Processing Method and Performance Evaluation of Flame-Retardant Corrugated Sandwich Panel

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Test Equipment

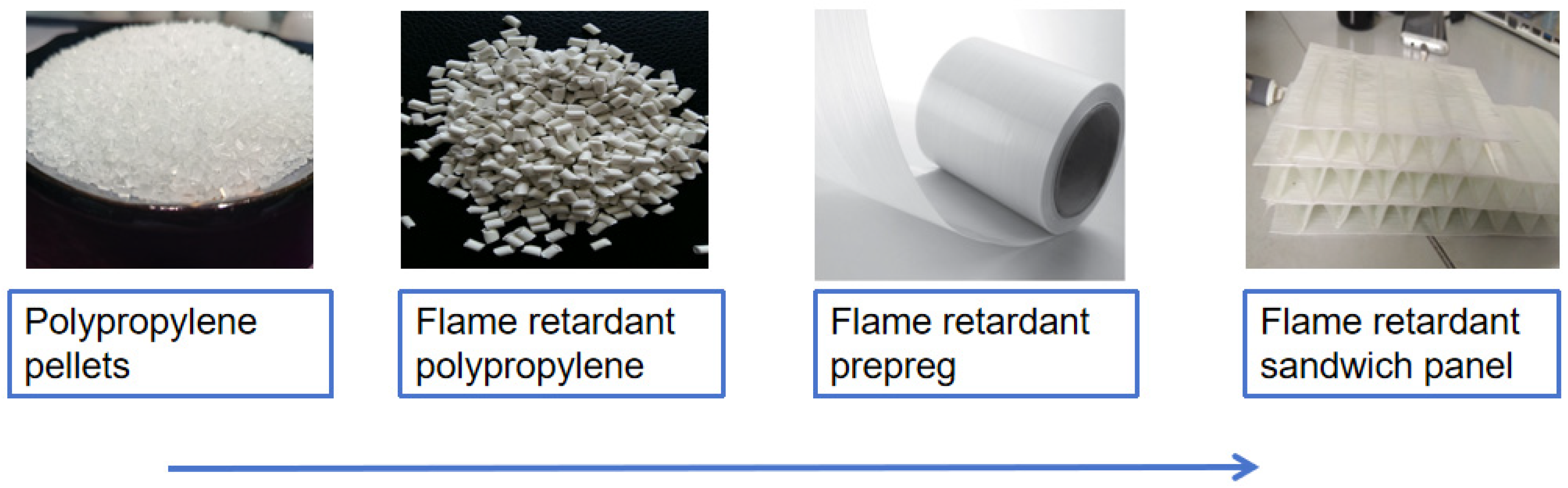

2.2. Preparation of Flame-Retardant Prepreg Tape

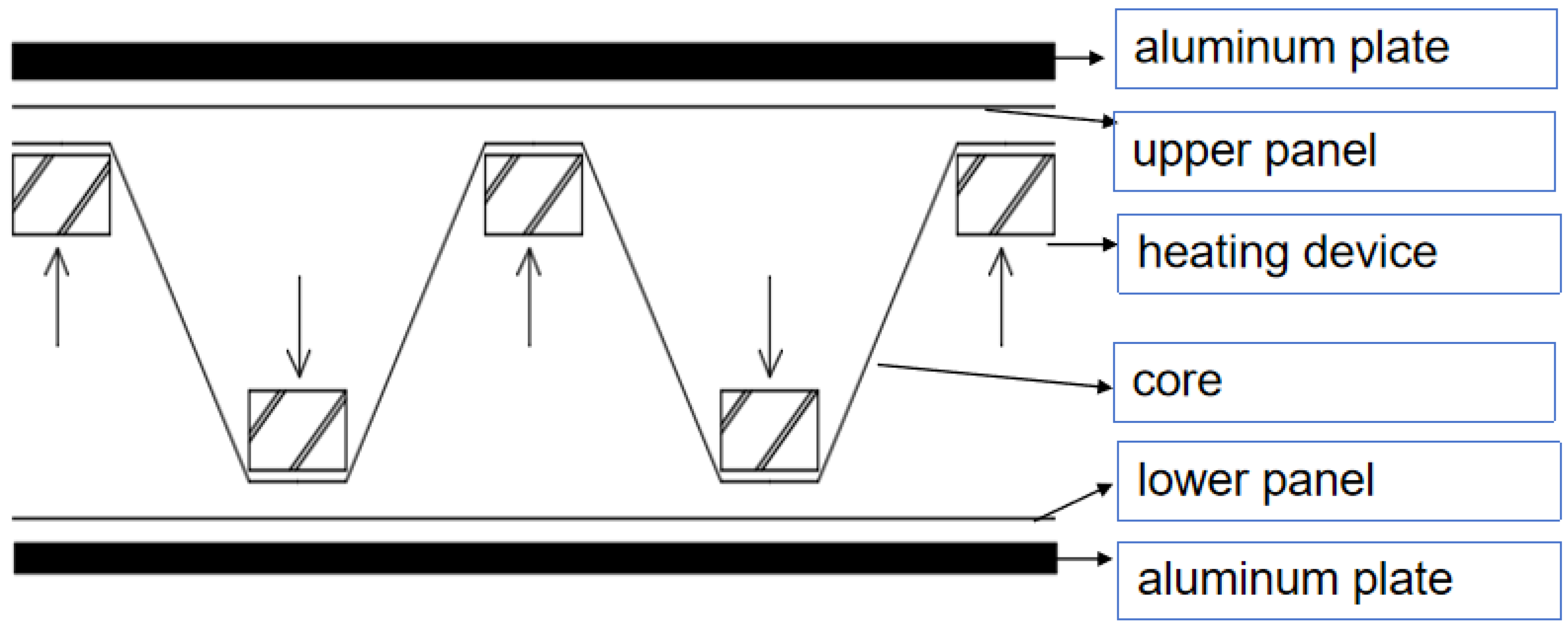

2.3. Preparation of Flame-Retardant Corrugated Sandwich Panels

2.3.1. Preparation of Upper and Lower Panels of Corrugated Plates by Molding Method

2.3.2. Preparation of Core Material for Corrugated Plate by Roller Pressing Method

2.3.3. Hot Melt Method of Bonding Upper and Lower Panels and Corrugated Core Materials

2.3.4. Water Cutting Method for Cutting Specimens

2.4. Performance Test

2.4.1. Limiting Oxygen Index Test

2.4.2. Vertical Combustion Test

2.4.3. Cone Calorimetry Test

2.4.4. Mechanical Properties Test

3. Results and Discussion

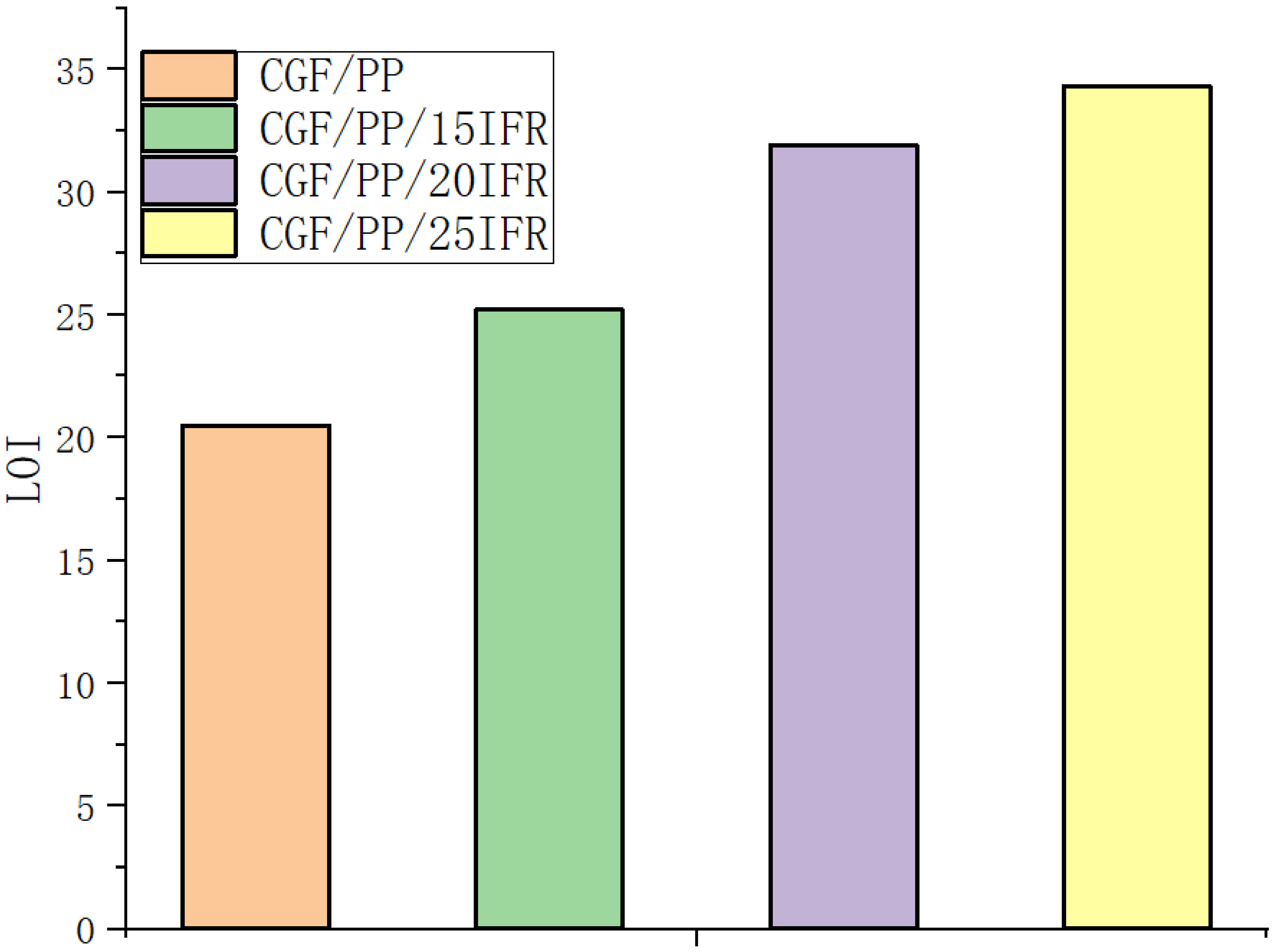

3.1. Limiting Oxygen Index and Combustion Rate Test

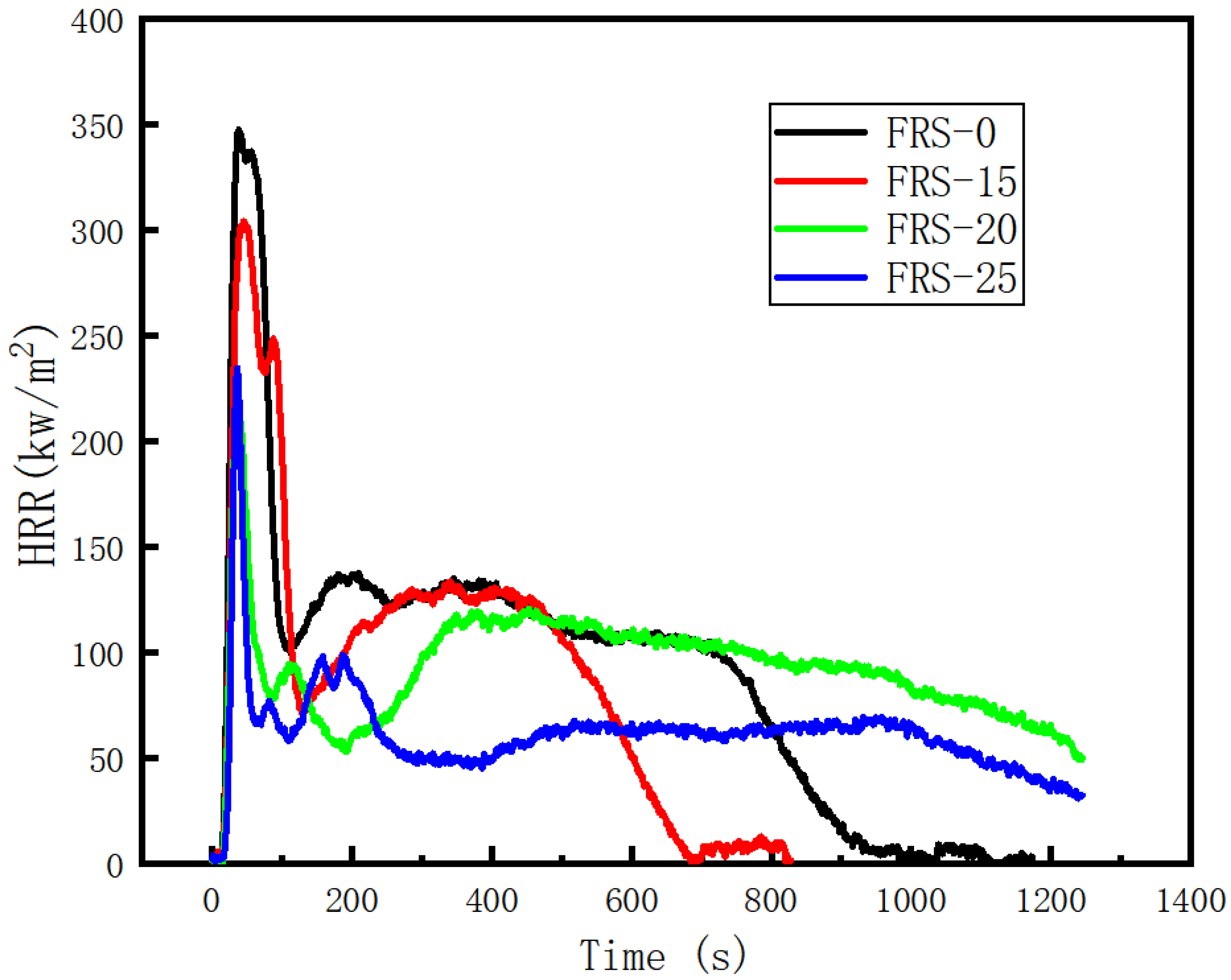

3.2. Cone Calorimetry Test

4. Conclusions

- The hot pressing scheme for preparing corrugated plates was explored. The skin and core material of the corrugated plate were prepared by the hot pressing method. The skin and core material were welded together by the hot melt method, which not only ensures the quality of the forming process but also has high production efficiency. The production and preparation process can be further optimized and improved in subsequent research.

- The amount of flame retardant added to the corrugated plate can be determined according to the needs of different use scenarios to achieve a balance of the flame retardant performance, molding process, and cost-effectiveness of the material. The flame retardant efficiency is the highest with the addition of 20% flame retardant. This can meet the primary flame retardant demand while reducing the amount of flame retardant added and can significantly reduce the cost of materials, thereby ensuring the economic viability of the flame-retardant corrugated plates.

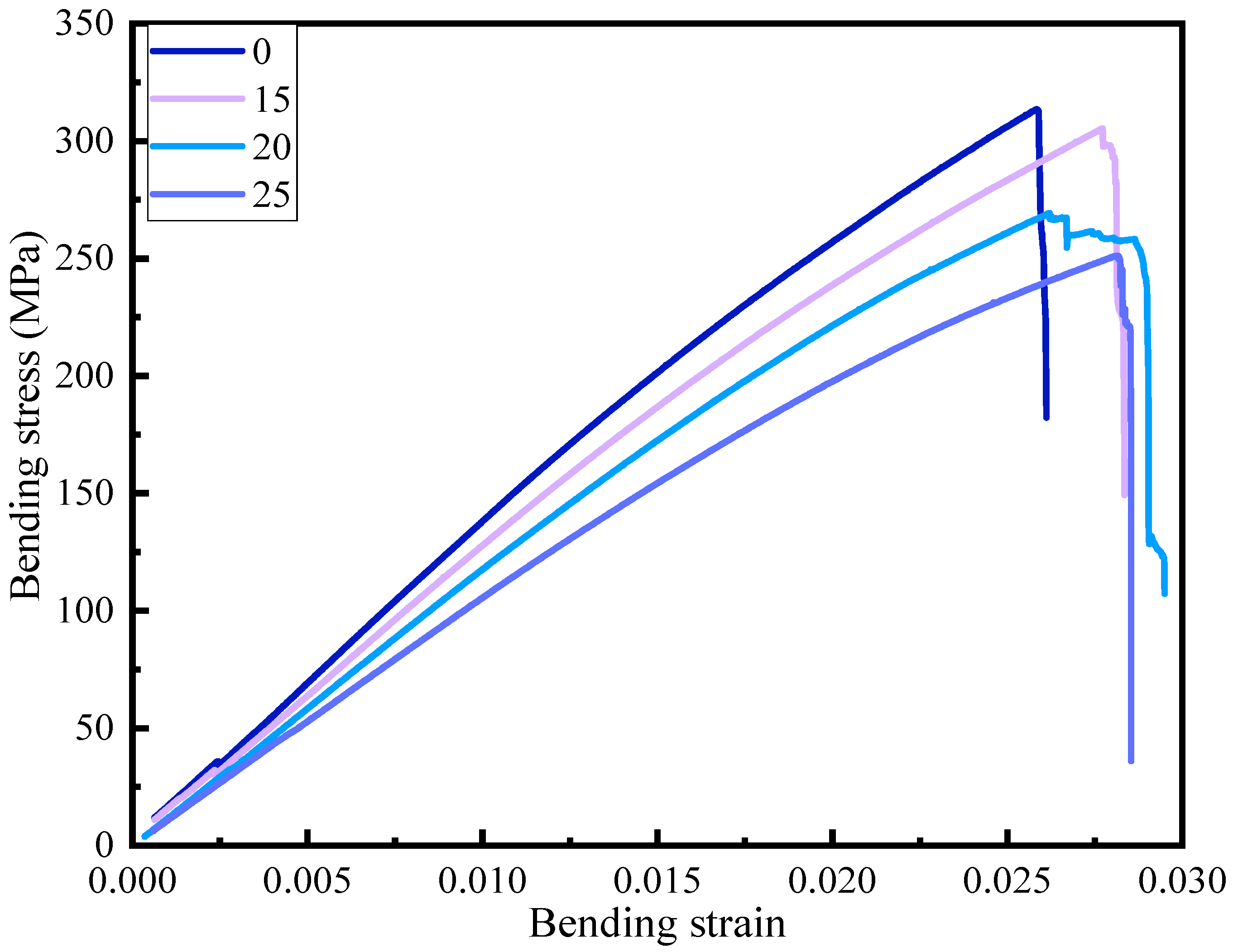

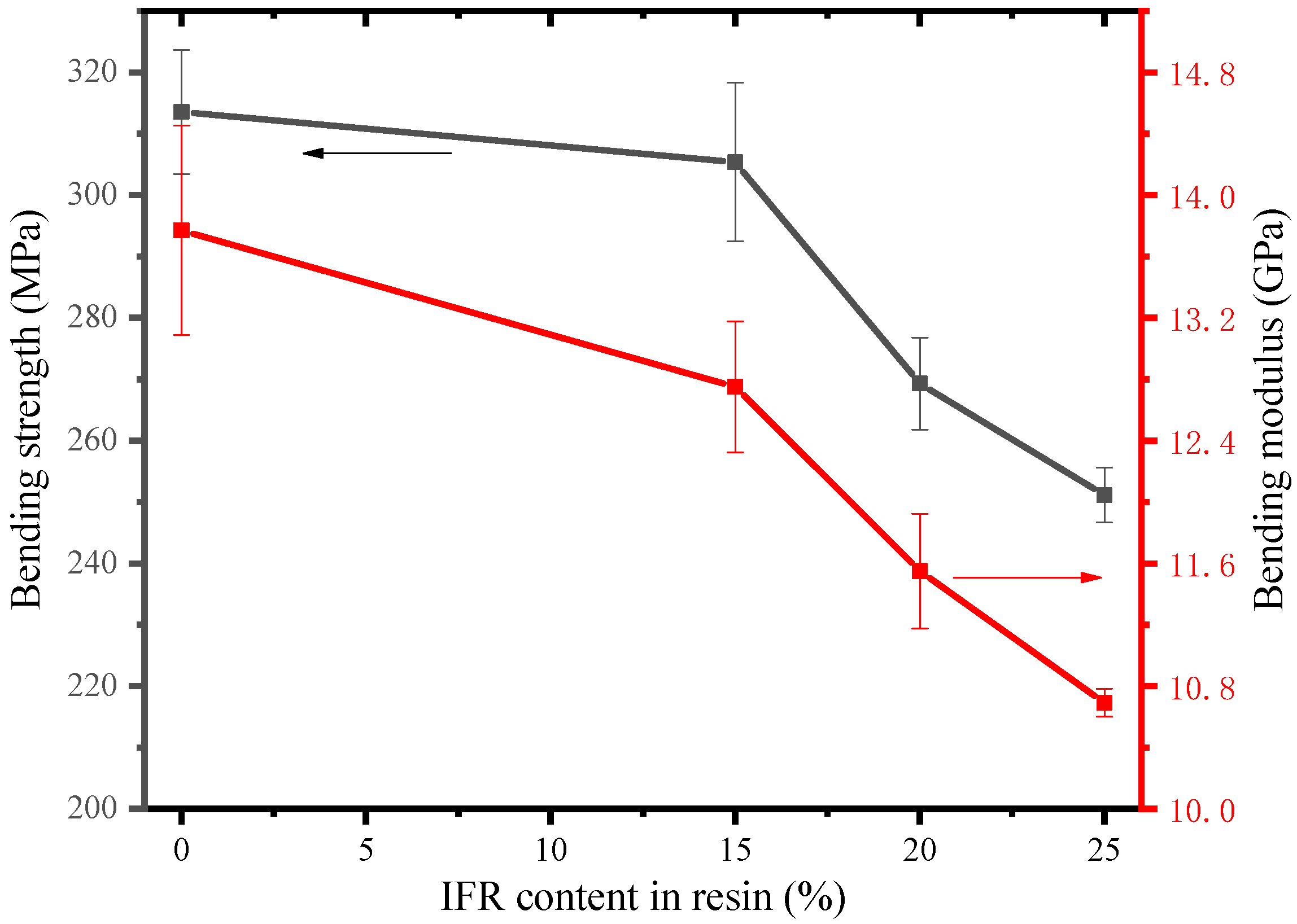

- The use of flame retardant will have a certain impact on the mechanical properties of the material, but by optimizing the molding process and selecting the appropriate amount of flame retardant, the mechanical properties can meet the requirements of the corresponding grade when the flame retardant performance meets the requirements of the corresponding rates.

- The flame retardant performance of the corrugated plate can be further designed because the skin and core material of the corrugated plate are formed separately. The amount of flame retardant added to the core material and the skin can be different to achieve a balance between flame retardant properties, mechanical properties, and the economic cost of materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Utekar, S.; Suriya, V.K.; More, N.; Rao, A. Comprehensive study of recycling of thermosetting polymer composites—Driving force, challenges and methods. Compos. Part B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Wang, B.; Fan, S.; Chen, J.; Yang, W.; Liu, W.; Li, Y. A review on prediction and control of curing process-induced deformation of continuous fiber-reinforced thermosetting composite structures. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107321. [Google Scholar] [CrossRef]

- Mahshid, R.; Isfahani, M.N.; Heidari-Rarani, M.; Mirkhalaf, M. Recent advances in development of additively manufactured thermosets and fiber reinforced thermosetting composites: Technologies, materials, and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2023, 171, 107584. [Google Scholar] [CrossRef]

- Ozturk, F.; Cobanoglu, M.; Ece, R.E. Recent advancements in thermoplastic composite materials in aerospace industry. J. Thermoplast. Compos. Mater. 2023. [Google Scholar] [CrossRef]

- Zhao, W.; Kumar Kundu, C.; Li, Z.; Li, X.; Zhang, Z. Flame retardant treatments for polypropylene: Strategies and recent advances. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106382. [Google Scholar] [CrossRef]

- Hopmann, C.; Wilms, E.; Beste, C.; Schneider, D.; Fischer, K.; Stender, S. Investigation of the influence of melt-impregnation parameters on the morphology of thermoplastic UD-tapes and a method for quantifying the same. J. Thermoplast. Compos. Mater. 2019, 34, 1299–1312. [Google Scholar] [CrossRef]

- Sun, Y.; Li, J.; Li, H. Flame Retardancy Performance of Continuous Glass-Fiber-Reinforced Polypropylene Halogen-Free Flame-Retardant Prepreg. Coatings 2022, 12, 976. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Ni, A.; Ding, A.; Sun, Z.; Han, X. Effect of novel intumescent flame retardant on mechanical and flame retardant properties of continuous glass fibre reinforced polypropylene composites. Compos. Struct. 2018, 203, 894–902. [Google Scholar] [CrossRef]

- Guo, H.; Yuan, H.; Zhang, J.; Ruan, D. Review of sandwich structures under impact loadings: Experimental, numerical and theoretical analysis. Thin-Walled Struct. 2024, 196, 111541. [Google Scholar] [CrossRef]

- Cheon, Y.-J.; Kim, H.-G. An equivalent plate model for corrugated-core sandwich panels. J. Mech. Sci. Technol. 2015, 29, 1217–1223. [Google Scholar] [CrossRef]

- Rejab, M.R.M.; Cantwell, W.J. The mechanical behaviour of corrugated-core sandwich panels. Compos. Part B Eng. 2013, 47, 267–277. [Google Scholar] [CrossRef]

- Valdevit, L.; Wei, Z.; Mercer, C.; Zok, F.W.; Evans, A.G. Structural performance of near-optimal sandwich panels with corrugated cores. Int. J. Solids Struct. 2006, 43, 4888–4905. [Google Scholar] [CrossRef]

- Dayyani, I.; Shaw, A.D.; Saavedra Flores, E.I.; Friswell, M.I. The mechanics of composite corrugated structures: A review with applications in morphing aircraft. Compos. Struct. 2015, 133, 358–380. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Jiang, Z.; Zhu, M.; Zhang, J.; Huang, H.; Liang, J. Comprehensive performance of multifunctional lightweight composite reinforced with integrated preform for thermal protection system exposed to extreme environment. Aerosp. Sci. Technol. 2022, 126, 107647. [Google Scholar] [CrossRef]

- Lurie, S.A.; Solyaev, Y.O.; Volkov-Bogorodskiy, D.B.; Bouznik, V.M.; Koshurina, A.A. Design of the corrugated-core sandwich panel for the arctic rescue vehicle. Compos. Struct. 2017, 160, 1007–1019. [Google Scholar] [CrossRef]

- Hörold, A.; Schartel, B.; Trappe, V.; Korzen, M.; Bünker, J. Fire stability of glass-fibre sandwich panels: The influence of core materials and flame retardants. Compos. Struct. 2017, 160, 1310–1318. [Google Scholar] [CrossRef]

- Wi, S.; Yang, S.; Yun, B.Y.; Kang, Y.; Kim, S. Fire retardant performance, toxicity and combustion characteristics, and numerical evaluation of core materials for sandwich panels. Environ. Pollut. 2022, 312, 120067. [Google Scholar] [CrossRef] [PubMed]

| Raw Materials | Provider | Product Grade |

|---|---|---|

| Polypropylene | SK | Bx3900 |

| Polypropylene | LyondellBasell | MF650X |

| MAPP | Exxon Mobil | Exxelor PO 1020 |

| Continuous fiberglass yarn | Chongqing International Co. | 4305s |

| IFR | Xinxiu Chemical | IFR-PP-1 |

| Device | Manufacturer | Device Model |

|---|---|---|

| Prepreg belt production M | Designed and assembled in laboratory | BUAA-2019 |

| Molding machine | DiDa Machinery Manufacturing Factory (Chengdu, China) | Y35-100T |

| Limiting oxygen index tester | Jiangning Analytical Instrument Co., Ltd. (Nanjing, China) | JF-3 |

| Combustion grade tester | Yaoke (Shanghai, China) | YK-Y0142 |

| Cone calorimeter | VOUCH (Shanghai, China) | 6810 |

| Sample | UL-94 Rating | Dripping |

|---|---|---|

| CGF/PP | No rating | NO |

| CGF/PP/15IFR | No rating | NO |

| CGF/PP/20IFR | V1 | NO |

| CGF/PP/25IFR | V0 | NO |

| Sample Name | FRS-0 | FRS-15 | FRS-20 | FRS-25 |

|---|---|---|---|---|

| Weight (g) | 46.3 | 44.7 | 47.6 | 46.9 |

| Heat release peak (kw/m2) | 347.7 | 304.3 | 234.7 | 217.5 |

| Total heat release (J) | 121.8 | 101.9 | 93.1 | 80.3 |

| Time to heat release peak (s) | 29 | 34 | 24 | 26 |

| Time to Ignition (s) | 10 | 12 | 11 | 13 |

| FPI | 0.0287 | 0.0394 | 0.0469 | 0.0598 |

| FGI | 11.99 | 8.95 | 9.78 | 8.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Li, J.; Zhang, B. Processing Method and Performance Evaluation of Flame-Retardant Corrugated Sandwich Panel. Polymers 2024, 16, 696. https://doi.org/10.3390/polym16050696

Sun Y, Li J, Zhang B. Processing Method and Performance Evaluation of Flame-Retardant Corrugated Sandwich Panel. Polymers. 2024; 16(5):696. https://doi.org/10.3390/polym16050696

Chicago/Turabian StyleSun, Yiliang, Jingwen Li, and Boming Zhang. 2024. "Processing Method and Performance Evaluation of Flame-Retardant Corrugated Sandwich Panel" Polymers 16, no. 5: 696. https://doi.org/10.3390/polym16050696

APA StyleSun, Y., Li, J., & Zhang, B. (2024). Processing Method and Performance Evaluation of Flame-Retardant Corrugated Sandwich Panel. Polymers, 16(5), 696. https://doi.org/10.3390/polym16050696