Low-Density and High-Performance Fiber-Reinforced PP/POE Composite Foam via Irradiation Crosslinking

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP/POE Blend Sheets Ready to Foam

2.3. Radiation Crosslinking and Foaming of PP/POE Blend Sheet

2.4. Characterizations

3. Results and Discussion

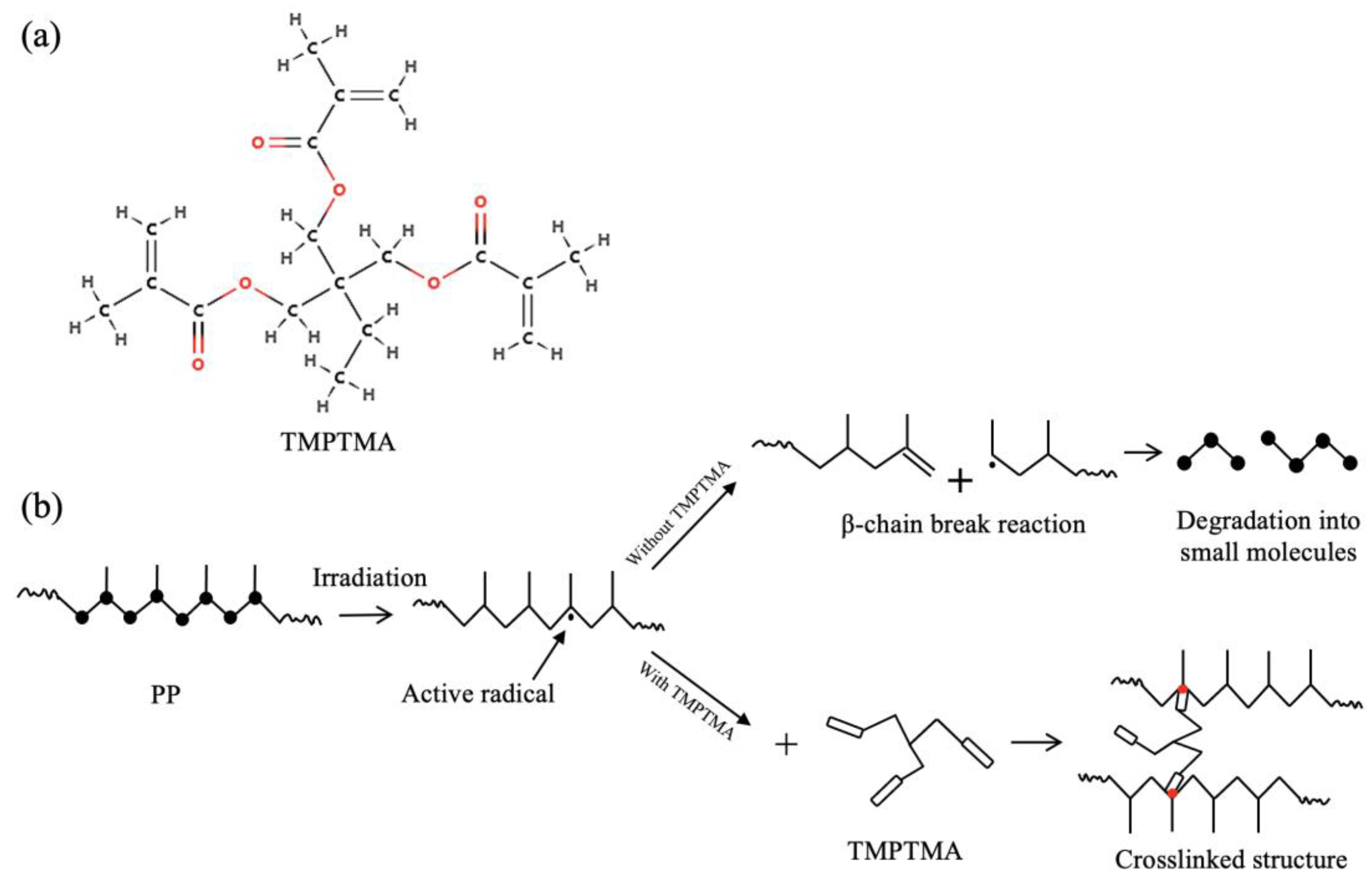

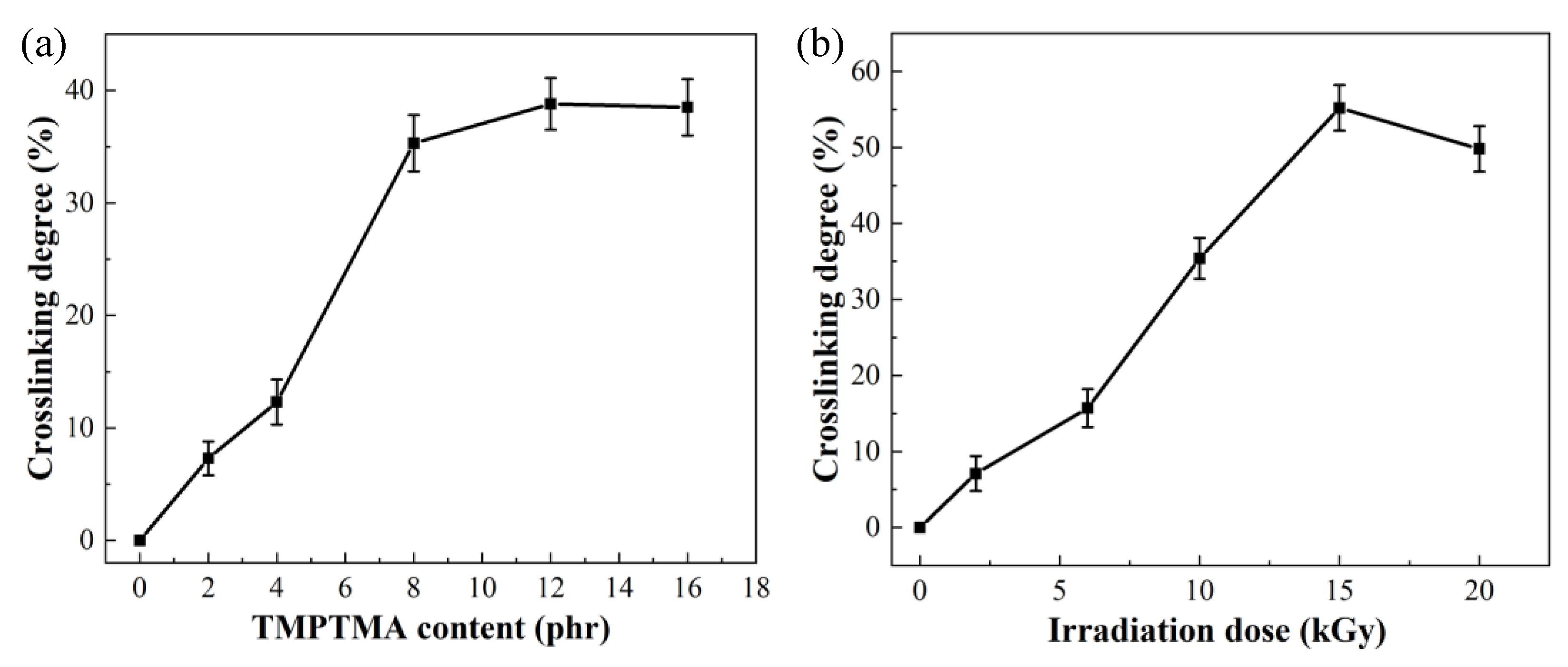

3.1. Irradiation Crosslinking Process Optimization of PP/POE Foam

3.1.1. Crosslinking Degree

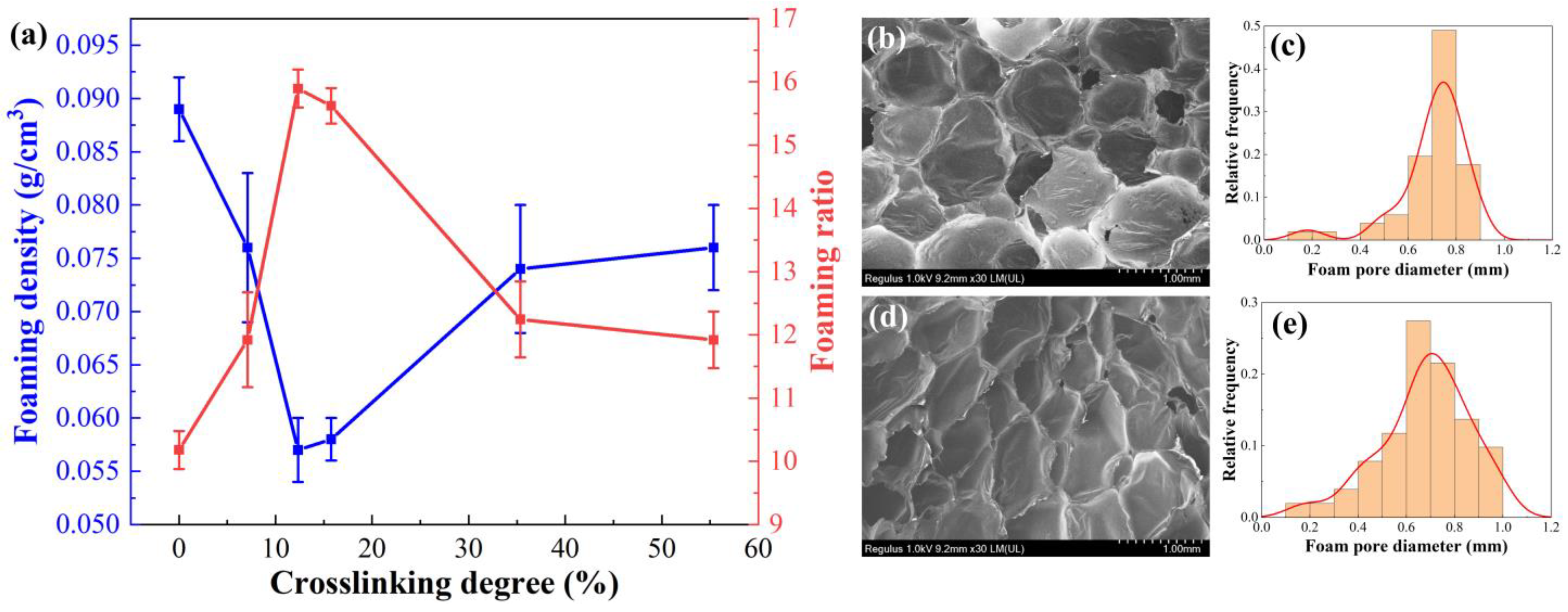

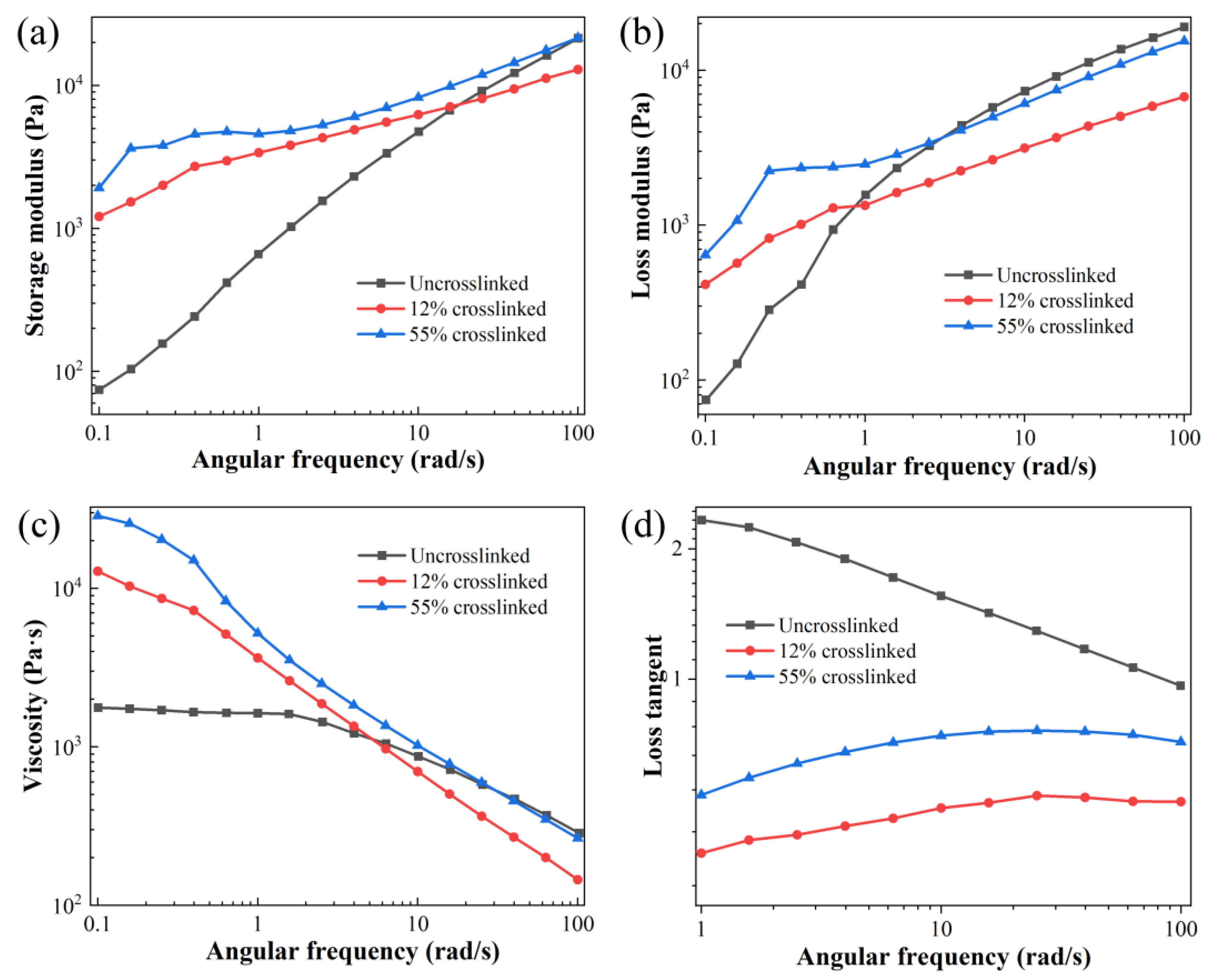

3.1.2. Foaming and Rheological Behaviors

3.1.3. Thermal and Mechanical Properties

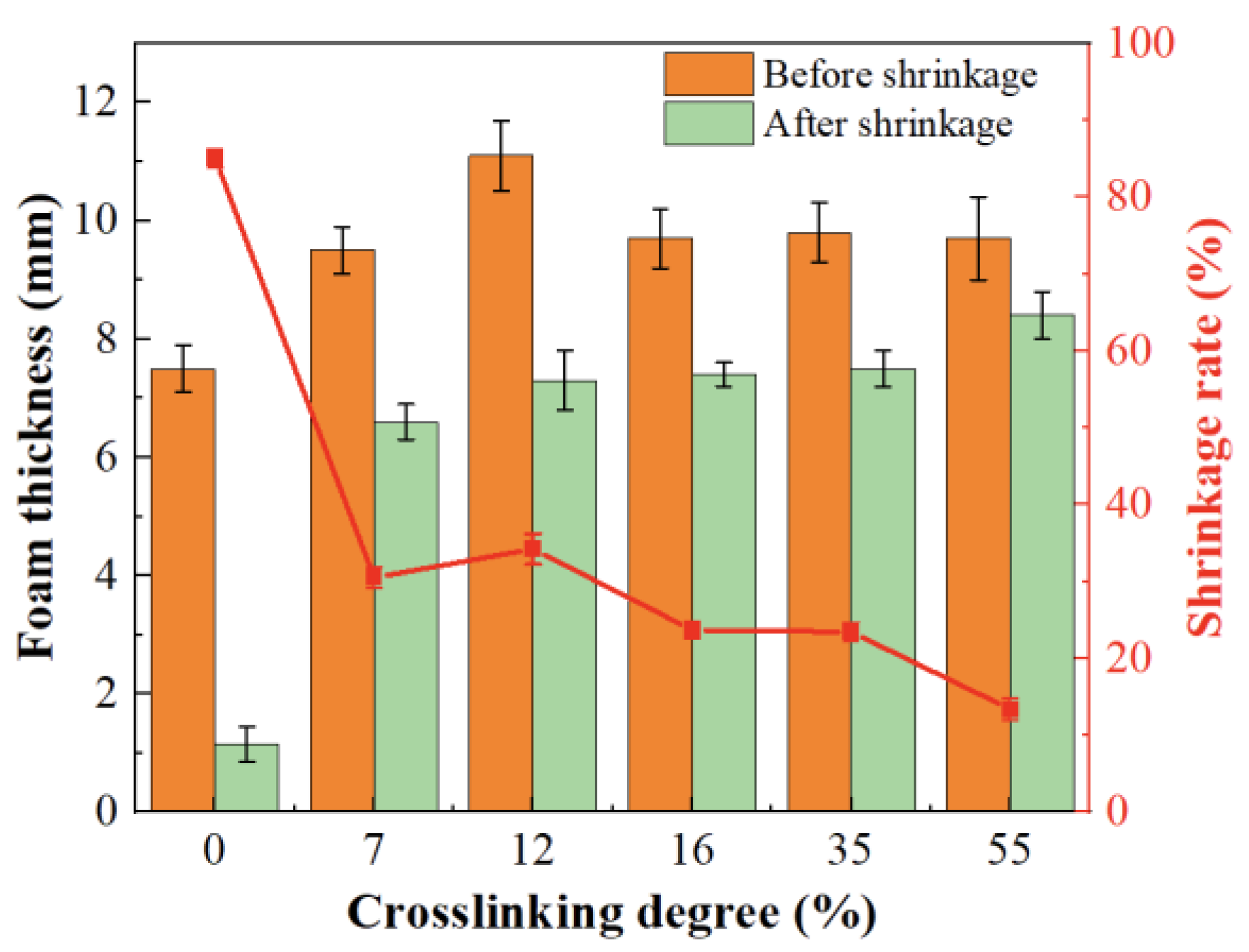

Thermal Shrinkage Performance

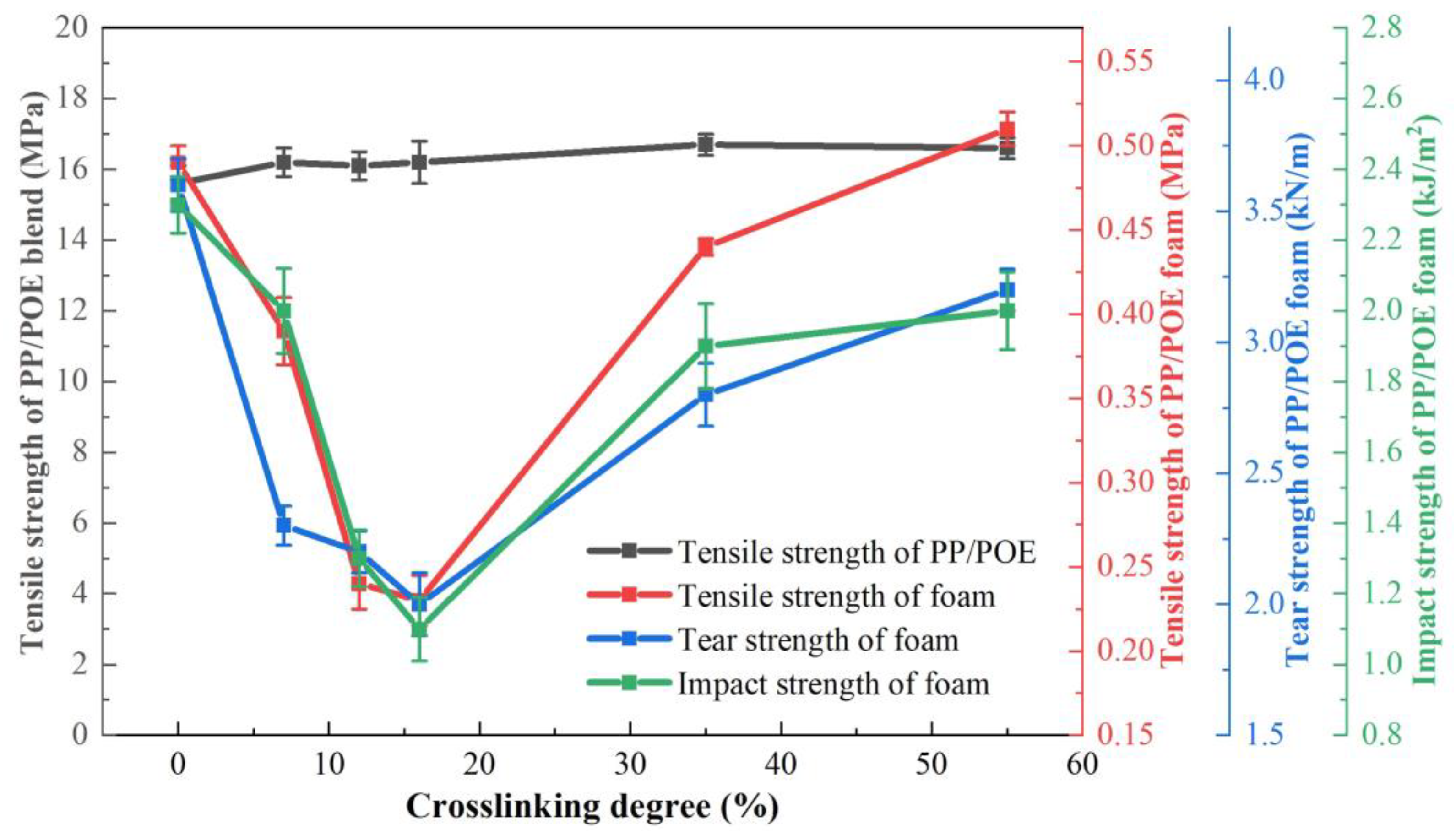

Mechanical Properties

3.2. Fiber-Reinforced Crosslinked PP/POE Composite Foam

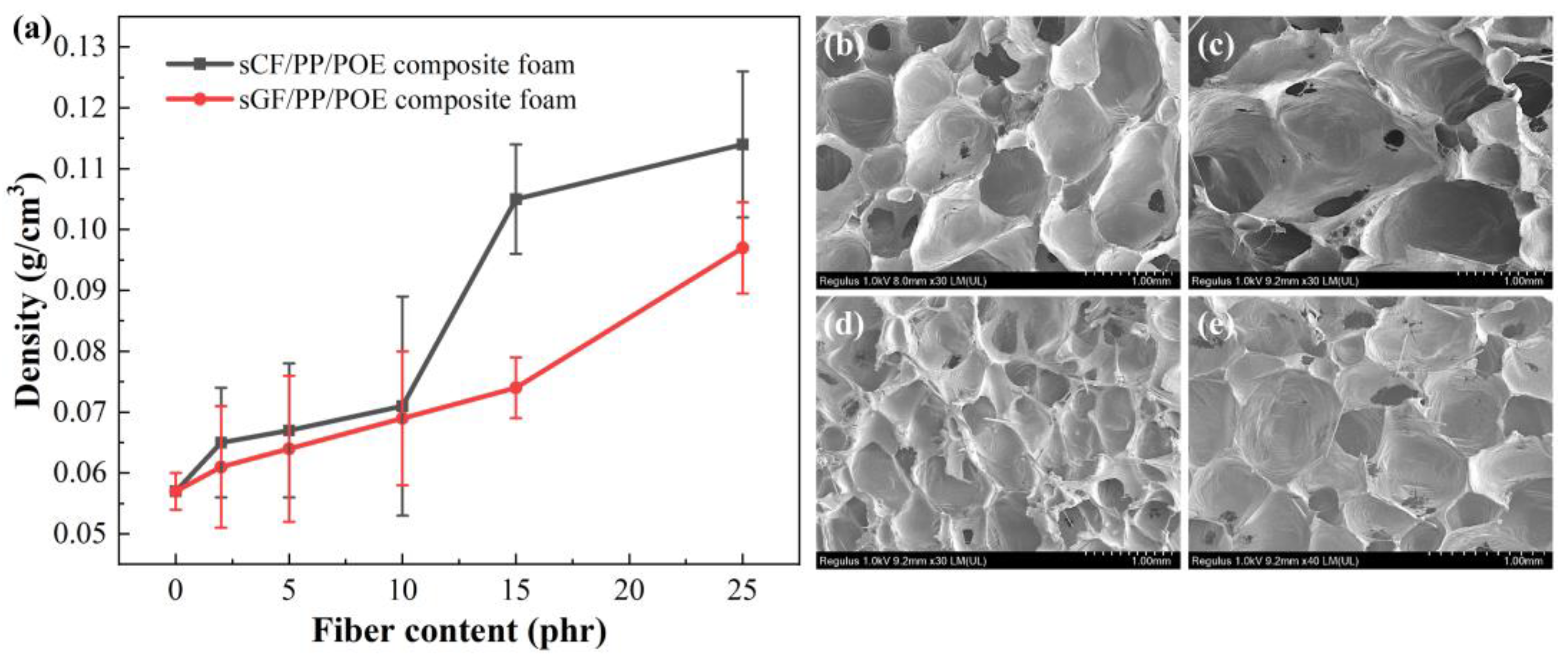

3.2.1. Impact of Fibers on Foaming Behavior

3.2.2. Impact of Fibers on Thermal and Mechanical Properties of Foam

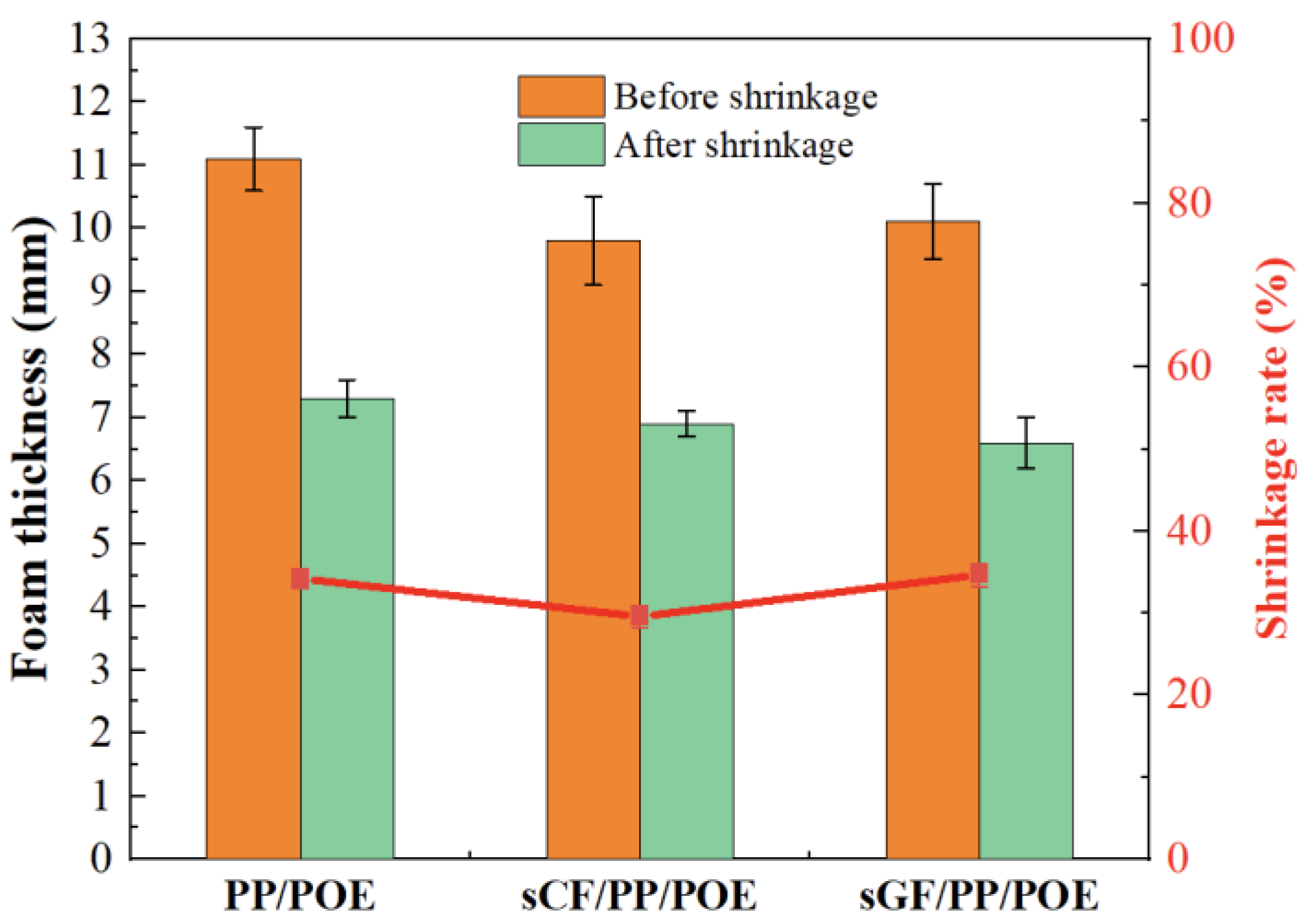

Thermal Shrinkage Performance

Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Sadiku, R.; Ibrahim, D.; Agboola, O.; Owonubi, S.J.; Fasiku, V.O.; Kupolati, W.K.; Jamiru, T.; Eze, A.A.; Adekomaya, O.S.; Varaprasad, K. Automotive components composed of polyolefins. In Polyolefin Fibres; Elsevier: Amsterdam, The Netherlands, 2017; pp. 449–496. [Google Scholar]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Lee, P.C.; Kaewmesri, W.; Wang, J.; Park, C.B.; Pumchusak, J.; Folland, R.; Praller, A. Effect of die geometry on foaming behaviors of high-melt-strength polypropylene with CO2. J. Appl. Polym. 2008, 109, 3122–3132. [Google Scholar] [CrossRef]

- Burt, J.G. The elements of expansion of thermoplastics Part II. J. Cell. Plast. 1978, 14, 341–345. [Google Scholar] [CrossRef]

- Tang, L.; Zhai, W.; Zheng, W. Autoclave preparation of expanded polypropylene/poly (lactic acid) blend bead foams with a batch foaming process. J. Cell. Plast. 2011, 47, 429–446. [Google Scholar] [CrossRef]

- Antunes, M.; Velasco, J.I.; Haurie, L. Characterization of highly filled magnesium hydroxide-polypropylene composite foams. J. Cell. Plast. 2011, 47, 17–30. [Google Scholar] [CrossRef]

- Gong, W.; Fu, H.; Zhang, C.; Ban, D.; Yin, X.; He, Y.; He, L.; Pei, X. Study on foaming quality and impact property of foamed polypropylene composites. Polymers 2018, 10, 1375. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wan, D.; Zhang, Z.; Liu, F.; Xing, H.; Wang, Y.; Tang, T. Synthesis and structure–property relationships of polypropylene-g-poly (ethylene-co-1-butene) graft copolymers with well-defined long chain branched molecular structures. Macromolecules 2011, 44, 4167–4179. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, H.; Yu, J.; Dong, J.Y.; He, J. Foaming behavior of isotactic polypropylene in supercritical CO2 influenced by phase morphology via chain grafting. Polymer 2008, 49, 3146–3156. [Google Scholar] [CrossRef]

- Chen, P.; Zhao, L.; Gao, X.; Xu, Z.; Liu, Z.; Hu, D. Engineering of polybutylene succinate with long-chain branching toward high foamability and degradation. Polym. Degrad. Stab. 2021, 194, 109745. [Google Scholar] [CrossRef]

- Wang, L.; Ishihara, S.; Ando, M.; Minato, A.; Hikima, Y.; Ohshima, M. Fabrication of high expansion microcellular injection-molded polypropylene foams by adding long-chain branches. Ind. Eng. Chem. Res. 2016, 55, 11970–11982. [Google Scholar] [CrossRef]

- Liu, H.; Chuai, C.; Iqbal, M.; Wang, H.; Kalsoom, B.B.; Khattak, M.; Qasim Khattak, M. Improving foam ability of polypropylene by crosslinking. J. Appl. Polym. 2011, 122, 973–980. [Google Scholar] [CrossRef]

- Yang, C.; Xing, Z.; Zhao, Q.; Wang, M.; Wu, G. A strategy for the preparation of closed-cell and crosslinked polypropylene foam by supercritical CO2 foaming. J. Appl. Polym. 2018, 135, 45809. [Google Scholar] [CrossRef]

- Wang, S.; Wang, K.; Pang, Y.; Li, Y.; Wu, F.; Wang, S.; Zheng, W. Open-cell polypropylene/polyolefin elastomer blend foams fabricated for reusable oil-sorption materials. J. Appl. Polym. 2016, 133, 43812. [Google Scholar] [CrossRef]

- Han, D.H.; Jang, J.H.; Kim, H.Y.; Kim, B.N.; Shin, B.Y. Manufacturing and foaming of high melt viscosity of polypropylene by using electron beam radiation technology. Polym. Eng. Sci. 2006, 46, 431–437. [Google Scholar] [CrossRef]

- Feng, J.M.; Wang, W.K.; Yang, W.; Xie, B.H.; Yang, M.B. Structure and properties of radiation cross-linked polypropylene foam. Polym. Plast. Technol. Eng. 2011, 50, 1027–1034. [Google Scholar] [CrossRef]

- Yang, C.; Xing, Z.; Zhang, M.; Zhao, Q.; Wang, M.; Wu, G. Supercritical CO2 foaming of radiation crosslinked polypropylene/high-density polyethylene blend: Cell structure and tensile property. Radiat. Phys. Chem. 2017, 141, 276–283. [Google Scholar] [CrossRef]

- Cheng, S.; Phillips, E.; Parks, L. Processability improvement of polyolefins through radiation-induced branching. Radiat. Phys. Chem. 2010, 79, 329–334. [Google Scholar] [CrossRef]

- Taki, K.; Yanagimoto, T.; Funami, E.; Okamoto, M.; Ohshima, M. Visual observation of CO2 foaming of polypropylene-clay nanocomposites. Polym. Eng. Sci. 2004, 44, 1004–1011. [Google Scholar] [CrossRef]

- Jiang, X.L.; Bao, J.B.; Liu, T.; Zhao, L.; Xu, Z.M.; Yuan, W.K. Microcellular foaming of polypropylene/clay nanocomposites with supercritical carbon dioxide. J. Cell. Plast. 2009, 45, 515–538. [Google Scholar] [CrossRef]

- Mohebbi, A.; Mighri, F.; Ajji, A.; Rodrigue, D. Current issues and challenges in polypropylene foaming: A review. Cell. Polym. 2015, 34, 299–338. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Y.K.; Ai, F.F.; Fan, J.; Xia, Z.P.; Liu, Y. Hierarchical porous polyamide 6 by solution foaming: Synthesis, characterization and properties. Polymers 2018, 10, 1310. [Google Scholar] [CrossRef]

- Llewelyn, G.; Rees, A.; Griffiths, C.A.; Jacobi, M. A novel hybrid foaming method for low-pressure microcellular foam production of unfilled and talc-filled copolymer polypropylenes. Polymers 2019, 11, 1896. [Google Scholar] [CrossRef]

- Mao, H.; He, B.; Guo, W.; Hua, L.; Yang, Q. Effects of nano-CaCO3 content on the crystallization, mechanical properties, and cell structure of PP nanocomposites in microcellular injection molding. Polymers 2018, 10, 1160. [Google Scholar] [CrossRef]

- Yang, C.; Wang, M.; Xing, Z.; Zhao, Q.; Wang, M.; Wu, G. A new promising nucleating agent for polymer foaming: Effects of hollow molecular-sieve particles on polypropylene supercritical CO2 microcellular foaming. RSC Adv. 2018, 8, 20061–20067. [Google Scholar] [CrossRef]

- Albooyeh, A. The effect of addition of Multiwall Carbon Nanotubes on the vibration properties of Short Glass Fiber reinforced polypropylene and polypropylene foam composites. Polym. Test. 2019, 74, 86–98. [Google Scholar] [CrossRef]

- Ellingham, T.; Duddleston, L.; Turng, L.S. Sub-critical gas-assisted processing using CO2 foaming to enhance the exfoliation of graphene in polypropylene+ graphene nanocomposites. Polymer 2017, 117, 132–139. [Google Scholar] [CrossRef]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Dixit, N.; Jain, P.K. 3D printed carbon fiber reinforced thermoplastic composites: A review. Mater. Today Proc. 2021, 43, 678–681. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.A. Ultra-high-performance concrete: Impacts of steel fibre shape and content on flowability, compressive strength and modulus of rupture. Case Stud. Constr. Mater. 2022, 17, e01615. [Google Scholar] [CrossRef]

- Althoey, F.; Hakeem, I.Y.; Hosen, M.A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of concrete reinforced with date palm fibers. Materials 2022, 15, 7923. [Google Scholar] [CrossRef]

- Zhang, H.; Rizvi, G.; Park, C. Development of an extrusion system for producing fine-celled HDPE/wood-fiber composite foams using CO2 as a blowing agent. Adv. Polym. Technol. J. Polym. Process. Inst. 2004, 23, 263–276. [Google Scholar] [CrossRef]

- Yang, J.; Li, P. Characterization of short glass fiber reinforced polypropylene foam composites with the effect of compatibilizers: A comparison. J. Reinf. Plast. Compos. 2015, 34, 534–546. [Google Scholar] [CrossRef]

- Cai, L.; Zhao, K.; Huang, X.; Ye, J.; Zhao, Y. Effective elastic modulus of foamed long glass fiber reinforced polypropylene: Experiment and computation. Proc. Inst. Mech. Eng. J. Mater. Des. Appl. 2021, 235, 202–215. [Google Scholar] [CrossRef]

- Yang, C.; Wang, G.; Zhao, J.; Zhao, G.; Zhang, A. Lightweight and strong glass fiber reinforced polypropylene composite foams achieved by mold-opening microcellular injection molding. J. Mater. Res. Technol. 2021, 14, 2920–2931. [Google Scholar] [CrossRef]

- Abedi, M.M.; Nedoushan, R.J.; Yu, W.-R. Enhanced compressive and energy absorption properties of braided lattice and polyurethane foam hybrid composites. Int. J. Mech. Sci. 2021, 207, 106627. [Google Scholar] [CrossRef]

- Sebaey, T.A.; Rajak, D.K.; Mehboob, H. Internally stiffened foam-filled carbon fiber reinforced composite tubes under impact loading for energy absorption applications. Compos. Struct. 2021, 255, 112910. [Google Scholar] [CrossRef]

- Chuang, Y.C.; Li, T.T.; Huang, C.H.; Huang, C.L.; Lou, C.W.; Chen, Y.S.; Lin, J.-H. Protective rigid fiber-reinforced polyurethane foam composite boards: Sound absorption, drop-weight impact and mechanical properties. Fibers Polym. 2016, 17, 2116–2123. [Google Scholar] [CrossRef]

- Kumar, M.; Kaur, R. Glass fiber reinforced rigid polyurethane foam: Synthesis and characterization. e-Polymers 2017, 17, 517–521. [Google Scholar] [CrossRef]

- Kuranchie, C.; Yaya, A.; Bensah, Y.D. The effect of natural fibre reinforcement on polyurethane composite foams—A review. Sci. Afr. 2021, 11, e00722. [Google Scholar] [CrossRef]

- Shen, J.; Zeng, C.; Lee, L.J. Synthesis of polystyrene—Carbon nanofibers nanocomposite foams. Polymer 2005, 46, 5218–5224. [Google Scholar] [CrossRef]

- Yunus, R.B.; Zahari, N.; Salleh, M.; Ibrahim, N.A. Mechanical properties of carbon fiber-reinforced polypropylene composites. Key Eng. Mater. 2011, 471, 652–657. [Google Scholar] [CrossRef]

- Li, J.; Cai, C.L. Friction and wear properties of carbon fiber reinforced polypropylene composites. Adv. Mater. Res. 2011, 284, 2380–2383. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2009, 30, 260–263. [Google Scholar] [CrossRef]

- Wang, C.; Ying, S.; Xiao, Z. Preparation of short carbon fiber/polypropylene fine-celled foams in supercritical CO2. J. Cell. Plast. 2013, 49, 65–82. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Selke, S.; Matuana, L. Microcellular foam of polymer blends of HDPE/PP and their composites with wood fiber. J. Appl. Polym. 2003, 88, 2842–2850. [Google Scholar] [CrossRef]

- Saiz-Arroyo, C.; de Saja, J.A.; Velasco, J.I.; Rodríguez-Pérez, M.Á. Moulded polypropylene foams produced using chemical or physical blowing agents: Structure—Properties relationship. J. Mater. Sci. 2012, 47, 5680–5692. [Google Scholar] [CrossRef]

- Auhl, D.; Stange, J.; Münstedt, H.; Krause, B.; Voigt, D.; Lederer, A.; Lappan, U.; Lunkwitz, K. Long-chain branched polypropylenes by electron beam irradiation and their rheological properties. Macromolecules 2004, 37, 9465–9472. [Google Scholar] [CrossRef]

- Schulze, D.; Trinkle, S.; Mülhaupt, R.; Friedrich, C. Rheological evidence of modifications of polypropylene by β-irradiation. Rheol. Acta 2003, 42, 251–258. [Google Scholar] [CrossRef]

- Cho, J.; Lee, S.K.; Eem, S.H.; Jang, J.G.; Yang, B. Enhanced mechanical and thermal properties of carbon fiber-reinforced thermoplastic polyketone composites. Compos. Appl. Sci. Manuf. 2019, 126, 105599. [Google Scholar] [CrossRef]

- Gavali, V.C.; Kubade, P.R.; Kulkarni, H.B. Mechanical and thermo-mechanical properties of carbon fiber reinforced thermoplastic composite fabricated using fused deposition modeling method. Mater. Today Proc. 2020, 22, 1786–1795. [Google Scholar] [CrossRef]

| Material | PP | POE | Nucleating Agent | Lubricating Agent | Antioxygen Agent | Foaming Agent | Crosslinking Agent | Reinforced Fibers |

|---|---|---|---|---|---|---|---|---|

| Brand | S131 | 6202 | TMA-3 | Stearic acid | 1076G | ADC | TMPTMA | sCF or sGF |

| Content (g) | 60 | 40 | 0.4 | 1.0 | 0.5 | 15 | 0–16 | 0–20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, T.; Cui, C.; Mu, Y.; Niu, K. Low-Density and High-Performance Fiber-Reinforced PP/POE Composite Foam via Irradiation Crosslinking. Polymers 2024, 16, 745. https://doi.org/10.3390/polym16060745

Li H, Wang T, Cui C, Mu Y, Niu K. Low-Density and High-Performance Fiber-Reinforced PP/POE Composite Foam via Irradiation Crosslinking. Polymers. 2024; 16(6):745. https://doi.org/10.3390/polym16060745

Chicago/Turabian StyleLi, Hongfu, Tianyu Wang, Changwei Cui, Yuxi Mu, and Kangmin Niu. 2024. "Low-Density and High-Performance Fiber-Reinforced PP/POE Composite Foam via Irradiation Crosslinking" Polymers 16, no. 6: 745. https://doi.org/10.3390/polym16060745

APA StyleLi, H., Wang, T., Cui, C., Mu, Y., & Niu, K. (2024). Low-Density and High-Performance Fiber-Reinforced PP/POE Composite Foam via Irradiation Crosslinking. Polymers, 16(6), 745. https://doi.org/10.3390/polym16060745