Evaluation of 3D-Printed Balls with Photopolymer Resin as Grinding Medium Used to Alternatively Reduce Warmup During Dry Milling

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

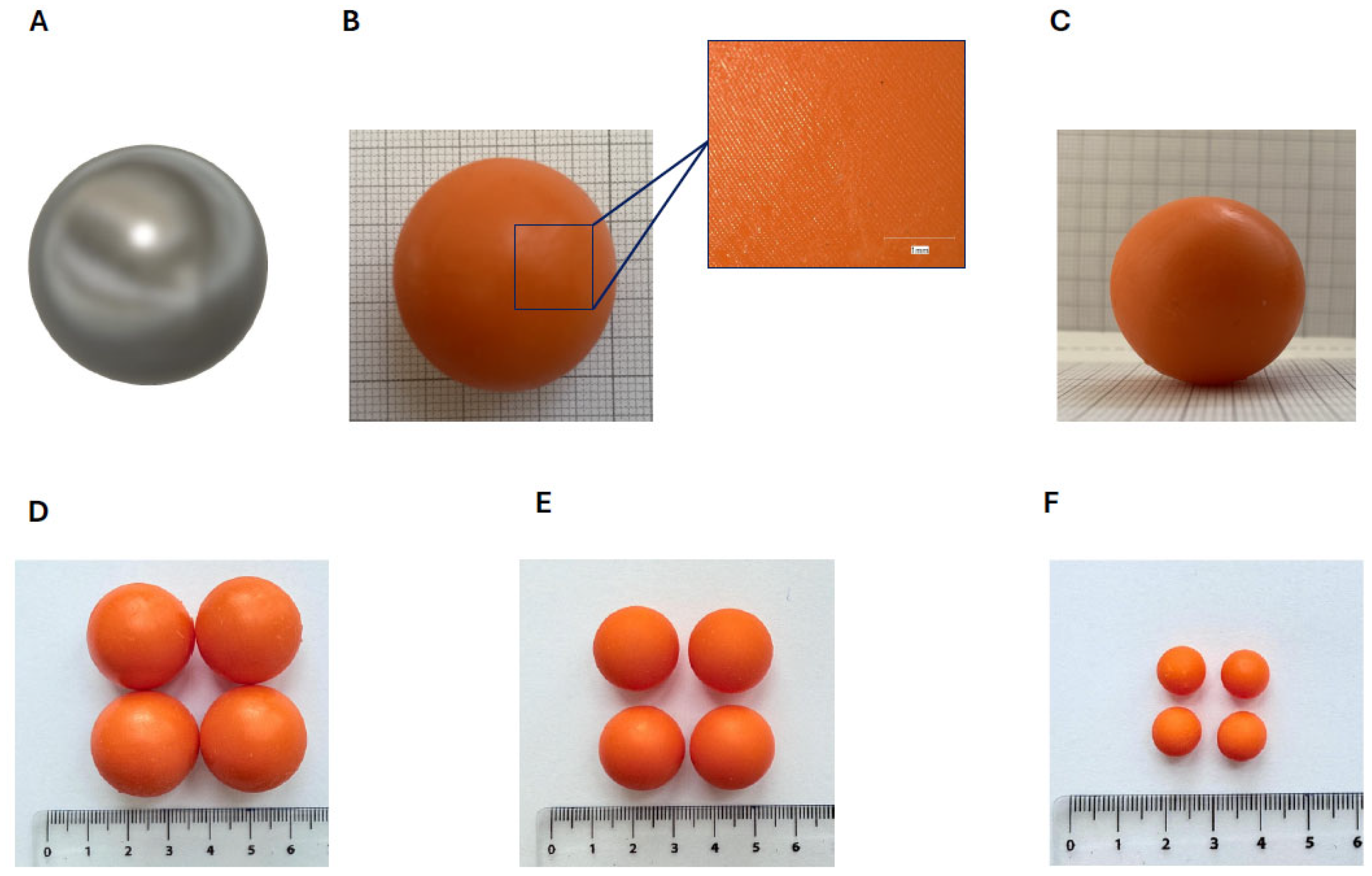

2.2.1. Design of the Grinding Balls

2.2.2. SLS Printing

2.2.3. Densities of the Different Milling Balls

2.2.4. Microscopic Images of the Milling Balls

2.2.5. Weight Loss Test

2.2.6. Grinding

Grinding of Saccharose and Particle Size Distribution Measurement

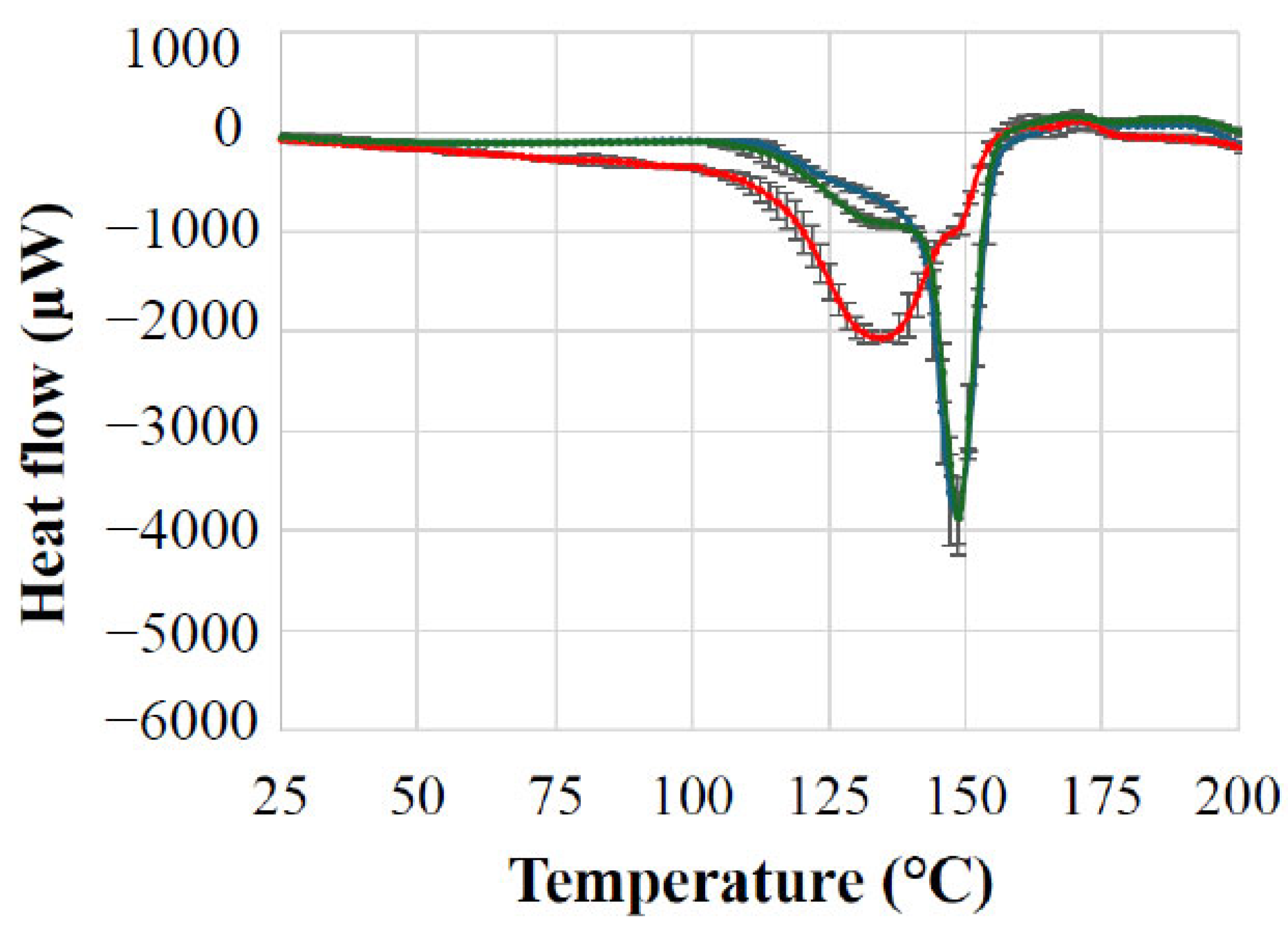

Structural Changes in Lactose Monohydrate During Milling Process

Warming of the Grinding Jar and Milling Balls

Statistical Analysis of Warmup

3. Results

3.1. Fabrication of the Printlets

3.2. Densities of the Grinding Balls

3.3. Weight Loss of the Printed Milling Balls

3.4. Particle Size Reduction

3.5. Warmup of the System in Planetary Ball Mill

3.5.1. The Effect of the Warmup on the Lactose Monohydrate Model Material

Mechanistic Implications

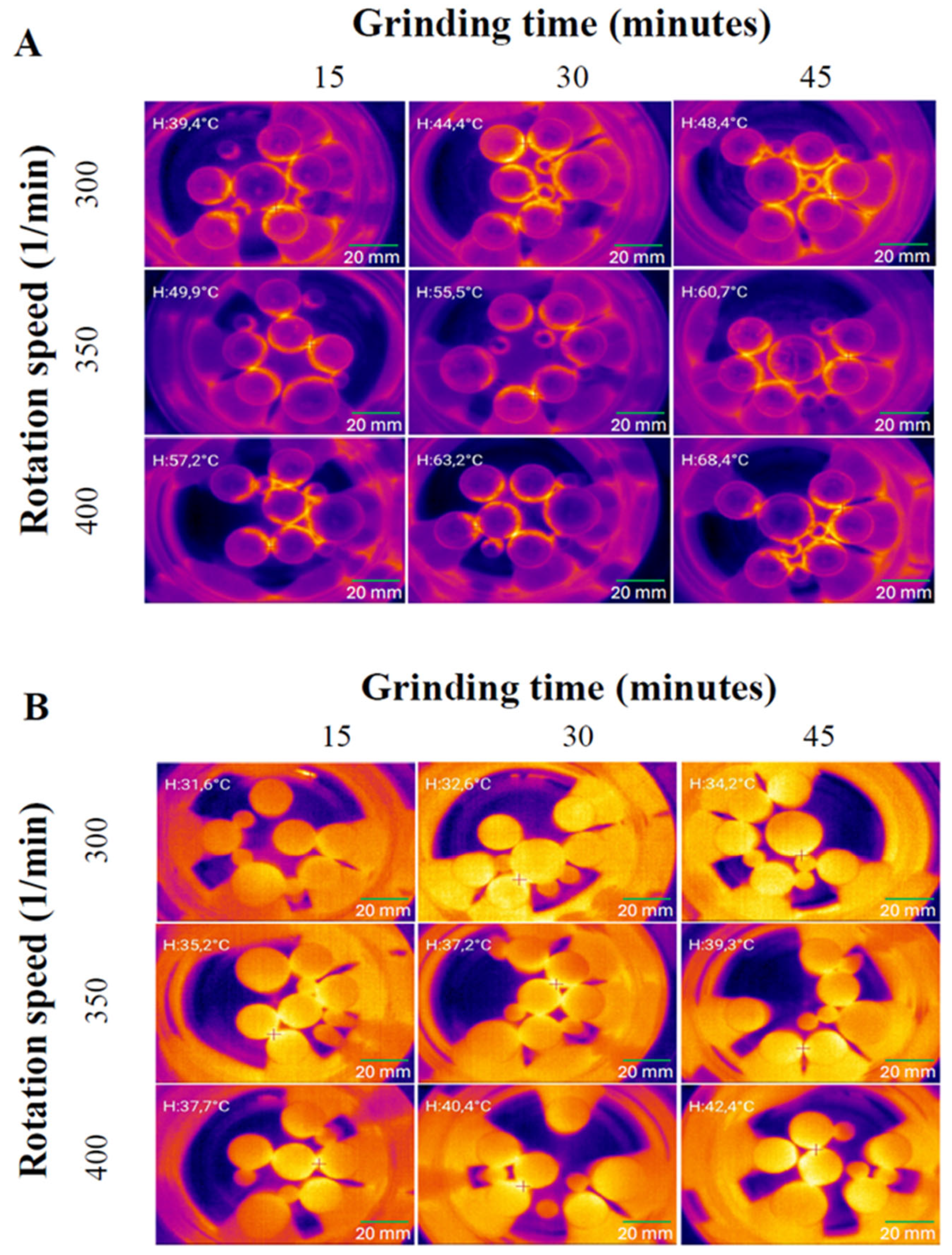

3.5.2. Thermocamera Measurements

3.5.3. Statistical Analysis of the Warmup

Temperature Spike Phenomenon

- Mathematical Definition and Origin

- Temperature Response Analysis: Demonstration of Temperature Spike Phenomenon in Ball Milling

- Physical Mechanism Behind Temperature Spikes

Correlation Between Statistical Analysis and Experimental Findings

- Direct Evidence from DSC Analysis

- Thermal Camera Data Validation

- Process Performance Correlation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAD | Computer-Aided Design |

| API | Active Pharmaceutical Ingredient |

| BCS | Biopharmaceutical Classification System |

| rpm | Revolutions Per Minute |

| SLA | Stereolithography |

| 3D | Three-Dimensional |

| UV | Ultraviolet |

| DSC | Differential Scanning Calorimetry |

References

- Amidon, G.E.; Secreast, P.J.; Mudie, D. Chapter 8—Particle, Powder, and Compact Characterization. In Developing Solid Oral Dosage Forms; Qiu, Y., Chen, Y., Zhang, G.G.Z., Liu, L., Porter, W.R., Eds.; Academic Press: San Diego, CA, USA, 2009; pp. 163–186. [Google Scholar]

- Papich, M.G.; Martinez, M.N. Applying Biopharmaceutical Classification System (BCS) Criteria to Predict Oral Absorption of Drugs in Dogs: Challenges and Pitfalls. AAPS J. 2015, 17, 948–964. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, V.; Meenakshi, S.; Jyothirmayee, N.; Bullebbai, M.; Noorjahan, S.; Rajeswari, G.; Nagesh Babu, G.; Madhavi, D. Enhancement of Solubility, Dissolution rate and Bioavailability of BCS Class II Drugs. Int. J. Pharma Chem. Res. 2016, 2, 80–95. [Google Scholar]

- Chu, K.R.; Lee, E.; Jeong, S.H.; Park, E.-S. Effect of particle size on the dissolution behaviors of poorly water-soluble drugs. Arch. Pharmacal Res. 2012, 35, 1187–1195. [Google Scholar] [CrossRef] [PubMed]

- Sandeep, K.; Pritam, S. Various techniques for solubility enhancement: An overview. Pharma Innov. J. 2016, 5, 23–28. [Google Scholar]

- Kubavat, H.A.; Shur, J.; Ruecroft, G.; Hipkiss, D.; Price, R. Influence of primary crystallisation conditions on the mechanical and interfacial properties of micronised budesonide for dry powder inhalation. Int. J. Pharm. 2012, 430, 26–33. [Google Scholar] [CrossRef]

- Bhalani, D.V.; Nutan, B.; Kumar, A.; Singh Chandel, A.K. Bioavailability Enhancement Techniques for Poorly Aqueous Soluble Drugs and Therapeutics. Biomedicines 2022, 10, 2055. [Google Scholar] [CrossRef]

- Da Silva, F.L.O.; Marques, M.B.D.F.; Kato, K.C.; Carneiro, G. Nanonization techniques to overcome poor water-solubility with drugs. Expert Opin. Drug Discov. 2020, 15, 853–864. [Google Scholar] [CrossRef]

- Denduyver, P.; Vervaet, C.; Vanhoorne, V. The effect of filler particle size on API homogeneity of controlled release formulations via continuous twin-screw wet granulation. Int. J. Pharm. 2025, 669, 124990. [Google Scholar] [CrossRef]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Comparative evaluation of powder flow parameters with reference to particle size and shape. Int. J. Pharm. 2018, 547, 133–141. [Google Scholar] [CrossRef]

- Stavrou, A.G.; Hare, C.; Hassanpour, A.; Wu, C.-Y. Investigation of powder flowability at low stresses: Influence of particle size and size distribution. Powder Technol. 2020, 364, 98–114. [Google Scholar] [CrossRef]

- Shah, U.V.; Karde, V.; Ghoroi, C.; Heng, J.Y.Y. Influence of particle properties on powder bulk behaviour and processability. Int. J. Pharm. 2017, 518, 138–154. [Google Scholar] [CrossRef] [PubMed]

- Shah, U.V.; Wang, Z.; Olusanmi, D.; Narang, A.S.; Hussain, M.A.; Tobyn, M.J.; Heng, J.Y.Y. Effect of milling temperatures on surface area, surface energy and cohesion of pharmaceutical powders. Int. J. Pharm. 2015, 495, 234–240. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Guo, X.; Lu, H.; Liu, H. Experimental study on the effects of particle characteristics and pressurization methods on powder compression. Chem. Eng. Sci. 2022, 260, 117927. [Google Scholar] [CrossRef]

- Nakach, M.; Authelin, J.-R.; Chamayou, A.; Dodds, J. Comparison of various milling technologies for grinding pharmaceutical powders. Int. J. Miner. Process. 2004, 74, S173–S181. [Google Scholar] [CrossRef]

- Bentham, A.C.; Kwan, C.C.; Boerefijn, R.; Ghadiri, M. Fluidised-bed jet milling of pharmaceutical powders. Powder Technol. 2004, 141, 233–238. [Google Scholar] [CrossRef]

- Patel, R.P.; Baria, A.H.; Patel, N.A. An overview of size reduction technologies in the field of pharmaceutical manufacturing. Asian J. Pharm. 2014, 2, 216. [Google Scholar] [CrossRef]

- Matsanga, N.; Nheta, W.; Chimwani, N. A Review of the Grinding Media in Ball Mills for Mineral Processing. Minerals 2023, 13, 1373. [Google Scholar] [CrossRef]

- Li, P.; Cao, Z.; Zhao, R.; Li, G.; Yu, M.; Zhang, S. The kinetics and efficiency of batch ball grinding with cemented tungsten carbide balls. Adv. Powder Technol. 2020, 31, 2412–2420. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Kawatra, S. Effects of Grinding Media on Grinding Products and Flotation Performance of Sulfide Ores. Miner. Process. Extr. Metall. Rev. 2020, 42, 172–183. [Google Scholar] [CrossRef]

- Patravale, V.B.; Date, A.A.; Kulkarni, R.M. Nanosuspensions: A promising drug delivery strategy. J. Pharm. Pharmacol. 2004, 56, 827–840. [Google Scholar] [CrossRef]

- Guner, G.; Heidari, H.; Lehman, K.; Desai, P.M.; Clancy, D.; Bilgili, E.; Chattoraj, S. Comparative analysis of polystyrene versus zirconia beads on breakage kinetics, heat generation, and amorphous formation during wet bead milling. J. Pharm. Sci. 2025, 114, 1175–1185. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Bai, Y.; Dong, H.; Wu, Q.; Ye, X. Influence of ball size distribution on grinding effect in horizontal planetary ball mill. Adv. Powder Technol. 2014, 25, 983–990. [Google Scholar] [CrossRef]

- AmanNejad, M.; Barani, K. Effects of Ball Size Distribution and Mill Speed and Their Interactions on Ball Milling Using DEM. Miner. Process. Extr. Metall. Rev. 2021, 42, 374–379. [Google Scholar] [CrossRef]

- Memarvar, D.; Yaqoubi, S.; Hamishehkar, H.; Lam, M.; Nokhodchi, A. Impact of grinding balls on the size reduction of Aprepitant in wet ball milling procedure. Pharm. Dev. Technol. 2024, 29, 353–358. [Google Scholar] [CrossRef]

- Kuziora, P.; Wyszyńska, M.; Polanski, M.; Bystrzycki, J. Why the ball to powder ratio (BPR) is insufficient for describing the mechanical ball milling process. Int. J. Hydrogen Energy 2014, 39, 9883–9887. [Google Scholar] [CrossRef]

- Canakci, A.; Erdemir, F.; Varol, T.; Patir, A. Determining the effect of process parameters on particle size in mechanical milling using the Taguchi method: Measurement and analysis. Measurement 2013, 46, 3532–3540. [Google Scholar] [CrossRef]

- Chen, Y.; Lian, X.; Li, Z.; Zheng, S.; Wang, Z. Effects of rotation speed and media density on particle size distribution and structure of ground calcium carbonate in a planetary ball mill. Adv. Powder Technol. 2015, 26, 505–510. [Google Scholar] [CrossRef]

- Watanabe, H. Critical rotation speed for ball-milling. Powder Technol. 1999, 104, 95–99. [Google Scholar] [CrossRef]

- Jaśkowska, J.; Drabczyk, A.K.; Michorczyk, P.; Kułaga, D.; Zaręba, P.; Jodłowski, P.; Majka, Z.; Jakubski, J.; Pindelska, E. Mechanochemical Synthesis Method for Drugs Used in the Treatment of CNS Diseases under PTC Conditions. Catalysts 2022, 12, 464. [Google Scholar] [CrossRef]

- Sarkar, S.; Chatterjee, R.; Mukherjee, A.; Mukherjee, D.; Chandra Mandal, N.; Mahato, S.; Santra, S.; Zyryanov, G.V.; Majee, A. Mechanochemical Synthesis and Antimicrobial Studies of 4-Hydroxy-3-thiomethylcoumarins Using Imidazolium Zwitterionic Molten Salt as an Organocatalyst. ACS Sustain. Chem. Eng. 2021, 9, 5557–5569. [Google Scholar] [CrossRef]

- Slámová, M.; Prausová, K.; Epikaridisová, J.; Brokešová, J.; Kuentz, M.; Patera, J.; Zámostný, P. Effect of co-milling on dissolution rate of poorly soluble drugs. Int. J. Pharm. 2021, 597, 120312. [Google Scholar] [CrossRef] [PubMed]

- Stasiak, T.; Kumaran, S.N.; Touzin, M.; Béclin, F.; Cordier, C. Novel Multicomponent Powders from the AlCrFeMnMo Family Synthesized by Mechanical Alloying. Adv. Eng. Mater. 2019, 21, 1900808. [Google Scholar] [CrossRef]

- Marushka, J.; Brokešová, J.; Ugo Ogadah, C.; Kazemi, A.; Duintjer Tebbens, J.; Šklubalová, Z. Milling of pharmaceutical powder carrier excipients: Application of central composite design. Adv. Powder Technol. 2022, 33, 103881. [Google Scholar] [CrossRef]

- Zaharani, L.; Khaligh, N.G. Study the crystal structure of 4,4′-(propane-1,3-diyl)dipiperidinium sulfate monohydrate and its hydrogen bond catalytic activity in the mechanochemical synthesis of BIMs. J. Mol. Struct. 2023, 1278, 134917. [Google Scholar] [CrossRef]

- Becerra-Anaya, S.J.; Merchán Arenas, D.R.; Kouznetsov, V.V. A Simple and Effective Protocol for the Pechmann Reaction to Obtain 4-Methylcoumarin Derivatives Using a High-Speed Mixer Ball Mill Process. Chemistry 2023, 5, 1077–1088. [Google Scholar] [CrossRef]

- Brokešová, J.; Slámová, M.; Zámostný, P.; Kuentz, M.; Koktan, J.; Krejčík, L.; Vraníková, B.; Svačinová, P.; Šklubalová, Z. Mechanistic study of dissolution enhancement by interactive mixtures of chitosan with meloxicam as model. Eur. J. Pharm. Sci. 2022, 169, 106087. [Google Scholar] [CrossRef]

- Descamps, M.; Willart, J.F. Perspectives on the amorphisation/milling relationship in pharmaceutical materials. Adv. Drug Deliv. Rev. 2016, 100, 51–66. [Google Scholar] [CrossRef]

- Schmidt, R.; Martin Scholze, H.; Stolle, A. Temperature progression in a mixer ball mill. Int. J. Ind. Chem. 2016, 7, 181–186. [Google Scholar] [CrossRef]

- Loh, Z.H.; Samanta, A.K.; Sia Heng, P.W. Overview of milling techniques for improving the solubility of poorly water-soluble drugs. Asian J. Pharm. Sci. 2015, 10, 255–274. [Google Scholar] [CrossRef]

- Kotake, N.; Kuboki, M.; Kiya, S.; Kanda, Y. Influence of dry and wet grinding conditions on fineness and shape of particle size distribution of product in a ball mill. Adv. Powder Technol. 2011, 22, 86–92. [Google Scholar] [CrossRef]

- Manoj Prabhakar, M.; Saravanan, A.K.; Haiter Lenin, A.; Jerin leno, I.; Mayandi, K.; Sethu Ramalingam, P. A short review on 3D printing methods, process parameters and materials. Mater. Today Proc. 2021, 45, 6108–6114. [Google Scholar] [CrossRef]

- Mathew, E.; Pitzanti, G.; Larrañeta, E.; Lamprou, D.A. 3D Printing of Pharmaceuticals and Drug Delivery Devices. Pharmaceutics 2020, 12, 266. [Google Scholar] [CrossRef] [PubMed]

- Basa, B.; Jakab, G.; Kállai-Szabó, N.; Borbás, B.; Fülöp, V.; Balogh, E.; Antal, I. Evaluation of Biodegradable PVA-Based 3D Printed Carriers during Dissolution. Materials 2021, 14, 1350. [Google Scholar] [CrossRef] [PubMed]

- Lamichhane, S.; Bashyal, S.; Keum, T.; Noh, G.; Seo, J.E.; Bastola, R.; Choi, J.; Sohn, D.H.; Lee, S. Complex formulations, simple techniques: Can 3D printing technology be the Midas touch in pharmaceutical industry? Asian J. Pharm. Sci. 2019, 14, 465–479. [Google Scholar] [CrossRef]

- Ogochukwu, L.O.-M.; Hany, H.; Reem, K.; Amr, E. 3D Printing of Solid Oral Dosage Forms: Numerous Challenges with Unique Opportunities. J. Pharm. Sci. 2020, 109, 3535–3550. [Google Scholar]

- Borbás, B.; Kállai-Szabó, N.; Lengyel, M.; Balogh, E.; Basa, B.; Süvegh, K.; Zelkó, R.; Antal, I. Microfabrication of controlled release osmotic drug delivery systems assembled from designed elements. Expert Opin. Drug Deliv. 2024, 21, 1637–1649. [Google Scholar] [CrossRef]

- Curti, C.; Kirby, D.J.; Russell, C.A. Stereolithography Apparatus Evolution: Enhancing Throughput and Efficiency of Pharmaceutical Formulation Development. Pharmaceutics 2021, 13, 616. [Google Scholar] [CrossRef]

- Ameta, K.L.; Solanki, V.S.; Singh, V.; Devi, A.P.; Chundawat, R.S.; Haque, S. Critical appraisal and systematic review of 3D & 4D printing in sustainable and environment-friendly smart manufacturing technologies. Sustain. Mater. Technol. 2022, 34, e00481. [Google Scholar] [CrossRef]

- Melocchi, A.; Uboldi, M.; Maroni, A.; Foppoli, A.; Palugan, L.; Zema, L.; Gazzaniga, A. 3D printing by fused deposition modeling of single- and multi-compartment hollow systems for oral delivery—A review. Int. J. Pharm. 2020, 579, 119155. [Google Scholar] [CrossRef]

- GombÁs, Á.; Szabó-Révész, P.; Kata, M.; Regdon, G.; István, E. Quantitative Determination of Crystallinity of α-Lactose Monohydrate by DSC. J. Therm. Anal. Calorim. 2002, 68, 503–510. [Google Scholar] [CrossRef]

- Takacs, L.; McHenry, J.S. Temperature of the milling balls in shaker and planetary mills. J. Mater. Sci. 2006, 41, 5246–5249. [Google Scholar] [CrossRef]

- Kwon, Y.-S.; Gerasimov, K.B.; Yoon, S.-K. Ball temperatures during mechanical alloying in planetary mills. J. Alloys Compd. 2002, 346, 276–281. [Google Scholar] [CrossRef]

- Kulla, H.; Wilke, M.; Fischer, F.; Röllig, M.; Maierhofer, C.; Emmerling, F. Warming up for mechanosynthesis—Temperature development in ball mills during synthesis. Chem. Commun. 2017, 53, 1664–1667. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Yang, Q.; Chen, P.; Lu, K.; Wu, Y. An Improved Mathematical Model of Cutting Temperature in End Milling Al7050 Based on the Influence of Tool Geometry Parameters and Milling Parameters. Math. Probl. Eng. 2021, 2021, 5705091. [Google Scholar] [CrossRef]

| rpm (1/min) | Process Time (min) | Number of Balls | Diameter of Balls (mm) | Reference |

|---|---|---|---|---|

| 300; 700 | 10 | 12 | 10 | [30] |

| 500 | 60 | 4 | 10 | [31] |

| 250 | 20 | 5 | 10 | [32] |

| 300 | 60 | 6; 3 | 10; 20 | [33] |

| 300 | 15 | 100 | 5 | [34] |

| 600 | 40 | 180 | 5 | [35] |

| 500 | 120 | 10 | 5 | [36] |

| 300 | 30 | 100 | 5 | [37] |

| Coded Value | Actual Values of x (1/min) | Actual Values of y (min) | ||

|---|---|---|---|---|

| −1 | 300 | 15 | ||

| 0 | 350 | 30 | ||

| +1 | 400 | 45 | ||

| Experimental matrix | Stainless-steel balls | Printed balls | ||

| Trial No. | Coded Values of x | Coded Values of y | Temperature (°C) | Temperature (°C) |

| 1 | +1 | −1 | 57.2 ± 0.1 | 37.8 ± 0.1 |

| 2 | +1 | 0 | 63.3 ± 0.1 | 40.3 ± 0.1 |

| 3 | +1 | +1 | 68.4 ± 0.1 | 42.4 ± 0.1 |

| 4 | 0 | −1 | 49.8 ± 0.2 | 35.2 ± 0.2 |

| 5 | 0 | 0 | 55.4 ± 0.1 | 37.1 ± 0.2 |

| 6 | 0 | +1 | 61.0 ± 0.3 | 39.1 ± 0.2 |

| 7 | −1 | −1 | 39.3 ± 0.1 | 31.6 ± 0.1 |

| 8 | −1 | 0 | 44.4 ± 0.0 | 32.6 ± 0.2 |

| 9 | −1 | +1 | 48.4 ± 0.1 | 34.4 ± 0.2 |

| Diameter | Density of Stainless-Steel Balls (g/cm3) | RSD (%) | Density of 3D-Printed Balls (g/cm3) | RSD (%) |

|---|---|---|---|---|

| 25 mm | 0.9642 | 0.01 | 0.1491 | 0.75 |

| 20 mm | 0.9620 | 0.01 | 0.1507 | 0.19 |

| 10 mm | 0.9649 | 0.04 | 0.1554 | 0.11 |

| Material | Initial/Grinded | Average Particle Size (μm) | SD (μm) | SPAN | SD |

|---|---|---|---|---|---|

| Metal ball | initial | 386.30 | ±3.42 | 1.01 | 0.03 |

| milled | 359.89 | ±4.14 | 1.10 | 0.03 | |

| 3D-printed balls (6 pcs with postcuring) | initial | 374.02 | ±24.31 | 1.05 | 0.10 |

| milled | 207.55 | ±12.00 | 1.33 | 0.03 | |

| 3D-printed balls (4 pcs with postcuring) | initial | 427.97 | ±37.38 | 0.82 | 0.10 |

| milled | 307.73 | ±18.27 | 1.38 | 0.05 | |

| 3D-printed balls (4 pcs without postcuring) | initial | 382.91 | ±12.82 | 1.15 | 0.23 |

| milled | 287.30 | ±9.79 | 1.26 | 0.14 |

| Grinding Time (min) | ||||

|---|---|---|---|---|

| Rotation Speed (1/min) | 15 | 30 | 45 | |

| Stainless-steel balls | 300 | 39.4 °C | 44.4 °C | 48.4 °C |

| 350 | 49.9 °C | 55.5 °C | 60.7 °C | |

| 400 | 57.2 °C | 63.2 °C | 68.4 °C | |

| 3D-printed balls | 300 | 31.6 °C | 32.6 °C | 34.2 °C |

| 350 | 35.2 °C | 37.2 °C | 39.3 °C | |

| 400 | 37.7 °C | 40.4 °C | 42.4 °C | |

| Coefficients | |||||||

|---|---|---|---|---|---|---|---|

| Sample Name | Parameters | a | b | c | d | e | f |

| Stainless-steel balls | Value | 55.63 | 9.47 | 5.25 | −1.90 | −0.35 | 0.53 |

| Std Error | 0.302 | 0.165 | 0.165 | 0.286 | 0.286 | 0.202 | |

| p > ItI | 0.000 | 0.000 | 0.000 | 0.007 | 0.308 | 0.080 | |

| printed balls | Value | 37.08 | 3.65 | 1.88 | −0.62 | 0.08 | 0.45 |

| Std Error | 0.158 | 0.086 | 0.086 | 0.150 | 0.150 | 0.106 | |

| p > ItI | 0.000 | 0.000 | 0.000 | 0.026 | 0.617 | 0.106 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borbás, B.; Kohod, Z.; Kállai-Szabó, N.; Basa, B.; Lengyel, M.; Zelkó, R.; Antal, I. Evaluation of 3D-Printed Balls with Photopolymer Resin as Grinding Medium Used to Alternatively Reduce Warmup During Dry Milling. Polymers 2025, 17, 1795. https://doi.org/10.3390/polym17131795

Borbás B, Kohod Z, Kállai-Szabó N, Basa B, Lengyel M, Zelkó R, Antal I. Evaluation of 3D-Printed Balls with Photopolymer Resin as Grinding Medium Used to Alternatively Reduce Warmup During Dry Milling. Polymers. 2025; 17(13):1795. https://doi.org/10.3390/polym17131795

Chicago/Turabian StyleBorbás, Bence, Zsófia Kohod, Nikolett Kállai-Szabó, Bálint Basa, Miléna Lengyel, Romána Zelkó, and István Antal. 2025. "Evaluation of 3D-Printed Balls with Photopolymer Resin as Grinding Medium Used to Alternatively Reduce Warmup During Dry Milling" Polymers 17, no. 13: 1795. https://doi.org/10.3390/polym17131795

APA StyleBorbás, B., Kohod, Z., Kállai-Szabó, N., Basa, B., Lengyel, M., Zelkó, R., & Antal, I. (2025). Evaluation of 3D-Printed Balls with Photopolymer Resin as Grinding Medium Used to Alternatively Reduce Warmup During Dry Milling. Polymers, 17(13), 1795. https://doi.org/10.3390/polym17131795