Mechanical Properties of Dual-Layer Electrospun Fiber Mats

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Zhu, J.; Cheng, H.; Li, G.; Cho, H.; Jiang, M.; Gao, Q.; Zhang, X. Developments of Advanced Electrospinning Techniques: A Critical Review. Adv. Mater. Technol. 2021, 6, 2100410. [Google Scholar] [CrossRef]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial Upscaling of Electrospinning and Applications of Polymer Nanofibers: A Review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Caloian, I.; Trapp, J.; Williams, M.W.; Kim, R.A.; Moustafa, M.E.; Stwodah, E.H.; Tang, C. Direct Fabrication of Functional Shapes on 3D Surfaces Using Electrospinning. Polymers 2023, 15, 533. [Google Scholar] [CrossRef] [PubMed]

- Dasdemir, M.; Topalbekiroglu, M.; Demir, A. Electrospinning of Thermoplastic Polyurethane Microfibers and Nanofibers from Polymer Solution and Melt. J. Appl. Polym. Sci. 2013, 127, 1901–1908. [Google Scholar] [CrossRef]

- Nguyen, J.; Stwodah, R.M.; Vasey, C.L.; Rabatin, B.E.; Atherton, B.; D’Angelo, P.A.; Swana, K.W.; Tang, C. Thermochromic Fibers via Electrospinning. Polymers 2020, 12, 842. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Y.; Zhang, S.; Li, T.; Ramakrishna, S.; Liu, Y. Progress of Improving Mechanical Strength of Electrospun Nanofibrous Membranes. Macromol. Mater. Eng. 2020, 305, 2000230. [Google Scholar] [CrossRef]

- Borisova, I.; Stoilova, O.; Manolova, N.; Rashkov, I. Modulating the Mechanical Properties of Electrospun PHB/PCL Materials by Using Different Types of Collectors and Heat Sealing. Polymers 2020, 12, 693. [Google Scholar] [CrossRef]

- Tumbic, J.; Romo-Uribe, A.; Boden, M.; Mather, P.T. Hot-Compacted Interwoven Webs of Biodegradable Polymers. Polymer 2016, 101, 127–138. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, C.H.; Pant, H.R.; Tijing, L.D.; Yu, M.H.; Kim, Y.; Kim, C.S. An Angled Robotic Dual-Nozzle Electrospinning Set-Up for Preparing PU/PA6 Composite Fibers. Text. Res. J. 2013, 83, 311–320. [Google Scholar] [CrossRef]

- Bazmandeh, A.Z.; Mirzaei, E.; Fadaie, M.; Shirian, S.; Ghasemi, Y. Dual Spinneret Electrospun Nanofibrous/Gel Structure of Chitosan-Gelatin/Chitosan-Hyaluronic Acid as a Wound Dressing: In-Vitro and in-Vivo Studies. Int. J. Biol. Macromol. 2020, 162, 359–373. [Google Scholar] [CrossRef]

- Hu, W.W.; Yu, H.N. Coelectrospinning of Chitosan/Alginate Fibers by Dual-Jet System for Modulating Material Surfaces. Carbohydr. Polym. 2013, 95, 716–727. [Google Scholar] [CrossRef]

- Gu, M.; Wang, K.; Li, W.; Qin, C.; Wang, J.-J.; Dai, L. Preparation and Characterization of PVA/PU Blend Nanofiber Mats by Dual-Jet Electrospinning. Fibers Polym. 2011, 12, 65–72. [Google Scholar] [CrossRef]

- Birjandi Nejad, H.; Robertson, J.M.; Mather, P.T. Interwoven Polymer Composites via Dual-Electrospinning with Shape Memory and Self-Healing Properties. MRS Commun. 2015, 5, 211–221. [Google Scholar] [CrossRef]

- Hussein, M.A.M.; Gunduz, O.; Sahin, A.; Grinholc, M.; El-Sherbiny, I.M.; Megahed, M. Dual Spinneret Electrospun Polyurethane/PVA-Gelatin Nanofibrous Scaffolds Containing Cinnamon Essential Oil and Nanoceria for Chronic Diabetic Wound Healing: Preparation, Physicochemical Characterization and In-Vitro Evaluation. Molecules 2022, 27, 2146. [Google Scholar] [CrossRef] [PubMed]

- Sanhueza, C.; Hermosilla, J.; Bugallo-Casal, A.; Da Silva-Candal, A.; Taboada, C.; Millán, R.; Concheiro, A.; Alvarez-Lorenzo, C.; Acevedo, F. One-Step Electrospun Scaffold of Dual-Sized Gelatin/Poly-3-Hydroxybutyrate Nano/Microfibers for Skin Regeneration in Diabetic Wound. Mater. Sci. Eng. C 2021, 119, 111602. [Google Scholar] [CrossRef]

- Wlodarczyk, J.; Musial-Kulik, M.; Jelonek, K.; Stojko, M.; Karpeta-Jarzabek, P.; Pastusiak, M.; Janeczek, H.; Dobrzynski, P.; Sobota, M.; Kasperczyk, J. Dual-Jet Electrospun PDLGA/PCU Nonwovens as Promising Mesh Implant Materials with Controlled Release of Sirolimus and Diclofenac. Int. J. Pharm. 2022, 625, 122113. [Google Scholar] [CrossRef]

- Robertson, J.M.; Birjandi Nejad, H.; Mather, P.T. Dual-Spun Shape Memory Elastomeric Composites. ACS Macro Lett. 2015, 4, 436–440. [Google Scholar] [CrossRef]

- Ai, J.; Xia, M.; Zeng, B.; Pang, Y.; Shen, J.; Zheng, Y.; Guo, S. Shape-Memory Performance of Electrospun Thermoplastic Polyurethane/Polyethylene Oxide Blend Fibrous Membranes with Diverse Morphological Structures. Polymer 2023, 288, 126470. [Google Scholar] [CrossRef]

- Wlodarczyk, J.; Stojko, M.; Musial-Kulik, M.; Karpeta-Jarzabek, P.; Pastusiak, M.; Janeczek, H.; Dobrzynski, P.; Sobota, M.; Kasperczyk, J. Dual-Jet Electrospun PDLGA/PCU Nonwovens and Their Mechanical and Hydrolytic Degradation Properties. J. Mech. Behav. Biomed. Mater. 2022, 126, 105050. [Google Scholar] [CrossRef]

- Yoon, J.W.; Park, Y.; Kim, J.; Park, C.H. Multi-Jet Electrospinning of Polystyrene/Polyamide 6 Blend: Thermal and Mechanical Properties. Fash. Text. 2017, 4, 9. [Google Scholar] [CrossRef]

- Wu, H.; Shi, J.; Ning, X.; Long, Y.Z.; Zheng, J. The High Flux of Superhydrophilic-Superhydrophobic Janus Membrane of CPVA-PVDF/PMMA/GO by Layer-By-Layer Electrospinning for High Efficiency Oil-Water Separation. Polymers 2022, 14, 621. [Google Scholar] [CrossRef]

- Qin, S.; Wang, Y.; Wu, X.; Zhang, X.; Zhu, Y.; Yu, N.; Zhang, Y.; Wu, Y. Nylon-Based Composite Gel Membrane Fabricated via Sequential Layer-by-Layer Electrospinning for Rechargeable Lithium Batteries with High Performance. Polymers 2020, 12, 1572. [Google Scholar] [CrossRef] [PubMed]

- Sajesh, K.M.; Kiran, K.; Nair, S.V.; Jayakumar, R. Sequential Layer-by-Layer Electrospinning of Nano SrCO3/PRP Loaded PHBV Fibrous Scaffold for Bone Tissue Engineering. Compos. Part B Eng. 2016, 99, 445–452. [Google Scholar] [CrossRef]

- Lin, S.J.; Xue, Y.P.; Chang, G.; Han, Q.L.; Chen, L.F.; Jia, Y.B.; Zheng, Y.G. Layer-by-Layer 3-Dimensional Nanofiber Tissue Scaffold with Controlled Gap by Electrospinning. Mater. Res. Express 2018, 5, 025401. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, W.; Wang, B.; Pei, G.; Li, C. Multilevel-Layer-Structured Polyamide 6/Poly(Trimethylene Terephthalate) Nanofibrous Membranes for Low-Pressure Air Filtration. J. Appl. Polym. Sci. 2017, 134, 44716. [Google Scholar] [CrossRef]

- Woo, Y.C.; Tijing, L.D.; Park, M.J.; Yao, M.; Choi, J.S.; Lee, S.; Kim, S.H.; An, K.J.; Shon, H.K. Electrospun Dual-Layer Nonwoven Membrane for Desalination by Air Gap Membrane Distillation. Desalination 2017, 403, 187–198. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Luan, C.; Wang, Z.; Yao, X.; Fu, J. Additive Manufacturing of Polyamide 66: Effect of Process Parameters on Crystallinity and Mechanical Properties. J. Mater. Eng. Perform. 2022, 31, 191–200. [Google Scholar] [CrossRef]

- Abbasi, A.; Nasef, M.M.; Takeshi, M.; Faridi-Majidi, R. Electrospinning of Nylon-6,6 Solutions into Nanofibers: Rheology and Morphology Relationships. Chinese J. Polym. Sci. 2014, 32, 793–804. [Google Scholar] [CrossRef]

- Carrizales, C.; Pelfrey, S.; Rincon, R.; Eubanks, T.M.; Kuang, A.; McClure, M.J.; Bowlin, G.L.; Macossay, J. Thermal and Mechanical Properties of Electrospun PMMA, PVC, Nylon 6, and Nylon 6,6. Polym. Adv. Technol. 2008, 19, 124–130. [Google Scholar] [CrossRef]

- Ewaldz, E.; Brettmann, B. Molecular Interactions in Electrospinning: From Polymer Mixtures to Supramolecular Assemblies. ACS Appl. Polym. Mater. 2019, 1, 298–308. [Google Scholar] [CrossRef]

- Sikdar, P.; Dip, T.M.; Dhar, A.K.; Bhattacharjee, M.; Hoque, M.S.; Ali, S.B. Polyurethane (PU) Based Multifunctional Materials: Emerging Paradigm for Functional Textiles, Smart, and Biomedical Applications. J. Appl. Polym. Sci. 2022, 139, e52832. [Google Scholar] [CrossRef]

- Marett, J.M. The Isolation of Cellulose Nanocrystals from Pistachio Shells and Their Use in Water Actuating Smart Composites. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2017. [Google Scholar]

- Chen, R.; Liu, J.; Yang, C.; Weitz, D.A.; He, H.; Li, D.; Chen, D.; Liu, K.; Bai, H. Transparent Impact-Resistant Composite Films with Bioinspired Hierarchical Structure. ACS Appl. Mater. Interfaces 2019, 11, 23616–23622. [Google Scholar] [CrossRef]

- Ojha, S.S.; Afshari, M.; Kotek, R.; Gorga, R.E. Morphology of Electrospun Nylon-6 Nanofibers as a Function of Molecular Weight and Processing Parameters. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Thornton, B.T.E.; Harrison, A.; Pham, A.L.A.L.; Castano, C.E.; Tang, C. Polyaniline-Functionalized Nanofibers for Colorimetric Detection of HCl Vapor. ACS Omega 2018, 3, 3587–3591. [Google Scholar] [CrossRef]

- Lasenko, I.; Sanchaniya, J.V.; Kanukuntla, S.P.; Ladani, Y.; Viluma-gudmona, A.; Kononova, O.; Lusis, V.; Tipans, I.; Selga, T. The Mechanical Properties of Nanocomposites Reinforced with PA6 Electrospun Nanofibers. Polymers 2023, 15, 673. [Google Scholar] [CrossRef]

- Erdem, R.; Usta, I.; Akalin, M.; Atak, O.; Yuksek, M.; Pars, A. The Impact of Solvent Type and Mixing Ratios of Solvents on the Properties of Polyurethane Based Electrospun Nanofibers. Appl. Surf. Sci. 2015, 334, 227–230. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Wei, S.; Huang, Y.; Yang, S.; Xue, Y.; Xuan, H.; Yuan, H. A Solvent System Involved Fabricating Electrospun Polyurethane Nanofibers for Biomedical Applications. Polymers 2020, 12, 3038. [Google Scholar] [CrossRef]

- Shenoy, S.L.; Bates, W.D.; Frisch, H.L.; Wnek, G.E. Role of Chain Entanglements on Fiber Formation during Electrospinning of Polymer Solutions: Good Solvent, Non-Specific Polymer-Polymer Interaction Limit. Polymer 2005, 46, 3372–3384. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Yalcinkaya, B.; Jirsak, O. Influence of Salts on Electrospinning of Aqueous and Nonaqueous Polymer Solutions. J. Nanomater. 2015, 2015, 134251. [Google Scholar] [CrossRef]

- Ryu, Y.J.; Kim, H.Y.; Lee, K.H.; Park, H.C.; Lee, D.R. Transport Properties of Electrospun Nylon 6 Nonwoven Mats. Eur. Polym. J. 2003, 39, 1883–1889. [Google Scholar] [CrossRef]

- Bazbouz, M.B.; Stylios, G.K. Alignment and Optimization of Nylon 6 Nanofibers by Electrospinning. J. Appl. Polym. Sci. 2007, 107, 3023–3032. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, C.H.; Tijing, L.D.; Lee, D.H.; Yu, M.H.; Pant, H.R.; Kim, Y.; Kim, C.S. Preparation and Characterization of (Polyurethane/Nylon-6) Nanofiber/(Silicone) Film Composites via Electrospinning and Dip-Coating. Fibers Polym. 2012, 13, 339–345. [Google Scholar] [CrossRef]

- Nirmala, R.; Navamathavan, R.; El-Newehy, M.H.; Kim, H.Y. Preparation and Characterization of Electrospun Ultrafine Polyamide-6 Nanofibers. Polym. Int. 2011, 60, 1475–1480. [Google Scholar] [CrossRef]

- Zhang, H.; Sakagami, D.; Huang, W.; Kimura, H.; Okamura, Y. Measurement and Modelling of Tensile Moduli of Polymer Blend Thin Films with Phase Separated Structures. Polymer 2020, 190, 122233. [Google Scholar] [CrossRef]

- Miao, Y.; He, H.; Li, Z. Strain Hardening Behaviors and Mechanisms of Polyurethane Under Various Strain Rate Loading. Polym. Eng. Sci. 2020, 60, 1083–1092. [Google Scholar] [CrossRef]

- Scetta, G.; Ju, J.; Selles, N.; Heuillet, P.; Ciccotti, M.; Creton, C. Strain Induced Strengthening of Soft Thermoplastic Polyurethanes Under Cyclic Deformation. J. Polym. Sci. 2021, 59, 685–696. [Google Scholar] [CrossRef]

- Ge, C.; Wang, S.; Zhai, W. Influence of Cell Type and Skin-Core Structure on the Tensile Elasticity of the Microcellular Thermoplastic Polyurethane Foam. J. Cell. Plast. 2020, 56, 207–226. [Google Scholar] [CrossRef]

- Tijing, L.D.; Choi, W.; Jiang, Z.; Amarjargal, A.; Park, C.H.; Pant, H.R.; Im, I.T.; Kim, C.S. Two-Nozzle Electrospinning of (MWNT/PU)/PU Nanofibrous Composite Mat with Improved Mechanical and Thermal Properties. Curr. Appl. Phys. 2013, 13, 1247–1255. [Google Scholar] [CrossRef]

- Haryńska, A.; Kucinska-Lipka, J.; Sulowska, A.; Gubanska, I.; Kostrzewa, M.; Janik, H. Medical-Grade PCL Based Polyurethane System for FDM 3D Printing-Characterization and Fabrication. Materials 2019, 12, 887. [Google Scholar] [CrossRef]

- Marett, J.; Aning, A.; Foster, E.J. The Isolation of Cellulose Nanocrystals from Pistachio Shells via Acid Hydrolysis. Ind. Crops Prod. 2017, 109, 869–874. [Google Scholar] [CrossRef]

- Asghari Mooneghi, S.; Gharehaghaji, A.A.; Hosseini-Toudeshky, H.; Torkaman, G. Failure Mechanism of Polyamide 66 Nanofiber Yarns Under Fatigue and Static Tensile Loading. J. Appl. Polym. Sci. 2015, 132, 41925. [Google Scholar] [CrossRef]

- You, Y.J.; Kim, J.H.J.; Park, K.T.; Seo, D.W.; Lee, T.H. Modification of Rule of Mixtures for Tensile Strength Estimation of Circular GFRP Rebars. Polymers 2017, 9, 682. [Google Scholar] [CrossRef]

- Fan, Z.; Tsakiropoulos, P.; Miodownik, A.P. A Generalized Law of Mixtures. J. Mater. Sci. 1994, 29, 141–150. [Google Scholar] [CrossRef]

- Pal, R. New Models for Effective Young’s Modulus of Particulate Composites. Compos. Part B Eng. 2005, 36, 513–523. [Google Scholar] [CrossRef]

- Charfeddine, I.; Majeste, J.C.; Carrot, C.; Lhost, O. Predicting the Young’s Modulus and the Impact Strength of Immiscible Polyolefin Blends. Polymer 2020, 204, 122795. [Google Scholar] [CrossRef]

- Zussman, E.; Burman, M.; Yarin, A.L.; Khalfin, R.; Cohen, Y. Tensile Deformation of Electrospun Nylon-6,6 Nanofibers. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1482–1489. [Google Scholar] [CrossRef]

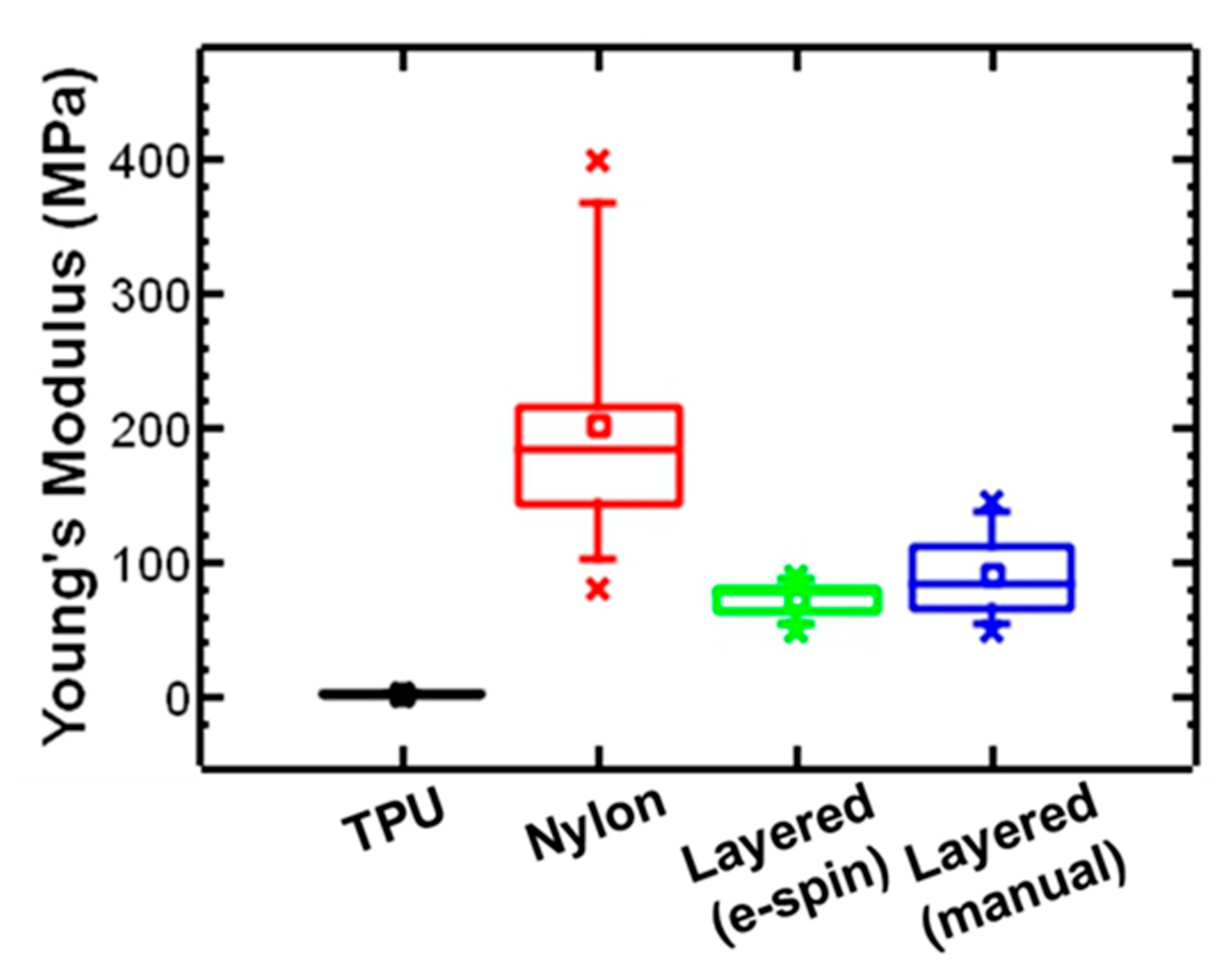

| Young’s Modulus (MPa) | Ultimate Strength (MPa) | Elongation at Break (%) | |

|---|---|---|---|

| TPU * | 1.2 ± 0.2 | n.d. † | >310 |

| Nyon ** | 202.6 ± 95.3 | 16 ± 10 | 24 ± 7 |

| TPU–Nylon-layered structure (manual) ** | 90.4 ± 31.2 | 8 ± 4 | 27 ± 6 |

| TPU–Nylon-layered structure—electrospinning with sequential layer deposition electrospinning ** | 73.1 ± 12.5 | 6 ± 1 | 30 ± 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caloian, I.; Trapp, J.; Kantepalle, B.Y.; Latimer, P.; Lawton, T.J.; Tang, C. Mechanical Properties of Dual-Layer Electrospun Fiber Mats. Polymers 2025, 17, 1777. https://doi.org/10.3390/polym17131777

Caloian I, Trapp J, Kantepalle BY, Latimer P, Lawton TJ, Tang C. Mechanical Properties of Dual-Layer Electrospun Fiber Mats. Polymers. 2025; 17(13):1777. https://doi.org/10.3390/polym17131777

Chicago/Turabian StyleCaloian, Ioana, Jocelyn Trapp, Bhalaji Yadav Kantepalle, Patrick Latimer, Timothy J. Lawton, and Christina Tang. 2025. "Mechanical Properties of Dual-Layer Electrospun Fiber Mats" Polymers 17, no. 13: 1777. https://doi.org/10.3390/polym17131777

APA StyleCaloian, I., Trapp, J., Kantepalle, B. Y., Latimer, P., Lawton, T. J., & Tang, C. (2025). Mechanical Properties of Dual-Layer Electrospun Fiber Mats. Polymers, 17(13), 1777. https://doi.org/10.3390/polym17131777