Performance Evaluation of HDPE-Bakelite Dual-Modified Asphalt Mixtures for Sustainable Pavements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design and Sample Preparation

2.3. Performance Experimental Program

2.3.1. Indirect Tensile Strength Test

2.3.2. Resilient Modulus Test

2.3.3. Hamburg Wheel Tracking Test

3. Results and Discussion

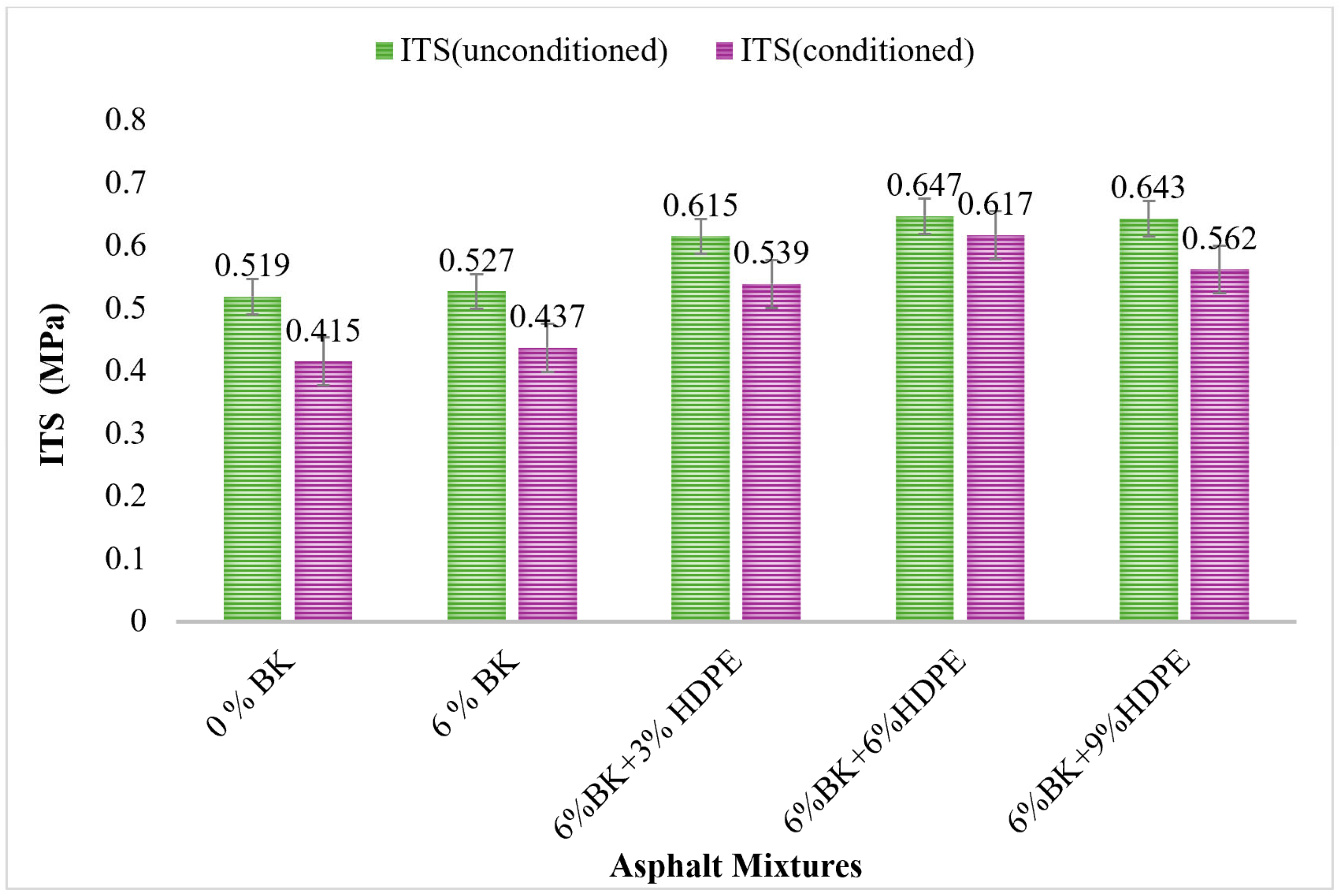

3.1. Indirect Tensile Strength (ITS) Results

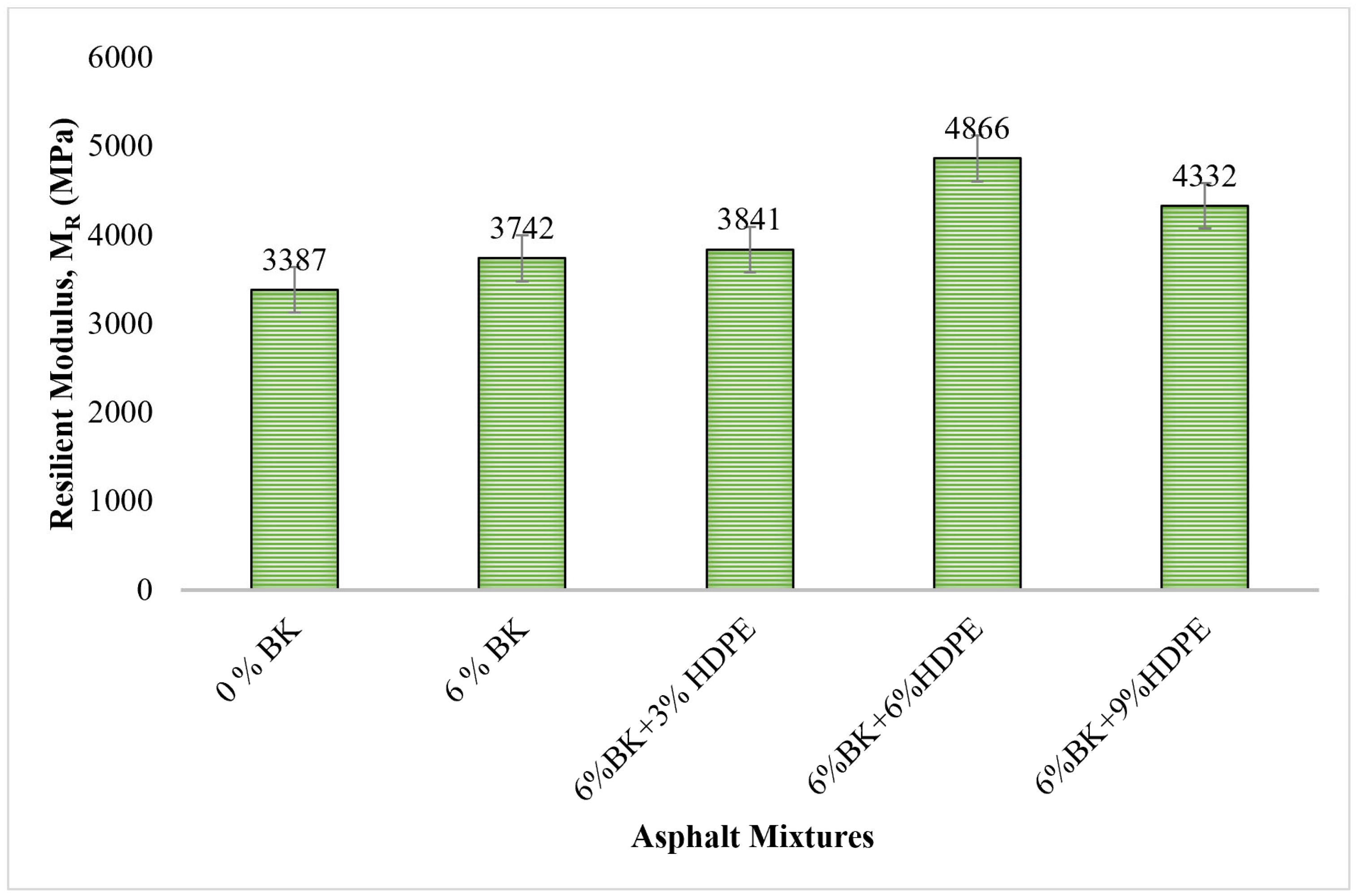

3.2. Resilient Modulus Results

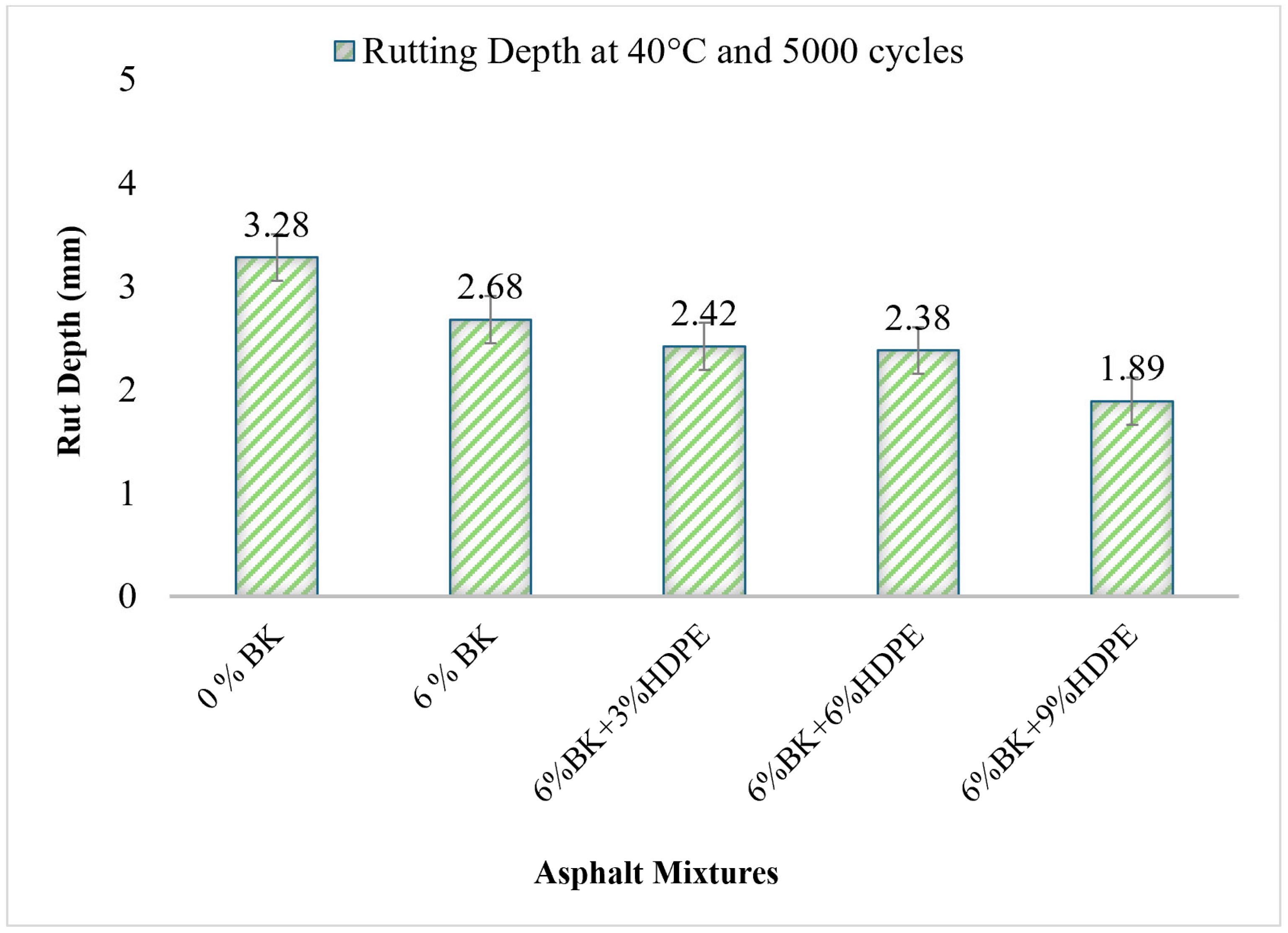

3.3. Hamburg Wheel Tracking Test (HWTT)—Rutting Resistance

4. Conclusions

- The 6%BK + 6%HDPE combination emerged as the optimal formulation, demonstrating balanced improvements across all performance parameters. This composition achieved 24.7% improvement in unconditioned ITS, 48.7% improvement in conditioned ITS, 95.36% TSR (exceeding AASHTO T283 requirements by 19%), 43.7% enhancement in resilient modulus, and 27.4% reduction in rutting depth compared to control mixtures.

- The superior performance of 6%BK + 6%HDPE results from complementary reinforcement mechanisms. At 6% concentration, HDPE forms a continuous three-dimensional polymer network that provides elastic recovery and flexibility, while Bakelite particles act as rigid reinforcing nodes embedded within this network, enhancing stiffness and load transfer efficiency. This dual-phase system achieves an optimal balance between flexibility and rigidity that neither modifier provides individually.

- Polymer modification dramatically improved moisture damage resistance, with the optimal 6%BK + 6%HDPE composition achieving a TSR of 95.36% compared to 79.96% for control mixtures. This represents a critical advancement for Pakistani pavements subjected to monsoon conditions and temperature extremes, potentially extending service life by reducing moisture-induced distress, including stripping and raveling.

- The modified mixtures demonstrated superior performance at elevated temperatures (40 °C HWTT) while maintaining adequate low-temperature properties. The 6%BK + 6%HDPE formulation reduced rutting depth by 27.4%, addressing the primary distress mechanism in Pakistan’s hot climate regions where summer temperatures regularly exceed 45 °C.

- Increasing HDPE content beyond 6% (i.e., 9%HDPE combinations) resulted in performance degradation in tensile strength and resilient modulus, which may be related to mixture stiffness, embrittlement, and possible phase separation or storage instability of the polymer-modified binder. In contrast, rutting resistance continued improving at 9% HDPE, indicating that the optimum HDPE content can differ depending on the governing distress mechanism or failure mode. Future work will incorporate microstructural analyses to directly observe the internal morphology of HDPE–Bakelite modified binders and validate these proposed mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AASHTO | American Association of State Highway and Transportation Officials |

| ASTM | American Society for Testing and Materials |

| BK | Bakelite |

| HDPE | High-Density Polyethylene |

| HWTT | Hamburg Wheel Tracking Test |

| ITS | Indirect Tensile Strength |

| LVDT | Linear Variable Differential Transformer |

| MR | Resilient Modulus |

| NHA | National Highway Authority |

| OBC | Optimum Bitumen Content |

| PE | Polyethylene |

| PP | Polypropylene |

| SBR | Styrene-Butadiene Rubber |

| SBS | Styrene-Butadiene-Styrene |

| TSR | Tensile Strength Ratio |

References

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of moisture damage on asphalt mixtures. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Datta, D.; Khattak, N.; Ghabchi, R. Aging Mechanisms of Polymer-and Non-Polymer-Modified Asphalt Binders. In Proceedings of the International Conference on Transportation and Development 2024, Atlanta, GA, USA, 15–18 June 2024. [Google Scholar]

- Alia, Y.; Hussaina, M.; Riazb, K.; Yousafa, A.; Tufailc, R.F.; Navandard, Y.V.; Rayede, A.M.; Shaha, S.M.A. Investigation of Effect of Bakelite on Mechanical Properties of Hot Mix Asphalt Mixes-A Full Factorial Design Experiment. J. Kejuruter. 2021, 33, 993–1005. [Google Scholar] [CrossRef]

- Junaid, M.; Shah, M.Z.A.; Yaseen, G.; Awan, H.H.; Khan, D.; Jawad, M. Investigating the effect of gradation, temperature and loading duration on the resilient modulus of asphalt concrete. Civ. Eng. J. 2022, 8, 278–289. [Google Scholar] [CrossRef]

- Sultana, M.; Rahman, A.; Chowdhury, S. Performance based maintenance of road infrastructure by contracting-A challenge for developing countries. J. Sevice Sci. Manag. 2012, 5, 118–123. [Google Scholar] [CrossRef]

- Javaid, F.; Siraj, U. Connectivity through belt and road initiative (BRI) and central Asian regional economic cooperation (CAREC) between central Asia and South Asia: A case study of Pakistan. In Proceedings of the 79th Midwest Political Science Association, Chicago, IL, USA, 7–10 April 2022. [Google Scholar]

- Khattak, N.U. Performance Evaluation of Bakelite and Nano-Clay Modified Asphalt Concrete Mixtures. Ph.D. Thesis, National University of Sciences and Technology, Islamabad, Pakistani, 2022. [Google Scholar]

- Al-Hadidy, A.; Tan, Y.-Q. Effect of styrene-butadiene-styrene on the properties of asphalt and stone-matrix-asphalt mixture. J. Mater. Civ. Eng. 2011, 23, 504–510. [Google Scholar] [CrossRef]

- Riccardi, C.; Indacoechea, I.; Wang, D.; Lastra-González, P.; Falchetto, A.C.; Castro-Fresno, D. Low temperature performances of fiber-reinforced asphalt mixtures for surface, binder, and base layers. Cold Reg. Sci. Technol. 2023, 206, 103738. [Google Scholar] [CrossRef]

- Villanueva, A.; Ho, S.; Zanzotto, L. Asphalt modification with used lubricating oil. Can. J. Civ. Eng. 2008, 35, 148–157. [Google Scholar] [CrossRef]

- Noor, A.; Rehman, M.A.U. A mini-review on the use of plastic waste as a modifier of the bituminous mix for flexible pavement. Clean. Mater. 2022, 4, 100059. [Google Scholar] [CrossRef]

- Khan, D.; Khan, R.; Khan, M.T.; Alam, M.; Hassan, T. Performance of hot-mix asphalt using polymer-modified bitumen and marble dust as a filler. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 385–398. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.M.M.; Tauste-Martínez, R.; De Matos, J.M.; Rubio-Gamez, M.C. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Gorkem, C.; Sengoz, B. Predicting stripping and moisture induced damage of asphalt concrete prepared with polymer modified bitumen and hydrated lime. Constr. Build. Mater. 2009, 23, 2227–2236. [Google Scholar] [CrossRef]

- Khattak, N.; Ghabchi, R. Effect of Different Aging Scenarios on the Adhesion and Moisture-Induced Damage Potential of Asphalt Binders. In Airfield and Highway Pavements 2025; American Society of Civil Engineers: Reston, VA, USA, 2025; pp. 38–47. [Google Scholar]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Olard, F.; Perraton, D. On the optimization of the aggregate packing characteristics for the design of high-performance asphalt concretes. Road Mater. Pavement Des. 2010, 11 (Suppl. S1), 145–169. [Google Scholar] [CrossRef]

- Qiao, Y. Flexible Pavements and Climate Change: Impact of Climate Change on the Performance, Maintenance, and Life-Cycle Costs of Flexible Pavements. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2015. [Google Scholar]

- Gadalla, A. The Effects of Extreme Weather Events on Flexible Pavement. Bachelor’s Thesis, University of Southern Queensland, Toowoomba, Australia, 2020. [Google Scholar]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Basheet, S.H.; Latief, R.H. Assessment of the properties of asphalt mixtures modified with LDPE and HDPE polymers. Int. J. Appl. Sci. Eng. 2025, 21, 2024265. [Google Scholar] [CrossRef]

- Mansourian, A.; Goahri, A.R.; Khosrowshahi, F.K. Performance evaluation of asphalt binder modified with EVA/HDPE/nanoclay based on linear and non-linear viscoelastic behaviors. Constr. Build. Mater. 2019, 208, 554–563. [Google Scholar] [CrossRef]

- Masri, K.A.; Arshad, A.K.; Samsudin, M.S. Mechanical properties of porous asphalt with nanosilica modified binder. J. Teknol. (Sci. Eng.) 2016, 78, 139–146. [Google Scholar] [CrossRef]

- Ahmad, M.; Beddu, S.; Hussain, S.; Manan, A.; Itam, Z.B. Mechanical properties of hot-mix asphalt using waste crumber rubber and phenol formaldehyde polymer. AIMS Mater. Sci. 2019, 6, 1164–1175. [Google Scholar] [CrossRef]

- Saha, S.K.; Suman, S. Characterization of bakelite-modified bitumen. Innov. Infrastruct. Solut. 2017, 2, 3. [Google Scholar] [CrossRef]

- Ullah, S.; Raheel, M.; Khan, R.; Khan, M.T. Characterization of physical & mechanical properties of asphalt concrete containing low-& high-density polyethylene waste as aggregates. Constr. Build. Mater. 2021, 301, 124127. [Google Scholar]

- Vargas, C.; Hanandeh, A.E. The utilisation of polyethylene waste pyrolytic wax as an additive to enhance the performance of virgin and polypropylene-modified bitumen. Int. J. Pavement Res. Technol. 2024, 17, 929–951. [Google Scholar] [CrossRef]

- ASTM C128-25; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2025. [CrossRef]

- ASTM C131; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- BS 812-110; Testing Aggregates—Methods for Determination of Aggregate Crushing Value (ACV). British Standards Institution (BSI): London, UK, 1990.

- BS 812-105; Testing Aggregates. Methods for Determination of Particle Shape—Flakiness Index. British Standards Institution (BSI): London, UK, 1985.

- BS 812-106; Testing Aggregates—Method for Determination of shell Content in Coarse Aggregate. British Standards Institution (BSI): London, UK, 1985.

- ASTM D 5; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D92; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM 70; Standard Test Method for Density of Semi-Solid Asphalt Binder (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- AASHTO T283; Standard Method of Test for Resistance of Compacted Asphalt Mixture to Moisture lnduced Damage. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- ASTM D4123; Standard Test Method for Indirect Tension Test for Resilient Modulus of Bituminous Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- AASHTO T324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2023.

- Khan, A.; Ahmed, S.; Khattak, N.U.; Hoy, M.; Se, C. Effect of Nanoclay on the Performance Characteristics of SBS-Modified Asphalt Concrete Mixtures. Coatings 2025, 15, 984. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Feng, C.P.; Al-Hadidy, A. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Khattak, N.U.; Irfan, M.; Hoy, M.; Khan, A. Effects of synergistic combined Bakelite and Nano clay modification on asphalt mixture performance properties. Road Mater. Pavement Des. 2025, 26, 2414–2430. [Google Scholar] [CrossRef]

- Zhang, X.; Han, C.; Yang, J.; Xu, X.; Zhang, F. Evaluating the rheological properties of high-modulus asphalt binders modified with rubber polymer composite modifier. Materials 2021, 14, 7727. [Google Scholar] [CrossRef] [PubMed]

- Moghadas Nejad, F.; Gholami, M.; Naderi, K.; Rahi, M. Evaluation of rutting properties of high density polyethylene modified binders. Mater. Struct. 2015, 48, 3295–3305. [Google Scholar] [CrossRef]

- Hu, Y.; Yin, Y.; Sreeram, A.; Liu, J.; Si, W.; Tang, D.; Airey, G.D. Nano-aggregation of asphaltenes and its influence on the multiscale properties of bitumen recycled through multiple ageing and rejuvenation cycles. Chem. Eng. J. 2025, 512, 162348. [Google Scholar] [CrossRef]

| Test | Standard | Aggregate | Specification | |

|---|---|---|---|---|

| Coarse | Fine | |||

| Specific Gravity | ASTM C127/C128 [28] | 2.63 | 2.64 | - |

| Water Absorption (%) | ASTM C127/C128 [28] | 0.93 | 2.61 | <3% |

| Los Angeles Abrasion (%) | ASTM C131 [29] | 27 | - | <30% |

| Aggregate Crushing Value (%) | BS 812-110 [30] | 19 | - | <30% |

| Flakiness Index (%) | BS 812-105 [31] | 8.5 | - | <10% |

| Elongation Index (%) | BS 812-106 [32] | 3.85 | - | <10% |

| Test | Standard | Results | Specification |

|---|---|---|---|

| Penetration 25 (°C), mm | ASTM D 5 [33] | 63 | 60–70 |

| Flash point (°C) | ASTM D92 [34] | 260 | 232 (min) |

| Fire Point (°C) | ASTM D92 [34] | 292 | 270 (min) |

| Specific gravity | ASTM 70 [35] | 1.04 | 1.01–1.06 |

| Ductility Test, cm | ASTM D113 [36] | 123 | >100 |

| Properties | Results |

|---|---|

| Density (kg/cm2) | 0.948–0.953 |

| Softening point (°C) | 122 |

| Tensile strength at yield (kg/cm2) | 190 |

| Flexural modulus (kg/cm2) | 8000 |

| Properties | Results |

|---|---|

| Specific gravity | 1.36 |

| Melting point range (°C) | 150–165 |

| Decomposition temp. range (°C) | 270–350 |

| Sieve analysis | Passing sieve#100 (150 µm) |

| Sieve Size | Passing (%) |

|---|---|

| 19 mm (3/4”) | 100 |

| 12.5 mm (1/2”) | 75–90 |

| 9.5 mm (3/8”) | 60–80 |

| 4.75 mm (No. 4) | 40–60 |

| 2.36 mm (No. 8) | 20–40 |

| 0.300 mm (No. 50) | 5–15 |

| 0.075 mm (No. 200) | 3–8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yasir, M.; Khattak, N.U.; Khan, I.; Hoy, M. Performance Evaluation of HDPE-Bakelite Dual-Modified Asphalt Mixtures for Sustainable Pavements. Polymers 2025, 17, 3065. https://doi.org/10.3390/polym17223065

Yasir M, Khattak NU, Khan I, Hoy M. Performance Evaluation of HDPE-Bakelite Dual-Modified Asphalt Mixtures for Sustainable Pavements. Polymers. 2025; 17(22):3065. https://doi.org/10.3390/polym17223065

Chicago/Turabian StyleYasir, Muhammad, Naqeeb Ullah Khattak, Inamullah Khan, and Menglim Hoy. 2025. "Performance Evaluation of HDPE-Bakelite Dual-Modified Asphalt Mixtures for Sustainable Pavements" Polymers 17, no. 22: 3065. https://doi.org/10.3390/polym17223065

APA StyleYasir, M., Khattak, N. U., Khan, I., & Hoy, M. (2025). Performance Evaluation of HDPE-Bakelite Dual-Modified Asphalt Mixtures for Sustainable Pavements. Polymers, 17(22), 3065. https://doi.org/10.3390/polym17223065