The Influence of Selected Fillers on the Functional Properties of Polycarbonate Dedicated to 3D Printing Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

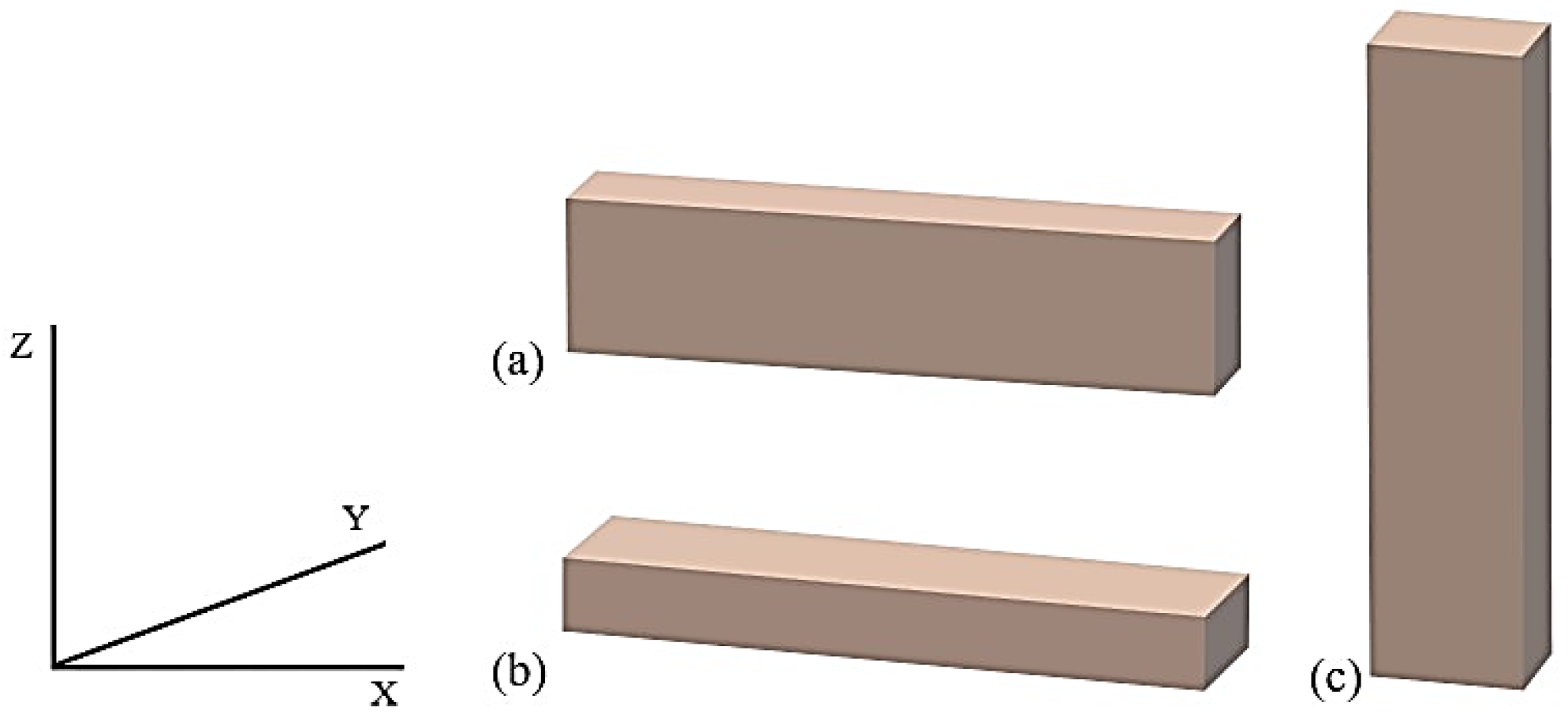

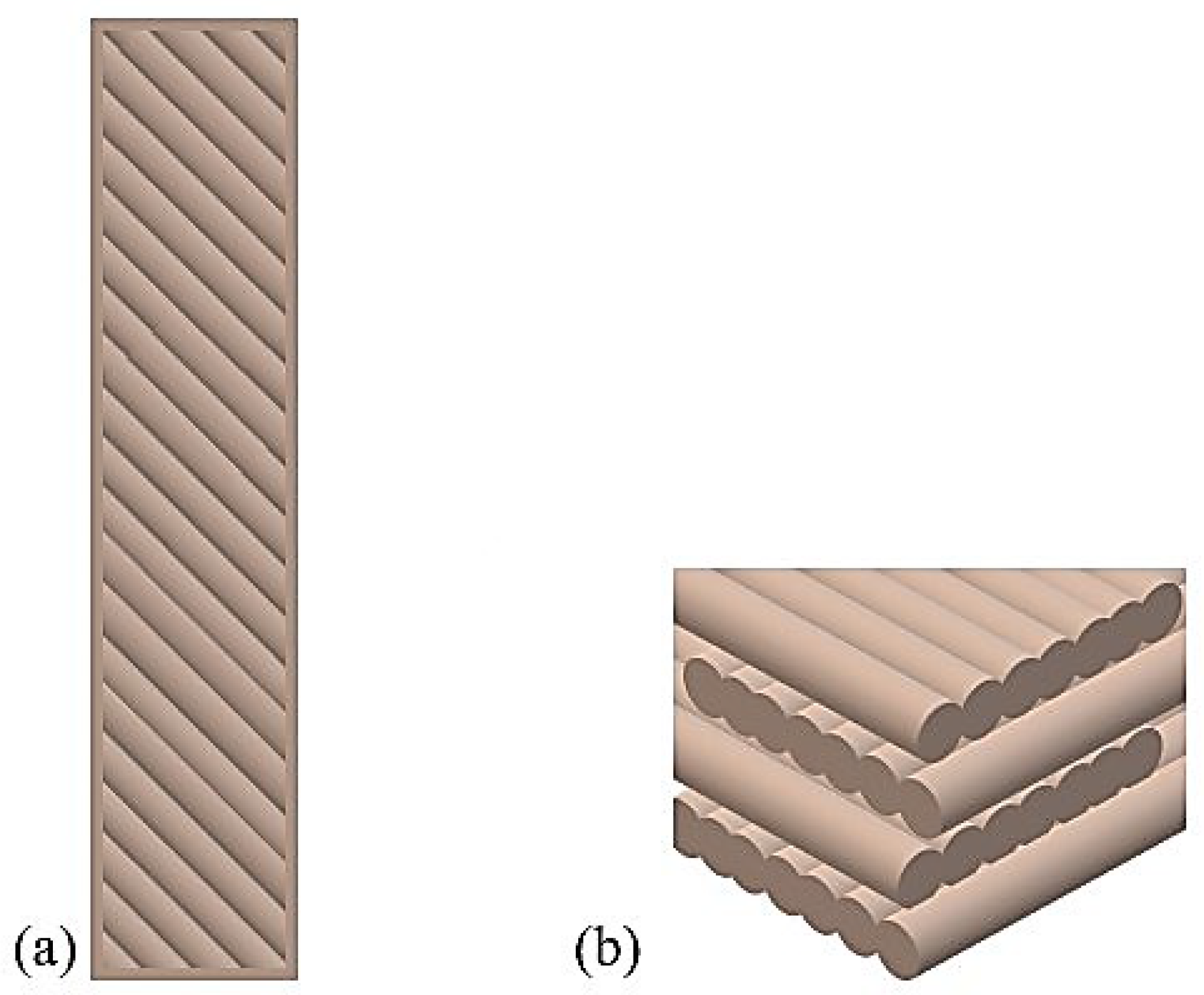

2.2. Sample Preparation

2.3. Methods

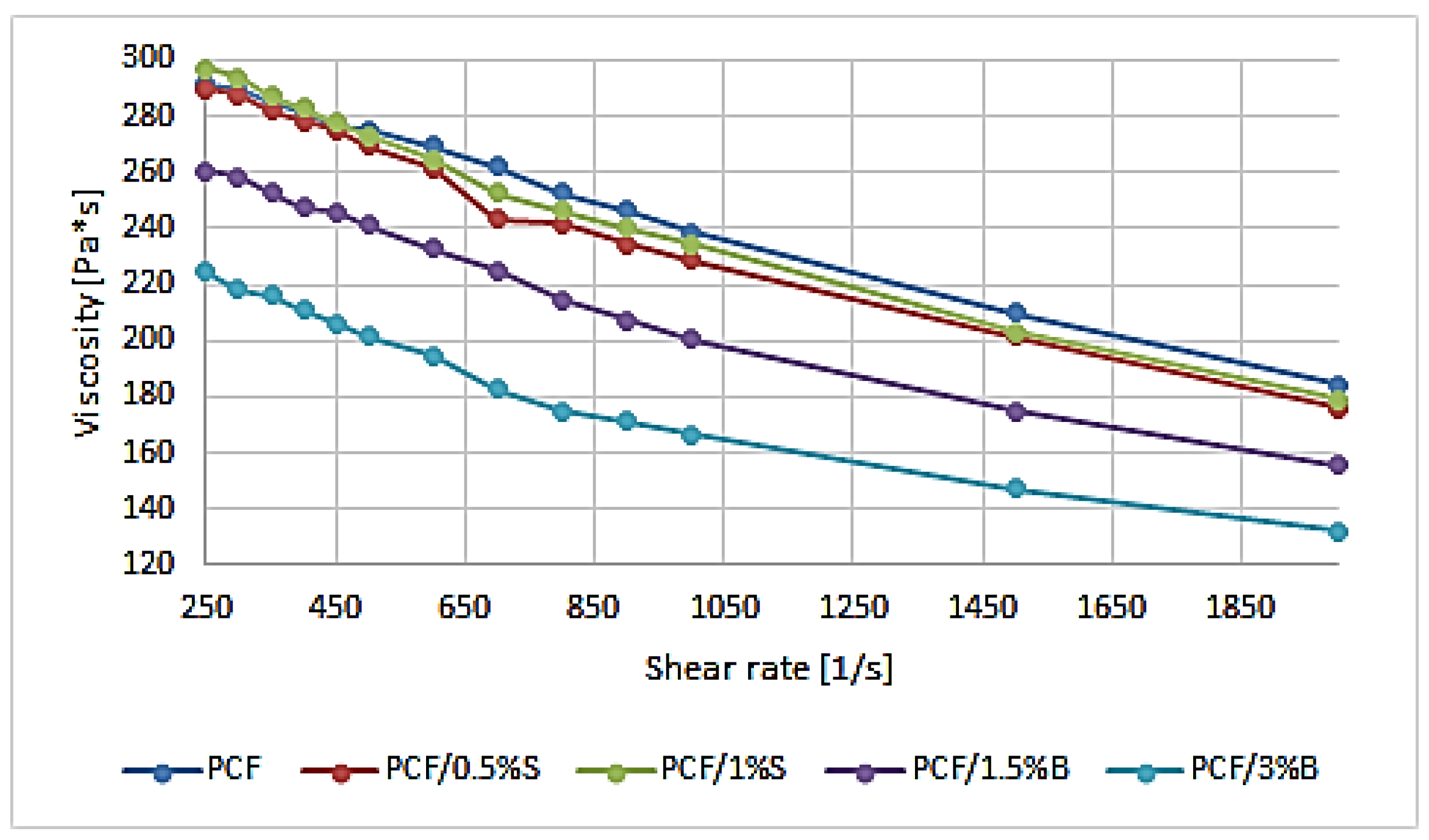

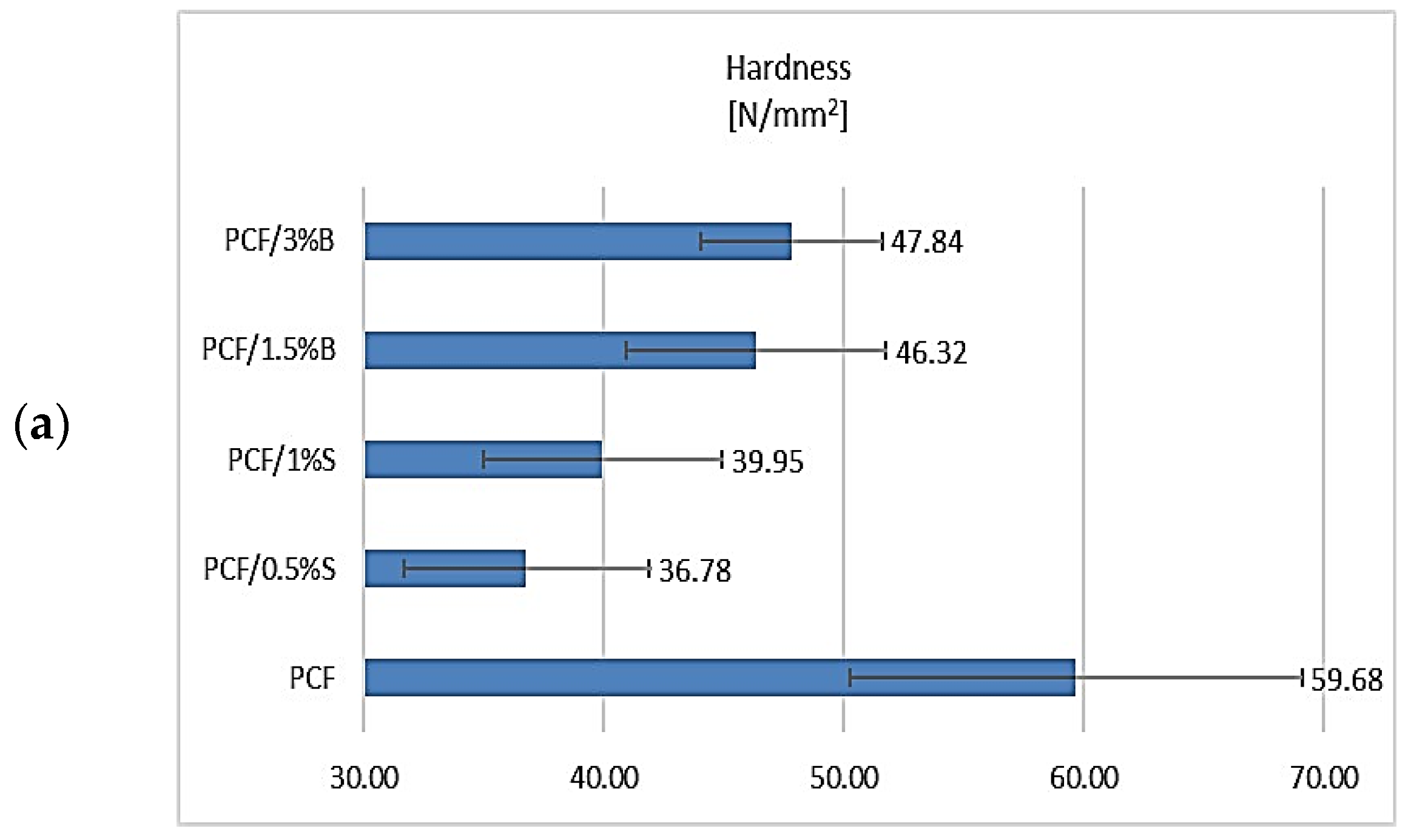

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, C.; Kim, S.; Kim, H.; Ahn, S. Measurement of Anisotropic Compressive Strength of Rapid Prototyping Parts. J. Am. Acad. Dermatol. 2007, 187–188, 627–630. [Google Scholar] [CrossRef]

- Pandey, P.M. On the Rapid Prototyping Technologies and Applications in Product Design and Manufacturing. Mater. Sci. Forum 2012, 710, 101–109. [Google Scholar] [CrossRef]

- Caban, J.; Czuba, Ł.; Szala, M.; Kęsik, J. Wykorzystanie druku 3D w zastosowaniach automotive. Autobusy Tech. Eksploat. Syst. Transp. 2017, 18, 573–579. [Google Scholar]

- Rajpurohit, S.R.; Dave, H.K. Effect of Process Parameters on Tensile Strength of FDM Printed PLA Part. Rapid Prototyp. J. 2018, 24, 1317–1324. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental Investigation of FDM Process for Improvement of Mechanical Properties and Production Cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Mathematical Modeling and FDM Process Parameters Optimization Using Response Surface Methodology Based on Q-Optimal Design. Appl. Math. Model. 2016, 40, 10052–10073. [Google Scholar] [CrossRef]

- Górski, F.; Kuczko, W.; Wichniarek, R.; Hamrol, A. Mechanical Properties of Composite Parts Manufactured in FDM Technology. Rapid Prototyp. J. 2018, 24, 1281–1287. [Google Scholar] [CrossRef]

- Beniak, J.; Križan, P.; Matúš, M.; Šajgalík, M. Experimental Testing of PLA Biodegradable Thermoplastic in the frame of 3D printing FDM technology. In Proceedings of the XXII Slovak-Polish Scientific Conference on Machine Modelling and Simulations 2017 (Mms 2017), Sklené Teplice, Slovakia, 5–8 September 2017; EDP Sciences: Les Ulis, France, 2018; Volume 157, p. 06001. [Google Scholar]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed]

- Baran, E.H.; Erbil, H.Y. Surface Modification of 3D Printed PLA Objects by Fused Deposition Modeling: A Review. Coll. Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Cuiffo, M.A.; Snyder, J.; Elliott, A.M.; Romero, N.; Kannan, S.; Halada, G.P. Impact of the Fused Deposition (FDM) Printing Process on Polylactic Acid (PLA) Chemistry and Structure. Appl. Sci. 2017, 7, 579. [Google Scholar] [CrossRef]

- Ostrowska-Czubenko, J.; Pieróg, M.; Gierszewska, M. Modyfikacja Chitozanu–Krótki Przegląd; Wiadomości Chemiczne: Wrocław, Poland, 2016; Volume 70, pp. 9–10. ISSN 0043-5104. [Google Scholar]

- Szlezyngier, W. Tworzywa Sztuczne–Tom 2; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 1996; pp. 593–666. [Google Scholar]

- Dębek, C. Wpływ silanów na właściwości kompozytów SBS modyfikowanych montmorylonitem interkalowanym polimerem rozpuszczalnym w wodzie. Elastomery 2016, 20, 2. [Google Scholar]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Warrick, E.L.; Pierce, O.R.; Polmanteer, K.E.; Saam, J.C. Silicone Elastomer Developments 1967–1977. Rubber Chem. Technol. 1979, 52, 437–525. [Google Scholar] [CrossRef]

- Wei, L.; Hu, N.; Zhang, Y. Synthesis of Polymer—Mesoporous Silica Nanocomposites. Materials 2010, 3, 4066–4079. [Google Scholar] [CrossRef] [PubMed]

- Asif, M.; Lee, J.H.; Lin-Yip, M.J.; Chiang, S.; Levaslot, A.; Giffney, T.; Ramezani, M.; Aw, K.C. A New Photopolymer Extrusion 5-Axis 3D Printer. Addit. Manuf. 2018, 23, 355–361. [Google Scholar] [CrossRef]

- Ramachandran, M.G.; Rajeswari, N. Influence of Nano Silica on Mechanical and Tribological Properties of Additive Manufactured PLA Bio Nanocomposite. Silicon 2022, 14, 703–709. [Google Scholar] [CrossRef]

- Seng, C.T.; Noum, S.Y.A.E.; Sivanesan, S.K.A.; Yu, L.-J. Reduction of Hygroscopicity of PLA Filament for 3D Printing by Introducing Nano Silica as Filler. In Proceedings of the 13th International Engineering Research Conference (13th Eureca 2019), Selangor Darul Ehsan, Malaysia, 27 November 2019; Phang, S.K., Ed.; Amer Inst Physics: College Park, MD, USA, 2020; Volume 2233, p. 020024. [Google Scholar]

- Szynkiewicz, D.; Ulenberg, S.; Georgiev, P.; Hejna, A.; Mikolaszek, B.; Bączek, T.; Baron, G.V.; Denayer, J.F.M.; Desmet, G.; Belka, M. Development of a 3D-Printable, Porous, and Chemically Active Material Filled with Silica Particles and Its Application to the Fabrication of a Microextraction Device. Anal. Chem. 2023, 95, 11632–11640. [Google Scholar] [CrossRef]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D Printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef]

- Alhallak, L.M.; Tirkes, S.; Tayfun, U. Mechanical, Thermal, Melt-Flow and Morphological Characterizations of Bentonite-Filled ABS Copolymer. Rapid Prototyp. J. 2020, 26, 1305–1312. [Google Scholar] [CrossRef]

- Elkawash, H.; Tirkes, S.; Hacioglu, F.; Tayfun, U. Physical and Mechanical Performance of Bentonite and Barite Loaded Low Density Polyethylene Composites: Influence of Surface Silanization of Minerals. J. Compos. Mater. 2020, 54, 4359–4368. [Google Scholar] [CrossRef]

- Wirjosentono, B.; Tamrin, T.; Rihayat, T. Processing and Characterization of Natural Bentonite from Aceh, Indonesia as Filler of Poly-Caprolactone/Poly-Lactic Acid/Chitosan, (PCL/PLA/Chitosan) Nanocomposites. In Proceedings of the 5th International Conference on Me-chanical Engineering Research 2019 (Icmer 2019), Kuantan, Malaysia, 30 July–31 July 2019; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 788, p. 012039. [Google Scholar]

- Mandal, M.; Maji, T.K. Preparation, Physical Properties and Ultraviolet Resistance of Wood Nanocomposites Based on Modified Soybean Oil and Bentonite. Wood Mater. Sci. Eng. 2019, 14, 381–391. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R. Polymer Compositum Based on Polycarbonate/Acrylonitrile-Prototyping Technology. Polymers 2023, 15, 1565. [Google Scholar] [CrossRef] [PubMed]

- Bulanda, K.; Oleksy, M.; Oliwa, R. Hybrid Polymer Composites Based on Polystyrene (PS) Used in the Melted and Extruded Manufacturing Technology. Polymers 2022, 14, 5000. [Google Scholar] [CrossRef] [PubMed]

- Bulanda, K.; Oleksy, M.; Oliwa, R. Polymer Composites Based on Glycol-Modified Poly(Ethylene Terephthalate) Applied to Additive Manufacturing Using Melted and Extruded Manufacturing Technology. Polymers 2022, 14, 1605. [Google Scholar] [CrossRef] [PubMed]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszłowski, Ł.; Fal, J.; Jesionowski, T. Polymer Composites Based on Polycarbonate (PC) Applied to Additive Manufacturing Using Melted and Extruded Manufacturing (MEM) Technology. Polymers 2021, 13, 2455. [Google Scholar] [CrossRef] [PubMed]

- Cerda-Avila, S.N.; Medellín-Castillo, H.I.; Lim, T. An Experimental Methodology to Analyse the Structural Behaviour of FDM Parts with Variable Process Parameters. Rapid Prototyp. J. 2020, 26, 1615–1625. [Google Scholar] [CrossRef]

- Raut, S.; Jatti, V.S.; Khedkar, N.K.; Singh, T. Investigation of the Effect of Built Orientation on Mechanical Properties and Total Cost of FDM Parts. Procedia Mater. Sci. 2014, 6, 1625–1630. [Google Scholar] [CrossRef]

- Sayanjali, M.; Rezadoust, A.M.; Sourki, F.A. Tailoring Physico-Mechanical Properties and Rheological Behavior of ABS Filaments for FDM via Blending with SEBS TPE. Rapid Prototyp. J. 2020, 26, 1687–1700. [Google Scholar] [CrossRef]

- Knoop, F.; Kloke, A.; Schoeppner, V. Quality Improvement of FDM Parts by Parameter Optimization. In Proceedings of the PPS-32: The 32nd International Conference of the Polymer Processing Society, Lyon, France, 25–29 July 2017; Amer Inst Physics: College Park, MD, USA, 2017; Volume 1914, p. 190001. [Google Scholar]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive Manufacturing of PLA Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Naveed, N. Investigate the Effects of Process Parameters on Material Properties and Microstructural Changes of 3D-Printed Specimens Using Fused Deposition Modelling (FDM). Mater. Technol. 2021, 36, 317–330. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material Property Testing of 3D-Printed Specimen in PLA on an Entry-Level 3D Printer; Volume 2A: Advanced Manufacturing; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V02AT02A014. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of Part Build Orientations on Fatigue Behaviour of FDM-Processed PLA Material. Prog. Addit. Manuf. 2016, 1, 21–28. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS With Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Fatimatuzahraa, A.; Farahaina, B.; Yusoff, W. The effect of employing different raster orientations on the mechanical properties and microstructure of Fused Deposition Modeling parts. In Proceedings of the 2011 IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA), Langkawi, Malaysia, 25–28 September 2011; pp. 22–27. [Google Scholar] [CrossRef]

- Radhwan, H.; Shayfull, Z.; Abdellah, A.E.-H.; Irfan, A.R.; Kamarudin, K. Optimization Parameter Effects on the Strength of 3D-Printing Process Using Taguchi Method. In Proceedings of the 5th International Conference on Green Design and Manufacture 2019 (Icongdm 2019), Jawa Barat, Indonesia, 29–30 April 2019; Zredagowane przez PP. Z. B. Rahim i M. M. A. BinAbdullah. Amer Inst Physics: College Park, MD, USA, 2019; Volume 2129, p. 020154. [Google Scholar]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Moradi, M.; Moghadam, M.K.; Shamsborhan, M.; Bodaghi, M. The Synergic Effects of FDM 3D Printing Parameters on Mechanical Behaviors of Bronze Poly Lactic Acid Composites. J. Compos. Sci. 2020, 4, 17. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Bardiya, S.; Jerald, J.; Satheeshkumar, V. Effect of Process Parameters on the Impact Strength of Fused Filament Fabricated (FFF) Polylactic Acid (PLA) Parts. Mater. Today Proc. 2021, 41, 1103–1106. [Google Scholar] [CrossRef]

- Bardiya, S.; Jerald, J.; Satheeshkumar, V. The Impact of Process Parameters on the Tensile Strength, Flexural Strength and the Manufacturing Time of Fused Filament Fabricated (FFF) Parts. Mater. Today Proc. 2021, 39, 1362–1366. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and Prediction of the Tensile Properties of Continuous Fiber-Reinforced 3D Printed Structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Aloyaydi, B.; Sivasankaran, S.; Mustafa, A. Investigation of Infill-Patterns on Mechanical Response of 3D Printed Poly-Lactic-Acid. Polym. Test. 2020, 87, 106557. [Google Scholar] [CrossRef]

- Çevik, Ç.; Kam, M. A Review Study on Mechanical Properties of Obtained Products by FDM Method and Metal/Polymer Composite Filament Production. J. Nanomater. 2020, 2020, 6187149. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Envi-ronmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Vicente, C.M.; Martins, T.S.; Leite, M.; Ribeiro, A.; Reis, L. Influence of Fused Deposition Modeling Parameters on the Mechanical Properties of ABS Parts. Polym. Adv. Technol. 2020, 31, 501–507. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [PubMed]

- Chohan, J.S.; Singh, R. Pre and Post Processing Techniques to Improve Surface Characteristics of FDM Parts: A State of Art Review and Future Applications. Rapid Prototyp. J. 2017, 23, 495–513. [Google Scholar] [CrossRef]

- Lužanin, O.; Movrin, D.; Plančak, M. Experimental Investigation of Extrusion Speed and Temperature Effects on Arithmetic Mean Surface Roughness in FDM-Built Specimens. J. Technol. Plast. 2013, 38, 179–190. [Google Scholar]

- Reddy, B.V.; Reddy, N.V.; Ghosh, A. Fused Deposition Modelling Using Direct Extrusion. Virtual Phys. Prototyp. 2007, 2, 51–60. [Google Scholar] [CrossRef]

- ISO 1133-1:2022(En); Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/obp/ui/en/#iso:std:83905:en (accessed on 20 February 2024).

- ISO 11443:2021(En); Plastics—Determination of the Fluidity of Plastics Using Capillary and Slit-Die Rheometers. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/80003.html (accessed on 20 February 2024).

- ISO 6508-1:2023(En); Metallic Materials—Rockwell Hardness Test. Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/84343.html (accessed on 20 February 2024).

- ISO 527-1:2019(En); Plastics—Determination of Tensile Properties. Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/75824.html (accessed on 20 February 2024).

- Tanahashi, M.; Watanabe, Y.; Lee, J.-C.; Takeda, K.; Fujisawa, T. Melt Flow and Mechanical Properties of Silica/Perfluoropolymer Nanocomposites Fabricated by Direct Melt-Compounding without Surface Modification on Nano-Silica. J. Nanosci. Nanotechnol. 2009, 9, 539–549. [Google Scholar] [CrossRef]

- Janik, J. Nanocomposites of Polyolefine Matrix Part I. Polypropylene/CLAY. Compos. Theory Pract. 2009, 9, 34–39. Available online: https://www.webofscience.com/wos/woscc/full-record/WOS:000218765600005 (accessed on 20 February 2024).

- Perera, R.; Rosales, C.; Araque, M.; Coelho, M. Composites of Pet and PBT/PP with Bentonite. Adv. Mater. Res. 2008, 47–50, 1019–1022. [Google Scholar] [CrossRef]

- Bakır, A.A.; Atik, R.; Özerinç, S. Mechanical Properties of Thermoplastic Parts Produced by Fused Deposition Modeling: A Review. Rapid Prototyp. J. 2021, 27, 537–561. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszlowski, L.; Mazurkow, A. Biodegradable Polymer Composites Used in Rapid Prototyping Technology by Melt Extrusion Polymers (MEP). Polimery 2020, 65, 430–436. [Google Scholar] [CrossRef]

- Bere, P.; Neamtu, C.; Udroiu, R. Novel Method for the Manufacture of Complex CFRP Parts Using FDM-Based Molds. Polymers 2020, 12, 2220. [Google Scholar] [CrossRef] [PubMed]

- Budzik, G.; Magniszewski, M.; Przeszlowski, L.; Oleksy, M.; Oliwa, R.; Bernaczek, J. Torsional Strength Testing of Machine Elements Manufacture by Incremental Technology from Polymeric Materials. Polimery 2018, 63, 830–832. [Google Scholar] [CrossRef]

- Alekseeva, O.V.; Rodionova, A.N.; Bagrovskaya, N.A.; Noskov, A.V.; Agafonov, A.V. Bentonite Filler Effect on Structure and Properties of Polystyrene-Based Composites. Iran. Polym. J. 2019, 28, 123–133. [Google Scholar] [CrossRef]

- Ahmed, M.; Elshafie, M.; Kandil, U.; Taha, M.R. Improving the Mechanical Properties of Thermoplastic Polyolefins Using Recycled Low-Density Polyethylene and Multi-Walled Carbon Nanotubes. Egypt. J. Chem. 2021, 64, 2517–2523. [Google Scholar] [CrossRef]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A Novel Functional Silica/Lignin Hybrid Material as a Potential Bio-Based Polypropylene Filler. Polym. Compos. 2015, 36, 913–922. [Google Scholar] [CrossRef]

- Nouh, S.A.; Elfadl, A.A.; Alhazime, A.A.; Al-Harbi, A.M. Effect of proton irradiation on the physical properties of PC/PBT blends. Radiat. Eff. Defects Solids 2018, 173, 629–642. [Google Scholar] [CrossRef]

- Oleksy, M.; Szwarc-Rzepka, K.; Heneczkowski, M.; Oliwa, R.; Jesionowski, T. Epoxy Resin Composite Based on Functional Hybrid Fillers. Materials 2014, 7, 6064–6091. [Google Scholar] [CrossRef]

| Composition | PCF Content (wt.%) | S Content (wt.%) | B Content (wt.%) | C Content (wt.%) |

|---|---|---|---|---|

| PCF | 100.0 | - | - | - |

| PCF/0.5% S | 98.5 | 0.5 | - | 1.0 |

| PCF/1% S | 98.0 | 1.0 | - | 1.0 |

| PCF/1.5% B | 97.5 | - | 1.5 | 1.0 |

| PCF/3% B | 96.0 | - | 3.0 | 1.0 |

| Parameter | Nozzle Diameter [mm] | Layer Height [mm] | Filling [%] | Fill Pattern | Extrusion Temperature [°C] | Worktable Temperature [°C] | Print Speed [mm/s] |

|---|---|---|---|---|---|---|---|

| Value | 0.4 | 0.2 | 100 | 45°/+45° | 250 | 90 | 70 |

| Parameter | Injection Temperature [°C] | Mold Temperature [°C] | Injection Time [s] | Plasticizing Time [s] | Injection Pressure [bar] | Post-Injection Pressure [bar] |

|---|---|---|---|---|---|---|

| Value | 250 | 70 | 5 | 120 | paddles | |

| 750 | 700 | |||||

| bars | ||||||

| 850 | 800 | |||||

| Composite | PCF | PCF/0.5%S | PCF/1%S | PCF/1.5%B | PCF/3%B |

|---|---|---|---|---|---|

| MFR | 16.8 ± 0.17 | 16.37 ± 0.23 | 16.91 ± 0.02 | 17.87 ± 0.49 | 20.23 ± 0.06 |

| Composition | Young’s Modulus [MPa] | Stress at Break [MPa] | Strain at Break [%] | Young’s Modulus [MPa] | Stress at Break [MPa] | Strain at Break [%] |

|---|---|---|---|---|---|---|

| 3D Printing | Injection | |||||

| PCF | 1846.00 ± 29.54 | 67.27 ± 5.03 | 6.70 ± 0.16 | 1978.04 ± 87.41 | 56.09 ± 0.29 | 32.81 ± 20.22 |

| PCF/0.5%S | 1661.02 ± 37.25 | 60.21 ± 0.63 | 5.69 ± 0.62 | 1988.33 ± 8.16 | 54.63 ± 2.31 | 17.42 ± 3.53 |

| PCF/1%S | 1686.59 ± 56.41 | 60.93 ± 1.53 | 6.16 ± 0.48 | 2044.90 ± 6.03 | 56.58 ± 1.86 | 13.75 ± 6.56 |

| PCF/1.5%B | 1799.36 ± 1.93 | 63.62 ± 1.13 | 5.37 ± 0.14 | 2046.66 ± 18.27 | 55.83 ± 0.99 | 21.78 ± 9.83 |

| PCF/3%B | 1747.75 ± 21.53 | 59.73 ± 0.16 | 5.82 ± 0.36 | 2124.70 ± 33.76 | 53.72 ± 2.87 | 16.51 ± 10.92 |

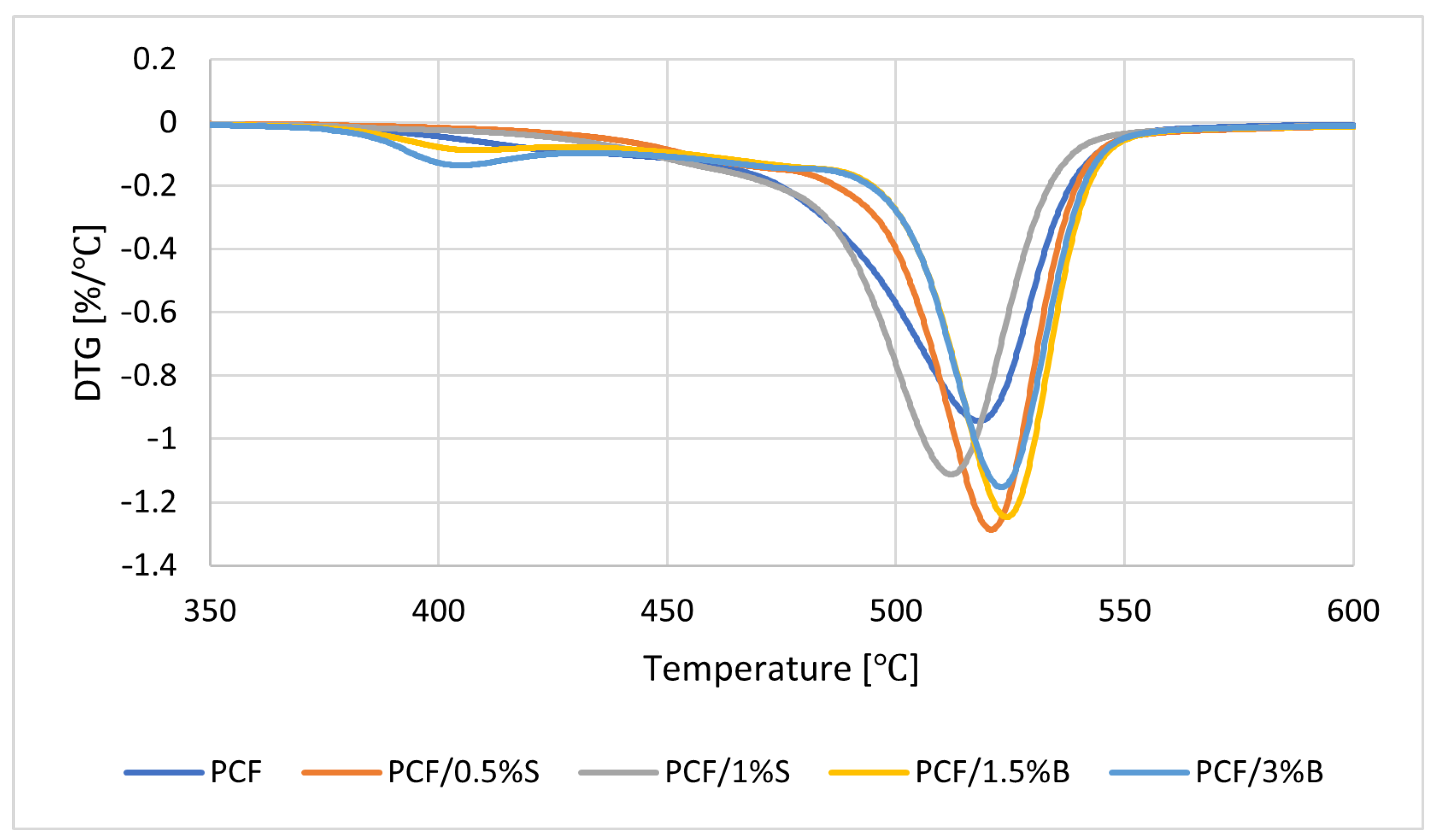

| Composites | T2% [°C] | T5% [°C] | T1 [°C] | ΔV1 [%/°C] | T2 [°C] | ΔV2 [%/°C] | R600 [%] |

|---|---|---|---|---|---|---|---|

| PCF | 418.07 | 449.41 | 524.77 | 0.94 | - | - | 27.04 |

| PCF/0.5%S | 446.07 | 472.64 | 525.99 | 1.29 | - | - | 29.29 |

| PCF/1%S | 437.83 | 464.10 | 518.47 | 1.11 | - | - | 27.61 |

| PCF/1.5%B | 409.74 | 445.70 | 406.04 | 0.09 | 529.85 | 1.25 | 27.15 |

| PCF/3%B | 400.95 | 424.67 | 404.65 | 0.13 | 528.82 | 1.15 | 26.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulanda, K.; Oleksy, M.; Oliwa, R. The Influence of Selected Fillers on the Functional Properties of Polycarbonate Dedicated to 3D Printing Applications. Polymers 2024, 16, 592. https://doi.org/10.3390/polym16050592

Bulanda K, Oleksy M, Oliwa R. The Influence of Selected Fillers on the Functional Properties of Polycarbonate Dedicated to 3D Printing Applications. Polymers. 2024; 16(5):592. https://doi.org/10.3390/polym16050592

Chicago/Turabian StyleBulanda, Katarzyna, Mariusz Oleksy, and Rafał Oliwa. 2024. "The Influence of Selected Fillers on the Functional Properties of Polycarbonate Dedicated to 3D Printing Applications" Polymers 16, no. 5: 592. https://doi.org/10.3390/polym16050592

APA StyleBulanda, K., Oleksy, M., & Oliwa, R. (2024). The Influence of Selected Fillers on the Functional Properties of Polycarbonate Dedicated to 3D Printing Applications. Polymers, 16(5), 592. https://doi.org/10.3390/polym16050592