Fused Filament Fabrication 3D Printing Parameters Affecting the Translucency of Polylactic Acid Parts

Abstract

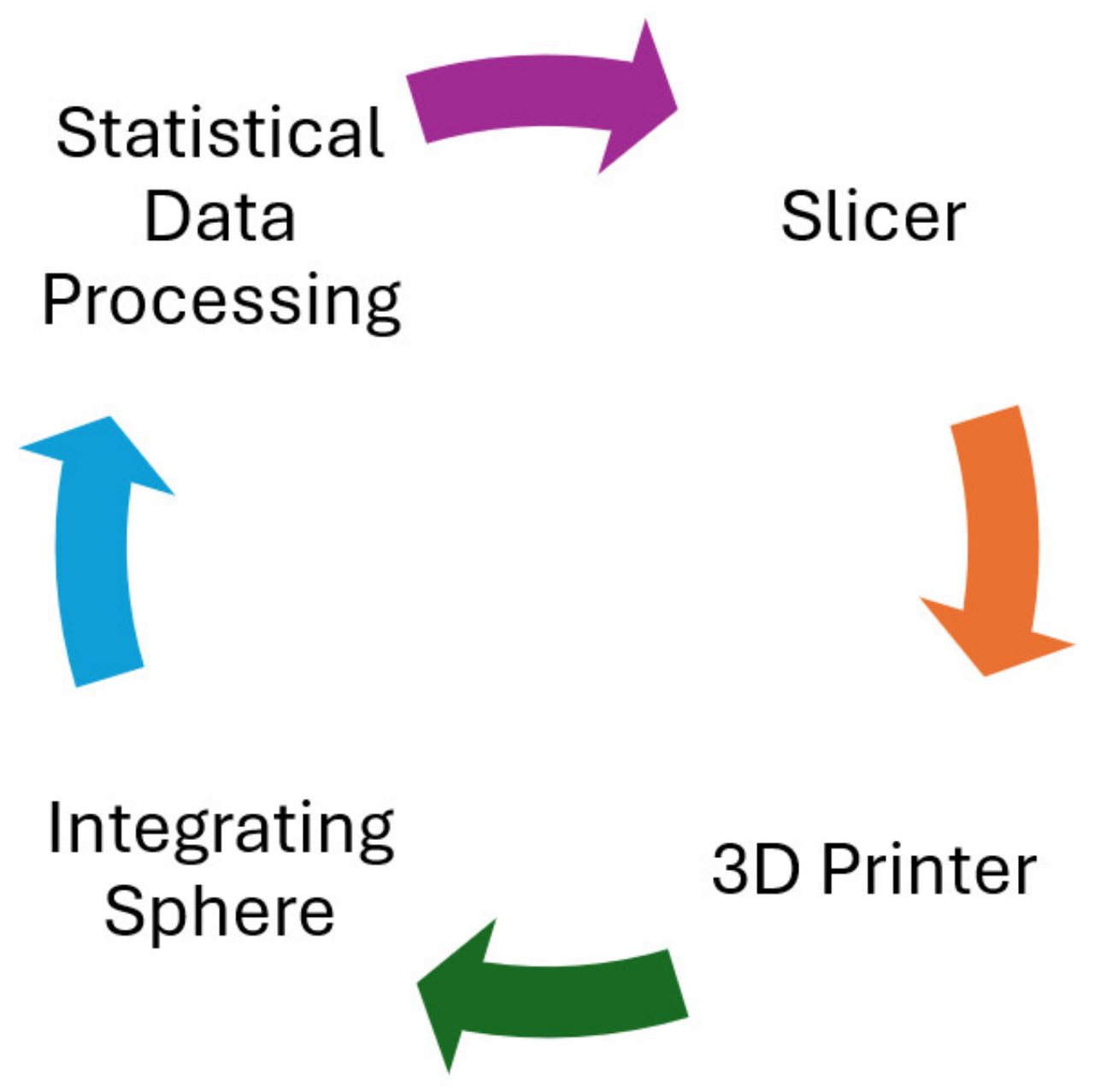

1. Introduction

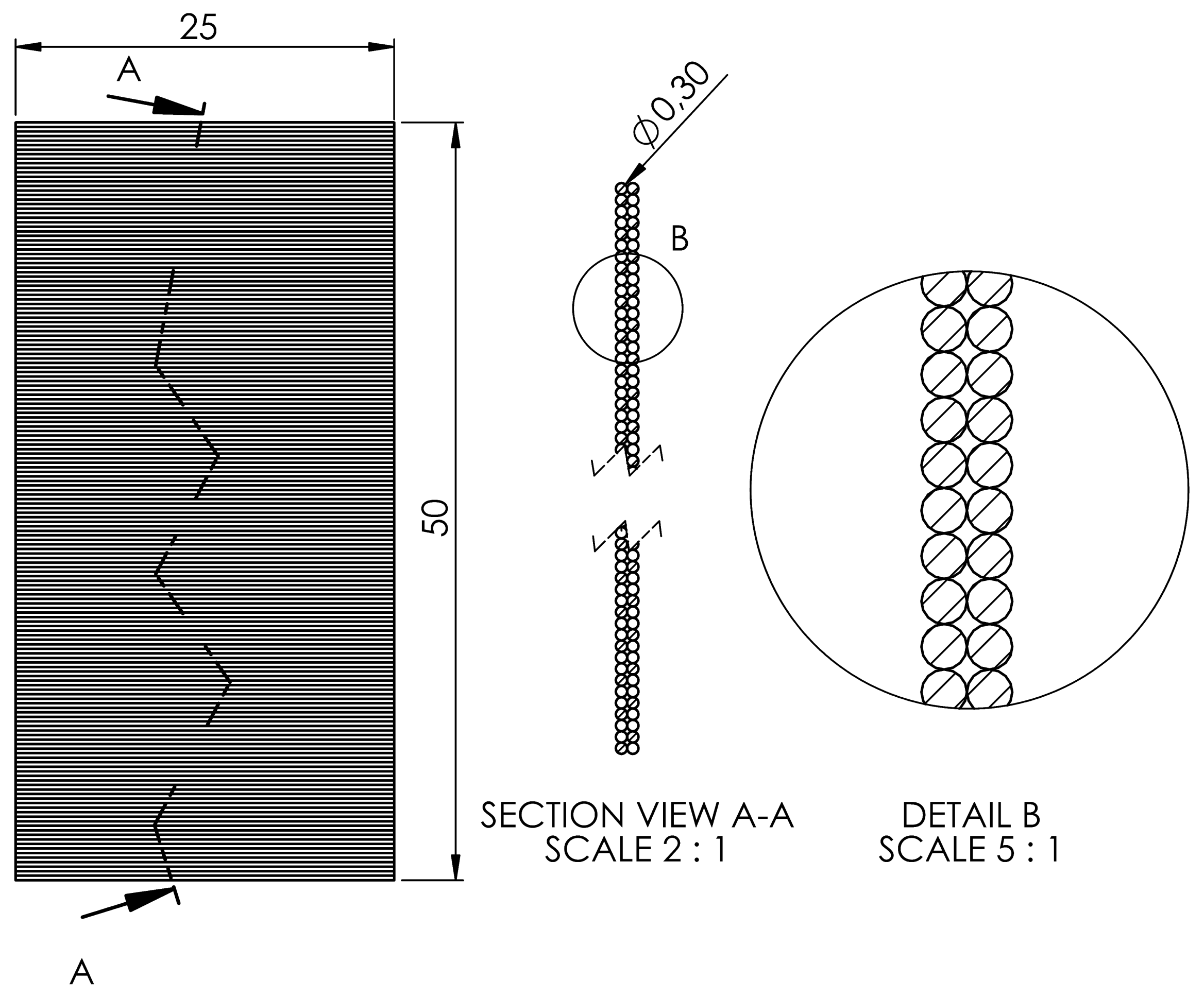

2. Materials and Methods

2.1. Filament, 3D Printer, Slicer

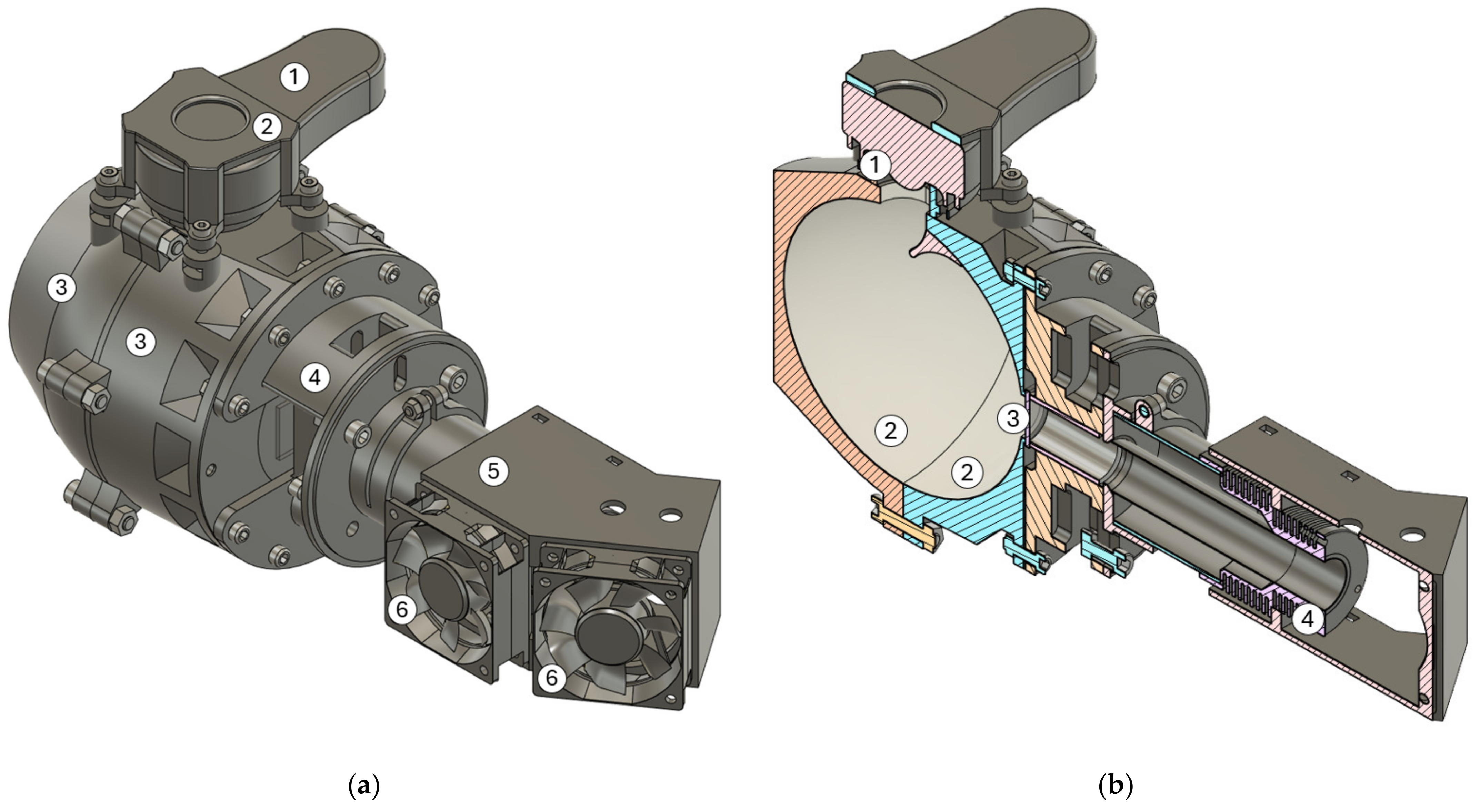

2.2. Integrating Sphere, Luxmeter, Light Source, Power Supply

2.3. Printing Parameters in the Slicer

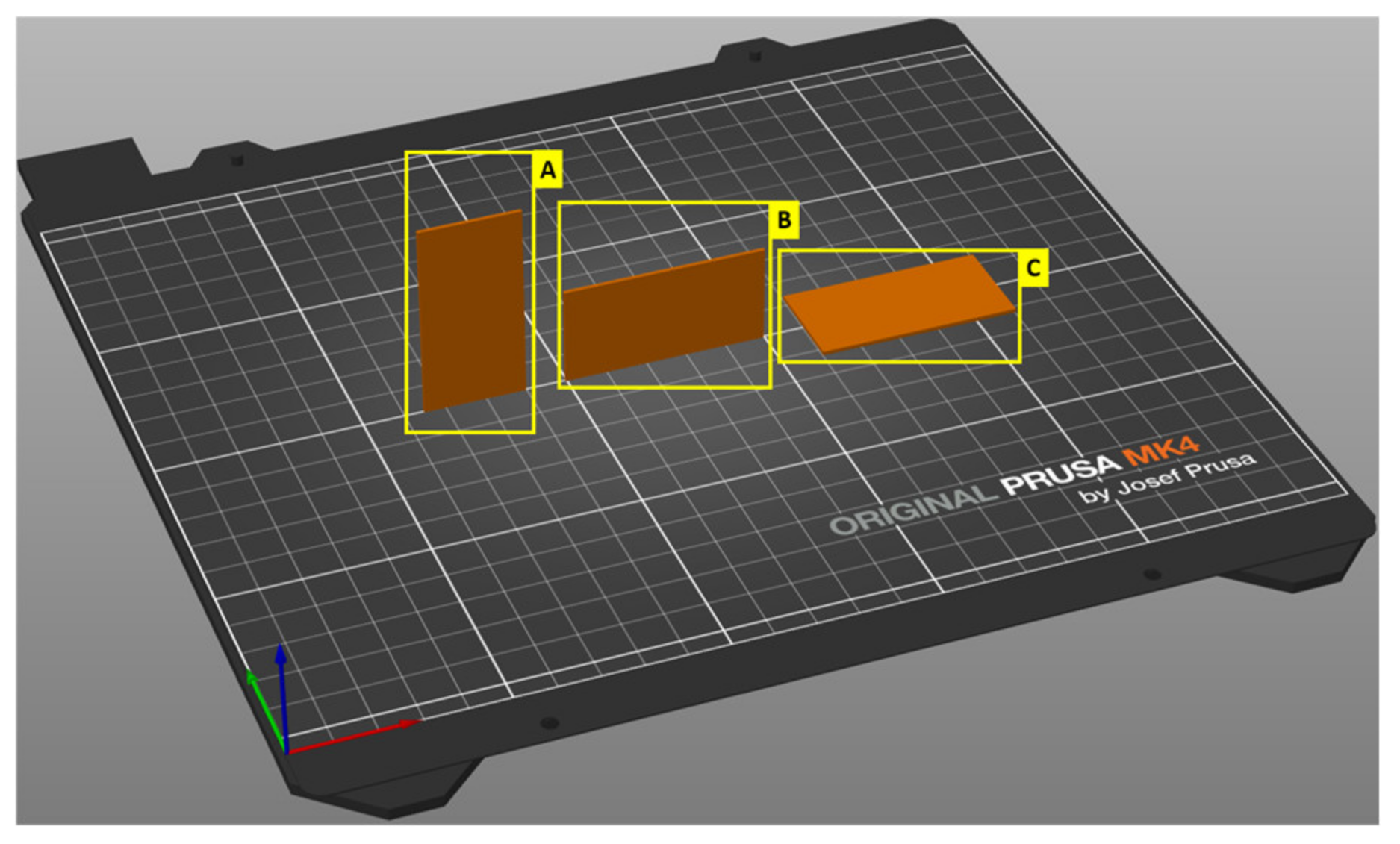

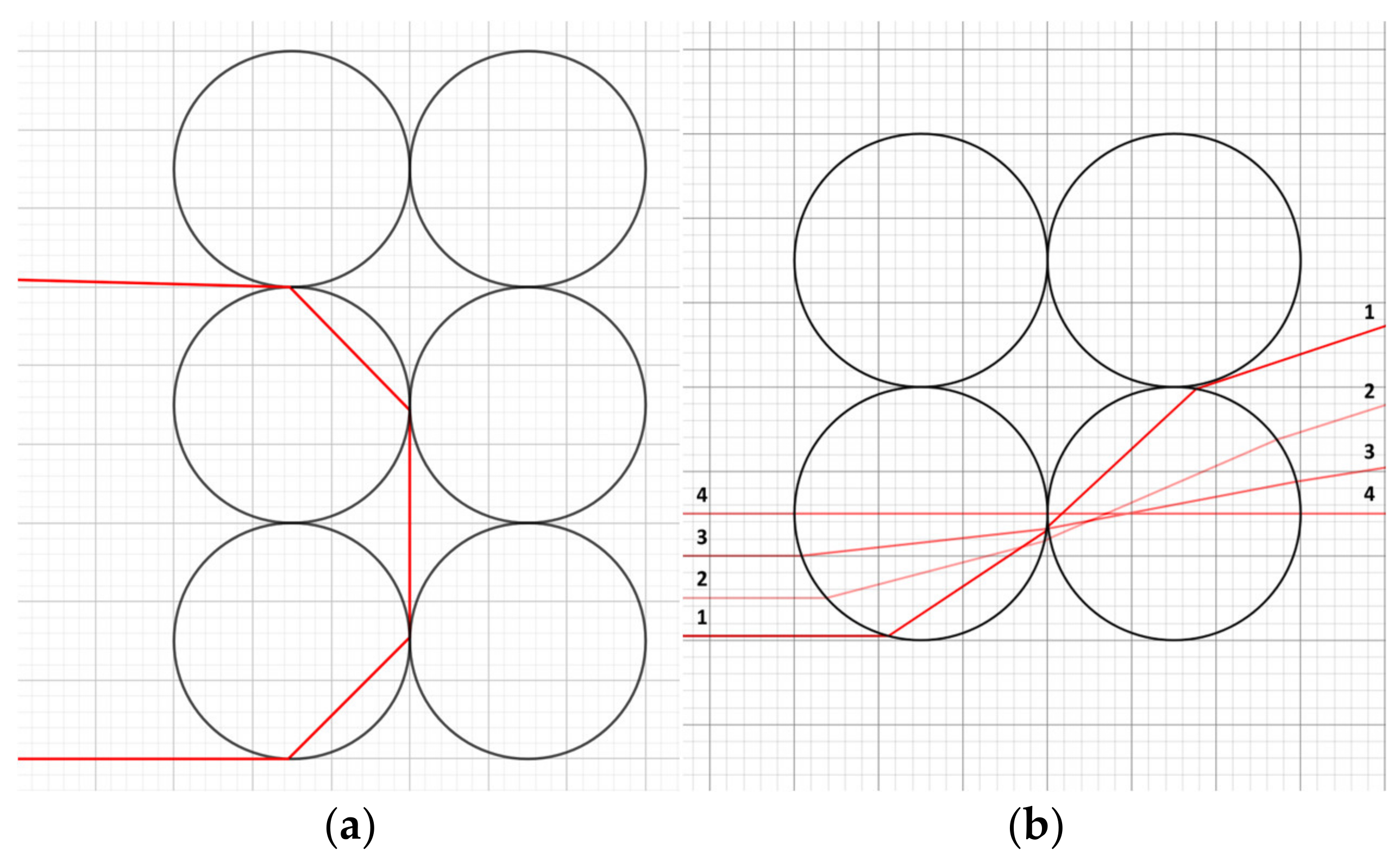

2.3.1. Object Orientation

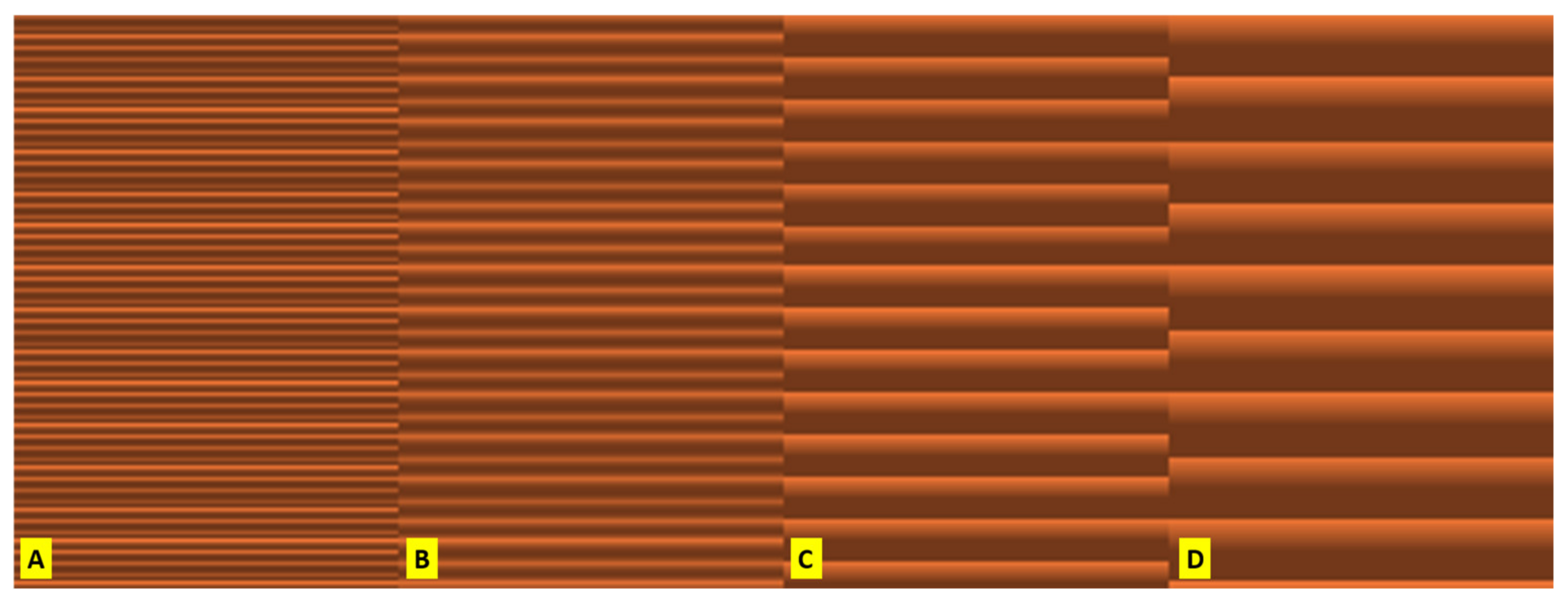

2.3.2. Layer Height

2.3.3. Nozzle Temperature

2.3.4. Fan Speed

2.3.5. Extrusion Multiplier

2.3.6. Speed for Print Moves—External Perimeters

2.4. Statistical Data Processing

2.5. SEM Analysis

3. Results and Discussion

3.1. Object Orientation

3.2. Layer Height

3.3. Nozzle Temperature

3.4. Fan Speed

3.5. Extrusion Multiplier

3.6. Speed of Print Moves

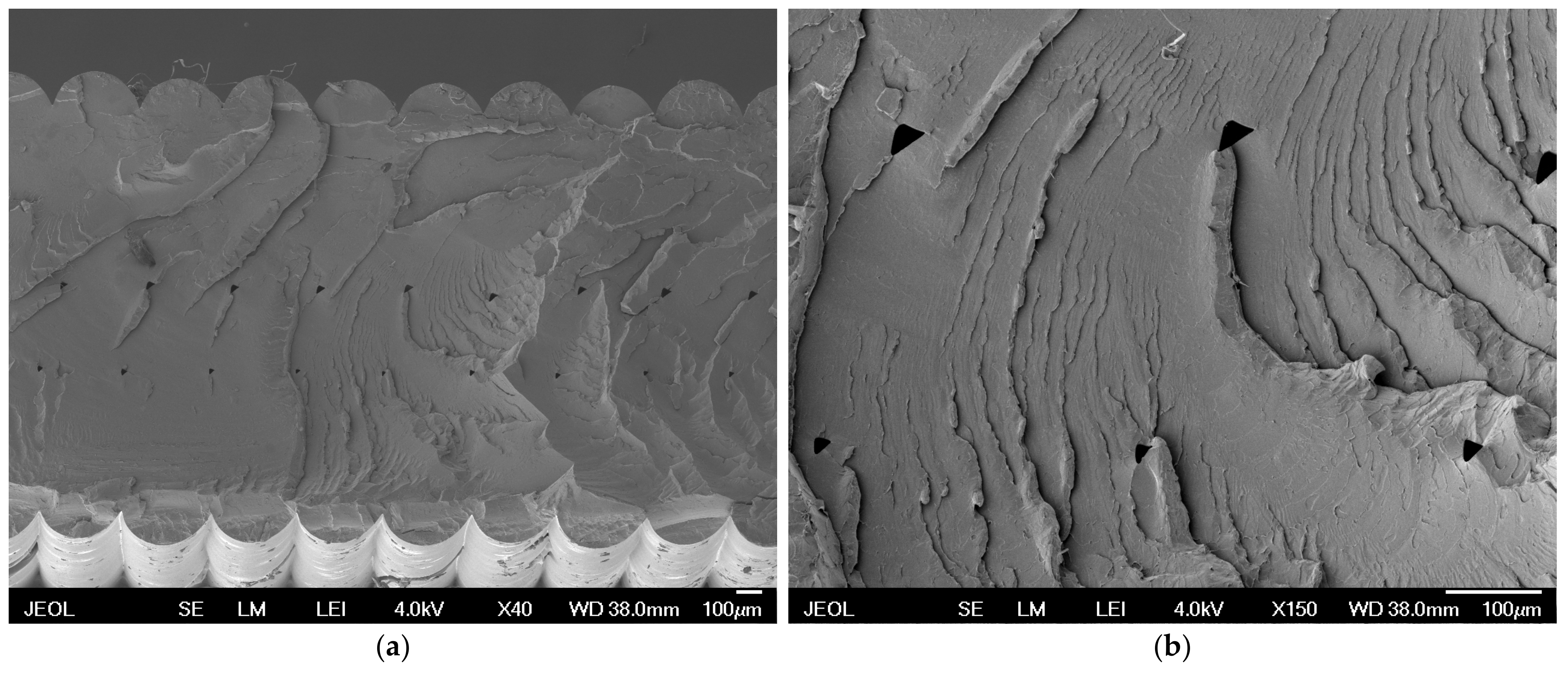

3.7. Ideal Settings

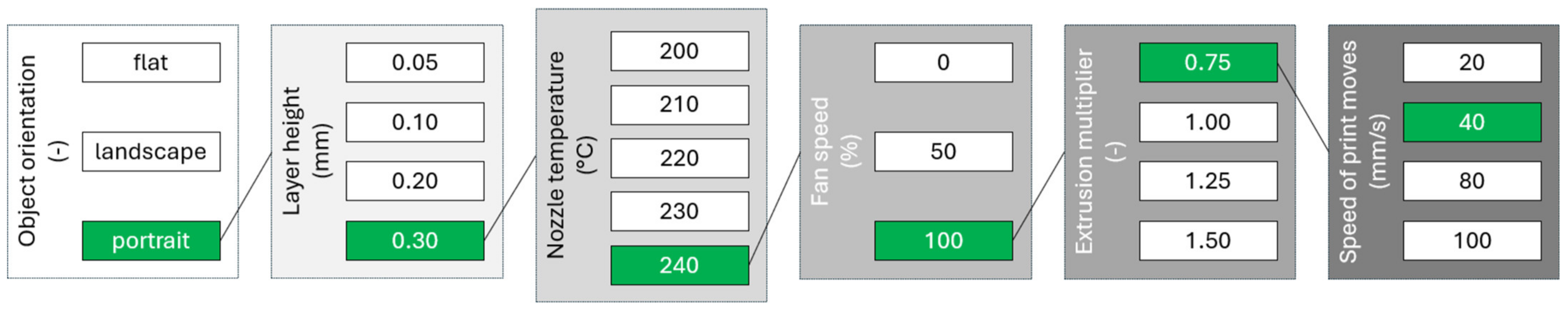

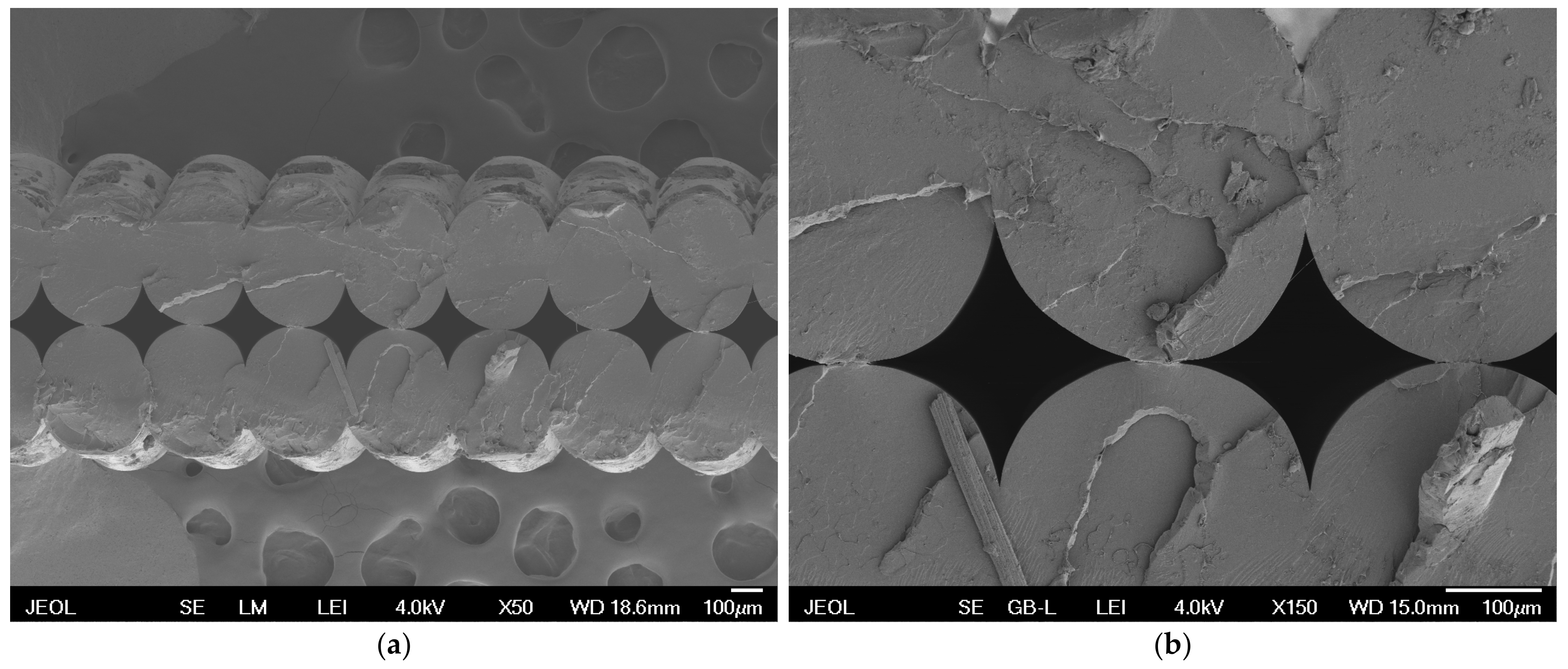

3.7.1. SEM Analysis

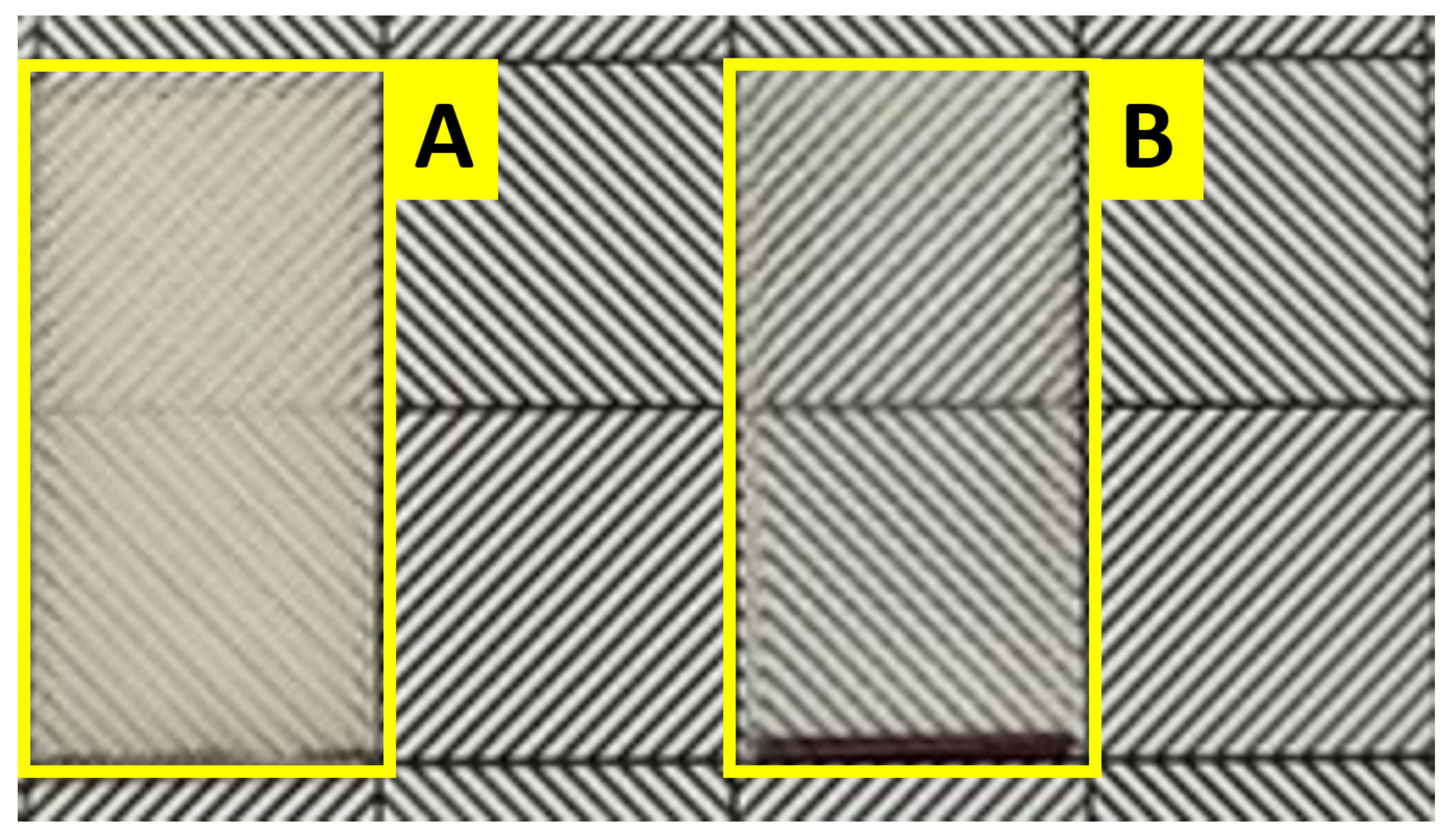

3.7.2. Qualitative Comparison Using a Black and White Raster

3.7.3. Application of Results in Practise—Pythagoras Cup and Tantalus Cup

4. Conclusions

- The orientation of the object was one of the key parameters that affected the translucency. The results showed that printing in portrait orientation provided better translucency than printing in landscape orientation. Portrait orientation allows for a more uniform distribution of material, which contributes to higher translucency.

- The height of the layer had a significant effect on the optical properties of the printed parts. An optimum layer height of 0.30 mm was identified as the best compromise between printing time and achieved translucency.

- The nozzle temperature affects the melting and flow of the material during printing. The best results were achieved at 240 °C (compared to the manufacturer’s recommended temperature of 200–220 °C), which ensured a sufficient melt of the material and minimised internal defects that could reduce translucency.

- Fan speed plays a role in cooling the material after extrusion. The higher fan speed (100%) resulted in better translucency due to the faster solidification of the material, which minimised deformation and improved surface quality.

- The extrusion multiplier affects the amount of material extruded. A lower extrusion multiplier of 0.75 resulted in thinner layers of material, which contributed to better translucency by reducing excessive material build-up and internal stresses in the printed parts.

- Print speed also had a significant effect on the quality and translucency of the printed parts. The optimum speed of 40 mm/s ensured uniform material deposition without defects that could adversely affect translucency. Higher printing speeds led to insufficient heating and the fusion of layers, which impaired translucency.

- The combination of these parameters resulted in optimum conditions for printing translucent parts. The best translucency values were obtained with a portrait orientation, a layer height of 0.30 mm, a nozzle temperature of 240 °C, a fan speed of 100%, an extrusion multiplier of 0.75 and a print speed of 40 mm/s. This optimised setting resulted in a translucency of up to 88% compared to the default setting’s 65%. The ability of visible light to pass through the print (translucency) has improved by 23%.

5. Application of the Results in Practise

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haleem, A.; Javaid, M. Additive Manufacturing Applications in Industry 4.0: A Review. J. Ind. Integr. Manag. 2019, 04. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Baechle-Clayton, M.; Loos, E.; Taheri, M.; Taheri, H. Failures and Flaws In Fused Deposition Modeling (FDM) Additively Manufactured Polymers And Composites. J. Compos. Sci. 2022, 6, 202. [Google Scholar] [CrossRef]

- Năstase, M.-S.; Costea, M.; Jiga, G.; Alexandru, T.G. Comparative Studies between Two Plastic Materials Used in 3D Printing. Macromol. Symp. 2023, 411, 2200178. [Google Scholar] [CrossRef]

- Souza, D.H.S.; Santoro, P.V.; Dias, M.L. Isothermal Crystallization Kinetics of Poly(Lactic Acid) Stereocomplex/Graphene Nanocomposites. Mater. Res. 2018, 21. [Google Scholar] [CrossRef]

- Taib, R.M.; Yin, T.C. Determination of the Equilibrium Melting Temperature of Polylactic Acid/Ethylene Acrylate Copolymer Blends. Mater. Today 2019, 17, 1112–1116. [Google Scholar] [CrossRef]

- Pyda, M.; Bopp, R.; Wunderlich, B. Heat capacity of poly(lactic acid). J. Chem. Thermodyn. 2004, 36, 731–742. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Recca, G.; Tosto, C. Specific Heat Capacity and Thermal Conductivity Measurements of PLA-Based 3D-Printed Parts with Milled Carbon Fiber Reinforcement. Entropy 2022, 24, 654. [Google Scholar] [CrossRef]

- Topcu, İ. Mechanical Properties of PLA and ABS Parts Produced with Fused Filament Fabrication Method. J. Ceram. Process. Res. 2021, 22, 143–148. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative Study of the Sensitivity of PLA, ABS, PEEK, and PETG’s Mechanical Properties to FDM Printing Process Parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Otieno, D.B.; Bosire, G.O.; Onyari, J.M.; Mwabora, J.M. Comparative analysis of 3D-printed polylactic acid and acrylonitrile butadiene styrene: Experimental and Materials-Studio-based theoretical studies. J. Polym. Res. 2022, 29, 1–14. [Google Scholar] [CrossRef]

- Hutchinson, M.H.; Dorgan, J.R.; Knauss, D.M.; Hait, S.B. Optical Properties of Polylactides. J. Polym. Environ. 2006, 14, 119–124. [Google Scholar] [CrossRef]

- Clark, A.T.; Federici, J.F.; Gatley, I.; Kong, L.B. Effect of 3D Printing Parameters on the Refractive Index, Attenuation Coefficient, and Birefringence of Plastics in Terahertz Range. Adv. Mater. Sci. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Squires, A.D.; Constable, E.; Lewis, R.A. 3D Printed Terahertz Diffraction Gratings and Lenses. J. Infrared Millim. Terahertz Waves 2015, 36, 72–80. [Google Scholar] [CrossRef]

- Murr, L.E. Frontiers of 3D Printing/Additive Manufacturing: From Human Organs to Aircraft Fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Ji, S.; Guvendiren, M. Recent Advances in Bioink Design for 3D Bioprinting of Tissues and Organs. Front. Bioeng. Biotechnol. 2017, 5, 23. [Google Scholar] [CrossRef]

- Jang, H.; Jang, H.W.; Kim, A.Y.; Youk, J.H. Partially Bio-Based Colorless and Transparent Poly(Amide-Imide)s Derived from 2,5-Furandicarboxylic Acid. Fibers Polym. 2020, 21, 2161–2165. [Google Scholar] [CrossRef]

- Bansal, N.; Tanwer, A.K.; Karnwal, S.; Singh, A.P. Robotic Arm by Using 3D Printing and Polylactic Acid (PLA) Wire—Challenges and Solutions. In Proceedings of the 2023 1st International Conference on Intelligent Computing and Research Trends (ICRT), Roorkee, India, 3–4 February 2023; pp. 1–11. [Google Scholar]

- Chen, Q.; Li, C.; Hao, X. A micro quadruped crawling robot manufactured from PLA material. Vibroengineering PROCEDIA 2023, 53, 91–96. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Singh, S.K.; Deshmukh, S. Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects. Mater. Today Proc. 2021, 50, 2269–2275. [Google Scholar] [CrossRef]

- Cojocaru, V.; Frunzaverde, D.; Miclosina, C.-O.; Marginean, G. The Influence of the Process Parameters on the Mechanical Properties of PLA Specimens Produced by Fused Filament Fabrication—A Review. Polymers 2022, 14, 886. [Google Scholar] [CrossRef]

- Cele, H.; Ojijo, V.; Chen, H.; Kumar, S.; Land, K.; Joubert, T.; de Villiers, M.; Ray, S. Effect of nanoclay on optical properties of PLA/clay composite films. Polym. Test. 2014, 36, 24–31. [Google Scholar] [CrossRef]

- Jacquez, J.A.; Kuppenheim, H.F. Theory of the Integrating Sphere. J. Opt. Soc. Am. 1955, 45, 460–470. [Google Scholar] [CrossRef]

- Poh, A.H.; Jamaludin, M.F.; Fadzallah, I.A.; Ibrahim, N.M.J.N.; Yusof, F.; Adikan, F.; Moghavvemi, M. Diffuse reflectance spectroscopic analysis of barium sulfate as a reflection standard within 173–2500 nm: From pure to sintered form. J. Near Infrared Spectrosc. 2019, 27, 393–401. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of Print Orientation on Surface Roughness in Fused Deposition Modeling (FDM) Processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef]

- Bintara, R.D.; Lubis, D.Z.; Pradana, Y.R.A. The effect of layer height on the surface roughness in 3D Printed Polylactic Acid (PLA) using FDM 3D printing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012096. [Google Scholar] [CrossRef]

- Aliheidari, N.; Tripuraneni, R.; Hohimer, C.; Christ, J.; Ameli, A.; Nadimpalli, S. The impact of nozzle and bed temperatures on the fracture resistance of FDM printed materials. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Portland, OR, USA, 26–28 March 2017; p. 1016512. [Google Scholar]

- Jerez-Mesa, R.; Gomez-Gras, G.; Travieso-Rodriguez, J.; Garcia-Plana, V. A comparative study of the thermal behavior of three different 3D printer liquefiers. Mechatronics 2018, 56, 297–305. [Google Scholar] [CrossRef]

- Buonamici, F.; Carfagni, M.; Furferi, R.; Governi, L.; Saccardi, M.; Volpe, Y. Optimizing Fabrication Outcome in Low-Cost FDM Machines. Part 2—Tests. Manuf. Technol. 2018, 18, 552–558. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Effect of Print Speed and Extrusion Temperature on Properties of 3D Printed PLA Using Fused Deposition Modeling Process. Mater. Today Proc. 2021, 45, 5462–5468. [Google Scholar] [CrossRef]

- Fatimatuzahraa, A.; Farahaina, B.; Yusoff, W. The effect of employing different raster orientations on the mechanical properties and microstructure of Fused Deposition Modeling parts. In Proceedings of the 2011 IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA), Langkawi, Malaysia, 25–28 September 2011; pp. 22–27. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS With Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Hozdić, E. Characterization and Comparative Analysis of Mechanical Parameters of FDM- and SLA-Printed ABS Materials. Appl. Sci. 2024, 14, 649. [Google Scholar] [CrossRef]

- Naveed, N. Investigating the Material Properties and Microstructural Changes of Fused Filament Fabricated PLA and Tough-PLA Parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef]

- Kumar, M.S.; Farooq, M.U.; Ross, N.S.; Yang, C.-H.; Kavimani, V.; Adediran, A.A. Achieving effective interlayer bonding of PLA parts during the material extrusion process with enhanced mechanical properties. Sci. Rep. 2023, 13, 1–21. [Google Scholar] [CrossRef]

- Chaidas, D.; Kechagias, J.D. An investigation of PLA/W parts quality fabricated by FFF. Mater. Manuf. Process. 2021, 37, 582–590. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Rismalia, M.; Hidajat, S.C.; Permana, I.G.R.; Hadisujoto, B.; Muslimin, M.; Triawan, F. Infill Pattern and Density Effects on the Tensile Properties of 3D Printed PLA Material. J. Phys. Conf. Ser. 2019, 1402, 044041. [Google Scholar] [CrossRef]

- Kovan, V.; Altan, G.; Topal, E.S. Effect of layer thickness and print orientation on strength of 3D printed and adhesively bonded single lap joints. J. Mech. Sci. Technol. 2017, 31, 2197–2201. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; Mclouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Spoerk, M. Optimisation of the Mechanical Properties and Processing of Polypropylene and Poly(Lactic Acid) Parts Produced by Extrusion-Based Additive Manufacturing. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Steiermark, Austria, 28 November 2018. [Google Scholar]

- Elhattab, K.; Bhaduri, S.B.; Sikder, P. Influence of Fused Deposition Modelling Nozzle Temperature on the Rheology and Mechanical Properties of 3D Printed β-Tricalcium Phosphate (TCP)/Polylactic Acid (PLA) Composite. Polymers 2022, 14, 1222. [Google Scholar] [CrossRef] [PubMed]

- Alsoufi, M.S.; Alhazmi, M.W.; Suker, D.K.; Alghamdi, T.A.; Sabbagh, R.A.; Felemban, M.A.; Bazuhair, F.K. Experimental Characterization of the Influence of Nozzle Temperature in FDM 3D Printed Pure PLA and Advanced PLA+. Am. J. Mech. Eng. 2019, 7, 45–60. [Google Scholar] [CrossRef]

- Schiavone, N.; Verney, V.; Askanian, H. Effect of 3D Printing Temperature Profile on Polymer Materials Behavior. 3D Print. Addit. Manuf. 2020, 7, 311–325. [Google Scholar] [CrossRef]

- Mishra, A.A.; Momin, A.; Strano, M.; Rane, K. Implementation of viscosity and density models for improved numerical analysis of melt flow dynamics in the nozzle during extrusion-based additive manufacturing. Prog. Addit. Manuf. 2021, 7, 41–54. [Google Scholar] [CrossRef]

- Altan, M.; Eryildiz, M.; Gumus, B.; Kahraman, Y. Effects of process parameters on the quality of PLA products fabricated by fused deposition modeling (FDM): Surface roughness and tensile strength. Mater. Test. 2018, 60, 471–477. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Ishigami, A.; Kurose, T.; Kobayashi, Y.; Ito, H. Influence of Ambient Temperature and Crystalline Structure on Fracture Toughness and Production of Thermoplastic by Enclosure FDM 3D Printer. J. Manuf. Mater. Process. 2023, 7, 44. [Google Scholar] [CrossRef]

- Bala, A.S.; bin Wahab, S.; Ahmad, M.B. Elements and Materials Improve the FDM Products: A Review. Adv. Eng. Forum 2016, 16, 33–51. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Li, Y.; Yang, M.; Yuan, Q. Experimental Investigations for Optimizing the Extrusion Parameters on FDM PLA Printed Parts. J. Mater. Eng. Perform. 2018, 28, 169–182. [Google Scholar] [CrossRef]

- Lendvai, L.; Fekete, I.; Rigotti, D.; Pegoretti, A. Experimental study on the effect of filament-extrusion rate on the structural, mechanical and thermal properties of material extrusion 3D-printed polylactic acid (PLA) products. Prog. Addit. Manuf. 2024, 1–11. [Google Scholar] [CrossRef]

- Ghorbani, J.; Koirala, P.; Shen, Y.-L.; Tehrani, M. Eliminating voids and reducing mechanical anisotropy in fused filament fabrication parts by adjusting the filament extrusion rate. J. Manuf. Process. 2022, 80, 651–658. [Google Scholar] [CrossRef]

- Bail, R. Extrusion Temperature and Flow Rate Effects on Tensile Properties of Additively Processed Poly(Ethylene-co-Trimethylene Terephthalate). Defect Diffus. Forum 2018, 382, 104–108. [Google Scholar] [CrossRef]

- Vidakis, N.; David, C.; Petousis, M.; Sagris, D.; Mountakis, N.; Moutsopoulou, A. The effect of six key process control parameters on the surface roughness, dimensional accuracy, and porosity in material extrusion 3D printing of polylactic acid: Prediction models and optimization supported by robust design analysis. Adv. Ind. Manuf. Eng. 2022, 5, 100104. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Lee, S.; Manaf, M.E.A.; Tsuji, M.; Yokohara, T. Modification of orientation birefringence of cellulose ester by addition of poly(lactic acid). Eur. Polym. J. 2010, 46, 2269–2274. [Google Scholar] [CrossRef]

- Buber, A. Science and values: Pythagorean Cup of Justice activity. Sci. Act. Classr. Proj. Curric. Ideas 2024, 61, 44–55. [Google Scholar] [CrossRef]

- Kasper, L.; Vogt, P. Magic Tricks and Wonders: Acrobatic Mechanics. In Uncorking the Physics of Wine; Springer: Berlin/Heidelberg, Germany, 2024; pp. 103–135. [Google Scholar] [CrossRef]

- Oettinger, N. Linguistic and Cultural Interactions between Greece and Anatolia; BRILL: Leiden, The Netherlands, 2021; pp. 116–130. ISBN 9789004461598. [Google Scholar]

- Vochozka, V. 3D Tisk Ve Výuce Fyziky; SPN: Praha, Czech Republic, 2022; pp. 181–198. ISBN 978-80-7235-665-2. [Google Scholar]

| Printing Parameter | Option 1 | Option 2 | Option 3 | Option 4 | Option 5 |

|---|---|---|---|---|---|

| Object orientation (OO) | portrait | landscape | flat | ||

| Layer height (LH) | 0.05 mm | 0.10 mm | 0.20 mm | 0.30 mm | |

| Nozzle temperature (NT) | 200 °C | 210 °C 1 | 220 °C | 230 °C | 240 °C |

| Fan speed (FS) | 0% | 50% | 100%1 | ||

| Extrusion multiplier (EM) | 0.75 | 1.00 1 | 1.25 | 1.50 | |

| Speed of print moves (SOPM) | 20 mm/s | 40 mm/s 1 | 80 mm/s | 100 mm/s |

| No. | OO (-) | LH (mm) | NT (°C) | FS (%) | EM (-) | SOPM (mm/s) | No. | OO (-) | LH (mm) | NT (°C) | FS (%) | EM (-) | SOPM (mm/s) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | flat | 0.30 | 210 | 100 | 1.00 | 40 | 17 | portrait | 0.30 | 220 | 0 | 1.00 | 40 |

| 2 | landscape | 0.30 | 210 | 100 | 1.00 | 40 | 18 | portrait | 0.30 | 220 | 50 | 1.00 | 40 |

| 3 | portrait | 0.30 | 210 | 100 | 1.00 | 40 | 19 | portrait | 0.30 | 220 | 100 | 0.75 | 40 |

| 4 | flat | 0.20 | 210 | 100 | 1.00 | 40 | 20 | portrait | 0.30 | 220 | 100 | 1.25 | 40 |

| 5 | landscape | 0.20 | 210 | 100 | 1.00 | 40 | 21 | portrait | 0.30 | 220 | 100 | 1.50 | 40 |

| 6 | portrait | 0.20 | 210 | 100 | 1.00 | 40 | 22 | portrait | 0.30 | 220 | 100 | 1.00 | 20 |

| 7 | flat | 0.10 | 210 | 100 | 1.00 | 40 | 23 | portrait | 0.30 | 220 | 100 | 1.00 | 80 |

| 8 | landscape | 0.10 | 210 | 100 | 1.00 | 40 | 24 | portrait | 0.30 | 220 | 100 | 1.00 | 100 |

| 9 | portrait | 0.10 | 210 | 100 | 1.00 | 40 | 25 | portrait | 0.30 | 240 | 100 | 0.75 | 20 |

| 10 | flat | 0.05 | 210 | 100 | 1.00 | 40 | 26 | portrait | 0.30 | 240 | 100 | 0.75 | 40 |

| 11 | landscape | 0.05 | 210 | 100 | 1.00 | 40 | 27 | portrait | 0.30 | 240 | 100 | 0.75 | 80 |

| 12 | portrait | 0.05 | 210 | 100 | 1.00 | 40 | 28 | portrait | 0.30 | 240 | 100 | 0.75 | 100 |

| 13 | portrait | 0.30 | 200 | 100 | 1.00 | 40 | 29 | portrait | 0.30 | 240 | 100 | 1.50 | 20 |

| 14 | portrait | 0.30 | 220 | 100 | 1.00 | 40 | 30 | portrait | 0.30 | 240 | 100 | 1.50 | 40 |

| 15 | portrait | 0.30 | 230 | 100 | 1.00 | 40 | 31 | portrait | 0.30 | 240 | 100 | 1.50 | 80 |

| 16 | portrait | 0.30 | 240 | 100 | 1.00 | 40 | 32 | portrait | 0.30 | 240 | 100 | 1.50 | 100 |

| Object Orientation | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| flat | 194.2 | 5.0 | 0.000 |

| landscape | 240.8 | 3.2 | |

| portrait | 246.0 | 0.3 |

| Layer Height (mm) | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| 0.05 | 245.4A | 1.3 | 0.000 |

| 0.10 | 229.4B | 0.4 | |

| 0.20 | 232.4B | 0.7 | |

| 0.30 | 246.0A | 0.3 |

| Nozzle Temperature (°C) | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| 200 | 242.1 | 0.5 | 0.000 |

| 210 | 246.0 | 0.3 | |

| 220 | 248.7 | 0.2 | |

| 230 | 247.8 | 0.2 | |

| 240 | 263.5 | 0.2 |

| Fan Speed (%) | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| 0 | 243.9 | 2.0 | 0.000 |

| 50 | 246.9A | 1.8 | |

| 100 | 248.7A | 0.2 |

| Extrusion Multiplier (-) | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| 0.75 | 255.6 | 0.5 | 0.000 |

| 1.00 | 248.7 | 0.2 | |

| 1.25 | 228.4 | 3.8 | |

| 1.50 | 222.6 | 2.5 |

| Speed of Print Moves (mm/s) | Average (lx) | Standard Deviation | p-Value |

|---|---|---|---|

| 20 | 251.8 | 0.5 | 0.000 |

| 40 | 255.6 | 0.5 | |

| 80 | 231.9 | 2.3 | |

| 100 | 223.9 | 5.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vochozka, V.; Černý, P.; Šramhauser, K.; Špalek, F.; Kříž, P.; Čech, J.; Zoubek, T.; Bartoš, P.; Kresan, J.; Stehlík, R. Fused Filament Fabrication 3D Printing Parameters Affecting the Translucency of Polylactic Acid Parts. Polymers 2024, 16, 2862. https://doi.org/10.3390/polym16202862

Vochozka V, Černý P, Šramhauser K, Špalek F, Kříž P, Čech J, Zoubek T, Bartoš P, Kresan J, Stehlík R. Fused Filament Fabrication 3D Printing Parameters Affecting the Translucency of Polylactic Acid Parts. Polymers. 2024; 16(20):2862. https://doi.org/10.3390/polym16202862

Chicago/Turabian StyleVochozka, Vladimír, Pavel Černý, Karel Šramhauser, František Špalek, Pavel Kříž, Jiří Čech, Tomáš Zoubek, Petr Bartoš, Jan Kresan, and Radim Stehlík. 2024. "Fused Filament Fabrication 3D Printing Parameters Affecting the Translucency of Polylactic Acid Parts" Polymers 16, no. 20: 2862. https://doi.org/10.3390/polym16202862

APA StyleVochozka, V., Černý, P., Šramhauser, K., Špalek, F., Kříž, P., Čech, J., Zoubek, T., Bartoš, P., Kresan, J., & Stehlík, R. (2024). Fused Filament Fabrication 3D Printing Parameters Affecting the Translucency of Polylactic Acid Parts. Polymers, 16(20), 2862. https://doi.org/10.3390/polym16202862