Experimental and Numerical Study of Laser Beam Welding of PBT-G30 for Electronic Housings in Automotive Applications

Abstract

1. Introduction

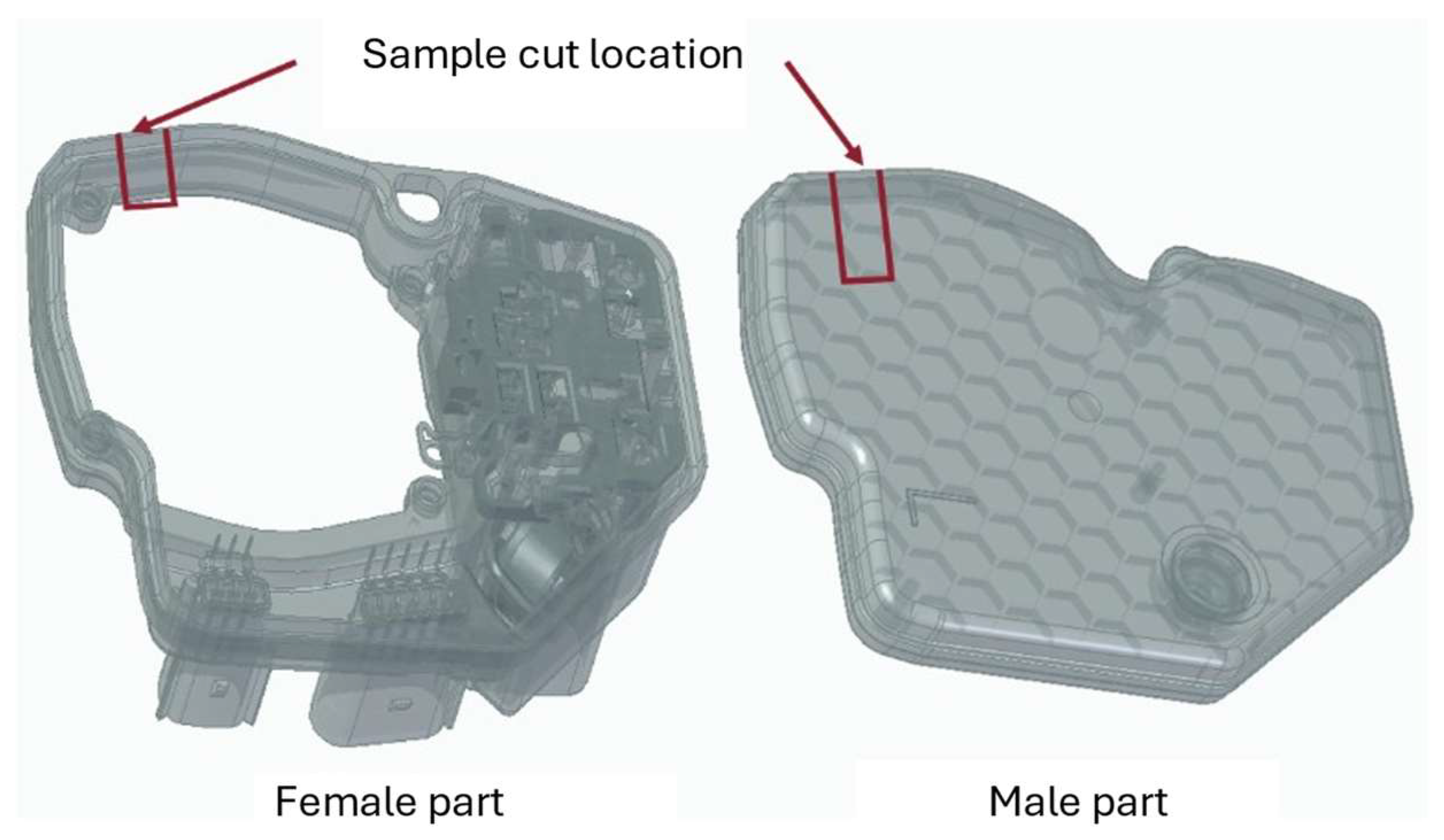

2. Experimental Methodology

2.1. Laser Welding Process

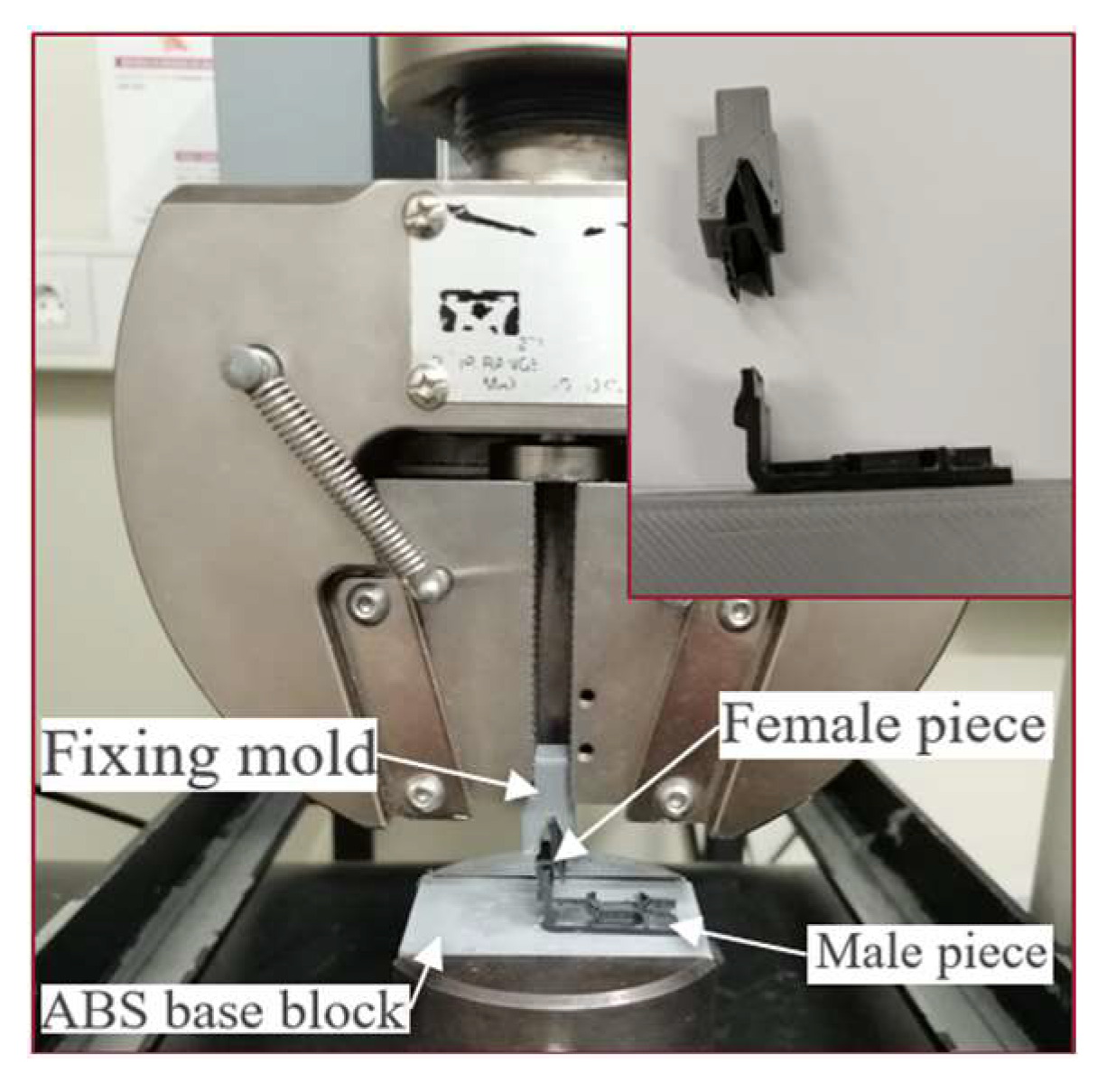

2.1.1. Welding Fixtures

2.1.2. Test Fixtures

2.1.3. Displacement Measurement

3. Experimental Results

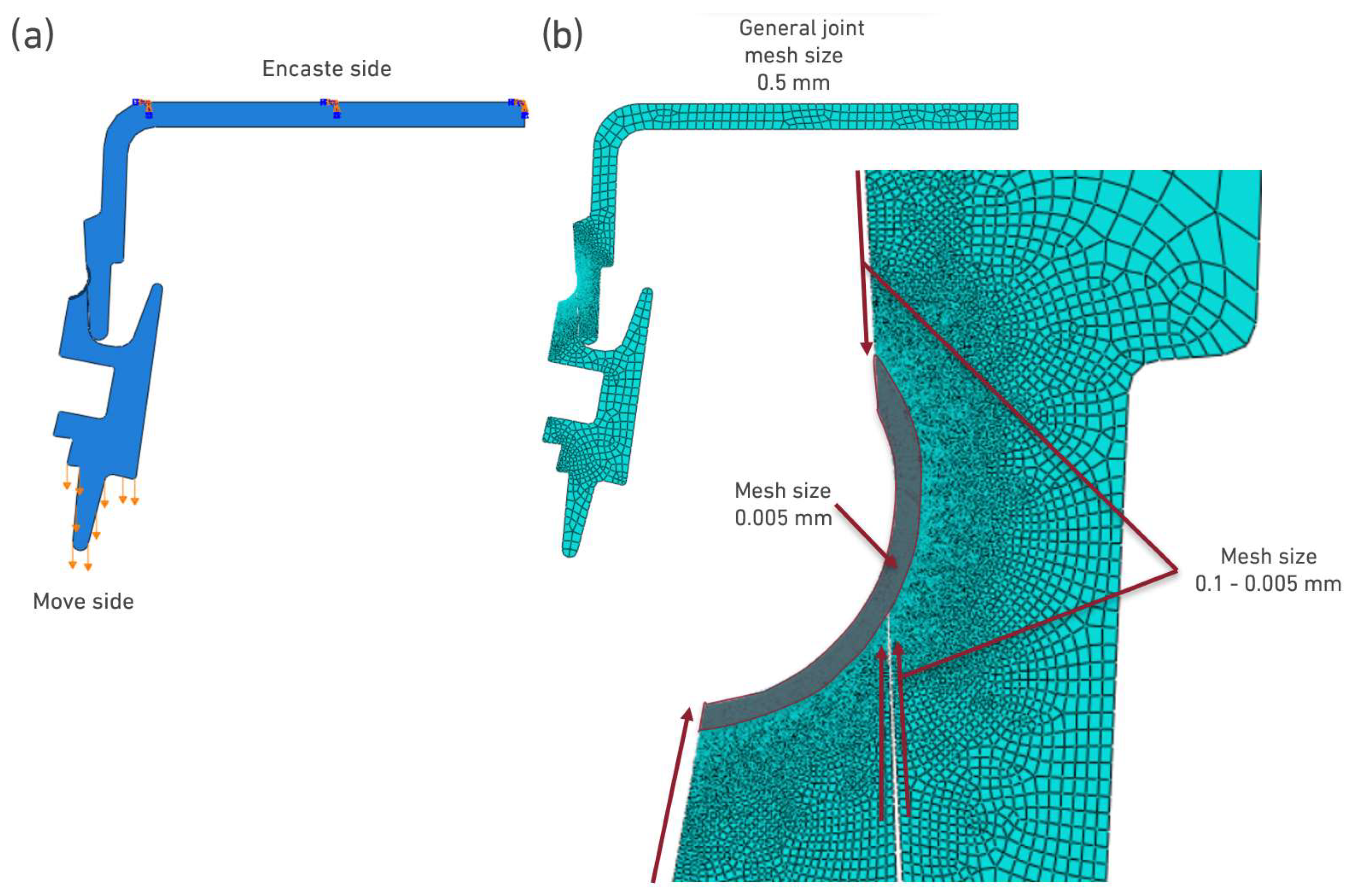

4. Numerical Details

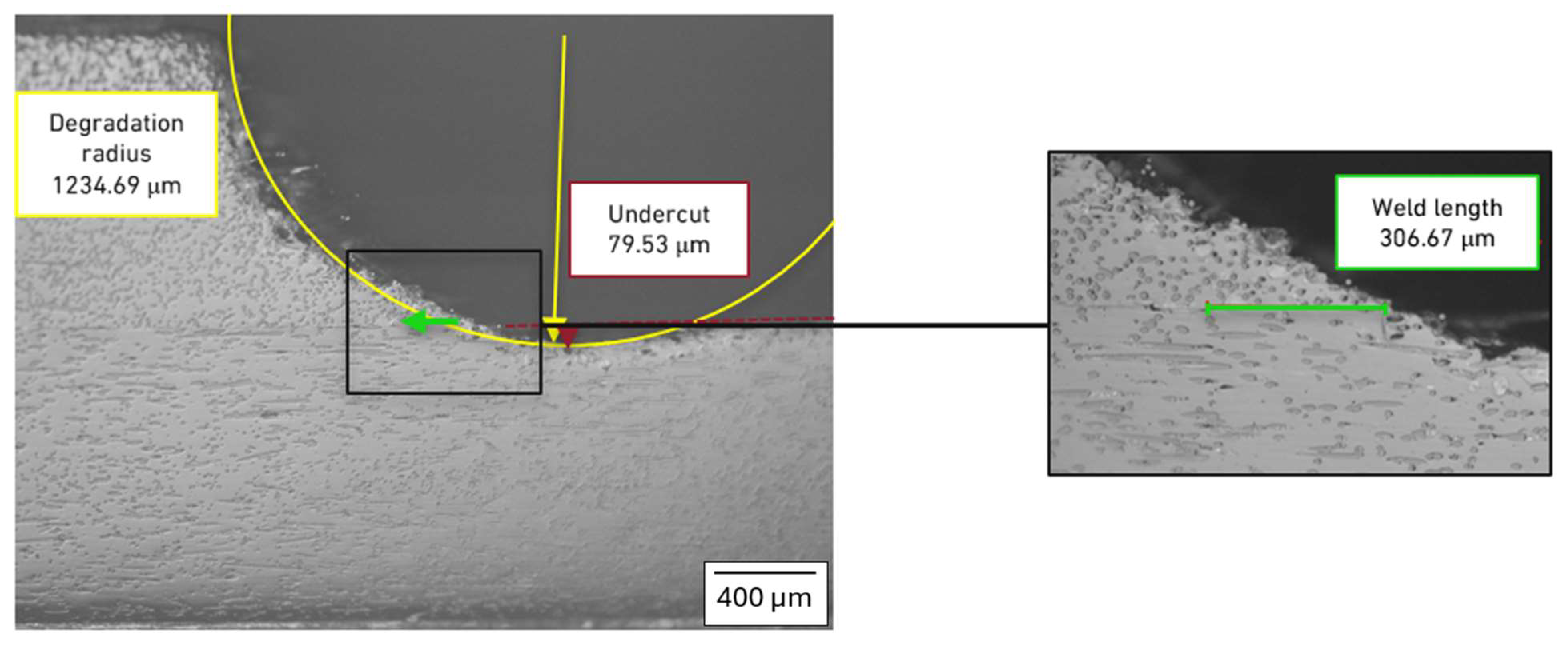

4.1. Microscopical Analysis

4.2. Modelling Details

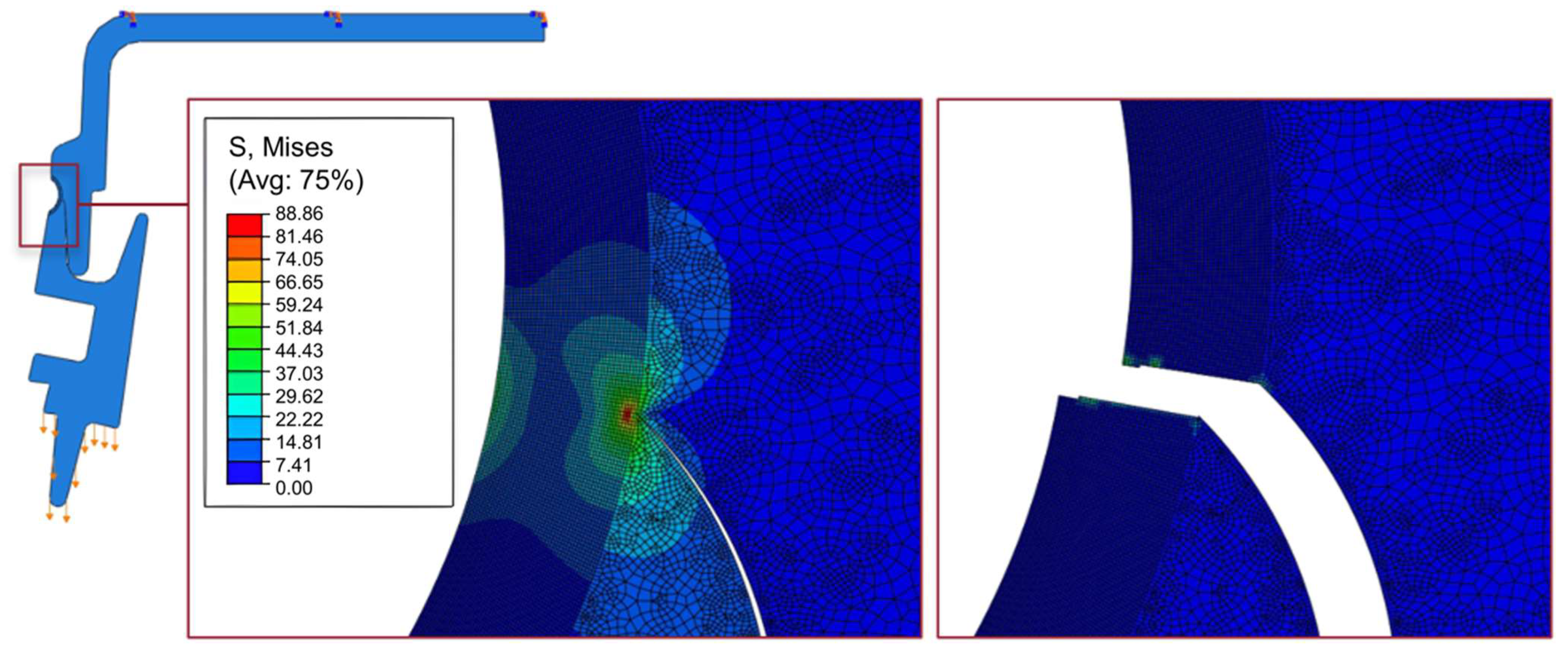

5. Numerical Results

6. Conclusions

- The butt-overlap joint configuration created a stronger connection than a purely overlapped one, as it could resist both shear and normal stresses simultaneously.

- Digital Image Correlation (DIC) was validated as a robust method for accurately evaluating joint performance by providing precise displacement data.

- Elasto-plastic numerical models with ductile damage formulations were found to be a practical design tool for these joints, showing good convergence in predicting failure loads. However, they faced challenges in accurately matching the real specimen’s overall compliance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taub, A.; De Moor, E.; Luo, A.; Matlock, D.K.; Speer, J.G.; Vaidya, U. Materials for automotive lightweighting. Annu. Rev. Mater. Res. 2019, 49, 327–359. [Google Scholar] [CrossRef]

- Begum, S.A.; Rane, A.V.; Kanny, K. Applications of compatibilized polymer blends in automobile industry. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 563–593. [Google Scholar]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Olhan, S.; Khatkar, V.; Behera, B. Textile-based natural fibre-reinforced polymeric composites in automotive lightweighting. J. Mater. Sci. 2021, 56, 18867–18910. [Google Scholar] [CrossRef]

- Patel, M.; Pardhi, B.; Chopara, S.; Pal, M. Lightweight composite materials for automotive-a review. Carbon 2018, 1, 151. [Google Scholar]

- Pervaiz, M.; Panthapulakkal, S.; Sain, M.; Tjong, J. Emerging trends in automotive lightweighting through novel composite materials. Mater. Sci. Appl. 2016, 7, 26. [Google Scholar] [CrossRef]

- Vyavahare, S.A.; Kharat, B.M.; More, A.P. Polybutylene terephthalate (PBT) blends and composites: A review. Vietnam J. Chem. 2024, 62, 579–589. [Google Scholar] [CrossRef]

- Borges, C.S.; Akhavan-Safar, A.; Marques, E.A.; Carbas, R.J.; Ueffing, C.; Weißgraeber, P.; da Silva, L.F. Effect of water ingress on the mechanical and chemical properties of polybutylene terephthalate reinforced with glass fibers. Materials 2021, 14, 1261. [Google Scholar] [CrossRef] [PubMed]

- Mortazavian, S.; Fatemi, A. Tensile and fatigue behaviors of polymers for automotive applications: Zähigkeits-und Ermüdungsverhalten von Polymeren für Automobilanwendungen. Mater. Werkst. 2015, 46, 204–213. [Google Scholar] [CrossRef]

- Niu, L.; Xu, J.; Yang, W.; Ma, J.; Zhao, J.; Kang, C.; Su, J. Study on the synergetic fire-retardant effect of nano-Sb2O3 in PBT Matrix. Materials 2018, 11, 1060. [Google Scholar] [CrossRef]

- Dobrotă, D.; Lazăr, S.V. Redesign of the geometry of parts produced from PBT composite to improve their operational behavior. Polymers 2021, 13, 2536. [Google Scholar] [CrossRef]

- Mu, B.; Jiang, Z.; Yang, B.; Cui, J.; Wang, X.; Guo, J.; Bao, X.; Chen, L. Tribological and mechanical properties of PBT composites with microcapsules and potassium titanate whiskers. Polym. Eng. Sci. 2019, 59, 490–499. [Google Scholar] [CrossRef]

- Pegoretti, A. Towards sustainable structural composites: A review on the recycling of continuous-fiber-reinforced thermoplastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 105–115. [Google Scholar] [CrossRef]

- Silva, L.; Marques, E.; da Silva, L.F. Polymer joining techniques state of the art review. Weld. World 2021, 65, 2023–2045. [Google Scholar] [CrossRef]

- Acherjee, B. Laser transmission welding of polymers–a review on welding parameters, quality attributes, process monitoring, and applications. J. Manuf. Process. 2021, 64, 421–443. [Google Scholar] [CrossRef]

- Chen, M.; Zak, G.; Bates, P.J. Effect of carbon black on light transmission in laser welding of thermoplastics. J. Mater. Process. Technol. 2011, 211, 43–47. [Google Scholar] [CrossRef]

- Okuizumi, R.; Hirota, S.; Takagi, Y.; Sudoh, M.; Okano, Y. Process analysis of laser welding method with polybutyleneterephthalate (PBT). Adv. Mater. Res. 2011, 222, 150–153. [Google Scholar] [CrossRef]

- Hu, S.; Li, F.; Zuo, P. Numerical simulation of laser transmission welding—A review on temperature field, stress field, melt flow field, and thermal degradation. Polymers 2023, 15, 2125. [Google Scholar] [CrossRef] [PubMed]

- Labeas, G.; Moraitis, G.; Katsiropoulos, C.V. Optimization of laser transmission welding process for thermoplastic composite parts using thermo-mechanical simulation. J. Compos. Mater. 2010, 44, 113–130. [Google Scholar] [CrossRef]

- Fernandes, F.A.; Pereira, A.B.; Guimarães, B.; Almeida, T. Laser welding of transmitting high-performance engineering thermoplastics. Polymers 2020, 12, 402. [Google Scholar] [CrossRef]

- Borges, C.; Nunes, P.; Akhavan-Safar, A.; Marques, E.; Carbas, R.; Alfonso, L.; Silva, L. A strain rate dependent cohesive zone element for mode I modeling of the fracture behavior of adhesives. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 610–621. [Google Scholar] [CrossRef]

- Kagan, V.; Pinho, G. Laser transmission welding of semicrystalline thermoplastics-part II: Analysis of mechanical performance of welded nylon. J. Reinf. Plast. Compos. 2004, 23, 95–107. [Google Scholar] [CrossRef]

- Xu, X.; Deng, J.; Nie, S.; Lan, Z.; Xu, Z. Effect of thermal aging on mechanical properties and morphology of GF/PBT composites. Polymers 2023, 15, 3798. [Google Scholar] [CrossRef] [PubMed]

- Bonora, N.; Gentile, D.; Pirondi, A.; Newaz, G. Ductile damage evolution under triaxial state of stress: Theory and experiments. Int. J. Plast. 2005, 21, 981–1007. [Google Scholar] [CrossRef]

- Beygi, R.; Akhavan-Safar, A.; Carbas, R.; Barbosa, A.; Marques, E.; da Silva, L. Utilizing a ductile damage criterion for fracture analysis of a dissimilar aluminum/steel joint made by friction stir welding. Eng. Fract. Mech. 2022, 274, 108775. [Google Scholar] [CrossRef]

- Kasaei, M.M.; Pereira, J.A.; Carbas, R.J.; Marques, E.A.; da Silva, L.F. Ductile fracture prediction in hole hemming of aluminum and magnesium sheets. Metals 2023, 13, 1559. [Google Scholar] [CrossRef]

| Power | 64 W | Scheme picture |

| Inclination | 1.5 mm | |

| Aim position | 1.5 ms | |

| Frequency | Manual operation | |

| Speed rate | ||

| Focus distance | See scheme | |

| Inclination | ||

| Aim position |

| Material [PBT GF30] | Young’s Modulus [MPa] | Poisson Ratio | Density [g/cm3] |

|---|---|---|---|

| As received | 8398 | 0.45 | 1.31 |

| Treated at 225 °C | 5317 | 0.42 | 1.31 |

| Treated at 237 °C | 5183 | 0.42 | 1.31 |

| Treated at 257 °C | 4826 | 0.42 | 1.31 |

| Material | Fracture Strain [mm/mm] | Stress Triaxiality | Strain Rate [s−1] | Displacement at Failure [mm] |

|---|---|---|---|---|

| As received | 0.011492123 | −0.33 | 0 | 0.001 |

| Treated at 225 °C | 0.006559261 | −0.33 | 0 | 0.001 |

| Treated at 237 °C | 0.003570756 | −0.33 | 0 | 0.0007 |

| Treated at 257 °C | 0.000821712 | −0.33 | 0 | 0.0007 |

| External Layer | Middle Layer | Internal Layer |

|---|---|---|

| Treated at 225 °C | Treated at 237 °C | Treated at 257 °C |

| 61.60% | 15.40% | 23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, L.R.R.; Nunes, P.D.P.; Marques, E.A.S.; Carbas, R.J.C.; da Silva, L.F.M. Experimental and Numerical Study of Laser Beam Welding of PBT-G30 for Electronic Housings in Automotive Applications. Polymers 2025, 17, 2662. https://doi.org/10.3390/polym17192662

Silva LRR, Nunes PDP, Marques EAS, Carbas RJC, da Silva LFM. Experimental and Numerical Study of Laser Beam Welding of PBT-G30 for Electronic Housings in Automotive Applications. Polymers. 2025; 17(19):2662. https://doi.org/10.3390/polym17192662

Chicago/Turabian StyleSilva, Luiz R. R., Paulo D. P. Nunes, Eduardo A. S. Marques, Ricardo J. C. Carbas, and Lucas F. M. da Silva. 2025. "Experimental and Numerical Study of Laser Beam Welding of PBT-G30 for Electronic Housings in Automotive Applications" Polymers 17, no. 19: 2662. https://doi.org/10.3390/polym17192662

APA StyleSilva, L. R. R., Nunes, P. D. P., Marques, E. A. S., Carbas, R. J. C., & da Silva, L. F. M. (2025). Experimental and Numerical Study of Laser Beam Welding of PBT-G30 for Electronic Housings in Automotive Applications. Polymers, 17(19), 2662. https://doi.org/10.3390/polym17192662

_Yang.png)