Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers

Abstract

1. Introduction

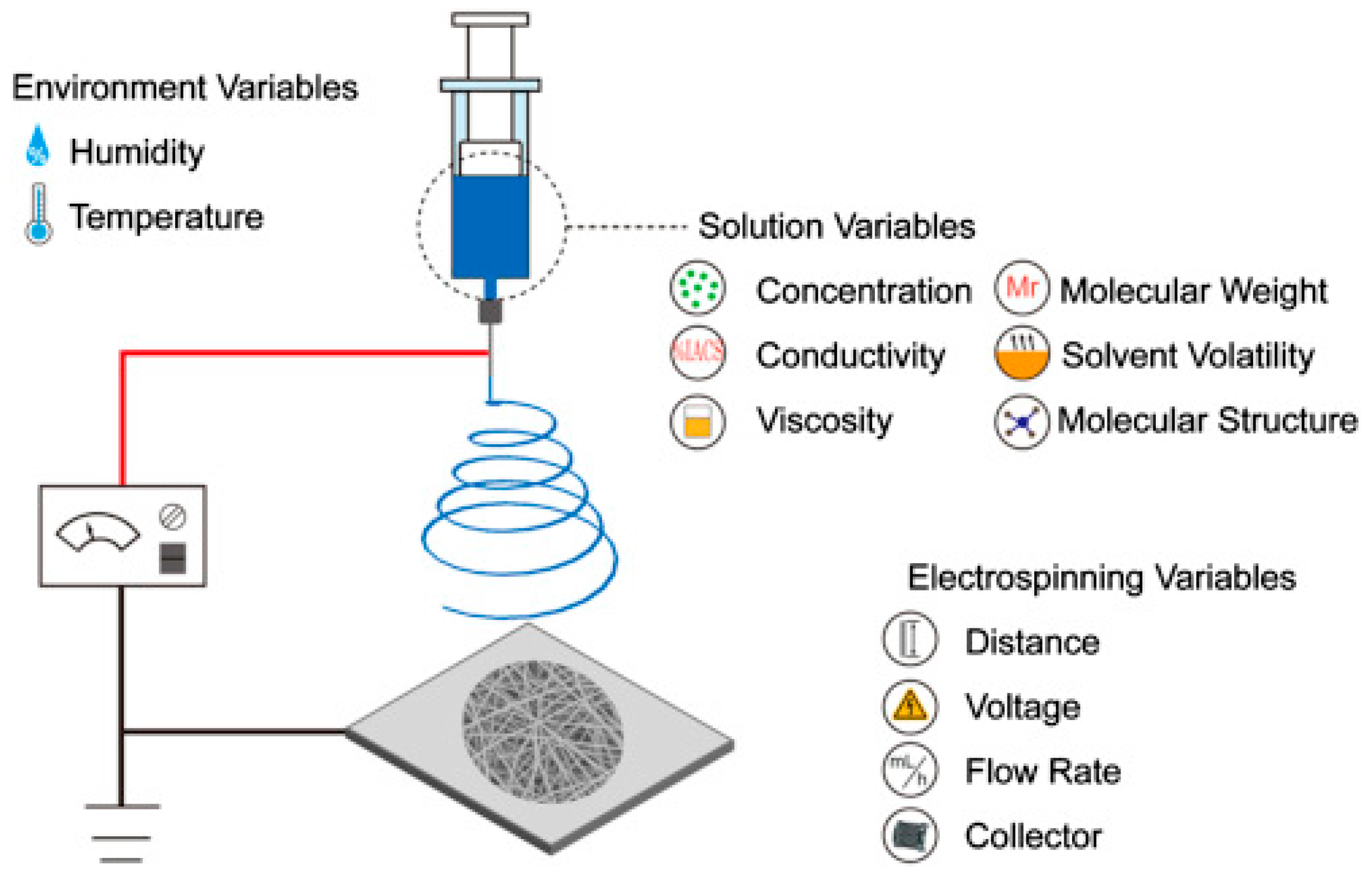

2. Fundamentals of Electrospinning

- High-Voltage Power Supply: The high-voltage power supply is a critical component of the electrospinning setup, providing the electric field necessary to generate the electrospun jet. Voltages typically range from a few kilovolts to tens of kilovolts, depending on the specific polymer solution and desired fiber properties. The power supply must deliver a stable and controllable voltage to ensure consistent electrospinning performance.

- Syringe Pump or Spinneret: The polymer solution or molten polymer is commonly inserted into a syringe attached to either a syringe pump or spinneret. The syringe pump regulates the polymer solution flow, enabling accurate management of the deposition rate and fiber diameter. In contrast, a spinneret can extrude the polymer solution or molten polymer at a controlled rate.

- Collector: The collector is a conductive substrate placed at a fixed distance from the spinneret to collect the electrospun fibers. Depending on the desired fiber alignment and morphology, the collector can take various forms, including flat plates, rotating drums, or mandrels. The collector can also be grounded to provide an electrical path for the charged fibers, preventing charge accumulation and promoting uniform deposition.

- Grounded Electrode: A grounded electrode is typically placed close to the collector to provide an electrical path for the charged polymer solution or melt. The grounded electrode helps to neutralize the charges on the collected fibers, preventing them from repelling each other and forming aggregates. The grounded electrode can be positioned below or surrounding the collector, depending on the specific electrospinning setup.

- Flow Rate: The flow rate of the polymer solution or melt is a critical parameter that determines the deposition rate and fiber diameter during electrospinning. Higher flow rates generally result in thicker fibers due to increased polymer deposition, while lower flow rates produce finer fibers. The flow rate can be adjusted using the syringe pump or spinneret to optimize the electrospinning process for a given polymer system.

- Voltage: The applied voltage plays a crucial role in controlling the electrospinning process by governing the formation and behavior of the electrified jet. Higher voltages increase electrostatic repulsion between the charged polymer chains, promoting jet elongation and thinning. However, excessively high voltages can cause jet instability and lead to beads or non-uniform fibers forming. The voltage should be optimized based on the polymer solution properties and desired fiber morphology.

- Distance: The distance between the spinneret and the collector is another important parameter influencing the electrospinning process. The distance affects the trajectory and stretching of the ejected jet and the deposition pattern and fiber alignment on the collector. Closer distances generally result in finer fibers due to increased stretching, while larger distances produce thicker fibers. The distance should be carefully adjusted to achieve the desired fiber morphology and alignment.

- Solution Properties: The properties of the polymer solution or melt, including viscosity, conductivity, surface tension, and concentration, influence the electrospinning process and fiber morphology. Higher-viscosity solutions tend to produce thicker fibers due to increased resistance to jet elongation, while lower-viscosity solutions produce finer fibers. Similarly, higher-conductivity solutions promote more efficient charge dissipation and jet stabilization, leading to finer and more uniform fibers. The concentration of the polymer solution also affects the fiber morphology, with higher concentrations generally resulting in thicker fibers.

3. Synthesis of PEDOT-Based Nanofibers via Electrospinning

- High surface area and porosity: Electrospinning produces nanofibers with a high surface area-to-volume ratio, which is valuable for applications requiring high reactivity and interaction with the environment, such as sensors and catalysts [25].

- Flexibility and comfort: The nanofibers mats produced are highly flexible, making them suitable for wearable electronics where comfort and adaptability to body movements are essential [26].

- Enhanced conductivity: By incorporating materials like reduced graphene oxide (rGO), the conductivity of PEDOT-based nanofibers can be significantly enhanced, which is crucial for electronic applications [27].

- Versatility in material composition: Electrospinning allows for the incorporation of various materials, such as nanocarbons, to enhance the mechanical and electrical properties of the fibers, making them suitable for a wide range of applications from photovoltaics to biomedical devices [28].

- Improved mechanical properties: The process can improve the mechanical properties of the fibers, such as tensile strength, which is important for structural applications [27].

3.1. Solution-Based Electrospinning

3.2. Melt-Electrospinning

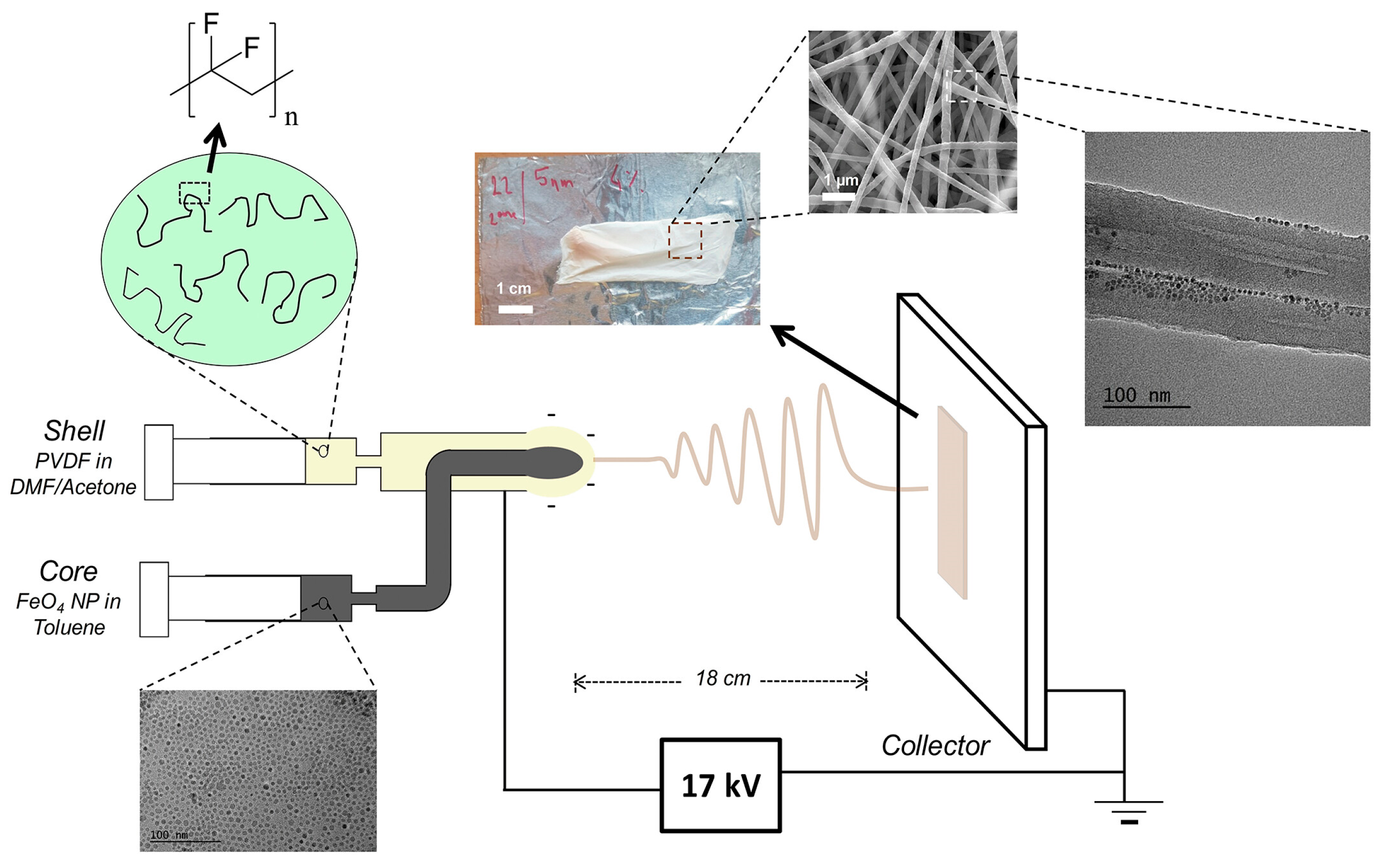

3.3. Coaxial Electrospinning

4. Main Characterization Techniques for PEDOT Nanofibers

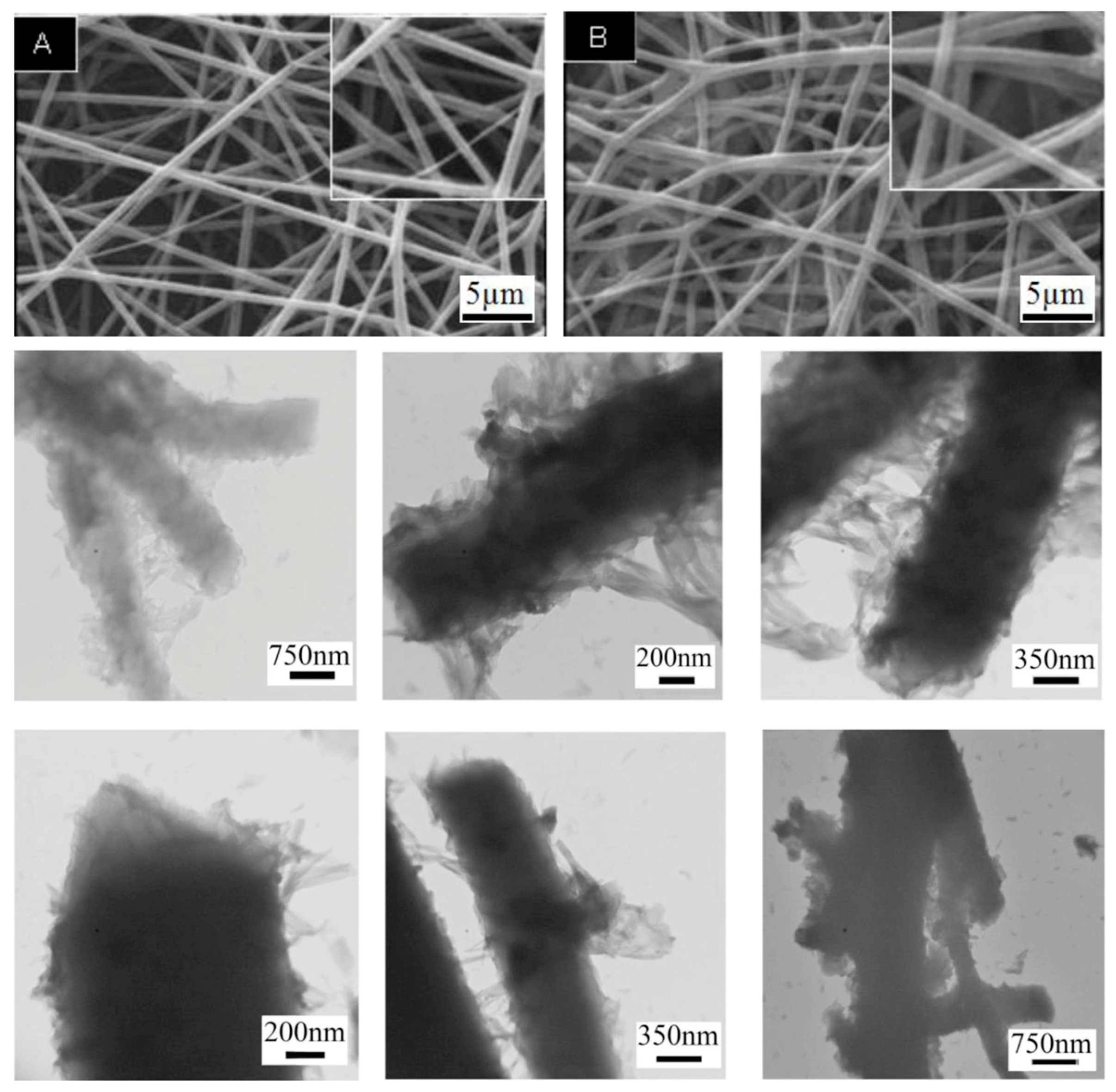

4.1. Scanning Electron Microscopy (SEM)

4.2. Transmission Electron Microscopy (TEM)

4.3. X-ray Diffraction (XRD)

4.4. Fourier Transform Infrared Spectroscopy (FTIR)

4.5. Conductivity Measurements

5. Properties of PEDOT Nanofibers

5.1. Electrical Properties

5.2. Mechanical Properties

5.3. Thermal Properties

6. Applications of PEDOT Nanofibers

6.1. Sensors

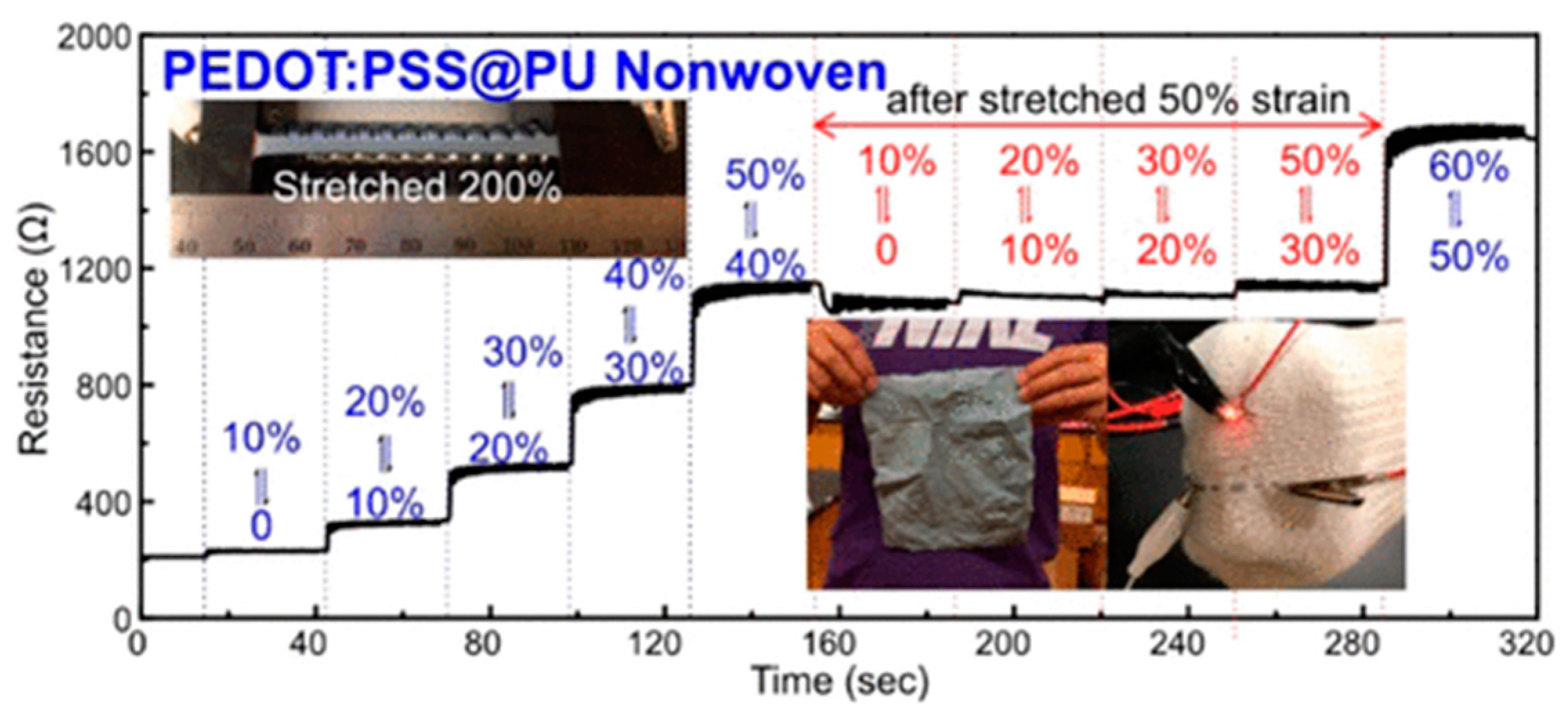

6.1.1. Strain and Pressure Sensors

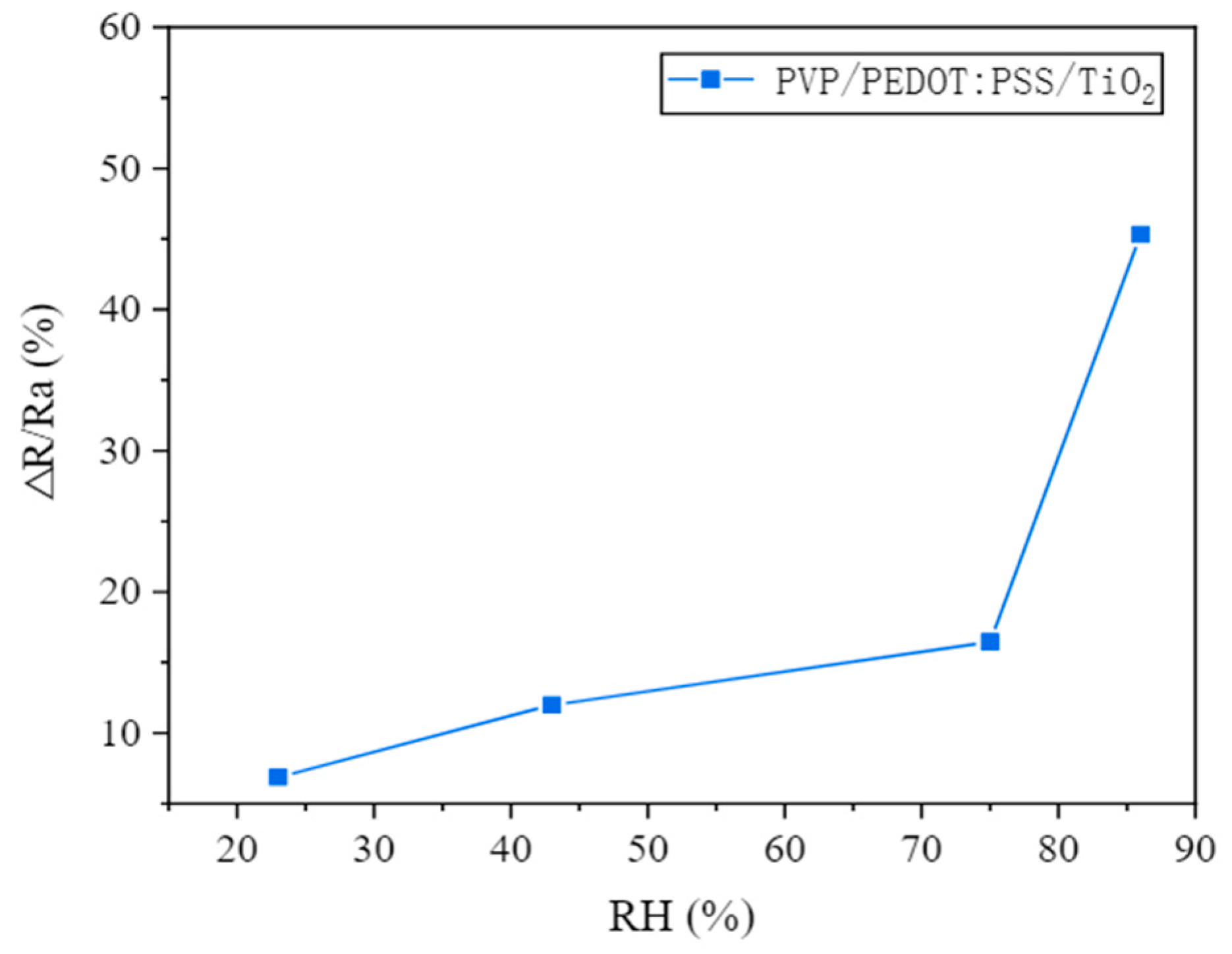

6.1.2. Chemical Sensors

6.1.3. Biosensors

6.2. Biomedical

6.2.1. Tissue Engineering

6.2.2. Drug Delivery Systems

6.3. Wearable Electronics

Flexible Soft Electronics

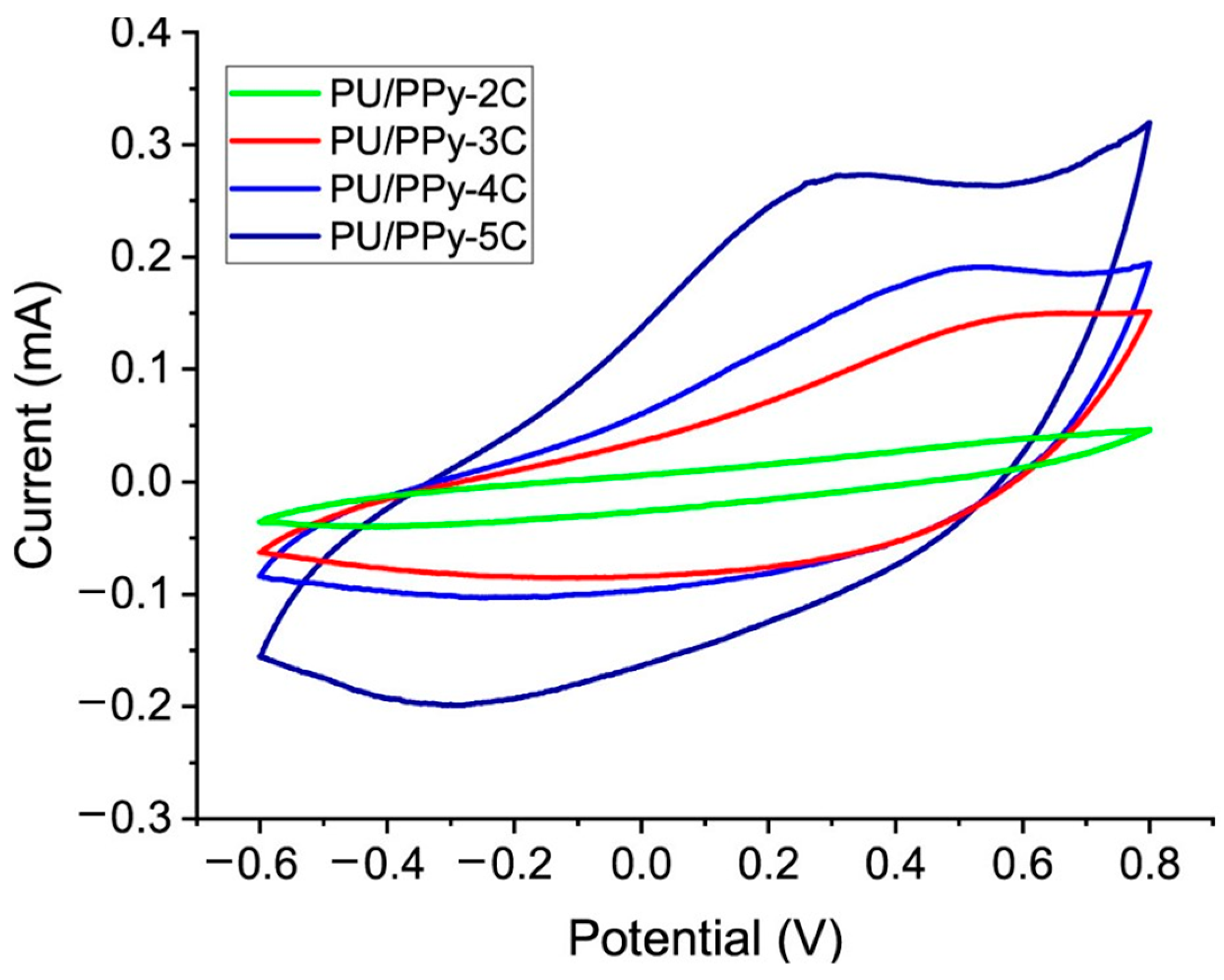

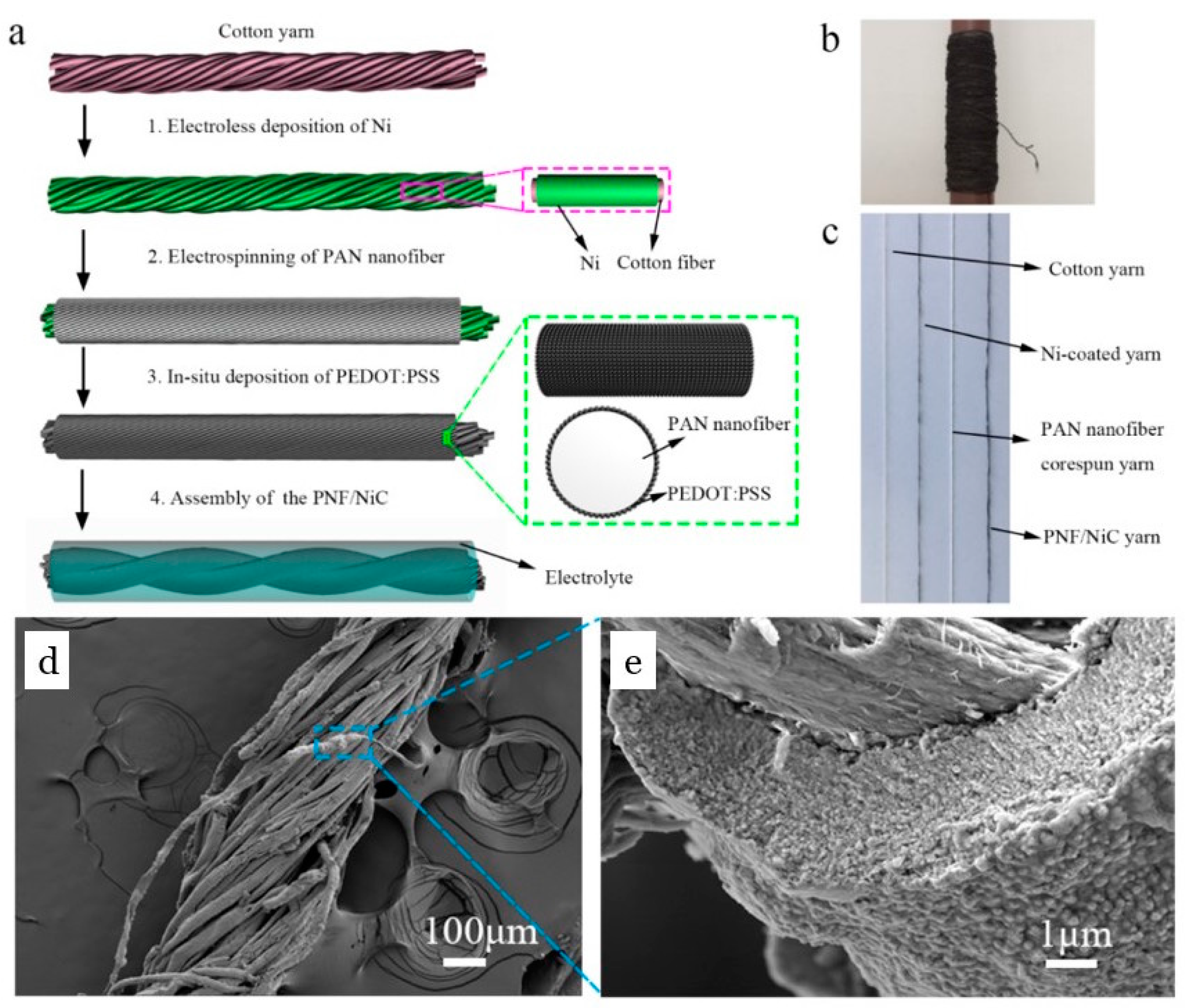

6.4. Energy Storage

7. Challenges and Future Perspectives

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yi, H.; Patel, R.; Patel, K.D.; Bouchard, L.-S.; Jha, A.; Perriman, A.W.; Patel, M. Conducting Polymer-Based Scaffolds for Neuronal Tissue Engineering. J. Mater. Chem. B 2023, 11, 11006–11023. [Google Scholar] [CrossRef]

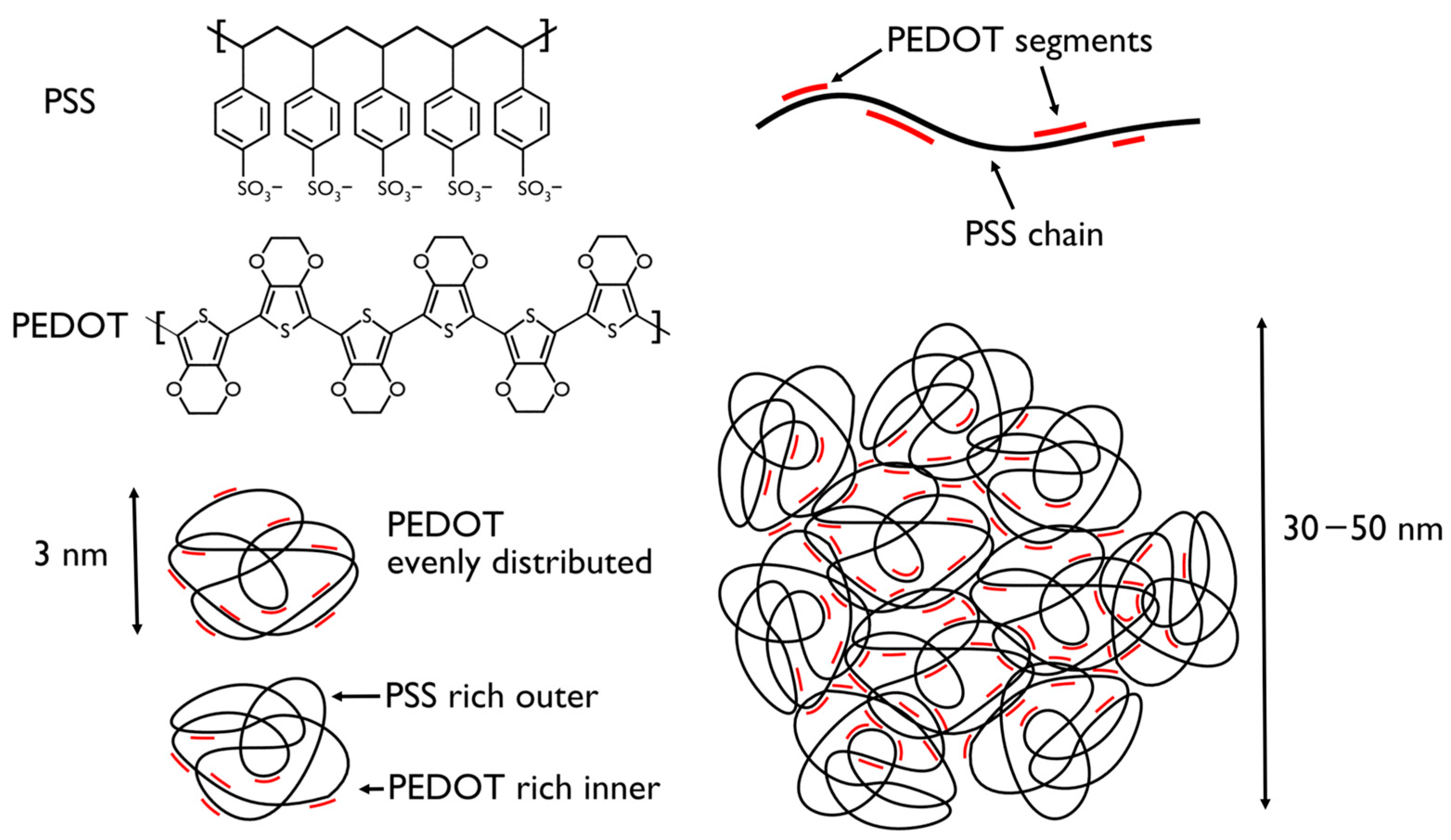

- Seiti, M.; Giuri, A.; Corcione, C.E.; Ferraris, E. Advancements in Tailoring PEDOT: PSS Properties for Bioelectronic Applications: A Comprehensive Review. Biomater. Adv. 2023, 154, 213655. [Google Scholar] [CrossRef] [PubMed]

- Keirouz, A.; Wang, Z.; Reddy, V.S.; Nagy, Z.K.; Vass, P.; Buzgo, M.; Ramakrishna, S.; Radacsi, N. The History of Electrospinning: Past, Present, and Future Developments. Adv. Mater. Technol. 2023, 8, 2201723. [Google Scholar] [CrossRef]

- Asai, H. Actuators with Nanofiber Mat Electrodes: Effect of Electrode Preparation Method on Actuator Performance. Polym. J. 2021, 53, 1083–1091. [Google Scholar] [CrossRef]

- Long, Y.-Z.; Li, M.-M.; Gu, C.; Wan, M.; Duvail, J.-L.; Liu, Z.; Fan, Z. Recent Advances in Synthesis, Physical Properties and Applications of Conducting Polymer Nanotubes and Nanofibers. Prog. Polym. Sci. 2011, 36, 1415–1442. [Google Scholar] [CrossRef]

- Verpoorten, E.; Massaglia, G.; Ciardelli, G.; Pirri, C.F.; Quaglio, M. Design and Optimization of Piezoresistive PEO/PEDOT:PSS Electrospun Nanofibers for Wearable Flex Sensors. Nanomaterials 2020, 10, 2166. [Google Scholar] [CrossRef] [PubMed]

- Gawali, C.R.; Daweshar, E.; Kolhe, A.; Kumar, S. Recent Advances in Nanostructured Conducting Polymer Electrospun for Application in Electrochemical Biosensors. Microchem. J. 2024, 200, 110326. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Ko, J.M.; Kim, H.J.; Kim, S.K.; Cho, S.H.; Nam, J.D.; Lee, J.Y. Electrochemical Properties of Poly(3,4-Ethylenedioxythiophene) Nanofiber Non-Woven Web Formed by Electrospinning. J. Nanosci. Nanotechnol. 2008, 8, 4718–4721. [Google Scholar] [CrossRef]

- Kim, N.; Kee, S.; Lee, S.H.; Lee, B.H.; Kahng, Y.H.; Jo, Y.; Kim, B.; Lee, K. Transparent Electrodes: Highly Conductive PEDOT:PSS Nanofibrils Induced by Solution-Processed Crystallization (Adv. Mater. 14/2014). Adv. Mater. 2014, 26, 2109. [Google Scholar] [CrossRef]

- Babaie, A.; Bakhshandeh, B.; Abedi, A.; Mohammadnejad, J.; Shabani, I.; Ardeshirylajimi, A.; Moosavi, S.R.; Amini, J.; Tayebi, L. Synergistic Effects of Conductive PVA/PEDOT Electrospun Scaffolds and Electrical Stimulation for More Effective Neural Tissue Engineering. Eur. Polym. J. 2020, 140, 110051. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, L.; Luo, G.; Dong, L.; Xia, Y.; Li, M.; Li, Z.; Wang, K.; Maeda, R.; Jiang, Z. Highly Sensitive Piezoresistive and Thermally Responsive Fibrous Networks from the In Situ Growth of PEDOT on MWCNT-Decorated Electrospun PU Fibers for Pressure and Temperature Sensing. Microsyst. Nanoeng. 2023, 9, 113. [Google Scholar] [CrossRef]

- Lang, U.; Müller, E.; Naujoks, N.; Dual, J. Microscopical Investigations of PEDOT:PSS Thin Films. Adv. Funct. Mater. 2009, 19, 1215–1220. [Google Scholar] [CrossRef]

- Barroso-Solares, S.; Pinto, J.; Salvo-Comino, C.; Cuadra-Rodríguez, D.; García-Cabezón, C.; Rodríguez-Pérez, M.A.; Rodríguez-Méndez, M.L. Tuning the Electrochemical Response of PCL-PEDOT:PSS Fibers-Based Sensors by Gas Dissolution Foaming. Appl. Surf. Sci. 2023, 638, 158062. [Google Scholar] [CrossRef]

- Laforgue, A. Electrically Controlled Colour-Changing Textiles Using the Resistive Heating Properties of PEDOT Nanofibers. J. Mater. Chem. 2010, 20, 8233–8235. [Google Scholar] [CrossRef]

- Laforgue, A.; Robitaille, L. Production of Conductive PEDOT Nanofibers by the Combination of Electrospinning and Vapor-Phase Polymerization. Macromolecules 2010, 43, 4194–4200. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.J.; Kim, S.; Ryu, H.W.; Lee, S.H.; Choi, H.H.; Cheong, I.W.; Kim, J.-H. Conducting Polymer Nanofiber Mats via Combination of Electrospinning and Oxidative Polymerization. Polymer 2013, 54, 4155–4160. [Google Scholar] [CrossRef]

- Jin, L.; Wang, T.; Feng, Z.-Q.; Leach, M.K.; Wu, J.; Mo, S.; Jiang, Q. A Facile Approach for the Fabrication of Core–Shell PEDOT Nanofiber Mats with Superior Mechanical Properties and Biocompatibility. J. Mater. Chem. B 2013, 1, 1818–1825. [Google Scholar] [CrossRef]

- Park, S.W.; Oh, T.H.; Hwang, J.S.; Lee, Y.J. Effect of Solvent and Blended Polymer on Electrical Conductivity of PEDOT:PSS/Polymer Blended Nanofibers. Fibers Polym. 2016, 17, 1171–1174. [Google Scholar] [CrossRef]

- Du, L.; Li, T.; Jin, F.; Wang, Y.; Li, R.; Zheng, J.; Wang, T.; Feng, Z.-Q. Design of High Conductive and Piezoelectric Poly (3,4-Ethylenedioxythiophene)/Chitosan Nanofibers for Enhancing Cellular Electrical Stimulation. J. Colloid Interface Sci. 2020, 559, 65–75. [Google Scholar] [CrossRef]

- Yu, C.-C.; Ho, B.-C.; Juang, R.-S.; Hsiao, Y.-S.; Naidu, R.V.R.; Kuo, C.-W.; You, Y.-W.; Shyue, J.-J.; Fang, J.-T.; Chen, P. Poly(3,4-Ethylenedioxythiophene)-Based Nanofiber Mats as an Organic Bioelectronic Platform for Programming Multiple Capture/Release Cycles of Circulating Tumor Cells. ACS Appl. Mater. Interfaces 2017, 9, 30329–30342. [Google Scholar] [CrossRef]

- Angkawinitwong, U.; Williams, G.R. Electrospun Polymers and Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 405–432. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, A. Conductive Electrospun Nanofiber Mats. Materials 2019, 13, 152. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.-Z.; Yan, X.; Wang, X.-X.; Zhang, J.; Yu, M. Electrospinning: Nanofabrication and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 21–52. [Google Scholar] [CrossRef]

- Cárdenas-Martínez, J.; España-Sánchez, B.L.; Esparza, R.; Ávila-Niño, J.A. Flexibleand Transparent Supercapacitors Using Electrospun PEDOT:PSS Electrodes. Synth. Met. 2020, 267, 116436. [Google Scholar] [CrossRef]

- Sahar, H.; Naseer, S.; Gilani, M.R.H.S.; Naqvi, S.A.R.; Aamir, M.; Akhtar, J. Sustainable Materials for Electrochemical Capacitors; John Wiley & Sons: Hoboken, NJ, USA, 2023; pp. 361–390. [Google Scholar] [CrossRef]

- Ewaldz, E.; Rinehart, J.M.; Miller, M.; Brettmann, B. Processability of Thermoelectric Ultrafine Fibers via Electrospinning for Wearable Electronics. ACS Omega 2023, 8, 30239–30246. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhuo, Y.; Lu, J.; Wang, L.; Ren, X. Novel Conductive RGO/PEDOT:PSS/PVA Nanofibers by Electrospinning. Integr. Ferroelectr. 2022, 229, 305–312. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I. Electrospinning Processing of Polymer/Nanocarbon Nanocomposite Nanofibers—Design, Features, and Technical Compliances. J. Compos. Sci. 2023, 7, 290. [Google Scholar] [CrossRef]

- Serrano-Garcia, W.; Ramakrishna, S.; Thomas, S.W. Electrospinning Technique for Fabrication of Coaxial Nanofibers of Semiconductive Polymers. Polymers 2022, 14, 5073. [Google Scholar] [CrossRef]

- Acosta, M.; Santiago, M.D.; Irvin, J.A. Electrospun Conducting Polymers: Approaches and Applications. Materials 2022, 15, 8820. [Google Scholar] [CrossRef]

- Zarrin, N.; Tavanai, H.; Abdolmaleki, A.; Bazarganipour, M.; Alihosseini, F. An Investigation on the Fabrication of Conductive Polyethylene Dioxythiophene (PEDOT) Nanofibers through Electrospinning. Synth. Met. 2018, 244, 143–149. [Google Scholar] [CrossRef]

- Pinto, N.J.; Rivera, D.; Melendez, A.; Ramos, I.; Lim, J.H.; Johnson, A.T.C. Electrical Response of Electrospun PEDOT-PSSA Nanofibers to Organic and Inorganic Gases. Sens. Actuators B Chem. 2011, 156, 849–853. [Google Scholar] [CrossRef]

- Oliva, F.S.N.; Picart, L.; Leon-Valdivieso, C.Y.; Benalla, A.; Lenglet, L.; Ospina, A.; Jestin, J.; Bedoui, F. Coaxial Electrospinning Process toward Optimal Nanoparticle Dispersion in Polymeric Matrix. Polym. Compos. 2021, 42, 1565–1573. [Google Scholar] [CrossRef]

- Han, D.; Steckl, A.J. Coaxial Electrospinning Formation of Complex Polymer Fibers and Their Applications. ChemPlusChem 2019, 84, 1453–1497. [Google Scholar] [CrossRef] [PubMed]

- Costa, E.L.; Muniz, E.C.; Cava, C.E. PEDOT:PSS/AgNWs Nanofibers Obtained by Electrospun and the Post-Treatment via DMSO Vapor Exposure. Synth. Met. 2023, 298, 117442. [Google Scholar] [CrossRef]

- Lim, J.; Choi, S.; Kim, H.S. Electrospinning Behavior and Piezoelectric Property of PVDF/PEDOT:PSS Composite Web by PEDOT:PSS Addition. Polym. Adv. Technol. 2023, 34, 1959–1966. [Google Scholar] [CrossRef]

- Huang, T.-M.; Batra, S.; Hu, J.; Miyoshi, T.; Cakmak, M. Chemical Cross-Linking of Conducting Poly(3,4-Ethylenedioxythiophene):Poly(Styrenesulfonate) (PEDOT:PSS) Using Poly(Ethylene Oxide) (PEO). Polymer 2013, 54, 6455–6462. [Google Scholar] [CrossRef]

- Chotimah; Winandianto, B.; Munir, M.; Kartini, I.; Kusumaatmaja, A.; Triyana, K. The Electrical Properties of PEDOT:PSS Nanofibers. AIP Conf. Proc. 2016, 1755, 150013. [CrossRef]

- Basri, N.A.F.; Mustafa, M.N.; Sulaiman, Y. Facile Fabrication of PVA Nanofiber Coated with PEDOT as a Counter Electrode for Dye-Sensitized Solar Cell. J. Mater. Sci. Mater. Electron. 2019, 30, 8705–8711. [Google Scholar] [CrossRef]

- Ebadi, S.V.; Fashandi, H.; Semnani, D.; Rezaei, B.; Fakhrali, A. Electroactive Actuator Based on Polyurethane Nanofibers Coated with Polypyrrole through Electrochemical Polymerization: A Competent Method for Developing Artificial Muscles. Smart Mater. Struct. 2020, 29, 045008. [Google Scholar] [CrossRef]

- Shaker, A.; Hassanin, A.H.; Shaalan, N.M.; Hassan, M.A.; El-Moneim, A.A. Micropatterned Flexible Strain Gauge Sensor Based on Wet Electrospun Polyurethane/PEDOT: PSS Nanofibers. Smart Mater. Struct. 2019, 28, 075029. [Google Scholar] [CrossRef]

- Zhu, C.; Zheng, J.; Fu, J. Electrospinning Nanofibers as Stretchable Sensors for Wearable Devices. Macromol. Biosci. 2024, 24, e2300274. [Google Scholar] [CrossRef]

- Chen, G.; Chen, G.; Pan, L.; Chen, D. Electrospun Flexible PVDF/GO Piezoelectric Pressure Sensor for Human Joint Monitoring. Diam. Relat. Mater. 2022, 129, 109358. [Google Scholar] [CrossRef]

- Ding, Y.; Xu, W.; Wang, W.; Fong, H.; Zhu, Z. Scalable and Facile Preparation of Highly Stretchable Electrospun PEDOT:PSS@PU Fibrous Nonwovens toward Wearable Conductive Textile Applications. ACS Appl. Mater. Interfaces 2017, 9, 30014–30023. [Google Scholar] [CrossRef] [PubMed]

- Verpoorten, E.; Massaglia, G.; Pirri, C.F.; Quaglio, M. Electrospun PEO/PEDOT:PSS Nanofibers for Wearable Physiological Flex Sensors. Sensors 2021, 21, 4110. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Sensing Mechanism of a Flexible Strain Sensor Developed Directly Using Electrospun Composite Nanofiber Yarn with Ternary Carbon Nanomaterials. iScience 2022, 25, 105162. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, W.; Xu, T.; Zhao, W.; Zhang, J.; Bai, C. Flexible Strain Sensors Based on Thermoplastic Polyurethane Fabricated by Electrospinning: A Review. Sensors 2024, 24, 4793. [Google Scholar] [CrossRef] [PubMed]

- Seyedin, M.Z.; Razal, J.M.; Innis, P.C.; Wallace, G.G. Strain-Responsive Polyurethane/PEDOT:PSS Elastomeric Composite Fibers with High Electrical Conductivity. Adv. Funct. Mater. 2014, 24, 2957–2966. [Google Scholar] [CrossRef]

- Huang, Y.-C.; Lo, T.-Y.; Chen, C.-H.; Wu, K.-H.; Lin, C.-M.; Whang, W.-T. Electrospinning of Magnesium-Ion Linked Binder-Less PEDOT:PSS Nanofibers for Sensing Organic Gases. Sens. Actuators B Chem. 2015, 216, 603–607. [Google Scholar] [CrossRef]

- Shiu, B.-C.; Liu, Y.-L.; Yuan, Q.-Y.; Lou, C.-W.; Lin, J.-H. Preparation and Characterization of PEDOT:PSS/TiO2 Micro/Nanofiber-Based Gas Sensors. Polymers 2022, 14, 1780. [Google Scholar] [CrossRef]

- Regmi, A.; Shin, D.; Na, N.; Chang, J. Suspended Graphene/PEDOT: PSS-PEO Channel for H2 Gas Sensing Fabricated Using Direct-Write Functional Fibers. Adv. Mater. Technol. 2023, 8, 2201505. [Google Scholar] [CrossRef]

- Zhang, H.-D.; Yan, X.; Zhang, Z.-H.; Yu, G.-F.; Han, W.-P.; Zhang, J.-C.; Long, Y.-Z. Electrospun PEDOT:PSS/PVP Nanofibers for CO Gas Sensing with Quartz Crystal Microbalance Technique. Int. J. Polym. Sci. 2016, 2016, 3021353. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, X.; Fu, J.; Liu, R.; He, H.; Ma, J.; Yu, M.; Ramakrishna, S.; Long, Y. Electrospinning of Ultrafine Conducting Polymer Composite Nanofibers with Diameter Less than 70 Nm as High Sensitive Gas Sensor. Materials 2018, 11, 1744. [Google Scholar] [CrossRef]

- Choi, J.; Lee, J.; Choi, J.; Jung, D.; Shim, S.E. Electrospun PEDOT:PSS/PVP Nanofibers as the Chemiresistor in Chemical Vapour Sensing. Synth. Met. 2010, 160, 1415–1421. [Google Scholar] [CrossRef]

- Saunier, V.; Flahaut, E.; Blatché, M.-C.; Bergaud, C.; Maziz, A. Carbon Nanofiber-PEDOT Composite Films as Novel Microelectrode for Neural Interfaces and Biosensing. Biosens. Bioelectron. 2020, 165, 112413. [Google Scholar] [CrossRef]

- Meng, L.; Turner, A.P.F.; Mak, W.C. Tunable 3D Nanofibrous and Bio-Functionalised PEDOT Network Explored as a Conducting Polymer-Based Biosensor. Biosens. Bioelectron. 2020, 159, 112181. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wang, J.; Zhao, Z.; Dong, F. Fabrication of Reduced Graphene Oxide Doped Poly(3,4-Ethylenedioxythiophene): Polystyrene (Sulfonate-Co-Acrylic Acid) Conductive Films with High Conductivity and Stability. Thin Solid Films 2022, 762, 139525. [Google Scholar] [CrossRef]

- Hu, Z.; Niu, Q.; Hsiao, B.S.; Yao, X.; Zhang, Y. Bioactive Polymer-Enabled Conformal Neural Interface and Its Application Strategies. Mater. Horiz. 2022, 10, 808–828. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chakraborty, G.; Narendren, S.; Katiyar, V. Fabrication and Characterization of Conductive Electrospun Nanofiber Mats of Carbon Nanofiber/Poly(Vinyl Alcohol)/Poly(Lactic Acid) Ternary Nanocomposites for Flexible Electronics Applications. Mater. Adv. 2023, 4, 6294–6303. [Google Scholar] [CrossRef]

- An, J.E.; Kim, K.H.; Park, S.J.; Seo, S.E.; Kim, J.; Ha, S.; Bae, J.; Kwon, O.S. Wearable Cortisol Aptasensor for Simple and Rapid Real-Time Monitoring. ACS Sens. 2022, 7, 99–108. [Google Scholar] [CrossRef]

- Ferraris, S.; Spriano, S.; Scalia, A.C.; Cochis, A.; Rimondini, L.; Cruz-Maya, I.; Guarino, V.; Varesano, A.; Vineis, C. Topographical and Biomechanical Guidance of Electrospun Fibers for Biomedical Applications. Polymers 2020, 12, 2896. [Google Scholar] [CrossRef]

- Latonen, R.-M.; Cabrera, J.A.W.; Lund, S.; Kosourov, S.; Vajravel, S.; Boeva, Z.; Wang, X.; Xu, C.; Allahverdiyeva, Y. Electrospinning of Electroconductive Water-Resistant Nanofibers of PEDOT–PSS, Cellulose Nanofibrils and PEO: Fabrication, Characterization, and Cytocompatibility. ACS Appl. Bio Mater. 2021, 4, 483–493. [Google Scholar] [CrossRef]

- Sordini, L.; Silva, J.C.; Garrudo, F.F.F.; Rodrigues, C.A.V.; Marques, A.C.; Linhardt, R.J.; Cabral, J.M.S.; Morgado, J.; Ferreira, F.C. PEDOT:PSS-Coated Polybenzimidazole Electroconductive Nanofibers for Biomedical Applications. Polymers 2021, 13, 2786. [Google Scholar] [CrossRef]

- Abedi, A.; Hasanzadeh, M.; Tayebi, L. Conductive Nanofibrous Chitosan/PEDOT:PSS Tissue Engineering Scaffolds. Mater. Chem. Phys. 2019, 237, 121882. [Google Scholar] [CrossRef]

- Furlani, F.; Campodoni, E.; Sangiorgi, N.; Montesi, M.; Sanson, A.; Sandri, M.; Panseri, S. Electroconductive Scaffolds Based on Gelatin and PEDOT:PSS for Cardiac Regeneration. Int. J. Biol. Macromol. 2023, 224, 266–280. [Google Scholar] [CrossRef]

- Chen, C.; Chen, X.; Zhang, H.; Zhang, Q.; Wang, L.; Li, C.; Dai, B.; Yang, J.; Liu, J.; Sun, D. Electrically-Responsive Core-Shell Hybrid Microfibers for Controlled Drug Release and Cell Culture. Acta Biomater. 2017, 55, 434–442. [Google Scholar] [CrossRef]

- Sarabia-Riquelme, R.; Andrews, R.; Anthony, J.E.; Weisenberger, M.C. Highly Conductive Wet-Spun PEDOT:PSS Fibers for Applications in Electronic Textiles. J. Mater. Chem. C 2020, 8, 11618–11630. [Google Scholar] [CrossRef]

- Yan, K.; Xu, L. Electrospun Composite Nanofiber Membranes for Electromagnetic Protection. ACS Appl. Nano Mater. 2024, 7, 4615–4629. [Google Scholar] [CrossRef]

- Lerond, M.; Subramanian, A.; Skene, W.G.; Cicoira, F. Combining Electrospinning and Electrode Printing for the Fabrication of Stretchable Organic Electrochemical Transistors. Front. Phys. 2021, 9, 708914. [Google Scholar] [CrossRef]

- Mendoza-Diaz, M.I.; Garcia-Gutierrez, D.F.; Sepulveda-Guzman, S.; Moreno-Cortez, I.E.; Garcia-Gutierrez, D.I. Tuning the Optoelectronic Properties of PEDOT:PSS-PVP Core–Shell Electrospun Nanofibers by Solvent-Quantum Dot Doping and Phase Inversion. Nanotechnology 2019, 30, 395601. [Google Scholar] [CrossRef] [PubMed]

- Bagherzadeh, R.; Gorji, M.; Bafgi, M.S.S.; Saveh-Shemshaki, N. Section Three: Electrospinning for Particular Fiber Types and Applications. In Electrospun Nanofibers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 467–519. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, X.; Tai, Y.; Zhou, J.; Li, H.; Li, Z.; Wang, R.; Zhang, J.; Zhang, Y.; Ge, W.; et al. Recent Advances in Nanofiber-Based Flexible Transparent Electrodes. Int. J. Extreme Manuf. 2023, 5, 032005. [Google Scholar] [CrossRef]

- Karagiorgis, X.; Shakthivel, D.; Khandelwal, G.; Ginesi, R.; Skabara, P.J.; Dahiya, R. Highly Conductive PEDOT:PSS: Ag Nanowire-Based Nanofibers for Transparent Flexible Electronics. ACS Appl. Mater. Interfaces 2024, 16, 19551–19562. [Google Scholar] [CrossRef]

- de Gramont, F.B.; Zhang, S.; Tomasello, G.; Kumar, P.; Sarkissian, A.; Cicoira, F. Highly Stretchable Electrospun Conducting Polymer Nanofibers. Appl. Phys. Lett. 2017, 111, 093701. [Google Scholar] [CrossRef]

- Bessaire, B.; Mathieu, M.; Salles, V.; Yeghoyan, T.; Celle, C.; Simonato, J.-P.; Brioude, A. Synthesis of Continuous Conductive PEDOT:PSS Nanofibers by Electrospinning: A Conformal Coating for Optoelectronics. ACS Appl. Mater. Interfaces 2017, 9, 950–957. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Park, J.; Kim, M.C.; Kim, M.; Park, P.; Yoon, I.-J.; Nah, J. Polyvinylidene Fluoride Core–Shell Nanofiber Membranes with Highly Conductive Shells for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2021, 13, 25428–25437. [Google Scholar] [CrossRef]

- Sharma, G.K.; James, N.R. Highly Flexible, PEDOT:PSS-Polyvinylpyrrolidone Coated Carbon Nanofiber-Polydimethylsiloxane Composite for Electromagnetic Interference Shielding. Synth. Met. 2023, 296, 117376. [Google Scholar] [CrossRef]

- Sun, X.; He, J.; Qiang, R.; Nan, N.; You, X.; Zhou, Y.; Shao, W.; Liu, F.; Liu, R. Electrospun Conductive Nanofiber Yarn for a Wearable Yarn Supercapacitor with High Volumetric Energy Density. Materials 2019, 12, 273. [Google Scholar] [CrossRef]

- Laforgue, A. All-Textile Flexible Supercapacitors Using Electrospun Poly(3,4-Ethylenedioxythiophene) Nanofibers. J. Power Sources 2011, 196, 559–564. [Google Scholar] [CrossRef]

- Du, H.; Zhang, M.; Liu, K.; Parit, M.; Jiang, Z.; Zhang, X.; Li, B.; Si, C. Conductive PEDOT:PSS/Cellulose Nanofibril Paper Electrodes for Flexible Supercapacitors with Superior Areal Capacitance and Cycling Stability. Chem. Eng. J. 2022, 428, 131994. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, C.; Yang, K.; Sun, S.; Bi, J.; Zhu, N.; Cai, Q.; Wang, J.; Yan, W. Conducting Polymers Meet Lithium–Sulfur Batteries: Progress, Challenges, and Perspectives. Energy Environ. Mater. 2023, 6, e12483. [Google Scholar] [CrossRef]

- Zeng, S.-Z.; Yao, Y.; Tu, J.; Tian, Z.; Zou, J.; Zeng, X.; Zhu, H.; Kong, L.B.; Han, P. Improving the Low-Rate Stability of Lithium-Sulfur Battery through the Coating of Conductive Polymer. Ionics 2021, 27, 3887–3893. [Google Scholar] [CrossRef]

- Abdah, M.A.A.M.; Mokhtar, M.; Khoon, L.T.; Sopian, K.; Dzulkurnain, N.A.; Ahmad, A.; Sulaiman, Y.; Bella, F.; Su’ait, M.S. Synthesis and Electrochemical Characterizations of Poly(3,4-Ethylenedioxythiophene/Manganese Oxide Coated on Porous Carbon Nanofibers as a Potential Anode for Lithium-Ion Batteries. Energy Rep. 2021, 7, 8677–8687. [Google Scholar] [CrossRef]

- Beaudoin, É.J.; Kubaski, M.M.; Samara, M.; Zednik, R.J.; Demarquette, N.R. Scaled-Up Multi-Needle Electrospinning Process Using Parallel Plate Auxiliary Electrodes. Nanomaterials 2022, 12, 1356. [Google Scholar] [CrossRef]

- Morkus, P.; Sibbald, S.; Choi, L.; Rassenberg, S.; Filipe, C.D.M.; Latulippe, D.R. Miniaturization of an Enclosed Electrospinning Process to Enhance Reproducibility in the Fabrication of Rapidly Dissolving Cell-based Biosensors. Biotechnol. J. 2024, 19, e2300306. [Google Scholar] [CrossRef]

- Lunni, D.; Giordano, G.; Pignatelli, F.; Filippeschi, C.; Linari, S.; Sinibaldi, E.; Mazzolai, B. Light-Assisted Electrospinning Monitoring for Soft Polymeric Nanofibers. Sci. Rep. 2020, 10, 16341. [Google Scholar] [CrossRef] [PubMed]

- Schultheiss, A.; Gueye, M.; Carella, A.; Benayad, A.; Pouget, S.; Faure-Vincent, J.; Demadrille, R.; Revaux, A.; Simonato, J.-P. Insight into the Degradation Mechanisms of Highly Conductive Poly(3,4-Ethylenedioxythiophene) Thin Films. ACS Appl. Polym. Mater. 2020, 2, 2686–2695. [Google Scholar] [CrossRef]

- Bontapalle, S.; Varughese, S. Understanding the Mechanism of Ageing and a Method to Improve the Ageing Resistance of Conducting PEDOT:PSS Films. Polym. Degrad. Stab. 2020, 171, 109025. [Google Scholar] [CrossRef]

- Duzcukoglu, H.; Kaybal, H.B.; Asmatulu, R. Enhancing the Coating Durability and Electrical Stability of Fiber Composites with SPEEK/PEDOT:PSS Permanent Coatings: A Novel Approach. Polym. Degrad. Stab. 2024, 228, 110908. [Google Scholar] [CrossRef]

- Yemata, T.A.; Zheng, Y.; Kyaw, A.K.K.; Wang, X.; Song, J.; Chin, W.S.; Xu, J. Improved Thermoelectric Properties and Environmental Stability of Conducting PEDOT:PSS Films Post-Treated With Imidazolium Ionic Liquids. Front. Chem. 2020, 7, 870. [Google Scholar] [CrossRef]

- Sau, S.; Kundu, S. Stretchable Polymeric Film with Enhanced Electrical and Mechanical Properties. Colloids Surf. A Physicochem. Eng. Asp. 2022, 636, 128130. [Google Scholar] [CrossRef]

- Qi, K.; He, J.; Wang, H.; Zhou, Y.; You, X.; Nan, N.; Shao, W.; Wang, L.; Ding, B.; Cui, S. A Highly Stretchable Nanofiber-Based Electronic Skin with Pressure-, Strain-, and Flexion-Sensitive Properties for Health and Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 42951–42960. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Chiu, C.-W. Facile Fabrication of a Stretchable and Flexible Nanofiber Carbon Film-Sensing Electrode by Electrospinning and Its Application in Smart Clothing for ECG and EMG Monitoring. ACS Appl. Electron. Mater. 2021, 3, 676–686. [Google Scholar] [CrossRef]

| Feature/Method | Electrospinning (PEDOT) | Other A.M. Methods |

|---|---|---|

| Surface area | High | Moderate to low |

| Porosity | High | Variable |

| Flexibility | High | Low to moderate |

| Conductivity | Enhanced with additives | Lower without additives |

| Material versatility | High | Limited |

| Mechanical properties | Improved with additives | Variable |

| Morphological control | Precise | Less precise |

| Applications | Broad (wearables, energy, biomedical) | Limited to specific fields |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slejko, E.A.; Carraro, G.; Huang, X.; Smerieri, M. Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers. Polymers 2024, 16, 2514. https://doi.org/10.3390/polym16172514

Slejko EA, Carraro G, Huang X, Smerieri M. Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers. Polymers. 2024; 16(17):2514. https://doi.org/10.3390/polym16172514

Chicago/Turabian StyleSlejko, Emanuele Alberto, Giovanni Carraro, Xiongchuan Huang, and Marco Smerieri. 2024. "Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers" Polymers 16, no. 17: 2514. https://doi.org/10.3390/polym16172514

APA StyleSlejko, E. A., Carraro, G., Huang, X., & Smerieri, M. (2024). Advances in the Fabrication, Properties, and Applications of Electrospun PEDOT-Based Conductive Nanofibers. Polymers, 16(17), 2514. https://doi.org/10.3390/polym16172514