Stability of TPU/PP Blends Exposed to UV Radiation for Industrial Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blend Preparation and Selection

2.3. Accelerated Aging via UV Radiation

2.4. Chemical and Mechanical Characterization

Surface Degradation by Determining Color Degradation

3. Results and Discussion

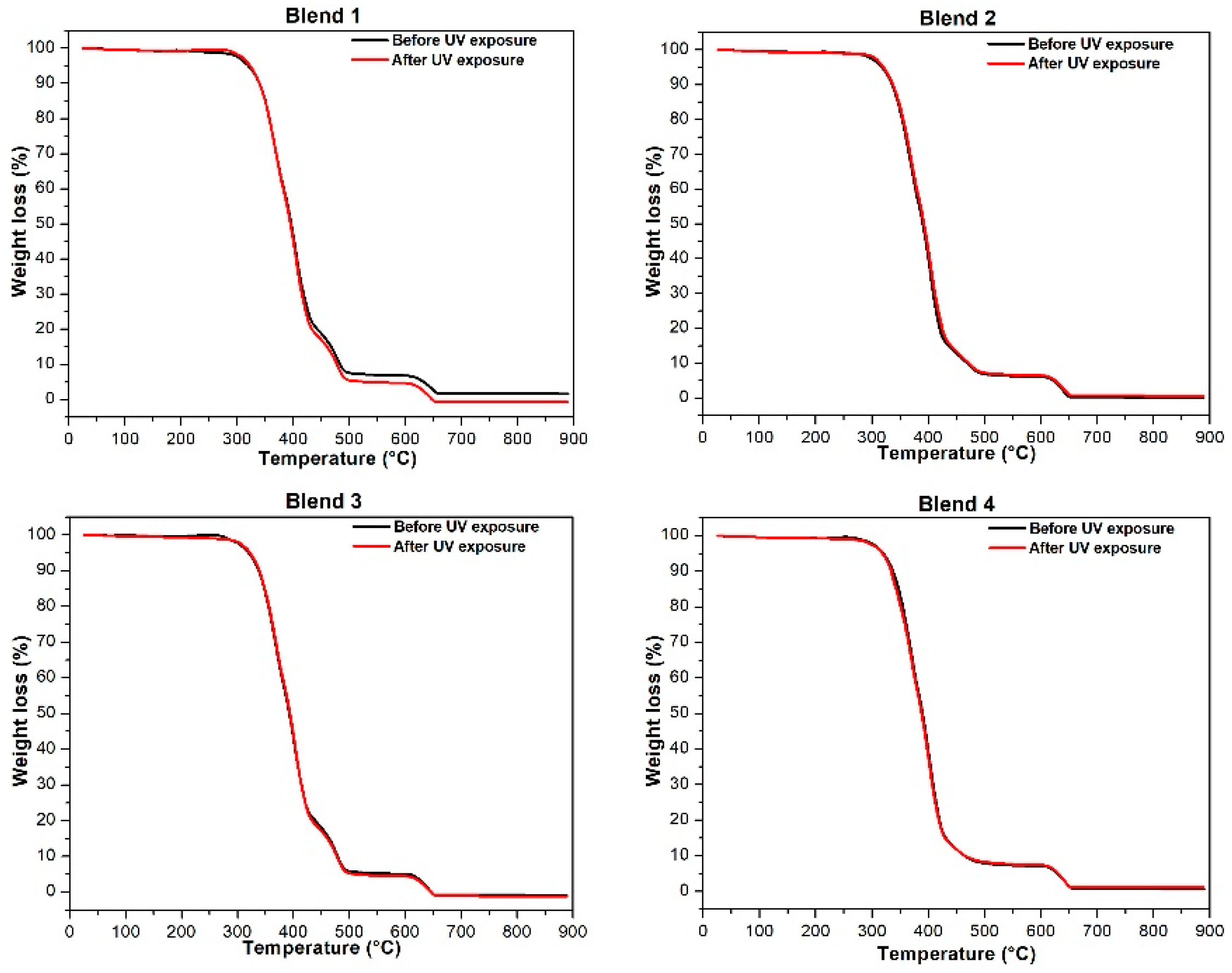

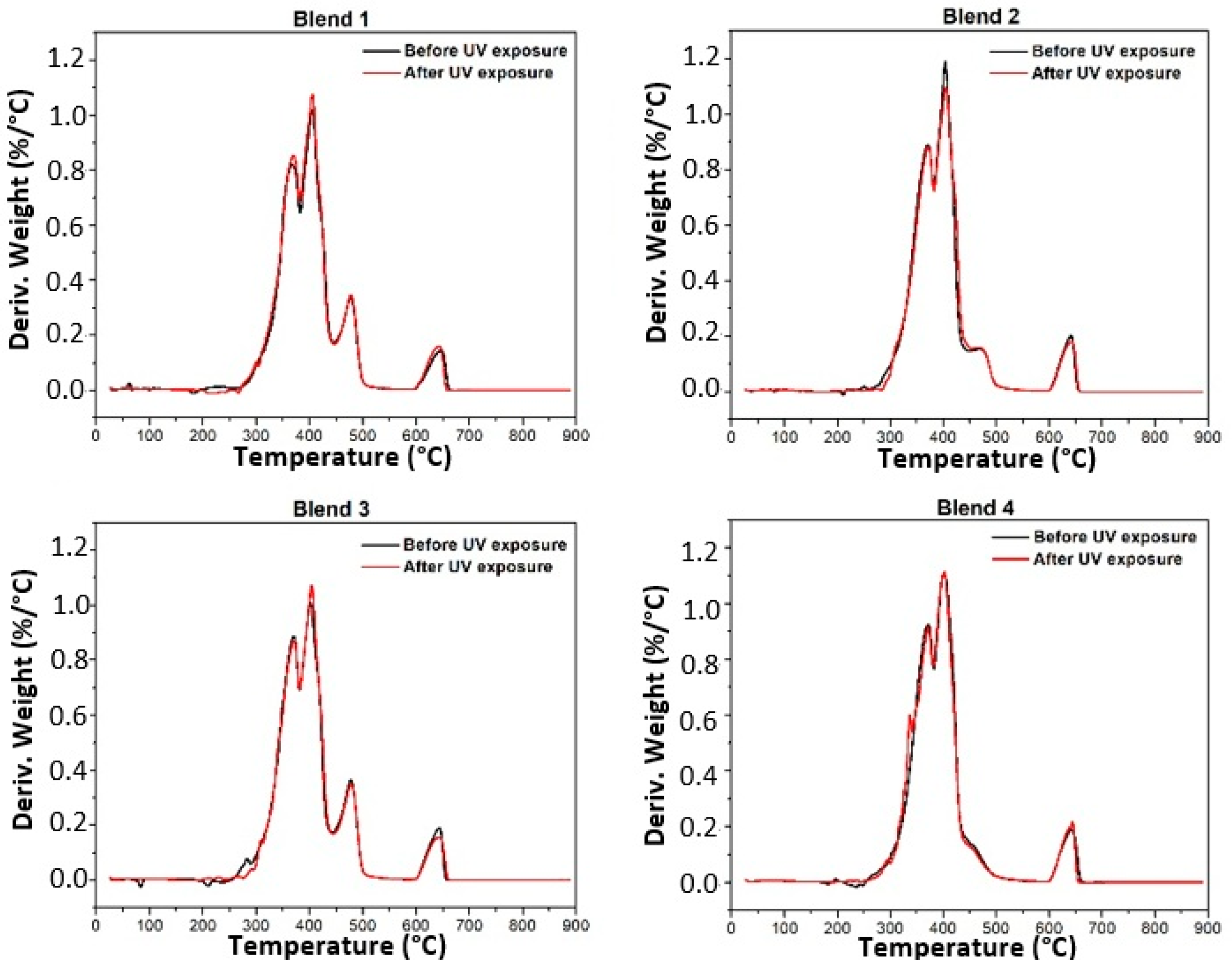

3.1. Thermogravimetric Analysis (TGA)

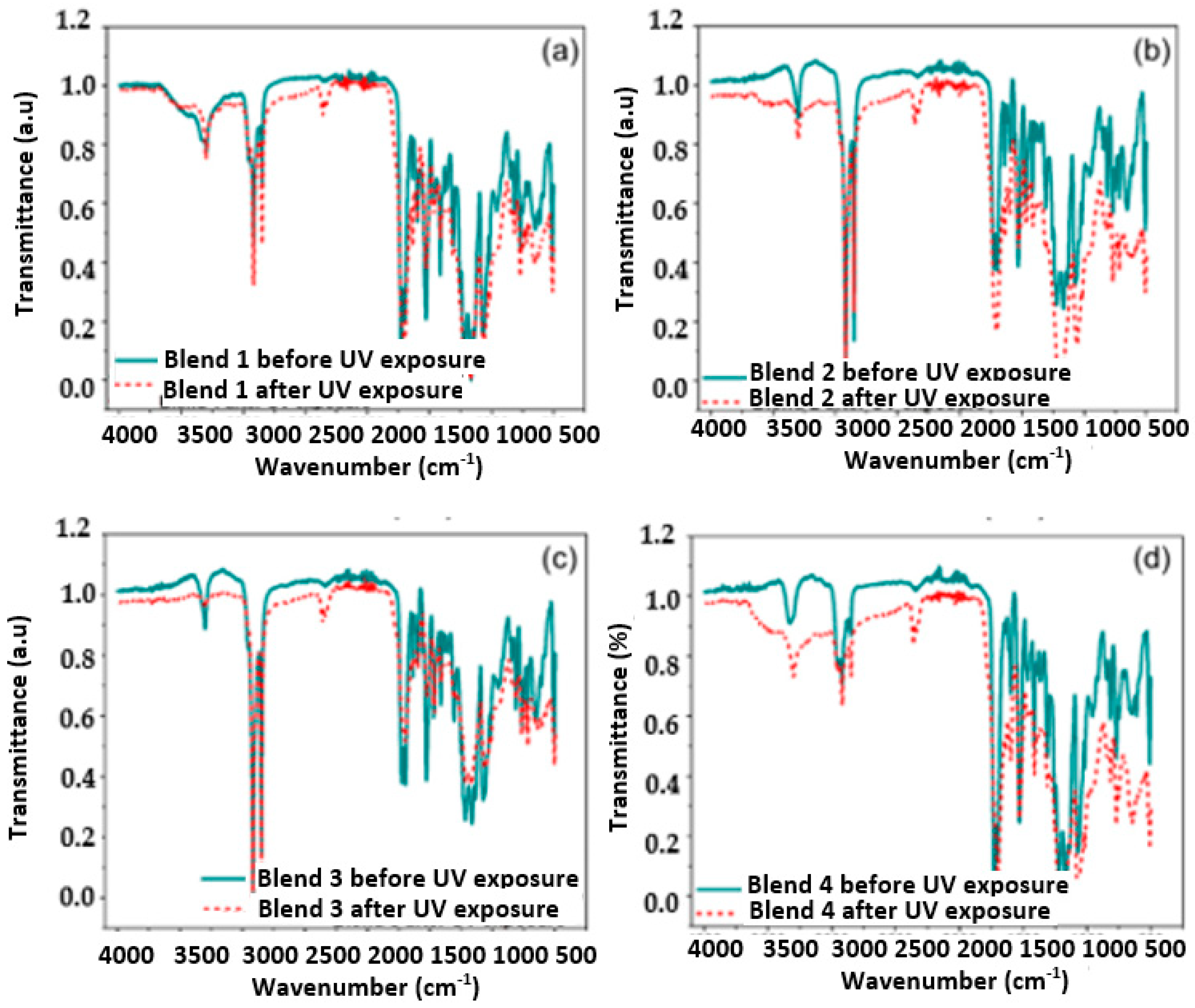

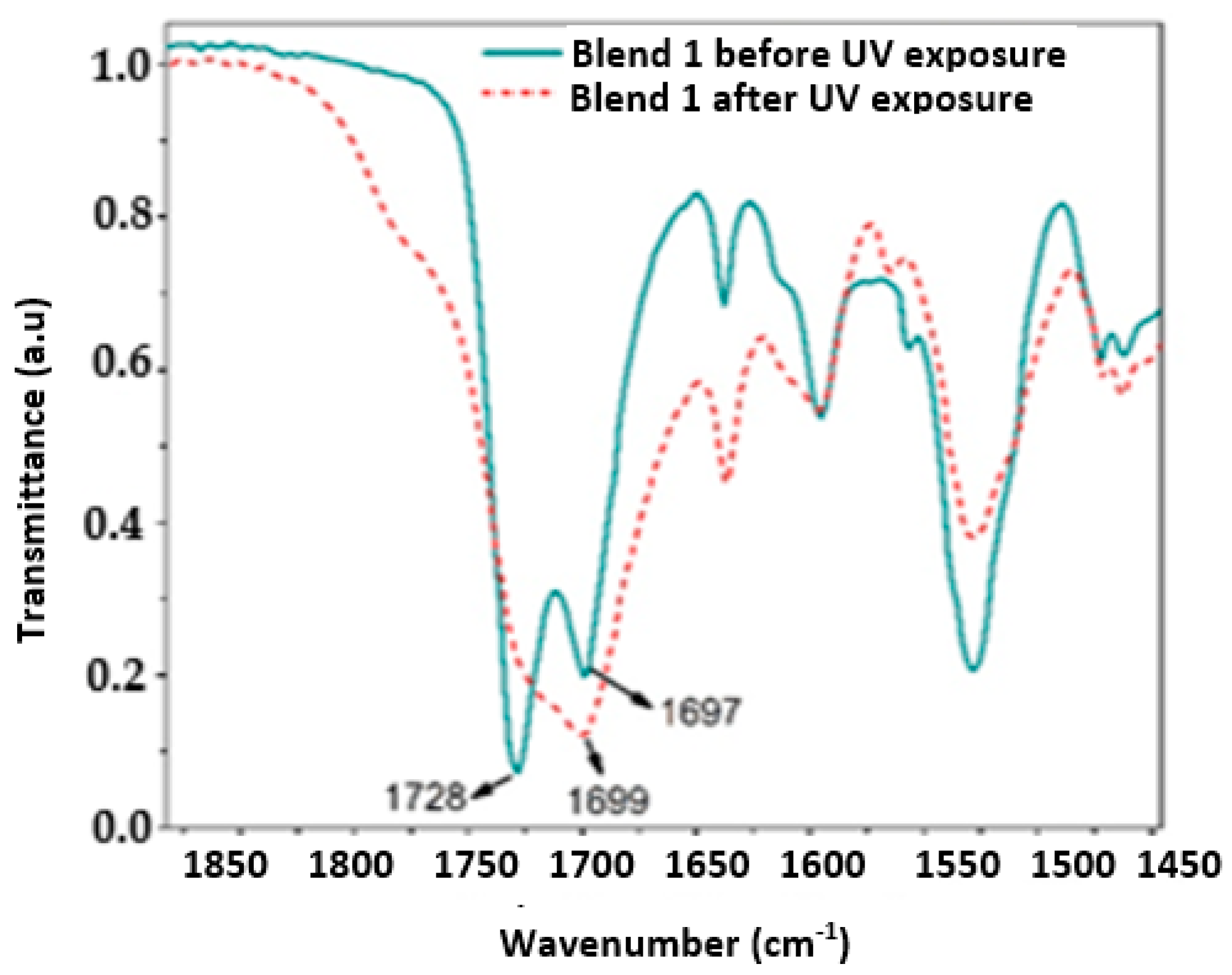

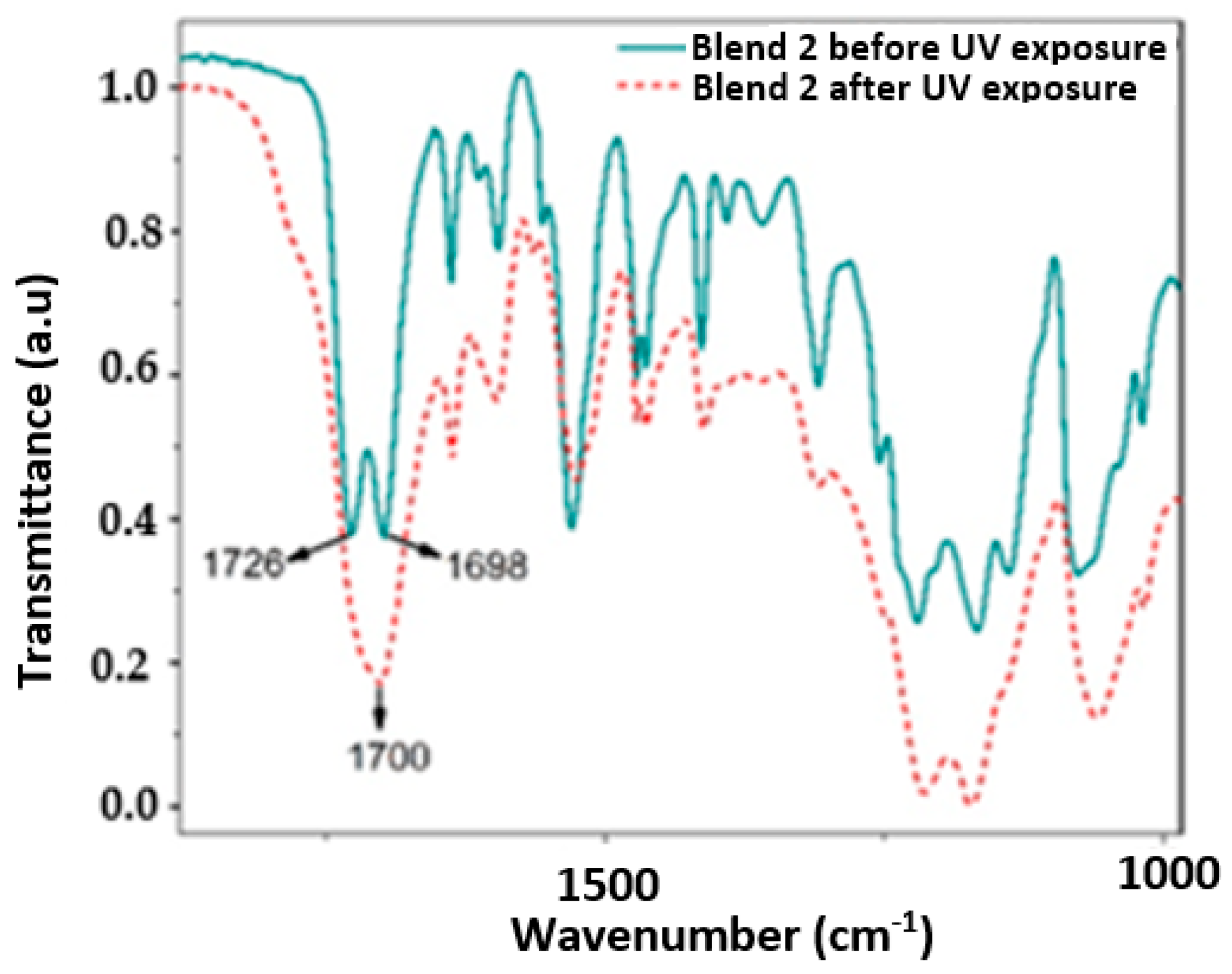

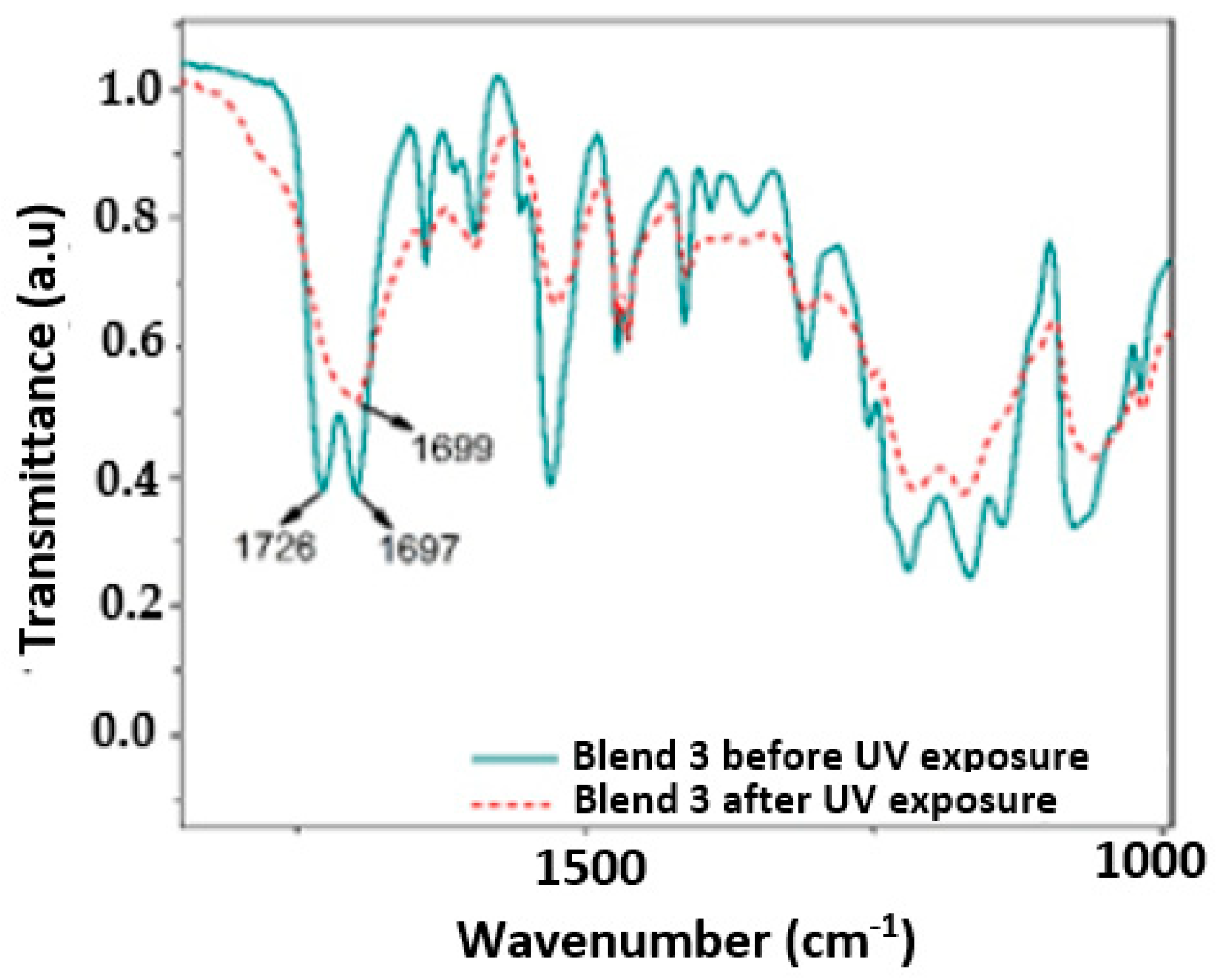

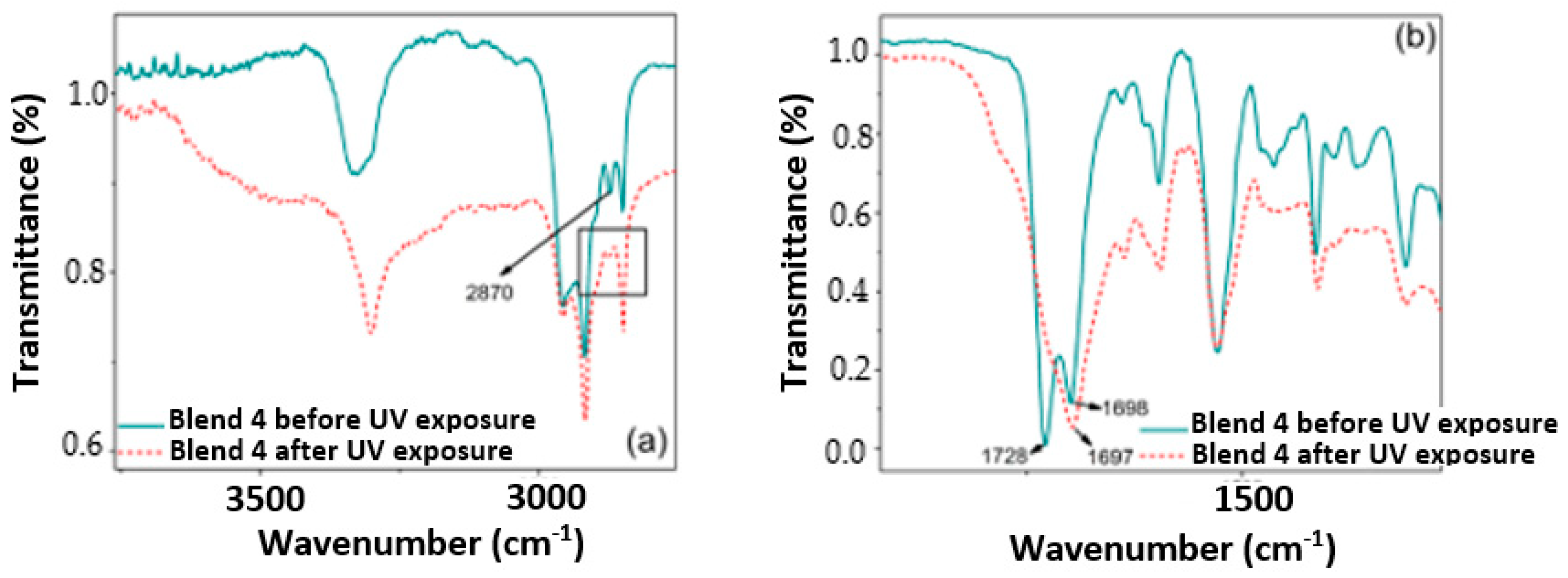

3.2. Fourier Transform Infrared (FTIR) Analysis

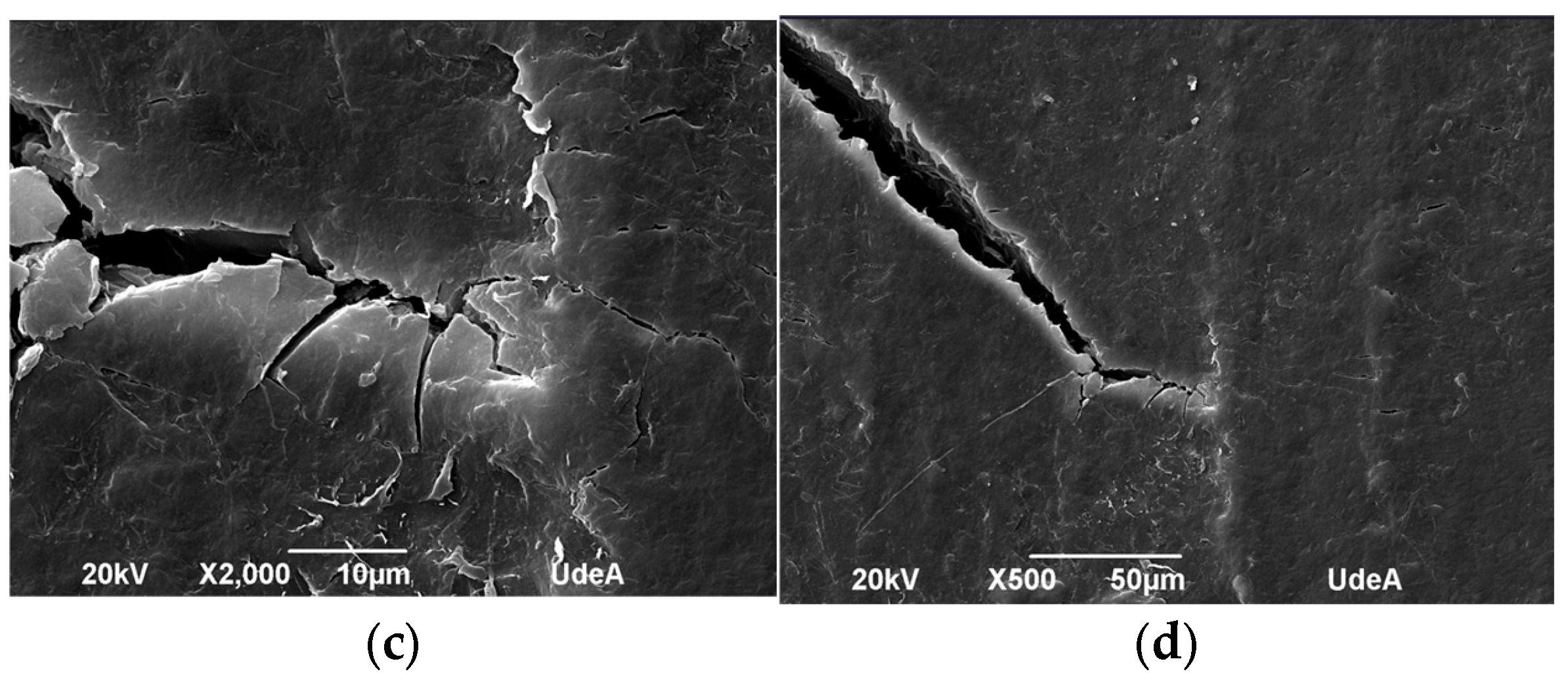

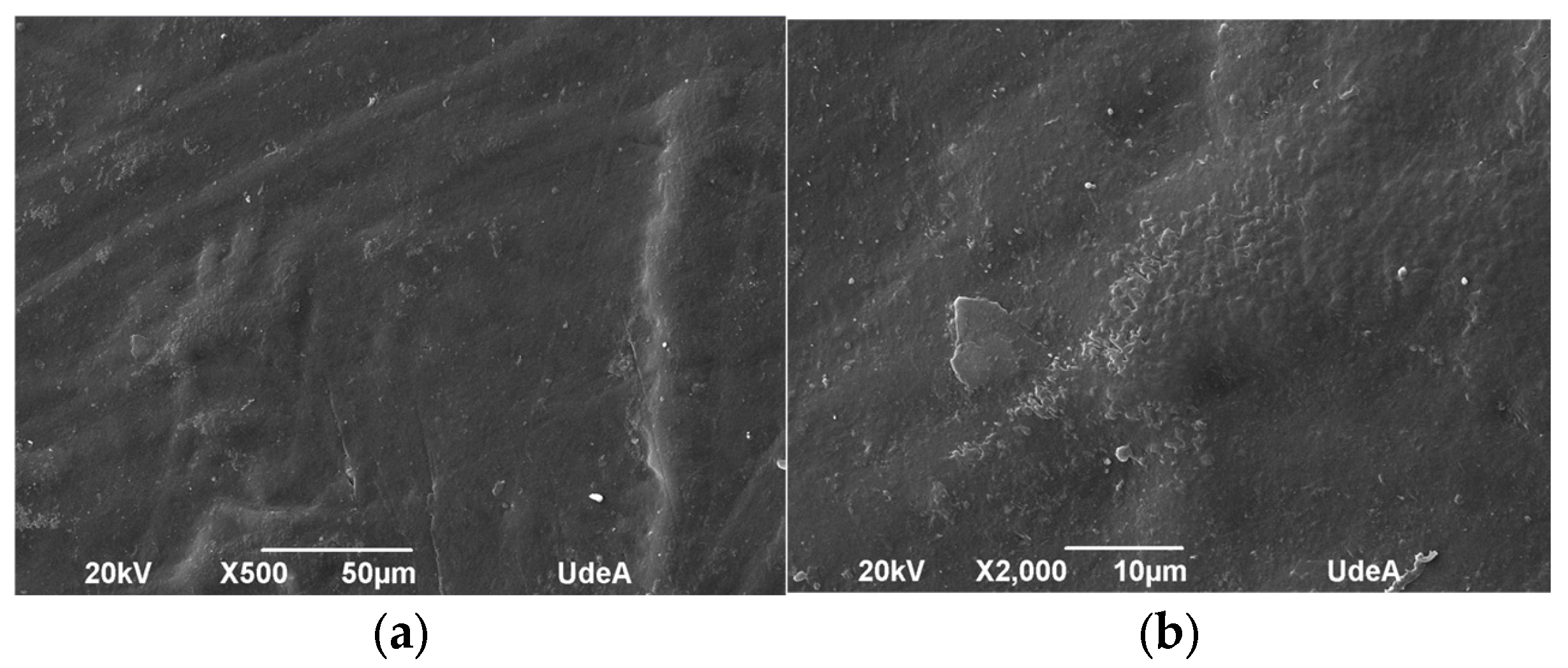

3.3. Scanning Electron Microscopy (SEM) Analysis

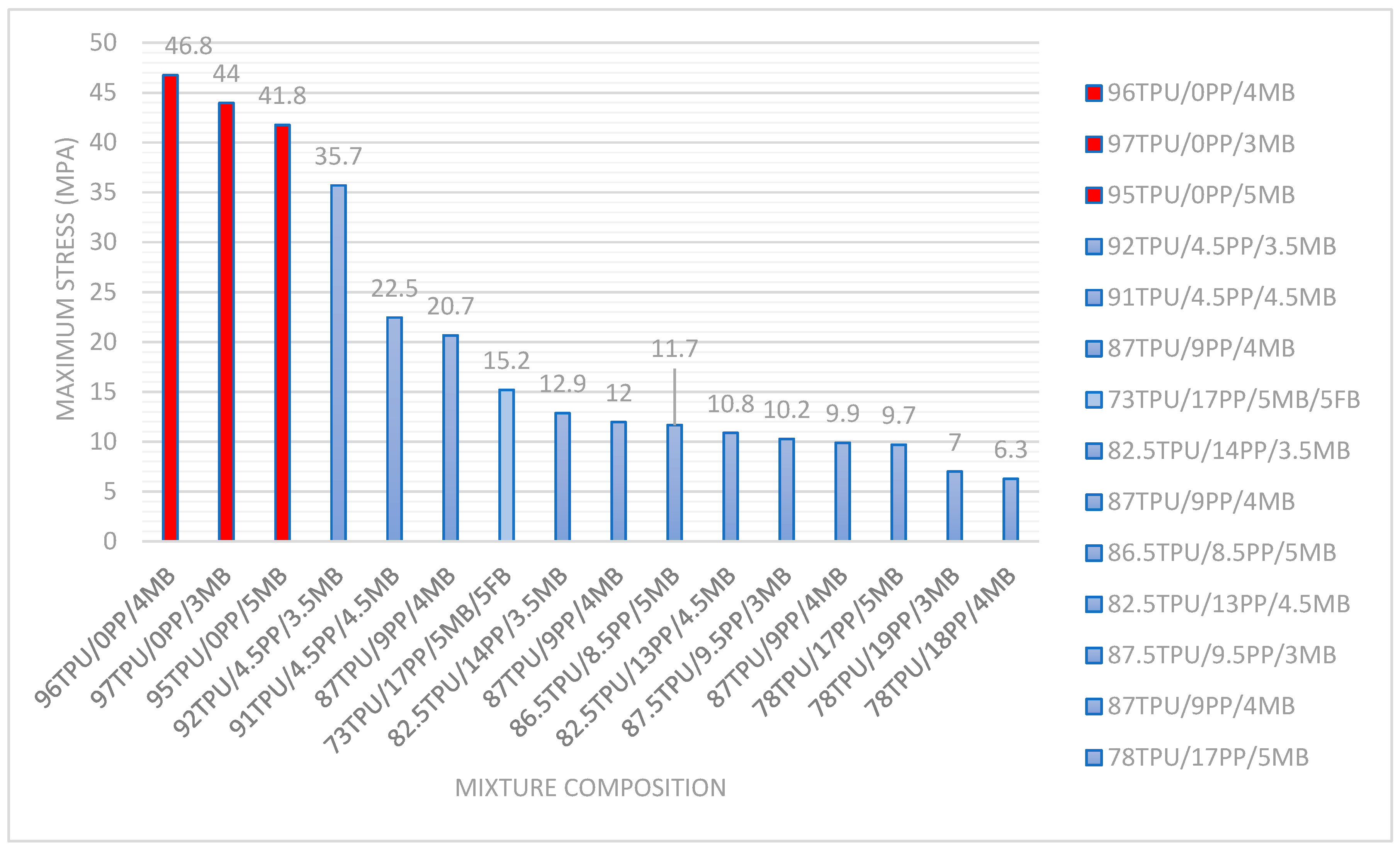

3.4. Analysis of Mechanical Properties

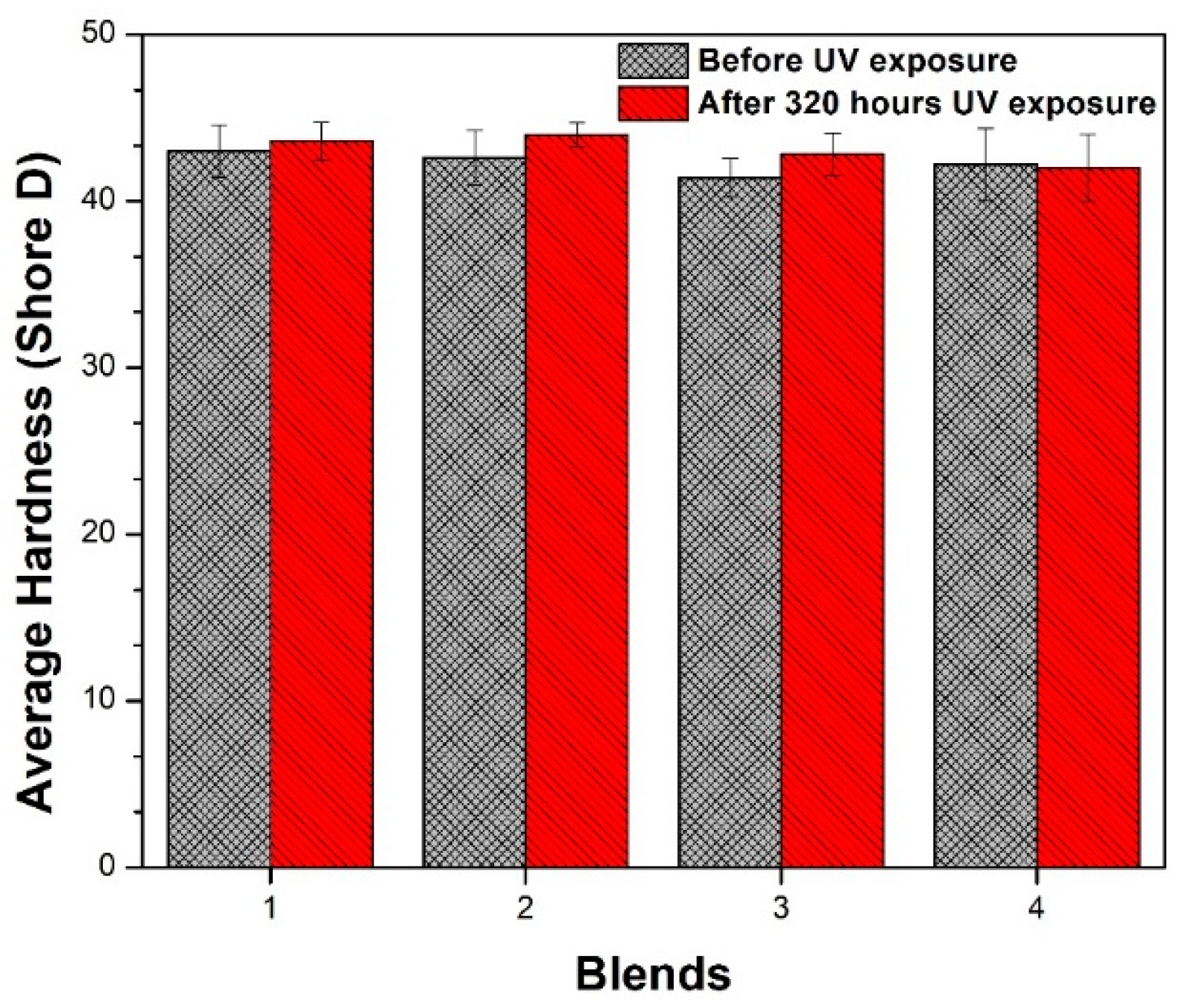

3.4.1. Hardness

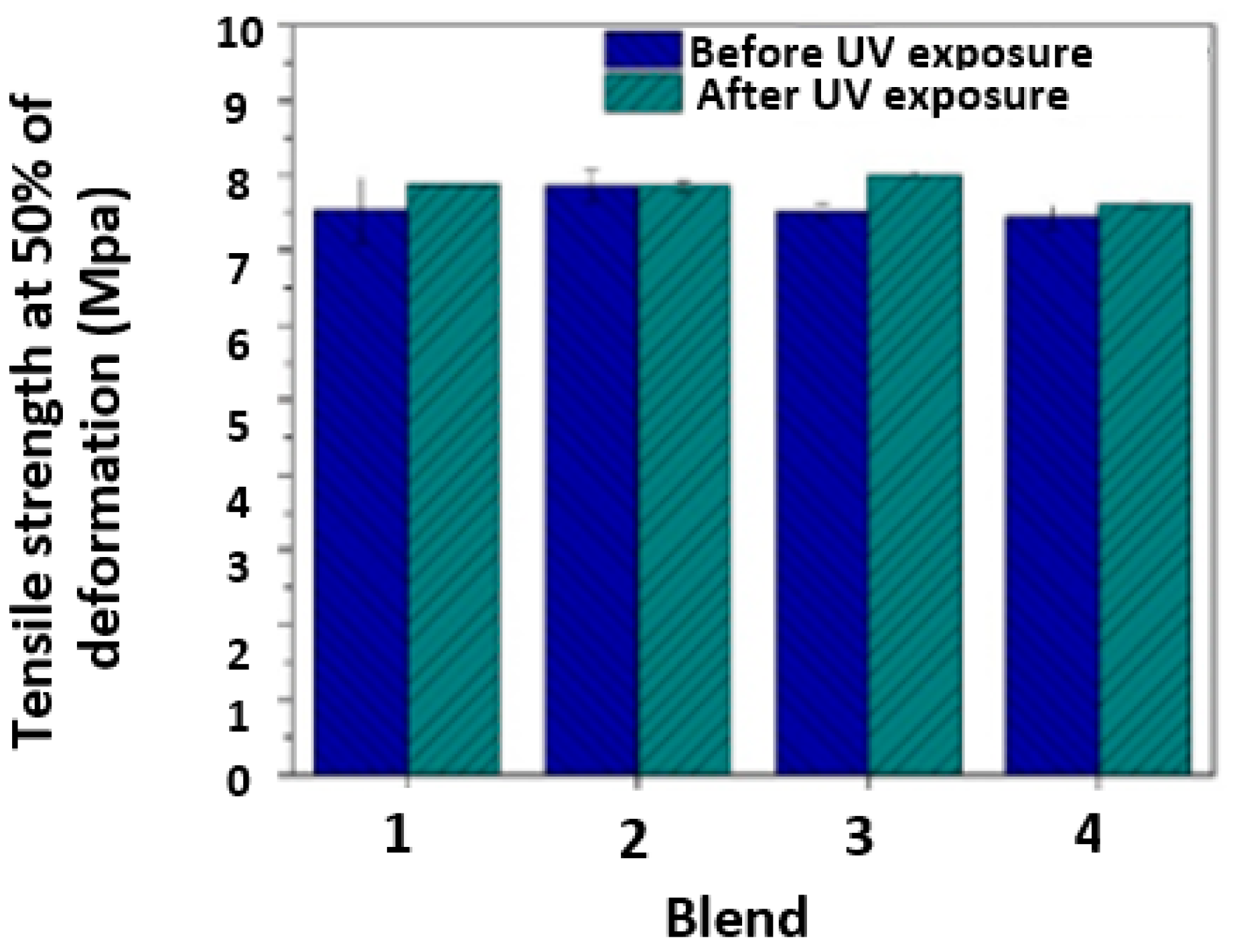

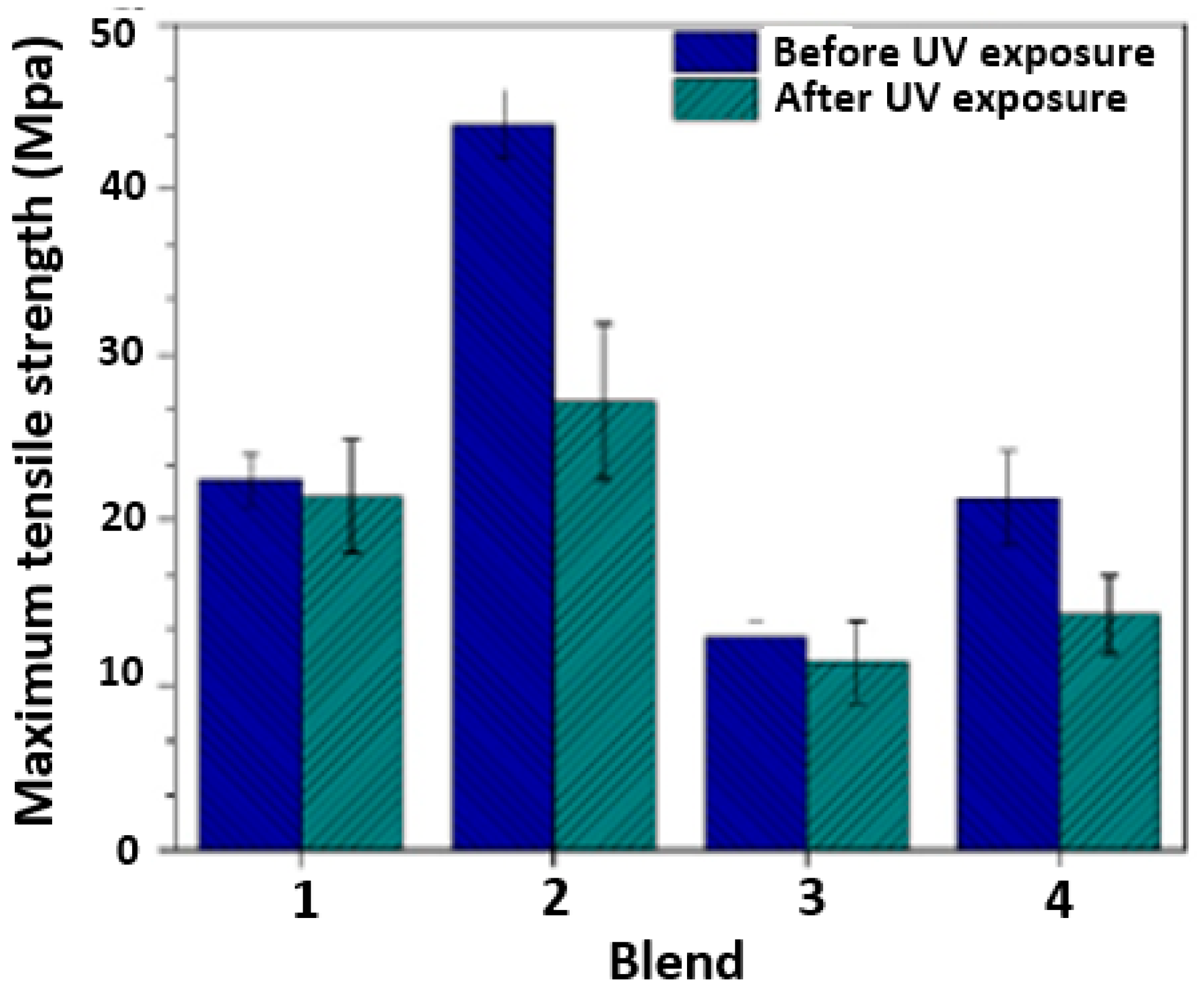

3.4.2. Tensile Strength

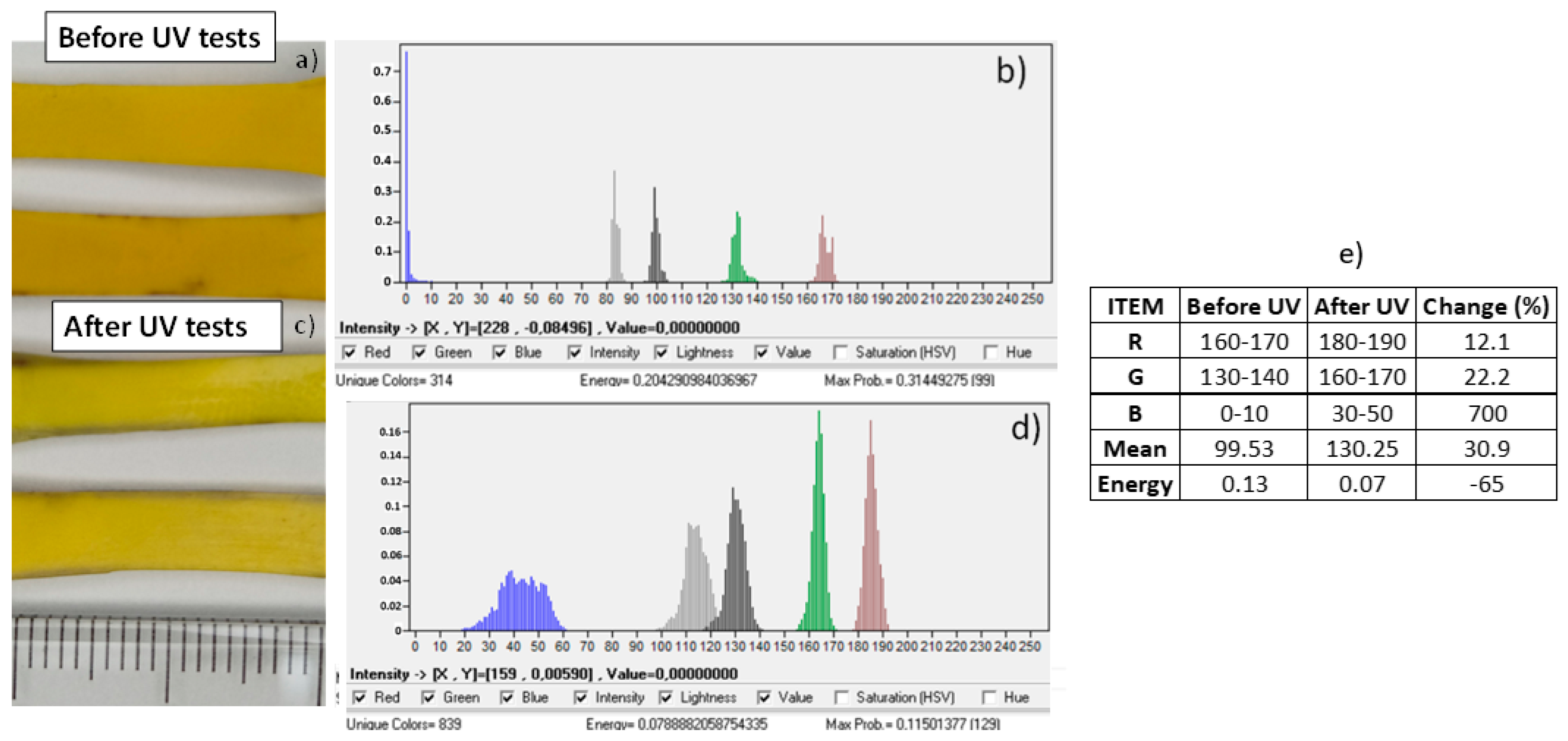

3.4.3. Surface Degradation Color Analysis Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scetta, G.; Selles, N.; Heuillet, P.; Ciccotti, M.; Creton, C. Cyclic fatigue failure of TPU using a crack propagation approach. Polym. Test. 2021, 97, 107140. [Google Scholar] [CrossRef]

- Martin, D.J.; Osman, A.F.; Andriani, Y.; Edwards, G.A. Thermoplastic polyurethane (TPU)-based polymer nanocomposites. In Advances in Polymer Nanocomposites: Types and Applications; Woodhead Publishing: Cambridge, UK, 2012; pp. 321–350. [Google Scholar] [CrossRef]

- Theiler, G.; Wachtendorf, V.; Elert, A.; Weidner, S. Effects of UV radiation on the friction behavior of thermoplastic polyurethanes. Polym. Test. 2018, 70, 467–473. [Google Scholar] [CrossRef]

- Palak, H.; Aktürk, B.; Kayaoğlu, B.K.; Göcek, I. Fabrication of montmorillonite nanoclay-loaded electrospun nanofibrous mats for UV protection. J. Ind. Text. 2021, 51, 4118S–4132S. [Google Scholar] [CrossRef]

- Wallheinke, K.; Fritsche, H.; Stutz, H.; Pötschke, P. Morphology and properties of blends with different thermoplastic polyurethanes and polyolefines. J. Appl. Polym. Sci. 1997, 64, 749–762. [Google Scholar] [CrossRef]

- Jašo, V.; Milić, J.; Divjaković, V.; Petrović, Z.S. Novel elastomeric polyurethane fibers modified with polypropylene microfibers. Eur. Polym. J. 2013, 49, 3947–3955. [Google Scholar] [CrossRef]

- Bajsić, E.G.; Filipan, V.; Bulatović, V.O.; Mandić, V. The influence of filler treatment on the mechanical properties and phase behavior of thermoplastic polyurethane/polypropylene blends. Polym. Bull. 2017, 74, 2939–2955. [Google Scholar] [CrossRef]

- Govorčin Bajsić, E.; Bulatović, V.O.; Rek, V. The Influence of Filler Treatment on the Properties of TPU/PP Blends: I. Thermal Properties and Stability. Polym. Eng. Sci. 2015, 55, 1920–1930. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, J.-H.; Bao, L. A study of reusability assessment and thermal behaviors for thermoplastic composite materials after melting process: Polypropylene/thermoplastic polyurethane blends. J. Clean. Prod. 2021, 279, 123473. [Google Scholar] [CrossRef]

- Bajsić, E.G.; Veljko, F.; Bulatović, V.O. Effect of Silane Treated and Untreated Talc on the Properties of Thermoplastic Polyurethane/Polypropylene Blends. Adv. Mater. Res. 2014, 849, 121–126. [Google Scholar] [CrossRef]

- Bulatovic, V.O.; Mihaljevic, A.; Bajsic, E.G. Mechanical and interfacial properties of compatibilized polyurethane blends. Polym. Eng. Sci. 2018, 58, 1911–1922. [Google Scholar] [CrossRef]

- Savaş, L.A. The effect of the use of compatibilizer and chemical composition on the contact angle and surface free energy properties of polypropylene/thermoplastic polyurethane blends. Tekst. Muhendis 2021, 28, 261–268. [Google Scholar] [CrossRef]

- Kannan, M.; Thomas, S.; Joseph, K. Flame-retardant properties of nanoclay-filled thermoplastic polyurethane/polypropylene nanocomposites. J. Vinyl Addit. Technol. 2017, 23, E72–E80. [Google Scholar] [CrossRef]

- Savaş, S. Effect of different parameters on the tribological performance of polypropylene/thermoplastic polyurethane blends under dry sliding conditions. Bull. Mater. Sci. 2019, 42, 92. [Google Scholar] [CrossRef]

- Mahdavi, H.; Hosseini, F.; Ghanbari, R. Incorporation of MIL-101(Fe)/Tannic acid-PEG to PES-TPU blend membrane to modify a membrane with riveting mechanical stability and separation performance. J. Ind. Eng. Chem. 2023, 120, 195–208. [Google Scholar] [CrossRef]

- Mahdavi, H.; Hosseini, F. Fabrication of high-performance mixed matrix blend membranes comprising PES and TPU reinforced with APTS functionalized-graphene oxide via VIPS-NIPS technique for aqueous dye treatment and antifouling properties. J. Taiwan Inst. Chem. Eng. 2023, 142, 104609. [Google Scholar] [CrossRef]

- Mahdavi, H.; Hosseini, F.; Heidari, A.A.; Karami, M. Polyethersulfone-TPU blend membrane coated with an environmentally friendly sabja seed mucilage-Cu2+ cross-linked layer with outstanding separation performance and superior antifouling. J. Ind. Eng. Chem. 2023, 121, 421–433. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical properties of additively manufactured thermoplastic polyurethane (TPU) material affected by various processing parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Wang, J.-W.; Wang, H.-Q.; Zhuang, G.-C.; Yang, J.-B.; Ma, Y.-J.; Zhang, Y.; Ren, H. Effects of a new compatibilizer on the mechanical properties of TPU/PEBA blends. Eur. Polym. J. 2022, 175, 111358. [Google Scholar] [CrossRef]

- Valenti, S.; Yousefzade, O.; Puiggalí, J.; Macovez, R. Phase-selective conductivity enhancement and cooperativity length in PLLA/TPU nanocomposite blends with carboxylated carbon nanotubes. Polymer 2020, 191, 122279. [Google Scholar] [CrossRef]

- Demewoz, N.M.; Yeh, S.-K. Fabrication and characterization of low-density nanocellular foam based on PMMA/TPU blends. Polymer 2022, 240, 124493. [Google Scholar] [CrossRef]

- Yu, P.; Huang, S.; Yang, Z.; Liu, T.; Qilin, Z.; Feng, J.; Zeng, B. Biomechanical properties of a customizable TPU/PCL blended esophageal stent fabricated by 3D printing. Mater. Today Commun. 2023, 34, 105196. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Shariatpanahi, H.; Neshati, J.; Akbarinezhad, E. Degradation of modified carbon black/epoxy nanocomposite coatings under ultraviolet exposure. Appl. Surf. Sci. 2015, 353, 530–539. [Google Scholar] [CrossRef]

- Al-Turaif, H.A. Surface morphology and chemistry of epoxy-based coatings after exposure to ultraviolet radiation. Prog. Org. Coatings 2013, 76, 677–681. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.-B.; Kumosa, M. Synergistic environmental degradation of glass reinforced polymer composites. Polym. Degrad. Stab. 2016, 131, 1–8. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, J.-H.; Bao, L. Polypropylene/thermoplastic polyurethane blends: Mechanical characterizations, recyclability and sustainable development of thermoplastic materials. J. Mater. Res. Technol. 2020, 9, 5304–5312. [Google Scholar] [CrossRef]

- Song, J.; Batra, A.; Rego, J.M.; Macosko, C.W. Polyethylene/polyurethane blends for improved paint adhesion. Prog. Org. Coat. 2011, 72, 492–497. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–16. [CrossRef]

- Arcoplast. FT Aditivo Arcoplast pe uv 10793. Arcoplast, “ft Aditivo Arcoplast pe uv 10793,” Medellin, Apr. 2024. Available online: https://github.com/adrian860909/ARCOPLAST_DatasheetPE10793/blob/main/FT_ADITIVO_ARCOPLAST_PE_UV_10793.pdf (accessed on 30 June 2024).

- BRana; Mandlekar, N.; Tomar, S.; Joshi, M.; Ali, S.W. Optimization of TPU/TiO2 Films Using UV Additives for Improved Weather Stability of LTA Hull Materials. In Lighter Than Air Systems; Lecture Notes in Mechanical Engineering; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2023; pp. 53–68. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Liu, D.; Sun, Z.; Wang, H. Effects of additives on weather-resistance properties of polyurethane films exposed to ultraviolet radiation and ozone atmosphere. J. Nanomater. 2014, 2014, 487343. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Development of multifunctional polyurethane elastomer composites containing fullerene: Mechanical, damping, thermal, and flammability behaviors. J. Elastomers Plast. 2019, 51, 262–279. [Google Scholar] [CrossRef]

- ASTM G154-16; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Materials. ASTM: West Conshohocken, PA, USA, 2023.

- ISO 48-4:2018; Rubber, Vulcanized or Thermoplastic—Determination of Hardness—Part 4: Indentation Hardness by Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2018.

- Kanbur, Y.; Tayfun, U. Investigating mechanical, thermal, and flammability properties of thermoplastic polyurethane/carbon nanotube composites. J. Thermoplast. Compos. Mater. 2018, 31, 1661–1675. [Google Scholar] [CrossRef]

- Kannan, M.; Bhagawan, S.S.; Thomas, S.; Joseph, K. Thermogravimetric analysis and differential scanning calorimetric studies on nanoclay-filled TPU/PP blends. J. Therm. Anal. Calorim. 2013, 112, 1231–1244. [Google Scholar] [CrossRef]

- Bell, J.; Nel, P.; Stuart, B. Non-invasive identification of polymers in cultural heritage collections: Evaluation, optimisation and application of portable FTIR (ATR and external reflectance) spectroscopy to three-dimensional polymer-based objects. Heritage Sci. 2019, 7, 95. [Google Scholar] [CrossRef]

- Gulmine, J.; Janissek, P.; Heise, H.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Rosu, D.; Rosu, L.; Cascaval, C.N. IR-change and yellowing of polyurethane as a result of UV irradiation. Polym. Degrad. Stab. 2009, 94, 591–596. [Google Scholar] [CrossRef]

- Bruckmoser, K.; Resch, K. Investigation of ageing mechanisms in thermoplastic polyurethanes by means of IR and raman spectroscopy. Macromol. Symp. 2014, 339, 70–83. [Google Scholar] [CrossRef]

- Hsu, Y.-C.; Weir, M.P.; Truss, R.W.; Garvey, C.J.; Nicholson, T.M.; Halley, P.J. A fundamental study on photo-oxidative degradation of linear low density polyethylene films at embrittlement. Polymer 2012, 53, 2385–2393. [Google Scholar] [CrossRef]

- Valadez-González, A.; Veleva, L. Mineral filler influence on the photo-oxidation mechanism degradation of high density polyethylene. Part II: Natural exposure test. Polym. Degrad. Stab. 2004, 83, 139–148. [Google Scholar] [CrossRef]

- Gardette, J.-L.; Mailhot, B.; Posada, F.; Rivaton, A.; Wilhelm, C. Photooxidative degradation of polyether-based polymers. Macromol. Symp. 1999, 143, 95–109. [Google Scholar] [CrossRef]

- Seeger, P.; Ratfisch, R.; Moneke, M.; Burkhart, T. Addition of thermo-plastic polyurethane (TPU) to poly(methyl methacrylate) (PMMA) to improve its impact strength and to change its scratch behavior. Wear 2018, 406–407, 68–74. [Google Scholar] [CrossRef]

- White, J.; Shyichuk, A. Macromolecular scission and crosslinking rate changes during polyolefin photo-oxidation. Polym. Degrad. Stab. 2007, 92, 1161–1168. [Google Scholar] [CrossRef]

- Rodriguez, A.; Mansoor, B.; Ayoub, G.; Colin, X.; Benzerga, A. Effect of UV-aging on the mechanical and fracture behavior of low density polyethylene. Polym. Degrad. Stab. 2020, 180, 109185. [Google Scholar] [CrossRef]

- Ajili, S.H.; Ebrahimi, N.G.; Khorasani, M.T. Study on thermoplastic polyurethane/polypropylene (TPU/PP) blend as a blood bag material. J. Appl. Polym. Sci. 2003, 89, 2496–2501. [Google Scholar] [CrossRef]

- Do, T.T.; Nguyen, V.-T.; Toan, H.D.S.; Minh, P.S.; Uyen, T.M.T.; Huynh, T.H.; Nguyen, V.T.; Nguyen, V.T.T. Influences of TPU Content on the Weld Line Characteristics of PP and ABS Blends. Polymers 2023, 15, 2321. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chen, X.; Zhang, M.; Zhi, M. Polyurethane/Polyolefin Blends: Morphology, Compatibilization and Mechanical Properties. Polym. Polym. Compos. 2005, 14, 1–11. [Google Scholar] [CrossRef]

- Chow, W.S.; Bakar, A.A.; Ishak, Z.A.M.; Karger-Kocsis, J.; Ishiaku, U.S. Effect of maleic anhydride-grafted ethylene–propylene rubber on the mechanical, rheological and morphological properties of organoclay reinforced polyamide 6/polypropylene nanocomposites. Eur. Polym. J. 2005, 41, 687–696. [Google Scholar] [CrossRef]

| Blend | TPU (wt.%) | PE Masterbatch UV (wt.%) | PP (wt.%) |

|---|---|---|---|

| 1 | 91 | 4.5 | 4.5 |

| 2 | 97 | 3 | - |

| 3 | 90 | 4 | 6 |

| 4 * 100% Material TPU | 100 | - | - |

| Sample | Before UV Exposure | After UV Exposure | ||

|---|---|---|---|---|

| Tmax of Degradation (°C) | Weight Loss (%) | Tmax of Degradation (°C) | Weight Loss (%) | |

| Blend 1 | 405.5 | 41.0 | 405.6 | 41.7 |

| Blend 2 | 403.3 | 45.3 | 404.7 | 54.7 |

| Blend 3 | 401.8 | 40.0 | 403.9 | 41.8 |

| Blend 4 | 400.8 | 48.8 | 401.5 | 48.6 |

| Blend Composition. | Compatibilizer | Tensile Strength (Mpa) | Elongation at Break (%) | Notes |

|---|---|---|---|---|

| PP/TPU/70/30 | None | 27 * | 315 * | Strength and ductility decrease with more PP |

| PP/TPU/80/20/EC4 (1%) | Ethylenic copolymer (EC4) | 34.5 * | 440 * | Compatibilizer improves both strength and elongation |

| PP/TPU/PP-g-NH2 70/25/5% | PP-g-NH2 | 21 | 860 | Strong compatibilization effect |

| Blend 1: TPU/PP/PE Masterbatch UV (wt.%)/91/4.5/4.5 | PE Masterbatch UV | Before UV Exposure: 22 After UV exposure: 21 | Before UV Exposure: 235 After UV exposure: 205 | Blend 1 is recommended for applications that require enhanced resistance to UV radiation |

| Blend 2: TPU/PE Masterbatch UV (wt.%)/97/3 | PE Masterbatch UV | Before UV Exposure:44 After UV exposure: 29 | Before UV Exposure:283 After UV exposure: 241 | Blend 2 is recommended for applications that require enhanced resistance to UV radiation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas-Isaza, C.; Tamayo, J.A.; Baena, L.M.; Marin, J.F.S.; Benitez-Lozano, A.J. Stability of TPU/PP Blends Exposed to UV Radiation for Industrial Applications. Polymers 2025, 17, 1842. https://doi.org/10.3390/polym17131842

Vargas-Isaza C, Tamayo JA, Baena LM, Marin JFS, Benitez-Lozano AJ. Stability of TPU/PP Blends Exposed to UV Radiation for Industrial Applications. Polymers. 2025; 17(13):1842. https://doi.org/10.3390/polym17131842

Chicago/Turabian StyleVargas-Isaza, Carlos, Jose A. Tamayo, Libia M. Baena, Juan Felipe Santa Marin, and Adrian José Benitez-Lozano. 2025. "Stability of TPU/PP Blends Exposed to UV Radiation for Industrial Applications" Polymers 17, no. 13: 1842. https://doi.org/10.3390/polym17131842

APA StyleVargas-Isaza, C., Tamayo, J. A., Baena, L. M., Marin, J. F. S., & Benitez-Lozano, A. J. (2025). Stability of TPU/PP Blends Exposed to UV Radiation for Industrial Applications. Polymers, 17(13), 1842. https://doi.org/10.3390/polym17131842