Valorization of Polymethylmethacrylate Scrap Reinforced with Nano Carbon Black with Optimized Ratio in Extrusion-Based Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixtures, Filaments, and 3D Printed Coupon Preparation

2.3. Raman Characteristics and Procedure

- Excitation: solid-state laser module of 532 nm

- Maximum output power: 90 Mw

- Raman spectral resolution: ≈2 cm−1

- Grating with 600 grooves

2.4. Rheological and Thermal Examination Procedure

2.5. Mechanical Testing Characteristics

2.6. Morphology and Structure Inspection

3. Results

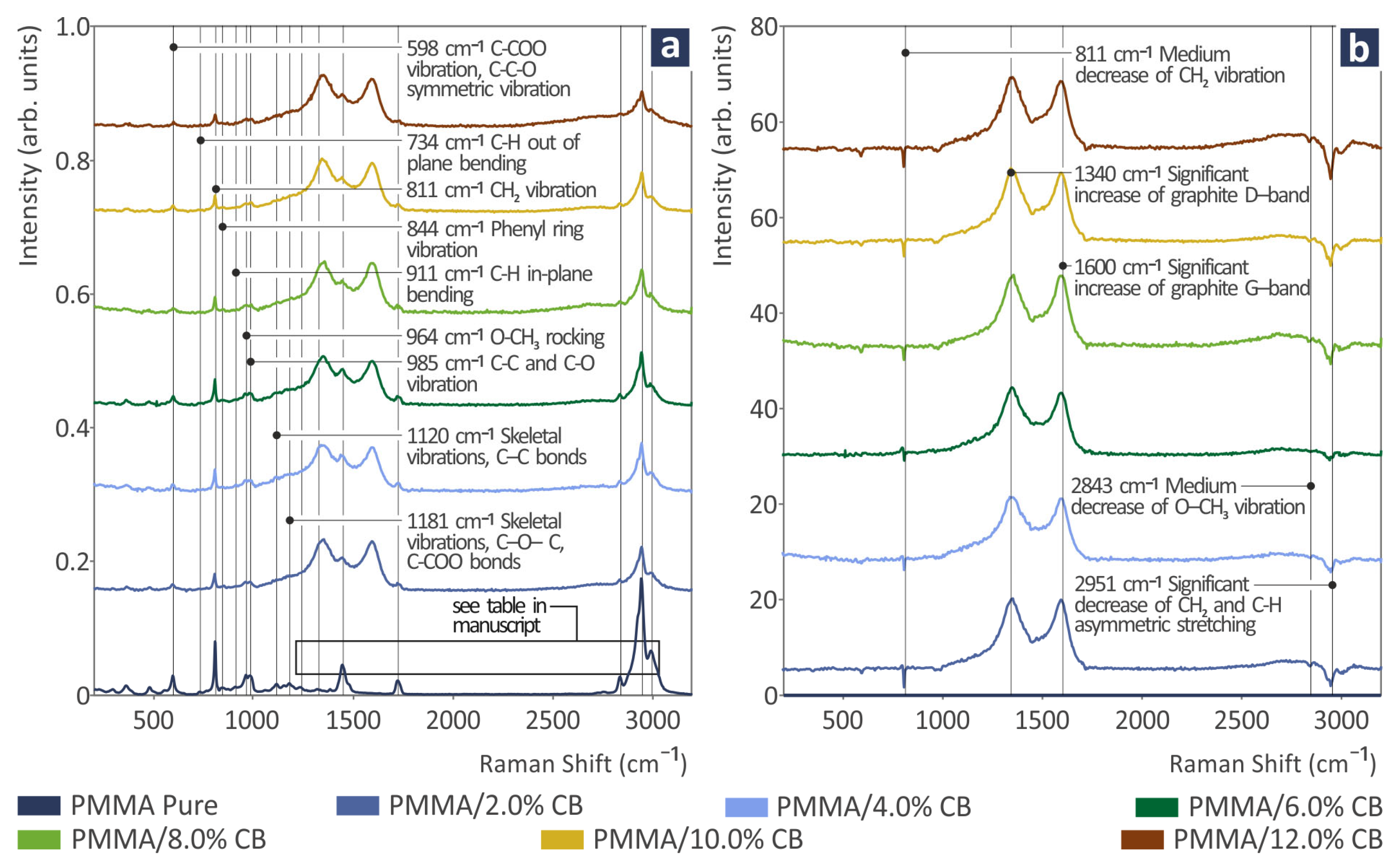

3.1. Raman Evaluation

3.2. Rheology

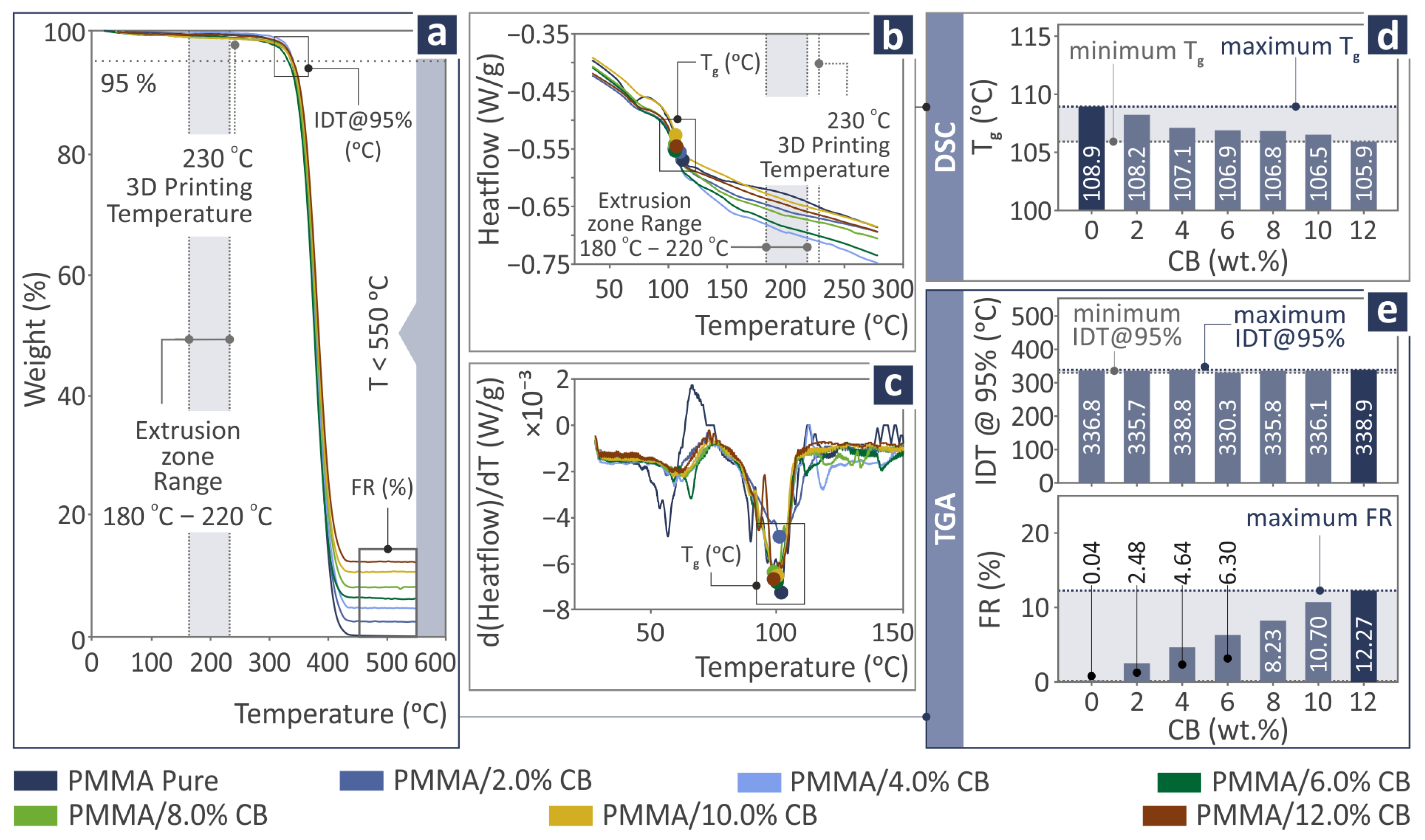

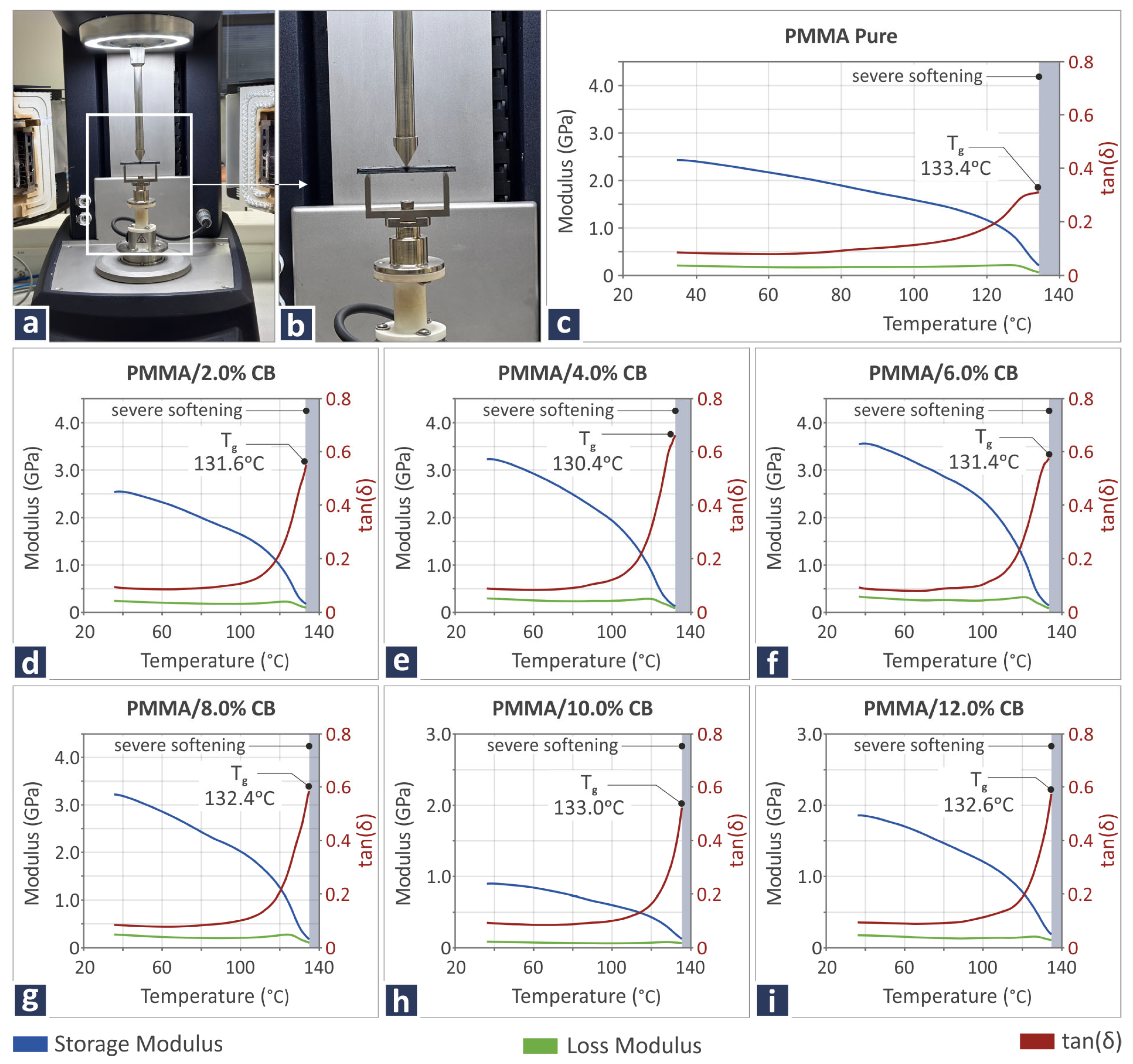

3.3. TGA/DSC/DMA Results

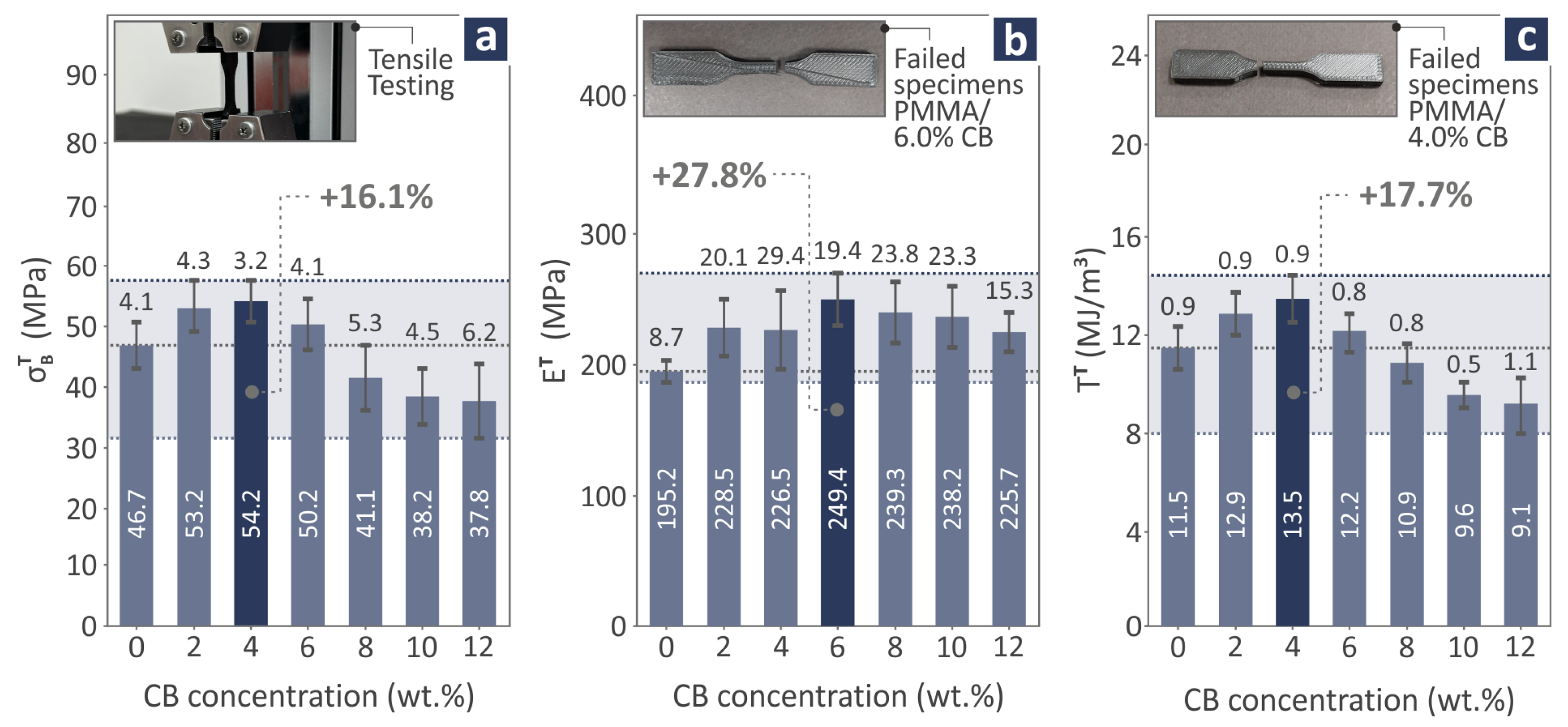

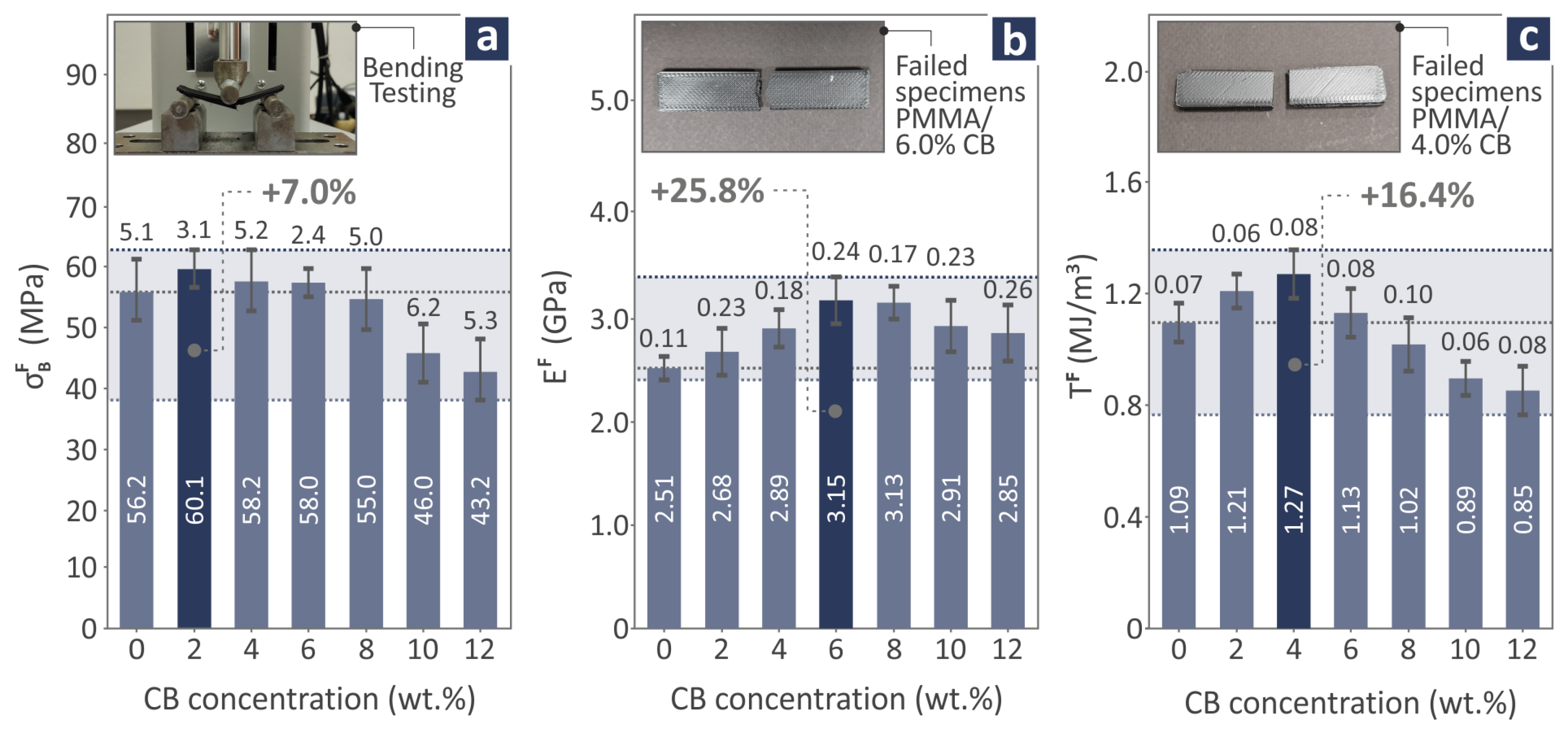

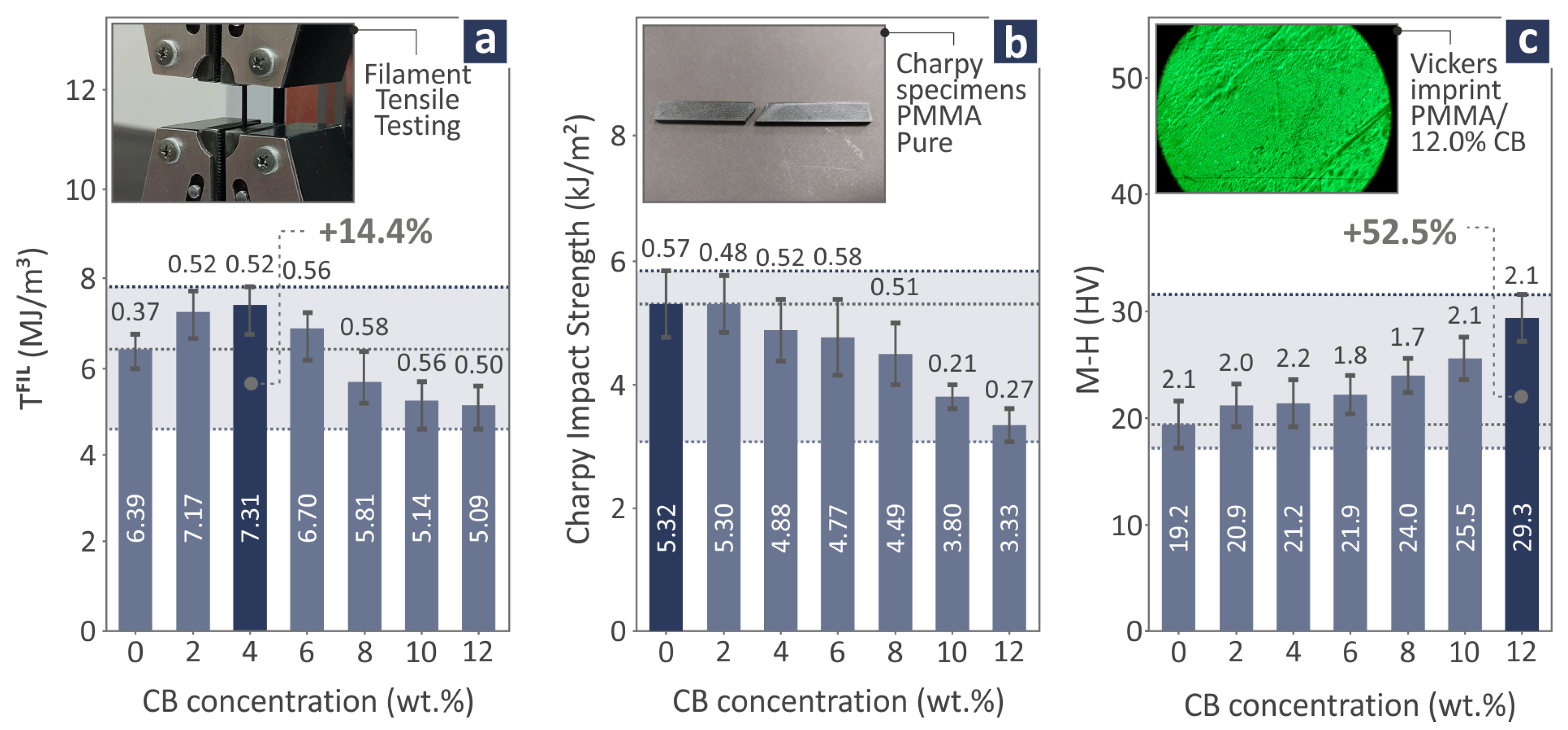

3.4. Mechanical Performance at Room Temperature

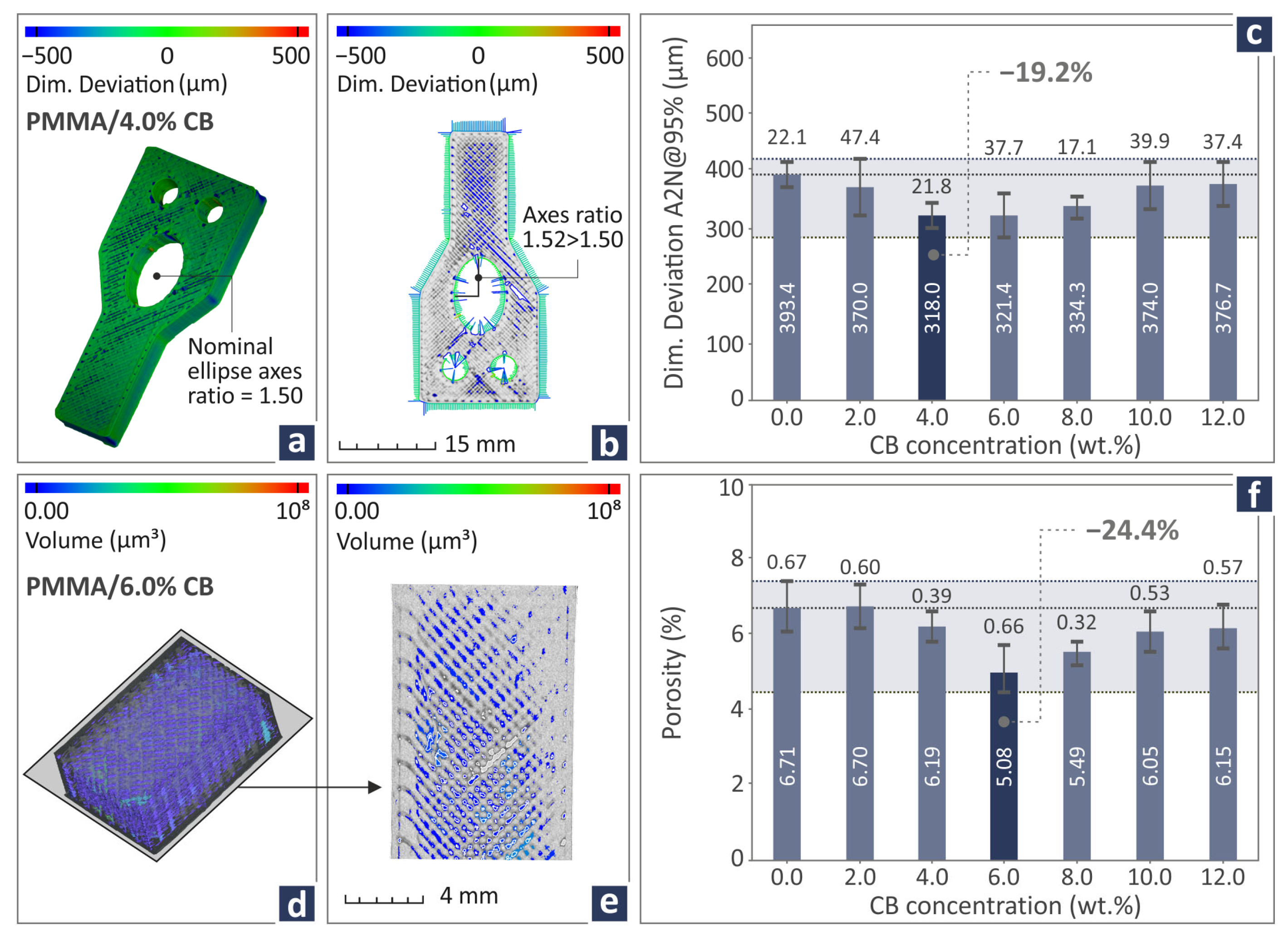

3.5. Structural Performance

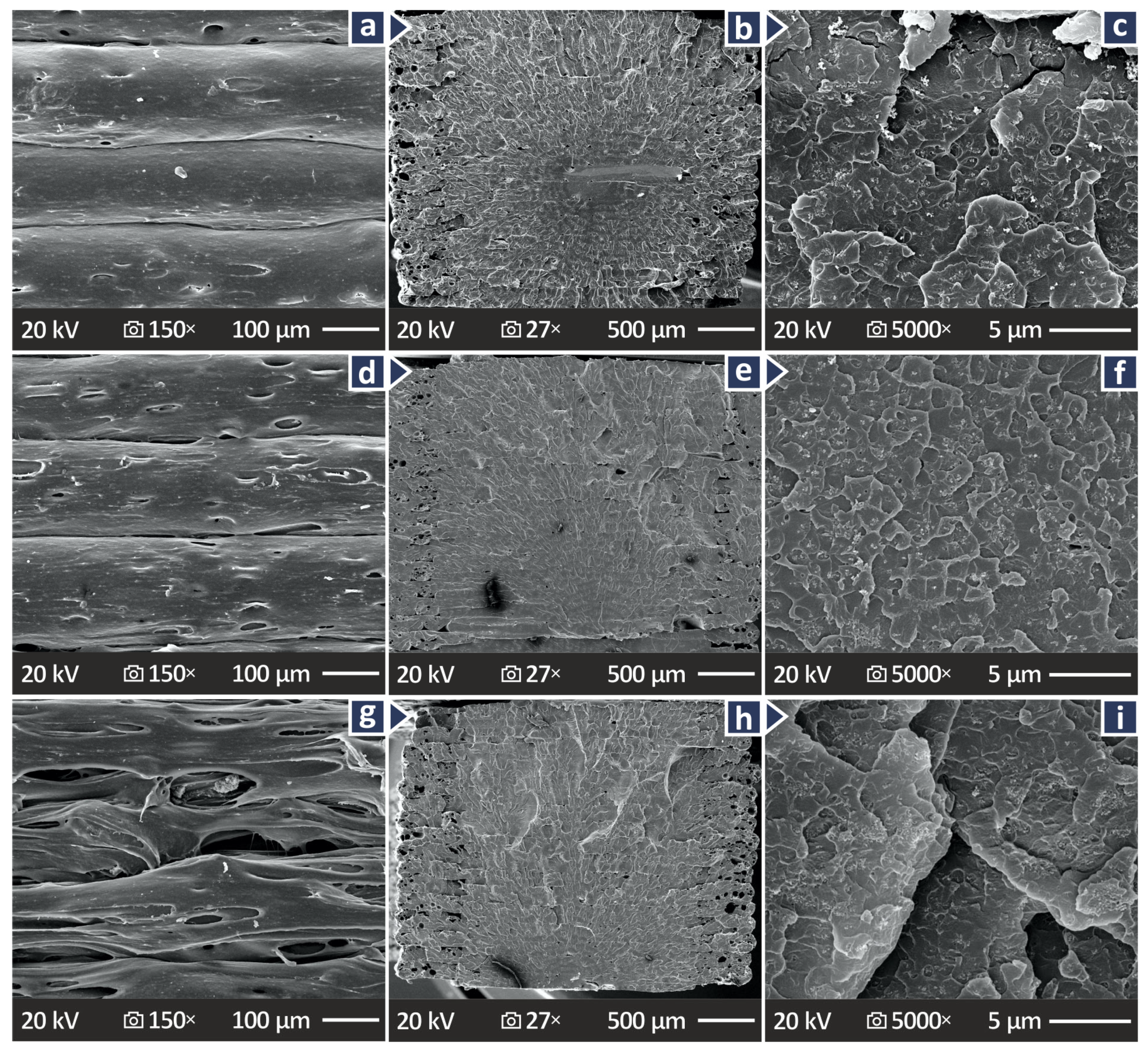

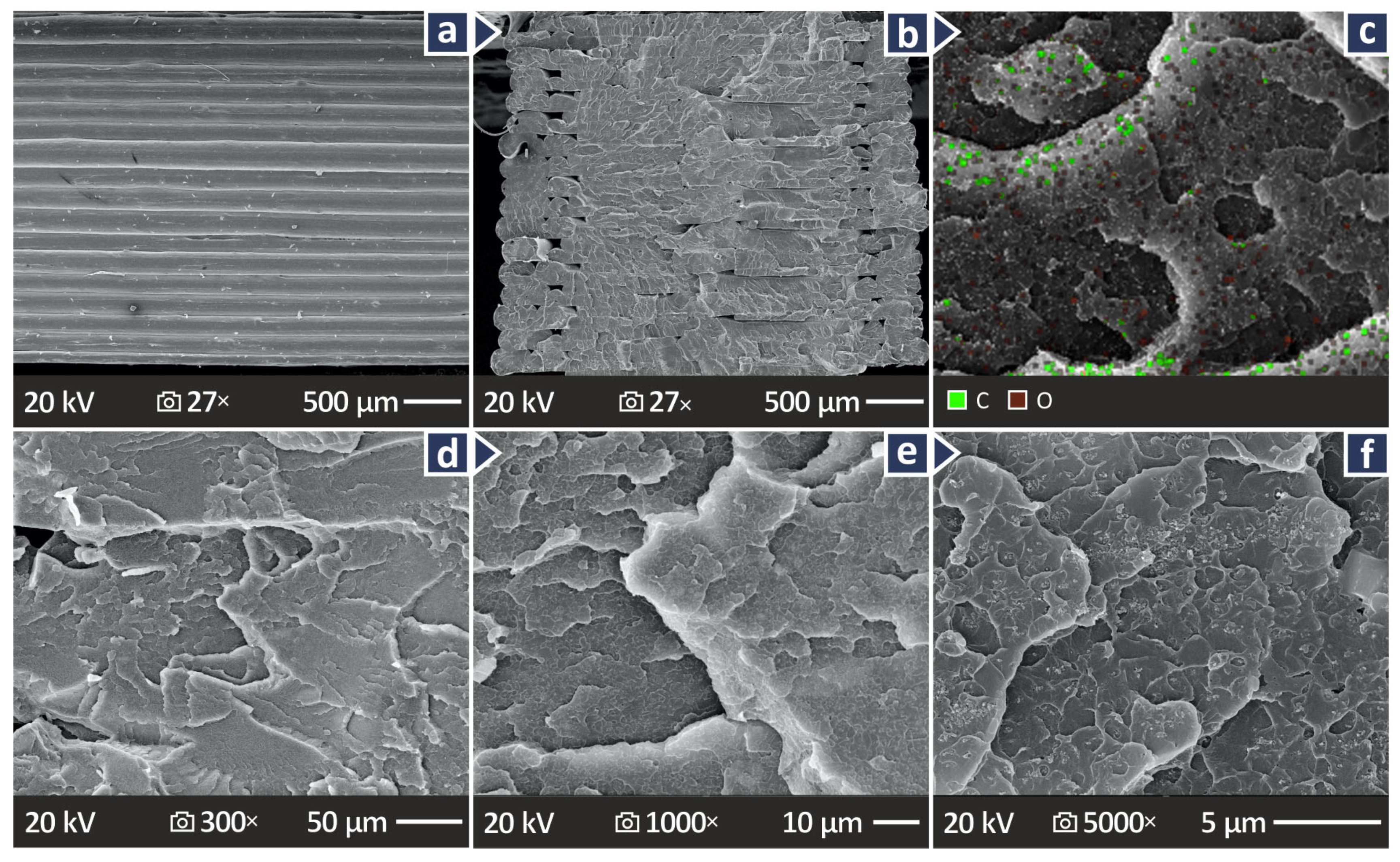

3.6. SEM

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nadagouda, M.N.; Rastogi, V.; Ginn, M. A Review on 3D Printing Techniques for Medical Applications. Curr. Opin. Chem. Eng. 2020, 28, 152–157. [Google Scholar] [CrossRef]

- Aimar, A.; Palermo, A.; Innocenti, B. The Role of 3D Printing in Medical Applications: A State of the Art. J. Healthc. Eng. 2019, 2019, 5340616. [Google Scholar] [CrossRef] [PubMed]

- Palmara, G.; Frascella, F.; Roppolo, I.; Chiappone, A.; Chiadò, A. Functional 3D Printing: Approaches and Bioapplications. Biosens. Bioelectron. 2021, 175, 112849. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mandal, B.B. A Three-Dimensional Printed Silk-Based Biomimetic Tri-Layered Meniscus for Potential Patient-Specific Implantation. Biofabrication 2019, 12, 015003. [Google Scholar] [CrossRef]

- Yang, J.; Li, B.; Liu, J.; Tu, Z.; Wu, X. Application of Additive Manufacturing in the Automobile Industry: A Mini Review. Processes 2024, 12, 1101. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing Transportation: An Overview of 3D Printing in Aviation, Automotive, and Space Industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Karkun, M.S.; Dharmalinga, S. 3D Printing Technology in Aerospace Industry—A Review. Int. J. Aviat. Aeronaut. Aerosp. 2022, 9, 4. [Google Scholar] [CrossRef]

- Kalender, M.; Kilic, S.E.; Ersoy, S.; Bozkurt, Y.; Salman, S. Additive Manufacturing and 3D Printer Technology in Aerospace Industry. In Proceedings of the 2019 9th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 11–14 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 689–694. [Google Scholar]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D Printing of Thermoplastic Polymer Composites and Nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Crisostomo, J.L.B.; Dizon, J.R.C. 3D Printing Applications in Agriculture, Food Processing, and Environmental Protection and Monitoring. Adv. Sustain. Sci. Eng. Technol. 2021, 3, 0210201. [Google Scholar] [CrossRef]

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-Printing and Advanced Manufacturing for Electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, M.; Chitrakar, B.; Adhikari, B. Recent Advances in Functional 3D Printing of Foods: A Review of Functions of Ingredients and Internal Structures. Crit. Rev. Food Sci. Nutr. 2021, 61, 3489–3503. [Google Scholar] [CrossRef] [PubMed]

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D Printing in Construction: A Review of Methods, Research, Applications, Opportunities and Challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of Polymer Composites: A Short Review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Tariq, A.; Hossain, M.; Ahmed Khan, K.; Umer, R. 3D Printing of Magneto-Active Smart Materials for Advanced Actuators and Soft Robotics Applications. Eur. Polym. J. 2024, 205, 112718. [Google Scholar] [CrossRef]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of Macronutrients Printability and 3D-Printer Parameters on 3D-Food Printing: A Review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Kanagaraj, G.; Idris, M.S. 3D Printing: Overview of ABS Evolvement. AIP Conf. Proc. 2019, 2059, 020041. [Google Scholar]

- Subramaniam, S.R.; Samykano, M.; Selvamani, S.K.; Ngui, W.K.; Kadirgama, K.; Sudhakar, K.; Idris, M.S. 3D Printing: Overview of PLA Progress. AIP Conf. Proc. 2019, 2059, 020015. [Google Scholar]

- Petousis, M.; Michailidis, N.; Kulas, V.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Argyros, A.; Valsamos, J.; Nasikas, N.K.; Vidakis, N. Sustainability-Driven Additive Manufacturing: Implementation and Content Optimization of Fine Powder Recycled Glass in Polylactic Acid for Material Extrusion 3D Printing. Int. J. Lightweight Mater. Manuf. 2025, in press. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material Extrusion-based Additive Manufacturing of Polypropylene: A Review on How to Improve Dimensional Inaccuracy and Warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Petousis, M.; Nasikas, N.K.; Papadakis, V.; Spyridaki, M.; Sfakiotakis, E.; Moutsopoulou, A.; Argyros, A.; Dimitriou, E.; Michailidis, N.; Vidakis, N. Polycarbonate/Antibacterial Blend Nanocomposites in Material Extrusion 3D Printing: Thermomechanical Response, Rheology, and Biocidal Metrics. Biomed. Eng. Adv. 2025, 9, 100160. [Google Scholar] [CrossRef]

- Bolanakis, N.; Maravelakis, E.; Papadakis, V.; Kalderis, D.; Michailidis, N.; Argyros, A.; Mountakis, N.; Petousis, M.; Vidakis, N. Valorization of Biochar as a Reinforcement Agent in Polyethylene Terephthalate Glycol for Additive Manufacturing: A Comprehensive Content Optimization Course. J. Manuf. Mater. Process. 2025, 9, 68. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, J.; Liang, J.; Yuan, D.; Zhao, W. Research Progress of Poly(Methyl Methacrylate) Microspheres: Preparation, Functionalization and Application. Eur. Polym. J. 2022, 175, 111379. [Google Scholar] [CrossRef]

- Lourinho, C.; Salgado, H.; Correia, A.; Fonseca, P. Mechanical Properties of Polymethyl Methacrylate as Denture Base Material: Heat-Polymerized vs. 3D-Printed—Systematic Review and Meta-Analysis of In Vitro Studies. Biomedicines 2022, 10, 2565. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D Printing of High Density Polyethylene by Fused Filament Fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Kumar, S.; Ramesh, M.R.; Doddamani, M.; Rangappa, S.M.; Siengchin, S. Mechanical Characterization of 3D Printed MWCNTs/HDPE Nanocomposites. Polym. Test. 2022, 114, 107703. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable Polymer Composites Manufacturing through 3D Printing Technologies by Using Recycled Polymer and Filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Djonyabe Habiba, R.; Malça, C.; Branco, R. Exploring the Potential of Recycled Polymers for 3D Printing Applications: A Review. Materials 2024, 17, 2915. [Google Scholar] [CrossRef]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G. Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers 2024, 16, 1104. [Google Scholar] [CrossRef] [PubMed]

- Gubanova, E.; Kupinets, L.; Deforzh, H.; Koval, V.; Gaska, K. Recycling of polymer waste in the context of developing circular economy. Archit. Civ. Eng. Environ. 2020, 12, 99–108. [Google Scholar] [CrossRef]

- Cabrera, F.C. Eco-friendly Polymer Composites: A Review of Suitable Methods for Waste Management. Polym. Compos. 2021, 42, 2653–2677. [Google Scholar] [CrossRef]

- Huang, S.J. Polymer Waste Management–Biodegradation, Incineration, and Recycling. J. Macromol. Sci. Part A 1995, 32, 593–597. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. PMMA-Based Nanocomposites for Odontology Applications: A State-of-the-Art. Int. J. Mol. Sci. 2022, 23, 10288. [Google Scholar] [CrossRef]

- Aati, S.; Aneja, S.; Kassar, M.; Leung, R.; Nguyen, A.; Tran, S.; Shrestha, B.; Fawzy, A. Silver-Loaded Mesoporous Silica Nanoparticles Enhanced the Mechanical and Antimicrobial Properties of 3D Printed Denture Base Resin. J. Mech. Behav. Biomed. Mater. 2022, 134, 105421. [Google Scholar] [CrossRef]

- Ahmad, N.; Ahmad, S.I.; Ahmedi, S.; Yadav, P.; Manzoor, N.; Parwaz, M.; Khan, Z.H. Structural, Optical and Antifungal Properties of the PMMA-ZnO Nanocomposites: Potential Applications in Odontology. Mater. Chem. Phys. 2023, 309, 128382. [Google Scholar] [CrossRef]

- Kreve, S.; Cândido dos Reis, A. Antibiofilm Capacity of PMMA Surfaces: A Review of Current Knowledge. Microb. Pathog. 2025, 202, 107426. [Google Scholar] [CrossRef] [PubMed]

- Karatepe, U.Y.; Ozdemir, T. Improving Mechanical and Antibacterial Properties of PMMA via Polyblend Electrospinning with Silk Fibroin and Polyethyleneimine towards Dental Applications. Bioact. Mater. 2020, 5, 510–515. [Google Scholar] [CrossRef]

- Sathya, S.; Murthy, P.S.; Devi, V.G.; Das, A.; Anandkumar, B.; Sathyaseelan, V.S.; Doble, M.; Venugopalan, V.P. Antibacterial and Cytotoxic Assessment of Poly (Methyl Methacrylate) Based Hybrid Nanocomposites. Mater. Sci. Eng. C 2019, 100, 886–896. [Google Scholar] [CrossRef] [PubMed]

- Rao, S.; B.T, N.; Preman, N.K.; Johnson, R.P.; Ginjupalli, K.; P., P.; Prabhu, A.; Das, R.; K, J.; Pai, V. Synthesis, Characterization, and Evaluation of Quaternary Ammonium-Based Polymerizable Antimicrobial Monomers for Prosthodontic Applications. Heliyon 2022, 8, e10374. [Google Scholar] [CrossRef]

- Hassan, M.; Asghar, M.; Din, S.U.; Zafar, M.S. Thermoset Polymethacrylate-Based Materials for Dental Applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 273–308. [Google Scholar]

- Marin, E.; Mukai, M.; Boschetto, F.; Sunthar, T.P.M.; Adachi, T.; Zhu, W.; Rondinella, A.; Lanzutti, A.; Kanamura, N.; Yamamoto, T.; et al. Production of Antibacterial PMMA-Based Composites through Stereolithography. Mater. Today Commun. 2022, 32, 103943. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.B.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Moutsopoulou, A.; Karapidakis, E. Energy Consumption vs. Tensile Strength of Poly [Methyl Methacrylate] in Material Extrusion 3D Printing: The Impact of Six Control Settings. Polymers 2023, 15, 845. [Google Scholar] [CrossRef]

- Petousis, M.; Ntintakis, I.; David, C.; Sagris, D.; Nasikas, N.K.; Korlos, A.; Moutsopoulou, A.; Vidakis, N. A Coherent Assessment of the Compressive Strain Rate Response of PC, PETG, PMMA, and TPU Thermoplastics in MEX Additive Manufacturing. Polymers 2023, 15, 3926. [Google Scholar] [CrossRef]

- Petousis, M.; Nasikas, N.K.; Papadakis, V.; Valsamos, I.; Gkagkanatsiou, K.; Mountakis, N.; Argyros, A.; Dimitriou, E.; Michailidis, N.; Vidakis, N. Printability and Performance Metrics of New-Generation Multifunctional PMMA/Antibacterial Blend Nanocomposites in MEX Additive Manufacturing. Polymers 2025, 17, 410. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Kechagias, J.D. Optimization of Friction Stir Welding Parameters in Hybrid Additive Manufacturing: Weldability of 3D-Printed Poly(Methyl Methacrylate) Plates. J. Manuf. Mater. Process. 2022, 6, 77. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Arrigo, R.; Battegazzore, D.; Bernagozzi, G.; Cravero, F.; Ribero Pedraza, D.N.; Frache, A. Recycled PP for 3D Printing: Material and Processing Optimization through Design of Experiment. Appl. Sci. 2022, 12, 10840. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-Assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Edo, G.I.; Ndudi, W.; Ali, A.B.M.; Yousif, E.; Zainulabdeen, K.; Onyibe, P.N.; Akpoghelie, P.O.; Ekokotu, H.A.; Isoje, E.F.; Igbuku, U.A.; et al. An Updated Review on the Modifications, Recycling, Polymerization, and Applications of Polymethyl Methacrylate (PMMA). J. Mater. Sci. 2024, 59, 20496–20539. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Papadakis, V.; Mountakis, N.; Argyros, A.; Spiridaki, M.; Valsamos, J. Cyclic Economy Driven Additive Manufacturing: Valorization of Mechanically Recycled Poly(Methyl Methacrylate) Scrap in Material Extrusion 3D Printing. J. Clean. Prod. 2025, 486, 144639. [Google Scholar] [CrossRef]

- Market Research Firm. Polymethyl Methacrylate (PMMA) Market by Grade (General Purpose, Optical), Form (Extruded Sheet, Cast Acrylic Sheet, Pellets, Beads), End-Use Industry (Signs & Displays, Constructio, Automotive, Lighting Fixtures, Electronics)–Global Forecast to 2029. Available online: https://www.marketresearch.com/MarketsandMarkets-v3719/Polymethyl-Methacrylate-PMMA-Grade-General-38325060/ (accessed on 1 March 2025).

- Mordor Intelligence. Polymethyl Methacrylate (PMMA) Market SIZE & SHARE ANALYSIS–GROWTH TRENDS & FORECASTS UP TO 2029. Available online: https://www.mordorintelligence.com/Industry-reports/polymethyl-methacrylate-pmma-market (accessed on 1 March 2025).

- Fact.MR. Polymethyl Methacrylate (PMMA) Market Outlook 2022 to 2023. Available online: https://www.sphericalinsights.com/reports/polymethyl-methacrylate-market#:~:text=The%20Global%20Polymethyl%20Methacrylate%20Market,fastest%20during%20the%20forecast%20period (accessed on 1 March 2025).

- Strategy and Stats Insider. Polymethyl Methacrylate (PMMA) Market Size, Share and Segmentation by Form (Extruded Sheet, Cast Acrylic Sheet, Pellets, Beads, Others), By Grade (General Purpose Grade, Optical Grade), By End-Use Industry (Automotive, Building & Construction, Lighting Fixtures, Electrical & Electronics, Marine, Healthcare, Agriculture, Consumer Goods, Others), and by Regions Global Forecast 2024–2032. Available online: https://www.snsinsider.com/reports/polymethyl-methacrylate-pmma-market-1725 (accessed on 1 March 2025).

- Grand View Research. GVR Report Cover Polymethyl Methacrylate (PMMA) Market Size, Share & Trends Analysis Report By Form (Beads, Extruded Sheets), By Grade (General Purpose, Optical), By End-Use (Signs & Displays, Automotive), By Region, And Segment Forecasts, 2023–2030. Available online: https://www.grandviewresearch.com/industry-analysis/polymethyl-methacrylate-pmma-industry (accessed on 1 March 2025).

- Precedence Research. Polymethyl Methacrylate (PMMA) Market Size, Share, and Trends 2024 to 2034. Available online: https://www.precedenceresearch.com/polymethyl-methacrylate-market (accessed on 1 March 2025).

- Polaris Market Research. Polymethyl Methacrylate (PMMA) Market Share, Size, Trends, Industry Analysis Report, 2022–2030. Available online: https://www.polarismarketresearch.com/industry-analysis/polymethyl-methacrylate-pmma-market (accessed on 1 March 2025).

- Vidakis, N.; Petousis, M.; Maniadi, A. Sustainable Additive Manufacturing: Mechanical Response of High-Density Polyethylene over Multiple Recycling Processes. Recycling 2021, 6, 4. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Sagris, D.; David, C.; Papadakis, V.; Spyridaki, M.; Argyros, A.; Valsamos, I.; Dimitriou, E.; et al. Thermomechanical Recyclability of Acrylonitrile Styrene Acrylate (ASA) for Cyclic Economy-Driven MEX Additive Manufacturing. Clean. Eng. Technol. 2025, 25, 100925. [Google Scholar] [CrossRef]

- Silva, T.A.; Moraes, F.C.; Janegitz, B.C.; Fatibello-Filho, O. Electrochemical Biosensors Based on Nanostructured Carbon Black: A Review. J. Nanomater. 2017, 2017, 4571614. [Google Scholar] [CrossRef]

- Wang, M.; Gray, C.A.; Reznek, S.A.; Mahmud, K.; Kutsovsky, Y. Carbon Black. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Kausar, A. Emerging Trends in Poly(Methyl Methacrylate) Containing Carbonaceous Reinforcements—Carbon Nanotube, Carbon Black, and Carbon Fiber. J. Plast. Film Sheeting 2020, 36, 409–429. [Google Scholar] [CrossRef]

- Richter, E.M.; Rocha, D.P.; Cardoso, R.M.; Keefe, E.M.; Foster, C.W.; Munoz, R.A.A.; Banks, C.E. Complete Additively Manufactured (3D-Printed) Electrochemical Sensing Platform. Anal. Chem. 2019, 91, 12844–12851. [Google Scholar] [CrossRef]

- Abdalla, A.; Hamzah, H.H.; Keattch, O.; Covill, D.; Patel, B.A. Augmentation of Conductive Pathways in Carbon Black/PLA 3D-Printed Electrodes Achieved through Varying Printing Parameters. Electrochim. Acta 2020, 354, 136618. [Google Scholar] [CrossRef]

- Katseli, V.; Economou, A.; Kokkinos, C. A Novel All-3D-Printed Cell-on-a-Chip Device as a Useful Electroanalytical Tool: Application to the Simultaneous Voltammetric Determination of Caffeine and Paracetamol. Talanta 2020, 208, 120388. [Google Scholar] [CrossRef]

- Kausar, A. Contemporary Applications of Carbon Black-Filled Polymer Composites: An Overview of Essential Aspects. J. Plast. Film Sheeting 2018, 34, 256–299. [Google Scholar] [CrossRef]

- Dong, P.; Maneerung, T.; Ng, W.C.; Zhen, X.; Dai, Y.; Tong, Y.W.; Ting, Y.-P.; Koh, S.N.; Wang, C.-H.; Neoh, K.G. Chemically Treated Carbon Black Waste and Its Potential Applications. J. Hazard. Mater. 2017, 321, 62–72. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Fowler, G.D.; Zhao, M. The Past, Present and Future of Carbon Black as a Rubber Reinforcing Filler—A Review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Statista. Carbon Black Market Size Worldwide in 2018 and 2023, with a Forecast for 2030. Available online: https://www.statista.com/statistics/1350339/global-carbon-black-market-size/ (accessed on 1 March 2025).

- Fortune Buisiness Insights. Carbon Black Market Size, Share & Industry Analysis, By Process Type (Furnace Black, Thermal Black, Acetylene Black, and Others), By Grade (Standard Grade and Specialty Grade), By Application (Tire, Non-Tire Rubber, Inks & Toners, Plastics, and Others), and Regional Forecast, 2024–2032. Available online: https://www.Fortunebusinessinsights.com/industry-reports/carbon-black-market-101718 (accessed on 1 March 2025).

- Straits Research. Carbon Black Market Size, Share & Trends Analysis Report By Process Type (Furnace Black, Gas Block, Lamp Black, Thermal Black), By Applications (Tires and Industrial Rubber Products, Plastics, Toners and Printing Inks, Paints and Coatings, Textile Fibers, Others) and By Region(North America, Europe, APAC, Middle East and Africa, LATAM) Forecasts, 2025–2033. Available online: https://straitsresearch.com/report/carbon-black-market (accessed on 1 March 2025).

- Mordor Intelligence. Carbon Black Market Report—Industry Growth, Size & Forecast Analysis (2025–2030). Available online: https://www.mordorintelligence.com/industry-reports/carbon-black-market (accessed on 1 March 2025).

- Grand View Research. Carbon Black Market Size, Share & Trends Analysis Report By Type, By Application (Tire, Non- Tire Rubber, Plastics, Inks & Coatings, Other), By Grade, By Region, And Segment Forecasts, 2024–2030. Available online: https://www.grandviewresearch.com/industry-analysis/carbon-black-market (accessed on 1 March 2025).

- IMARC. Carbon Black Market Size, Share, Trends and Forecast by Type, Grade, Application, and Region, 2025–2033. Available online: https://www.imarcgroup.com/carbon-black-market (accessed on 1 March 2025).

- Transparency Market Research. Carbon Black Market (Grade: Standard and Specialty; Type: Furnace Black, Lamp Black, Thermal Black, and Acetylene Black; and Application: Rubber Reinforcement, Paints & Coatings, Plastics, Battery Electrodes, Inks & Toners, and Others)—Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2021–2031. Available online: https://www.transparencymarketresearch.com/carbon-black-market.html (accessed on 1 March 2025).

- Lei, L.; Yao, Z.; Zhou, J.; Wei, B.; Fan, H. 3D Printing of Carbon Black/Polypropylene Composites with Excellent Microwave Absorption Performance. Compos. Sci. Technol. 2020, 200, 108479. [Google Scholar] [CrossRef]

- Silva-Neto, H.A.; Santhiago, M.; Duarte, L.C.; Coltro, W.K.T. Fully 3D Printing of Carbon Black-Thermoplastic Hybrid Materials and Fast Activation for Development of Highly Stable Electrochemical Sensors. Sens. Actuators B Chem. 2021, 349, 130721. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Fused Filament Fabrication Three-Dimensional Printing Multi-Functional of Polylactic Acid/Carbon Black Nanocomposites. C 2021, 7, 52. [Google Scholar] [CrossRef]

- Callanan, C.J.; Hsu, L.; McGee, A. Formulation and Evaluation of Carbon Black 3D Printing Materials. In Proceedings of the OCEANS 2018 MTS/IEEE Charleston, Charleston, SC, USA, 22–25 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar]

- N, J.; P, S. Application of 3D Printed ABS Based Conductive Carbon Black Composite Sensor in Void Fraction Measurement. Compos. B Eng. 2019, 159, 224–230. [Google Scholar] [CrossRef]

- Masiuchok, O.; Iurzhenko, M.; Kolisnyk, R.; Mamunya, Y.; Godzierz, M.; Demchenko, V.; Yermolenko, D.; Shadrin, A. Polylactide/Carbon Black Segregated Composites for 3D Printing of Conductive Products. Polymers 2022, 14, 4022. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Mountakis, N.; Argyros, A.; Spiridaki, M.; Moutsopoulou, A.; Papadakis, V.; Charitidis, C. High-Density Polyethylene/Carbon Black Composites in Material Extrusion Additive Manufacturing: Conductivity, Thermal, Rheological, and Mechanical Responses. Polymers 2023, 15, 4717. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Velidakis, E.; Mountakis, N.; Grammatikos, S.A. Polyamide 12/Multiwalled Carbon Nanotube and Carbon Black Nanocomposites Manufactured by 3D Printing Fused Filament Fabrication: A Comparison of the Electrical, Thermoelectric, and Mechanical Properties. C 2021, 7, 38. [Google Scholar] [CrossRef]

- Konishi, Y.; Cakmak, M. Nanoparticle Induced Network Self-Assembly in Polymer–Carbon Black Composites. Polymer 2006, 47, 5371–5391. [Google Scholar] [CrossRef]

- Ahmad, I.A.; Kim, H.-K.; Deveci, S.; Kumar, R.V. Non-Isothermal Crystallisation Kinetics of Carbon Black- Graphene-Based Multimodal-Polyethylene Nanocomposites. Nanomaterials 2019, 9, 110. [Google Scholar] [CrossRef]

- Severin, E.J.; Doleman, B.J.; Lewis, N.S. An Investigation of the Concentration Dependence and Response to Analyte Mixtures of Carbon Black/Insulating Organic Polymer Composite Vapor Detectors. Anal. Chem. 2000, 72, 658–668. [Google Scholar] [CrossRef]

- Plagge, J.; Lang, A. Filler-Polymer Interaction Investigated Using Graphitized Carbon Blacks: Another Attempt to Explain Reinforcement. Polymer 2021, 218, 123513. [Google Scholar] [CrossRef]

- Varol, H.S.; Meng, F.; Hosseinkhani, B.; Malm, C.; Bonn, D.; Bonn, M.; Zaccone, A.; Parekh, S.H. Nanoparticle Amount, and Not Size, Determines Chain Alignment and Nonlinear Hardening in Polymer Nanocomposites. Proc. Natl. Acad. Sci. USA 2017, 114, E3170–E3177. [Google Scholar] [CrossRef]

- Baye, T.M.; Mekonone, S.T. Particle Concentration and Size Effect on Mechanical Properties of Natural-Hydroxyapatite Reinforced High-Density Polyethylene Composite. Polym. Polym. Compos. 2025, 33, 09673911241313175. [Google Scholar] [CrossRef]

- Li, X.; Song, Y.; Bian, Y.; Wang, F.; Gu, C.; Yang, X.; Jiang, X. Effects of Root Exudates on the Sorption of Polycyclic Aromatic Hydrocarbons onto Biochar. Environ. Pollut. Bioavailab. 2019, 31, 156–165. [Google Scholar] [CrossRef]

- De Sousa, D.V.; Guimarães, L.M.; Félix, J.F.; Ker, J.C.; Schaefer, C.E.R.G.; Rodet, M.J. Dynamic of the Structural Alteration of Biochar in Ancient Anthrosol over a Long Timescale by Raman Spectroscopy. PLoS ONE 2020, 15, e0229447. [Google Scholar] [CrossRef]

- Veluthandath, A.V.; Bisht, P.B. Identification of Whispering Gallery Mode (WGM) Coupled Photoluminescence and Raman Modes in Complex Spectra of MoS 2 in Polymethyl Methacrylate (PMMA) Microspheres. J. Lumin. 2017, 187, 255–259. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate—Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature Studies of Polycarbonate Using Fourier Transform Raman Spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence Spectroscopy of Polycarbonate Matrices Irradiated with Different Energy 28Si+ Ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing Cellulose Structures with Vibrational Spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, X.; He, Z.; Liang, X.; Wang, M.; Jin, G. Thermal Degradation Kinetics Study of Molten Polylactide Based on Raman Spectroscopy. Polym. Eng. Sci. 2021, 61, 201–210. [Google Scholar] [CrossRef]

- Badr, Y.A.; Abd El-Kader, K.M.; Khafagy, R.M. Raman Spectroscopic Study of CdS, PVA Composite Films. J. Appl. Polym. Sci. 2004, 92, 1984–1992. [Google Scholar] [CrossRef]

- Hu, C.; Chen, X.; Chen, J.; Zhang, W.; Zhang, M.Q. Observation of Mutual Diffusion of Macromolecules in PS/PMMA Binary Films by Confocal Raman Microscopy. Soft Matter 2012, 8, 4780–4787. [Google Scholar] [CrossRef]

- Sengwa, R.J.; Dhatarwal, P. Toward Multifunctionality of PEO/PMMA/MMT Hybrid Polymer Nanocomposites: Promising Morphological, Nanostructural, Thermal, Broadband Dielectric, and Optical Properties. J. Phys. Chem. Solids 2022, 166, 110708. [Google Scholar] [CrossRef]

- Habasaki, J. Atomistic Molecular Dynamics in Polyethylene Oxide and Polymethyl Methacrylate Blends Having Significantly Different Glass Transition Temperatures. Int. J. Appl. Glass Sci. 2022, 13, 347–358. [Google Scholar] [CrossRef]

- Mayumi, K.; Liu, C.; Yasuda, Y.; Ito, K. Softness, Elasticity, and Toughness of Polymer Networks with Slide-Ring Cross-Links. Gels 2021, 7, 91. [Google Scholar] [CrossRef]

- Nielsen, L.E. Cross-Linking–Effect on Physical Properties of Polymers. J. Macromol. Sci. Part C 1969, 3, 69–103. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E. Brittleness of Materials: Implications for Composites and a Relation to Impact Strength. J. Mater. Sci. 2010, 45, 242–250. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Intensity | Raman Peak Assignment |

|---|---|---|

| 598 | Strong | C-COO vibration, C-C-O symmetric vibration [102] |

| 734 | Small | C-H out-of-plane bending [103,104] |

| 811 | Strong | CH2 vibration [102] |

| 844 | Small | Phenyl ring vibration [105] |

| 911 | Small | C-H in-plane bending [104] |

| 964 | Strong | O-CH3 rocking [102] |

| 985 | Strong | C-C and C-O vibration [106] |

| 1120 | Medium | Skeletal vibrations, C–C bonds [102,106] |

| 1181 | Small | Skeletal vibrations, C–O– C, C-COO bonds [102,103,106] |

| 1240 | Small | C-O-C stretching [104] |

| 1326 | Small | C-O-C stretching [104] |

| 1449 | Strong | C-H3 deformation [102,103,104]; C-H2 deformation [103,104]; C-H3 symmetric bending [104,105,107]; |

| 1727 | Strong | C = O bond [102,108] C-O-C symmetric stretching [109] |

| 2843 | Medium | O-CH3 vibration [102] |

| 2951 | Strong | CH2 and C-H asymmetric stretching [102,106] |

| 3000 | Medium | C-H stretching [104] |

| 811 cm−1 | Gradual decrease | Medium decrease of CH2 vibration |

| 1340 cm−1 | Gradual increase | Significant increase of graphite D-band |

| 1600 cm−1 | Gradual increase | Significant increase of graphite G-band |

| 2843 cm−1 | Gradual decrease | Medium decrease of O-CH3 vibration |

| 2951 cm−1 | Gradual decrease | Significant decrease of CH2 and C-H asymmetric stretching |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michailidis, N.; Vidakis, N.; David, C.; Sagris, D.; Papadakis, V.M.; Argyros, A.; Mountakis, N.; Spyridaki, M.; Petousis, M. Valorization of Polymethylmethacrylate Scrap Reinforced with Nano Carbon Black with Optimized Ratio in Extrusion-Based Additive Manufacturing. Polymers 2025, 17, 1383. https://doi.org/10.3390/polym17101383

Michailidis N, Vidakis N, David C, Sagris D, Papadakis VM, Argyros A, Mountakis N, Spyridaki M, Petousis M. Valorization of Polymethylmethacrylate Scrap Reinforced with Nano Carbon Black with Optimized Ratio in Extrusion-Based Additive Manufacturing. Polymers. 2025; 17(10):1383. https://doi.org/10.3390/polym17101383

Chicago/Turabian StyleMichailidis, Nikolaos, Nectarios Vidakis, Constantine David, Dimitrios Sagris, Vassilis M. Papadakis, Apostolos Argyros, Nikolaos Mountakis, Maria Spyridaki, and Markos Petousis. 2025. "Valorization of Polymethylmethacrylate Scrap Reinforced with Nano Carbon Black with Optimized Ratio in Extrusion-Based Additive Manufacturing" Polymers 17, no. 10: 1383. https://doi.org/10.3390/polym17101383

APA StyleMichailidis, N., Vidakis, N., David, C., Sagris, D., Papadakis, V. M., Argyros, A., Mountakis, N., Spyridaki, M., & Petousis, M. (2025). Valorization of Polymethylmethacrylate Scrap Reinforced with Nano Carbon Black with Optimized Ratio in Extrusion-Based Additive Manufacturing. Polymers, 17(10), 1383. https://doi.org/10.3390/polym17101383