High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Adhesive Preparation, Bonding and Testing

3. Results

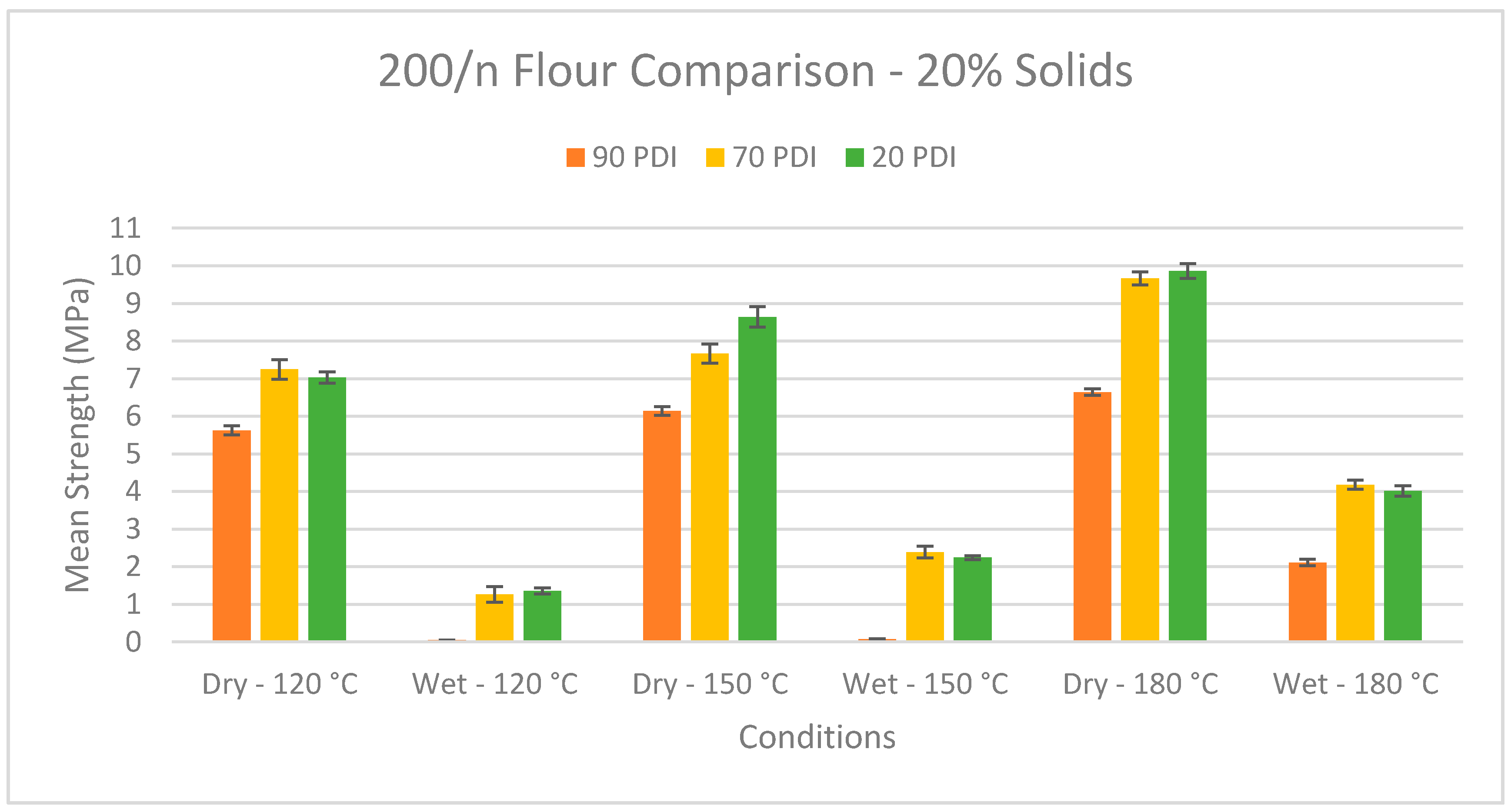

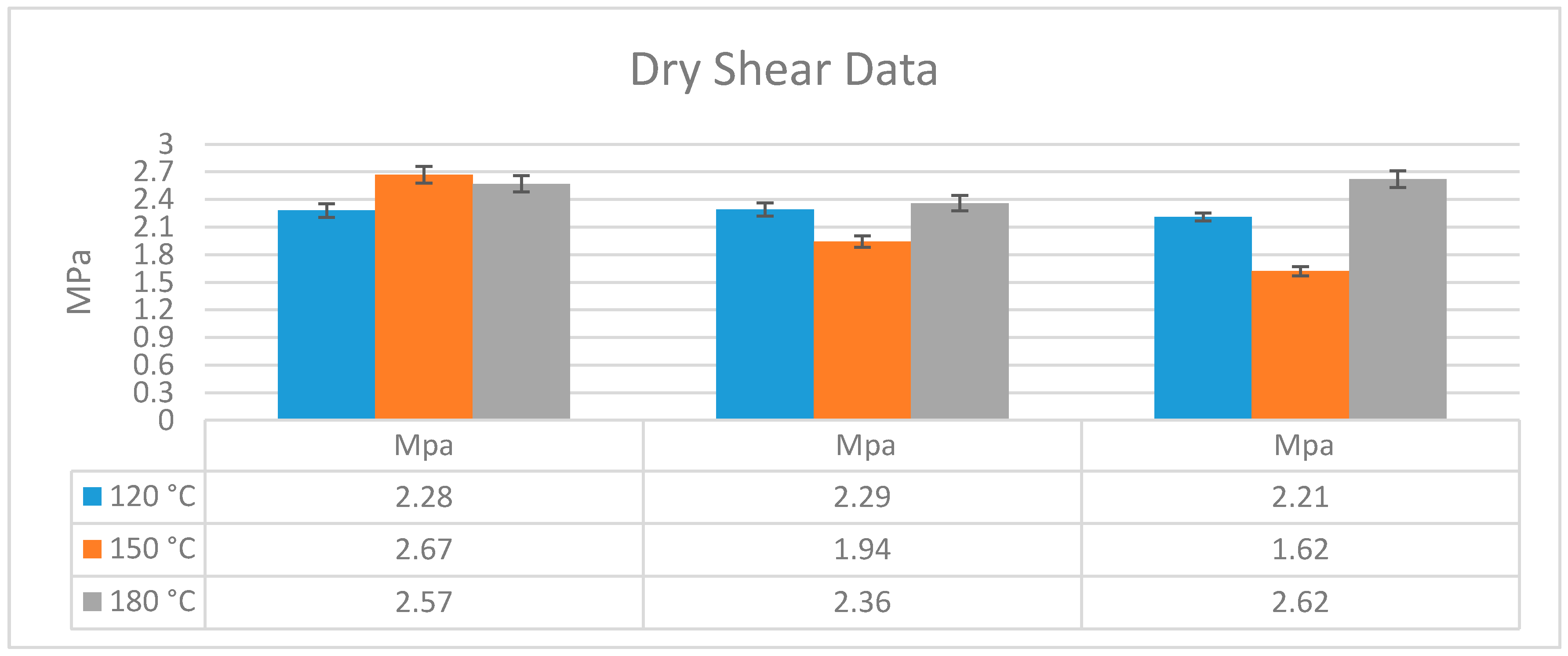

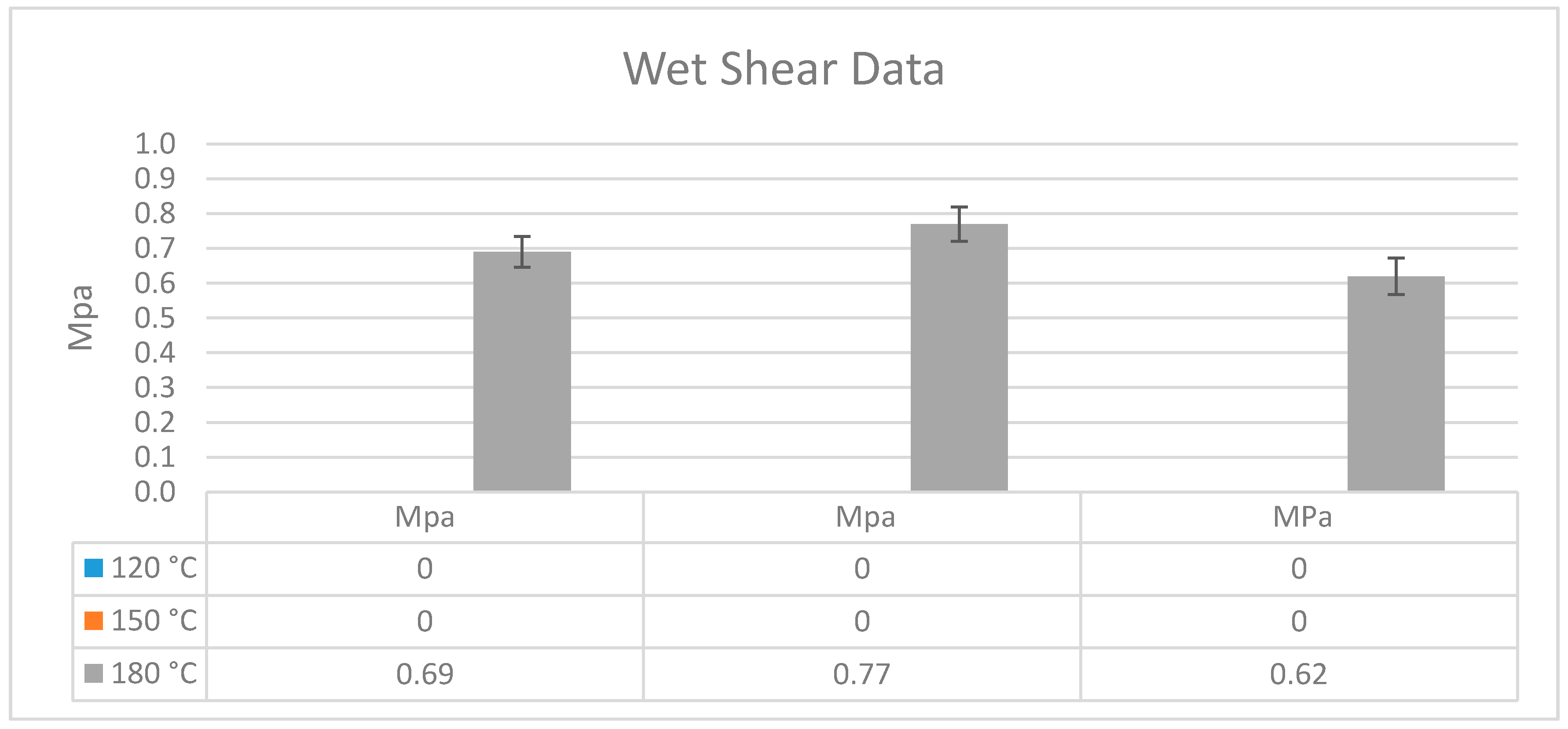

3.1. Soy Flour

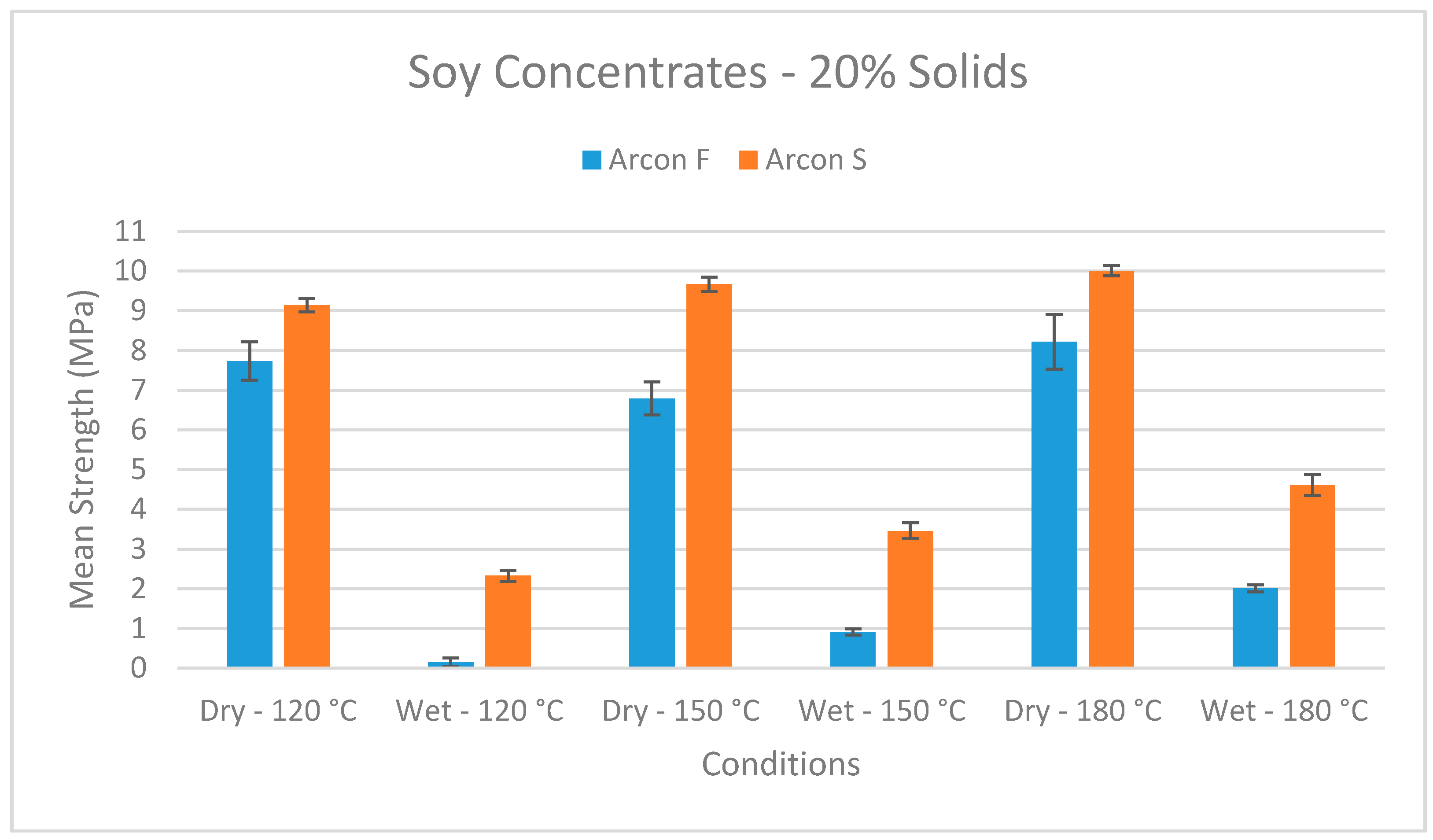

3.2. Soy Concentrate

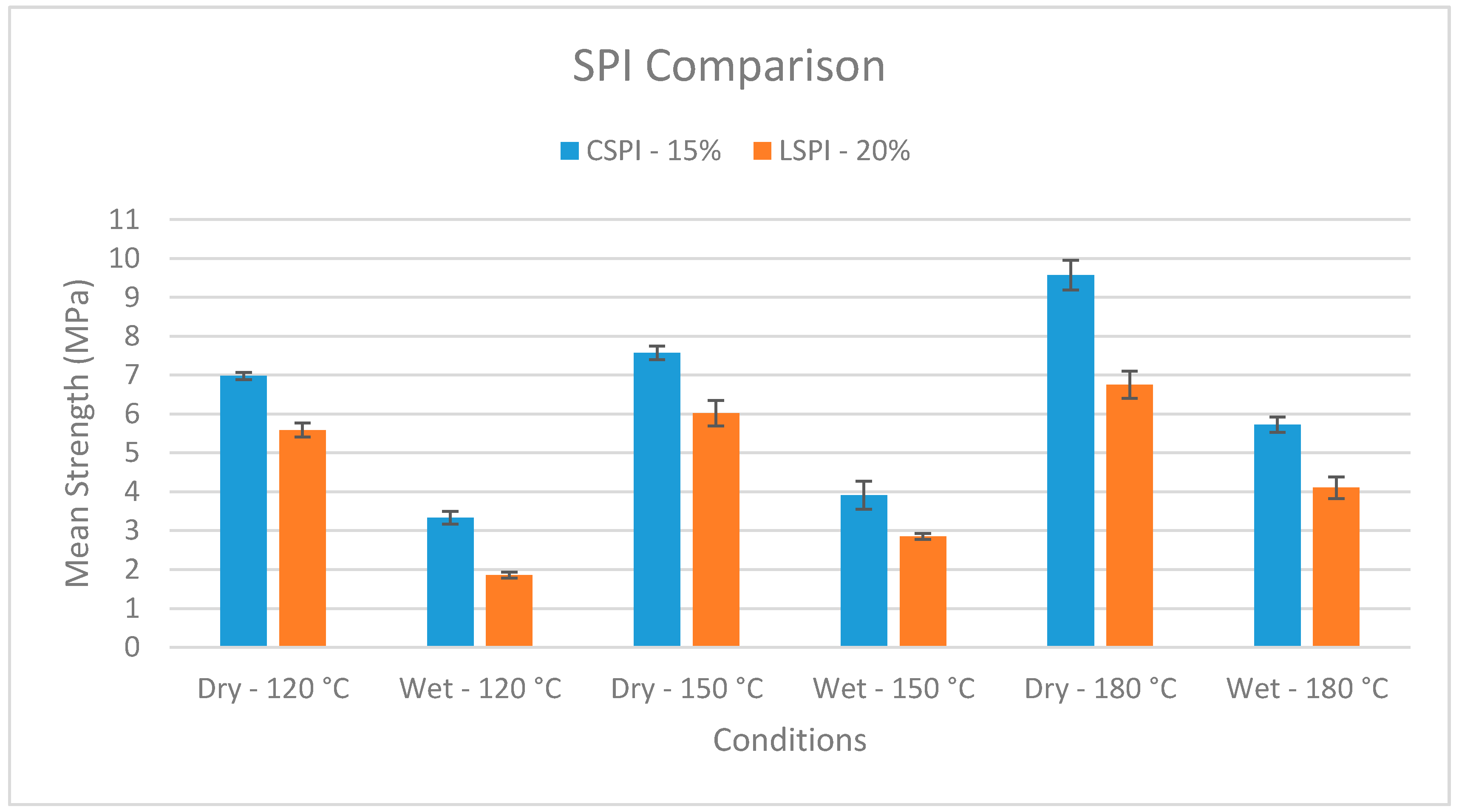

3.3. Soy Protein Isolate

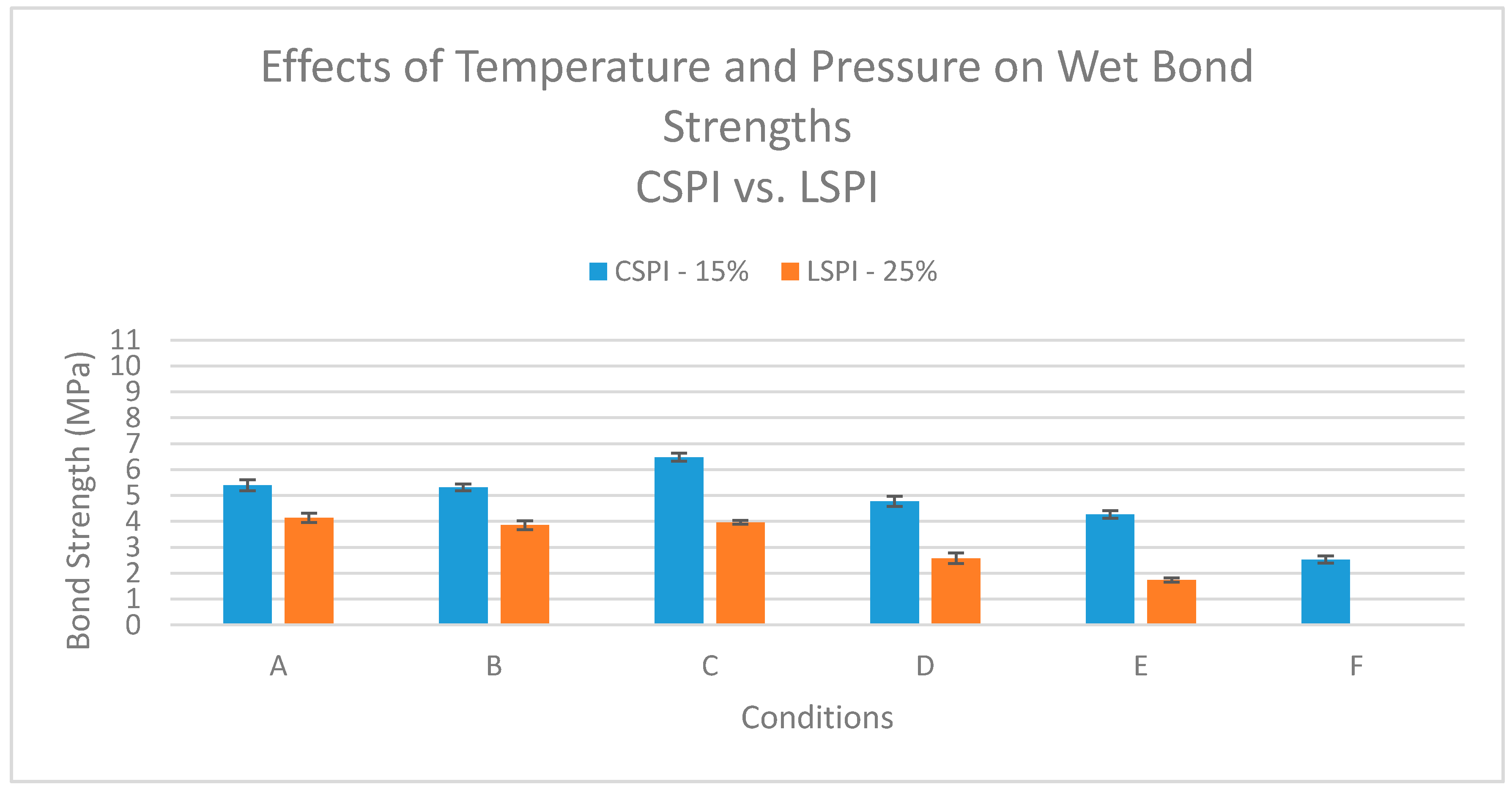

3.4. Oven Bonding and Reheating

3.5. Plywood Bonding

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lambuth, A.L. Soybean Glues. In Handbook of Adhesives; Skeist, I., Ed.; Van Nostrand Reinhold Co.: New York, NY, USA, 1977; pp. 172–180. [Google Scholar]

- Pizzi, A. Urea-formaldehyde adhesives. In Handbook of Adhesive Technology; Pizzi, A., Mittal, K., Eds.; Marcel Dekker: New York, NY, USA, 2003; pp. 635–652. [Google Scholar]

- Sedliačik, J.; Bekhta, P.; Potapova, O. Technology of low-temperature production of plywood bonded with modified phenol-formaldehyde resin. Wood Res. 2010, 55, 123–130. [Google Scholar]

- Wang, X.M.; Li, J.Z.; Zhang, J.Z.; Gao, Q. Technics and Properties of Plywood Manufacture with Modified Urea-formaldehyde Resin. Adv. Mater. Res. 2013, 602, 743–746. [Google Scholar] [CrossRef]

- Frihart, C.R.; Birkeland, M.J. Soy properties and soy wood adhesives. In Soy-Based Chemicals and Materials; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2014; pp. 167–192. [Google Scholar]

- Li, X.; Li, Y.; Zhong, Z.; Wang, D.; Ratto, J.A.; Sheng, K.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.; Sun, X.S.; Fang, X.; Ratto, J.A. Adhesion properties of soy protein with fiber cardboard. J. Am. Oil Chem. Soc. 2001, 78, 37–41. [Google Scholar] [CrossRef]

- Li, H.; Li, C.; Chen, H.; Zhang, D.; Zhang, S.; Li, J. Effects of hot-pressing parameters on shear strength of plywood bonded with modified soy protein adhesives. BioResources 2014, 9, 5858–5870. [Google Scholar] [CrossRef]

- Wang, D.; Sun, X.S.; Yang, G.; Wang, Y. Improved Water Resistance of Soy Protein Adhesive at Isoelectric Point. Trans. ASABE 2009, 52, 173–177. [Google Scholar] [CrossRef]

- Vnučec, D.; Goršek, A.; Kutnar, A.; Mikuljan, M. Thermal modification of soy proteins in the vacuum chamber and wood adhesion. Wood Sci. Technol. 2014, 49, 225–239. [Google Scholar] [CrossRef]

- Vnučec, D.; Kutnar, A.; Goršek, A. Soy-based adhesives for wood-bonding—A review. J. Adhes. Sci. Technol. 2016, in press. [Google Scholar]

- Humphrey, P.E. Thermal and Chemical Injection Effects on PF, PMDI and UF Adhesion Kinetics. In Proceedings of the International Conference on Wood Adhesives 2009; Frihart, C.R., Hunt, C.G., Moon, R.J., Eds.; Forest Products Society: Madison, WI, USA, 2010; pp. 213–223. [Google Scholar]

- Chowdhury, M.J.A.; Humphrey, P.A. The effect of acetylation on the shear strength development kinetics of phenolic resin-to-wood bonds. Wood Fiber Sci. 1999, 1, 293–299. [Google Scholar]

- Frihart, C.R.; Dally, B.N.; Wescott, J.M.; Birkeland, M.J. Bio-Based Adhesives and Reliable Rapid Small Scale Bond Strength Testing. In Proceedings of the International Symposium on Advanced Biomass Science and Technology for Bio-based Products, Beijing, China, 23–25 May 2007.

- Frihart, C.R.; Satori, H. Soy flour dispersibility and performance as wood adhesive. J. Adhes. Sci. Technol. 2013, 27, 2043–2052. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; van Boekel, M.A.J.S. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2001, 11, 364–373. [Google Scholar] [CrossRef]

- Chen, N.; Lin, Q.; Rao, J.; Zeng, Q. Water resistances and bonding strengths of soy-based adhesives containing different carbohydrates. Ind. Crops Prod. 2013, 50, 44–49. [Google Scholar] [CrossRef]

- Bainy, E.M.; Tosh, S.M.; Corredig, M.; Poysa, V.; Woodrow, L. Varietal differences of carbohydrates in defatted soybean flour and soy protein isolate by-products. Carbohydr. Polym. 2008, 72, 664–675. [Google Scholar] [CrossRef]

- Middelbos, I.S.; Fahey, G.C., Jr. Soybean Carbohydrates. In Soybeans-Chemistry, Production, Processing, and Utilization; Johnson, L.A., White, P.J., Galoway, R., Eds.; AOCS Press: Urbana, IL, USA, 2008; pp. 269–296. [Google Scholar]

- Huang, W.; Sun, X. Adhesive Properties of Soy Proteins Modified by Sodium Dodecyl Sulfate and Sodium Dodecylbenzene Sulfonate. J. Am. Oil Chem. Soc. 2000, 77, 705–708. [Google Scholar] [CrossRef]

- Petruccelli, S.; Cristina, M. Soy Protein Isolate Components and Their Interactions. J. Agric. Food Chem. 1995, 43, 1762–1767. [Google Scholar] [CrossRef]

- Egbert, W.R. Isolated Soy Protein: Technology, Properties, and Applications. In Soybeans as Functional Foods and Ingredients; Liu, K., Ed.; AOCS Press: Champaign, IL, USA, 2004; pp. 134–162. [Google Scholar]

- Wang, Y.; Sun, X.S.; Wang, D. Effects of preheating treatment on thermal property and adhesion performance of soy protein isolates. J. Adhes. Sci. Technol. 2007, 21, 281–286. [Google Scholar] [CrossRef]

- Lorenz, L.; Birkeland, M.; Daurio, C.; Frihart, C.R. Soy Flour Adhesive Strength Compared with That of Purified Soy Proteins. For. Prod. J. 2015, 65, 26–30. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Guo, S.; Phillips, G.O. Soy proteins: A review on composition, aggregation and emulsification. Food Hydrocoll. 2014, 39, 301–318. [Google Scholar] [CrossRef]

| Conditions | |

|---|---|

| A | Bonded @ 120 °C with ABES, Reheated @ 180 °C with ABES |

| B | Bonded @ 120 °C with ABES, Reheated @ 180 °C in oven (10 min) |

| C | Bonded @ 180 °C with ABES |

| D | Bonded @ 180 °C in oven (10 min) |

| E | Bonded @ 120 °C with ABES (10 min) |

| F | Bonded @ 120 °C in oven (10 min) |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frihart, C.R.; Coolidge, T.; Mock, C.; Valle, E. High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength. Polymers 2016, 8, 394. https://doi.org/10.3390/polym8110394

Frihart CR, Coolidge T, Mock C, Valle E. High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength. Polymers. 2016; 8(11):394. https://doi.org/10.3390/polym8110394

Chicago/Turabian StyleFrihart, Charles R., Thomas Coolidge, Chera Mock, and Eder Valle. 2016. "High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength" Polymers 8, no. 11: 394. https://doi.org/10.3390/polym8110394

APA StyleFrihart, C. R., Coolidge, T., Mock, C., & Valle, E. (2016). High Bonding Temperatures Greatly Improve Soy Adhesive Wet Strength. Polymers, 8(11), 394. https://doi.org/10.3390/polym8110394