [Google Scholar] [CrossRef]

- Evstatiev, O.; Evstatiev, M.; Friedrich, K. Effect of Compatibilization on the Properties of Microfibrillar Reinforced Composites Based on Poly(ethyleneterephthalate) and Polypropylene. Report for Max Buchner Stiftung. 2005. [Google Scholar]

- Friedrich, K.; Ueda, E.; Kamo, H.; Evstatiev, M.; Krasteva, B.; Fakirov, S. Direct electron microscopic observation of transcrystalline layers in microfibrillar reinforced polymer-polymer composites. J. Mater. Sci. 2002, 37, 4299–4305. [Google Scholar] [CrossRef]

- Li, W. PET/PP-Based Polymer Composites: Effects of Compatibilizer and Nanofillers on the Processing-Structure-Property Relationships. Ph.D. Thesis, Institute for Composite Materials, University of Kaiserslautern, Kaiserslautern, Germany, 2009. [Google Scholar]

- Shibata, S.; Bozlur, R.M.; Fukumoto, I.; Kanda, Y. Effects of injection temperature on mechanical properties of bagasse/polypropylene injection molding composites. BioResources 2010, 5, 2097–2111. [Google Scholar]

- Jayanarayanan, K.; Joseph, K.; Thomas, S. Microfibrils Reinforced composites based on PP and PET: Effect of draw ratio on morphology, static and dynamic mechanical properties, crystallization and rheology. In Synthetic Polymer-Polymer Composites; Bhattacharyya, D., Fakirov, S., Eds.; Elsevier Inc.: Munich, Germany, 2012; pp. 525–562. [Google Scholar]

- Viana, J.C.; Alves, N.M.; Mano, J.F. Morphology and mechanical properties of injection molded poly(ethylene terephthalate). Polym. Eng. Sci. 2004, 44, 2174–2184. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Bhagawan, S.S.; Thomas, S.; Joseph, K. Morphology development and non-isothermal crystallization behaviour of drawn blends and microfibrillar composites from PP and PET. Polym. Bull. 2008, 60, 525–532. [Google Scholar] [CrossRef]

- Peterson, J.D.; Vyazovkin, S.; Wight, C.A. Kinetics of the thermal and thermo-oxidative degradation of polystyrene, polyethylene and poly(propylene). Macromol. Chem. Phys. 2001, 202, 775–784. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Grulke, E.; Hilding, J.; Harris, R.; Awad, W.; Douglas, J. Thermal degradation and flammability properties of poly(propylene)/carbon nanotube composites. Macromol. Rapid Commun. 2002, 23, 761–765. [Google Scholar] [CrossRef]

- Zhu, Y.; Liang, C.; Bo, Y.; Xu, S. Non-isothermal crystallization behavior of compatibilized polypropylene/recycled polyethylene terephthalate blends. J. Therm. Anal. Calorim. 2015, 119, 2005–2013. [Google Scholar] [CrossRef]

- Thanomchat, S.; Srikulkit, K.; Suksut, B.; Schlarb, A.K. Morphology and Crystallization of Polypropylene/Microfibrillated Cellulose Composites. Int. J. Appl. Sci. Technol. 2014, 4, 23–34. [Google Scholar] [CrossRef]

- Shields, R.J.; Bhattacharyya, D.; Fakirov, S. Application opportunities of the microfibril reinforced composite concept. In Synthetic Polymer-Polymer Composites; Bhattacharyya, D., Fakirov, S., Eds.; Elsevier Inc.: Munich, Germany, 2012; pp. 589–626. [Google Scholar]

- Lei, Y.; Wua, Q.; Zhang, Q. Morphology and properties of microfibrillar composites based on recycled poly(ethylene terephthalate) and high density polyethylene. Compos. Part A Appl. Sci. Manuf. 2009, 40, 904–912. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; George, G.; Thomas, S.; Joseph, K. Morphology development of normal blends, microfibrillar blends and composites from LDPE and PET. Acad. Rev. 2009, 16, 66–76. [Google Scholar]

- Perilla, J.E.; Jana, S.C. Coalescence of immiscible polymer blends in chaotic mixers. AIChE J. 2005, 51, 2675–2685. [Google Scholar] [CrossRef]

- Huang, W.; Shen, J.; Chen, X. Effect of composition on phase morphology and mechanical properties of PP/PA66 in situ composites via extrusion-drawing-injection method. J. Mater. Sci. 2003, 38, 541–547. [Google Scholar] [CrossRef]

- Padilla-Lopez, H.; Vazquez, M.O.; González-Núñez, R.; Rodrigue, D. Influence of postextrusion parameters on the final morphology of polystyrene/high density polyethylene blends. Polym. Eng. Sci. 2003, 43, 1646–1656. [Google Scholar] [CrossRef]

- Rodriguez-Gonzalez, F.J.; Virgilio, N.; Ramsay, B.A.; Favis, B.D. Influence of melt drawing on the morphology of one- and two-step processed LDPE/thermoplastic starch blends. Adv. Polym. Technol. 2003, 22, 297–305. [Google Scholar] [CrossRef]

- Perilla, J.E.; Jana, S.C. A time-scale approach for analysis of coalescence in processing flows. Polym. Eng. Sci. 2004, 44, 2254–2265. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Krasucki, J.; Sterzynski, T. Fabrication of the Self-Reinforced Composites Using Co-Extrusion Technique. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Van Bruggen, E.P.A.; Koster, R.P.; Picken, S.J.; Ragaert, K. Influence of processing parameters and composition on the effective compatibilization of polypropylene–poly(ethylene terephthalate) blends. Int. Polym. Process. 2016, 31, 179–187. [Google Scholar] [CrossRef]

- Abdullah, M.Z.; Pechstein, L.; Lin, R.J.T.; Bhattacharyya, D. Behaviour of microfibrillar composite blends during product manufacturing. In Processing and Fabrication of Advanced Materials-XVI; Bhatangar, N., Srivatsan, T.S., Eds.; IK International: New Delhi, India, 2009; Volume 2, p. 1320. [Google Scholar]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Yi, X.; Chen, C.; Zhong, G.J.; Xu, L.; Tang, J.H.; Ji, X.; Li, Z.M. Suppressing the skin–core structure of injection-molded isotactic polypropylene via combination of an in situ microfibrillar network and an interfacial compatibilizer. J. Phys. Chem. B 2011, 115, 7497–7504. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Mallick, P.K. Effects of melt temperature and hold pressure on the tensile and fatigue properties of an injection molded talc-filled polypropylene. Polym. Eng. Sci. 2005, 45, 755–763. [Google Scholar] [CrossRef]

- Fakirov, S. Transreactions in Condensation Polymers; Fakirov, S., Ed.; Wiley: New York, NY, USA, 2008. [Google Scholar]

- Krumova, M.; Michler, G.H.; Evstatiev, M.; Friedrich, K.; Stribeck, N.; Fakirov, S. Transcrystallisation with reorientation of polypropylene in drawn PET/PP and PA66/PP blends. Part 2. Electron microscopic observations on the PET/PP blend. Progr. Colloid Polym. Sci. 2005, 130, 167–173. [Google Scholar]

| Sample | Tonset (°C) | Tmax (°C) | Tendset (°C) | Char yield at 550 °C (wt %) |

|---|---|---|---|---|

| PP IM | 342.1 | 417.6 | 435.9 | 0.1 |

| PET IM | 396.5 | 441.4 | 490.8 | 14.5 |

| 70PP/30PET IMB | 349.3 | 419.1 | 469.2 | 4.7 |

| 70PP/30PET MFC | 361.5 | 430.8 | 470.2 | 5.8 |

| System | Heating | Cooling | ||||||

|---|---|---|---|---|---|---|---|---|

| Sample | TmPP (°C) | ΔHmpp (J/g) | TmPET (°C) | ΔHmPET (J/g) | αcPP % | TcPP (°C) | HcPP (J/g) | TcPET (°C) |

| PP IM | 171.7 | 73.74 | - | - | 35.6 | 114.8 | 112.80 | - |

| PET IM | - | - | 256.0 | 30.13 | - | - | - | 196.3 |

| 70PP/30PET IMB | 169.2 | 45.60 | 254.9 | 5.85 | 31.5 | 118.8 | 72.12 | 189.1 |

| 70PP/30PET MFC | 169.0 | 55.89 | 250.7 | 5.37 | 38.6 | 119.2 | 77.84 | 193.0 |

| Sample | Temperature (°C) | Diameter min/max fiber or sphere (μm) | Average diameter (μm) |

|---|---|---|---|

| Extrusion blend | - | 1.0–5.0 | 2.8 ± 1.25 |

| Stretched blend | - | 0.5–2.0 | 1.5 ± 1.81 |

| 70PP/30PET IMB | 210 | 1.0–2.5 | 1.7 ± 0.72 |

| 230 | 1.0–3.0 | 2.0 ± 0.79 | |

| 280 | 2.0–6.0 | 3.6 ± 1.21 | |

| 70PP/30PET MFC | 210 | 1.0–2.0 | 1.8 ± 1.04 |

| 230 | 2.5–6.5 | 3.7 ± 1.47 | |

| 280 | 3.0–7.2 | 4.2 ± 1.80 |

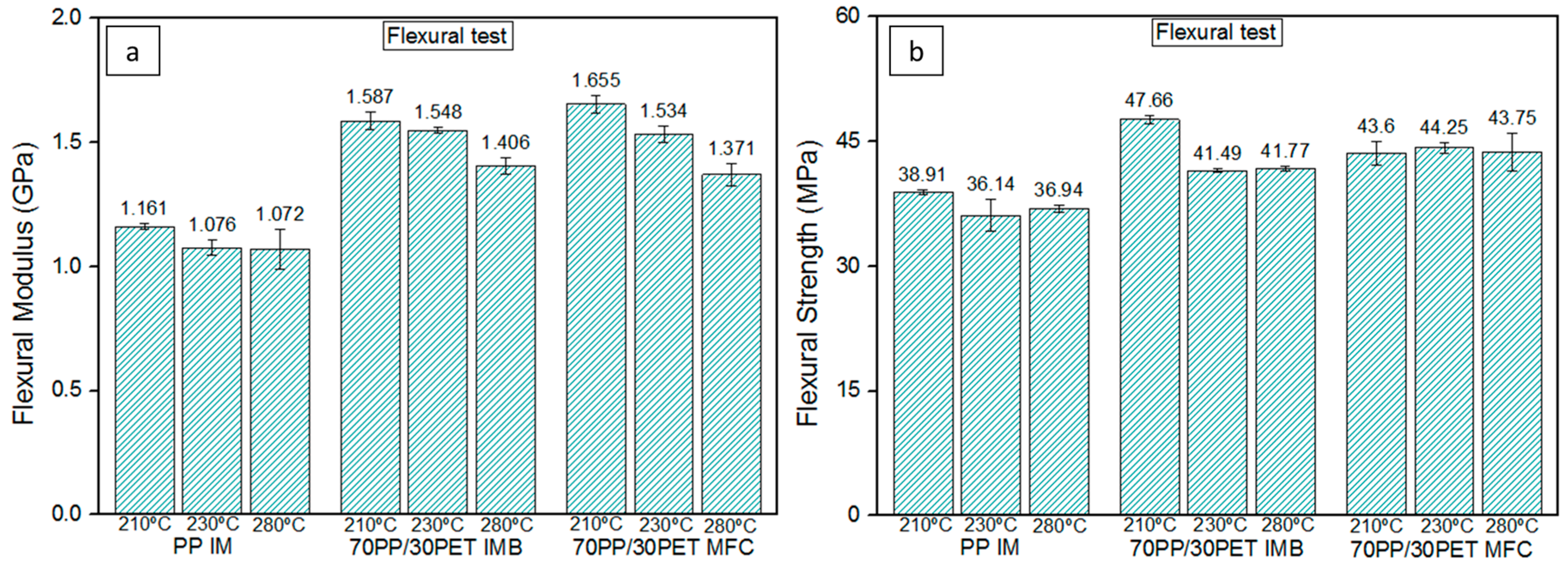

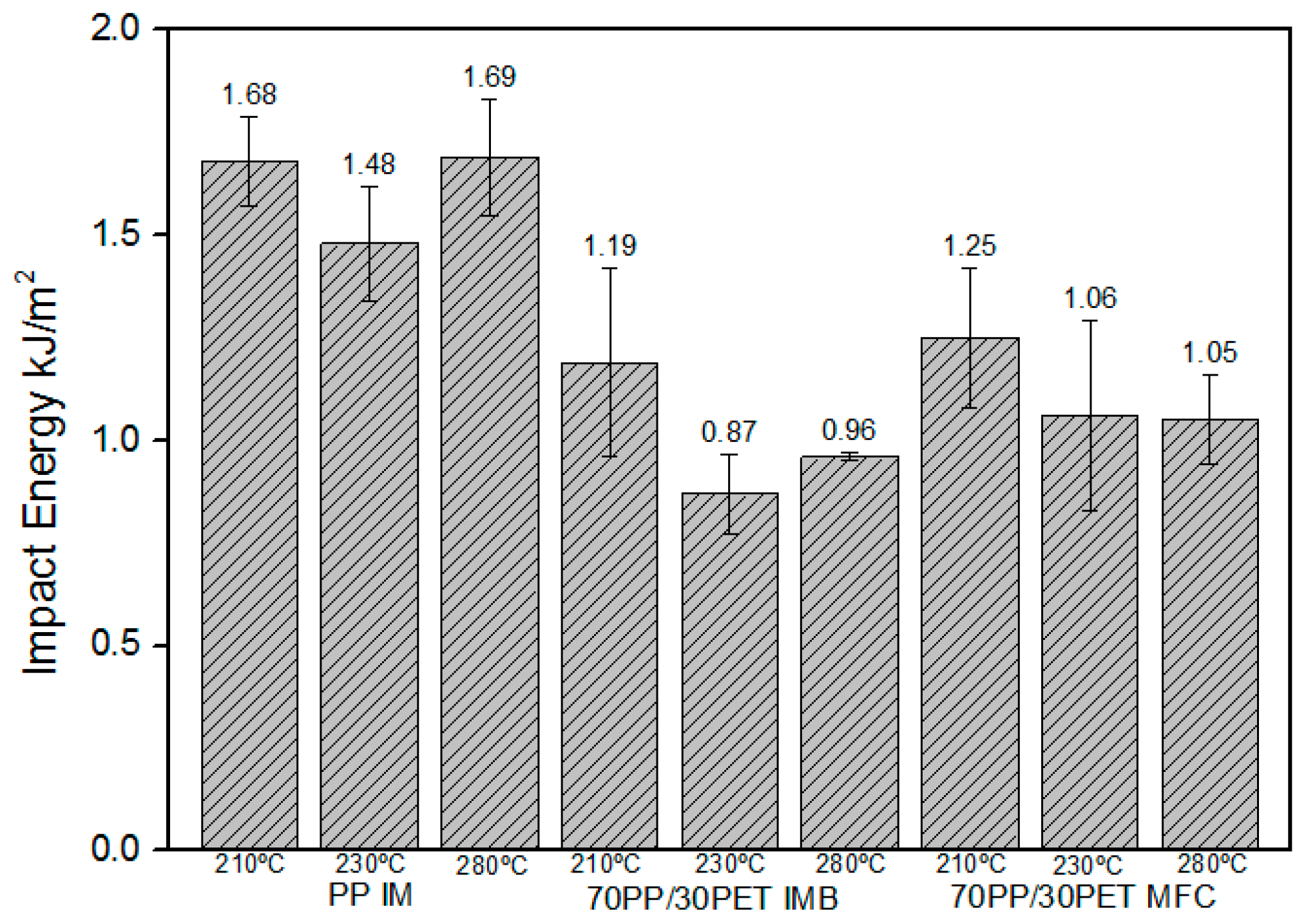

| Sample | Samples made at 210 °C | |||

|---|---|---|---|---|

| Impact | Flexural | |||

| Strength (kJ/m2) | Modulus (GPa) | Strength (MPa) | Strain at maximum flexural stress (%) | |

| PP IM | 1.68 ± 0.11 | 1.161 ± 0.010 | 38.91 ± 0.29 | 8.11 ± 0.13 |

| PET IM | 2.32 ± 0.39 | 2.301 ± 0.056 | 81.95 ± 1.48 | 5.68 ± 0.09 |

| 70PP/30PET IMB | 1.19 ± 0.22 | 1.587 ± 0.034 | 47.66 ± 0.45 | 5.82 ± 0.11 |

| 70PP/30PET MFC | 1.25 ± 0.17 | 1.655 ± 0.030 | 43.60 ± 0.03 | 5.50 ± 0.28 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites. Polymers 2016, 8, 355. https://doi.org/10.3390/polym8100355

Kuzmanović M, Delva L, Cardon L, Ragaert K. The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites. Polymers. 2016; 8(10):355. https://doi.org/10.3390/polym8100355

Chicago/Turabian StyleKuzmanović, Maja, Laurens Delva, Ludwig Cardon, and Kim Ragaert. 2016. "The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites" Polymers 8, no. 10: 355. https://doi.org/10.3390/polym8100355

APA StyleKuzmanović, M., Delva, L., Cardon, L., & Ragaert, K. (2016). The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites. Polymers, 8(10), 355. https://doi.org/10.3390/polym8100355